JP4601552B2 - 複合誘電体用樹脂組成物および複合誘電体、該誘電体を使用した電気回路基板 - Google Patents

複合誘電体用樹脂組成物および複合誘電体、該誘電体を使用した電気回路基板 Download PDFInfo

- Publication number

- JP4601552B2 JP4601552B2 JP2005514395A JP2005514395A JP4601552B2 JP 4601552 B2 JP4601552 B2 JP 4601552B2 JP 2005514395 A JP2005514395 A JP 2005514395A JP 2005514395 A JP2005514395 A JP 2005514395A JP 4601552 B2 JP4601552 B2 JP 4601552B2

- Authority

- JP

- Japan

- Prior art keywords

- dielectric

- composite dielectric

- composite

- liquid composition

- aromatic polymer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000002131 composite material Substances 0.000 title claims description 100

- 239000011342 resin composition Substances 0.000 title description 2

- 239000000203 mixture Substances 0.000 claims description 52

- 239000007788 liquid Substances 0.000 claims description 41

- 125000003118 aryl group Chemical group 0.000 claims description 40

- 229920000642 polymer Polymers 0.000 claims description 40

- 238000006243 chemical reaction Methods 0.000 claims description 12

- USIUVYZYUHIAEV-UHFFFAOYSA-N diphenyl ether Chemical group C=1C=CC=CC=1OC1=CC=CC=C1 USIUVYZYUHIAEV-UHFFFAOYSA-N 0.000 claims description 7

- 125000001153 fluoro group Chemical group F* 0.000 claims description 7

- IISBACLAFKSPIT-UHFFFAOYSA-N bisphenol A Chemical group C=1C=C(O)C=CC=1C(C)(C)C1=CC=C(O)C=C1 IISBACLAFKSPIT-UHFFFAOYSA-N 0.000 claims description 6

- 239000000470 constituent Substances 0.000 claims description 5

- 238000006116 polymerization reaction Methods 0.000 claims description 5

- PXKLMJQFEQBVLD-UHFFFAOYSA-N bisphenol F Chemical group C1=CC(O)=CC=C1CC1=CC=C(O)C=C1 PXKLMJQFEQBVLD-UHFFFAOYSA-N 0.000 claims description 4

- 125000001424 substituent group Chemical group 0.000 claims description 4

- YWFPGFJLYRKYJZ-UHFFFAOYSA-N 9,9-bis(4-hydroxyphenyl)fluorene Chemical group C1=CC(O)=CC=C1C1(C=2C=CC(O)=CC=2)C2=CC=CC=C2C2=CC=CC=C21 YWFPGFJLYRKYJZ-UHFFFAOYSA-N 0.000 claims description 2

- 125000003545 alkoxy group Chemical group 0.000 claims description 2

- 125000000217 alkyl group Chemical group 0.000 claims description 2

- 125000003983 fluorenyl group Chemical group C1(=CC=CC=2C3=CC=CC=C3CC12)* 0.000 claims description 2

- 125000004435 hydrogen atom Chemical group [H]* 0.000 claims description 2

- 239000000758 substrate Substances 0.000 description 22

- 239000010408 film Substances 0.000 description 15

- 239000003990 capacitor Substances 0.000 description 13

- SECXISVLQFMRJM-UHFFFAOYSA-N N-Methylpyrrolidone Chemical compound CN1CCCC1=O SECXISVLQFMRJM-UHFFFAOYSA-N 0.000 description 12

- 238000000034 method Methods 0.000 description 12

- 239000002904 solvent Substances 0.000 description 12

- 239000003989 dielectric material Substances 0.000 description 11

- 239000010409 thin film Substances 0.000 description 11

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 9

- 229920000620 organic polymer Polymers 0.000 description 9

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 8

- 230000015572 biosynthetic process Effects 0.000 description 8

- 239000011888 foil Substances 0.000 description 8

- 229910052751 metal Inorganic materials 0.000 description 8

- 239000002184 metal Substances 0.000 description 8

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 8

- BWHMMNNQKKPAPP-UHFFFAOYSA-L potassium carbonate Chemical compound [K+].[K+].[O-]C([O-])=O BWHMMNNQKKPAPP-UHFFFAOYSA-L 0.000 description 8

- 239000011347 resin Substances 0.000 description 8

- 229920005989 resin Polymers 0.000 description 8

- 230000009477 glass transition Effects 0.000 description 7

- 238000003786 synthesis reaction Methods 0.000 description 7

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 6

- 238000005530 etching Methods 0.000 description 6

- 239000000463 material Substances 0.000 description 6

- -1 phenol compound Chemical class 0.000 description 6

- 239000003822 epoxy resin Substances 0.000 description 5

- 229910052731 fluorine Inorganic materials 0.000 description 5

- 229920000647 polyepoxide Polymers 0.000 description 5

- 238000001308 synthesis method Methods 0.000 description 5

- 238000012360 testing method Methods 0.000 description 5

- FXHOOIRPVKKKFG-UHFFFAOYSA-N N,N-Dimethylacetamide Chemical compound CN(C)C(C)=O FXHOOIRPVKKKFG-UHFFFAOYSA-N 0.000 description 4

- 239000004721 Polyphenylene oxide Substances 0.000 description 4

- DQEPMTIXHXSFOR-UHFFFAOYSA-N benzo[a]pyrene diol epoxide I Chemical compound C1=C2C(C3OC3C(C3O)O)=C3C=C(C=C3)C2=C2C3=CC=CC2=C1 DQEPMTIXHXSFOR-UHFFFAOYSA-N 0.000 description 4

- 230000000052 comparative effect Effects 0.000 description 4

- RTZKZFJDLAIYFH-UHFFFAOYSA-N ether Chemical group CCOCC RTZKZFJDLAIYFH-UHFFFAOYSA-N 0.000 description 4

- 239000002245 particle Substances 0.000 description 4

- 229910052697 platinum Inorganic materials 0.000 description 4

- 229910000027 potassium carbonate Inorganic materials 0.000 description 4

- ZWEHNKRNPOVVGH-UHFFFAOYSA-N 2-Butanone Chemical compound CCC(C)=O ZWEHNKRNPOVVGH-UHFFFAOYSA-N 0.000 description 3

