JP4210285B2 - セルロース繊維の製造方法 - Google Patents

セルロース繊維の製造方法 Download PDFInfo

- Publication number

- JP4210285B2 JP4210285B2 JP2005374370A JP2005374370A JP4210285B2 JP 4210285 B2 JP4210285 B2 JP 4210285B2 JP 2005374370 A JP2005374370 A JP 2005374370A JP 2005374370 A JP2005374370 A JP 2005374370A JP 4210285 B2 JP4210285 B2 JP 4210285B2

- Authority

- JP

- Japan

- Prior art keywords

- cellulose

- solution

- nmmo

- kneader

- dissolved

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 27

- 229920003043 Cellulose fiber Polymers 0.000 title claims description 13

- 239000001913 cellulose Substances 0.000 claims abstract description 119

- 229920002678 cellulose Polymers 0.000 claims abstract description 110

- LFTLOKWAGJYHHR-UHFFFAOYSA-N N-methylmorpholine N-oxide Chemical compound CN1(=O)CCOCC1 LFTLOKWAGJYHHR-UHFFFAOYSA-N 0.000 claims abstract description 107

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 claims abstract description 64

- 238000000034 method Methods 0.000 claims abstract description 42

- 239000007788 liquid Substances 0.000 claims abstract description 34

- 230000008569 process Effects 0.000 claims abstract description 17

- 230000008961 swelling Effects 0.000 claims abstract description 16

- 239000000835 fiber Substances 0.000 claims abstract description 15

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 30

- 238000001035 drying Methods 0.000 claims description 12

- 229920000642 polymer Polymers 0.000 claims description 8

- 239000000126 substance Substances 0.000 claims description 6

- 230000015271 coagulation Effects 0.000 claims description 5

- 238000005345 coagulation Methods 0.000 claims description 5

- 238000005406 washing Methods 0.000 claims description 5

- 238000009987 spinning Methods 0.000 claims description 4

- 238000010035 extrusion spinning Methods 0.000 claims description 2

- 238000012545 processing Methods 0.000 claims description 2

- 239000003795 chemical substances by application Substances 0.000 claims 1

- 230000001112 coagulating effect Effects 0.000 claims 1

- 238000004804 winding Methods 0.000 claims 1

- 238000007711 solidification Methods 0.000 abstract description 10

- 230000008023 solidification Effects 0.000 abstract description 10

- 238000002156 mixing Methods 0.000 abstract description 5

- 239000012456 homogeneous solution Substances 0.000 abstract description 3

- 235000010980 cellulose Nutrition 0.000 description 98

- 239000000243 solution Substances 0.000 description 92

- 238000004090 dissolution Methods 0.000 description 11

- 238000003860 storage Methods 0.000 description 11

- 239000000843 powder Substances 0.000 description 10

- 229920003124 powdered cellulose Polymers 0.000 description 10

- 235000019814 powdered cellulose Nutrition 0.000 description 10

- 238000001704 evaporation Methods 0.000 description 9

- 239000002904 solvent Substances 0.000 description 9

- 239000002243 precursor Substances 0.000 description 8

- 239000010409 thin film Substances 0.000 description 8

- 238000001816 cooling Methods 0.000 description 6

- 239000002245 particle Substances 0.000 description 6

- 238000012546 transfer Methods 0.000 description 6

- 230000008020 evaporation Effects 0.000 description 5

- 230000006837 decompression Effects 0.000 description 4

- 230000000694 effects Effects 0.000 description 4

- 239000010408 film Substances 0.000 description 4

- 238000000746 purification Methods 0.000 description 4

- 239000002994 raw material Substances 0.000 description 4

- 241000157282 Aesculus Species 0.000 description 3

- 229920000875 Dissolving pulp Polymers 0.000 description 3

- 238000005054 agglomeration Methods 0.000 description 3

- 230000002776 aggregation Effects 0.000 description 3

- 230000015556 catabolic process Effects 0.000 description 3

- 230000008859 change Effects 0.000 description 3

- 230000000052 comparative effect Effects 0.000 description 3

- 230000007423 decrease Effects 0.000 description 3

- 238000006731 degradation reaction Methods 0.000 description 3

