EP2785472B2 - Vorrichtung zum sichten von körnigem gut - Google Patents

Vorrichtung zum sichten von körnigem gut Download PDFInfo

- Publication number

- EP2785472B2 EP2785472B2 EP12790561.0A EP12790561A EP2785472B2 EP 2785472 B2 EP2785472 B2 EP 2785472B2 EP 12790561 A EP12790561 A EP 12790561A EP 2785472 B2 EP2785472 B2 EP 2785472B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- separator

- housing

- static

- accordance

- dynamic

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B4/00—Separating solids from solids by subjecting their mixture to gas currents

- B07B4/08—Separating solids from solids by subjecting their mixture to gas currents while the mixtures are supported by sieves, screens, or like mechanical elements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C21/00—Disintegrating plant with or without drying of the material

- B02C21/002—Disintegrating plant with or without drying of the material using a combination of a roller mill and a drum mill

- B02C21/005—Disintegrating plant with or without drying of the material using a combination of a roller mill and a drum mill the roller mill having cooperating rollers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C23/00—Auxiliary methods or auxiliary devices or accessories specially adapted for crushing or disintegrating not provided for in preceding groups or not specially adapted to apparatus covered by a single preceding group

- B02C23/08—Separating or sorting of material, associated with crushing or disintegrating

- B02C23/10—Separating or sorting of material, associated with crushing or disintegrating with separator arranged in discharge path of crushing or disintegrating zone

- B02C23/12—Separating or sorting of material, associated with crushing or disintegrating with separator arranged in discharge path of crushing or disintegrating zone with return of oversize material to crushing or disintegrating zone

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C23/00—Auxiliary methods or auxiliary devices or accessories specially adapted for crushing or disintegrating not provided for in preceding groups or not specially adapted to apparatus covered by a single preceding group

- B02C23/08—Separating or sorting of material, associated with crushing or disintegrating

- B02C23/14—Separating or sorting of material, associated with crushing or disintegrating with more than one separator

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B4/00—Separating solids from solids by subjecting their mixture to gas currents

- B07B4/02—Separating solids from solids by subjecting their mixture to gas currents while the mixtures fall

- B07B4/04—Separating solids from solids by subjecting their mixture to gas currents while the mixtures fall in cascades

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B7/00—Selective separation of solid materials carried by, or dispersed in, gas currents

- B07B7/08—Selective separation of solid materials carried by, or dispersed in, gas currents using centrifugal force

- B07B7/083—Selective separation of solid materials carried by, or dispersed in, gas currents using centrifugal force generated by rotating vanes, discs, drums, or brushes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B9/00—Combinations of apparatus for screening or sifting or for separating solids from solids using gas currents; General arrangement of plant, e.g. flow sheets

- B07B9/02—Combinations of similar or different apparatus for separating solids from solids using gas currents

Definitions

- the granular material to be sifted can be, for example, cement, cement-containing materials, cement raw material, limestone or slag, but also ores or the like.

- roller presses or material bed roller mills are used in particular to crush such granular materials.

- this high-pressure crushing of the granular material to be ground it is crushed in the gap between two press rollers (material bed crushing).

- material bed crushing During the crushing process, agglomerates are formed, which are referred to as flakes.

- Material bed roller mills of this type can be operated in a closed circuit with a static and/or dynamic sifter.

- the material bed roller mill is then positioned below a sifter, for example, so that the coarse material fraction emerging from the sifter is (re)fed to the roller mill.

- the material emerging from the roller mill is in turn fed to the material inlet of the classifying device, which is a multi-stage device consisting of a static classifier and a dynamic classifier.

- the static classifier the slugs are deagglomerated via the impact and guide elements, and at the same time the coarse material fraction is separated and fed to the roller press.

- the "finer" material enters the dynamic classifier with the classifying gases, where it is subjected to fine classification.

- the fine material classified from this classifier is discharged together with the classifying gas and collected as finished product in the following cyclones and/or filters.

- the middle fraction classified from the dynamic classifier can, for example, also be fed back to the roller press or to another grinding stage.

- Such measures are known from the state of the art (see, for example, DE 43 37 215 A1

- a generic viewing device of the type described above is known, for example, from the DE 42 23 762 B4

- This sifting device has a rotating rod basket in a housing with turbo elements distributed around the circumference of the rotor and with inlets and outlets for sifting air, sifting material, fines, medium material and coarse material.

- a shaft-shaped screening chamber is arranged at the same height on the side in front of the horizontally arranged rod basket, which has an inlet opening for the sifting material at the top that is separate from the sifting air, an opening for the sifting air arranged opposite the rod basket at the side, a discharge opening for a sifted coarse grain fraction at the bottom and two opposing shaft boundary walls that form a screening zone between them and are permeable to the sifting air.

- These shaft boundary walls of the screening chamber that are permeable to the sifting air have blind-like guide plates that are inclined diagonally downwards in the direction of the discharge opening for the sifted coarse material fraction, which act as impact and guide fittings and also ensure deagglomeration of the slugs.

- the sifting device consists of several concentric housings, with a rod basket rotating around a vertical axis serving as the secondary sifting stage.

- the secondary sifting stage is formed by a simple cyclone, with the sifting material and the sifting gas being fed in via a common feed line that is connected in a spiral to the sifter housing. Deagglomeration of the slugs is only possible to a limited extent in the static sifting stage.

- a device for classifying granular material into at least three grain fractions with a static classifier and a dynamic classifier, which are arranged rotationally symmetrically about a common axis in a common housing.

- the EN 10 2006 039 775 A1 a special design sifter with static Cascade sifter and a further sifter known as a post-sifter, wherein the cascade sifter has two packages of cone rings arranged spaced apart one above the other and concentrically to one another.

