JP2005297728A - 駆動輪用転がり軸受ユニットの製造方法及びその製造装置 - Google Patents

駆動輪用転がり軸受ユニットの製造方法及びその製造装置 Download PDFInfo

- Publication number

- JP2005297728A JP2005297728A JP2004115864A JP2004115864A JP2005297728A JP 2005297728 A JP2005297728 A JP 2005297728A JP 2004115864 A JP2004115864 A JP 2004115864A JP 2004115864 A JP2004115864 A JP 2004115864A JP 2005297728 A JP2005297728 A JP 2005297728A

- Authority

- JP

- Japan

- Prior art keywords

- peripheral surface

- cylindrical surface

- fitting cylindrical

- inner ring

- spline

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C19/00—Bearings with rolling contact, for exclusively rotary movement

- F16C19/02—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows

- F16C19/14—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load

- F16C19/18—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load with two or more rows of balls

- F16C19/181—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load with two or more rows of balls with angular contact

- F16C19/183—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load with two or more rows of balls with angular contact with two rows at opposite angles

- F16C19/184—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load with two or more rows of balls with angular contact with two rows at opposite angles in O-arrangement

- F16C19/186—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load with two or more rows of balls with angular contact with two rows at opposite angles in O-arrangement with three raceways provided integrally on parts other than race rings, e.g. third generation hubs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60B—VEHICLE WHEELS; CASTORS; AXLES FOR WHEELS OR CASTORS; INCREASING WHEEL ADHESION

- B60B27/00—Hubs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60B—VEHICLE WHEELS; CASTORS; AXLES FOR WHEELS OR CASTORS; INCREASING WHEEL ADHESION

- B60B27/00—Hubs

- B60B27/0005—Hubs with ball bearings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60B—VEHICLE WHEELS; CASTORS; AXLES FOR WHEELS OR CASTORS; INCREASING WHEEL ADHESION

- B60B27/00—Hubs

- B60B27/001—Hubs with roller-bearings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60B—VEHICLE WHEELS; CASTORS; AXLES FOR WHEELS OR CASTORS; INCREASING WHEEL ADHESION

- B60B27/00—Hubs

- B60B27/0015—Hubs for driven wheels

- B60B27/0021—Hubs for driven wheels characterised by torque transmission means from drive axle

- B60B27/0026—Hubs for driven wheels characterised by torque transmission means from drive axle of the radial type, e.g. splined key

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60B—VEHICLE WHEELS; CASTORS; AXLES FOR WHEELS OR CASTORS; INCREASING WHEEL ADHESION

- B60B27/00—Hubs

- B60B27/0078—Hubs characterised by the fixation of bearings

- B60B27/0084—Hubs characterised by the fixation of bearings caulking to fix inner race

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60B—VEHICLE WHEELS; CASTORS; AXLES FOR WHEELS OR CASTORS; INCREASING WHEEL ADHESION

- B60B27/00—Hubs

- B60B27/0094—Hubs one or more of the bearing races are formed by the hub

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60B—VEHICLE WHEELS; CASTORS; AXLES FOR WHEELS OR CASTORS; INCREASING WHEEL ADHESION

- B60B3/00—Disc wheels, i.e. wheels with load-supporting disc body

- B60B3/04—Disc wheels, i.e. wheels with load-supporting disc body with a single disc body not integral with rim, i.e. disc body and rim being manufactured independently and then permanently attached to each other in a second step, e.g. by welding

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C35/00—Rigid support of bearing units; Housings, e.g. caps, covers

- F16C35/04—Rigid support of bearing units; Housings, e.g. caps, covers in the case of ball or roller bearings

- F16C35/06—Mounting or dismounting of ball or roller bearings; Fixing them onto shaft or in housing

- F16C35/063—Fixing them on the shaft

- F16C35/0635—Fixing them on the shaft the bore of the inner ring being of special non-cylindrical shape which co-operates with a complementary shape on the shaft, e.g. teeth, polygonal sections

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C43/00—Assembling bearings

- F16C43/04—Assembling rolling-contact bearings

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D1/00—Couplings for rigidly connecting two coaxial shafts or other movable machine elements

- F16D1/10—Quick-acting couplings in which the parts are connected by simply bringing them together axially

- F16D1/108—Quick-acting couplings in which the parts are connected by simply bringing them together axially having retaining means rotating with the coupling and acting by interengaging parts, i.e. positive coupling

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C19/00—Bearings with rolling contact, for exclusively rotary movement

- F16C19/22—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings

- F16C19/34—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings for both radial and axial load

- F16C19/38—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings for both radial and axial load with two or more rows of rollers