- QTBSBXVTEAMEQO-UHFFFAOYSA-N Acetic acid Chemical compound CC(O)=O QTBSBXVTEAMEQO-UHFFFAOYSA-N 0.000 description 3

- CSCPPACGZOOCGX-UHFFFAOYSA-N Acetone Chemical compound CC(C)=O CSCPPACGZOOCGX-UHFFFAOYSA-N 0.000 description 3

- WEVYAHXRMPXWCK-UHFFFAOYSA-N Acetonitrile Chemical compound CC#N WEVYAHXRMPXWCK-UHFFFAOYSA-N 0.000 description 3

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 3

- KWYUFKZDYYNOTN-UHFFFAOYSA-M Potassium hydroxide Chemical compound [OH-].[K+] KWYUFKZDYYNOTN-UHFFFAOYSA-M 0.000 description 3

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 3

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 description 3

- 238000010521 absorption reaction Methods 0.000 description 3

- 238000004458 analytical method Methods 0.000 description 3

- JFDZBHWFFUWGJE-UHFFFAOYSA-N benzonitrile Chemical compound N#CC1=CC=CC=C1 JFDZBHWFFUWGJE-UHFFFAOYSA-N 0.000 description 3

- 150000001875 compounds Chemical class 0.000 description 3

- 239000004020 conductor Substances 0.000 description 3

- LNEPOXFFQSENCJ-UHFFFAOYSA-N haloperidol Chemical compound C1CC(O)(C=2C=CC(Cl)=CC=2)CCN1CCCC(=O)C1=CC=C(F)C=C1 LNEPOXFFQSENCJ-UHFFFAOYSA-N 0.000 description 3

- 238000005259 measurement Methods 0.000 description 3

- 238000002156 mixing Methods 0.000 description 3

- 239000012299 nitrogen atmosphere Substances 0.000 description 3

- 239000003960 organic solvent Substances 0.000 description 3

- 229920000090 poly(aryl ether) Polymers 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 239000000047 product Substances 0.000 description 3

- 238000004544 sputter deposition Methods 0.000 description 3

- 239000010936 titanium Substances 0.000 description 3

- OGIDPMRJRNCKJF-UHFFFAOYSA-N titanium oxide Inorganic materials [Ti]=O OGIDPMRJRNCKJF-UHFFFAOYSA-N 0.000 description 3

- 229910052725 zinc Inorganic materials 0.000 description 3

- 239000011701 zinc Substances 0.000 description 3

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 description 2

- YCKRFDGAMUMZLT-UHFFFAOYSA-N Fluorine atom Chemical compound [F] YCKRFDGAMUMZLT-UHFFFAOYSA-N 0.000 description 2

- QIGBRXMKCJKVMJ-UHFFFAOYSA-N Hydroquinone Chemical compound OC1=CC=C(O)C=C1 QIGBRXMKCJKVMJ-UHFFFAOYSA-N 0.000 description 2

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 2

- 239000004952 Polyamide Substances 0.000 description 2

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 2

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 2

- 229910002367 SrTiO Inorganic materials 0.000 description 2

- 229910052782 aluminium Inorganic materials 0.000 description 2

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 2

- 239000003849 aromatic solvent Substances 0.000 description 2

- 150000007514 bases Chemical class 0.000 description 2

- 125000004432 carbon atom Chemical group C* 0.000 description 2

- 239000003795 chemical substances by application Substances 0.000 description 2

- 229910052804 chromium Inorganic materials 0.000 description 2

- 239000011651 chromium Substances 0.000 description 2

- 239000011248 coating agent Substances 0.000 description 2

- 238000000576 coating method Methods 0.000 description 2

- 238000013329 compounding Methods 0.000 description 2

- 229910052802 copper Inorganic materials 0.000 description 2

- 239000010949 copper Substances 0.000 description 2

- JHIVVAPYMSGYDF-UHFFFAOYSA-N cyclohexanone Chemical compound O=C1CCCCC1 JHIVVAPYMSGYDF-UHFFFAOYSA-N 0.000 description 2

- BGTOWKSIORTVQH-UHFFFAOYSA-N cyclopentanone Chemical compound O=C1CCCC1 BGTOWKSIORTVQH-UHFFFAOYSA-N 0.000 description 2

- 238000011982 device technology Methods 0.000 description 2

- 239000002270 dispersing agent Substances 0.000 description 2

- 239000006185 dispersion Substances 0.000 description 2

- 238000005553 drilling Methods 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 238000011156 evaluation Methods 0.000 description 2

- 238000001914 filtration Methods 0.000 description 2

- 239000011737 fluorine Substances 0.000 description 2

- 239000011521 glass Substances 0.000 description 2

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 2

- 229910052737 gold Inorganic materials 0.000 description 2

- 239000010931 gold Substances 0.000 description 2

- 238000010438 heat treatment Methods 0.000 description 2

- 238000009434 installation Methods 0.000 description 2

- 238000003475 lamination Methods 0.000 description 2

- 229910052749 magnesium Inorganic materials 0.000 description 2

- 239000011777 magnesium Substances 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- LQNUZADURLCDLV-UHFFFAOYSA-N nitrobenzene Chemical compound [O-][N+](=O)C1=CC=CC=C1 LQNUZADURLCDLV-UHFFFAOYSA-N 0.000 description 2

- 238000007747 plating Methods 0.000 description 2

- 229920002647 polyamide Polymers 0.000 description 2

- 229920000570 polyether Polymers 0.000 description 2

- 229920006380 polyphenylene oxide Polymers 0.000 description 2

- 229920001343 polytetrafluoroethylene Polymers 0.000 description 2

- 239000004810 polytetrafluoroethylene Substances 0.000 description 2

- 238000007639 printing Methods 0.000 description 2

- GHMLBKRAJCXXBS-UHFFFAOYSA-N resorcinol Chemical compound OC1=CC=CC(O)=C1 GHMLBKRAJCXXBS-UHFFFAOYSA-N 0.000 description 2