- the DD253771A1 an air classifier for classifying fine-grained bulk materials in particular into at least two fractions, consisting of a cylindrical upper housing section, which is followed at the bottom by a semolina cone with semolina discharge.

- the rod basket rotates around a vertical axis. The aim is to improve the distribution of the material in the classifying chamber of classifiers with rod baskets so that the separation accuracy is increased and the energy consumption, related to the end product, is reduced, regardless of the speed and shape of a spreading plate.

- a ring container with a fluidizing bottom is provided as a dispersing device, which is arranged above the classifying gas inlet nozzle in the area of the rod basket inside or outside the classifier housing and is connected to the classifying chamber via an annular gap and/or an annular channel.

- the invention is therefore based on the object of creating a device for classifying granular material into at least three fractions of the type described at the beginning, which is characterized not only by a particularly compact structure, but also in particular by low investment and operating costs and higher classifying efficiency.

- a classifying device should enable economical operation of a grinding plant with at least one roller press with high classifying efficiency.

- the invention provides a device for sifting granular material into at least three fractions, which has the features of claim 1.

- the invention is based first of all on the fundamentally known finding that it is advantageous to combine a static sifter and a dynamic sifter in the form of a rod basket sifter, since a first coarse material fraction can be sifted out via the static sifter, so that the dynamic sifter with the relatively sensitive rotating components is not unnecessarily burdened with coarse material.

- the static and dynamic sifters are combined in a particularly efficient and compact design by using a rod basket with a vertical axis of rotation and by connecting the static sifter directly to the side of the dynamic sifter, with the static sifter fulfilling both the task of slug deagglomeration and a first coarse separation in terms of process technology.

- the static sifter and dynamic sifter are therefore brought spatially close together so that both sifters work particularly efficiently in terms of energy, and the static sifter can simultaneously fulfill the task of slug deagglomeration.

- the sifter housing of the static sifter opens into the sifter housing of the dynamic sifter in a tangential or spiral orientation.

- the sifter housing of the static sifter is always compactly connected laterally to the sifter housing of the dynamic sifter, so that the static sifter housing merges into the dynamic sifter housing.

- the sifter according to the invention therefore has housing areas which can be assigned to both the static sifter and the dynamic sifter as a transition between the static sifter and the dynamic sifter.

- the sifter housing of the dynamic sifter has an upper housing section in which the rotating rod basket is arranged, and a lower housing section in which a discharge funnel for the middle material is arranged, the static sifter being connected with its housing to the lower housing section of the dynamic sifter and merging into this lower housing section.

- This lower housing section of the dynamic sifter therefore forms the transition area between the static sifter and the dynamic sifter.

- the housing of the dynamic classifier is cylindrical, so that the upper housing section and the lower housing section are cylindrical.

- the lower housing section of the dynamic classifier then also functions as a cyclone, which can influence both the function of the static classifier and the function of the dynamic classifier.

- This cyclone formed by the lower housing section can influence the effect of the static classifying stage.

- this cyclone can also be viewed as part of the dynamic classifier, since it forms an inflow channel for the vertical impact on the rod basket and since the discharge funnel of the dynamic classifier can also be arranged within this housing section or cyclone.

- the static classifier and the dynamic classifier are closely connected spatially and functionally.

- the static classifier is preferably attached to the lower housing section of the dynamic

- the static sifter is then usually positioned below the rod basket (in a side view).

- the static separator not only is there an initial separation of coarse and medium material, but a deagglomeration of the slugs can also take place.

- the deagglomeration of the slugs is achieved with the help of the impact and guide elements integrated into the static separator.

- the impact and guide elements can be formed in a known manner by impact plates or guide plates inclined against each other. In a preferred embodiment, these plates or plates can be adjusted in their inclination, e.g. pivoted or rotated about a horizontal axis. Since the functioning of the static separator during operation - in contrast to a dynamic separator - can only be influenced to a limited extent, such an adjustment option is useful.

- the desired conditions of the static separator can be set so that the flow conditions in particular can be optimized.

- the impact and guide elements can also be formed by roof-like installations, such as those from the EN 1 002 600 are known.

- the roof-like fittings can optionally be moved horizontally.

- the static sifter always combines the task of slug deagglomeration on the one hand and an initial coarse material separation on the other.

- the static sifter housing of the dynamic sifter is usually cylindrical or at least partially cylindrical

- the static sifter has a shaft-like or box-like housing that is preferably aligned at an angle to the vertical, so that the impact and guide fittings arranged inside are also arranged along a slope.

- the shaft-like housing has the material inlet or inlets for the material to be sifted and at least one sifting gas inlet, via which air is supplied, for example.

- the shaft-like housing can have a (lower) shaft wall that is oriented at a predetermined angle ⁇ between 10° and 80°, e.g. 40° to 60°.

- the housing can therefore be arranged (in side view) overall at an angle to the vertical.

- the invention also includes a shaft-like housing which is not oriented at an angle to the vertical, but parallel to the vertical.

- the sifting gas inlet can be formed, for example, by at least one inlet opening arranged diagonally above the internals.

- the sifting gas inlet can be formed by one or more openings arranged in the shaft wall. These openings can be closed, for example, by flaps, so that the sifting gas supply can be varied by opening and closing. It is therefore within the scope of the invention that either an (upper) inlet opening of the type described is provided or that openings are provided in the shaft wall.