- F16C19/383—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings for both radial and axial load with two or more rows of rollers with tapered rollers, i.e. rollers having essentially the shape of a truncated cone

- F16C19/385—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings for both radial and axial load with two or more rows of rollers with tapered rollers, i.e. rollers having essentially the shape of a truncated cone with two rows, i.e. double-row tapered roller bearings

- F16C19/386—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings for both radial and axial load with two or more rows of rollers with tapered rollers, i.e. rollers having essentially the shape of a truncated cone with two rows, i.e. double-row tapered roller bearings in O-arrangement

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C2326/00—Articles relating to transporting

- F16C2326/01—Parts of vehicles in general

- F16C2326/02—Wheel hubs or castors

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D1/00—Couplings for rigidly connecting two coaxial shafts or other movable machine elements

- F16D1/10—Quick-acting couplings in which the parts are connected by simply bringing them together axially

- F16D2001/103—Quick-acting couplings in which the parts are connected by simply bringing them together axially the torque is transmitted via splined connections

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49636—Process for making bearing or component thereof

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49636—Process for making bearing or component thereof

- Y10T29/49696—Mounting

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49826—Assembling or joining

- Y10T29/49908—Joining by deforming

- Y10T29/49909—Securing cup or tube between axially extending concentric annuli

- Y10T29/49911—Securing cup or tube between axially extending concentric annuli by expanding inner annulus

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49826—Assembling or joining

- Y10T29/49908—Joining by deforming

- Y10T29/49915—Overedge assembling of seated part

- Y10T29/4992—Overedge assembling of seated part by flaring inserted cup or tube end

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/53—Means to assemble or disassemble

- Y10T29/53104—Roller or ball bearing

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/53—Means to assemble or disassemble

- Y10T29/53104—Roller or ball bearing

- Y10T29/53109—Roller or ball bearing including deforming means

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Rolling Contact Bearings (AREA)

- Mounting Of Bearings Or Others (AREA)

Abstract

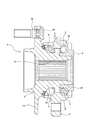

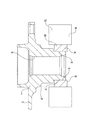

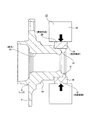

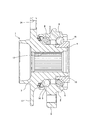

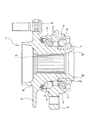

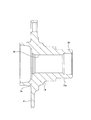

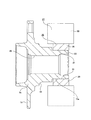

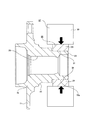

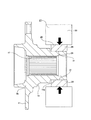

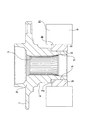

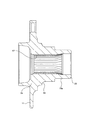

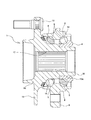

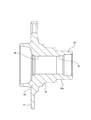

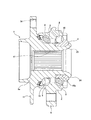

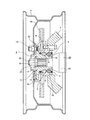

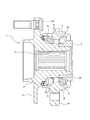

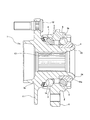

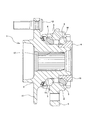

【解決手段】 ハブ3を把持する為の把持手段28を構成する各把持部材29、29を、小径段部15の径方向内方に変位させ、素孔25の軸方向内端部内周面を、この小径段部15に内輪を締り嵌めで外嵌固定する事に基づいて弾性変形するのと同じ若しくはそれよりも僅かに大きく弾性変形させる。この状態で、上記素孔25にスプライン孔を構成する為の雌スプライン部を形成する。

【選択図】 図4

Description

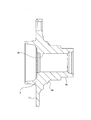

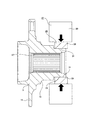

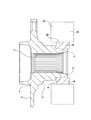

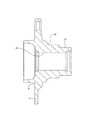

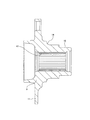

このうちの外輪は、外周面に懸架装置に結合固定する為の第一のフランジを、内周面に複列の外輪軌道を、それぞれ有するものである。

又、上記ハブは、中心部にスプライン孔を、外周面の軸方向外端寄り部分に駆動輪を支持固定する為の第二のフランジを、外周面の軸方向中間部に第一の内輪軌道を、外周面の軸方向内端寄り部分に嵌合円筒面部を、それぞれ有するものである。

又、上記内輪は、外周面に第二の内輪軌道を有し、上記嵌合円筒部に締り嵌めで外嵌固定されたものである。

又、上記各転動体は、上記複列の外輪軌道と上記第一、第二の内輪軌道との間に、それぞれ複数個ずつ転動自在に設けられている。

尚、上記スプライン孔の内端部内周面の弾性変形量は、上記把持手段のうちで上記嵌合円筒面部を把持する部分の内径寸法を規制する事により、容易に調節できる。

この様に構成すれば、単純な構造で、上記嵌合円筒面部の外周面に径方向内方に向かう荷重を、この嵌合円筒面部の周方向に亙り均等に加える事ができ、スプライン孔の軸方向内端部内周面の弾性変形量を所望の状態に規制し易くできる。