- 238000009826 distribution Methods 0.000 description 3

- 238000011156 evaluation Methods 0.000 description 3

- 235000010181 horse chestnut Nutrition 0.000 description 3

- 238000002844 melting Methods 0.000 description 3

- 230000008018 melting Effects 0.000 description 3

- 239000000203 mixture Substances 0.000 description 3

- 230000035515 penetration Effects 0.000 description 3

- 230000000704 physical effect Effects 0.000 description 3

- 238000006116 polymerization reaction Methods 0.000 description 3

- 239000002002 slurry Substances 0.000 description 3

- 239000007787 solid Substances 0.000 description 3

- NLXLAEXVIDQMFP-UHFFFAOYSA-N Ammonia chloride Chemical compound [NH4+].[Cl-] NLXLAEXVIDQMFP-UHFFFAOYSA-N 0.000 description 2

- 229920000433 Lyocell Polymers 0.000 description 2

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 2

- 229920002522 Wood fibre Polymers 0.000 description 2

- 239000000654 additive Substances 0.000 description 2

- 239000003963 antioxidant agent Substances 0.000 description 2

- 230000003078 antioxidant effect Effects 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 238000006243 chemical reaction Methods 0.000 description 2

- 238000007796 conventional method Methods 0.000 description 2

- 238000002845 discoloration Methods 0.000 description 2

- 238000005265 energy consumption Methods 0.000 description 2

- 238000010309 melting process Methods 0.000 description 2

- 238000005070 sampling Methods 0.000 description 2

- 238000010008 shearing Methods 0.000 description 2

- 230000007704 transition Effects 0.000 description 2

- 238000005303 weighing Methods 0.000 description 2

- 239000002025 wood fiber Substances 0.000 description 2

- 101100165177 Caenorhabditis elegans bath-15 gene Proteins 0.000 description 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 239000004698 Polyethylene Substances 0.000 description 1

- 239000002202 Polyethylene glycol Substances 0.000 description 1

- 239000004372 Polyvinyl alcohol Substances 0.000 description 1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 1

- 235000019270 ammonium chloride Nutrition 0.000 description 1

- 239000007864 aqueous solution Substances 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- ATSGLBOJGVTHHC-UHFFFAOYSA-N bis(ethane-1,2-diamine)copper(2+) Chemical compound [Cu+2].NCCN.NCCN ATSGLBOJGVTHHC-UHFFFAOYSA-N 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 210000002421 cell wall Anatomy 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 239000013078 crystal Substances 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 238000004821 distillation Methods 0.000 description 1

- 239000000428 dust Substances 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- 239000008187 granular material Substances 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-M hydroxide Chemical compound [OH-] XLYOFNOQVPJJNP-UHFFFAOYSA-M 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 238000004898 kneading Methods 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 238000000691 measurement method Methods 0.000 description 1

- 239000000155 melt Substances 0.000 description 1

- 229920003229 poly(methyl methacrylate) Polymers 0.000 description 1

- -1 polyethylene Polymers 0.000 description 1

- 229920000573 polyethylene Polymers 0.000 description 1

- 229920001223 polyethylene glycol Polymers 0.000 description 1

- 239000004926 polymethyl methacrylate Substances 0.000 description 1

- 229920002451 polyvinyl alcohol Polymers 0.000 description 1

- 238000010298 pulverizing process Methods 0.000 description 1

- 239000012779 reinforcing material Substances 0.000 description 1

- 230000002522 swelling effect Effects 0.000 description 1

- 229920002994 synthetic fiber Polymers 0.000 description 1

- 239000004408 titanium dioxide Substances 0.000 description 1

- 238000005292 vacuum distillation Methods 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01F—CHEMICAL FEATURES IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS; APPARATUS SPECIALLY ADAPTED FOR THE MANUFACTURE OF CARBON FILAMENTS

