JP2015516352A - 強化ガラスを加工するための方法及び装置並びにこれにより生成された製品 - Google Patents

強化ガラスを加工するための方法及び装置並びにこれにより生成された製品 Download PDFInfo

- Publication number

- JP2015516352A JP2015516352A JP2014559989A JP2014559989A JP2015516352A JP 2015516352 A JP2015516352 A JP 2015516352A JP 2014559989 A JP2014559989 A JP 2014559989A JP 2014559989 A JP2014559989 A JP 2014559989A JP 2015516352 A JP2015516352 A JP 2015516352A

- Authority

- JP

- Japan

- Prior art keywords

- substrate

- recess

- region

- laser light

- forming

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 238000000034 method Methods 0.000 title claims abstract description 61

- 238000012545 processing Methods 0.000 title claims abstract description 26

- 239000005341 toughened glass Substances 0.000 title claims description 36

- 239000000758 substrate Substances 0.000 claims abstract description 192

- 230000006835 compression Effects 0.000 claims description 35

- 238000007906 compression Methods 0.000 claims description 35

- 230000003287 optical effect Effects 0.000 claims description 21

- 230000002093 peripheral effect Effects 0.000 claims description 15

- 238000000926 separation method Methods 0.000 claims description 5

- 230000031700 light absorption Effects 0.000 claims description 2

- 230000000149 penetrating effect Effects 0.000 claims description 2

- 230000001678 irradiating effect Effects 0.000 claims 5

- 230000008569 process Effects 0.000 description 26

- 239000011521 glass Substances 0.000 description 11

- 230000015572 biosynthetic process Effects 0.000 description 6

- 239000010410 layer Substances 0.000 description 5

- 239000000203 mixture Substances 0.000 description 4

- 238000012986 modification Methods 0.000 description 3

- 230000004048 modification Effects 0.000 description 3

- 238000007796 conventional method Methods 0.000 description 2

- 230000006378 damage Effects 0.000 description 2

- 238000005553 drilling Methods 0.000 description 2

- 230000006870 function Effects 0.000 description 2

- 239000002344 surface layer Substances 0.000 description 2

- 239000005407 aluminoborosilicate glass Substances 0.000 description 1

- 239000005354 aluminosilicate glass Substances 0.000 description 1

- 239000005388 borosilicate glass Substances 0.000 description 1

- -1 but not limited to Substances 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000003486 chemical etching Methods 0.000 description 1

- 238000003426 chemical strengthening reaction Methods 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 238000005342 ion exchange Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000010295 mobile communication Methods 0.000 description 1

- 238000000059 patterning Methods 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

- 239000005361 soda-lime glass Substances 0.000 description 1

- 238000005728 strengthening Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000005496 tempering Methods 0.000 description 1

- 230000003685 thermal hair damage Effects 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/08—Devices involving relative movement between laser beam and workpiece

- B23K26/083—Devices involving movement of the workpiece in at least one axial direction

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03B—MANUFACTURE, SHAPING, OR SUPPLEMENTARY PROCESSES

- C03B33/00—Severing cooled glass

- C03B33/09—Severing cooled glass by thermal shock

- C03B33/091—Severing cooled glass by thermal shock using at least one focussed radiation beam, e.g. laser beam

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/02—Positioning or observing the workpiece, e.g. with respect to the point of impact; Aligning, aiming or focusing the laser beam

- B23K26/06—Shaping the laser beam, e.g. by masks or multi-focusing

- B23K26/062—Shaping the laser beam, e.g. by masks or multi-focusing by direct control of the laser beam

- B23K26/0622—Shaping the laser beam, e.g. by masks or multi-focusing by direct control of the laser beam by shaping pulses

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/08—Devices involving relative movement between laser beam and workpiece

- B23K26/082—Scanning systems, i.e. devices involving movement of the laser beam relative to the laser head

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/08—Devices involving relative movement between laser beam and workpiece

- B23K26/082—Scanning systems, i.e. devices involving movement of the laser beam relative to the laser head

- B23K26/0821—Scanning systems, i.e. devices involving movement of the laser beam relative to the laser head using multifaceted mirrors, e.g. polygonal mirror

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/36—Removing material

- B23K26/38—Removing material by boring or cutting

- B23K26/382—Removing material by boring or cutting by boring

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/36—Removing material

- B23K26/38—Removing material by boring or cutting

- B23K26/382—Removing material by boring or cutting by boring

- B23K26/386—Removing material by boring or cutting by boring of blind holes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/36—Removing material

- B23K26/38—Removing material by boring or cutting

- B23K26/382—Removing material by boring or cutting by boring

- B23K26/389—Removing material by boring or cutting by boring of fluid openings, e.g. nozzles, jets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/36—Removing material

- B23K26/40—Removing material taking account of the properties of the material involved

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B3/00—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form

- B32B3/26—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer

- B32B3/266—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer characterised by an apertured layer, the apertures going through the whole thickness of the layer, e.g. expanded metal, perforated layer, slit layer regular cells B32B3/12

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2103/00—Materials to be soldered, welded or cut

- B23K2103/50—Inorganic material, e.g. metals, not provided for in B23K2103/02 – B23K2103/26

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03B—MANUFACTURE, SHAPING, OR SUPPLEMENTARY PROCESSES

- C03B33/00—Severing cooled glass

- C03B33/02—Cutting or splitting sheet glass or ribbons; Apparatus or machines therefor

- C03B33/0222—Scoring using a focussed radiation beam, e.g. laser

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24273—Structurally defined web or sheet [e.g., overall dimension, etc.] including aperture

Landscapes

- Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Engineering & Computer Science (AREA)

- Plasma & Fusion (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Toxicology (AREA)

- Thermal Sciences (AREA)

- Health & Medical Sciences (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Laser Beam Processing (AREA)

- Re-Forming, After-Treatment, Cutting And Transporting Of Glass Products (AREA)

- Processing Of Stones Or Stones Resemblance Materials (AREA)

Abstract

Description

Claims (22)

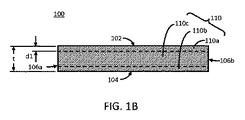

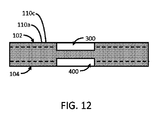

- 第1の面と該第1の面とは反対側の第2の面とを有する基板を用意し、

前記第1の面及び前記第2の面の少なくとも一方には圧縮応力がかかり、前記基板の内部は引っ張り状態となっており、

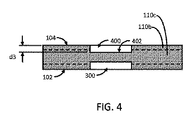

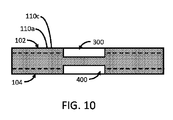

前記第1の面から前記第2の面に向かって延びる第1の凹部を前記基板に形成し、

前記第2の面から前記第1の面に向かって延びる第2の凹部を前記基板に形成し、

前記基板の前記第1の凹部から前記第2の凹部まで延びる部分を除去して、前記第1の面から前記第2の面まで延びる開口を前記基板に形成する、

方法。 - 前記基板は、前記第1の面及び前記第2の面の前記少なくとも一方から前記基板の内部に延びる少なくとも1つの圧縮領域を含み、該少なくとも1つの圧縮領域内の応力が600MPaよりも大きい、請求項1の方法。

- 前記第1の凹部、前記第2の凹部、及び前記開口からなる群から選択される少なくとも1つを形成する際に、

レーザ光源を用意し、

前記レーザ光源を用いてレーザ光ビームを生成し、

前記レーザ光ビームを光路に沿って前記基板上に照射し、

前記照射されたレーザ光ビームを用いて前記基板の部分を除去する、

請求項1の方法。 - 前記レーザ光ビームを照射する際に、10フェムト秒(fs)よりも長いパルス持続時間を有するレーザ光の少なくとも1つのパルスを照射する、請求項3の方法。

- 前記レーザ光ビームを照射する際に、100ナノ秒(ns)よりも短いパルス持続時間を有するレーザ光の少なくとも1つのパルスを照射する、請求項3の方法。

- 前記レーザ光ビームを照射する際に、前記レーザ光ビームの焦点を合わせて前記基板の外側に又は前記第1の面上に又は前記第2の面上に位置するビームウェストを生成する、請求項3の方法。

- 前記照射されるレーザ光ビームを用いて前記基板の部分を除去する際に、前記基板の部分をアブレートする、請求項3の方法。

- 前記照射されるレーザ光ビームを用いて前記基板の部分を除去する際に、前記基板の部分での光の多光子吸収を誘起する、請求項3の方法。

- さらに、

前記基板の加工領域内で複数の除去経路に沿って前記光路を移動させ、

前記光路の移動に基づいて前記加工領域内で前記基板の部分を除去する、

請求項3の方法。 - 前記複数の除去経路のうちの少なくとも1つの除去経路が前記複数の除去経路のうちの他の除去経路と同心的である、請求項9の方法。

- 前記複数の除去経路のうちの少なくとも1つの除去経路が前記複数の除去経路のうちの他の除去経路と平行である、請求項9の方法。

- 前記第1の凹部を形成する際に、前記レーザ光ビームを前記第1の面を通過させ、該第1の面の通過後に前記第2の面を通過させるように照射する、請求項3の方法。

- 前記第2の凹部を形成する際に、前記レーザ光ビームを前記第1の面を通過させ、該第1の面の通過後に前記第2の面を通過させるように照射する、請求項3の方法。

- さらに、前記第1の凹部の形成と前記第2の凹部の形成との間で、前記基板に対する前記ビームウェストの位置を光軸に沿って変化させる、請求項3の方法。

- 前記第1の凹部から前記第2の凹部まで延びる前記基板の部分を除去する際に、前記レーザ光ビームを前記第1の凹部を通過させ、該第1の凹部の通過後に前記第2の凹部を通過させるように照射する、請求項3の方法。

- 前記第1の面及び前記第2の面の少なくとも一方は縁部と境界を接しており、前記第1の面及び前記第2の面の少なくとも一方に形成された前記開口の周縁は前記縁部から離間している、請求項1の方法。

- 前記周縁により囲まれる面積は0.7mm2よりも大きく50mm2よりも小さい、請求項16の方法。

- 前記周縁は、0.25mm-1よりも大きく2mm-1よりも小さい曲率半径を有する湾曲部を有する、請求項16の方法。

- 前記周縁は、第1の直線領域と第2の直線領域とを有し、前記第2の直線領域は、前記第1の直線領域から0.5mmよりも大きく8mmよりも小さい最小離間距離だけ離れている、請求項16の方法。

- 第1の圧縮領域と、第2の圧縮領域と、前記第1の圧縮領域と前記第2の圧縮領域との間に配置された引っ張り領域とを備えた強化ガラス基板に開口を形成する方法であって、

前記第1の圧縮領域内に配置された前記基板の第1の部分を除去し、

前記第2の圧縮領域内に配置された前記基板の第2の部分を除去し、

前記第1の部分及び前記第2の部分の除去後に、前記引っ張り領域内に配置された前記基板の第3の部分を除去する、

方法。 - 強化ガラス製品であって、

前記製品の表面から前記製品内の40μm以上の層深さ(DOL)まで延びる外側領域であって、600MPa以上の圧縮応力に等しい圧縮応力がかかる外側領域と、

前記製品内でかつ前記外側領域に隣接する内側領域であって、引っ張り応力がかかる内側領域と、

前記外側領域及び前記内側領域を貫通する開口と、

を備える、強化ガラス製品。 - 第1の面と該第1の面とは反対側の第2の面とを有する基板に開口を形成するための装置であって、

ビームウェストを有するレーザ光集束ビームを光路に沿って照射するように構成されるレーザシステムと、

強化ガラス基板を支持するように構成されるワークピース支持システムと、

前記レーザシステム及び前記ワークピース支持システムの少なくとも一方に連結されるコントローラと、

を備え、

前記コントローラは、

前記第1の面から前記第2の面に向かって延びる第1の凹部を前記基板に形成し、

前記第2の面から前記第1の面に向かって延びる第2の凹部を前記基板に形成し、

前記基板の前記第1の凹部から前記第2の凹部まで延びる部分を除去して、前記第1の面から前記第2の面まで延びる開口を前記基板に形成するように、

前記レーザシステム及び前記ワークピース支持システムの前記少なくとも一方を制御するための指令を実行するように構成されるプロセッサと、

前記指令を格納するように構成されるメモリと、

を備える、

装置。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201261604544P | 2012-02-29 | 2012-02-29 | |

| US61/604,544 | 2012-02-29 | ||

| PCT/US2013/028022 WO2013130608A1 (en) | 2012-02-29 | 2013-02-27 | Methods and apparatus for machining strengthened glass and articles produced thereby |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2015516352A true JP2015516352A (ja) | 2015-06-11 |

| JP2015516352A5 JP2015516352A5 (ja) | 2016-04-14 |

Family

ID=49003161

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014559989A Ceased JP2015516352A (ja) | 2012-02-29 | 2013-02-27 | 強化ガラスを加工するための方法及び装置並びにこれにより生成された製品 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US9227868B2 (ja) |

| JP (1) | JP2015516352A (ja) |

| KR (1) | KR20140131520A (ja) |

| CN (1) | CN104114506B (ja) |

| TW (1) | TWI573186B (ja) |

| WO (1) | WO2013130608A1 (ja) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2020199556A (ja) * | 2019-06-05 | 2020-12-17 | 株式会社ディスコ | 切削ブレードの製造方法、及び切削ブレード |

Families Citing this family (46)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9610653B2 (en) | 2012-09-21 | 2017-04-04 | Electro Scientific Industries, Inc. | Method and apparatus for separation of workpieces and articles produced thereby |

| WO2014079478A1 (en) * | 2012-11-20 | 2014-05-30 | Light In Light Srl | High speed laser processing of transparent materials |

| EP2754524B1 (de) | 2013-01-15 | 2015-11-25 | Corning Laser Technologies GmbH | Verfahren und Vorrichtung zum laserbasierten Bearbeiten von flächigen Substraten, d.h. Wafer oder Glaselement, unter Verwendung einer Laserstrahlbrennlinie |

| EP2781296B1 (de) | 2013-03-21 | 2020-10-21 | Corning Laser Technologies GmbH | Vorrichtung und verfahren zum ausschneiden von konturen aus flächigen substraten mittels laser |

| DE102013005136A1 (de) * | 2013-03-26 | 2014-10-02 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Verfahren zurn Abtragen von sprödhartem Material mittels Laserstrahlung |

| US9328011B2 (en) * | 2013-06-04 | 2016-05-03 | Coherent, Inc. | Laser-scribing of chemically strengthened glass |

| CN104513004B (zh) * | 2013-09-30 | 2018-04-24 | 鸿富锦精密工业(深圳)有限公司 | 化学强化玻璃的切割方法 |

| US20150165560A1 (en) | 2013-12-17 | 2015-06-18 | Corning Incorporated | Laser processing of slots and holes |

| US9676167B2 (en) | 2013-12-17 | 2017-06-13 | Corning Incorporated | Laser processing of sapphire substrate and related applications |

| US9850160B2 (en) | 2013-12-17 | 2017-12-26 | Corning Incorporated | Laser cutting of display glass compositions |

| US10442719B2 (en) | 2013-12-17 | 2019-10-15 | Corning Incorporated | Edge chamfering methods |

| US9815730B2 (en) | 2013-12-17 | 2017-11-14 | Corning Incorporated | Processing 3D shaped transparent brittle substrate |

| US11556039B2 (en) | 2013-12-17 | 2023-01-17 | Corning Incorporated | Electrochromic coated glass articles and methods for laser processing the same |

| US9517963B2 (en) | 2013-12-17 | 2016-12-13 | Corning Incorporated | Method for rapid laser drilling of holes in glass and products made therefrom |

| US9701563B2 (en) | 2013-12-17 | 2017-07-11 | Corning Incorporated | Laser cut composite glass article and method of cutting |

| EP3166895B1 (en) | 2014-07-08 | 2021-11-24 | Corning Incorporated | Methods and apparatuses for laser processing materials |

| JP2017530867A (ja) * | 2014-07-14 | 2017-10-19 | コーニング インコーポレイテッド | 長さおよび直径の調節可能なレーザビーム焦線を用いて透明材料を加工するためのシステムおよび方法 |

| US10335902B2 (en) | 2014-07-14 | 2019-07-02 | Corning Incorporated | Method and system for arresting crack propagation |

| CN107073641B (zh) | 2014-07-14 | 2020-11-10 | 康宁股份有限公司 | 接口块;用于使用这种接口块切割在波长范围内透明的衬底的系统和方法 |

| EP3169635B1 (en) | 2014-07-14 | 2022-11-23 | Corning Incorporated | Method and system for forming perforations |

| US10047001B2 (en) | 2014-12-04 | 2018-08-14 | Corning Incorporated | Glass cutting systems and methods using non-diffracting laser beams |

| WO2016115017A1 (en) | 2015-01-12 | 2016-07-21 | Corning Incorporated | Laser cutting of thermally tempered substrates using the multi photon absorption method |

| WO2016154284A1 (en) | 2015-03-24 | 2016-09-29 | Corning Incorporated | Laser cutting and processing of display glass compositions |

| DE102015104802A1 (de) * | 2015-03-27 | 2016-09-29 | Schott Ag | Verfahren zum Trennen von Glas mittels eines Lasers, sowie verfahrensgemäß hergestelltes Glaserzeugnis |

| WO2016160391A1 (en) | 2015-03-27 | 2016-10-06 | Corning Incorporated | Gas permeable window and method of fabricating the same |

| CN107925217A (zh) * | 2015-06-16 | 2018-04-17 | 伊雷克托科学工业股份有限公司 | 用于处理透明材料的方法及设备 |

| KR102499697B1 (ko) | 2015-07-10 | 2023-02-14 | 코닝 인코포레이티드 | 유연한 기판 시트에서의 홀의 연속 제조 방법 및 이에 관한 물품 |

| US10442720B2 (en) * | 2015-10-01 | 2019-10-15 | AGC Inc. | Method of forming hole in glass substrate by using pulsed laser, and method of producing glass substrate provided with hole |

| FR3050990B1 (fr) * | 2016-05-03 | 2018-05-18 | Saint-Gobain Glass France | Faconnage de verre apres trempe |

| MY194570A (en) | 2016-05-06 | 2022-12-02 | Corning Inc | Laser cutting and removal of contoured shapes from transparent substrates |

| US10410883B2 (en) | 2016-06-01 | 2019-09-10 | Corning Incorporated | Articles and methods of forming vias in substrates |

| US10794679B2 (en) | 2016-06-29 | 2020-10-06 | Corning Incorporated | Method and system for measuring geometric parameters of through holes |

| WO2018022476A1 (en) | 2016-07-29 | 2018-02-01 | Corning Incorporated | Apparatuses and methods for laser processing |

| JP2019532908A (ja) | 2016-08-30 | 2019-11-14 | コーニング インコーポレイテッド | 強度マッピング光学システムによる材料のレーザー切断 |

| JP6923284B2 (ja) | 2016-09-30 | 2021-08-18 | コーニング インコーポレイテッド | 非軸対称ビームスポットを用いて透明被加工物をレーザ加工するための装置及び方法 |

| JP7066701B2 (ja) | 2016-10-24 | 2022-05-13 | コーニング インコーポレイテッド | シート状ガラス基体のレーザに基づく加工のための基体処理ステーション |

| US10752534B2 (en) | 2016-11-01 | 2020-08-25 | Corning Incorporated | Apparatuses and methods for laser processing laminate workpiece stacks |

| US10688599B2 (en) | 2017-02-09 | 2020-06-23 | Corning Incorporated | Apparatus and methods for laser processing transparent workpieces using phase shifted focal lines |

| US10580725B2 (en) | 2017-05-25 | 2020-03-03 | Corning Incorporated | Articles having vias with geometry attributes and methods for fabricating the same |

| US11078112B2 (en) | 2017-05-25 | 2021-08-03 | Corning Incorporated | Silica-containing substrates with vias having an axially variable sidewall taper and methods for forming the same |

| US10626040B2 (en) | 2017-06-15 | 2020-04-21 | Corning Incorporated | Articles capable of individual singulation |

| US11554984B2 (en) | 2018-02-22 | 2023-01-17 | Corning Incorporated | Alkali-free borosilicate glasses with low post-HF etch roughness |

| CN108381042A (zh) * | 2018-03-23 | 2018-08-10 | 伊欧激光科技(苏州)有限公司 | 晶片加工系统及晶片加工方法 |

| US11052490B2 (en) * | 2018-04-27 | 2021-07-06 | The Boeing Company | Inner barrel of an engine inlet with laser-machined acoustic perforations |

| US11524366B2 (en) * | 2018-07-26 | 2022-12-13 | Coherent Munich GmbH & Co. KG | Separation and release of laser-processed brittle material |

| CN109128513B (zh) * | 2018-08-27 | 2020-09-29 | 蓝思科技(长沙)有限公司 | 一种盲孔的加工方法 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2012031018A (ja) * | 2010-07-30 | 2012-02-16 | Asahi Glass Co Ltd | 強化ガラス基板及び強化ガラス基板の溝加工方法と強化ガラス基板の切断方法 |

| JP2013043795A (ja) * | 2011-08-23 | 2013-03-04 | Nippon Electric Glass Co Ltd | 強化ガラス及びその製造方法 |

Family Cites Families (120)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4702042A (en) | 1984-09-27 | 1987-10-27 | Libbey-Owens-Ford Co. | Cutting strengthened glass |

| US4828900A (en) | 1987-12-23 | 1989-05-09 | Ppg Industries, Inc. | Discrete glass cutting and edge shaping |

| GB2227965B (en) | 1988-10-12 | 1993-02-10 | Rolls Royce Plc | Apparatus for drilling a shaped hole in a workpiece |

| DE69132523D1 (de) | 1990-05-09 | 2001-03-08 | Canon Kk | Erzeugung von Mustern und Herstellungsverfahren für Halbleiteranordnungen mit diesem Muster |

| RU2024441C1 (ru) | 1992-04-02 | 1994-12-15 | Владимир Степанович Кондратенко | Способ резки неметаллических материалов |

| US5637244A (en) | 1993-05-13 | 1997-06-10 | Podarok International, Inc. | Method and apparatus for creating an image by a pulsed laser beam inside a transparent material |

| US5665134A (en) | 1995-06-07 | 1997-09-09 | Hughes Missile Systems Company | Laser machining of glass-ceramic materials |

| US6373026B1 (en) | 1996-07-31 | 2002-04-16 | Mitsubishi Denki Kabushiki Kaisha | Laser beam machining method for wiring board, laser beam machining apparatus for wiring board, and carbonic acid gas laser oscillator for machining wiring board |

| JP3923526B2 (ja) | 1995-08-31 | 2007-06-06 | コーニング インコーポレイテッド | 壊れやすい材料の分断方法および装置 |

| US6820330B1 (en) | 1996-12-13 | 2004-11-23 | Tessera, Inc. | Method for forming a multi-layer circuit assembly |

| US5973290A (en) | 1997-02-26 | 1999-10-26 | W. L. Gore & Associates, Inc. | Laser apparatus having improved via processing rate |

| JP3957010B2 (ja) | 1997-06-04 | 2007-08-08 | 日本板硝子株式会社 | 微細孔を有するガラス基材 |

| US6577472B2 (en) | 1997-07-24 | 2003-06-10 | Hitachi, Ltd. | Glass substrate for a magnetic disk, a magnetic disk which can be formed with a stable texture |

| DE19741329C1 (de) | 1997-09-19 | 1998-10-22 | Fraunhofer Ges Forschung | Verfahren und Vorrichtung zur Materialbearbeitung mit Plasma induzierender Hochenergiestrahlung |

| JPH11134645A (ja) | 1997-10-30 | 1999-05-21 | Hoya Corp | 情報記録媒体用ガラス基板及びその製造方法 |

| JP3449201B2 (ja) * | 1997-11-28 | 2003-09-22 | 日亜化学工業株式会社 | 窒化物半導体素子の製造方法 |

| DE10029110B4 (de) | 1999-06-15 | 2006-05-18 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Verfahren für die Materialbearbeitung und Verwendung desselben |

| US6795274B1 (en) | 1999-09-07 | 2004-09-21 | Asahi Glass Company, Ltd. | Method for manufacturing a substantially circular substrate by utilizing scribing |

| WO2001054853A2 (en) | 2000-01-27 | 2001-08-02 | National Research Council Of Canada | Method and apparatus for repair of defects in materials with short laser pulses |

| US20010035447A1 (en) | 2000-05-05 | 2001-11-01 | Andreas Gartner | Methods for laser cut initiation |

| JP2001354439A (ja) | 2000-06-12 | 2001-12-25 | Matsushita Electric Ind Co Ltd | ガラス基板の加工方法および高周波回路の製作方法 |

| JP4786783B2 (ja) * | 2000-08-18 | 2011-10-05 | 日本板硝子株式会社 | ガラス板の切断方法及び記録媒体用ガラス円盤 |

| JP3722731B2 (ja) * | 2000-09-13 | 2005-11-30 | 浜松ホトニクス株式会社 | レーザ加工方法 |

| JP4659300B2 (ja) | 2000-09-13 | 2011-03-30 | 浜松ホトニクス株式会社 | レーザ加工方法及び半導体チップの製造方法 |

| WO2002024396A1 (en) | 2000-09-20 | 2002-03-28 | Electro Scientific Industries, Inc. | Uv laser cutting or shape modification of brittle, high melting temperature target materials such as ceramics or glasses |

| JP4150155B2 (ja) | 2000-10-10 | 2008-09-17 | 株式会社日立製作所 | 情報記録媒体、情報の記録方法、再生方法、記録記録装置及び情報再生装置 |

| US6962279B1 (en) * | 2000-10-18 | 2005-11-08 | Ge Medical Systems Global Technology Company, Llc | Apparatus and method for glass separation for flat panel displays |

| JP4512786B2 (ja) | 2000-11-17 | 2010-07-28 | 独立行政法人産業技術総合研究所 | ガラス基板の加工方法 |

| US6812430B2 (en) | 2000-12-01 | 2004-11-02 | Lg Electronics Inc. | Glass cutting method and apparatus with controlled laser beam energy |

| US20030044539A1 (en) | 2001-02-06 | 2003-03-06 | Oswald Robert S. | Process for producing photovoltaic devices |

| JP2002241141A (ja) | 2001-02-08 | 2002-08-28 | Nippon Steel Techno Research Corp | レーザによるガラスの加工方法及び装置 |

| JP4631196B2 (ja) * | 2001-04-04 | 2011-02-16 | ソニー株式会社 | ガラス基板の製造方法およびガラス基板の製造装置 |

| WO2003002289A1 (en) | 2001-06-28 | 2003-01-09 | Electro Scientific Industries, Inc. | Multistep laser processing of wafers supporting surface device layers |

| US6642476B2 (en) | 2001-07-23 | 2003-11-04 | Siemens Automative Corporation | Apparatus and method of forming orifices and chamfers for uniform orifice coefficient and surface properties by laser |

| US6521862B1 (en) | 2001-10-09 | 2003-02-18 | International Business Machines Corporation | Apparatus and method for improving chamfer quality of disk edge surfaces with laser treatment |

| US6642477B1 (en) | 2001-10-23 | 2003-11-04 | Imra America, Inc. | Method for laser drilling a counter-tapered through-hole in a material |

| US7553390B2 (en) * | 2001-11-08 | 2009-06-30 | Sharp Kabushiki Kaisha | Method and device for parting glass substrate, liquid crystal panel, and liquid crystal panel manufacturing device |

| JP2003160348A (ja) | 2001-11-21 | 2003-06-03 | Nippon Sheet Glass Co Ltd | 情報記録媒体用ガラス基板及びその製造方法 |

| US6720519B2 (en) | 2001-11-30 | 2004-04-13 | Matsushita Electric Industrial Co., Ltd. | System and method of laser drilling |

| JP2003226551A (ja) | 2002-02-05 | 2003-08-12 | Nippon Sheet Glass Co Ltd | 微細孔を有するガラス板およびその製造方法 |

| RU2226183C2 (ru) | 2002-02-21 | 2004-03-27 | Алексеев Андрей Михайлович | Способ резки прозрачных неметаллических материалов |

| JP4267240B2 (ja) | 2002-02-22 | 2009-05-27 | 日本板硝子株式会社 | ガラス構造物の製造方法 |

| US6756563B2 (en) | 2002-03-07 | 2004-06-29 | Orbotech Ltd. | System and method for forming holes in substrates containing glass |

| FR2839508B1 (fr) * | 2002-05-07 | 2005-03-04 | Saint Gobain | Vitrage decoupe sans rompage |

| US6809291B1 (en) | 2002-08-30 | 2004-10-26 | Southeastern Universities Research Assn., Inc. | Process for laser machining and surface treatment |

| KR100497820B1 (ko) | 2003-01-06 | 2005-07-01 | 로체 시스템즈(주) | 유리판절단장치 |

| JP2004299969A (ja) | 2003-03-31 | 2004-10-28 | Toshiba Ceramics Co Ltd | シリカガラスのスライス方法 |

| CA2424442C (en) | 2003-03-31 | 2011-09-20 | Institut National D'optique | Method for engraving materials using laser etched v-grooves |

| JP2004343008A (ja) | 2003-05-19 | 2004-12-02 | Disco Abrasive Syst Ltd | レーザ光線を利用した被加工物分割方法 |

| US6949449B2 (en) * | 2003-07-11 | 2005-09-27 | Electro Scientific Industries, Inc. | Method of forming a scribe line on a ceramic substrate |

| US20050087522A1 (en) | 2003-10-24 | 2005-04-28 | Yunlong Sun | Laser processing of a locally heated target material |

| JP2005268752A (ja) | 2004-02-19 | 2005-09-29 | Canon Inc | レーザ割断方法、被割断部材および半導体素子チップ |

| FI120082B (fi) | 2004-03-18 | 2009-06-30 | Antti Salminen | Menetelmä materiaalin työstämiseksi suuritehotiheyksisellä sähkömagneettisella säteilyllä |

| DE102004020737A1 (de) | 2004-04-27 | 2005-11-24 | Lzh Laserzentrum Hannover E.V. | Vorrichtung zum Durchtrennen von Bauteilen aus sprödbrüchigen Materialien mit spannungsfreier Bauteillagerung |

| DE102004024475A1 (de) | 2004-05-14 | 2005-12-01 | Lzh Laserzentrum Hannover E.V. | Verfahren und Vorrichtung zum Trennen von Halbleitermaterialien |

| US7060933B2 (en) | 2004-06-08 | 2006-06-13 | Igor Troitski | Method and laser system for production of laser-induced images inside and on the surface of transparent material |

| JP4916312B2 (ja) | 2004-07-30 | 2012-04-11 | 三星ダイヤモンド工業株式会社 | 基板の垂直クラック形成方法および垂直クラック形成装置 |

| US7598167B2 (en) | 2004-08-24 | 2009-10-06 | Micron Technology, Inc. | Method of forming vias in semiconductor substrates without damaging active regions thereof and resulting structures |

| US7378342B2 (en) | 2004-08-27 | 2008-05-27 | Micron Technology, Inc. | Methods for forming vias varying lateral dimensions |

| US7528342B2 (en) | 2005-02-03 | 2009-05-05 | Laserfacturing, Inc. | Method and apparatus for via drilling and selective material removal using an ultrafast pulse laser |

| US20070012665A1 (en) | 2005-07-12 | 2007-01-18 | Hewlett-Packard Development Company Lp | Laser ablation |

| JP2007283318A (ja) | 2006-04-13 | 2007-11-01 | Seiko Epson Corp | 基体の製造方法、レーザ加工装置、表示装置、電気光学装置、電子機器 |

| JP2007290011A (ja) | 2006-04-26 | 2007-11-08 | Seiko Epson Corp | 基板ならびに基板の分断方法、電気光学装置、電子機器 |

| US20070272666A1 (en) | 2006-05-25 | 2007-11-29 | O'brien James N | Infrared laser wafer scribing using short pulses |

| US8624157B2 (en) | 2006-05-25 | 2014-01-07 | Electro Scientific Industries, Inc. | Ultrashort laser pulse wafer scribing |

| JP2007319881A (ja) | 2006-05-31 | 2007-12-13 | Seiko Epson Corp | 基体の製造方法、レーザ加工装置、表示装置、電気光学装置、電子機器 |

| US8394301B2 (en) | 2006-06-02 | 2013-03-12 | Electro Scientific Industries, Inc. | Process for forming panel with an optically transmissive portion and products related thereto |

| US20080093775A1 (en) | 2006-08-19 | 2008-04-24 | Colorado State University Research Foundation | Nanometer-scale ablation using focused, coherent extreme ultraviolet/soft x-ray light |

| DE102006046313B3 (de) | 2006-09-29 | 2008-01-24 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Verfahren und Anordnung zum Strukturieren einer lichtleitenden Faser entlang deren Längsachse (longitudinale Strukturierung) basierend auf der nicht-linearen Absorption von Laserstrahlung |

| US8530784B2 (en) | 2007-02-01 | 2013-09-10 | Orbotech Ltd. | Method and system of machining using a beam of photons |

| DE102007009786B4 (de) | 2007-02-27 | 2013-09-05 | Schott Ag | Beschichtetes vorgespanntes Glas, Verfahren zu dessen Herstellung und dessen Verwendung |

| US7982162B2 (en) | 2007-05-15 | 2011-07-19 | Corning Incorporated | Method and apparatus for scoring and separating a brittle material with a single beam of radiation |

| US20080290077A1 (en) | 2007-05-22 | 2008-11-27 | Demeritt Jeffery Alan | Separation of transparent glasses and systems and methods therefor |

| US8710402B2 (en) | 2007-06-01 | 2014-04-29 | Electro Scientific Industries, Inc. | Method of and apparatus for laser drilling holes with improved taper |

| US20090020511A1 (en) | 2007-07-17 | 2009-01-22 | Kommera Swaroop K | Ablation |

| US20090045179A1 (en) | 2007-08-15 | 2009-02-19 | Ellen Marie Kosik Williams | Method and system for cutting solid materials using short pulsed laser |

| JP2009061462A (ja) | 2007-09-05 | 2009-03-26 | Sumitomo Electric Ind Ltd | 基板の製造方法および基板 |

| CN101610870B (zh) | 2007-10-16 | 2013-09-11 | 三星钻石工业股份有限公司 | 脆性材料基板的u形槽加工方法以及使用该方法的去除加工方法、打孔加工方法和倒角方法 |

| JP2009167086A (ja) * | 2007-12-18 | 2009-07-30 | Hoya Corp | 携帯端末用カバーガラス及びその製造方法、並びに携帯端末装置 |

| ES2362696T3 (es) | 2008-02-26 | 2011-07-11 | Rioglass Solar, S.A. | Elemento reflector para un reflector de calor solar y método para producir el mismo. |

| CN102006964B (zh) | 2008-03-21 | 2016-05-25 | Imra美国公司 | 基于激光的材料加工方法和系统 |

| US8093532B2 (en) | 2008-03-31 | 2012-01-10 | Electro Scientific Industries, Inc. | Laser machining of fired ceramic and other hard and/or thick materials |

| JP2009280452A (ja) | 2008-05-23 | 2009-12-03 | Central Glass Co Ltd | ガラス基板及び製造方法 |

| CN103043900A (zh) | 2008-08-08 | 2013-04-17 | 康宁股份有限公司 | 强化的玻璃制品及其制造方法 |

| US9346130B2 (en) * | 2008-12-17 | 2016-05-24 | Electro Scientific Industries, Inc. | Method for laser processing glass with a chamfered edge |

| US8347651B2 (en) | 2009-02-19 | 2013-01-08 | Corning Incorporated | Method of separating strengthened glass |

| US8341976B2 (en) | 2009-02-19 | 2013-01-01 | Corning Incorporated | Method of separating strengthened glass |

| US8327666B2 (en) | 2009-02-19 | 2012-12-11 | Corning Incorporated | Method of separating strengthened glass |

| US9685186B2 (en) | 2009-02-27 | 2017-06-20 | Applied Materials, Inc. | HDD pattern implant system |

| KR101041137B1 (ko) | 2009-03-25 | 2011-06-13 | 삼성모바일디스플레이주식회사 | 기판 절단 장치 및 이를 이용한 기판 절단 방법 |

| US8350187B2 (en) | 2009-03-28 | 2013-01-08 | Electro Scientific Industries, Inc. | Method and apparatus for laser machining |

| TWI523720B (zh) | 2009-05-28 | 2016-03-01 | 伊雷克托科學工業股份有限公司 | 應用於雷射處理工件中的特徵的聲光偏轉器及相關雷射處理方法 |

| US8932510B2 (en) | 2009-08-28 | 2015-01-13 | Corning Incorporated | Methods for laser cutting glass substrates |

| US8943855B2 (en) * | 2009-08-28 | 2015-02-03 | Corning Incorporated | Methods for laser cutting articles from ion exchanged glass substrates |

| JP5565659B2 (ja) * | 2009-10-22 | 2014-08-06 | 株式会社ブイ・テクノロジー | レーザ加工装置 |

| US8946590B2 (en) | 2009-11-30 | 2015-02-03 | Corning Incorporated | Methods for laser scribing and separating glass substrates |

| US20110127242A1 (en) | 2009-11-30 | 2011-06-02 | Xinghua Li | Methods for laser scribing and separating glass substrates |

| JP5795000B2 (ja) * | 2009-11-30 | 2015-10-14 | コーニング インコーポレイテッド | ガラス基板のレーザスクライブおよび分離方法 |

| JP5451443B2 (ja) * | 2010-02-15 | 2014-03-26 | 株式会社ジャパンディスプレイ | 電気的固体装置の製造方法 |

| US8743165B2 (en) | 2010-03-05 | 2014-06-03 | Micronic Laser Systems Ab | Methods and device for laser processing |

| TWI494284B (zh) | 2010-03-19 | 2015-08-01 | Corning Inc | 強化玻璃之機械劃割及分離 |

| DE102010012265B4 (de) | 2010-03-22 | 2012-09-06 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Verfahren zum Heraustrennen von Einzelscheiben aus einer Verbundglastafel und Verwendung einer Vorrichtung dafür |

| JP5693705B2 (ja) | 2010-03-30 | 2015-04-01 | イムラ アメリカ インコーポレイテッド | レーザベースの材料加工装置及び方法 |

| EP2371778A1 (en) | 2010-03-30 | 2011-10-05 | Linde Aktiengesellschaft | Method for producing toughened flat glass with anti-reflective properties |

| US8383984B2 (en) | 2010-04-02 | 2013-02-26 | Electro Scientific Industries, Inc. | Method and apparatus for laser singulation of brittle materials |

| JP2011230940A (ja) | 2010-04-26 | 2011-11-17 | Mitsuboshi Diamond Industrial Co Ltd | 脆性材料基板の割断方法 |

| JP2011251879A (ja) | 2010-06-02 | 2011-12-15 | Asahi Glass Co Ltd | 化学強化ガラスの切断方法および切断装置 |

| JP5664471B2 (ja) * | 2010-06-28 | 2015-02-04 | 信越化学工業株式会社 | 半導体用合成石英ガラス基板の製造方法 |

| US8393175B2 (en) * | 2010-08-26 | 2013-03-12 | Corning Incorporated | Methods for extracting strengthened glass substrates from glass sheets |

| US8584354B2 (en) * | 2010-08-26 | 2013-11-19 | Corning Incorporated | Method for making glass interposer panels |

| US8607590B2 (en) * | 2010-11-30 | 2013-12-17 | Corning Incorporated | Methods for separating glass articles from strengthened glass substrate sheets |

| US8616024B2 (en) * | 2010-11-30 | 2013-12-31 | Corning Incorporated | Methods for forming grooves and separating strengthened glass substrate sheets |

| US20120168412A1 (en) * | 2011-01-05 | 2012-07-05 | Electro Scientific Industries, Inc | Apparatus and method for forming an aperture in a substrate |

| US8539794B2 (en) | 2011-02-01 | 2013-09-24 | Corning Incorporated | Strengthened glass substrate sheets and methods for fabricating glass panels from glass substrate sheets |

| US8584490B2 (en) | 2011-02-18 | 2013-11-19 | Corning Incorporated | Laser cutting method |

| US8635887B2 (en) * | 2011-08-10 | 2014-01-28 | Corning Incorporated | Methods for separating glass substrate sheets by laser-formed grooves |

| JP4932059B1 (ja) * | 2011-12-16 | 2012-05-16 | 株式会社ミクロ技術研究所 | 強化ガラス、タッチパネル、及び強化ガラスの製造方法 |

| CN104125934A (zh) | 2012-02-28 | 2014-10-29 | 伊雷克托科学工业股份有限公司 | 用于分离强化玻璃的方法及装置及由该强化玻璃生产的物品 |

| US9828277B2 (en) | 2012-02-28 | 2017-11-28 | Electro Scientific Industries, Inc. | Methods for separation of strengthened glass |

| US9828278B2 (en) | 2012-02-28 | 2017-11-28 | Electro Scientific Industries, Inc. | Method and apparatus for separation of strengthened glass and articles produced thereby |

-

2013

- 2013-02-27 CN CN201380009749.6A patent/CN104114506B/zh not_active Expired - Fee Related

- 2013-02-27 JP JP2014559989A patent/JP2015516352A/ja not_active Ceased

- 2013-02-27 KR KR1020147023835A patent/KR20140131520A/ko active Search and Examination

- 2013-02-27 WO PCT/US2013/028022 patent/WO2013130608A1/en active Application Filing

- 2013-02-27 US US13/779,183 patent/US9227868B2/en not_active Expired - Fee Related

- 2013-03-01 TW TW102107470A patent/TWI573186B/zh not_active IP Right Cessation

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2012031018A (ja) * | 2010-07-30 | 2012-02-16 | Asahi Glass Co Ltd | 強化ガラス基板及び強化ガラス基板の溝加工方法と強化ガラス基板の切断方法 |

| JP2013043795A (ja) * | 2011-08-23 | 2013-03-04 | Nippon Electric Glass Co Ltd | 強化ガラス及びその製造方法 |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2020199556A (ja) * | 2019-06-05 | 2020-12-17 | 株式会社ディスコ | 切削ブレードの製造方法、及び切削ブレード |

| JP7368110B2 (ja) | 2019-06-05 | 2023-10-24 | 株式会社ディスコ | 切削ブレードの製造方法、及び切削ブレード |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20140131520A (ko) | 2014-11-13 |

| TW201351496A (zh) | 2013-12-16 |

| CN104114506B (zh) | 2017-05-24 |

| US9227868B2 (en) | 2016-01-05 |

| TWI573186B (zh) | 2017-03-01 |

| US20130224433A1 (en) | 2013-08-29 |

| WO2013130608A1 (en) | 2013-09-06 |

| CN104114506A (zh) | 2014-10-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2015516352A (ja) | 強化ガラスを加工するための方法及び装置並びにこれにより生成された製品 | |

| TWI679077B (zh) | 雷射鑽孔材料的方法及玻璃物件 | |

| JP2015511571A (ja) | 強化ガラスの分離のための方法及び装置並びにこれにより生成された製品 | |

| TWI659793B (zh) | 用於使用可調整雷射束焦線來處理透明材料的系統及方法 | |

| US9850160B2 (en) | Laser cutting of display glass compositions | |

| US20160009066A1 (en) | System and method for cutting laminated structures | |

| KR102288419B1 (ko) | 3d 형상의 투명한 취성 기판 처리 | |

| US20170305780A9 (en) | Method and apparatus for separation of strengthened glass and articles produced thereby | |

| US10611667B2 (en) | Method and system for forming perforations | |

| TWI650231B (zh) | 雷射切割複合玻璃製品及切割方法 | |

| JP2021102552A (ja) | ディスプレイガラス組成物のレーザ切断及び加工 | |

| CN104339081B (zh) | 用于在透明材料内执行激光成丝的方法和设备 | |

| TW201825216A (zh) | 玻璃基材中孔洞及狹槽的產生法 | |

| JP2015511572A (ja) | 強化ガラスの分離のための方法及び装置並びにこれにより生成された製品 | |

| JP2012240881A (ja) | 脆性材料基板の加工方法 | |

| JP2014177369A (ja) | 強化ガラス部材の製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160226 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20160226 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20170224 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20170307 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170606 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20171107 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20180123 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20180213 |

|

| A045 | Written measure of dismissal of application [lapsed due to lack of payment] |

Free format text: JAPANESE INTERMEDIATE CODE: A045 Effective date: 20180626 |