- 238000007650 screen-printing Methods 0.000 description 2

- 229910052709 silver Inorganic materials 0.000 description 2

- 239000004332 silver Substances 0.000 description 2

- 230000002194 synthesizing effect Effects 0.000 description 2

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 2

- 229910052721 tungsten Inorganic materials 0.000 description 2

- 239000010937 tungsten Substances 0.000 description 2

- 238000007740 vapor deposition Methods 0.000 description 2

- 230000004580 weight loss Effects 0.000 description 2

- RNFJDJUURJAICM-UHFFFAOYSA-N 2,2,4,4,6,6-hexaphenoxy-1,3,5-triaza-2$l^{5},4$l^{5},6$l^{5}-triphosphacyclohexa-1,3,5-triene Chemical compound N=1P(OC=2C=CC=CC=2)(OC=2C=CC=CC=2)=NP(OC=2C=CC=CC=2)(OC=2C=CC=CC=2)=NP=1(OC=1C=CC=CC=1)OC1=CC=CC=C1 RNFJDJUURJAICM-UHFFFAOYSA-N 0.000 description 1

- DJOYTAUERRJRAT-UHFFFAOYSA-N 2-(n-methyl-4-nitroanilino)acetonitrile Chemical compound N#CCN(C)C1=CC=C([N+]([O-])=O)C=C1 DJOYTAUERRJRAT-UHFFFAOYSA-N 0.000 description 1

- PTTPXKJBFFKCEK-UHFFFAOYSA-N 2-Methyl-4-heptanone Chemical compound CC(C)CC(=O)CC(C)C PTTPXKJBFFKCEK-UHFFFAOYSA-N 0.000 description 1

- GIXNHONPKYUROG-UHFFFAOYSA-N 4-(9h-fluoren-1-yl)phenol Chemical group C1=CC(O)=CC=C1C1=CC=CC2=C1CC1=CC=CC=C12 GIXNHONPKYUROG-UHFFFAOYSA-N 0.000 description 1

- MWSKJDNQKGCKPA-UHFFFAOYSA-N 6-methyl-3a,4,5,7a-tetrahydro-2-benzofuran-1,3-dione Chemical compound C1CC(C)=CC2C(=O)OC(=O)C12 MWSKJDNQKGCKPA-UHFFFAOYSA-N 0.000 description 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- CTQNGGLPUBDAKN-UHFFFAOYSA-N O-Xylene Chemical compound CC1=CC=CC=C1C CTQNGGLPUBDAKN-UHFFFAOYSA-N 0.000 description 1

- 239000004962 Polyamide-imide Substances 0.000 description 1

- 239000004695 Polyether sulfone Substances 0.000 description 1

- 239000004697 Polyetherimide Substances 0.000 description 1

- 239000004642 Polyimide Substances 0.000 description 1

- 239000004793 Polystyrene Substances 0.000 description 1

- BLRPTPMANUNPDV-UHFFFAOYSA-N Silane Chemical compound [SiH4] BLRPTPMANUNPDV-UHFFFAOYSA-N 0.000 description 1

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 1

- FKSZLDCMQZJMFN-UHFFFAOYSA-N [Mg].[Pb] Chemical compound [Mg].[Pb] FKSZLDCMQZJMFN-UHFFFAOYSA-N 0.000 description 1

- 238000012644 addition polymerization Methods 0.000 description 1

- 238000004220 aggregation Methods 0.000 description 1

- 230000002776 aggregation Effects 0.000 description 1

- WNROFYMDJYEPJX-UHFFFAOYSA-K aluminium hydroxide Chemical compound [OH-].[OH-].[OH-].[Al+3] WNROFYMDJYEPJX-UHFFFAOYSA-K 0.000 description 1

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 1

- 239000003963 antioxidant agent Substances 0.000 description 1

- 230000003078 antioxidant effect Effects 0.000 description 1

- JRPBQTZRNDNNOP-UHFFFAOYSA-N barium titanate Chemical compound [Ba+2].[Ba+2].[O-][Ti]([O-])([O-])[O-] JRPBQTZRNDNNOP-UHFFFAOYSA-N 0.000 description 1

- 229910002113 barium titanate Inorganic materials 0.000 description 1

- 229910021523 barium zirconate Inorganic materials 0.000 description 1

- DQBAOWPVHRWLJC-UHFFFAOYSA-N barium(2+);dioxido(oxo)zirconium Chemical compound [Ba+2].[O-][Zr]([O-])=O DQBAOWPVHRWLJC-UHFFFAOYSA-N 0.000 description 1

- 125000003236 benzoyl group Chemical group [H]C1=C([H])C([H])=C(C([H])=C1[H])C(*)=O 0.000 description 1

- 239000011218 binary composite Substances 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- ZFVMWEVVKGLCIJ-UHFFFAOYSA-N bisphenol AF Chemical compound C1=CC(O)=CC=C1C(C(F)(F)F)(C(F)(F)F)C1=CC=C(O)C=C1 ZFVMWEVVKGLCIJ-UHFFFAOYSA-N 0.000 description 1

- 239000011575 calcium Substances 0.000 description 1

- AOWKSNWVBZGMTJ-UHFFFAOYSA-N calcium titanate Chemical compound [Ca+2].[O-][Ti]([O-])=O AOWKSNWVBZGMTJ-UHFFFAOYSA-N 0.000 description 1

- 230000015556 catabolic process Effects 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 239000007795 chemical reaction product Substances 0.000 description 1

- 239000007822 coupling agent Substances 0.000 description 1

- 239000013078 crystal Substances 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 238000006731 degradation reaction Methods 0.000 description 1

- NKTZYSOLHFIEMF-UHFFFAOYSA-N dioxido(dioxo)tungsten;lead(2+) Chemical compound [Pb+2].[O-][W]([O-])(=O)=O NKTZYSOLHFIEMF-UHFFFAOYSA-N 0.000 description 1

- NKZSPGSOXYXWQA-UHFFFAOYSA-N dioxido(oxo)titanium;lead(2+) Chemical compound [Pb+2].[O-][Ti]([O-])=O NKZSPGSOXYXWQA-UHFFFAOYSA-N 0.000 description 1

- 239000012153 distilled water Substances 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000012776 electronic material Substances 0.000 description 1

- 238000007720 emulsion polymerization reaction Methods 0.000 description 1

- 125000001033 ether group Chemical group 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 238000011049 filling Methods 0.000 description 1

- 239000003063 flame retardant Substances 0.000 description 1

- 238000010528 free radical solution polymerization reaction Methods 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 238000001879 gelation Methods 0.000 description 1