- flaps Preferably, however, a combination of these measures is implemented, so that at least one inlet opening arranged diagonally above the internals and one or more openings arranged in the shaft wall are provided, whereby these openings can optionally be closed, for example, by flaps. It is then possible to work with "variable" air supply and consequently air volume control. It is expedient if the individual flaps can be opened and closed individually, in groups and/or together, whereby variable and targeted adjustment is particularly preferably possible by adjusting the openings.

- flaps generally mean means for opening and closing the openings and in particular for adjusting the amount of air passing through. By regulating the air volume appropriately, it is possible to further increase the visibility efficiency.

- the classifying gas inlet prefferably be formed by an area of the classifier housing that is free of shaft walls.

- the shaft wall is not required, so that the system can then operate with an open flow.

- the first separator housing which is connected laterally, e.g. tangentially or spirally, with the rod basket arranged in a vertical orientation.

- the direction of rotation of the rod basket can be oriented with or against the tangential or spiral-like connection direction of the static separator housing.

- the dynamic classifier is particularly preferably provided with one or more additional material inlets in the upper part, e.g. in the upper housing section. This is particularly useful if the classifier is integrated into a multi-stage grinding system, because the ground material can then be fed to a second stage for classifying via this (second) material inlet. This can, for example, be the discharge material from a second comminution device, e.g. a ball mill.

- a second comminution device e.g. a ball mill.

- a single static separator in the inventive, e.g. tangential or spiral, type is connected to the dynamic separator.

- two or more static sifters are connected to the dynamic sifter.

- the sifting for sifting a coarse material fraction and for deagglomerating the slugs can therefore be carried out in parallel in several sifting stages, with the individual sifting stages then acting in parallel on one and the same dynamic sifter.

- the connection of the several static sifters is preferably symmetrical (in plan view).

- the several static sifters are arranged "symmetrically" and thus equidistantly around the circumference.

- the offset is 360°/n in relation to the circumference, where "n" means the number of static sifters.

- two static sifters are used, they are preferably connected to the dynamic sifter offset by an angle of 180° in plan view.

- three static classifiers are used, they are preferably arranged offset by an angle of approximately 120°, and if four static classifiers are used, they are preferably arranged offset by an angle of 90° from each other, etc.

- impact fittings in the area of the dynamic classifier, e.g. inside the classifier housing of the dynamic classifier, preferably in its lower housing section, which can take on the function of a cyclone for the reasons explained.

- Impact fittings can be connected to the inside of the housing wall of this cyclone, which can function as "tripping edges” or “peeling edges". They are intended to counteract the cyclone effect of this part of the classifier and consequently reduce this cyclone effect. With the help of these fittings arranged on the wall, the material collecting in the wall area can be brought back towards the center or axis, so that the screening function is optimized.

- the sifter housing of the dynamic sifter is provided with one or more additional air inlets that take on the function of an air bypass. Not only is the air supplied via the air inlet of the static sifter, but additional air can also be supplied via the dynamic sifter. This then leads to the air supply in the area of the static sifter being reduced, so that an optimized adjustment of the air flow can be achieved in this way.

- This additional air supply can be implemented, for example, in the upper housing section of the sifter housing of the dynamic sifter.

- the sifting device according to the invention can be used for sifting a wide variety of granular materials, in particular for sifting cement, cement raw materials, limestone and similar materials.

- the invention also covers the sifting of ores or the like. The natural reserves of such raw materials have been largely exhausted, so that extraction is shifting to regions that are difficult to access and do not have sufficient water supplies.

- the sifter according to the invention can be used particularly efficiently there.

- a multi-stage, e.g. two-stage grinding system can be implemented, in which a further, separate sifter is provided in addition to the sifter according to the invention.

- the middle fraction of the first sifter according to the invention described is in turn fed to a second comminution device, e.g. a ball mill.

- the discharge material from this ball mill is then not - as previously described - fed to the first sifter, but to the second, separate sifter, whereby the coarse material emerging from this second sifter is fed to the ball mill again, while the fine material emerging from the second sifter can in turn be discharged as product.

- the invention also includes single-stage grinding systems in which both the coarse material emerging from the screening device according to the invention and the medium material are fed to a first (single) comminution device, e.g. a roller press, and the material emerging from this comminution device in turn enters the screening device according to the invention via the material inlet.

- a first (single) comminution device e.g. a roller press

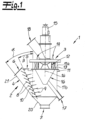

- the sifting device 1 shown serves to sift granular material, e.g. cement, into at least three fractions.

- the device 1 is composed of a static sifter 2 and a dynamic sifter 3, which are combined with one another in a particularly compact manner.

- the static sifter 2 forms a first sifting stage

- the dynamic sifter 3 which is arranged downstream of the static sifter 2 in the direction of the sifting medium flow, forms a second sifting stage.

- the static classifier 2 has a classifier housing 4 with a first material inlet 5, classifying gas inlet 6 and coarse material outlet 7.

- a classifier housing 4 with a first material inlet 5, classifying gas inlet 6 and coarse material outlet 7.

- several impact and guide elements 8, 9 are arranged one below the other in a staircase-like manner.

- these elements are designed as impact plates 8, 9, which also take on the function of guide plates for the static classifier.

- Fig.1 It can be seen that there are two groups of impact plates 8, 9 inclined towards each other, whereby these impact plates 8, 9 are adjustable about pivot axes 10 so that the inclination of the impact plates 8, 9 is adjustable.

- the second classifying stage is formed by the dynamic classifier 3, which has a classifier housing 11.

- This cylindrical classifier housing 11 has an upper cylindrical section 11a and a lower cylindrical section 11b.

- a rotating rod basket 12 is arranged, which is surrounded by a set of guide vanes 13. These are stationary guide vanes that are arranged at a fixed or adjustable angle of attack to the axis of rotation of the rod basket.