又、上記ハブ3に施す熱処理は、上記雌スプライン部の形成前に行なえば、この雌スプライン部を熱処理変形のないものとできるが、この雌スプライン部を形成した後に熱処理を施しても良い。

尚、前述した各実施例の説明は、雌スプライン部を形成する際のスプライン孔17の内周面の弾性変形量を、内輪4(1対の内輪4、4a)の締り嵌めに基づく変形量と、かしめ部24の形成に伴う変形量とをそれぞれ別にして規制した場合を例に説明した。但し、必要に応じて、これら内輪4(1対の内輪4、4a)の締り嵌めに基づく変形量と、かしめ部24の形成に伴う変形量との両方を考慮して規制する事も好ましい。

2 外輪

3、3a ハブ

4、4a 内輪

5、5a 転動体

6 第一のフランジ

7 ナックル

8、8a 外輪軌道

9 ホイール

10 ディスク

11 第二のフランジ

12 スタッド

13 ナット

14、14a 第一の内輪軌道

15、15a、15b 小径段部

16、16a 第二の内輪軌道

17 スプライン孔

18 等速ジョイント

19 スプライン軸

20 雄ねじ部

21 ナット

22 等速ジョイント用外輪

23 円筒部

24 かしめ部

25 素孔

26 治具

27 加工装置

28 把持手段

29 把持部材

30 駆動手段

31 内側面

32 テーパ面部

33 貫通孔

34 ねじ孔

Claims (5)

- 外輪と、ハブと、内輪と、複数の転動体とを備え、このうちの外輪は、外周面に懸架装置に結合固定する為の第一のフランジを、内周面に複列の外輪軌道を、それぞれ有するものであり、上記ハブは、中心部にスプライン孔を、外周面の軸方向外端寄り部分に駆動輪を支持固定する為の第二のフランジを、外周面の軸方向中間部に第一の内輪軌道を、外周面の軸方向内端寄り部分に嵌合円筒面部を、それぞれ有するものであり、上記内輪は、外周面に第二の内輪軌道を有し、上記嵌合円筒部に締り嵌めで外嵌固定されたものであり、上記各転動体は、上記複列の外輪軌道と上記第一、第二の内輪軌道との間に、それぞれ複数個ずつ転動自在に設けられているものである駆動輪用転がり軸受ユニットの製造方法であって、上記嵌合円筒面部に上記内輪を締り嵌めで外嵌固定するのに先立ち、この嵌合円筒面部を把持手段により把持すると共に、この把持手段のうちでこの嵌合円筒面部を把持した部分の内径をこの嵌合円筒面部の自由状態での外径よりも縮径する事により、上記スプライン孔の軸方向内端部内周面を径方向内方に弾性変形させた状態で、このスプライン孔を構成する為の雌スプライン部を形成した後、上記把持した部分の内径を上記嵌合円筒面部の外径よりも拡径する事により上記弾性変形を解除してから、この嵌合円筒面部に内輪を締り嵌めで外嵌固定する、駆動輪用転がり軸受ユニットの製造方法。

- スプライン孔の内端部内周面を、嵌合円筒面部に内輪を締り嵌めで外嵌固定する事に基づいて弾性変形するのと同じ若しくはそれよりも僅かに大きく弾性変形させる、請求項1に記載した駆動輪用転がり軸受ユニットの製造方法。

- 第一の内輪軌道が、嵌合円筒面部に締り嵌めで外嵌固定した別の内輪の外周面に設けられたものである、請求項1〜2の何れかに記載した駆動輪用転がり軸受ユニットの製造方法。

- 外輪と、ハブと、内輪と、複数の転動体とを備え、このうちの外輪は、外周面に懸架装置に結合固定する為の第一のフランジを、内周面に複列の外輪軌道を、それぞれ有するものであり、上記ハブは、中心部にスプライン孔を、外周面の軸方向外端寄り部分に駆動輪を支持固定する為の第二のフランジを、外周面の軸方向中間部に第一の内輪軌道を、外周面の軸方向内端寄り部分に嵌合円筒面部を、それぞれ有するものであり、上記内輪は、外周面に第二の内輪軌道を有し、上記嵌合円筒部に締り嵌めで外嵌固定されたものであり、上記各転動体は、上記複列の外輪軌道と上記第一、第二の内輪軌道との間に、それぞれ複数個ずつ転動自在に設けられているものである駆動輪用転がり軸受ユニットの製造装置であって、上記嵌合円筒面部を把持自在で、且つ、この嵌合円筒面部を把持する部分の内径をこの嵌合円筒面部の自由状態での外径よりも拡径並びに縮径自在とした把持手段と、上記スプライン孔を構成する為の雌スプライン部を形成する為の切削手段とを備え、上記嵌合円筒面部を上記把持手段により把持すると共に、この把持手段のうちでこの嵌合円筒面部を把持した部分の内径をこの嵌合円筒面部の自由状態での外径よりも縮径する事により、上記スプライン孔の軸方向内端部内周面を径方向内方に弾性変形させた状態で、上記切削手段により上記雌スプライン部を形成する、駆動輪用転がり軸受ユニットの製造装置。

- 把持手段は、嵌合円筒面部の径方向に変位自在の複数の把持部材を、この嵌合円筒面部の円周方向に等間隔に設けており、これら各把持部材をこの嵌合円筒面部の径方向に変位させる事により、上記把持手段のうちのこの嵌合円筒面部を把持する部分の内径を、この嵌合円筒面部の自由状態での外径よりも拡径並びに縮径自在とした、請求項3に記載した駆動輪用転がり軸受ユニットの製造装置。

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004115864A JP4696466B2 (ja) | 2004-04-09 | 2004-04-09 | 駆動輪用転がり軸受ユニットの製造方法及びその製造装置 |

| US11/085,043 US7707724B2 (en) | 2004-04-09 | 2005-03-22 | Manufacturing method for a drive wheel rolling bearing unit and manufacturing apparatus therefor |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004115864A JP4696466B2 (ja) | 2004-04-09 | 2004-04-09 | 駆動輪用転がり軸受ユニットの製造方法及びその製造装置 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2005297728A true JP2005297728A (ja) | 2005-10-27 |

| JP4696466B2 JP4696466B2 (ja) | 2011-06-08 |

Family

ID=35059047

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004115864A Expired - Lifetime JP4696466B2 (ja) | 2004-04-09 | 2004-04-09 | 駆動輪用転がり軸受ユニットの製造方法及びその製造装置 |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US7707724B2 (ja) |

| JP (1) | JP4696466B2 (ja) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2010089522A (ja) * | 2008-10-03 | 2010-04-22 | Nsk Ltd | 車輪支持用転がり軸受ユニットの製造方法 |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4904980B2 (ja) | 2006-08-14 | 2012-03-28 | 株式会社ジェイテクト | 車軸用軸受装置 |

| JP5597159B2 (ja) * | 2011-04-12 | 2014-10-01 | 住友重機械工業株式会社 | 歯車構造体の製造方法及び歯車構造体の中間構造体 |

| CN102734388B (zh) * | 2011-04-12 | 2015-09-02 | 住友重机械工业株式会社 | 具有齿轮结构体的变速装置系列及齿轮结构体系列 |

| JP2013159137A (ja) * | 2012-02-01 | 2013-08-19 | Ntn Corp | 車輪用軸受装置 |

| JP5867121B2 (ja) | 2012-02-02 | 2016-02-24 | 株式会社ジェイテクト | 車輪支持装置 |

| CN105522867A (zh) * | 2015-12-30 | 2016-04-27 | 长安马自达汽车有限公司 | 一种新型的驱动轮用轮毂轴承单元 |

| CN107035776A (zh) * | 2017-05-04 | 2017-08-11 | 泰州市众擎金属制品有限公司 | 一种内法兰盘 |

| JP7441609B2 (ja) * | 2019-03-25 | 2024-03-01 | Ntn株式会社 | 車輪用軸受装置 |

| DE102019130321B4 (de) * | 2019-11-11 | 2022-04-14 | Audi Ag | Radlagereinheit für ein Kraftfahrzeug sowie Verfahren zum Herstellen einer Radlagereinheit |

| FR3126900B1 (fr) | 2021-09-10 | 2023-12-08 | Ntn Snr Roulements | Procédé d’assemblage d’au moins une bague coopérant par frettage avec une portée de frettage d'une pièce |

| CN113953835B (zh) * | 2021-10-18 | 2022-08-02 | 泰州市东方传动技术有限公司 | 一种十字轴连接加工系统及加工工艺 |

| FR3147141B1 (fr) * | 2023-03-29 | 2025-11-21 | Ntn Snr Roulements | Procédé d’assemblage d’un ensemble de roulement de roue |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002106557A (ja) * | 2000-09-29 | 2002-04-10 | Nsk Ltd | 車輪駆動用軸受ユニット |