- 239000010439 graphite Substances 0.000 description 1

- 229910002804 graphite Inorganic materials 0.000 description 1

- 230000020169 heat generation Effects 0.000 description 1

- 239000003112 inhibitor Substances 0.000 description 1

- 239000011256 inorganic filler Substances 0.000 description 1

- 229910003475 inorganic filler Inorganic materials 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 150000002500 ions Chemical class 0.000 description 1

- 239000005453 ketone based solvent Substances 0.000 description 1

- 238000010030 laminating Methods 0.000 description 1

- XGZVUEUWXADBQD-UHFFFAOYSA-L lithium carbonate Chemical compound [Li+].[Li+].[O-]C([O-])=O XGZVUEUWXADBQD-UHFFFAOYSA-L 0.000 description 1

- 229910052808 lithium carbonate Inorganic materials 0.000 description 1

- 239000012046 mixed solvent Substances 0.000 description 1

- 150000002825 nitriles Chemical class 0.000 description 1

- 238000000059 patterning Methods 0.000 description 1

- 239000005011 phenolic resin Substances 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 239000004014 plasticizer Substances 0.000 description 1

- 239000002798 polar solvent Substances 0.000 description 1

- 229920001643 poly(ether ketone) Polymers 0.000 description 1

- 229920006122 polyamide resin Polymers 0.000 description 1

- 229920002312 polyamide-imide Polymers 0.000 description 1

- 238000012643 polycondensation polymerization Methods 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 229920006393 polyether sulfone Polymers 0.000 description 1

- 229920001601 polyetherimide Polymers 0.000 description 1

- 229920001721 polyimide Polymers 0.000 description 1

- 229920002223 polystyrene Polymers 0.000 description 1

- 239000002244 precipitate Substances 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 230000035484 reaction time Effects 0.000 description 1

- 229910000077 silane Inorganic materials 0.000 description 1

- 239000000377 silicon dioxide Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 238000003756 stirring Methods 0.000 description 1

- VEALVRVVWBQVSL-UHFFFAOYSA-N strontium titanate Chemical compound [Sr+2].[O-][Ti]([O-])=O VEALVRVVWBQVSL-UHFFFAOYSA-N 0.000 description 1

- 238000010557 suspension polymerization reaction Methods 0.000 description 1

- 239000011206 ternary composite Substances 0.000 description 1

- 230000008719 thickening Effects 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

- 239000008096 xylene Substances 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G4/00—Fixed capacitors; Processes of their manufacture

- H01G4/002—Details

- H01G4/018—Dielectrics

- H01G4/20—Dielectrics using combinations of dielectrics from more than one of groups H01G4/02 - H01G4/06

- H01G4/206—Dielectrics using combinations of dielectrics from more than one of groups H01G4/02 - H01G4/06 inorganic and synthetic material

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10K—ORGANIC ELECTRIC SOLID-STATE DEVICES

- H10K10/00—Organic devices specially adapted for rectifying, amplifying, oscillating or switching; Organic capacitors or resistors having potential barriers

- H10K10/40—Organic transistors

- H10K10/46—Field-effect transistors, e.g. organic thin-film transistors [OTFT]

- H10K10/462—Insulated gate field-effect transistors [IGFETs]

- H10K10/468—Insulated gate field-effect transistors [IGFETs] characterised by the gate dielectrics

- H10K10/478—Insulated gate field-effect transistors [IGFETs] characterised by the gate dielectrics the gate dielectric comprising a layer of composite material comprising interpenetrating or embedded materials, e.g. TiO2 particles in a polymer matrix

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L101/00—Compositions of unspecified macromolecular compounds

- C08L101/02—Compositions of unspecified macromolecular compounds characterised by the presence of specified groups, e.g. terminal or pendant functional groups

- C08L101/04—Compositions of unspecified macromolecular compounds characterised by the presence of specified groups, e.g. terminal or pendant functional groups containing halogen atoms

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K3/00—Use of inorganic substances as compounding ingredients

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K1/00—Printed circuits

- H05K1/16—Printed circuits incorporating printed electric components, e.g. printed resistor, capacitor, inductor

- H05K1/162—Printed circuits incorporating printed electric components, e.g. printed resistor, capacitor, inductor incorporating printed capacitors

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/01—Dielectrics

- H05K2201/0137—Materials

- H05K2201/015—Fluoropolymer, e.g. polytetrafluoroethylene [PTFE]

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/02—Fillers; Particles; Fibers; Reinforcement materials

- H05K2201/0203—Fillers and particles

- H05K2201/0206—Materials

- H05K2201/0209—Inorganic, non-metallic particles

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2203/00—Indexing scheme relating to apparatus or processes for manufacturing printed circuits covered by H05K3/00

- H05K2203/07—Treatments involving liquids, e.g. plating, rinsing

- H05K2203/0756—Uses of liquids, e.g. rinsing, coating, dissolving

- H05K2203/0759—Forming a polymer layer by liquid coating, e.g. a non-metallic protective coating or an organic bonding layer

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Organic Chemistry (AREA)

- Composite Materials (AREA)

- Materials Engineering (AREA)

- Inorganic Chemistry (AREA)

- Manufacturing & Machinery (AREA)

- Health & Medical Sciences (AREA)

- Compositions Of Macromolecular Compounds (AREA)

- Laminated Bodies (AREA)

- Inorganic Insulating Materials (AREA)

Description

本発明の複合誘電体用液状組成物において、フッ素化芳香族ポリマーと無機誘電体の含有量は、フッ素化芳香族ポリマーの100質量部に対して、無機誘電体が100〜2,000質量部の範囲内であることが好ましい。無機誘電体の含有量が100質量部未満では、液状組成物からなる複合誘電体の誘電率が低くなる恐れがある。一方、無機誘電体の含有量が2,000質量部を超えると該組成物の粘度が高くなり、取り扱い性が低下する恐れがある。無機誘電体の含有量のより好ましい下限は、フッ素化芳香族ポリマーの100質量部に対して500質量部以上であり、700質量部以上が最も好ましい。また、無機誘電体の含有量の好ましい上限は、フッ素化芳香族ポリマーの100質量部に対して1,500質量部以下であり、1,000質量部以下であることがさらに好ましい。

