EP2408568B2 - Elektrodenanordnung für einen elektrostatischen zerstäuber - Google Patents

Elektrodenanordnung für einen elektrostatischen zerstäuber Download PDFInfo

- Publication number

- EP2408568B2 EP2408568B2 EP10709704.0A EP10709704A EP2408568B2 EP 2408568 B2 EP2408568 B2 EP 2408568B2 EP 10709704 A EP10709704 A EP 10709704A EP 2408568 B2 EP2408568 B2 EP 2408568B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- atomizer

- electrode

- thread

- housing element

- axis

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000011248 coating agent Substances 0.000 claims description 88

- 238000000576 coating method Methods 0.000 claims description 69

- 239000003989 dielectric material Substances 0.000 claims description 57

- 239000007921 spray Substances 0.000 claims description 57

- 238000010422 painting Methods 0.000 claims description 41

- 238000009413 insulation Methods 0.000 claims description 40

- 239000003973 paint Substances 0.000 claims description 36

- 229920001343 polytetrafluoroethylene Polymers 0.000 claims description 25

- 239000011810 insulating material Substances 0.000 claims description 24

- 230000005686 electrostatic field Effects 0.000 claims description 20

- 239000002904 solvent Substances 0.000 claims description 11

- 238000000889 atomisation Methods 0.000 claims description 10

- -1 polytetrafluorethylene Polymers 0.000 claims description 10

- 239000000463 material Substances 0.000 claims description 8

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 6

- 230000007246 mechanism Effects 0.000 claims description 4

- 230000002265 prevention Effects 0.000 claims description 3

- 239000012777 electrically insulating material Substances 0.000 claims 4

- 238000000926 separation method Methods 0.000 claims 2

- 239000004810 polytetrafluoroethylene Substances 0.000 description 23

- 238000005507 spraying Methods 0.000 description 23

- 239000004033 plastic Substances 0.000 description 16

- 229920003023 plastic Polymers 0.000 description 16

- 238000004519 manufacturing process Methods 0.000 description 15

- 238000013461 design Methods 0.000 description 13

- 235000019271 petrolatum Nutrition 0.000 description 13

- 239000004519 grease Substances 0.000 description 12

- 230000000694 effects Effects 0.000 description 9

- 239000004922 lacquer Substances 0.000 description 8

- 239000003981 vehicle Substances 0.000 description 8

- 238000002955 isolation Methods 0.000 description 7

- 239000007788 liquid Substances 0.000 description 7

- 238000011017 operating method Methods 0.000 description 7

- 238000004140 cleaning Methods 0.000 description 6

- 229920002313 fluoropolymer Polymers 0.000 description 6

- 238000000034 method Methods 0.000 description 6

- 238000003860 storage Methods 0.000 description 6

- 238000011109 contamination Methods 0.000 description 5

- 239000007787 solid Substances 0.000 description 5

- 150000001875 compounds Chemical class 0.000 description 4

- 230000005611 electricity Effects 0.000 description 4

- 238000005516 engineering process Methods 0.000 description 4

- 238000012544 monitoring process Methods 0.000 description 4

- 239000000853 adhesive Substances 0.000 description 3

- 230000001070 adhesive effect Effects 0.000 description 3

- 239000012530 fluid Substances 0.000 description 3

- 229910052751 metal Inorganic materials 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- 229910052982 molybdenum disulfide Inorganic materials 0.000 description 3

- 239000006199 nebulizer Substances 0.000 description 3

- 239000003921 oil Substances 0.000 description 3

- 230000003071 parasitic effect Effects 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 238000007789 sealing Methods 0.000 description 3

- 102100030393 G-patch domain and KOW motifs-containing protein Human genes 0.000 description 2

- 230000006978 adaptation Effects 0.000 description 2

- 239000011324 bead Substances 0.000 description 2

- 230000008901 benefit Effects 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 238000004364 calculation method Methods 0.000 description 2

- 230000008859 change Effects 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 238000004132 cross linking Methods 0.000 description 2

- 230000001419 dependent effect Effects 0.000 description 2

- 230000005684 electric field Effects 0.000 description 2

- 238000009503 electrostatic coating Methods 0.000 description 2

- 238000011049 filling Methods 0.000 description 2

- 238000009421 internal insulation Methods 0.000 description 2

- 239000003595 mist Substances 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000004382 potting Methods 0.000 description 2

- 239000004065 semiconductor Substances 0.000 description 2

- 238000005245 sintering Methods 0.000 description 2

- 230000007704 transition Effects 0.000 description 2

- 238000011144 upstream manufacturing Methods 0.000 description 2

- 239000002966 varnish Substances 0.000 description 2

- 241001184544 Ficus pumila var. awkeotsang Species 0.000 description 1

- 239000004696 Poly ether ether ketone Substances 0.000 description 1

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- 238000009825 accumulation Methods 0.000 description 1

- 239000002216 antistatic agent Substances 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 230000002238 attenuated effect Effects 0.000 description 1

- JUPQTSLXMOCDHR-UHFFFAOYSA-N benzene-1,4-diol;bis(4-fluorophenyl)methanone Chemical compound OC1=CC=C(O)C=C1.C1=CC(F)=CC=C1C(=O)C1=CC=C(F)C=C1 JUPQTSLXMOCDHR-UHFFFAOYSA-N 0.000 description 1

- 239000002717 carbon nanostructure Substances 0.000 description 1

- 239000003575 carbonaceous material Substances 0.000 description 1

- 229910010293 ceramic material Inorganic materials 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 239000008199 coating composition Substances 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 239000004020 conductor Substances 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 230000001066 destructive effect Effects 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 239000003599 detergent Substances 0.000 description 1

- 229910003460 diamond Inorganic materials 0.000 description 1

- 239000010432 diamond Substances 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 238000010292 electrical insulation Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 230000005284 excitation Effects 0.000 description 1

- 239000003925 fat Substances 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 238000007373 indentation Methods 0.000 description 1

- 239000012212 insulator Substances 0.000 description 1

- 150000002632 lipids Chemical class 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- CWQXQMHSOZUFJS-UHFFFAOYSA-N molybdenum disulfide Chemical compound S=[Mo]=S CWQXQMHSOZUFJS-UHFFFAOYSA-N 0.000 description 1

- 239000013307 optical fiber Substances 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 229920002530 polyetherether ketone Polymers 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 239000011343 solid material Substances 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 238000004381 surface treatment Methods 0.000 description 1

- 239000010936 titanium Substances 0.000 description 1

- 229910052719 titanium Inorganic materials 0.000 description 1

- 238000012549 training Methods 0.000 description 1

- 230000001960 triggered effect Effects 0.000 description 1

- 239000004924 water-based lacquer Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B5/00—Electrostatic spraying apparatus; Spraying apparatus with means for charging the spray electrically; Apparatus for spraying liquids or other fluent materials by other electric means

- B05B5/025—Discharge apparatus, e.g. electrostatic spray guns

- B05B5/053—Arrangements for supplying power, e.g. charging power

- B05B5/0533—Electrodes specially adapted therefor; Arrangements of electrodes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B13/00—Machines or plants for applying liquids or other fluent materials to surfaces of objects or other work by spraying, not covered by groups B05B1/00 - B05B11/00

- B05B13/02—Means for supporting work; Arrangement or mounting of spray heads; Adaptation or arrangement of means for feeding work

- B05B13/0221—Means for supporting work; Arrangement or mounting of spray heads; Adaptation or arrangement of means for feeding work characterised by the means for moving or conveying the objects or other work, e.g. conveyor belts

- B05B13/0271—Means for supporting work; Arrangement or mounting of spray heads; Adaptation or arrangement of means for feeding work characterised by the means for moving or conveying the objects or other work, e.g. conveyor belts the object or work standing still during the spraying operation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B13/00—Machines or plants for applying liquids or other fluent materials to surfaces of objects or other work by spraying, not covered by groups B05B1/00 - B05B11/00

- B05B13/02—Means for supporting work; Arrangement or mounting of spray heads; Adaptation or arrangement of means for feeding work

- B05B13/04—Means for supporting work; Arrangement or mounting of spray heads; Adaptation or arrangement of means for feeding work the spray heads being moved during spraying operation

- B05B13/0431—Means for supporting work; Arrangement or mounting of spray heads; Adaptation or arrangement of means for feeding work the spray heads being moved during spraying operation with spray heads moved by robots or articulated arms, e.g. for applying liquid or other fluent material to 3D-surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B13/00—Machines or plants for applying liquids or other fluent materials to surfaces of objects or other work by spraying, not covered by groups B05B1/00 - B05B11/00

- B05B13/02—Means for supporting work; Arrangement or mounting of spray heads; Adaptation or arrangement of means for feeding work

- B05B13/04—Means for supporting work; Arrangement or mounting of spray heads; Adaptation or arrangement of means for feeding work the spray heads being moved during spraying operation

- B05B13/0447—Installation or apparatus for applying liquid or other fluent material to conveyed separate articles

- B05B13/0457—Installation or apparatus for applying liquid or other fluent material to conveyed separate articles specially designed for applying liquid or other fluent material to 3D-surfaces of the articles, e.g. by using several moving spray heads

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B16/00—Spray booths

- B05B16/90—Spray booths comprising conveying means for moving objects or other work to be sprayed in and out of the booth, e.g. through the booth

- B05B16/95—Spray booths comprising conveying means for moving objects or other work to be sprayed in and out of the booth, e.g. through the booth the objects or other work to be sprayed lying on, or being held above the conveying means, i.e. not hanging from the conveying means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B5/00—Electrostatic spraying apparatus; Spraying apparatus with means for charging the spray electrically; Apparatus for spraying liquids or other fluent materials by other electric means

- B05B5/005—Electrostatic spraying apparatus; Spraying apparatus with means for charging the spray electrically; Apparatus for spraying liquids or other fluent materials by other electric means the high voltage supplied to an electrostatic spraying apparatus being adjustable during spraying operation, e.g. for modifying spray width, droplet size

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B5/00—Electrostatic spraying apparatus; Spraying apparatus with means for charging the spray electrically; Apparatus for spraying liquids or other fluent materials by other electric means

- B05B5/025—Discharge apparatus, e.g. electrostatic spray guns

- B05B5/04—Discharge apparatus, e.g. electrostatic spray guns characterised by having rotary outlet or deflecting elements, i.e. spraying being also effected by centrifugal forces

- B05B5/0403—Discharge apparatus, e.g. electrostatic spray guns characterised by having rotary outlet or deflecting elements, i.e. spraying being also effected by centrifugal forces characterised by the rotating member

- B05B5/0407—Discharge apparatus, e.g. electrostatic spray guns characterised by having rotary outlet or deflecting elements, i.e. spraying being also effected by centrifugal forces characterised by the rotating member with a spraying edge, e.g. like a cup or a bell

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B5/00—Electrostatic spraying apparatus; Spraying apparatus with means for charging the spray electrically; Apparatus for spraying liquids or other fluent materials by other electric means

- B05B5/025—Discharge apparatus, e.g. electrostatic spray guns

- B05B5/04—Discharge apparatus, e.g. electrostatic spray guns characterised by having rotary outlet or deflecting elements, i.e. spraying being also effected by centrifugal forces

- B05B5/0422—Discharge apparatus, e.g. electrostatic spray guns characterised by having rotary outlet or deflecting elements, i.e. spraying being also effected by centrifugal forces comprising means for controlling speed of rotation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B5/00—Electrostatic spraying apparatus; Spraying apparatus with means for charging the spray electrically; Apparatus for spraying liquids or other fluent materials by other electric means

- B05B5/025—Discharge apparatus, e.g. electrostatic spray guns

- B05B5/053—Arrangements for supplying power, e.g. charging power

- B05B5/0533—Electrodes specially adapted therefor; Arrangements of electrodes

- B05B5/0536—Dimensional characteristics of electrodes, e.g. diameter or radius of curvature of a needle-like corona electrode

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B13/00—Machines or plants for applying liquids or other fluent materials to surfaces of objects or other work by spraying, not covered by groups B05B1/00 - B05B11/00

- B05B13/02—Means for supporting work; Arrangement or mounting of spray heads; Adaptation or arrangement of means for feeding work

- B05B13/04—Means for supporting work; Arrangement or mounting of spray heads; Adaptation or arrangement of means for feeding work the spray heads being moved during spraying operation

- B05B13/0447—Installation or apparatus for applying liquid or other fluent material to conveyed separate articles

- B05B13/0452—Installation or apparatus for applying liquid or other fluent material to conveyed separate articles the conveyed articles being vehicle bodies

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B16/00—Spray booths

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B5/00—Electrostatic spraying apparatus; Spraying apparatus with means for charging the spray electrically; Apparatus for spraying liquids or other fluent materials by other electric means

- B05B5/025—Discharge apparatus, e.g. electrostatic spray guns

- B05B5/04—Discharge apparatus, e.g. electrostatic spray guns characterised by having rotary outlet or deflecting elements, i.e. spraying being also effected by centrifugal forces

- B05B5/0426—Means for supplying shaping gas

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B5/00—Electrostatic spraying apparatus; Spraying apparatus with means for charging the spray electrically; Apparatus for spraying liquids or other fluent materials by other electric means

- B05B5/08—Plant for applying liquids or other fluent materials to objects

- B05B5/082—Plant for applying liquids or other fluent materials to objects characterised by means for supporting, holding or conveying the objects

- B05B5/084—Plant for applying liquids or other fluent materials to objects characterised by means for supporting, holding or conveying the objects the objects lying on, or being supported above conveying means, e.g. conveyor belts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B5/00—Electrostatic spraying apparatus; Spraying apparatus with means for charging the spray electrically; Apparatus for spraying liquids or other fluent materials by other electric means

- B05B5/08—Plant for applying liquids or other fluent materials to objects

- B05B5/087—Arrangements of electrodes, e.g. of charging, shielding, collecting electrodes

Definitions

- the invention relates to the field of coating workpieces by means of electrostatically assisted atomization, in particular by means of electrostatic rotary atomization.

- electrostatic atomizers for coating workpieces such as vehicle bodies, for example, electrostatic atomizers, in particular electrostatic rotary atomizers, with so-called external charging can be used, in which a spray jet is exposed to an electrostatic field generated by external electrodes.

- the paint droplets are charged by ion accumulation and transported to the grounded workpiece, for example, as described in the publications DE 10202711 A1 and EP 1 362 640 B1 is described.

- a disadvantage of the known external charging concepts is that the external electrodes required to generate the electrostatic field are used to coat narrow surfaces and narrow spaces such as B. in the interior of workpieces or in the interior of a vehicle door or in the entry areas of the vehicle body, or the coating of closely related items on a goods carrier, especially attachments with little distance, such as bumpers, complicate due to their size.

- the invention is based on the knowledge that an efficient external charging concept that enables both the internal / detailed coating (i.e. an internal coating and / or detailed coating) and the external coating of workpieces can be realized by an electrode arrangement with, for example, an electrode ring.

- the electrodes of the electrode arrangement are provided for generating an electrostatic field, which contributes to the generation of discharge currents flowing at least over a housing surface.

- Preferred is one in the direction of the axis of symmetry, i.e.

- a discharge current component of a discharge current that specifically influences the dielectric in particular damped.

- both directions of the respective axis can be taken into account.

- the invention enables in particular a minimization or avoidance of undesired or parasitic discharges, as a result of which an increased charging of the coating agent or the spray jet can advantageously be achieved.

- the dimensions of the electrostatic atomizers can be reduced, which simplifies the accessibility of interior parts of the body that are difficult to access.

- the electrodes can be arranged in such a way that the same electrostatic atomizer can be used both for the interior coating and for the exterior coating.

- an electrode arrangement that is to be used in each case and that can be modularly connected to the electrostatic atomizer can be adapted to the respective purpose, so that, for example, an electrode arrangement with smaller dimensions and for the interior painting the outer coating an electrode arrangement with larger dimensions can be used.

- telescopically displaceable electrodes can be provided, which can be pushed out for the exterior painting, for example by means of compressed air.

- the electrode arrangement can have electrodes with different lengths and / or inclination angles with respect to the axis of symmetry.

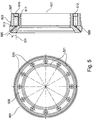

- the invention relates to an arrangement for one or more electrodes or an electrode arrangement for an electrostatic atomizer, for example for an electrostatic rotary atomizer, with an electrode holder device for holding at least one electrode generating an electrostatic field around an axis of symmetry, it being possible, for example, to provide a dielectric material, preferably for influencing a discharge current component of a discharge current extending in the direction of the axis of symmetry.

- the electrode arrangement is provided for the external charging of coating agents and is particularly suitable for the external charging of coating agents in the interior / detail coating and / or the exterior coating.

- the electrode arrangement can have one or more electrodes or be designed to receive one or more electrodes.

- the electrode arrangement and / or the electrode holder device and / or the dielectric material preferably has a central axis.

- the axis of symmetry preferably corresponds to the central axis of the electrode arrangement and / or the electrode holding device and / or the dielectric material.

- the axis of symmetry can be, for example, an axis of symmetry, in particular an axis of rotation, of the electrode holder device, which can be designed, for example, in a rotationally symmetrical, in particular annular, manner.

- the axis of symmetry can be an axis of symmetry of, for example, a rotationally symmetrical electrostatic field.

- the axis of symmetry can be defined by a spray direction of a jet sprayed by a spray element, or by an axis of a turbine shaft which drives the spray element, for example a bell cup.

- the aforementioned axes of symmetry can also coincide to form a common axis of symmetry, in particular in the case of rotary atomizers.

- the discharge current component extending towards the axis of symmetry can, in particular, extend at an arbitrary angle to the axis of symmetry and, for example, directly in the direction of the axis of symmetry, for example perpendicularly thereto, or at an angle which is less than 90 °, or along a housing surface or along one spread or extend the electric field lines of a predetermined path or in any way towards the axis of symmetry.

- the dielectric material can be, for example, an insulating material with a dielectric constant which differs from or exceeds that of the air.

- the dielectric material is preferably provided to influence the discharge current component extending in the direction of the axis of symmetry, and is arranged in particular in order to isolate the grounded or low-potential components (for example spray element (bell cup), drive turbine, bearing device, hand axis, etc.) , whereby the current flow can be specifically changed and / or minimized and / or interrupted.

- the current flow is changed or prevented by the insulation of, for example, earthed components, which also reduces wear, but has a positive influence on the current flow through the atomized paint.

- the dielectric material for example, a propagation path of the discharge current is extended towards the axis of symmetry, which causes an extension of a discharge path, so that the electrode arrangement can also be used for interior painting.

- the dielectric material is provided on the at least one electrode in such a way that, when the atomizer is in operation, insulation to the rear (for example in the direction of the hand axis or on the hand axis side or in the direction facing away from the spray element or towards the side facing away from the spray element) and / or to the (radially) inside (e.g. in the direction of the drive turbine or other internal atomizing technology) and / or to the front (e.g.

- the concept according to the invention is also particularly advantageously suitable for use in a painting booth, for example in a universal booth or in a painting box.

- the concept of the invention can be used in a box concept which is described in the publication WO 2007/131660 A1 , is described.

- the dielectric material is arranged or designed asymmetrically, for example, with respect to an electrode that can be held or held by the electrode holding device, so that the discharge current component extending in the direction of the axis of symmetry can be influenced in a targeted manner.

- the dielectric material can, for example, be arched toward the axis of symmetry, which advantageously effects a direction-dependent influencing of the discharge current component.

- the electrode arrangement comprises at least one electrode, which can be coupled in particular mechanically and / or electrically to the electrode holder device for generating the electrostatic field.

- the at least one electrode can be at least partially or completely embedded or housed or inserted into the electrode holder device or up to an electrode end, which can be between approximately 1 mm to 5 mm long, or completely or largely.

- the at least one electrode can furthermore be completely or almost completely recessed in the electrode holder device or in at least one electrode receiving space.

- the dielectric material can, for example, be an integral part of the electrode holding device, which can or consist of a dielectric material.

- At least one electrode and / or at least one electrode receiving space is preferably accommodated in the electrode holder device.

- resistors with a length of approximately 30 mm or between approximately 30 mm to 100 mm and / or a diameter of approximately 8 mm or between approximately 6 mm can be provided in the electrode holder device or in an insulating material of the electrode holder device or in the dielectric material and 12 mm are embedded in an insulating medium. Voltage flashovers can thereby be prevented in an advantageous manner.

- a resistor or a plurality of resistors can be provided.

- the resistance can e.g. be a resistance element which is made of partially conductive plastic or a semiconductor, which preferably permanently provides essentially the same resistance value as a commercially available thick-film resistor.

- the electrode arrangement can have one or a plurality of preferably cylindrical or sleeve-shaped resistance receiving means for receiving at least one resistor.

- the at least one resistance receiving means can be provided with an insulating medium, e.g. be coated or filled.

- the at least one resistor can be coated or encased by an insulating medium or embedded in an insulating medium.

- the resistance receiving means in particular its receiving space, can be made with a closing means, preferably made of plastic, e.g. a cap, can be designed to be closable, which can prevent e.g. liquid insulation medium emerges.

- the at least one resistor and / or the at least one resistor receiving means can be arranged essentially parallel to the axis of symmetry.

- the isolating medium or isolating fluid can be, for example, lipids (oils, fats, etc.).

- the insulating medium can be gaseous (eg SF 6 ), solid, liquid or fluid. It is also possible to use potting compound or suitable adhesives as the insulating medium.

- the insulation medium should have very good insulation properties. It is also possible to arrange or embed the parts to be insulated (for example the electrodes, the resistors, etc.) directly in insulating or dielectric material.

- the electrode holder device preferably comprises at least one, for example cylindrical or sleeve-shaped, receiving space for receiving an electrode.

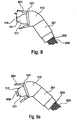

- the electrode arrangement preferably comprises at least one electrode and / or at least one electrode receiving space, which is arranged at an angle with respect to the axis of symmetry and / or extends obliquely outwards and / or forward.

- the electrode and / or the electrode receiving space are thus preferably arranged non-parallel to the axis of symmetry.

- the electrode arrangement comprises at least one electrode (or at least one electrode receiving space), which can be coupled mechanically and / or electrically to the electrode holder device for generating the electrostatic field, for example, an angle between the at least one electrode and the axis of symmetry being greater than 0 ° and not larger, preferably smaller than 90 ° or 180 °, for example larger than approximately 40 °, 45 ° or 50 ° and / or smaller than approximately 60 °, 65 ° or 70 °, in particular approximately 55 °. It is also possible that the angle has negative values down to approximately -90 °.

- the electrodes or the electrode receiving spaces can thus in particular be arranged obliquely or at an angle to the axis of symmetry, for example extending forward and / or outward, but also extending forward and / or inward. Even an outward and / or rearward extension is possible.

- the electrodes or electrode receiving spaces can be arranged essentially parallel or non-parallel or skewed to the axis of symmetry. In the arrangement that is not parallel to the axis of symmetry, angles between 0 ° and +/- 180 ° are possible.

- the axis of symmetry and at least one electrode receiving space and / or at least one electrode may extend in a fictitious common plane.

- the electrode arrangement comprises at least one electrode which can be mechanically and / or electrically coupled to the electrode holder device for generating the electrostatic field, the dielectric material being arranged, for example, between the at least one electrode and the axis of symmetry, or enclosing the at least one electrode asymmetrically or does not enclose or only partially encloses.

- the dielectric material can be shaped, for example, in the form of a dielectric bead or a dielectric projection, in particular a collar-shaped projection.

- the discharge current component of the discharge current pointing towards the axis of symmetry is advantageously influenced by extending a propagation path towards the axis of symmetry along the dielectric and / or (during operation of the atomizer) insulation to the rear (for example on the hand axis side or in the direction of the hand axis or into the relative to the spray element facing away).

- the dielectric material in particular the dielectric bead or the dielectric projection, to project outward and / or forward, for example obliquely or curved, for example to expand conically and / or to be arranged coaxially with the axis of symmetry, in particular in a ring around the axis of symmetry extend.

- the dielectric or insulating material can be provided essentially in a ring shape with or without interruptions. It is also possible for the at least one electrode to extend into the bulge or the projection and even protrude from the bulge or the projection.

- the dielectric material is provided to influence or not to influence or not to influence or to dampen or to dampen a further discharge current component which is directed opposite to the aforementioned discharge current component less than the discharge current component which points in the direction of or towards the axis of symmetry to dampen.

- a current discharge path is advantageously extended towards the axis of symmetry, so that the electrode arrangement as a whole can have more compact dimensions, which are advantageous for the inner coating.

- the electrode holder device is shaped, for example, in a ring around the axis of symmetry, so that the axis of symmetry coincides with an axis of rotation of the electrode holder device.

- the axis of symmetry can be the axis about which the electrostatic field can be generated, which can be generated by a plurality of electrodes arranged around the axis of symmetry and electrically and / or mechanically coupled to the electrode holder device, e.g. can extend coronary.

- the electrostatic field can be extended in the direction of the axis of symmetry.

- both axes of symmetry preferably coincide, so that the dielectric material can only be shaped with respect to one axis of symmetry. If the symmetry axes mentioned above do not coincide, the dielectric material can be provided to take only one of the symmetry axes into account. Furthermore, the dielectric material can be arranged with respect to both axes of symmetry as described above.

- the axis of symmetry preferably coincides with the central axis of a spraying element and / or a central axis of the atomizer (e.g. a central axis of an atomizer housing element or a housing element) and / or an axis of rotation of the atomizer (coaxial).

- the previous central axes preferably merge or intersect.

- an inner circumference of the electrode arrangement is in contact with an outer circumference of a housing element of the atomizer in order to ensure a compact atomizer structure.

- the electrode arrangement and / or the electrode holder device and / or the dielectric material can preferably be fastened on the end face, in particular on an end face of the atomizer (preferably an atomizer housing element), preferably in an annular contact and / or thread-like or other fastening.

- the atomizer preferably an atomizer housing element

- the electrode arrangement comprises a plurality of electrode receiving spaces and / or a plurality of electrodes, which are arranged around the axis of symmetry and are in particular electrically and / or mechanically coupled to the electrode holder device, the ends of the plurality of electrodes facing away from the electrode holder device being along one Circular path are arranged.

- a ratio of a radius of the circular path to a radius of a cross section of a spray element of the electrostatic atomizer, in particular a bell cup of a rotary atomizer, or to a radius of a cross section of the electrode holder device is preferably predetermined.

- the ratio within a tolerance range for example ⁇ ⁇ / 4, is equal to n.

- the ratio can be within a ratio range, in particular ⁇ 1% or ⁇ 2%, between 2 and 4 or between 2.5 and 3.5 or between 3 and 3.2 are.

- a ratio of a product of a radius of the circular path and a distance of the circular path to a spray element of the electrostatic atomizer, for example to a bell plate or to a bell plate edge, to a squared diameter of this spray element can be in a range between 2 n and 4 n , This design rule defines an advantageous distance between the electrode ends with respect to the spray element.

- the electrode arrangement comprises at least one electrode which is mechanically and / or electrically coupled to the electrode holder device for generating the electrostatic field.

- the at least one electrode preferably comprises a variable electrode length or at least one movable electrode section, which can be telescopically pushed onto or inserted into a further electrode section.

- the changeable electrode length can be set, for example, by means of compressed air, so that, for example, a ring electrode arrangement can advantageously be adapted for the exterior and interior painting.

- the electrode arrangement comprises at least one electrode which is electrically and / or mechanically coupled to the electrode holder device for generating the electrostatic field.

- the at least one electrode is preferably coated with a dielectric material, symmetrical or asymmetrical, which can be, for example, polytetrafluoroethylene.

- the electrode fingers are advantageously insulated.

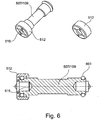

- the electrode arrangement comprises a thread, which can preferably be provided coaxially to the central axis and / or axis of symmetry.

- the thread can be provided with an insulating medium (for example insulating grease such as petroleum jelly), which improves the insulation, which contributes to directional absorption or removal or prevention or minimization of the discharge current.

- the thread can also be provided, with the electrode holder device to connect a housing of an electrostatic atomizer preferably detachably by means of a thread engagement.

- the thread can also be formed from an insulating or dielectric material, as a result of which the insulation properties can be further improved.

- the thread can be tapered to create a self-locking.

- the thread is preferably arranged coaxially to the axis of symmetry. It is possible for the thread to extend around the electrode arrangement and / or the electrode holding device and / or the axis of symmetry.

- the thread may or may be provided with an insulating medium, preferably to prevent or minimize a discharge current or a discharge current component.

- the thread can be provided in order to achieve a preferably enlarged discharge path and / or a labyrinth for discharge current (for example from a part that is at high voltage, such as an electrode tip, to a part that is at a lower voltage or to a grounded part, such as a bell plate or one Drive turbine), and in particular to ensure internal and / or rearward isolation or to reduce or avoid undesired discharges.

- the electrode holder device comprises a first electrical connection or a connection ring for contacting at least one electrode.

- the first electrical connection can furthermore have a resistor or have a resistor in order to bring about an electrical resistance adaptation of the electrode.

- the first electrical connection can also be provided to contact a plurality of electrodes, wherein one or more resistors can be provided for this.

- the electrode arrangement or the electrode holding device comprises a corresponding second electrical connection or a connection ring for contacting the first electrical connection, the second electrical connection being guided to the outside or accessible from the outside.

- the electrode arrangement and / or the electrode holding device and / or the dielectric material is preferably shaped essentially in a ring shape around the axis of symmetry or is arranged coaxially to the axis of symmetry.

- the electrode arrangement and / or the electrode holding device and / or the dielectric material and / or the first and / or second diaphragm mentioned below can define a central opening for receiving a part of the atomizer (for example a housing element of the atomizer, which is a storage unit or a drive turbine, for example) houses) and / or for the passage of a coating agent or other internal atomizing technology (e.g. paint / air supply, etc.).

- a coating agent or other internal atomizing technology e.g. paint / air supply, etc.

- One or more electrode receiving spaces are preferably connected to one or more resistance receiving means.

- one or more electrodes can be connected to one or more resistors.

- the one or more resistors can be provided in order to be connected to a charging part, preferably a charging ring, provided in an atomizer housing element.

- one or more electrode receiving spaces and / or electrodes and / or resistance receiving means and / or resistors can be arranged spaced apart from the central axis and / or the axis of symmetry.

- a plurality of electrode receiving spaces and / or electrodes and / or resistance receiving means and / or resistors around the central axis and / or the axis of symmetry are preferably provided, preferably evenly spaced apart from one another in the circumferential direction.

- the electrode arrangement and / or the electrode holding device can comprise a first diaphragm and / or a second diaphragm.

- the first diaphragm and / or the second diaphragm can be provided essentially in the form of a ring.

- the first diaphragm and / or the second diaphragm is preferably arranged essentially coaxially and / or parallel to the axis of symmetry.

- the first diaphragm preferably has a larger diameter than the second diaphragm. It is possible for the at least one resistance receiving means and / or the at least one resistance to be arranged between the first diaphragm and the second diaphragm.

- the screen can preferably have the thread.

- the thread is preferably provided on the outer circumference of the first screen.

- the second diaphragm is preferably made thicker or thicker than the first diaphragm.

- the first and / or second diaphragm is preferably made of dielectric or insulating material.

- the first and / or second diaphragm can be provided to form a sandwich-like arrangement, in particular with an atomizer housing element, which is provided with at least one corresponding diaphragm.

- the electrode arrangement, the electrode holding device and / or the dielectric material can comprise a substantially circular section and / or at least one section that widens and / or protrudes (preferably obliquely, curved or otherwise outwards and / or forwards, in particular essentially conically) ,

- the at least one widening section is preferably provided as the electrode holder device, in which at least one electrode and / or at least one electrode receiving space are preferably accommodated.

- the electrode arrangement can consist of the annular section and the widening section.

- the widening section can preferably have an essentially conical shape (for example with a rectilinearly shaped surface line or a curved surface line), funnel-shaped, plate-edge-shaped or rotational hyperboloid (ring) -shaped.

- a single widening section is preferably provided, which is shaped in a ring around the axis of symmetry and / or is arranged coaxially to the axis of symmetry.

- the widening section can have a multiplicity of Has interruptions and thus consequently comprises several sections or consists of several sections which, for example, can also protrude outwards and / or forwards, in particular can be evenly spaced from one another in the circumferential direction and moreover are oriented essentially parallel or not parallel or skewed to the axis of symmetry could be.

- the widening section can extend from the substantially circular section.

- the widening section (relative to the annular section and / or relative to the atomizer) preferably projects outward (radially) and / or forward (axially) and / or widens.

- the essentially circular section preferably comprises the thread and / or at least one resistor and / or at least one resistor receiving space and / or the first and / or the second diaphragm, the widening section preferably comprising one or more electrodes and / or one or takes up several electrode receiving spaces.

- the widening section preferably protrudes in particular obliquely forward (in the direction of the spraying element or to the side of the spraying element) and (radially) outwards, the annular section, at least in sections, preferably essentially completely, by a Atomizer housing element is covered.

- the widening section and / or one or more of the parts encompassed by the annular section can preferably be formed from dielectric or insulating material.

- the at least one widening section corresponds to the electrode holder device.

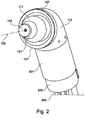

- the invention relates to an atomizer housing element, in particular for holding an electrode arrangement, as described for example above, for an electrostatic atomizer, in particular for a rotary atomizer, which has an atomizer housing with a housing element with a first diameter for directly or indirectly holding a steering air ring and / or for receiving or covering a bearing device for a spray element, in particular for a bell plate.

- the bearing device can, for example, comprise or be a turbine or a turbine shaft for driving the spraying element.

- the turbine or the turbine shaft can be held indirectly or directly by the housing element, for example.

- the housing element essentially serves to cover the turbine and / or the turbine shaft, which can be held, for example, by means of a flange on the hand axis side.

- the atomizer housing element can, for example, be directly upstream of the housing element and / or be connectable to the housing element.

- the atomizer housing element is preferably provided as a tube, which can be straight or angled.

- the housing element of the atomizer housing of the atomizer is not a feature of the atomizer housing element.

- the atomizer housing element can take over the function of the housing element or form an integral or one-piece unit with it.

- the atomizer housing element preferably comprises a second diameter, which differs from the first diameter, a difference in diameter between the first diameter and the second diameter defining an electrode holding area for holding the electrode arrangement.

- the electrode holder area can be formed, for example, by a circumferential surface, the width of which is determined by the difference in diameter. This surface can, for example, be arranged perpendicular to a surface, in particular to an outer surface, of the atomizer housing element, so that the electrode holder area is defined by a direct, abrupt transition, which is determined by the difference in diameter.

- the electrode holder area can be formed by a steady or inclined transition, which does not extend perpendicularly, but rather at a flatter angle with respect to the outer surface of the atomizer housing element.

- the electrode holder area can also be formed by the difference in diameter at a boundary between the atomizer housing element and the housing element.

- the atomizer housing element can comprise a first thread and / or a second thread at a first (axial) end of the atomizer housing element. Furthermore, a third thread can be provided on a second (axial) end of the atomizer housing element.

- the first thread is preferably provided for connecting the atomizer housing element to the electrode arrangement, the second thread for connecting the atomizer housing element to the housing element and the third thread for connecting the atomizer housing element to an insulating sleeve.

- the electrode holder area can extend between a surface of the atomizer housing element and the second thread.

- the atomizer housing element which can be provided, for example, for the isolated housing of at least one valve of an atomizer, comprises a connection area, which can for example comprise the first and / or second thread, for connecting the atomizer housing element to the housing element and / or the electrode arrangement, wherein the electrode holder region extends between a surface, in particular an outer surface, of the atomizer housing element and the connection region.

- the electrode holder area is thus formed by a section of the atomizer housing element, which is determined by the difference in diameter and is not covered by the housing element when connected to it.

- the thread or threads of the connection area can also be a further extension of a Effect discharge path and be provided with insulating medium (eg insulating grease, preferably petroleum jelly).

- the second diameter is preferably larger than the first diameter, so that the electrode holder area or its normal points, for example, in a spraying direction.

- the second diameter can be smaller than the first diameter, which enables the electrodes to be arranged or aligned directly on a surface of the atomizer housing.

- the difference in diameter defines an area, at least partially pointing in the direction of spraying, or an at least partially pointing in the direction of spraying, in particular circumferentially, for holding the electrode arrangement.

- the nebulizer housing member may include a central axis that extends through the nebulizer housing member.

- the axis of symmetry of the electrode arrangement and the central axis of the atomizer housing element can coincide (coaxial).

- the axis of symmetry and the central axis preferably merge or intersect at least.

- the atomizer housing element can comprise a first diaphragm and / or a second diaphragm, which are preferably provided essentially in a ring shape and in particular can be arranged coaxially and / or extending parallel to the central axis.

- the first diaphragm preferably has a larger diameter than the second diaphragm. It is possible that at least one receiving space for a resistance receiving means and / or a resistor is formed between the first diaphragm and the second diaphragm.

- the second aperture can be made stronger than the first aperture.

- the first diaphragm and / or the second diaphragm is provided in order to achieve internal insulation and / or a labyrinth or to reduce or avoid undesired discharges.

- the screens can be provided to form a sandwich-like arrangement, in particular with the electrode arrangement, which is provided with at least one matching screen.

- the first and / or second diaphragm is preferably made of dielectric or insulating material.

- the atomizer housing element is straight or, for example, angled in an angular range by approximately 60 °, which is advantageous for an inner coating.

- the nebulizer housing member is angled less than about 70 ° or 65 ° and / or more than about 50 ° or 55 °.

- the atomizer housing element can furthermore comprise at least one detachable insulating sleeve or an extension section which is formed in one piece or uniformly with the atomizer housing element in order to include a receiving device (for example a bore) for a fastening means (for example a central clamping pin) for assembling or disassembling an atomizer and / or a robot - Cover the hand axis with insulation.

- the electrode holder area comprises at least one electrical connection or a charging ring for electrically contacting at least one electrical connection of the electrode arrangement. This advantageously ensures electrode excitation or electrode contact via the atomizer housing element.

- the first thread and / or the second thread and / or the third thread can be arranged coaxially to the central axis of the atomizer housing element, preferably extend around the atomizer housing element and / or the central axis thereof, and in particular can be provided or provided with insulating medium, thereby preventing them or minimization of a discharge current or a discharge current component can be achieved.

- Previous threads can also be tapered to produce self-locking.

- first, the second and / or the third thread can generate an enlarged or lengthened discharge path and / or a labyrinth for discharge current, in particular in order to ensure insulation to the inside and / or to the rear or to reduce or reduce undesired discharges avoid, which can advantageously increase the charge of the coating agent.

- the invention relates to an atomizer housing for an electrostatic atomizer, in particular for a rotary atomizer, with a housing element with a first diameter, the housing element being suitable for receiving or covering a drive turbine and / or a bearing device for a spray element, in particular for a bell cup or is provided, and preferably the atomizer housing element for holding the electrode arrangement.

- the atomizer housing can consist of only the housing element; in another preferred embodiment, it can also comprise in particular the atomizer housing element.

- the housing element is preferably provided as a tube, which can be designed in particular in a straight line. It is possible for a central axis to extend through the housing element or the atomizer housing.

- the housing element can comprise a first thread at a first (axial) end and / or a second thread at a second (axial) end.

- the first thread can be provided for connection to the atomizer housing element, and the second thread can be provided for connection to an atomizer part having a steering air ring. It is also possible for the housing element and the atomizer part having the steering air ring (integral) to be provided in one piece or for the steering air ring to be incorporated into the housing element.

- the diameter of the first thread larger than the diameter of the second thread.

- the first thread and / or the second thread is arranged coaxially to the central axis of the housing element.

- the first thread and / or the second thread of the housing element can extend around the housing element and / or the central axis of the housing element, and can preferably be provided or provided with insulating medium. Similar to the threads already mentioned, the first thread and / or the second thread of the housing element is provided in particular for preventing or minimizing a discharge current or a discharge current component, can be conical in order to produce a self-locking, and can be provided in order to preferably to achieve increased discharge distance and / or a labyrinth for discharge current. In particular, insulation to the front and / or inside during operation of the atomizer is to be ensured or undesired discharges are to be reduced or avoided, as a result of which the charging of the coating agent can advantageously be increased.

- the electrode holder region is formed between an outer surface of the atomizer housing element and an outer surface of the housing element.

- the electrode holder area thus extends between the outer surfaces of the atomizer housing element and the housing element and is determined by the difference in diameter.

- the atomizer housing element is detachable from the housing element, for example connectable or connected by means of a threaded connection, and is arranged upstream of the atomizer housing element with respect to an arrangement of the spraying element or with respect to a spraying direction.

- the atomizer housing or the atomizer housing element comprises an insulating cover or dielectric insulating sleeve for covering a wall on the hand axis side or for covering a (robot) hand axis, which can be grounded and / or which can house, for example, a valve arrangement or supply hoses of an atomizer.

- the dielectric sleeve consists, for example, of a dielectric material, in particular of polytetrafluoroethylene, and can, for example, be connected to the atomizer housing or the atomizer housing element by means of a thread engagement or in particular form an (integral or) one-piece or one-piece unit with the atomizer housing element and e.g. can be clamped on the atomizer side via a circumferential collar.

- the invention also relates to an insulating sleeve per se.

- the insulating sleeve is provided for the insulation of built-in components such as paint / air feeds or atomizer housing elements or for the insulation of a wall on the hand axis side or a hand axis of the robot.

- the insulating sleeve can have a connection area for releasable connection, in particular by means of a threaded connection or a snap connection, to the atomizer housing element.

- the insulating sleeve is preferably formed from an insulating material, in particular from polytetrafluoroethylene.

- the insulating sleeve can comprise a first thread at a first (axial) end and / or a second thread at a second (axial) end.

- the insulating sleeve is preferably provided in a cylindrical manner, which can be formed in particular in a straight line.

- the insulating sleeve can preferably be detachably connected to a further insulating sleeve (“extension insulating sleeve”) in order to advantageously further increase the insulating effect in the direction of the hand axis or to the rear and / or to shield grounded components located under the at least one insulating sleeve.

- a single, correspondingly long insulating sleeve or the further insulating sleeve can be a receiving device (for example a bore) for a fastening means (for example a central clamping pin) with which the (preferably complete) atomizer can be dismantled in a simple manner, and / or cover a robotic hand axis isolating.

- a receiving device for example a bore

- a fastening means for example a central clamping pin

- the further insulating sleeve can be screwed onto the second thread of the insulating sleeve (on the hand axis side).

- the first thread is preferably provided for connection to the atomizer housing element.

- the insulating sleeve is preferably formed from an insulating material, in particular from polytetrafluoroethylene, but can differ in color from other insulating components by, for example, admixing MoS 2 .

- a central axis preferably extends through the at least one insulating sleeve.

- the diameter of the first thread can be essentially the same size as the diameter of the second thread.

- the first thread and / or the second thread can be arranged coaxially to the central axis of the insulating sleeve.

- first thread and / or the second thread can extend around the insulating sleeve and / or its central axis.

- first thread and / or the second thread of the insulating sleeve is provided in particular for preventing or minimizing a discharge current or a discharge current component, can be conical in order to produce a self-locking effect, and can be provided for preferably one to achieve increased discharge distance and / or a labyrinth for discharge current.

- insulation to the rear of the atomizer during operation is to be ensured or undesirable Discharges are reduced or avoided, which can advantageously increase the charge of the coating agent.

- the insulating sleeve has a length in a range between approximately 100 mm and 200 mm or approximately 140 mm or 160 mm.

- the insulating sleeve is preferably approximately 150 mm long.

- the surface of the insulating sleeve for enlarging the surface is not flat, but is, for example, wavy or structured or is provided with elevations and depressions, so that the surface of the insulating sleeve e.g. can resemble a golf ball surface with dimpled depressions.

- the surface of the atomizer housing element, the housing element or the electrode arrangement can likewise have such a surface configuration in order to enlarge the discharge path or creepage distance, as a result of which a greater resistance to the current can be achieved.

- the insulating sleeve can also be connectable to the atomizer housing element described above, for example by means of the first thread, which can be provided with an insulating medium (e.g. insulating grease, for example petroleum jelly).

- an insulating medium e.g. insulating grease, for example petroleum jelly.

- the invention relates to an electrostatic atomizer, in particular a rotary atomizer, preferably with the atomizer housing according to the invention, the electrode arrangement according to the invention and / or the at least one insulating sleeve according to the invention, as described above.

- the atomizer is advantageously suitable for external charging for one or for an outer coating and for one or for an inner coating and / or detailed coating.

- the atomizer is particularly suitable for interior / detail coating without electrical isolation.

- the electrostatic atomizer comprises a spray element, for example a bell cup, which can be held by a storage device.

- the bearing device can be, for example, a turbine or a turbine shaft, which is held or covered by the housing element.

- the housing element can also be provided for holding the steering air ring.

- the electrostatic atomizer further comprises at least one electrode which is held by the electrode arrangement.

- the electrostatic atomizer can preferably be held by means of a connecting element on the hand axis side, which can be covered, for example, with one or the above-mentioned insulating sleeve, for example a flange, for example on a robot arm, with a ratio of a distance between an electrode end of the at least one electrode, which is connected to the electrode arrangement can be mechanically and / or electrically coupled, to the spraying element, in particular to an edge of the spraying element, for example to a bell plate edge, to the hand axis-side, for example grounded, connecting element or to a plastic hand axis or to a housed hand axis in a range between 1.5 and 2 or 2 and 2.5 lies.

- a connecting element on the hand axis side which can be covered, for example, with one or the above-mentioned insulating sleeve, for example a flange, for example on a robot arm, with a ratio of a distance between an electrode end of the at least one

- a distance between an electrode end of the at least one electrode to the spray element, in particular to a spray element edge, for example a bell plate edge can be in a range between 80 mm and 200 mm and in particular be approximately 118 mm (preferably greater than or equal to approximately 80 mm, 120 mm, 160 mm , 200mm or 240mm and / or smaller about 100mm, 140mm, 180mm, 220mm or 260mm).

- a distance between the at least one electrode or its end to the first grounded hand axis element or to a connecting element, for example a grounded connecting flange, of the electrostatic atomizer can be in a range between approximately 120 mm and 625 mm or approximately 195 mm or 240 mm (with "Extension of insulating sleeve"). These dimensions ensure that the electrostatic atomizer is particularly suitable for interior painting and has good electrical insulation properties.

- the atomizing part having the steering air ring can partially or substantially completely and / or completely shield and / or shield the outer surface of the spray element facing away from the component to be coated from a discharge current component or discharge current and expose the spray element in such a way that a discharge, in particular can ignite a corona discharge, preferably at the edge of the bell plate.

- the spray element in particular the outer surface of the spray element facing away from the component to be coated, can also be arranged essentially exposed, whereby a free air gap between the at least one electrode and the spray element, in particular the outer surface of the spray element facing away from the component to be coated, is achieved.

- the spraying element e.g.

- a bell plate preferably does not protrude from the atomizer part having the steering air ring and / or the housing element, in this embodiment the front edge of the atomizing part having the steering air ring defining the front end of the atomizer. It is preferred that the spraying element is partially or completely accommodated in the atomizing part having the steering air ring and / or the housing element, for example by partially or completely enclosing the outer periphery of the spraying element by the atomizing part having the steering air ring and / or the housing element.

- the electrostatic atomizer comprises the insulating sleeve (s) described above, which covers a wall of the electrostatic atomizer or its housing.

- the electrostatic atomizer comprises the above-mentioned at least one insulating sleeve, wherein the electrostatic atomizer can furthermore have a steering air ring, the electrode arrangement has at least one electrode, and wherein the electrode arrangement and / or the housing element are formed from dielectric material for influencing a current component extending in the direction of the axis of symmetry and / or in the direction of the spraying element for charging an atomizable lacquer or atomized lacquer and / or the discharge current component.

- the electrode arrangement and / or the housing element and / or the insulating sleeve and / or the steering air ring are each coated or by means of a thread, in particular one with insulating medium or insulating fluid (for example insulating grease such as petroleum jelly) surrounding thread, can be held, and / or wherein the thread (on the electrode arrangement) has at least one screen, in particular a screen coated with insulating medium, the thread and / or the at least one screen being provided, an extension, in particular through a labyrinth, to cause a discharge current path.

- insulating medium or insulating fluid for example insulating grease such as petroleum jelly

- the at least one insulating sleeve and / or the steering air ring (or the atomizing part having the steering air ring) and / or the electrode arrangement and / or the housing element and / or the atomizing housing element and / or a spraying element, in particular a bell plate are modularly interchangeable and preferably adaptable or adapted to a respective application scenario which comprises an inner coating and an outer coating.

- the steering air ring (or the atomizing part having the steering air ring), the electrode holder (or electrode arrangement) and the spraying element, in particular a bell cup, are preferably modularly interchangeable.

- the invention relates to an operating method, preferably an electrostatically assisted atomization method, preferably with external charging of the coating agent and in particular for the external charging of the coating agent in the interior / detail coating, in which a spray jet is atomized by means of electrostatic atomization, in particular rotary atomization. with the steps of generating an electrostatic field for electrostatically charging the spray jet about an axis of symmetry, preferably about one of the aforementioned axes of symmetry, and for example electrically influencing a discharge current component of the discharge current, which can preferably extend in the direction of the axis of symmetry, by means of a dielectric material.

- the operating method can include carrying out an external charging of a coating agent in the interior / detail coating and preferably in the exterior coating.

- An interior / detail coating can advantageously be carried out without electrical isolation.

- the same atomizer and / or the same external charging system can advantageously be used to carry out an interior / detail coating and an exterior coating with preferably low-resistance paints (e.g. solvent-based paints) and / or water-based paints.

- the same atomizer and / or the same external charging system can advantageously be used for external charging of the coating agent in the internal / detailed coating and the external coating. For example, an inner coating can be carried out first and then an outer coating (or vice versa).

- the operating method preferably also includes external charging of a water-based lacquer or of a solvent lacquer in the interior painting and / or the detailed painting.

- the discharge current component of the discharge current opposite the discharge current component is less or not influenced, in particular less or not attenuated.

- the electrostatic field is generated by one or more electrodes arranged around the axis of symmetry.

- the operating method can be carried out with a painting distance between the front edge of the atomizer (e.g. the front edge of the spraying element or the front edge of the atomizer part having the steering air ring) and the component to be coated, which is greater than or equal to approximately 5 mm, 10 mm, 50 mm, 100 mm, 150 mm or 200 mm is; and / or is less than about 7.5mm, 25mm, 75mm, 125mm, 175mm or 225mm.

- a painting distance between the front edge of the atomizer e.g. the front edge of the spraying element or the front edge of the atomizer part having the steering air ring

- a painting distance between the front edge of the atomizer e.g. the front edge of the spraying element or the front edge of the atomizer part having the steering air ring

- a painting distance between the front edge of the atomizer e.g. the front edge of the spraying element or the front edge of the atomizer part having the steering air ring

- the invention further relates to a method for producing the electrode arrangement described above, comprising the steps of forming an electrode holder device for holding electrodes around an axis of symmetry and forming a dielectric material for influencing a discharge current component of the discharge current which extends in the direction of the axis of symmetry.

- the invention relates to a method for producing an atomizer housing as described above for holding an electrode holder as described above for an electrostatic atomizer, in particular for a rotary atomizer, with the step of forming the atomizer housing element with the second diameter, around an electrode holder region for holding the Determine electrode arrangement by a difference in diameter between the first diameter and the second diameter.

- the invention relates to a method for producing an atomizer housing as described above, comprising the steps of forming the housing element, which is used to receive or cover a bearing device, for example a turbine and / or a turbine shaft, for a spray element, in particular for a bell cup, and / or is suitable or provided for holding a steering air ring, with the first diameter, and the formation of the atomizer housing element.

- a bearing device for example a turbine and / or a turbine shaft

- a spray element in particular for a bell cup

- / or is suitable or provided for holding a steering air ring with the first diameter

- the invention further relates to a method for producing an electrostatic atomizer as described above, comprising the steps of forming the atomizer housing, forming the electrode arrangement and bringing the atomizer housing and the electrode arrangement together in order to obtain the electrostatic atomizer.

- the step of merging can include, for example, the step of connecting, for example by means of a thread engagement.

- the method comprises the step of forming the insulating sleeve, in particular for insulation on the hand axis side or influencing a discharge current component on the hand axis side.

- the invention further relates to a method for producing an insulating sleeve as described above, the connection region being formed with a thread to create a discharge gap.

- the invention relates to a use of the electrostatic atomizer described above for the interior / detail coating, in particular the interior / detail painting, of vehicle bodies (e.g. door entrances, windows, etc.) or preferably small parts or attachments or bumpers or bumpers made of plastic Bumpers, in particular bumper elements or bumpers or bumper strips.

- the invention relates to the use of an electrostatic rotary atomizer (preferably as described above) and / or an electrode arrangement (preferably as described above) for externally charging a coating agent in the interior / detail coating and preferably also in the exterior coating.

- the parts according to the invention are intended for external charging of the coating agent (for the inner / detailed coating and / or the outer coating).

- the parts according to the invention e.g. the electrode arrangement, the atomizer, the operating method, etc.

- the parts according to the invention are particularly suitable for the external coating of e.g. Motor vehicle bodies, add-on parts, etc., but preferably also for the interior / detail coating of e.g. Motor vehicle bodies (e.g. door entrances), add-on parts, small parts, bumpers or bumpers, bumper elements, bumpers, bumper strips, etc.

- position monitoring of an object to be coated can be achieved by evaluating current (I) and voltage (U).

- Position monitoring includes e.g. the position and / or the orientation or location of an object to be coated.

- the symmetry or central axis of the electrode arrangement, the central axis of the atomizer housing element, the central axis of the housing element, the central axis of the atomizer housing and / or the central axis of the insulating sleeve (s) coincide or go together at least one over the other or intersect.

- the electrode arrangement, the electrode holder device, the atomizer housing element, the housing element, the insulating sleeve and / or the atomizer part having the steering air ring can have dielectric or insulating material in sections or can be coated or encased by means of dielectric or insulating material.

- the electrode arrangement, the electrode holder device, the atomizer housing element, the housing element, the insulating sleeve and / or the atomizer part having the steering air ring can preferably be formed in one piece from dielectric or insulating material and / or essentially consist of dielectric or insulating material.

- Individual component groups e.g. the electrode arrangement, the at least one insulating sleeve, the atomizer housing element, the atomizer housing, the housing element and / or the steering air ring (or the atomizing part having the steering air ring)

- the atomizer housing element and the at least one insulating sleeve can be made in one piece or in one piece.

- the atomizer housing element and the at least one insulating sleeve and the electrode arrangement can be made in one piece or in one piece.

- the electrode arrangement can also be made in one piece or one piece with the housing element and / or the atomizer housing element It is also possible to use the housing element and the steering air ring (or the atomizing part having the steering air ring) to be made in one piece or in one piece, so that the steering air ring can preferably be incorporated in the housing element.

- the dielectric or insulating material is preferably a high-voltage-resistant material, in particular made of fluoroplastic or fluoroplastic compounds, for example polytetrafluoroethylene. Undesired discharges can thus be minimized or avoided, as a result of which the charging of the coating agent can advantageously be increased.

- the spray element e.g. a bell cup

- the spray element can also be made or consist at least partially of dielectric or insulating material, in particular if another counter electrode / ignition electrode is provided to ignite the necessary (corona) discharge.

- detachable connections e.g. snap connections, snap-in connections, clamp connections, Velcro fasteners, screw connections, etc.

- detachable connections can also be provided in an advantageous manner to the electrode arrangement, the housing element, the atomizer part having the steering air ring, the atomizer housing element and / or the at least one insulating sleeve To be able to assemble, disassemble or replace quickly and easily.