| JP2002317824A (ja) * | 2001-04-19 | 2002-10-31 | Nsk Ltd | 駆動輪用転がり軸受ユニットの製造方法及び車輪用駆動ユニット |

| JP2002327715A (ja) * | 2001-04-27 | 2002-11-15 | Koyo Seiko Co Ltd | 車軸用軸受装置、及びその車軸用軸受装置の製造方法 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3567629B2 (ja) * | 1996-07-25 | 2004-09-22 | マツダ株式会社 | 内歯を有する環状体の成形方法およびその装置 |

| JP3896751B2 (ja) * | 2000-02-23 | 2007-03-22 | 日本精工株式会社 | 車輪用軸受ユニットの製造方法 |

| JP2002089572A (ja) * | 2000-07-10 | 2002-03-27 | Koyo Seiko Co Ltd | 軸受装置 |

| JP3902415B2 (ja) | 2001-03-29 | 2007-04-04 | Ntn株式会社 | 駆動車輪用軸受装置 |

| JP4023129B2 (ja) | 2001-10-31 | 2007-12-19 | 日本精工株式会社 | 制動用回転部材及びホイール付転がり軸受ユニット |

-

2004

- 2004-04-09 JP JP2004115864A patent/JP4696466B2/ja not_active Expired - Lifetime

-

2005

- 2005-03-22 US US11/085,043 patent/US7707724B2/en active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002106557A (ja) * | 2000-09-29 | 2002-04-10 | Nsk Ltd | 車輪駆動用軸受ユニット |

| JP2002317824A (ja) * | 2001-04-19 | 2002-10-31 | Nsk Ltd | 駆動輪用転がり軸受ユニットの製造方法及び車輪用駆動ユニット |

| JP2002327715A (ja) * | 2001-04-27 | 2002-11-15 | Koyo Seiko Co Ltd | 車軸用軸受装置、及びその車軸用軸受装置の製造方法 |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2010089522A (ja) * | 2008-10-03 | 2010-04-22 | Nsk Ltd | 車輪支持用転がり軸受ユニットの製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| US7707724B2 (en) | 2010-05-04 |

| US20050223557A1 (en) | 2005-10-13 |

| JP4696466B2 (ja) | 2011-06-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2127902B1 (en) | Bearing device for driving wheel, and its assembling method | |

| JP4484132B2 (ja) | 振れを最小限に抑えたハブアセンブリとその製造方法 | |

| JP4696466B2 (ja) | 駆動輪用転がり軸受ユニットの製造方法及びその製造装置 | |

| JP2002200902A (ja) | 車輪駆動用ユニットとその製造方法 | |

| JP5228343B2 (ja) | 車輪支持用複列転がり軸受ユニット及びその製造方法 | |

| JP4114368B2 (ja) | 駆動輪用転がり軸受ユニットの製造方法 | |

| EP1902862A2 (en) | Rolling bearing apparatus for wheel | |

| JP4894652B2 (ja) | 車輪支持用転がり軸受ユニットの製造方法 | |

| JP2005306157A (ja) | 車輪支持用転がり軸受ユニット及びその製造方法 | |

| EP1902861B1 (en) | Wheel rolling bearing apparatus | |

| JP2010127305A (ja) | 転がり軸受装置の製造方法 | |

| JP3960005B2 (ja) | 車輪用回転支持装置 | |

| EP2587078A1 (en) | Wheel bearing device | |

| JP2009030618A (ja) | 駆動輪用転がり軸受ユニット及びその製造方法 | |

| JP4779953B2 (ja) | 軸受ユニット製造方法及び軸受ユニット | |

| JP2004338584A (ja) | 駆動車輪用軸受ユニットの製造方法および車輪用駆動ユニット | |

| JP2021165130A (ja) | ハブユニット軸受及び車両 | |

| JP2002301532A (ja) | 軸受装置のかしめ方法 | |

| JP2002337504A (ja) | 車輪駆動用軸受ユニットの組立方法及び組立用治具 | |

| JP2005119383A (ja) | 車輪用軸受装置 | |

| JP2000229501A (ja) | 車輪支持用ハブユニット | |

| JP2004263835A (ja) | 車輪用軸受装置 | |

| JP2004299666A (ja) | 車輪用軸受装置 | |

| JP2002274118A (ja) | 駆動輪用転がり軸受ユニット及び車輪用駆動ユニット | |

| JP2003120700A (ja) | 車輪用回転支持装置とその組立方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070323 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20070323 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20081224 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20091215 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20091224 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100601 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100716 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20110201 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20110214 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4696466 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| EXPY | Cancellation because of completion of term |