本発明の複合誘電体用液状組成物は、フッ素化芳香族ポリマー及び無機誘電体をそれぞれ1種又は2種以上含有することができる。

さらに、本発明のフッ素化芳香族ポリマーは、下記一般式(1)で表される繰り返し単位を含むフッ素原子を有するポリアリールエーテルであることが好ましい。フッ素含有芳香族ポリマーがこのような構造を有するものであると、無機誘電体との相互作用が適度に抑制されると考えられ、複合誘電体用液状組成物作製に支障をきたす現象、例えば大幅な増粘、ゲル化、流動性の損失、凝集等が低減される。よって、より多くの無機誘電体を配合した複合誘電体用液状組成物を作製することができ、複合誘電体としてより高い誘電率を示すものとすることができるだけでなく、粘度を低下させることができるため、複合誘電体を薄膜状に成形することが容易となる。なお、一般式(1)で表される繰り返し単位は、同一でも異なっていてもよく、ブロック状、ランダム状等の何れの形態であってもよい。

また、複合誘電体用液状組成物の安定性を高める、もしくは乾燥性を調整する、もしくは成形物・成形膜の物性を高めるために、いくつかの溶媒を併用した混合溶媒を用いてもよい。

本発明の複合誘電体の用途・機能としては、例えば、バイパスコンデンサー、充電素子、微分素子、終端負荷素子、フィルター、アンテナ、ノイズカット等が挙げられる。

また、本発明の複合誘電体を金属箔等の導電性材料に塗布する、導電性材料と密着させる、導電性材料ではさむ等して製造することができる。

本発明の複合誘電体用液状組成物は広範囲に塗布する、均一に塗布する、特定の部位に塗布する、印刷によりパターンを形成することができる。加えて、小型化、容量密度向上のために薄膜化が可能であることも利点の一つである。

さらに上記電気回路基板を、レーザー、溶剤、エッチング等を用いて穴あけ、パターニング、複合誘電体の除去等の加工をすることができる。

(1)複合誘電体の薄膜(フィルム)の上下にCu箔等の金属箔を貼着してコンデンサを形成する工程、そのコンデンサの上下に配線層を積層して電子回路基板を形成する工程により製造される電子回路基板。

(2)樹脂基板の上、又は、上下両面に貼着した下部電極上に複合誘電体層を形成し、その上に上部電極を貼着してコンデンサを形成する工程、この基板の上、又は、上下両面にコンデンサの形成された樹脂基板に積層・エッチングにより配線層を形成して電子回路基板を形成する工程により製造される電子回路基板。

(3)Cu箔等の金属箔上に誘電体層を形成し、その上にCu箔等の金属箔を貼着してコンデンサを形成する工程、このCu箔等の金属箔上にコンデンサが形成されたもの全体を反転させて、底面にCu箔等の金属箔が貼着した樹脂基板上に積層する工程、その樹脂基板の上下のCu箔等の金属箔のエッチング、配線層の積層・エッチングにより電子回路基板を形成する工程により製造される電子回路基板。

[図2]は本発明の複合誘電体(a)及び該複合誘電体から形成される電気回路用部品(電子素子)(b)を模式的に表すものである。

[図3]は本発明の複合誘電体から形成される電気回路用部品(電子素子)を内部に作り込んだ電子回路基板を模式的に表すものである。

2 接地電極

3 複合誘電体層

4 配線層

5 複合誘電体

6、6’ 電極

7 基板

8 他部品(ICチップ等)

温度計、冷却管、ガス導入管、および攪拌機を備えた反応器に、BPDE16.74部、6−FBA10.14部、炭酸カリウム4.34部および、N−メチル−2−ピロリドン(NMP)90部を仕込んだ。この混合物を60℃に加熱し、5時間反応した。反応終了後、反応溶液をブレンダーで激しく攪拌しながら、1%酢酸水溶液中に注加した。析出した反応物を濾別し、蒸留水及びメタノールで洗浄した後、減圧乾燥して、フッ素化芳香族ポリマー(1)を得た。該ポリマーのガラス転移点温度(Tg)は193℃、数平均分子量(Mn)が72,370、表面抵抗値は1.0×1018Ω/cm2以上であった。

合成例1と同様の反応器に、BPDE16.74部、HF10.5部、炭酸カリウム4.34部、ジメチルアセトアミド90部を仕込んだ。この混合物を80℃に加温し、8時間反応した。反応終了後、合成例1と同様にして、フッ素化芳香族ポリマー(2)を得た。該ポリマーのガラス転移点温度(Tg)は242℃、数平均分子量(Mn)が70,770、表面抵抗値は1.0×1018Ω/cm2以上であった。

合成例1と同様の反応器に、BPDE16.74部、BA5.88部、炭酸カリウム4.34部、ジメチルアセトアミド90部を仕込んだ。この混合物を80℃に加温し、10時間反応した。反応終了後、合成例1と同様にして、フッ素化芳香族ポリマー(3)を得た。該ポリマーのガラス転移点温度(Tg)は180℃、数平均分子量(Mn)が62,750、表面抵抗値は1.0×1018Ω/cm2以上であった。

本発明にかかる複合誘電体用液状組成物として、表1に記載した配合量でフッ素化芳香族ポリマー、有機溶剤、分散剤、さらに無機誘電体の順に配合して、ケミスターラーにより均一に混合して、液状組成物を得た。また、比較の液状組成物として、表2に記載した配合量で同様に混合して組成物を得た。

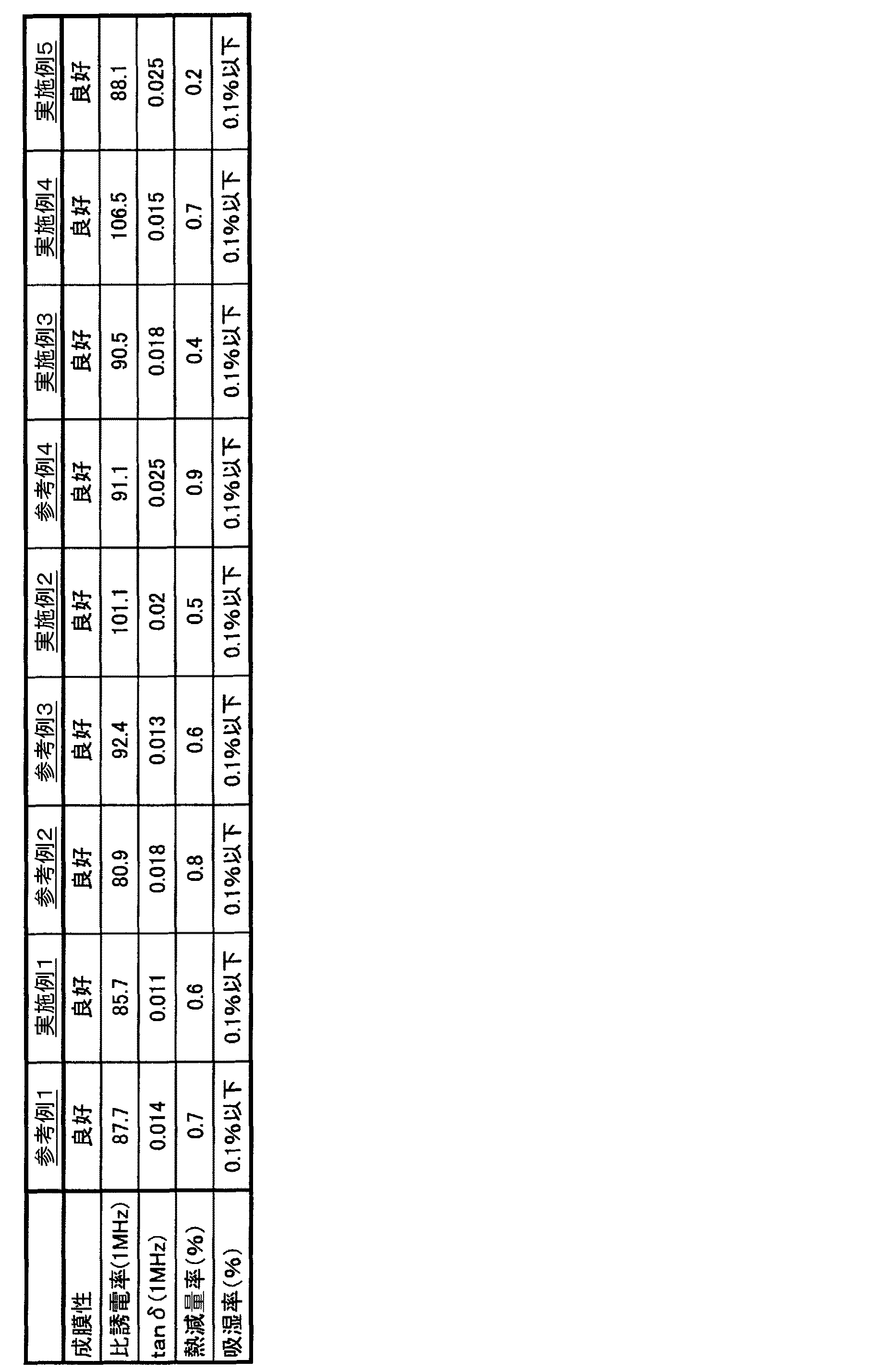

次に、あらかじめ白金膜を形成した、ガラス板上にスピンコーターにより上記の組成物を塗布した後、室温で30分間乾燥後、さらに所定温度のオーブン中で乾燥させ、厚み20μmの複合誘電体を得た。さらに、複合誘電体の表面にイオンスパッタにより白金膜を形成して、評価用の複合誘電体を作製した。この複合誘電体を以下の方法により評価した。その結果を表3および表4に記載した。

誘電特性

得られた各複合誘電体をインピーダンス・アナライザにより比誘電率および誘電正接を測定した。

(2)耐熱特性

得られた各複合誘電体をサーマルアナライザ(TG−DTA分析)により、300℃までの減量率を測定した。

吸湿特性

得られた各複合誘電体をPCT試験(135℃、3気圧、2時間)を行い、試験後の吸湿率を測定した。

SrTiO3:平均粒子径1.5μm、比表面積7m2/g

BYK W9010:商品名、ビックケミージャパン社製

フッ素樹脂

YD−127:商品名、東都化成社製、ビスフェノールA型エポキシ樹脂

MT−500:商品名、新日本理化社製、メチルテトラヒドロ無水フタル酸

ここでいう成膜性が悪いとは、複合誘電体用液状組成物の粘度が不適当、分散状態が悪い等で膜化できない又は成形した膜がもろい等で膜状態を維持できないことを指す。

Claims (6)

- 無機誘電体とフッ素化芳香族ポリマーを含有し、

該無機誘電体が、該フッ素化芳香族ポリマー100質量部に対して、700〜2000質量部の範囲にあり、

該フッ素化芳香族ポリマーは、20℃〜80℃の反応温度で合成されたものであって、下記一般式(1)で表される繰り返し単位を含むものであり、該一般式(1)で表される繰り返し単位のうち少なくとも1つが9,9−ビス(4−ヒドロキシフェニル)フルオレン骨格を含む

ことを特徴とする複合誘電体用液状組成物。

構造式群(2)

構造式(4−6)

構造式群(3)

- 前記フッ素化芳香族ポリマーは、前記一般式(1)におけるXが、ジフェニルエーテル鎖、ビスフェノールA鎖、ビスフェノールF鎖、又は、フルオレン鎖である

ことを特徴とする請求項1に記載の複合誘電体用液状組成物。 - 前記フッ素化芳香族ポリマーは、数平均分子量(Mn)が10000〜200000である

ことを特徴とする請求項1又は2に記載の複合誘電体用液状組成物。 - 請求項1〜3のいずれかに記載の複合誘電体用液状組成物を用いてなる複合誘電体。

- 前記複合誘電体は、厚みが0.1〜100μmであることを特徴とする請求項4に記載の複合誘電体。

- 請求項4又は5に記載の複合誘電体を構成部位として含む電気回路基板。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003338973 | 2003-09-30 | ||

| JP2003338973 | 2003-09-30 | ||

| PCT/JP2004/013764 WO2005033209A1 (ja) | 2003-09-30 | 2004-09-21 | 複合誘電体用樹脂組成物および複合誘電体、該誘電体を使用した電気回路基板 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JPWO2005033209A1 JPWO2005033209A1 (ja) | 2006-12-14 |