- the rod basket 12 rotates about a vertical axis 14.

- a drive 15 is connected to the rod basket 12.

- a discharge cone 16 is connected, which in turn is connected to the medium material outlet 17.

- the fine material outlet 18 is connected to the upper part 11a of the classifier housing 11, through which the gas-fine material mixture is discharged.

- further material inlets 19 are connected to the upper part 11a of the housing.

- the starting material to be sifted is fed to the sifting device 1 via the first material inlet 5.

- the material to be sifted then enters the first sifting stage and subsequently the static sifter 2 via this.

- the sifting gas e.g. air

- This can also be hot drying gases, for example.

- the material to be sifted now falls onto the system of impact and guide plates 8, 9, which in particular leads to the deagglomeration of the flakes and agglomerates created during grinding in a roller press.

- the sifting medium flows through the material and can dry it at the same time.

- the static sifter works as a cross-flow air sifter, so that the coarse material falls through the housing 2 into the lower discharge cone 20 and is discharged from there via the coarse material discharge 7.

- This discharge cone 20 is structurally connected to the lower part 11b of the separator housing 11 of the dynamic separator 3.

- the static classifier and the dynamic classifier are connected to one another in a very compact manner, so that the static classifier 2 merges into the dynamic classifier 3.

- the static classifier is connected with its classifier housing 4 laterally to the classifier housing 11 of the dynamic classifier.

- the classifier housing 4 of the static classifier 2 merges into the lower housing section 11b of the classifier housing 11, so that the housing section 11b of the classifier housing 11 can be functionally assigned to the static classifier on the one hand and the dynamic classifier on the other. It establishes the connection between the static classifier and the dynamic classifier, with the cylindrical lower housing section 11b also fulfilling the function of a cyclone.

- the fraction separated from the static classifier 2 enters the dynamic classifier 3 together with the separating gas, namely into the upper area 11a of the classifier housing 11 and there into the area of the rod basket 12.

- the desired fine separation takes place between this rotating rod basket 12 and the conductor blades 13.

- the "coarser" or medium-sized parts pass through the inner discharge funnel or discharge cone 16 to the discharge pipe and consequently the medium-sized material outlet 17 ("semolina discharge pipe").

- This medium-sized fraction is also referred to as "semolina”.

- the fine material is discharged from the classifier together with the gases through the fine material and gas outlet 18.

- Additional material can be fed directly to the second separation stage via the additional material inlets 19. This can, for example, be material that is fed from an additional crushing device, e.g. a ball mill. This will be discussed in connection with the Fig.6 discussed in more detail.

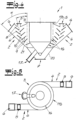

- Fig. 2 and 3 now show that the static classifier 2 according to the invention is connected directly to the second classifier housing 11 of the dynamic classifier 3 with a shaft-like first classifier housing 4 arranged obliquely to the vertical, in the embodiment in tangential or spiral orientation.

- Fig. 2 shows an embodiment with a spiral connection

- Fig.3 shows an embodiment with tangential connection.

- two static classifiers 2 with two classifier housings 4 are connected to the classifier housing 11 of the dynamic classifier 3.

- the dynamic classifier 3 is therefore acted upon in parallel by two static classifiers 2.

- the two static classifiers 2 are positioned offset by 180° in the exemplary embodiment.

- the direction of rotation of the rod basket can correspond to the connection direction of the tangential or spiral connection or can be designed in the opposite direction.

- the Fig. 4 and 5 corresponds essentially to the embodiment according to Fig.1 and 3 . It differs geometrically in particular in the arrangement and design of the discharge funnel 16 of the dynamic classifier, which in the embodiment according to the Fig. 4 and 5 over the entire height of the lower section 11 b of the sifter housing 11 and also over the entire height of the sifter housing 4 of the static sifter 2. Apart from that, the embodiments differ according to Fig. 1 to 3 on the one hand and 4 and 5 on the other hand in their geometric design, especially in the area of the static separator and its guide fittings. The basic structure and functionality are identical.

- the shaft-like first sifter housing which is connected to the second sifter housing in a tangential or spiral orientation, is of particular importance.

- the figures show that this shaft-like first housing 4 or its (lower) shaft wall 21 is oriented at a predetermined angle ⁇ obliquely to the vertical.

- this angle ⁇ is approximately 40° to 60°, e.g. approximately 50°.

- the viewing zone of the static sifter formed between the impact plates 8, 9 arranged one below the other in a step-like manner, is also oriented at a certain angle ⁇ obliquely to the vertical. In the exemplary embodiment, this angle ⁇ is approximately 20° to 40°, e.g. 25°.

- This overall obliquely oriented housing 4 is connected according to the invention in a spiral or tangential manner to the housing of the dynamic sifter.

- FIGS. 1-10 show an embodiment in which the static sifter is connected to the side of the dynamic sifter, but is positioned spatially below the rotating rod basket.

- embodiments can also be implemented optionally in which the static sifter is arranged (at least in some areas) at the same height as the rotating rod basket. The same applies to embodiments with several static sifters.

- the air supply takes place in particular via the illustrated sifting gas inlet 6.

- additional sifting gas inlets can be provided, which are formed in particular by openings arranged in the shaft wall 21. This is not shown in the figures. Such openings can be opened and closed by suitable means, e.g. flaps, slides or the like, whereby variable adjustment and thus air quantity control is possible in particular by adjustable means.

- the arrangement of the impact plates 8, 9 is shown in the figures only as an example. It is indicated that the articulation points of the impact plates 8, 9 do not have to lie on a common straight line, but can be arranged at a distance from each other. This is particularly evident in Fig.4 However, it is also within the scope of the invention that the articulation points of the baffle or guide plates are arranged (for example) on a straight line or are toothed and thus designed to mesh with one another. However, they can also be designed - as shown in the figures - with a distance between the articulation points, whereby this distance is Fig.4 is significantly larger than Fig.1 The vertical distance between the individual plates does not have to be the same, but can vary from plate to plate. The plates can also be set at different angles.

- the multi-stage classifier 1 according to the invention can be particularly preferably integrated into a single-stage or multi-stage grinding plant, as is shown for example in Fig.6 is shown.

- a cement grinding plant is shown as an example.

- the multi-stage classifier 1 can be seen, which is made up of a static classifier 2 and a dynamic classifier 3.

- a first crushing device 22 is shown in the embodiment as a roller press and thus a material bed roller mill 22.

- a second crushing device 23 is shown in the embodiment as a ball mill 23.

- the two-stage grinding system shown works as follows: The starting material to be shredded is fed from one or more bunkers 24, e.g. via the transport devices 25, 26, which open into the sifting device 1 via the material inlet 5. There, the material is sifted into three fractions in the manner already described. The coarse material sifted out from the coarse material outlet 7 is fed again to the roller press 22. From there, it reaches the sifting device 1 again via the transport devices 27 and 25, 26. The medium material sifted out from the second sifting stage, i.e. the middle fraction, is fed to the ball mill 23 via the medium material outlet 17 and the transport device 28.

- the grinding system therefore has the roller press 22 for pre-grinding the material and the ball mill 23 for regrinding the material.

- the ball mill 23 is e.g. B. equipped with a material discharge 29, a dust removal filter 30 and a mill fan 31.

- the material emerging from the ball mill 23 is then fed via the transport devices 29, 32, 33, with which it is brought to the dynamic classifier 3. There it again reaches the second classifying stage via the material inlets 19.

- the finest fraction is removed from the sifting device, namely from the dynamic sifter 3, together with the gases through the fines outlet 18 into the following separation cyclones 34.

- it is separated as a finished product from the gases, which are removed with the fan 35 and partly fed back into the sifting device 1 and partly or completely fed to a dust removal system.

- the two-stage grinding system shown can be modified in an alternative design.

- the roller press 22 can be placed above the sifting device 1, in contrast to the arrangement shown.

- the fresh material to be ground is first fed into the roller press, from which the pre-ground material is fed to the sifting device according to the invention. There, the material is again classified into three fractions in the manner described. This embodiment is not shown.

- a second, separate screening device into the two-stage grinding system, so that the discharge material from the ball mill is then fed not to the first screening device shown in the figures, but to a separate second screening device (not shown).

- a single comminution device e.g. the roller press shown, can be used, so that the additional ball mill is then dispensed with.

- the final grinding then takes place in the roller press, with the screening device according to the invention and the roller press then forming a "simple", "single-stage” circulating grinding system. This is also not shown in the figures.

- the multi-stage screen according to the invention can be used equally for the various types of grinding systems.

Landscapes

- Engineering & Computer Science (AREA)

- Food Science & Technology (AREA)

- Mechanical Engineering (AREA)

- Combined Means For Separation Of Solids (AREA)

- Crushing And Grinding (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102011055762.8A DE102011055762B4 (de) | 2011-11-28 | 2011-11-28 | Vorrichtung zum Sichten von körnigem Gut und Mahlanlage |

| PCT/EP2012/073513 WO2013079416A1 (de) | 2011-11-28 | 2012-11-23 | Vorrichtung zum sichten von körnigem gut |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2785472A1 EP2785472A1 (de) | 2014-10-08 |

| EP2785472B1 EP2785472B1 (de) | 2016-07-20 |

| EP2785472B2 true EP2785472B2 (de) | 2024-08-07 |

Family

ID=47221422

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12790561.0A Active EP2785472B2 (de) | 2011-11-28 | 2012-11-23 | Vorrichtung zum sichten von körnigem gut |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US9636712B2 (enExample) |

| EP (1) | EP2785472B2 (enExample) |

| CN (1) | CN104039466B (enExample) |

| DE (1) | DE102011055762B4 (enExample) |

| DK (1) | DK2785472T4 (enExample) |

| ES (1) | ES2592632T3 (enExample) |

| FI (1) | FI2785472T4 (enExample) |

| IN (1) | IN2014KN01125A (enExample) |

| WO (1) | WO2013079416A1 (enExample) |

Families Citing this family (26)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| PL232821B1 (pl) * | 2013-11-26 | 2019-07-31 | Czech Adam Przed Obrotu Surowcami Wtornymi Hermex | Urządzenie do czyszczenia i klasyfikacji ziarnowej drobnych odpadów metalurgicznych oraz sposób czyszczenia i klasyfikacji ziarnowej drobnych odpadów metalurgicznych |

| DE102013020888A1 (de) * | 2013-12-11 | 2015-06-11 | Khd Humboldt Wedag Gmbh | Kreislaufmahlanlage mit Vorsichter und Kugelmühle |

| DK3099426T3 (en) | 2014-01-31 | 2020-06-02 | Thyssenkrupp Ind Solutions Ag | Separator med bypass |

| DE102014001384B4 (de) * | 2014-02-01 | 2018-03-29 | Khd Humboldt Wedag Gmbh | Ringförmiger Kaskadensichter mit nachgeschaltetem Stabkorbsichter |

| DE102014108334A1 (de) * | 2014-06-13 | 2015-12-17 | Thyssenkrupp Ag | Mahlanlage und Verfahren zur Zerkleinerung von Mahlgut |

| CN105363677B (zh) * | 2014-08-15 | 2020-05-05 | 中联重科股份有限公司 | 矿物分选装置、矿物加工生产系统以及矿物分选方法 |

| DE102014015549A1 (de) * | 2014-10-22 | 2016-04-28 | Thyssenkrupp Ag | Mahlanlage zum Zerkleinern von Mahlgut sowie Verfahren zum Zerkleinern von Mahlgut |

| DE102014015550A1 (de) * | 2014-10-22 | 2016-04-28 | Thyssenkrupp Ag | Sichteinrichtung zum Sichten eines körnigen Materialstroms |

| WO2016126961A1 (en) * | 2015-02-06 | 2016-08-11 | Edw. C. Levy Co. | Closed-loop centrifugal air classifying system and method for utilizing the same |

| DE102015104340A1 (de) * | 2015-03-23 | 2016-09-29 | Maschinenfabrik Gustav Eirich Gmbh & Co. Kg | Formsandkühler |

| DE102015013892B3 (de) * | 2015-10-28 | 2017-02-02 | Khd Humboldt Wedag Gmbh | Pneumatisch verbundene Kaskadensichter und Kreislaufmahlanlage mit pneumatisch verbundenen Kaskadensichtern |

| US10500592B2 (en) * | 2016-03-24 | 2019-12-10 | Schenck Process Llc | Roller mill system with rejects removal system |

| DE102016121925A1 (de) * | 2016-11-15 | 2018-05-17 | Neuman & Esser Gmbh Mahl- Und Sichtsysteme | Sichter, Mühle und Verfahren zum Sichten eines Gas-Feststoff-Gemischs |

| CN107282447A (zh) * | 2017-08-25 | 2017-10-24 | 长沙深湘通用机器有限公司 | 组合分选机 |

| CN107309170A (zh) * | 2017-08-25 | 2017-11-03 | 长沙深湘通用机器有限公司 | 多粒级分级机 |

| CN107350162A (zh) * | 2017-08-25 | 2017-11-17 | 长沙深湘通用机器有限公司 | 多产品多级分级机 |

| CN107309174A (zh) * | 2017-08-25 | 2017-11-03 | 长沙深湘通用机器有限公司 | 分选装置 |

| CN108704571B (zh) * | 2018-04-28 | 2020-10-02 | 海宁文硕科技咨询有限公司 | 一种钒氮合金生产用的粉末原料入料机构 |

| DE102018112406A1 (de) * | 2018-05-24 | 2019-11-28 | Netzsch Trockenmahltechnik Gmbh | Verfahren und Anlage zur Herstellung eines Ausgangsmaterials für die Herstellung von Seltenerd-Magneten |

| CN109046631B (zh) * | 2018-07-23 | 2020-07-28 | 安徽省万佛山农业综合开发有限公司 | 一种茶叶加工机 |

| DE102018129538B4 (de) * | 2018-11-23 | 2020-10-01 | Khd Humboldt Wedag Gmbh | Pneumatisch miteinander verbundener Mehrfachsichter |

| CN113083459B (zh) * | 2021-04-30 | 2023-05-09 | 佛山市硕宸机械设备有限公司 | 一种钢水保温覆盖剂生产用研磨搅拌装置 |

| CN113477525B (zh) * | 2021-07-20 | 2022-06-21 | 天津水泥工业设计研究院有限公司 | 一种带有挡料锥的半成品粗细分离选粉机设计方法 |

| CN114700162A (zh) * | 2022-03-24 | 2022-07-05 | 张成群 | 一种用于粉体材料加工粉磨系统的一体化分选分级机 |

| CN114871100B (zh) * | 2022-05-10 | 2024-01-26 | 合肥工业大学 | 一种组合式空气动力三级分选设备及其调节方法 |

| TWI885921B (zh) * | 2024-05-28 | 2025-06-01 | 潤泰精密材料股份有限公司 | 物料分配系統及方法 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19944421A1 (de) † | 1999-09-16 | 2001-03-22 | Kloeckner Humboldt Wedag | Sichtereinrichtung zur Sichtung von körnigem Gut |

| DE102005045591A1 (de) † | 2005-09-23 | 2007-03-29 | Polysius Ag | Vorrichtung zum Sichten von Aufgabegut |

| DE102008019830A1 (de) † | 2008-04-11 | 2009-12-17 | Khd Humboldt Wedag Gmbh | Umwälzmahlanlage mit außen liegenden Steigrohren |

Family Cites Families (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1499721A (en) * | 1919-07-12 | 1924-07-01 | Fraser George Holt | Separator |

| DE1002600B (de) | 1955-05-18 | 1957-02-14 | Westfalia Dinnendahl Groeppel | Stromwindsichter |

| US2956680A (en) * | 1956-01-27 | 1960-10-18 | Babcock & Wilcox Co | Method of and apparatus for separating ash and cleaning shot |

| DE3506486A1 (de) | 1985-02-23 | 1986-08-28 | Klöckner-Humboldt-Deutz AG, 5000 Köln | Einrichtung zur zerkleinerung und mahlung sproeden mahlgutes wie zum beispiel zementklinker, erz, kohle oder dergleichen |

| DE3520069A1 (de) | 1985-06-04 | 1986-12-04 | Krupp Polysius Ag, 4720 Beckum | Verfahren und anlage zur zweistufigen zerkleinerung |

| DD253771A1 (de) * | 1986-11-21 | 1988-02-03 | Dessau Zementanlagenbau Veb | Windsichter |

| DE4112018A1 (de) | 1990-06-08 | 1991-12-12 | Kloeckner Humboldt Deutz Ag | Sichter |

| JPH0574681A (ja) | 1991-09-13 | 1993-03-26 | Nec Corp | 縮小投影露光装置 |

| JPH0574681U (ja) | 1992-03-11 | 1993-10-12 | 大阪セメント株式会社 | 多段分級機 |

| DE4223762B4 (de) | 1992-07-18 | 2009-07-23 | Khd Humboldt Wedag Gmbh | Sichtereinrichtung zum Sichten von körnigem Gut und Umlaufmahlanlage mit Einschaltung einer solchen Sichtereinrichtung |

| JPH06106135A (ja) | 1992-09-28 | 1994-04-19 | Ishikawajima Harima Heavy Ind Co Ltd | 多段風力式分級機 |

| DE4337215A1 (de) | 1993-10-30 | 1995-05-04 | Kloeckner Humboldt Deutz Ag | Umlaufmahlanlage |

| DE19751627A1 (de) | 1997-11-21 | 1999-05-27 | Werner Dr Ing Neu | Verfahren und Vorrichtung zur Trennung der Komponenten eines heterogenen Gemisches mit Hilfe von Luftströmungen |

| US6405405B1 (en) * | 2000-04-20 | 2002-06-18 | Carter Day International, Inc. | Product cleaner with air flow control |

| US6889843B1 (en) * | 2000-10-03 | 2005-05-10 | Polysius Corp. | Apparatus and methods for controlling the separation of particulate material |

| DE10119977A1 (de) * | 2001-04-24 | 2002-10-31 | Kloeckner Humboldt Wedag | Verfahren und Anlage zur Herstellung von Zementklinker |

| DE10142162A1 (de) * | 2001-08-29 | 2003-03-20 | Kloeckner Humboldt Wedag | Sichter zum Sichten von körnigem Gut |

| DE10221739A1 (de) | 2002-05-16 | 2003-12-04 | Kloeckner Humboldt Wedag | Kreislaufmahlanlage mit Mühle und Sichter |

| US6902126B2 (en) * | 2002-11-04 | 2005-06-07 | Alstom Technology Ltd | Hybrid turbine classifier |

| DE102004027128A1 (de) | 2004-06-03 | 2005-12-22 | Polysius Ag | Vorrichtung zum Sichten von körnigem Gut in wenigstens drei Kornfraktionen |

| DE102006039775A1 (de) | 2006-08-24 | 2008-02-28 | Khd Humboldt Wedag Gmbh | Sichteinrichtung zum Sichten körnigen Gutes und Kreislaufmahlanlage mit Einschaltung einer solchen Sichteinrichtung |

| DE102007021545B4 (de) * | 2007-05-08 | 2011-07-28 | Polysius AG, 59269 | Vorrichtung und Verfahren zum Sichten von Aufgabegut und Mahlanlage |

| DE102007045373A1 (de) * | 2007-09-22 | 2009-04-02 | Cemag Anlagenbau Gmbh | Verfahren und Vorrichtung zur Vor- und Fertigmahlung von mineralischen und nichtmineralischen Materialien |

| US7854406B2 (en) | 2008-01-10 | 2010-12-21 | Koppern Equipment, Inc. | Air separator for comminuted materials |

| CN201154322Y (zh) * | 2008-02-18 | 2008-11-26 | 国投新疆罗布泊钾盐有限责任公司 | 一种抛料式破碎振动筛分机 |

| RU2498854C2 (ru) * | 2008-07-02 | 2013-11-20 | Бюлер Аг | Способ получения муки из зерна, вальцовая мельница, применение вальцовой мельницы, зигзагообразная просеивающая машина, применение зигзагообразной просеивающей машины |

| CN201807527U (zh) * | 2010-07-04 | 2011-04-27 | 李三济 | 螺旋转动筛 |

-

2011

- 2011-11-28 DE DE102011055762.8A patent/DE102011055762B4/de not_active Withdrawn - After Issue

-

2012

- 2012-11-23 IN IN1125KON2014 patent/IN2014KN01125A/en unknown

- 2012-11-23 CN CN201280063825.7A patent/CN104039466B/zh active Active

- 2012-11-23 WO PCT/EP2012/073513 patent/WO2013079416A1/de not_active Ceased

- 2012-11-23 US US14/357,153 patent/US9636712B2/en active Active

- 2012-11-23 ES ES12790561.0T patent/ES2592632T3/es active Active

- 2012-11-23 DK DK12790561.0T patent/DK2785472T4/da active

- 2012-11-23 EP EP12790561.0A patent/EP2785472B2/de active Active

- 2012-11-23 FI FIEP12790561.0T patent/FI2785472T4/fi active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19944421A1 (de) † | 1999-09-16 | 2001-03-22 | Kloeckner Humboldt Wedag | Sichtereinrichtung zur Sichtung von körnigem Gut |

| DE102005045591A1 (de) † | 2005-09-23 | 2007-03-29 | Polysius Ag | Vorrichtung zum Sichten von Aufgabegut |

| DE102008019830A1 (de) † | 2008-04-11 | 2009-12-17 | Khd Humboldt Wedag Gmbh | Umwälzmahlanlage mit außen liegenden Steigrohren |

Non-Patent Citations (1)

| Title |

|---|

| MATTHIAS STIESS: "Mechanische Verfah- renstechnik- Partikel- technologie 1", 2009, ISBN: 978-3-540-32551-2, article "6.4 Stromungsklassieren Windsichten", pages: 313 - 319 † |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2785472A1 (de) | 2014-10-08 |

| FI2785472T4 (fi) | 2024-10-30 |

| DK2785472T4 (da) | 2024-09-16 |

| ES2592632T3 (es) | 2016-11-30 |

| DE102011055762B4 (de) | 2014-08-28 |

| DE102011055762A1 (de) | 2013-05-29 |

| DK2785472T3 (en) | 2016-10-24 |

| EP2785472B1 (de) | 2016-07-20 |

| CN104039466A (zh) | 2014-09-10 |

| CN104039466B (zh) | 2017-05-24 |

| IN2014KN01125A (enExample) | 2015-10-16 |

| WO2013079416A1 (de) | 2013-06-06 |

| US9636712B2 (en) | 2017-05-02 |

| US20140306044A1 (en) | 2014-10-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2785472B2 (de) | Vorrichtung zum sichten von körnigem gut | |

| EP2106301B1 (de) | Sichtereinrichtung für körniges gut und kreisaufmahlanlage mit einer solchen sichtereinrichtung | |

| EP1506058B1 (de) | Kreislaufmahlanlage mit mühle und sichter | |

| EP1919624B1 (de) | Trocknungsmühle und verfahren zum trocknen von mahlgut | |

| EP3292912B1 (de) | Verfahren zum betrieb eines multizyklons zum trennen von fein- und feinstkorn sowie multizyklon | |

| EP0460490B1 (de) | Sichter | |

| DE4223762A1 (de) | Sichter zum Sichten von körnigem Gut und Mahlanlage mit Einschaltung eines solchen Sichters | |

| DE69714333T2 (de) | Verfahren und Vorrichtung zum Mahlen von Zementklinker mittels einer vertikalen Walzenmühle | |

| EP0634219A1 (de) | Verfahren und Einrichtung zum Zerkleinern von Material unterschiedlicher Körnung | |

| WO2015086554A1 (de) | Kreislaufmahlanlage mit vorsichter und kugelmühle | |

| EP1948360B1 (de) | Wälzmühle | |

| DE3544798C2 (de) | Einrichtung zur Zerkleinerung und Mahlung und Trocknung (Mahltrocknung) von feuchtem Gut | |

| AT392923B (de) | Verfahren zum zerkleinern von stueckigem material sowie vorrichtung zur durchfuehrung dieses verfahrens | |

| DE19726523A1 (de) | Kreislaufmahleinrichtung mit Hochdruck-Walzenpresse und Sichter | |

| EP0350616A2 (de) | Sichter zum Sichten von körnigem, gegebenenfalls agglomeriertem Gut | |

| EP3895806A1 (de) | Vorrichtung und verfahren zum zerkleinern von festen materialien | |

| EP0237641A2 (de) | Anlage zur Zerkleinerung von sprödem Mahlgut | |

| WO2019016031A1 (de) | Zweistufiger mahlkreislauf und verfahren zur herstellung eines gemahlenen produkts mittels einer zweistufigen mahlung | |

| EP0801985B1 (de) | Hockdruck-Walzenpresse zur Druckzerkleinerung von körnigem Gutmaterial | |

| EP3368222B1 (de) | Pneumatisch verbundene kaskadensichter und kreislaufmahlanlage mit pneumatisch verbundenen kaskadensichtern | |

| EP2350239B1 (de) | Verfahren zur aufbereitung von braunkohle | |

| EP1090686A1 (de) | Mahlanlage | |

| WO2005000473A1 (de) | Kreislaufmahlanlage mit mühle und sichter | |

| EP4460398A1 (de) | Sichteranordnung für eine vertikalwälzmühle |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20140508 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20150709 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20160317 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B07B 4/08 20060101ALI20160304BHEP Ipc: B07B 7/083 20060101ALI20160304BHEP Ipc: B02C 23/14 20060101ALI20160304BHEP Ipc: B02C 23/12 20060101ALI20160304BHEP Ipc: B02C 21/00 20060101ALI20160304BHEP Ipc: B07B 4/04 20060101AFI20160304BHEP Ipc: B07B 9/02 20060101ALI20160304BHEP |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 813603 Country of ref document: AT Kind code of ref document: T Effective date: 20160815 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502012007734 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 Effective date: 20161021 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 5 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2592632 Country of ref document: ES Kind code of ref document: T3 Effective date: 20161130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161020 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161120 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161121 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161021 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 502012007734 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAF | Information modified related to communication of a notice of opposition and request to file observations + time limit |

Free format text: ORIGINAL CODE: EPIDOSCOBS2 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| 26 | Opposition filed |

Opponent name: KHD HUMBOLDT WEDAG GMBH Effective date: 20170418 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161020 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20161123 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161130 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161130 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161130 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161123 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161123 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20121123 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 |

|

| PLCK | Communication despatched that opposition was rejected |

Free format text: ORIGINAL CODE: EPIDOSNREJ1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20191220 Year of fee payment: 8 Ref country code: BE Payment date: 20191120 Year of fee payment: 8 Ref country code: IT Payment date: 20191128 Year of fee payment: 8 |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| APBQ | Date of receipt of statement of grounds of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA3O |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20201130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201123 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20220207 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201124 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201130 |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| RAP4 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: MASCHINENFABRIK KOEPPERN GMBH & CO. KG |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 502012007734 Country of ref document: DE Owner name: MASCHINENFABRIK KOEPPERN GMBH & CO. KG, DE Free format text: FORMER OWNER: MASCHINENFABRIK KOEPPERN GMBH & CO. KG, 45529 HATTINGEN, DE |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20240807 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 502012007734 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T4 Effective date: 20240910 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20241014 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 20241125 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FI Payment date: 20241122 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20241128 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20241121 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CZ Payment date: 20241118 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20251119 Year of fee payment: 14 |