- D01F2/00—Monocomponent artificial filaments or the like of cellulose or cellulose derivatives; Manufacture thereof

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01D—MECHANICAL METHODS OR APPARATUS IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS

- D01D1/00—Treatment of filament-forming or like material

- D01D1/02—Preparation of spinning solutions

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01F—CHEMICAL FEATURES IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS; APPARATUS SPECIALLY ADAPTED FOR THE MANUFACTURE OF CARBON FILAMENTS

- D01F1/00—General methods for the manufacture of artificial filaments or the like

- D01F1/02—Addition of substances to the spinning solution or to the melt

- D01F1/10—Other agents for modifying properties

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/04—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres having existing or potential cohesive properties, e.g. natural fibres, prestretched or fibrillated artificial fibres

- D04H1/28—Regenerated cellulose series

-

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2201/00—Cellulose-based fibres, e.g. vegetable fibres

- D10B2201/20—Cellulose-derived artificial fibres

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Artificial Filaments (AREA)

- Processes Of Treating Macromolecular Substances (AREA)

- Polysaccharides And Polysaccharide Derivatives (AREA)

- Spinning Methods And Devices For Manufacturing Artificial Fibers (AREA)

Description

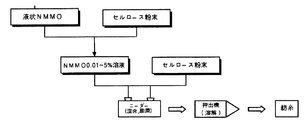

図1は、本発明の実施例としてNMMOにセルロースを少量溶解させて低温で均質なセルロース溶液及びこれから製造される繊維を製造する方法の工程順序を概略的に示したものである。

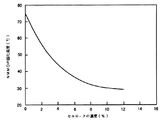

ニーダー内のセルロース粉末含有量が5重量%未満になれば、繊維としての物性を有することができなくなり、これとは違い、20重量%を超過すれば液状NMMOで溶解させることが難しく、均質な溶液を得ることができなくなる。

本発明で製造されたセルロース溶液の溶解性は、ニーダーを通過し、二軸押出機で排出された直後の溶液移送ラインでサンプリングをして偏光顕微鏡で肉眼観察した後に評価された。溶解された程度は5等級で区分され、完全溶解された状態を「1」として多量の未溶解分が存在する紡糸不可能な状態を「5」とした。その中間は、未溶解のセルロースの残存程度によって2、3、4に区分された。

溶解したセルロースの固有粘度[IV]は次のように測定された。ASTM D539−51Tによって作られた、0.1〜0.6g/dl濃度の0.5M水酸化キュプリエチレンジアミン(cupriethylenediamine hydroxide)溶液が、ウベロド(Uberod)粘度計を用いて25±0.01℃で測定された。

乾燥強度:107℃、2時間乾燥の後の強度(g/d)

湿潤強度:25℃、65RH%で24時間放置後に測定した強度(g/d)

重量平均重合体が1200であるセルロースシート(Buckeye社V−81)を、乾燥チャンバーを使用して6.5〜10%の水分率で調節した。そして500μmのスクリーンシーブが装着された粉砕機を利用して直径500μm以下で水分率が3.5〜7重量%のセルロース粉末を製造し、そして薄膜降下濃縮塔を介して87.5重量%に濃縮された90℃の液状NMMOを製造した。液状NMMOの濃縮過程で濃縮液状NMMOに対して0.001重量%の酸化防止剤を添加して溶解させた。

重量平均重合体が850であるセルロースシート(Buckeye社V−60)を、乾燥チャンバーを使用して6.5〜10%の水分率で調節した。そして500μmのスクリーンシーブが装着された粉砕機を利用して直径500μm以下で水分率が3.5〜7重量%のセルロース粉末を製造し、そして薄膜降下濃縮塔を介して87.5重量%に濃縮された85℃の液状NMMOを製造した。液状NMMOの濃縮過程で濃縮液状NMMOに対して0.001重量%の酸化防止剤を添加して溶解させた。