| JP4601552B2 true JP4601552B2 (ja) | 2010-12-22 |

Family

ID=34419140

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005514395A Expired - Fee Related JP4601552B2 (ja) | 2003-09-30 | 2004-09-21 | 複合誘電体用樹脂組成物および複合誘電体、該誘電体を使用した電気回路基板 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US7632884B2 (ja) |

| EP (1) | EP1669412A1 (ja) |

| JP (1) | JP4601552B2 (ja) |

| KR (1) | KR100884511B1 (ja) |

| CN (1) | CN100582167C (ja) |

| TW (1) | TW200513494A (ja) |

| WO (1) | WO2005033209A1 (ja) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101452594B1 (ko) | 2012-12-26 | 2014-10-21 | 주식회사 두산 | 수지 조성물 및 이를 포함하는 금속박 적층체 |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100884511B1 (ko) * | 2003-09-30 | 2009-02-18 | 가부시키가이샤 닛폰 쇼쿠바이 | 복합유전체용 수지 조성물 및 복합유전체, 그 유전체를사용한 전기회로기판 |

| US7521705B2 (en) * | 2005-08-15 | 2009-04-21 | Micron Technology, Inc. | Reproducible resistance variable insulating memory devices having a shaped bottom electrode |

| US8414962B2 (en) | 2005-10-28 | 2013-04-09 | The Penn State Research Foundation | Microcontact printed thin film capacitors |

| JP5595629B2 (ja) * | 2005-12-13 | 2014-09-24 | 東レ株式会社 | 誘電性樹脂組成物およびそれから得られる成形品 |

| CN101351855B (zh) * | 2006-04-05 | 2011-08-31 | 株式会社村田制作所 | 层叠型陶瓷电子器件的制造方法以及层叠型陶瓷电子器件 |

| JP4991185B2 (ja) * | 2006-06-05 | 2012-08-01 | 株式会社日本触媒 | ポリアリールスルホン系重合体及びその製造方法 |

| JP5470788B2 (ja) * | 2008-09-22 | 2014-04-16 | セイコーエプソン株式会社 | 有機半導体装置、有機半導体装置の製造方法、電子デバイスおよび電子機器 |

| JP5470787B2 (ja) * | 2008-09-22 | 2014-04-16 | セイコーエプソン株式会社 | 有機半導体装置、有機半導体装置の製造方法、電子デバイスおよび電子機器 |

| JP5708160B2 (ja) * | 2011-04-04 | 2015-04-30 | Jsr株式会社 | 高周波回路基板用樹脂基板および高周波回路基板 |

| CN103323897B (zh) * | 2012-03-22 | 2018-09-21 | 株式会社日本触媒 | 光选择透射滤光器、树脂片材和固态图像传感器 |

| US9809720B2 (en) * | 2015-07-06 | 2017-11-07 | University Of Massachusetts | Ferroelectric nanocomposite based dielectric inks for reconfigurable RF and microwave applications |

| US10839992B1 (en) | 2019-05-17 | 2020-11-17 | Raytheon Company | Thick film resistors having customizable resistances and methods of manufacture |

| CN112574521B (zh) * | 2020-12-09 | 2022-04-26 | 广东生益科技股份有限公司 | 一种含氟树脂组合物及包含其的树脂胶液、含氟介质片、层压板、覆铜板和印刷电路板 |

Family Cites Families (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2764718A (en) * | 1951-12-28 | 1956-09-25 | Sprague Electric Co | Electrical condensers |

| US4518737A (en) * | 1978-12-26 | 1985-05-21 | Rogers Corporation | Dielectric material and method of making the dielectric material |

| JPH02225358A (ja) * | 1989-02-23 | 1990-09-07 | Matsushita Electric Works Ltd | 複合誘電体 |

| US5114780A (en) * | 1990-04-17 | 1992-05-19 | Raychem Corporation | Electronic articles containing a fluorinated poly(arylene ether) dielectric |

| EP0505438A1 (en) * | 1989-12-08 | 1992-09-30 | AlliedSignal Inc. | Electronic articles containing a fluorinated poly(arylene ether) dielectric |

| US5275878A (en) * | 1990-02-06 | 1994-01-04 | Matsushita Electric Works, Ltd. | Composite dielectric and printed-circuit use substrate utilizing the same |

| JP2802173B2 (ja) * | 1990-02-06 | 1998-09-24 | 松下電工株式会社 | 複合誘電体 |

| US5115082A (en) * | 1990-04-17 | 1992-05-19 | Raychem Corporation | Fluorinated poly(arylene ether) |

| EP0524930B1 (en) * | 1990-04-17 | 1997-03-12 | AlliedSignal Inc. | Fluorinated poly(arylene ethers) |

| WO1992018213A1 (en) * | 1991-04-12 | 1992-10-29 | E.I. Du Pont De Nemours And Company | High dielectric constant flexible ceramic composite |

| JP2617639B2 (ja) * | 1991-11-06 | 1997-06-04 | 松下電工株式会社 | 複合誘電体および回路用基板 |

| US6207764B1 (en) | 1995-04-26 | 2001-03-27 | Monsanto Company | Halogenated elastomer compositions |

| US5739193A (en) * | 1996-05-07 | 1998-04-14 | Hoechst Celanese Corp. | Polymeric compositions having a temperature-stable dielectric constant |

| US6599631B2 (en) * | 2001-01-26 | 2003-07-29 | Nanogram Corporation | Polymer-inorganic particle composites |

| JPH11260148A (ja) | 1998-03-13 | 1999-09-24 | Hitachi Ltd | 薄膜誘電体とそれを用いた多層配線板とその製造方法 |

| JP4044236B2 (ja) | 1999-03-11 | 2008-02-06 | 株式会社東芝 | 半導体装置の製造方法 |

| TWI256959B (en) | 2000-07-31 | 2006-06-21 | Sumitomo Chemical Co | Aromatic liquid-crystalline polyester solution composition |

| JP4543518B2 (ja) * | 2000-08-11 | 2010-09-15 | 住友化学株式会社 | 誘電体ペースト及び誘電体膜 |

| KR100399018B1 (ko) * | 2000-12-19 | 2003-09-19 | 광주과학기술원 | 플로린을 함유한 광소자용 폴리아릴렌에테르설폰 또는 폴리아릴렌에테르설파이드 및 그 제조방법 |

| US6797345B2 (en) | 2001-04-27 | 2004-09-28 | Sumitomo Chemical Company, Limited | Aromatic liquid-crystalline polyester metal laminate |

| JP2002344100A (ja) * | 2001-05-21 | 2002-11-29 | Sumitomo Electric Ind Ltd | 基板用誘電体材料及びその製造方法 |

| JP4273739B2 (ja) | 2001-10-16 | 2009-06-03 | 東洋紡績株式会社 | 誘電加熱接着用樹脂組成物、ホットメルト接着剤、被接着材の接着方法、ホットメルト接着剤の被接着材として用いられる被接着用樹脂組成物および接着複合体 |

| US6706136B2 (en) | 2001-10-16 | 2004-03-16 | Toyo Boseki Kabushiki Kaisha | Resin composition for high-frequency bonding |

| JP2003138026A (ja) * | 2001-11-05 | 2003-05-14 | Nippon Shokubai Co Ltd | 樹脂組成物および成形品 |

| CA2487649C (en) * | 2002-05-28 | 2009-09-01 | National Research Council Of Canada | Techniques for the preparation of highly fluorinated polyethers |

| US7164197B2 (en) * | 2003-06-19 | 2007-01-16 | 3M Innovative Properties Company | Dielectric composite material |

| KR100884511B1 (ko) * | 2003-09-30 | 2009-02-18 | 가부시키가이샤 닛폰 쇼쿠바이 | 복합유전체용 수지 조성물 및 복합유전체, 그 유전체를사용한 전기회로기판 |

| JP2009016169A (ja) * | 2007-07-04 | 2009-01-22 | Nippon Shokubai Co Ltd | 複合誘電体用樹脂組成物および複合誘電体、該誘電体を使用した電気回路基板 |

-

2004

- 2004-09-21 KR KR1020067006140A patent/KR100884511B1/ko not_active Expired - Fee Related

- 2004-09-21 CN CN200480028531A patent/CN100582167C/zh not_active Expired - Fee Related

- 2004-09-21 WO PCT/JP2004/013764 patent/WO2005033209A1/ja not_active Ceased

- 2004-09-21 JP JP2005514395A patent/JP4601552B2/ja not_active Expired - Fee Related

- 2004-09-21 EP EP04787947A patent/EP1669412A1/en not_active Withdrawn

- 2004-09-28 US US10/950,454 patent/US7632884B2/en not_active Expired - Fee Related

- 2004-09-29 TW TW093129323A patent/TW200513494A/zh not_active IP Right Cessation

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101452594B1 (ko) | 2012-12-26 | 2014-10-21 | 주식회사 두산 | 수지 조성물 및 이를 포함하는 금속박 적층체 |

Also Published As

| Publication number | Publication date |

|---|---|

| US7632884B2 (en) | 2009-12-15 |

| CN100582167C (zh) | 2010-01-20 |

| CN1860184A (zh) | 2006-11-08 |

| WO2005033209A1 (ja) | 2005-04-14 |

| JPWO2005033209A1 (ja) | 2006-12-14 |

| TW200513494A (en) | 2005-04-16 |

| KR100884511B1 (ko) | 2009-02-18 |

| EP1669412A1 (en) | 2006-06-14 |

| US20050101714A1 (en) | 2005-05-12 |

| TWI304830B (ja) | 2009-01-01 |

| KR20060097719A (ko) | 2006-09-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4601552B2 (ja) | 複合誘電体用樹脂組成物および複合誘電体、該誘電体を使用した電気回路基板 | |

| EP1387367B1 (en) | Composite particle for dielectrics, ultramicroparticulate composite resin particle, composition for forming dielectrics and use thereof | |

| KR101115598B1 (ko) | 에폭시 수지 조성물 | |

| TWI778307B (zh) | 樹脂組成物、包含其的預浸材、包含其的層疊板、包含其的樹脂覆蓋式金屬箔 | |

| US20050031849A1 (en) | Composite dielectric, composite dielectric sheet, composite dielectric paste, metal-layered composite dielectric, wiring board and multilayer wiring board | |

| KR20020011086A (ko) | 방향족 액정 폴리에스테르 용액 조성물 | |

| KR20110108782A (ko) | 열경화성 조성물 및 그를 이용하는 인쇄회로기판 | |

| KR102871645B1 (ko) | 금속 피복 적층판 및 회로 기판 | |

| CN111344351A (zh) | 树脂组合物、带树脂铜箔、介电层、覆铜层叠板、电容器元件以及内置电容器的印刷电路板 | |

| CN115023348B (zh) | 树脂层叠体、电介质层、带树脂的金属箔、电容器元件及电容器内置印刷电路板 | |

| KR101107847B1 (ko) | 결정질 봉지재 | |

| JP2006019621A (ja) | キャパシタ用ポリマーセラミックコンポジット材料、多層配線板及びモジュール基板 | |

| KR102226117B1 (ko) | 회로보드 구조체 및 절연 기판을 형성하기 위한 복합물 | |

| JP2009096934A (ja) | 複合誘電体用組成物、複合誘電体、及び、該複合誘電体を含む電気回路基板 | |

| JP2009016169A (ja) | 複合誘電体用樹脂組成物および複合誘電体、該誘電体を使用した電気回路基板 | |

| JP2003105205A (ja) | 高誘電率複合材料、高誘電率フィルム、金属箔付き積層板およびプリント配線板 | |

| JP4045621B2 (ja) | フッ素含有ポリイミド樹脂を含む電気絶縁材料およびそれを用いた電子部品 | |

| JP2012055095A (ja) | エレクトレット材料用重合体組成物、エレクトレット材料 | |

| JP2003119379A (ja) | 樹脂組成物とその利用 | |

| JP2004315653A (ja) | 樹脂組成物とその利用 | |

| JP2005105193A (ja) | デンドリティック多量体及び高誘電率高分子材料 | |

| JP2005109316A (ja) | 高誘電率無機材料及びそれを用いた高誘電率コンポジット材料 | |

| JP7409512B2 (ja) | 配線基板及び多層配線基板 | |

| JPS5811899B2 (ja) | ポリアミドイミド組成物 | |

| CN118667157A (zh) | 聚酰亚胺前驱物及由其制备的聚酰亚胺 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090512 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090709 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20090709 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20100223 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100524 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20100607 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100706 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100903 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20100928 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20100928 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131008 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |