JP2010512426A - ブロックコポリマーとアクリル接着剤とのブレンド - Google Patents

ブロックコポリマーとアクリル接着剤とのブレンド Download PDFInfo

- Publication number

- JP2010512426A JP2010512426A JP2009540357A JP2009540357A JP2010512426A JP 2010512426 A JP2010512426 A JP 2010512426A JP 2009540357 A JP2009540357 A JP 2009540357A JP 2009540357 A JP2009540357 A JP 2009540357A JP 2010512426 A JP2010512426 A JP 2010512426A

- Authority

- JP

- Japan

- Prior art keywords

- adhesive

- sensitive adhesive

- block copolymer

- pressure sensitive

- tackifier

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 229920001400 block copolymer Polymers 0.000 title claims abstract description 117

- 239000000203 mixture Substances 0.000 title claims abstract description 96

- 239000003522 acrylic cement Substances 0.000 title claims abstract description 18

- 230000001070 adhesive effect Effects 0.000 claims abstract description 152

- 239000000853 adhesive Substances 0.000 claims abstract description 151

- 239000004820 Pressure-sensitive adhesive Substances 0.000 claims abstract description 79

- 238000004519 manufacturing process Methods 0.000 claims abstract description 7

- 239000006260 foam Substances 0.000 claims description 69

- 238000000034 method Methods 0.000 claims description 35

- 239000000178 monomer Substances 0.000 claims description 32

- 239000000758 substrate Substances 0.000 claims description 32

- 239000011347 resin Substances 0.000 claims description 24

- 229920005989 resin Polymers 0.000 claims description 24

- 125000003118 aryl group Chemical group 0.000 claims description 23

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Natural products C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 claims description 19

- 150000001993 dienes Chemical class 0.000 claims description 16

- NIXOWILDQLNWCW-UHFFFAOYSA-M Acrylate Chemical compound [O-]C(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-M 0.000 claims description 13

- -1 rosin acid ester Chemical class 0.000 claims description 13

- NIXOWILDQLNWCW-UHFFFAOYSA-N 2-Propenoic acid Natural products OC(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 claims description 12

- RRHGJUQNOFWUDK-UHFFFAOYSA-N Isoprene Chemical compound CC(=C)C=C RRHGJUQNOFWUDK-UHFFFAOYSA-N 0.000 claims description 12

- 239000004014 plasticizer Substances 0.000 claims description 12

- KAKZBPTYRLMSJV-UHFFFAOYSA-N Butadiene Chemical compound C=CC=C KAKZBPTYRLMSJV-UHFFFAOYSA-N 0.000 claims description 11

- 229920000642 polymer Polymers 0.000 claims description 11

- 239000007822 coupling agent Substances 0.000 claims description 10

- 239000002904 solvent Substances 0.000 claims description 10

- 239000011248 coating agent Substances 0.000 claims description 9

- 238000000576 coating method Methods 0.000 claims description 9

- 238000004132 cross linking Methods 0.000 claims description 9

- 238000007334 copolymerization reaction Methods 0.000 claims description 8

- 239000007788 liquid Substances 0.000 claims description 8

- 125000004432 carbon atom Chemical group C* 0.000 claims description 7

- 239000002131 composite material Substances 0.000 claims description 7

- 125000001931 aliphatic group Chemical group 0.000 claims description 6

- 229920001577 copolymer Polymers 0.000 claims description 6

- 238000001125 extrusion Methods 0.000 claims description 6

- 239000004831 Hot glue Substances 0.000 claims description 5

- RSWGJHLUYNHPMX-ONCXSQPRSA-N abietic acid Chemical class C([C@@H]12)CC(C(C)C)=CC1=CC[C@@H]1[C@]2(C)CCC[C@@]1(C)C(O)=O RSWGJHLUYNHPMX-ONCXSQPRSA-N 0.000 claims description 5

- HECLRDQVFMWTQS-RGOKHQFPSA-N 1755-01-7 Chemical compound C1[C@H]2[C@@H]3CC=C[C@@H]3[C@@H]1C=C2 HECLRDQVFMWTQS-RGOKHQFPSA-N 0.000 claims description 4

- 125000005233 alkylalcohol group Chemical group 0.000 claims description 4

- 238000003475 lamination Methods 0.000 claims description 4

- 229920001083 polybutene Polymers 0.000 claims description 4

- 230000005855 radiation Effects 0.000 claims description 4

- 230000003014 reinforcing effect Effects 0.000 claims description 4

- 150000003505 terpenes Chemical class 0.000 claims description 4

- 235000007586 terpenes Nutrition 0.000 claims description 4

- 229920001169 thermoplastic Polymers 0.000 claims description 4

- 239000004416 thermosoftening plastic Substances 0.000 claims description 4

- 229920000428 triblock copolymer Polymers 0.000 claims description 4

- KPAPHODVWOVUJL-UHFFFAOYSA-N 1-benzofuran;1h-indene Chemical compound C1=CC=C2CC=CC2=C1.C1=CC=C2OC=CC2=C1 KPAPHODVWOVUJL-UHFFFAOYSA-N 0.000 claims description 3

- SMZOUWXMTYCWNB-UHFFFAOYSA-N 2-(2-methoxy-5-methylphenyl)ethanamine Chemical compound COC1=CC=C(C)C=C1CCN SMZOUWXMTYCWNB-UHFFFAOYSA-N 0.000 claims description 3

- VSKJLJHPAFKHBX-UHFFFAOYSA-N 2-methylbuta-1,3-diene;styrene Chemical compound CC(=C)C=C.C=CC1=CC=CC=C1.C=CC1=CC=CC=C1 VSKJLJHPAFKHBX-UHFFFAOYSA-N 0.000 claims description 3

- 230000002708 enhancing effect Effects 0.000 claims description 3

- 239000011521 glass Substances 0.000 claims description 3

- 125000005397 methacrylic acid ester group Chemical group 0.000 claims description 3

- 125000003011 styrenyl group Chemical group [H]\C(*)=C(/[H])C1=C([H])C([H])=C([H])C([H])=C1[H] 0.000 claims description 3

- PSGCQDPCAWOCSH-UHFFFAOYSA-N (4,7,7-trimethyl-3-bicyclo[2.2.1]heptanyl) prop-2-enoate Chemical compound C1CC2(C)C(OC(=O)C=C)CC1C2(C)C PSGCQDPCAWOCSH-UHFFFAOYSA-N 0.000 claims description 2

- GOXQRTZXKQZDDN-UHFFFAOYSA-N 2-Ethylhexyl acrylate Chemical compound CCCCC(CC)COC(=O)C=C GOXQRTZXKQZDDN-UHFFFAOYSA-N 0.000 claims description 2

- CYUZOYPRAQASLN-UHFFFAOYSA-N 3-prop-2-enoyloxypropanoic acid Chemical compound OC(=O)CCOC(=O)C=C CYUZOYPRAQASLN-UHFFFAOYSA-N 0.000 claims description 2

- DXPPIEDUBFUSEZ-UHFFFAOYSA-N 6-methylheptyl prop-2-enoate Chemical group CC(C)CCCCCOC(=O)C=C DXPPIEDUBFUSEZ-UHFFFAOYSA-N 0.000 claims description 2

- 239000013032 Hydrocarbon resin Substances 0.000 claims description 2

- CERQOIWHTDAKMF-UHFFFAOYSA-N Methacrylic acid Chemical compound CC(=C)C(O)=O CERQOIWHTDAKMF-UHFFFAOYSA-N 0.000 claims description 2

- 229920002367 Polyisobutene Polymers 0.000 claims description 2

- PZJLPGLBKRUQFL-UHFFFAOYSA-N [3-(butylamino)-3-oxopropyl] prop-2-enoate Chemical compound CCCCNC(=O)CCOC(=O)C=C PZJLPGLBKRUQFL-UHFFFAOYSA-N 0.000 claims description 2

- CQEYYJKEWSMYFG-UHFFFAOYSA-N butyl acrylate Chemical compound CCCCOC(=O)C=C CQEYYJKEWSMYFG-UHFFFAOYSA-N 0.000 claims description 2

- 229920006270 hydrocarbon resin Polymers 0.000 claims description 2

- WFKDPJRCBCBQNT-UHFFFAOYSA-N n,2-dimethylprop-2-enamide Chemical compound CNC(=O)C(C)=C WFKDPJRCBCBQNT-UHFFFAOYSA-N 0.000 claims description 2

- QISNULGCGWEUKY-UHFFFAOYSA-N n-ethyl-2-methylidenebutanamide Chemical compound CCNC(=O)C(=C)CC QISNULGCGWEUKY-UHFFFAOYSA-N 0.000 claims description 2

- 239000002243 precursor Substances 0.000 claims description 2

- 238000001035 drying Methods 0.000 claims 2

- FACXGONDLDSNOE-UHFFFAOYSA-N buta-1,3-diene;styrene Chemical compound C=CC=C.C=CC1=CC=CC=C1.C=CC1=CC=CC=C1 FACXGONDLDSNOE-UHFFFAOYSA-N 0.000 claims 1

- 238000010030 laminating Methods 0.000 claims 1

- 230000035807 sensation Effects 0.000 claims 1

- 230000035945 sensitivity Effects 0.000 claims 1

- 229920000468 styrene butadiene styrene block copolymer Polymers 0.000 claims 1

- 229920001935 styrene-ethylene-butadiene-styrene Polymers 0.000 claims 1

- 229920001187 thermosetting polymer Polymers 0.000 claims 1

- 239000012790 adhesive layer Substances 0.000 description 21

- 239000010410 layer Substances 0.000 description 16

- 229920000058 polyacrylate Polymers 0.000 description 15

- 230000009477 glass transition Effects 0.000 description 7

- 239000004698 Polyethylene Substances 0.000 description 5

- 239000004793 Polystyrene Substances 0.000 description 5

- 239000000463 material Substances 0.000 description 5

- 229920000573 polyethylene Polymers 0.000 description 5

- 229920002223 polystyrene Polymers 0.000 description 5

- 229920002554 vinyl polymer Polymers 0.000 description 5

- 239000003973 paint Substances 0.000 description 4

- KWVGIHKZDCUPEU-UHFFFAOYSA-N 2,2-dimethoxy-2-phenylacetophenone Chemical compound C=1C=CC=CC=1C(OC)(OC)C(=O)C1=CC=CC=C1 KWVGIHKZDCUPEU-UHFFFAOYSA-N 0.000 description 3

- 229910052799 carbon Inorganic materials 0.000 description 3

- 238000005266 casting Methods 0.000 description 3

- 230000000052 comparative effect Effects 0.000 description 3

- 230000001143 conditioned effect Effects 0.000 description 3

- 238000010894 electron beam technology Methods 0.000 description 3

- 238000009472 formulation Methods 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- 229920001296 polysiloxane Polymers 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 239000006269 thermoset foam Substances 0.000 description 3

- JHPBZFOKBAGZBL-UHFFFAOYSA-N (3-hydroxy-2,2,4-trimethylpentyl) 2-methylprop-2-enoate Chemical compound CC(C)C(O)C(C)(C)COC(=O)C(C)=C JHPBZFOKBAGZBL-UHFFFAOYSA-N 0.000 description 2

- FQVLRGLGWNWPSS-BXBUPLCLSA-N (4r,7s,10s,13s,16r)-16-acetamido-13-(1h-imidazol-5-ylmethyl)-10-methyl-6,9,12,15-tetraoxo-7-propan-2-yl-1,2-dithia-5,8,11,14-tetrazacycloheptadecane-4-carboxamide Chemical compound N1C(=O)[C@@H](NC(C)=O)CSSC[C@@H](C(N)=O)NC(=O)[C@H](C(C)C)NC(=O)[C@H](C)NC(=O)[C@@H]1CC1=CN=CN1 FQVLRGLGWNWPSS-BXBUPLCLSA-N 0.000 description 2

- PMJHHCWVYXUKFD-SNAWJCMRSA-N (E)-1,3-pentadiene Chemical group C\C=C\C=C PMJHHCWVYXUKFD-SNAWJCMRSA-N 0.000 description 2

- MYRTYDVEIRVNKP-UHFFFAOYSA-N 1,2-Divinylbenzene Chemical compound C=CC1=CC=CC=C1C=C MYRTYDVEIRVNKP-UHFFFAOYSA-N 0.000 description 2

- 101150021974 Adh1 gene Proteins 0.000 description 2

- UFWIBTONFRDIAS-UHFFFAOYSA-N Naphthalene Chemical compound C1=CC=CC2=CC=CC=C21 UFWIBTONFRDIAS-UHFFFAOYSA-N 0.000 description 2

- BGYHLZZASRKEJE-UHFFFAOYSA-N [3-[3-(3,5-ditert-butyl-4-hydroxyphenyl)propanoyloxy]-2,2-bis[3-(3,5-ditert-butyl-4-hydroxyphenyl)propanoyloxymethyl]propyl] 3-(3,5-ditert-butyl-4-hydroxyphenyl)propanoate Chemical compound CC(C)(C)C1=C(O)C(C(C)(C)C)=CC(CCC(=O)OCC(COC(=O)CCC=2C=C(C(O)=C(C=2)C(C)(C)C)C(C)(C)C)(COC(=O)CCC=2C=C(C(O)=C(C=2)C(C)(C)C)C(C)(C)C)COC(=O)CCC=2C=C(C(O)=C(C=2)C(C)(C)C)C(C)(C)C)=C1 BGYHLZZASRKEJE-UHFFFAOYSA-N 0.000 description 2

- 239000006096 absorbing agent Substances 0.000 description 2

- 125000005396 acrylic acid ester group Chemical group 0.000 description 2

- 239000000654 additive Substances 0.000 description 2

- 238000007754 air knife coating Methods 0.000 description 2

- XYLMUPLGERFSHI-UHFFFAOYSA-N alpha-Methylstyrene Chemical compound CC(=C)C1=CC=CC=C1 XYLMUPLGERFSHI-UHFFFAOYSA-N 0.000 description 2

- MWPLVEDNUUSJAV-UHFFFAOYSA-N anthracene Chemical compound C1=CC=CC2=CC3=CC=CC=C3C=C21 MWPLVEDNUUSJAV-UHFFFAOYSA-N 0.000 description 2

- 239000003963 antioxidant agent Substances 0.000 description 2

- 230000003078 antioxidant effect Effects 0.000 description 2

- 239000000919 ceramic Substances 0.000 description 2

- 238000013329 compounding Methods 0.000 description 2

- 239000012792 core layer Substances 0.000 description 2

- 238000001723 curing Methods 0.000 description 2

- 238000007766 curtain coating Methods 0.000 description 2

- 230000007423 decrease Effects 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 239000005038 ethylene vinyl acetate Substances 0.000 description 2

- 238000007756 gravure coating Methods 0.000 description 2

- 125000000623 heterocyclic group Chemical group 0.000 description 2

- AHAREKHAZNPPMI-UHFFFAOYSA-N hexa-1,3-diene Chemical compound CCC=CC=C AHAREKHAZNPPMI-UHFFFAOYSA-N 0.000 description 2

- 238000002156 mixing Methods 0.000 description 2

- 229920001200 poly(ethylene-vinyl acetate) Polymers 0.000 description 2

- 239000002861 polymer material Substances 0.000 description 2

- 230000001737 promoting effect Effects 0.000 description 2

- 238000001542 size-exclusion chromatography Methods 0.000 description 2

- 238000005507 spraying Methods 0.000 description 2

- 150000003440 styrenes Chemical class 0.000 description 2

- 238000010345 tape casting Methods 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- PRJNEUBECVAVAG-UHFFFAOYSA-N 1,3-bis(ethenyl)benzene Chemical compound C=CC1=CC=CC(C=C)=C1 PRJNEUBECVAVAG-UHFFFAOYSA-N 0.000 description 1

- WEERVPDNCOGWJF-UHFFFAOYSA-N 1,4-bis(ethenyl)benzene Chemical compound C=CC1=CC=C(C=C)C=C1 WEERVPDNCOGWJF-UHFFFAOYSA-N 0.000 description 1

- FCMUPMSEVHVOSE-UHFFFAOYSA-N 2,3-bis(ethenyl)pyridine Chemical compound C=CC1=CC=CN=C1C=C FCMUPMSEVHVOSE-UHFFFAOYSA-N 0.000 description 1

- AMQQZUHWWJLUGS-UHFFFAOYSA-N 2,3-bis(ethenyl)thiophene Chemical compound C=CC=1C=CSC=1C=C AMQQZUHWWJLUGS-UHFFFAOYSA-N 0.000 description 1

- SDJHPPZKZZWAKF-UHFFFAOYSA-N 2,3-dimethylbuta-1,3-diene Chemical compound CC(=C)C(C)=C SDJHPPZKZZWAKF-UHFFFAOYSA-N 0.000 description 1

- SXXOSRMQLZJZHB-UHFFFAOYSA-N 2-butylhex-1-enylbenzene Chemical compound CCCCC(CCCC)=CC1=CC=CC=C1 SXXOSRMQLZJZHB-UHFFFAOYSA-N 0.000 description 1

- DDBYLRWHHCWVID-UHFFFAOYSA-N 2-ethylbut-1-enylbenzene Chemical compound CCC(CC)=CC1=CC=CC=C1 DDBYLRWHHCWVID-UHFFFAOYSA-N 0.000 description 1

- BTOVVHWKPVSLBI-UHFFFAOYSA-N 2-methylprop-1-enylbenzene Chemical compound CC(C)=CC1=CC=CC=C1 BTOVVHWKPVSLBI-UHFFFAOYSA-N 0.000 description 1

- KGIGUEBEKRSTEW-UHFFFAOYSA-N 2-vinylpyridine Chemical compound C=CC1=CC=CC=N1 KGIGUEBEKRSTEW-UHFFFAOYSA-N 0.000 description 1

- DXIJHCSGLOHNES-UHFFFAOYSA-N 3,3-dimethylbut-1-enylbenzene Chemical compound CC(C)(C)C=CC1=CC=CC=C1 DXIJHCSGLOHNES-UHFFFAOYSA-N 0.000 description 1

- CEBRPXLXYCFYGU-UHFFFAOYSA-N 3-methylbut-1-enylbenzene Chemical compound CC(C)C=CC1=CC=CC=C1 CEBRPXLXYCFYGU-UHFFFAOYSA-N 0.000 description 1

- JLBJTVDPSNHSKJ-UHFFFAOYSA-N 4-Methylstyrene Chemical compound CC1=CC=C(C=C)C=C1 JLBJTVDPSNHSKJ-UHFFFAOYSA-N 0.000 description 1

- NLHHRLWOUZZQLW-UHFFFAOYSA-N Acrylonitrile Chemical compound C=CC#N NLHHRLWOUZZQLW-UHFFFAOYSA-N 0.000 description 1

- 101100389815 Caenorhabditis elegans eva-1 gene Proteins 0.000 description 1

- KXDHJXZQYSOELW-UHFFFAOYSA-M Carbamate Chemical compound NC([O-])=O KXDHJXZQYSOELW-UHFFFAOYSA-M 0.000 description 1

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 1

- 229920000103 Expandable microsphere Polymers 0.000 description 1

- 229920002633 Kraton (polymer) Polymers 0.000 description 1

- GYCMBHHDWRMZGG-UHFFFAOYSA-N Methylacrylonitrile Chemical compound CC(=C)C#N GYCMBHHDWRMZGG-UHFFFAOYSA-N 0.000 description 1

- CTQNGGLPUBDAKN-UHFFFAOYSA-N O-Xylene Chemical compound CC1=CC=CC=C1C CTQNGGLPUBDAKN-UHFFFAOYSA-N 0.000 description 1

- 229910019142 PO4 Inorganic materials 0.000 description 1

- 229920002732 Polyanhydride Polymers 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- 229920005830 Polyurethane Foam Polymers 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- 150000001338 aliphatic hydrocarbons Chemical class 0.000 description 1

- 125000000217 alkyl group Chemical group 0.000 description 1

- 230000004075 alteration Effects 0.000 description 1

- 238000003149 assay kit Methods 0.000 description 1

- MPMBRWOOISTHJV-UHFFFAOYSA-N but-1-enylbenzene Chemical compound CCC=CC1=CC=CC=C1 MPMBRWOOISTHJV-UHFFFAOYSA-N 0.000 description 1

- XZKRXPZXQLARHH-UHFFFAOYSA-N buta-1,3-dienylbenzene Chemical compound C=CC=CC1=CC=CC=C1 XZKRXPZXQLARHH-UHFFFAOYSA-N 0.000 description 1

- 238000003490 calendering Methods 0.000 description 1

- 239000000969 carrier Substances 0.000 description 1

- 239000007795 chemical reaction product Substances 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 229920006037 cross link polymer Polymers 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 229920000359 diblock copolymer Polymers 0.000 description 1

- 150000001990 dicarboxylic acid derivatives Chemical class 0.000 description 1

- CJSBUWDGPXGFGA-UHFFFAOYSA-N dimethyl-butadiene Natural products CC(C)=CC=C CJSBUWDGPXGFGA-UHFFFAOYSA-N 0.000 description 1

- 229910000267 dualite Inorganic materials 0.000 description 1

- SQNZJJAZBFDUTD-UHFFFAOYSA-N durene Natural products CC1=CC(C)=C(C)C=C1C SQNZJJAZBFDUTD-UHFFFAOYSA-N 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000004070 electrodeposition Methods 0.000 description 1

- 238000001227 electron beam curing Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- STVZJERGLQHEKB-UHFFFAOYSA-N ethylene glycol dimethacrylate Chemical compound CC(=C)C(=O)OCCOC(=O)C(C)=C STVZJERGLQHEKB-UHFFFAOYSA-N 0.000 description 1

- 239000011888 foil Substances 0.000 description 1

- 125000000524 functional group Chemical group 0.000 description 1

- 238000013007 heat curing Methods 0.000 description 1

- 239000012943 hotmelt Substances 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- QWTDNUCVQCZILF-UHFFFAOYSA-N isopentane Chemical group CCC(C)C QWTDNUCVQCZILF-UHFFFAOYSA-N 0.000 description 1

- 239000000155 melt Substances 0.000 description 1

- 150000002734 metacrylic acid derivatives Chemical class 0.000 description 1

- 125000005395 methacrylic acid group Chemical group 0.000 description 1

- 239000004005 microsphere Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- HWXQYUCHSICMAS-UHFFFAOYSA-N octa-3,5-diene Chemical compound CCC=CC=CCC HWXQYUCHSICMAS-UHFFFAOYSA-N 0.000 description 1

- 239000003921 oil Substances 0.000 description 1

- 229920006280 packaging film Polymers 0.000 description 1

- 239000012785 packaging film Substances 0.000 description 1

- 238000004806 packaging method and process Methods 0.000 description 1

- 235000021317 phosphate Nutrition 0.000 description 1

- AQSJGOWTSHOLKH-UHFFFAOYSA-N phosphite(3-) Chemical class [O-]P([O-])[O-] AQSJGOWTSHOLKH-UHFFFAOYSA-N 0.000 description 1

- 150000003013 phosphoric acid derivatives Chemical class 0.000 description 1

- PMJHHCWVYXUKFD-UHFFFAOYSA-N piperylene Natural products CC=CC=C PMJHHCWVYXUKFD-UHFFFAOYSA-N 0.000 description 1

- 229920000647 polyepoxide Polymers 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 229920006267 polyester film Polymers 0.000 description 1

- 229920001228 polyisocyanate Polymers 0.000 description 1

- 239000005056 polyisocyanate Substances 0.000 description 1

- 229920001470 polyketone Polymers 0.000 description 1

- 229920006254 polymer film Polymers 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 229920002635 polyurethane Polymers 0.000 description 1

- 239000004814 polyurethane Substances 0.000 description 1

- 239000011496 polyurethane foam Substances 0.000 description 1

- 229920001447 polyvinyl benzene Polymers 0.000 description 1

- 229920002102 polyvinyl toluene Polymers 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 239000000047 product Substances 0.000 description 1

- HJWLCRVIBGQPNF-UHFFFAOYSA-N prop-2-enylbenzene Chemical compound C=CCC1=CC=CC=C1 HJWLCRVIBGQPNF-UHFFFAOYSA-N 0.000 description 1

- 238000003847 radiation curing Methods 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000009864 tensile test Methods 0.000 description 1

- 238000004804 winding Methods 0.000 description 1

- 239000008096 xylene Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J153/00—Adhesives based on block copolymers containing at least one sequence of a polymer obtained by reactions only involving carbon-to-carbon unsaturated bonds; Adhesives based on derivatives of such polymers

- C09J153/02—Vinyl aromatic monomers and conjugated dienes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C35/00—Heating, cooling or curing, e.g. crosslinking or vulcanising; Apparatus therefor

- B29C35/02—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould

- B29C35/08—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould by wave energy or particle radiation

- B29C35/10—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould by wave energy or particle radiation for articles of indefinite length

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/001—Combinations of extrusion moulding with other shaping operations

- B29C48/0021—Combinations of extrusion moulding with other shaping operations combined with joining, lining or laminating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/16—Articles comprising two or more components, e.g. co-extruded layers

- B29C48/18—Articles comprising two or more components, e.g. co-extruded layers the components being layers

- B29C48/21—Articles comprising two or more components, e.g. co-extruded layers the components being layers the layers being joined at their surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B27/065—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material of foam

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B3/00—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form

- B32B3/26—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B7/00—Layered products characterised by the relation between layers; Layered products characterised by the relative orientation of features between layers, or by the relative values of a measurable parameter between layers, i.e. products comprising layers having different physical, chemical or physicochemical properties; Layered products characterised by the interconnection of layers

- B32B7/04—Interconnection of layers

- B32B7/12—Interconnection of layers using interposed adhesives or interposed materials with bonding properties

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J133/00—Adhesives based on homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Adhesives based on derivatives of such polymers

- C09J133/04—Homopolymers or copolymers of esters

- C09J133/06—Homopolymers or copolymers of esters of esters containing only carbon, hydrogen and oxygen, the oxygen atom being present only as part of the carboxyl radical

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J7/00—Adhesives in the form of films or foils

- C09J7/20—Adhesives in the form of films or foils characterised by their carriers

- C09J7/22—Plastics; Metallised plastics

- C09J7/26—Porous or cellular plastics

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J7/00—Adhesives in the form of films or foils

- C09J7/30—Adhesives in the form of films or foils characterised by the adhesive composition

- C09J7/38—Pressure-sensitive adhesives [PSA]

- C09J7/381—Pressure-sensitive adhesives [PSA] based on macromolecular compounds obtained by reactions involving only carbon-to-carbon unsaturated bonds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2009/00—Use of rubber derived from conjugated dienes, as moulding material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2025/00—Use of polymers of vinyl-aromatic compounds or derivatives thereof as moulding material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2033/00—Use of polymers of unsaturated acids or derivatives thereof as moulding material

- B29K2033/04—Polymers of esters

- B29K2033/12—Polymers of methacrylic acid esters, e.g. PMMA, i.e. polymethylmethacrylate

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2096/00—Use of specified macromolecular materials not provided for in a single one of main groups B29K2001/00 - B29K2095/00, as moulding material

- B29K2096/04—Block polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2105/00—Condition, form or state of moulded material or of the material to be shaped

- B29K2105/0002—Condition, form or state of moulded material or of the material to be shaped monomers or prepolymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2105/00—Condition, form or state of moulded material or of the material to be shaped

- B29K2105/0085—Copolymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2105/00—Condition, form or state of moulded material or of the material to be shaped

- B29K2105/0097—Glues or adhesives, e.g. hot melts or thermofusible adhesives

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2009/00—Layered products

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/02—2 layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/03—3 layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/04—4 layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2270/00—Resin or rubber layer containing a blend of at least two different polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2405/00—Adhesive articles, e.g. adhesive tapes

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L2205/00—Polymer mixtures characterised by other features

- C08L2205/02—Polymer mixtures characterised by other features containing two or more polymers of the same C08L -group

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L33/00—Compositions of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides or nitriles thereof; Compositions of derivatives of such polymers

- C08L33/04—Homopolymers or copolymers of esters

- C08L33/06—Homopolymers or copolymers of esters of esters containing only carbon, hydrogen and oxygen, which oxygen atoms are present only as part of the carboxyl radical

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L33/00—Compositions of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides or nitriles thereof; Compositions of derivatives of such polymers

- C08L33/04—Homopolymers or copolymers of esters

- C08L33/14—Homopolymers or copolymers of esters of esters containing halogen, nitrogen, sulfur, or oxygen atoms in addition to the carboxy oxygen

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L53/00—Compositions of block copolymers containing at least one sequence of a polymer obtained by reactions only involving carbon-to-carbon unsaturated bonds; Compositions of derivatives of such polymers

- C08L53/02—Compositions of block copolymers containing at least one sequence of a polymer obtained by reactions only involving carbon-to-carbon unsaturated bonds; Compositions of derivatives of such polymers of vinyl-aromatic monomers and conjugated dienes

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J133/00—Adhesives based on homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Adhesives based on derivatives of such polymers

- C09J133/04—Homopolymers or copolymers of esters

- C09J133/06—Homopolymers or copolymers of esters of esters containing only carbon, hydrogen and oxygen, the oxygen atom being present only as part of the carboxyl radical

- C09J133/08—Homopolymers or copolymers of acrylic acid esters

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J133/00—Adhesives based on homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Adhesives based on derivatives of such polymers

- C09J133/04—Homopolymers or copolymers of esters

- C09J133/14—Homopolymers or copolymers of esters of esters containing halogen, nitrogen, sulfur or oxygen atoms in addition to the carboxy oxygen

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2433/00—Presence of (meth)acrylic polymer

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2433/00—Presence of (meth)acrylic polymer

- C09J2433/006—Presence of (meth)acrylic polymer in the substrate

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2453/00—Presence of block copolymer

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/249921—Web or sheet containing structurally defined element or component

- Y10T428/249953—Composite having voids in a component [e.g., porous, cellular, etc.]

- Y10T428/249982—With component specified as adhesive or bonding agent

- Y10T428/249983—As outermost component

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/249921—Web or sheet containing structurally defined element or component

- Y10T428/249953—Composite having voids in a component [e.g., porous, cellular, etc.]

- Y10T428/249982—With component specified as adhesive or bonding agent

- Y10T428/249985—Composition of adhesive or bonding component specified

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/31504—Composite [nonstructural laminate]

- Y10T428/31855—Of addition polymer from unsaturated monomers

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/31504—Composite [nonstructural laminate]

- Y10T428/31855—Of addition polymer from unsaturated monomers

- Y10T428/31931—Polyene monomer-containing

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Health & Medical Sciences (AREA)

- Oral & Maxillofacial Surgery (AREA)

- Physics & Mathematics (AREA)

- Toxicology (AREA)

- Thermal Sciences (AREA)

- Adhesives Or Adhesive Processes (AREA)

- Adhesive Tapes (AREA)

- Laminated Bodies (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Graft Or Block Polymers (AREA)

- Paints Or Removers (AREA)

- Compositions Of Macromolecular Compounds (AREA)

Abstract

Description

R−(G)m

(式中、Rはゴム状ブロックを表し、Gはガラス状ブロックを表し、ガラス状ブロックの数であるmは1又は2である)により記述することができる。ある実施形態では、mは1であり、直鎖ブロックコポリマーは1個のゴム状ブロックと1個のガラス状ブロックを含むジブロックコポリマーである。ある実施形態では、mは2であり、直鎖ブロックコポリマーは、2個のガラス状末端ブロックと1個のゴム状中央ブロックを含む、即ち、直鎖ブロックコポリマーはトリブロックコポリマーである。

45部のIOA、45部のBA、10部のAA、0.15部のイルガキュア651、及び0.06部のIOTGを混合することにより、アクリルポリマー(AP−1)を調製した。包装フィルム(CTフィルム(テキサス州ダラス(Dallas)からVA−24フィルムとして販売されている厚さ0.0635mmのエチレンビニルアセテートコポリマーフィルム)から目立たない(Discreet)フィルム包装を形成した。AP−1組成物を、約10センチメートル(cm)×5cm×厚さ0.5cmと測定されたフィルム包装内に密封した。約21℃と約32℃の間に維持された水浴中に浸漬している間、包装を、約3.5ミリワット/平方センチメートル(mW/sq cm)の強度及びNIST単位で測定したとき約1680ミリジュール/平方センチメートル(mJ/sq cm)の総エネルギーを有する紫外線(UV)に曝露した。包装の形成及び硬化方法は、米国特許第5,804,610号の実施例1に記載されており、その全文を参照することにより組み込むこととする。

第2表に示す組成物による感圧性接着剤を、60mmの共回転2軸押出成形機(バーストルフ(Berstorff)から入手可能)(第1接着剤押出成形機)を用いて配合した。多モードで非対称な星型ブロックコポリマー(「PASBC」)を、全文を参照することにより本明細書に組み込む、米国特許第5,393,373号に従って調製した。ポリマーは、ポリスチレン標準を用いて較正したSEC(サイズ排除クロマトグラフィー)により測定した、数平均分子量約6.6E−21g(4,000ダルトン)及び約3.6E−20g(21,500ダルトン)の2つの末端ブロックと、2.1E−19g(127,000ダルトン)〜2.4E−19g(147,000ダルトン)の腕と、約1.8E−18g(1,100,000ダルトン)の星を有していた。ポリスチレン含量は、9.5〜11.5重量%であった。高分子量である腕のモルパーセントは、約30%と推定された。

第3表に示す組成に従った感圧性接着剤を、以下を除いて、第1スキン接着剤Adh−1について記載したように、第1接着剤押出成形機内で配合した。これらの比較例の接着剤は、アクリルポリマーを含有せず、したがって非アクリルポリマーを押出成形機の第2領域に注入した。

12.70%の多モードで非対称な星型ブロックコポリマー(PASBC)、53.10(重量)%のAP−1、23.30%の粘着付与樹脂(エスコレス1310LC)、3.80%の粘着付与樹脂(スーパースターW115)、6.20%の可塑剤(サンチサイザー141)、0.26%の酸化防止剤(イルガノックス1010)、及び0.25%の紫外線吸収剤(チヌビン328)という組成であることを除き、第1スキン接着剤で記載したのと同じ方式で、感圧性接着剤を60mmの共回転2軸押出機(バーストルフ(Berstorff)から入手可能)(「第2接着剤押出成形機」)内で配合した。

第4表に示す組成を有する発泡体芯(FC1〜FC5)を、以下の手順に従って配合した。黒色に着色されたEVA(4900 CMB)を、90mmの共回転2軸押出成形機(「芯押出成形機」)(バーストルフ(Berstorff)(ドイツ、ハノーバー(Hannover))から入手可能)の第1領域に乾式注入した。ロールフィーダ押出成形機(バーストルフから入手可能)を用いて、アクリルポリマーAP−2及びAP−3の両方を加熱し、芯押出成形機の第2領域に注入した。デュアライト(DUALITE)U010−185D発泡性微小球(ヘンケル社(Henkel Corporation)(ペンシルバニア州ガルフミルズ(Gulph Mills)から入手可能な、アクリロニトリル及びメタクリルニトリルを含有するシェル組成物、並びに、イソペンタンの芯を有する発泡性微小球)を芯押出成形機の第9領域に注入した。

Claims (53)

- (A)92〜99.9部の、ブロックコポリマー接着剤組成物であって、

(i)第1重合共役ジエン、その水素添加誘導体、又はこれらの組み合わせを含む少なくとも1つのゴム状ブロックと、

(ii)第1重合モノビニル芳香族モノマーを含む少なくとも1つのガラス状ブロックと、を含む、第1ブロックコポリマー(a)、を含む、ブロックコポリマー接着剤組成物、及び

(B)0.1〜10部未満、任意に9部未満、任意に8部未満、任意に5部未満、任意に3部未満の、アクリル接着剤組成物であって、

(i)70〜100部の、少なくとも1つの、4〜20個の炭素原子を含有する非三級アルキルアルコールのアクリル酸又はメタクリル酸エステルと、

(ii)0〜30部の、共重合強化モノマーと、を含む、アクリル接着剤組成物、を含む、感圧性接着剤組成物。 - 第1ブロックコポリマーが、式Qn−Y(式中、

(a)Qは多腕ブロックコポリマーの腕を表し、各腕が独立に式R−G(式中、

(i)Rはゴム状ブロックを表し、

(ii)Gはガラス状ブロックを表す)を有し、

(b)nは腕の数を表し、少なくとも3の整数であり、

(c)Yは多官能性カップリング剤の残基である)の多腕ブロックコポリマーである、請求項1に記載の感圧性接着剤。 - 重合第2共役ジエン、その水素添加誘導体、又はこれらの組み合わせを含む少なくとも1つのゴム状ブロックと、第2重合モノビニル芳香族モノマーを含む少なくとも1つのガラス状ブロックと、を含む第2ブロックコポリマーを更に含む、請求項2に記載の感圧性接着剤。

- 第2ブロックコポリマーが直鎖ブロックコポリマーであり、任意に直鎖ブロックコポリマーがトリブロックコポリマーである、請求項3に記載の感圧性接着剤。

- 第2ブロックコポリマーが、スチレン−イソプレン−スチレン、スチレン−ブタジエン−スチレン、スチレン−エチレン−ブタジエン−スチレン、及びこれらの組み合わせからなる群から選択されるトリブロックコポリマーである、請求項4に記載の感圧性接着剤。

- ブロックコポリマー接着剤組成物が、少なくとも60℃のTgを有する第1高Tg粘着付与剤であって、少なくとも1つのゴム状ブロックに適合する第1高Tg粘着付与剤を更に含む、請求項1〜5のいずれか一項に記載の感圧性接着剤。

- ブロックコポリマー接着剤組成物が、少なくとも60℃のTgを有する第2高Tg粘着付与剤であって、少なくとも1つのガラス状ブロックに適合する第2高Tg粘着付与剤を更に含む、請求項6に記載の感圧性接着剤。

- 低Tg粘着付与剤、可塑剤、及びこれらの組み合わせからなる群から選択される少なくとも1種の成分を更に含む、請求項1〜7のいずれか一項に記載の感圧性接着剤。

- 第1共役ジエンが、イソプレン、ブタジエン、エチレンブタジエンコポリマー、及びこれらの組み合わせからなる群から選択される、請求項1〜8のいずれか一項に記載の感圧性接着剤。

- 第2共役ジエンが、イソプレン、ブタジエン、エチレンブタジエンコポリマー、及びこれらの組み合わせからなる群から選択される、請求項3〜9のいずれか一項に記載の感圧性接着剤。

- 第1モノビニル芳香族モノマーが、スチレン、スチレン適合性ブレンド、及びこれらの組み合わせからなる群から選択される、請求項1〜10のいずれか一項に記載の感圧性接着剤。

- 第2モノビニル芳香族モノマーが、スチレン、スチレン適合性ブレンド、及びこれらの組み合わせからなる群から選択される、請求項3〜11のいずれか一項に記載の感圧性接着剤。

- 第1ブロックコポリマーが、ポリモーダルで非対称な星型ブロックコポリマーである、請求項1〜12のいずれか一項に記載の感圧性接着剤。

- nが3以上5以下の整数であり、任意にnが4である、請求項2〜13のいずれか一項に記載の感圧性接着剤。

- アクリル酸又はメタクリル酸エステルが、アクリル酸イソオクチル、2−エチルヘキシルアクリレート、ブチルアクリレート、アクリル酸イソボルニル、及びこれらの組み合わせからなる群から選択される、請求項1〜14のいずれか一項に記載の感圧性接着剤。

- 共重合強化モノマーが、アクリル酸、メタクリル酸、2−カルボキシエチルアクリレート、N,N’ジメチルアクリルアミド、N,N’ジエチルアクリルアミド、ブチルカルバモイルエチルアクリレート、及びこれらの組み合わせからなる群から選択される、請求項1〜15のいずれか一項に記載の感圧性接着剤。

- 第1高Tg粘着付与剤のTgが、少なくとも65℃である、請求項6〜16のいずれか一項に記載の感圧性接着剤。

- 第2高Tg粘着付与剤のTgが、少なくとも65℃である、請求項6〜17のいずれか一項に記載の感圧性接着剤。

- 第1高Tg粘着付与剤が、少なくとも約115℃の軟化点を有し、任意に、少なくとも約120℃の軟化点を有する、請求項6〜18のいずれか一項に記載の感圧性接着剤。

- 第1高Tg粘着付与剤が、少なくとも約115℃の軟化点を有し、任意に、少なくとも約120℃の軟化点を有する、請求項6〜19のいずれか一項に記載の感圧性接着剤。

- 第1高Tg粘着付与剤が、重合テルペン、ヘテロ官能性テルペン、クマロン−インデン樹脂、ロジン酸エステル、不均化ロジン酸エステル、水素添加ロジン酸、C5脂肪族樹脂、C9水素添加芳香族樹脂、C5/C9脂肪族/芳香族樹脂、ジシクロペンタジエン樹脂、C5/C9及びジシクロペンタジエン前躯体から生じる水素添加炭化水素樹脂、水素添加スチレンモノマー樹脂、並びにこれらのブレンドからなる群から選択される、請求項6〜20のいずれか一項に記載の感圧性接着剤。

- 低Tg粘着付与剤が、ポリブテン樹脂からなる群から選択される、請求項8〜21のいずれか一項に記載の感圧性接着剤。

- 可塑剤が、ナフテン油、液体ポリブテン樹脂、ポリイソブチレン樹脂、及び液体イソプレンポリマーからなる群から選択される、請求項8〜22のいずれか一項に記載の感圧性接着剤。

- 感圧性接着剤が、ホットメルト接着剤である、請求項1〜23のいずれか一項に記載の感圧性接着剤。

- 感圧性接着剤が、溶媒型接着剤である、請求項1〜23のいずれか一項に記載の感圧性接着剤。

- 多腕ブロックコポリマーと直鎖ブロックコポリマーとの比が、1.5:1〜9:1の範囲、任意に多腕ブロックコポリマーと直鎖ブロックコポリマーとの比が、少なくとも1.85:1、任意に多腕ブロックコポリマーと直鎖ブロックコポリマーとの比が、5.7:1以下である、請求項4〜25のいずれか一項に記載の感圧性接着剤。

- 高Tg粘着付与剤とブロックコポリマーとの総量の比が、0.8:1〜1.25:1、任意に高Tg粘着付与剤とブロックコポリマーとの総量の比が、少なくとも0.85:1、任意に高Tg粘着付与剤とブロックコポリマーとの総量の比が、1.15:1以下である、請求項7〜26のいずれか一項に記載の感圧性接着剤。

- ゴム状ブロック適合性高Tg粘着付与剤とガラス状ブロック適合性高Tg粘着付与剤との比が、1:1〜9:1の範囲、任意にゴム状ブロック適合性高Tg粘着付与剤とガラス状ブロック適合性高Tg粘着付与剤との比が、少なくとも1.25:1、任意にゴム状ブロック適合性高Tg粘着付与剤とガラス状ブロック適合性高Tg粘着付与剤との比が、4:1以下である、請求項7〜27のいずれか一項に記載の感圧性接着剤。

- ブロックコポリマー及び高Tg粘着付与剤の組み合わせとアクリレート成分との比が、少なくとも8.3:1、任意にブロックコポリマー及び高Tg粘着付与剤の組み合わせとアクリレート成分との比が、少なくとも12.5:1である、請求項7〜28のいずれか一項に記載の感圧性接着剤。

- ブロックコポリマー、高Tg粘着付与剤、及びアクリレート成分の組み合わせと液体可塑剤との比が、32:1〜10:1の範囲、任意にブロックコポリマー、高Tg粘着付与剤、及びアクリレート成分の組み合わせと液体可塑剤との比が、25:1以下、任意にブロックコポリマー、高Tg粘着付与剤、及びアクリレート成分の組み合わせと液体可塑剤との比が、少なくとも12.5:1である、請求項8〜28のいずれか一項に記載の感圧性接着剤。

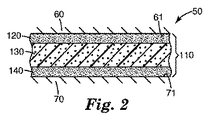

- 第1主表面及び第2主表面を有する発泡体裏材と、第1主表面に接着している第1接着スキンと、を含むテープであって、第1接着スキンが請求項1〜30のいずれか一項に記載の第1感圧性接着剤を含む、テープ。

- 第2主表面に接着している第2接着スキンを更に含む、請求項31に記載のテープ。

- 第1感圧性接着剤と第2感圧性接着剤が、同じ接着剤である、請求項32に記載のテープ。

- 第1主表面及び第2主表面を有する発泡体裏材と、第1主表面に接着している第1感圧性接着剤を含む第1接着スキンと、第2主表面に接着している第2感圧性接着剤を含む第2接着スキンと、を含むテープであって、第1感圧性接着剤及び第2感圧性接着剤がそれぞれ独立して請求項1〜30のいずれか一項に記載の感圧性接着剤を含む、テープ。

- 発泡体が、熱可塑性発泡体を含む、請求項31〜34のいずれか一項に記載のテープ。

- 発泡体が、熱硬化性発泡体を含む、請求項31〜34のいずれか一項に記載のテープ。

- 発泡体が、アクリル発泡体を含む、請求項31〜34のいずれか一項に記載のテープ。

- 発泡体裏材を押出成形する工程と、第1感圧性接着剤を共押出成形して発泡体裏材の第1主表面に接着している第1接着スキンを形成する工程と、を含む、請求項31〜37のいずれか一項に記載のテープの製造方法。

- 第2接着剤を押出成形して、発泡体裏材の第2主表面に接着している第2接着スキンを形成する工程を更に含む、請求項38に記載の方法。

- 第2接着剤の押出成形が、第2接着剤を第1感圧性接着剤及び発泡体裏材と共押出成形することを含む、請求項39に記載の方法。

- 第2接着剤が、請求項1〜30のいずれか一項に記載の感圧性接着剤である、請求項38又は39に記載の方法。

- 発泡体裏材を提供する工程と、第1感圧性接着剤を含む第1接着剤組成物を発泡体裏材の第1表面に適用する工程と、を含む、請求項31〜37のいずれか一項に記載のテープの製造方法。

- 第1接着剤組成物の適用が、積層を含む、請求項42に記載の方法。

- 第1接着剤組成物の適用が、コーティングを含み、任意に方法が第1接着剤組成物の架橋を更に含み、任意に第1接着剤組成物の架橋が放射線架橋を含む、請求項43に記載の方法。

- 第1接着剤組成物が、溶媒型接着剤であり、方法が第1接着剤組成物の乾燥を更に含む、請求項42〜44のいずれか一項に記載の方法。

- 第2接着剤組成物を発泡体の第2表面に適用する工程を更に含む、請求項42〜45のいずれか一項に記載の方法。

- 第2接着剤組成物が、請求項1〜30のいずれか一項に記載の感圧性接着剤を含む、請求項46に記載の方法。

- 第2接着剤組成物の適用が、積層を含む、請求項46又は47に記載の方法。

- 第2接着剤組成物の適用が、コーティングを含み、任意に方法が第2接着剤組成物の架橋を更に含み、任意に第2接着剤組成物の架橋が放射線架橋を含む、請求項46又は47に記載の方法。

- 第2接着剤組成物が溶媒型接着剤であり、方法が第2接着剤組成物の乾燥を更に含む、請求項46〜49のいずれか一項に記載の方法。

- 第1表面を有する第1基材と、

第2表面を有する第2基材と、

第1基材の第1表面と第2基材の第2表面との間の接着界面であって、請求項1〜30のいずれか一項に記載の感圧性接着剤を含む接着界面と、を含む、接着複合体。 - 第1表面を有する第1基材と、

第2表面を有する第2基材と、

第1基材の第1表面と第2基材の第2表面との間の接着界面であって、請求項31〜37のいずれか一項に記載のテープを含む接着界面と、を含む、接着複合体。 - 第1表面が、35ダイン/cm未満の表面エネルギーを有する、請求項51又は52に記載の接着複合体。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US86897506P | 2006-12-07 | 2006-12-07 | |

| PCT/US2007/083741 WO2008070386A1 (en) | 2006-12-07 | 2007-11-06 | Blends of block copolymer and acrylic adhesives |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014011725A Division JP2014080625A (ja) | 2006-12-07 | 2014-01-24 | ブロックコポリマーとアクリル接着剤とのブレンド |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010512426A true JP2010512426A (ja) | 2010-04-22 |

| JP2010512426A5 JP2010512426A5 (ja) | 2010-12-02 |

Family

ID=39492584

Family Applications (5)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009540357A Pending JP2010512426A (ja) | 2006-12-07 | 2007-11-06 | ブロックコポリマーとアクリル接着剤とのブレンド |

| JP2014011725A Withdrawn JP2014080625A (ja) | 2006-12-07 | 2014-01-24 | ブロックコポリマーとアクリル接着剤とのブレンド |

| JP2015121982A Active JP6338552B2 (ja) | 2006-12-07 | 2015-06-17 | ブロックコポリマーとアクリル接着剤とのブレンド |

| JP2018000406A Active JP6731428B2 (ja) | 2006-12-07 | 2018-01-05 | ブロックコポリマーとアクリル接着剤とのブレンド |

| JP2020070676A Active JP6865876B2 (ja) | 2006-12-07 | 2020-04-10 | ブロックコポリマーとアクリル接着剤とのブレンド |

Family Applications After (4)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014011725A Withdrawn JP2014080625A (ja) | 2006-12-07 | 2014-01-24 | ブロックコポリマーとアクリル接着剤とのブレンド |

| JP2015121982A Active JP6338552B2 (ja) | 2006-12-07 | 2015-06-17 | ブロックコポリマーとアクリル接着剤とのブレンド |

| JP2018000406A Active JP6731428B2 (ja) | 2006-12-07 | 2018-01-05 | ブロックコポリマーとアクリル接着剤とのブレンド |

| JP2020070676A Active JP6865876B2 (ja) | 2006-12-07 | 2020-04-10 | ブロックコポリマーとアクリル接着剤とのブレンド |

Country Status (8)

| Country | Link |

|---|---|

| US (3) | US20100075132A1 (ja) |

| EP (2) | EP2474587A1 (ja) |

| JP (5) | JP2010512426A (ja) |

| KR (1) | KR101605906B1 (ja) |

| CN (1) | CN101547989B (ja) |

| BR (1) | BRPI0720155A2 (ja) |

| CA (1) | CA2671436C (ja) |

| WO (1) | WO2008070386A1 (ja) |

Cited By (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2012026501A1 (ja) * | 2010-08-27 | 2012-03-01 | 株式会社クラレ | 熱可塑性重合体組成物および成形品 |

| JP2013538922A (ja) * | 2010-09-30 | 2013-10-17 | スリーエム イノベイティブ プロパティズ カンパニー | 高度に粘着付与されたホットメルト加工可能なアクリレート感圧性接着剤 |

| WO2014038810A1 (ko) * | 2012-09-04 | 2014-03-13 | 동우화인켐 주식회사 | 점착제 조성물 |

| JP2014055235A (ja) * | 2012-09-12 | 2014-03-27 | Nitto Denko Corp | 両面粘着シート |

| JP2014534303A (ja) * | 2011-10-11 | 2014-12-18 | エルジー・ハウシス・リミテッドLg Hausys,Ltd. | 自動車用粘着テープ |

| WO2016006353A1 (ja) * | 2014-07-11 | 2016-01-14 | 綜研化学株式会社 | 粘着剤組成物、粘着シート、積層体、画像表示装置及び入出力装置 |

| JP2017036352A (ja) * | 2015-08-06 | 2017-02-16 | 藤森工業株式会社 | 接着性樹脂組成物、接着剤の製造方法、接着剤、接着性積層体、及び積層体 |

| JP2017119777A (ja) * | 2015-12-28 | 2017-07-06 | 日立マクセル株式会社 | 両面粘着テープ |

| JP2017524045A (ja) * | 2014-07-17 | 2017-08-24 | スリーエム イノベイティブ プロパティズ カンパニー | 平坦でない基材への結合に適した感圧性接着剤アセンブリ |

| JP2017165971A (ja) * | 2009-03-05 | 2017-09-21 | スリーエム イノベイティブ プロパティズ カンパニー | アクリルフォーム層を含む接着剤物品 |

| WO2018062192A1 (ja) * | 2016-09-27 | 2018-04-05 | 株式会社クラレ | 樹脂組成物、ペレット、ベール、制振材、遮音材および合わせガラス用中間膜 |

| JP2020503403A (ja) * | 2016-12-19 | 2020-01-30 | スリーエム イノベイティブ プロパティズ カンパニー | 低voc特性を有するゴム系多層感圧接着剤アセンブリ |

| JP2020514438A (ja) * | 2016-12-19 | 2020-05-21 | スリーエム イノベイティブ プロパティズ カンパニー | 低voc特性を有する多層感圧接着剤アセンブリ |

| JP2021529857A (ja) * | 2018-06-27 | 2021-11-04 | スリーエム イノベイティブ プロパティズ カンパニー | 接着剤組成物、アセンブリ、及びその方法 |

Families Citing this family (41)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| MX2007008590A (es) * | 2005-01-26 | 2007-08-14 | Procter & Gamble | Panal desechable tipo calzon que tiene una cintura elastica de recuperacion lenta con fuerza baja. |

| CA2671033C (en) | 2006-12-07 | 2016-04-19 | 3M Innovative Properties Company | Block copolymer blend adhesives with multiple tackifiers |

| JP4903914B2 (ja) * | 2008-07-02 | 2012-03-28 | スリーエム イノベイティブ プロパティズ カンパニー | 低表面エネルギー接着剤 |

| JP5465678B2 (ja) * | 2008-12-05 | 2014-04-09 | 株式会社クラレ | 光学フィルム用粘着剤組成物 |

| JP5676590B2 (ja) | 2009-06-18 | 2015-02-25 | スリーエム イノベイティブ プロパティズ カンパニー | ポリマー発泡体 |

| JP5418399B2 (ja) * | 2009-07-17 | 2014-02-19 | 日立化成株式会社 | 接着剤組成物及び該接着剤組成物を用いた回路部材の接続構造体 |

| JP5502543B2 (ja) * | 2010-03-25 | 2014-05-28 | 日東電工株式会社 | アクリル系粘着テープ |

| EP2426181B1 (en) | 2010-09-03 | 2013-07-17 | 3M Innovative Properties Company | Method for applying elongate strip to door frame of vehicle |

| DE102010050665A1 (de) * | 2010-11-09 | 2012-05-10 | Abb Ag | Elektrischer Schaltschrank |

| BR112013031508A2 (pt) | 2011-06-07 | 2016-12-13 | 3M Innovative Properties Co | sistema e método para gerenciamento de um telhado |

| EP2760957B1 (en) | 2011-09-29 | 2016-02-24 | 3M Innovative Properties Company | Catalyzing amino-substituted organosilane ester primers |

| CN104640954B (zh) * | 2012-04-13 | 2017-05-17 | 3M创新有限公司 | 压敏粘合剂泡沫和由其制得的制品 |

| DE102012212883A1 (de) * | 2012-07-23 | 2014-05-15 | Tesa Se | Geschäumtes Klebeband zur Verklebung auf unpolaren Oberflächen |

| DE102013000995A1 (de) | 2012-08-16 | 2014-02-20 | Lohmann Gmbh & Co. Kg | Klebemittel mit Klebstoffblend aus Acrylat und Styrol-Block-Copolymer |

| DE602012043935C5 (de) | 2012-12-19 | 2023-03-30 | 3M Innovative Properties Company | Haftklebebandrolle, Herstellungsverfahren dafür und Verwendung davon zur Herstellung von wasserdichten Streifen |

| EP2757135B1 (en) | 2013-01-18 | 2017-11-29 | 3M Innovative Properties Company | Method of bonding parts to a vehicle by an acrylic foam tape |

| DE102013215296A1 (de) * | 2013-08-02 | 2015-02-05 | Tesa Se | Haftklebemasse |

| DE102013215297A1 (de) | 2013-08-02 | 2015-02-05 | Tesa Se | Haftklebemasse |

| CN104342231B (zh) * | 2013-08-08 | 2016-12-07 | 中国石油化工股份有限公司 | 一种润滑油粘度指数改进剂及其制备方法 |

| ES2735876T3 (es) * | 2013-08-30 | 2019-12-20 | Kuraray Co | Copolímero acrílico de bloques modificado, método para producirlo y uso previsto del mismo |

| JP6487633B2 (ja) * | 2014-05-30 | 2019-03-20 | 綜研化学株式会社 | 粘着剤組成物及びその製造方法、ならびに、粘着剤層及びその製造方法 |

| EP3233949A1 (en) * | 2014-12-19 | 2017-10-25 | 3M Innovative Properties Company | Pressure sensitive adhesives comprising a polymodal asymmetric multiarm elastomeric block copolymer |

| DE102015109659A1 (de) | 2015-06-17 | 2016-12-22 | Lohmann Gmbh & Co. Kg | Klebmasse |

| EP3156465A1 (en) * | 2015-10-15 | 2017-04-19 | 3M Innovative Properties Company | Multilayer pressure sensitive adhesive foam tape for outdooor applications |

| EP3156466B1 (en) * | 2015-10-15 | 2020-11-25 | 3M Innovative Properties Company | Multilayer pressure sensitive adhesive foam tape for outdooor applications |

| KR102047288B1 (ko) * | 2015-12-10 | 2019-11-21 | 주식회사 엘지화학 | 점착제 조성물 |

| CN105419698B (zh) * | 2015-12-31 | 2020-09-29 | 光山县博正树脂有限公司 | 无色透明接枝胶及其制备方法 |

| DE102016205822A1 (de) | 2016-04-07 | 2017-10-12 | Tesa Se | Haftklebmasse |

| US10982116B2 (en) | 2016-04-29 | 2021-04-20 | 3M Innovative Properties Company | Adhesive and damping film |

| EP3243886A1 (en) * | 2016-05-13 | 2017-11-15 | 3M Innovative Properties Company | Rubber-based pressure-sensitive adhesive having low voc characteristics |

| WO2018116067A2 (en) * | 2016-12-19 | 2018-06-28 | 3M Innovative Properties Company | Adhesive compositions and articles |

| JP7124428B2 (ja) * | 2018-05-09 | 2022-08-24 | Dic株式会社 | 粘着剤層を有する積層体 |

| JP7489985B2 (ja) | 2018-12-19 | 2024-05-24 | スリーエム イノベイティブ プロパティズ カンパニー | 剥離層及びそれらを含む物品 |

| CA3144026A1 (en) * | 2019-08-13 | 2021-02-18 | Todd P. Macallen | Flexible furniture with wood panels and related methods |

| US20230068396A1 (en) * | 2019-12-20 | 2023-03-02 | 3M Innovative Properties Company | Articles, dies and methods of making the same |

| DE102020204065A1 (de) | 2020-03-30 | 2021-09-30 | Tesa Se | Verfahren zur Herstellung eines mehrschichtigen Klebebandes mit Schaumträger |

| DE102021206697A1 (de) | 2021-06-28 | 2022-12-29 | Tesa Se | Schockresistente Haftklebmasse |

| EP4433525A1 (en) | 2021-11-16 | 2024-09-25 | 3M Innovative Properties Company | Release composition, articles prepared from the release composition, and related methods |

| WO2023111955A1 (en) | 2021-12-16 | 2023-06-22 | 3M Innovative Properties Company | Articles including a spacer and articles including a slit film and processes for making and using the articles |

| DE102022107747A1 (de) | 2022-03-31 | 2023-10-05 | Tesa Se | Haftklebemasse auf Basis von hydrierten Polyvinylaromaten-Polydien-Blockcopolymeren |

| DE102022107748A1 (de) | 2022-03-31 | 2023-10-05 | Tesa Se | Klebeband zur Verklebung auf Lacken |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH11501956A (ja) * | 1995-02-16 | 1999-02-16 | ミネソタ マイニング アンド マニュファクチャリング カンパニー | 感圧接着剤 |

| JP2000502919A (ja) * | 1995-12-22 | 2000-03-14 | ミネソタ マイニング アンド マニュファクチャリング カンパニー | 皮膚に好適な感圧接着剤およびその製造方法 |

| JP2003522275A (ja) * | 2000-02-08 | 2003-07-22 | スリーエム イノベイティブ プロパティズ カンパニー | 放射状ブロックおよびアクリレートポリマーを含む感圧接着剤および物品 |

Family Cites Families (57)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4167433A (en) * | 1977-11-03 | 1979-09-11 | Gulf Oil Corporation | Adhesive composition and process for bonding |

| US4288567A (en) | 1979-08-27 | 1981-09-08 | The Goodyear Tire & Rubber Company | Adhesive composition and method of preparation |

| US4948825A (en) * | 1987-06-03 | 1990-08-14 | Avery International Corporation | Curable film forming compositions |

| US5141789A (en) * | 1987-12-16 | 1992-08-25 | Kanzaki Paper Manufacturing Co., Ltd. | Self-adhesive sheet |

| US5399627A (en) * | 1989-08-11 | 1995-03-21 | The Dow Chemical Company | Radial styrene-isoprene-butadiene multi-armed block copolymers and compositions and articles containing block copolymers |

| US5292819A (en) | 1989-08-11 | 1994-03-08 | The Dow Chemical Company | Radial block copolymers containing butadiene endblock |

| US5393373A (en) | 1991-07-11 | 1995-02-28 | Goldstar Electron Co., Ltd. | Methods of patterning and manufacturing semiconductor devices |

| FR2698630B1 (fr) * | 1992-11-27 | 1995-01-06 | Atochem Elf Sa | Procédé de préparation de copolymères séquences élastomères thermoplastiques dérivés de diènes conjugués et de méthacrylate de méthyle, à tenue à la chaleur améliorée et produits obtenus. |

| US5896855A (en) * | 1992-12-24 | 1999-04-27 | Rhone-Poulenc Rorer Limited | Multi dose inhaler apparatus |

| US5296547A (en) | 1993-01-28 | 1994-03-22 | Minnesota Mining And Manufacturing Company | Block copolymer having mixed molecular weight endblocks |

| JPH06228522A (ja) | 1993-02-03 | 1994-08-16 | Nippon Zeon Co Ltd | 熱溶融型両面テープ用粘着剤組成物 |

| US5412031A (en) * | 1993-05-25 | 1995-05-02 | Minnesota Mining & Manufacturing Company | Multi-arm block copolymers, and pressure sensitive adhesive and tape employing a multi-arm elastomeric block copolymer |

| DE69413823T2 (de) | 1993-07-14 | 1999-03-18 | Shell Internationale Research Maatschappij B.V., Den Haag/S'gravenhage | Verfahren zur härtung einer durch uv-strahlen härtbaren blockcopolymerzusammensetzung |

| US6231962B1 (en) * | 1993-08-31 | 2001-05-15 | 3M Innovative Properties Company | Removable foam adhesive tape |

| US5393841A (en) | 1993-11-09 | 1995-02-28 | Shell Oil Company | Dissimilar arm asymmetric radial or star block copolymers for adhesives and sealants |

| IT1265225B1 (it) * | 1993-11-26 | 1996-10-31 | Enichem Elastomeri Srl | Composizioni adesive hot meli per applicazioni speciali a base di copolimeri a blocchi |

| US5677376A (en) | 1994-01-14 | 1997-10-14 | Minnesota Mining And Manufacturing Company | Acrylate-containing polymer blends |

| US5602202A (en) * | 1994-01-14 | 1997-02-11 | Minnesota Mining And Manufacturing Company | Methods of using acrylate-containing polymer blends |

| US5804610A (en) | 1994-09-09 | 1998-09-08 | Minnesota Mining And Manufacturing Company | Methods of making packaged viscoelastic compositions |

| US5550196A (en) | 1994-11-09 | 1996-08-27 | Shell Oil Company | Low viscosity adhesive compositions containing asymmetric radial polymers |

| US5663241A (en) * | 1994-12-13 | 1997-09-02 | Minnesota Mining And Manufacturing Company | Removable pressure sensitive adhesive and article |

| US6632522B1 (en) * | 1995-02-16 | 2003-10-14 | 3M Innovative Properties Company | Blended pressure-sensitive adhesives |

| WO1996027644A1 (en) * | 1995-03-03 | 1996-09-12 | Minnesota Mining And Manufacturing Company | Pressure sensitive adhesive comprising a block copolymer having low molecular weight endblocks and endblock-compatible tackifier or oil |

| JP3212475B2 (ja) | 1995-03-16 | 2001-09-25 | 積水化学工業株式会社 | 表面保護フィルムの製造方法 |

| JP3465833B2 (ja) * | 1995-06-07 | 2003-11-10 | 株式会社日本触媒 | 溶剤型の粘着剤組成物 |

| US5605964A (en) * | 1995-06-22 | 1997-02-25 | Minnesota Mining And Manufacturing Company | Acrylate-containing polymer blends and methods of using |

| US5795834A (en) * | 1995-12-22 | 1998-08-18 | Minnesota Mining & Manufacturing Company | Adhesive tape and method of making |

| US5750607A (en) * | 1996-03-08 | 1998-05-12 | Shell Oil Company | Adhesive compositions comprising block copolymers of a monovinylaromatic compound and butadiene |

| USH2100H1 (en) | 1996-03-26 | 2004-04-06 | Kraton Polymers Llc | Low stress relaxation adhesive having high molecular weight endblock copolymer |

| US5750623A (en) * | 1996-05-20 | 1998-05-12 | The Dow Chemical Co. | Hot-melt adhesives for disposable items and articles made therefrom |

| WO1998003587A1 (en) * | 1996-07-22 | 1998-01-29 | Icc Industries Inc. | Flame retardant polyolefins for molding applications |

| DE69815073T3 (de) | 1997-03-14 | 2008-07-03 | Minnesota Mining And Manufacturing Co., St. Paul | Auf-anfrage-härtung von feuchtigkeithärtbaren zusammensetzungen mit reaktiven funktionellen silangruppen |

| US6103152A (en) * | 1998-07-31 | 2000-08-15 | 3M Innovative Properties Co. | Articles that include a polymer foam and method for preparing same |

| US6734256B1 (en) | 1998-12-29 | 2004-05-11 | 3M Innovative Properties Company | Block copolymer hot-melt processable adhesives, methods of their preparation, and articles therefrom |

| US6162859A (en) * | 1999-06-07 | 2000-12-19 | National Starch And Chemical Investment Holding Corporation | Hot melt pressure sensitive adhesives based on compatibilized blends of elastomers |

| CN1538999A (zh) * | 1999-09-10 | 2004-10-20 | 布莱迪世界公司 | 用于数据存储设备的压敏粘合剂 |

| DE10000966A1 (de) | 2000-01-12 | 2001-07-19 | Gnan Karl Heinz | Mehrfachscheibe mit räumlicher Einlage |

| US6630531B1 (en) * | 2000-02-02 | 2003-10-07 | 3M Innovative Properties Company | Adhesive for bonding to low surface energy surfaces |

| US20030211308A1 (en) * | 2001-02-02 | 2003-11-13 | Khandpur Ashish K | Adhesive for bonding to low surface energy surfaces |

| JP4230080B2 (ja) * | 2000-02-18 | 2009-02-25 | リンテック株式会社 | ウエハ貼着用粘着シート |

| US6579941B1 (en) * | 2000-06-12 | 2003-06-17 | Avery Dennison Corporatoin | Adhesive compositions and constructions with outstanding cutting performance |

| US6569521B1 (en) * | 2000-07-06 | 2003-05-27 | 3M Innovative Properties Company | Stretch releasing pressure sensitive adhesive tape and articles |

| JP4787397B2 (ja) * | 2000-08-28 | 2011-10-05 | 日東電工株式会社 | 粘着剤組成物および粘着テープもしくはシート |

| ATE312147T1 (de) * | 2000-10-25 | 2005-12-15 | 3M Innovative Properties Co | Verfahren zur verwendung von latenten, über- tackifizierten klebstoffen |

| EP1354016B1 (en) * | 2001-01-18 | 2010-03-03 | Kraton Polymers Research B.V. | Adhesive composition |

| US6780484B2 (en) * | 2001-02-02 | 2004-08-24 | 3M Innovative Properties Company | Adhesive article and method of preparing |

| US6805933B2 (en) * | 2001-07-31 | 2004-10-19 | 3M Innovative Properties Company | Articles comprising a release liner having a high coefficient of friction and good roll stability |

| US20030082362A1 (en) | 2001-07-31 | 2003-05-01 | Khandpur Ashish K. | High cohesive strength pressure sensitive adhesive foam |

| GB0123027D0 (en) | 2001-09-25 | 2001-11-14 | Exxonmobil Chem Patents Inc | Adhesives based on radial block copolymers with improved die-cutting performance |

| US7141621B2 (en) * | 2002-02-07 | 2006-11-28 | Kraton Polymers U.S. Llc | Gels from controlled distribution block copolymers |

| US7589152B2 (en) | 2003-12-22 | 2009-09-15 | Kraton Polymers U.S. Llc | Adhesive formulations for novel radial (S-I/B)x polymers |

| US7655720B2 (en) | 2004-02-13 | 2010-02-02 | Henkel Ag & Co. Kgaa | Adhesive containing radial block copolymer |

| US7070051B2 (en) * | 2004-03-26 | 2006-07-04 | Atrion Medical Products, Inc. | Needle counter device including troughs of cohesive material |

| US7348376B2 (en) * | 2004-04-13 | 2008-03-25 | Kraton Polymers U.S. Llc | Adhesive composition |

| EP1586606A1 (en) * | 2004-04-14 | 2005-10-19 | KRATON Polymers Research B.V. | An asphalt binder based on polymer modified bitumen, hot mix asphalts made thereof, and pavements made therefrom |

| US8592035B2 (en) * | 2004-12-13 | 2013-11-26 | 3M Innovative Properties Company | Adhesive composition, adhesive tape and adhesion structure |

| CA2671033C (en) * | 2006-12-07 | 2016-04-19 | 3M Innovative Properties Company | Block copolymer blend adhesives with multiple tackifiers |

-

2007

- 2007-11-06 EP EP20120163461 patent/EP2474587A1/en not_active Withdrawn

- 2007-11-06 WO PCT/US2007/083741 patent/WO2008070386A1/en active Application Filing

- 2007-11-06 CN CN2007800445501A patent/CN101547989B/zh active Active

- 2007-11-06 BR BRPI0720155-9A patent/BRPI0720155A2/pt not_active IP Right Cessation

- 2007-11-06 KR KR1020097011610A patent/KR101605906B1/ko active IP Right Grant

- 2007-11-06 EP EP07844895A patent/EP2094803A4/en not_active Ceased

- 2007-11-06 US US12/514,865 patent/US20100075132A1/en not_active Abandoned

- 2007-11-06 JP JP2009540357A patent/JP2010512426A/ja active Pending

- 2007-11-06 CA CA2671436A patent/CA2671436C/en not_active Expired - Fee Related

-

2014

- 2014-01-24 JP JP2014011725A patent/JP2014080625A/ja not_active Withdrawn

- 2014-09-12 US US14/484,890 patent/US20140377535A1/en not_active Abandoned

- 2014-09-12 US US14/484,952 patent/US9556367B2/en active Active

-

2015

- 2015-06-17 JP JP2015121982A patent/JP6338552B2/ja active Active

-

2018

- 2018-01-05 JP JP2018000406A patent/JP6731428B2/ja active Active

-

2020

- 2020-04-10 JP JP2020070676A patent/JP6865876B2/ja active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH11501956A (ja) * | 1995-02-16 | 1999-02-16 | ミネソタ マイニング アンド マニュファクチャリング カンパニー | 感圧接着剤 |

| JP2000502919A (ja) * | 1995-12-22 | 2000-03-14 | ミネソタ マイニング アンド マニュファクチャリング カンパニー | 皮膚に好適な感圧接着剤およびその製造方法 |

| JP2003522275A (ja) * | 2000-02-08 | 2003-07-22 | スリーエム イノベイティブ プロパティズ カンパニー | 放射状ブロックおよびアクリレートポリマーを含む感圧接着剤および物品 |

Cited By (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2017165971A (ja) * | 2009-03-05 | 2017-09-21 | スリーエム イノベイティブ プロパティズ カンパニー | アクリルフォーム層を含む接着剤物品 |

| JP2020125494A (ja) * | 2009-03-05 | 2020-08-20 | スリーエム イノベイティブ プロパティズ カンパニー | アクリルフォーム層を含む接着剤物品 |

| US9670354B2 (en) | 2010-08-27 | 2017-06-06 | Kuraray Co., Ltd. | Thermoplastic polymer composition and molded article |

| JPWO2012026501A1 (ja) * | 2010-08-27 | 2013-10-28 | 株式会社クラレ | 熱可塑性重合体組成物および成形品 |

| WO2012026501A1 (ja) * | 2010-08-27 | 2012-03-01 | 株式会社クラレ | 熱可塑性重合体組成物および成形品 |

| JP5809150B2 (ja) * | 2010-08-27 | 2015-11-10 | 株式会社クラレ | 熱可塑性重合体組成物および成形品 |

| JP2013538922A (ja) * | 2010-09-30 | 2013-10-17 | スリーエム イノベイティブ プロパティズ カンパニー | 高度に粘着付与されたホットメルト加工可能なアクリレート感圧性接着剤 |

| JP2014534303A (ja) * | 2011-10-11 | 2014-12-18 | エルジー・ハウシス・リミテッドLg Hausys,Ltd. | 自動車用粘着テープ |

| WO2014038810A1 (ko) * | 2012-09-04 | 2014-03-13 | 동우화인켐 주식회사 | 점착제 조성물 |

| JP2014055235A (ja) * | 2012-09-12 | 2014-03-27 | Nitto Denko Corp | 両面粘着シート |

| JP2016020403A (ja) * | 2014-07-11 | 2016-02-04 | 綜研化学株式会社 | 粘着剤組成物、粘着シート、積層体、画像表示装置及び入出力装置 |

| WO2016006353A1 (ja) * | 2014-07-11 | 2016-01-14 | 綜研化学株式会社 | 粘着剤組成物、粘着シート、積層体、画像表示装置及び入出力装置 |

| JP2017524045A (ja) * | 2014-07-17 | 2017-08-24 | スリーエム イノベイティブ プロパティズ カンパニー | 平坦でない基材への結合に適した感圧性接着剤アセンブリ |

| JP2017036352A (ja) * | 2015-08-06 | 2017-02-16 | 藤森工業株式会社 | 接着性樹脂組成物、接着剤の製造方法、接着剤、接着性積層体、及び積層体 |

| WO2017115850A1 (ja) * | 2015-12-28 | 2017-07-06 | 日立マクセル株式会社 | 両面粘着テープ |

| JP2017119777A (ja) * | 2015-12-28 | 2017-07-06 | 日立マクセル株式会社 | 両面粘着テープ |

| WO2018062192A1 (ja) * | 2016-09-27 | 2018-04-05 | 株式会社クラレ | 樹脂組成物、ペレット、ベール、制振材、遮音材および合わせガラス用中間膜 |

| JP6313918B1 (ja) * | 2016-09-27 | 2018-04-18 | 株式会社クラレ | 樹脂組成物、ペレット、ベール、制振材、遮音材および合わせガラス用中間膜 |

| US10913843B2 (en) | 2016-09-27 | 2021-02-09 | Kuraray Co., Ltd. | Resin composition, pellet, veil, damping material, sound insulation material, and intermediate film for laminated glass |

| JP2020503403A (ja) * | 2016-12-19 | 2020-01-30 | スリーエム イノベイティブ プロパティズ カンパニー | 低voc特性を有するゴム系多層感圧接着剤アセンブリ |

| JP2020514438A (ja) * | 2016-12-19 | 2020-05-21 | スリーエム イノベイティブ プロパティズ カンパニー | 低voc特性を有する多層感圧接着剤アセンブリ |

| JP7035056B2 (ja) | 2016-12-19 | 2022-03-14 | スリーエム イノベイティブ プロパティズ カンパニー | 低voc特性を有する多層感圧接着剤アセンブリ |

| JP2021529857A (ja) * | 2018-06-27 | 2021-11-04 | スリーエム イノベイティブ プロパティズ カンパニー | 接着剤組成物、アセンブリ、及びその方法 |

| JP7373513B2 (ja) | 2018-06-27 | 2023-11-02 | スリーエム イノベイティブ プロパティズ カンパニー | 接着剤組成物、アセンブリ、及びその方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20090094441A (ko) | 2009-09-07 |

| US20140377535A1 (en) | 2014-12-25 |

| JP2018066020A (ja) | 2018-04-26 |

| WO2008070386A1 (en) | 2008-06-12 |

| JP6731428B2 (ja) | 2020-07-29 |

| JP6338552B2 (ja) | 2018-06-06 |

| CN101547989A (zh) | 2009-09-30 |

| BRPI0720155A2 (pt) | 2014-02-04 |

| CA2671436A1 (en) | 2008-06-12 |

| JP2015178637A (ja) | 2015-10-08 |

| US20140377533A1 (en) | 2014-12-25 |

| KR101605906B1 (ko) | 2016-03-23 |

| US20100075132A1 (en) | 2010-03-25 |

| JP2014080625A (ja) | 2014-05-08 |

| JP2020125480A (ja) | 2020-08-20 |

| EP2474587A1 (en) | 2012-07-11 |

| CN101547989B (zh) | 2011-07-06 |

| EP2094803A1 (en) | 2009-09-02 |

| JP6865876B2 (ja) | 2021-04-28 |

| EP2094803A4 (en) | 2010-01-20 |

| US9556367B2 (en) | 2017-01-31 |

| CA2671436C (en) | 2015-03-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6338552B2 (ja) | ブロックコポリマーとアクリル接着剤とのブレンド | |

| JP5801533B2 (ja) | 複数の粘着付与剤を含むブロックコポリマーブレンド接着剤 | |

| JP2017165971A (ja) | アクリルフォーム層を含む接着剤物品 | |

| JP5676590B2 (ja) | ポリマー発泡体 | |

| US20060251888A1 (en) | Pressure sensitive adhesive (PSA) laminates | |

| US20060251889A1 (en) | Pressure sensitive adhesive (PSA) laminates | |

| JP2018505932A (ja) | 多モード非対称多腕エラストマー性ブロックコポリマーを含む感圧接着剤 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20101018 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20101018 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130115 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20130412 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20130419 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20130924 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140124 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20140130 |

|

| A912 | Re-examination (zenchi) completed and case transferred to appeal board |

Free format text: JAPANESE INTERMEDIATE CODE: A912 Effective date: 20140404 |