実施例1〜22とは違い、比較例1〜5の場合、NMMOにセルロース粉末を溶解せずに純粋な高温のNMMOをニーダーに注入してセルロース粉末と混合及び膨潤し、押出機で溶解させてセルロース溶液を製造した。

2 乾燥チャンバー

3 乾燥空気

4 水分率測定装置

5 ニップローラ

6 粉砕機

7 送風装置

8 バッグフィルタ

9 ロータリバルブ

10 貯蔵槽

11 精密重量式計量装置

12 強制移送装置

13 凝固浴

14 水洗浴

15 調整槽

16 ポンプ

17 精製塔

18 供給槽

19 薄膜降下型濃縮塔

20 ジャケット式貯蔵槽

21 精密重量式計量装置

22 溶解槽

23 溶液貯蔵槽

24 ギヤポンプ

25 ニーダー

26 二軸押出機

27 フィルター

28 ノズル

29 乾燥装置

Claims (6)

- (A)液状濃縮N−メチルモルフォリン−N−オキシドに0.01〜5重量%のセルロース粉末を少量溶解させてN−メチルモルフォリン−N−オキシド溶液を製造する工程;

(B)前記セルロース粉末が少量溶解されたN−メチルモルフォリン−N−オキシド溶液及びセルロース粉末を50℃〜95℃に保持されるニーダーに注入した後、ニーダー内で減圧過程なしにセルロースを混合、膨潤及び部分溶解させてペースト状に作製した後、前記ペーストを押出機に供給して均質化されたセルロース溶液を得る工程;

(C)前記セルロース溶液を、紡糸ノズルを介して押出紡糸した後、空気層を介して凝固浴に到達させた後、凝固させてマルチフィラメントを得る工程;

(D)前記得られたマルチフィラメントを水洗、乾燥及び油剤処理して巻き取る工程を含むセルロース繊維の製造方法。 - 前記(A)工程で、セルロースが少量溶解した後、液状N−メチルモルフォリン−N−オキシドは50℃〜95℃の温度で保持されることを特徴とする請求項1記載のセルロース繊維の製造方法。

- 前記(B)工程の押出機内で溶解させた最終セルロース溶液は、全体重量に対するセルロースの含有量が5〜20重量%の濃度であることを特徴とする請求項1記載のセルロース繊維の製造方法。

- 前記(A)工程で、N−メチルモルフォリン−N−オキシド溶液は全体重量に対する水分含有量が10〜18重量%であることを特徴とする請求項1に記載セルロース繊維の製造方法。

- 前記(B)工程でセルロースが少量溶解した液状N−メチルモルフォリン−N−オキシドが、50℃〜95℃の温度で保持されてニーダーに供給されることを特徴とする請求項1記載のセルロース繊維の製造方法。

- 前記(A)または(B)工程でのセルロース粉末は、他の高分子物質と混合されることを特徴とする請求項1記載のセルロース繊維の製造方法。

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020040116907A KR100575388B1 (ko) | 2004-12-30 | 2004-12-30 | 고균질 셀룰로오스 용액 및 이로 부터 제조된 섬유 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2006188806A JP2006188806A (ja) | 2006-07-20 |

| JP4210285B2 true JP4210285B2 (ja) | 2009-01-14 |

Family

ID=36615178

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005374370A Expired - Fee Related JP4210285B2 (ja) | 2004-12-30 | 2005-12-27 | セルロース繊維の製造方法 |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US20080054516A1 (ja) |

| EP (1) | EP1841905B1 (ja) |

| JP (1) | JP4210285B2 (ja) |

| KR (1) | KR100575388B1 (ja) |

| CN (1) | CN100354461C (ja) |

| AT (1) | ATE483044T1 (ja) |

| DE (1) | DE602005023907D1 (ja) |

| RU (1) | RU2362845C2 (ja) |

| TW (1) | TW200626617A (ja) |

| WO (1) | WO2006071101A1 (ja) |

Families Citing this family (30)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100949556B1 (ko) * | 2006-12-26 | 2010-03-25 | 주식회사 코오롱 | 셀룰로오스-폴리비닐알코올 가교 복합섬유의 제조방법 및이로부터 제조되는 가교 복합섬유 |

| KR100824980B1 (ko) * | 2006-12-28 | 2008-04-28 | 주식회사 효성 | 단면 변동 계수가 낮은 셀룰로오스 멀티 필라멘트 |

| EP2185754B1 (en) * | 2007-09-07 | 2012-06-06 | Kolon Industries Inc. | Lyocell filament fiber and cellulose based tire cord |

| CN101353824B (zh) * | 2008-09-10 | 2010-06-23 | 浙江大学 | 二次加溶剂物理溶解草植物纤维的方法 |

| CN101787576B (zh) * | 2010-03-10 | 2011-08-17 | 常熟绣珀纤维有限公司 | 一种连续冻胶纺丝法制备超高分子量聚乙烯纤维的方法及超高分子量聚乙烯纤维 |

| CN103328701B (zh) | 2010-11-30 | 2016-05-04 | 株式会社普利司通 | 精制纤维素纤维、纤维-橡胶复合体和轮胎 |

| US20130037635A1 (en) * | 2011-08-09 | 2013-02-14 | Anirudh Singh | Process for defiberizing pulp |

| CN104471121A (zh) | 2012-05-21 | 2015-03-25 | 株式会社普利司通 | 精制多糖类纤维的制造方法、精制多糖类纤维、纤维-橡胶复合体和轮胎 |

| EP2853623A4 (en) | 2012-05-21 | 2016-01-20 | Bridgestone Corp | CORD, RUBBER CORD ASSOCIATED STRUCTURE AND TIRES |

| JP2014227619A (ja) | 2013-05-21 | 2014-12-08 | 株式会社ブリヂストン | 精製多糖類繊維の製造方法、精製多糖類繊維、及びタイヤ |

| KR101455002B1 (ko) * | 2013-06-28 | 2014-11-03 | 코오롱인더스트리 주식회사 | 담배필터용 라이오셀 소재 및 그 제조방법 |

| EP3584357A1 (en) * | 2013-10-29 | 2019-12-25 | Braskem S.A. | Continuous system and method for producing at least one polymeric yarn |

| TWI667378B (zh) | 2014-01-03 | 2019-08-01 | 奧地利商蘭精股份有限公司 | 纖維素纖維 |

| KR102211219B1 (ko) | 2014-06-30 | 2021-02-03 | 코오롱인더스트리 주식회사 | 담배필터용 이형단면 라이오셀 소재 및 그 제조방법 |

| KR102211186B1 (ko) | 2014-12-31 | 2021-02-03 | 코오롱인더스트리 주식회사 | 담배필터용 라이오셀 소재 및 그 제조방법 |

| KR101888067B1 (ko) * | 2017-01-19 | 2018-08-14 | 주식회사 효성 | 첨가제를 포함하는 라이오셀 섬유 |

| KR101896476B1 (ko) * | 2017-06-19 | 2018-10-18 | 재단법인대구경북과학기술원 | 공용매를 이용한 고결정성 재생 셀룰로오스 섬유의 제조 방법 |

| CN110258162A (zh) * | 2019-06-12 | 2019-09-20 | 当阳市鸿阳新材料科技有限公司 | 制备纤维素纺丝浆液装置及其制备方法 |

| DE102019116736B4 (de) * | 2019-06-20 | 2022-03-24 | List Technology Ag | Herstellungsverfahren und Vorrichtung zur Herstellung einer Spinnlösung aus Recyclingfasern unter Verwendung des Lösungsmittelverfahrens |

| CN116120597A (zh) * | 2019-10-17 | 2023-05-16 | 武汉纺织大学 | 一种nmmo醇溶液快速溶解纤维素的方法 |

| CN113087927A (zh) * | 2020-01-09 | 2021-07-09 | 雅思雅思拉普 | 使用n-甲基吗啉-n-氧化物的均质纤维素溶液的制备方法 |

| CN111892718B (zh) * | 2020-06-22 | 2022-11-25 | 中国纺织科学研究院有限公司 | 一种干法溶解纤维素的方法 |

| FI20206386A1 (en) * | 2020-12-31 | 2022-07-01 | Infinited Fiber Company Oy | Continuous dissolution of cellulose derivatives |

| KR20230084279A (ko) * | 2021-01-04 | 2023-06-12 | 아사히 가세이 가부시키가이샤 | 셀룰로오스 섬유의 제조 방법 |

| CN112779612B (zh) * | 2021-01-07 | 2023-11-14 | 山东鸿泰鼎新材料科技有限公司 | 一种莱赛尔纤维的高效生产制造方法及设备 |

| DE102022102177A1 (de) | 2022-01-31 | 2023-08-03 | List Technology Ag | Anlage und Verfahren zur Verarbeitung eines Ausgangsmaterials zu einer Formlösung nach dem Trockenlöseverfahren |

| KR20240148820A (ko) | 2022-01-31 | 2024-10-11 | 리스트 테크놀로지 아게 | 건식 용해법에 따라 출발 물질을 처리하여 성형 용액을 제공하는 시스템 및 방법 |

| EP4219567A1 (de) | 2022-01-31 | 2023-08-02 | LIST Technology AG | Anlage und verfahren zur verarbeitung eines ausgangsmaterials zu einer formlösung nach dem trockenlöseverfahren |

| CN115182096B (zh) * | 2022-05-27 | 2024-03-22 | 杭州诺邦无纺股份有限公司 | 一种纤维素长丝非织造材料及其制备方法 |

| CN115323501B (zh) * | 2022-06-30 | 2023-06-20 | 武汉纺织大学 | 加工Lyocell纤维纺丝原液的成膜蒸发器和方法 |

Family Cites Families (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3447935A (en) * | 1967-12-21 | 1969-06-03 | Lawrence L Marley | Fluid polishing composition and method of making |

| US4144080A (en) * | 1977-07-26 | 1979-03-13 | Akzona Incorporated | Process for making amine oxide solution of cellulose |

| US4142913A (en) * | 1977-07-26 | 1979-03-06 | Akzona Incorporated | Process for making a precursor of a solution of cellulose |

| US5094690A (en) * | 1988-08-16 | 1992-03-10 | Lenzing Aktiengesellschaft | Process and arrangement for preparing a solution of cellulose |

| GB9219693D0 (en) * | 1992-09-17 | 1992-10-28 | Courtaulds Plc | Forming solutions |

| US5456748A (en) * | 1993-05-24 | 1995-10-10 | Courtaulds Fibres (Holdings) Ltd. | Premix storage hopper |

| US5370322A (en) * | 1993-05-24 | 1994-12-06 | Courtaulds Fibres (Holdings) Limited | Filtering particulate cellulosic-based material |

| KR970011096B1 (ko) * | 1993-09-09 | 1997-07-07 | 한국과학기술연구원 | 셀룰로오스와 3급 아민옥사이드의 펠렛상 혼합 분말과 셀룰로오스 방사 용액 및 그의 제조 방법 |

| RU2075560C1 (ru) * | 1994-02-10 | 1997-03-20 | Всероссийский научно-исследовательский институт полимерных волокон с опытным заводом | Способ получения раствора целлюлозы для изготовления формованных изделий |

| GB9500388D0 (en) * | 1995-01-10 | 1995-03-01 | Courtaulds Fibres Ltd | Forming solutions |

| AU5146196A (en) * | 1995-03-31 | 1996-10-16 | Akzo Nobel N.V. | Method of producing solutions of cellulose in water-containi ng tertiary-amin-n-oxides |

| AT402411B (de) * | 1995-04-19 | 1997-05-26 | Chemiefaser Lenzing Ag | Anlage sowie integriertes folien- und faserwerk zur herstellung cellulosischer folien und fasern |

| AT409130B (de) * | 1995-04-25 | 2002-05-27 | Chemiefaser Lenzing Ag | Verwendung einer vorrichtung zum halten und abgeben einer homogenen cellulosesuspension |

| DE19607953A1 (de) * | 1996-03-01 | 1997-09-04 | Kalle Nalo Gmbh | Nach dem Aminoxidverfahren hergestellte Nahrungsmittelhüllen auf Cellulosebasis |

| DE69719326T2 (de) * | 1996-06-10 | 2003-10-16 | Hanil Synthetic Fiber Co. Ltd., Masan | Verfahren zur herstellung einer homogenen celluloselösung in n-methylmorpholin-n-oxid |

| US5951933A (en) | 1997-07-24 | 1999-09-14 | Alfacel S.A. | Processes for precipitating tertiary amine oxide cellulose solutions containing water soluble polymers and products made therefrom |

| US5891375A (en) * | 1997-07-24 | 1999-04-06 | Alfacel S.A. | Processes for precipitating tertiary amine oxide cellulose solutions containing esters and products made therefrom |

| RU2156265C1 (ru) * | 1999-03-31 | 2000-09-20 | Санкт-Петербургский государственный университет технологии и дизайна | Способ получения растворов целлюлозы |

| KR100611891B1 (ko) * | 2002-04-01 | 2006-08-11 | 주식회사 효성 | 셀룰로오즈 섬유 및 그 제조 방법 |

| KR100611890B1 (ko) * | 2002-05-31 | 2006-08-11 | 주식회사 효성 | 고균질 셀룰로오스 용액의 제조방법 |

| CN1309886C (zh) * | 2003-06-30 | 2007-04-11 | 株式会社晓星 | 溶于n-甲基吗啉-n-氧化物的纤维素溶液及使用该溶液的纤维素纤维的制造方法 |

| KR100488604B1 (ko) * | 2003-07-25 | 2005-05-11 | 주식회사 효성 | 라이오셀 멀티 필라멘트 |

| US20050056956A1 (en) * | 2003-09-16 | 2005-03-17 | Biax Fiberfilm Corporation | Process for forming micro-fiber cellulosic nonwoven webs from a cellulose solution by melt blown technology and the products made thereby |

-

2004

- 2004-12-30 KR KR1020040116907A patent/KR100575388B1/ko not_active Expired - Fee Related

-

2005

- 2005-12-23 TW TW094146220A patent/TW200626617A/zh unknown

- 2005-12-27 JP JP2005374370A patent/JP4210285B2/ja not_active Expired - Fee Related

- 2005-12-30 AT AT05804903T patent/ATE483044T1/de active

- 2005-12-30 RU RU2007124513/04A patent/RU2362845C2/ru not_active IP Right Cessation

- 2005-12-30 CN CNB2005100971020A patent/CN100354461C/zh not_active Expired - Fee Related

- 2005-12-30 WO PCT/KR2005/004677 patent/WO2006071101A1/en not_active Ceased

- 2005-12-30 US US10/565,098 patent/US20080054516A1/en not_active Abandoned

- 2005-12-30 DE DE602005023907T patent/DE602005023907D1/de active Active

- 2005-12-30 EP EP05804903A patent/EP1841905B1/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| DE602005023907D1 (de) | 2010-11-11 |

| EP1841905A4 (en) | 2009-08-19 |

| EP1841905B1 (en) | 2010-09-29 |

| WO2006071101A1 (en) | 2006-07-06 |

| US20080054516A1 (en) | 2008-03-06 |

| TWI310386B (ja) | 2009-06-01 |

| RU2362845C2 (ru) | 2009-07-27 |

| RU2007124513A (ru) | 2009-02-10 |

| ATE483044T1 (de) | 2010-10-15 |

| JP2006188806A (ja) | 2006-07-20 |

| CN1796624A (zh) | 2006-07-05 |

| CN100354461C (zh) | 2007-12-12 |

| EP1841905A1 (en) | 2007-10-10 |

| TW200626617A (en) | 2006-08-01 |

| KR100575388B1 (ko) | 2006-05-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4210285B2 (ja) | セルロース繊維の製造方法 | |

| JP4004501B2 (ja) | N−メチルモルフォリン−n−オキシドに溶解させたセルロースを含む溶液及びそれを用いた高強力リヨセル繊維 | |

| JP4104596B2 (ja) | 高均質セルロース溶液及びそれを用いた高強力リヨセル繊維 | |

| JP3701643B2 (ja) | 高均質セルロース溶液の製造方法 | |

| US5584919A (en) | Pelletized pre-dope granules of cellulose and tertiary amine oxide, spinning solution, of cellulose and process for making them | |

| KR101888067B1 (ko) | 첨가제를 포함하는 라이오셀 섬유 | |

| EP1191038B1 (en) | Process for preparing homogeneous cellulose solution by using supercooled liquid n-methymorpholine-n-oxide hydrate solvent | |

| KR100540343B1 (ko) | 엔-메틸모포린-엔-옥사이드를 이용한 셀룰로오스 용액 및그의 제조방법 | |

| KR101110106B1 (ko) | 엔-메틸모폴린 엔-옥사이드를 이용한 셀룰로오스 용액 및이를 이용한 고강도 라이오셀 필라멘트 | |

| JP2024501697A (ja) | セルロース誘導体の連続溶解 | |

| KR20030097558A (ko) | 가공성이 우수한 셀룰로오즈 용액의 제조방법 | |

| KR20190049048A (ko) | 친환경 첨가제를 포함하는 라이오셀 섬유 | |

| KR101928868B1 (ko) | 고무 성분을 가지는 첨가제를 포함하는 라이오셀 섬유 | |

| KR100486815B1 (ko) | 엔-메틸모포린-엔-옥사이드를 이용한 셀룰로오스 용액 및이를 이용한 고강력 라이오셀 섬유 | |

| KR101888068B1 (ko) | 친환경 첨가제를 포함하는 라이오셀 섬유 | |

| JP3937216B2 (ja) | セルロース成形体の製造方法 | |

| KR100486811B1 (ko) | 고균질 셀룰로오스 용액으로부터 제조한 셀룰로오스섬유의 제조방법 | |

| JP2001316938A (ja) | セルロース成形体の製造方法 | |

| Gunawan et al. | the preparation of high-performance lyocell fiber—fundamental theory and industrial practice | |

| KR100488603B1 (ko) | 셀룰로오스 섬유의 제조방법 | |

| KR20180112183A (ko) | 아마이드 구조를 가지는 첨가제를 포함하는 라이오셀 섬유 | |

| JP2672937B2 (ja) | セルロースと第三アミンオキシドとのプレドープ顆粒及びその製造方法 | |

| EP0727439B1 (en) | Pelletized pre-dope granules of cellulose and tertiary amine oxide, process for making them and process for making shaped articles thereof | |

| TW201040333A (en) | Manufacturing method of cellulose fiber | |

| KR20110078122A (ko) | 펄프 용해공정을 개선한 셀룰로오스 용액의 제조방법 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20051227 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20080701 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A132 Effective date: 20080704 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20081002 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20081017 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20081024 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4210285 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111031 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121031 Year of fee payment: 4 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121031 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131031 Year of fee payment: 5 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313111 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |