EP1582277A1 - Dispositif de lissage des roues dentées - Google Patents

Dispositif de lissage des roues dentées Download PDFInfo

- Publication number

- EP1582277A1 EP1582277A1 EP04003106A EP04003106A EP1582277A1 EP 1582277 A1 EP1582277 A1 EP 1582277A1 EP 04003106 A EP04003106 A EP 04003106A EP 04003106 A EP04003106 A EP 04003106A EP 1582277 A1 EP1582277 A1 EP 1582277A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- carriage

- smoothing

- smoothed

- gear

- wheel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21H—MAKING PARTICULAR METAL OBJECTS BY ROLLING, e.g. SCREWS, WHEELS, RINGS, BARRELS, BALLS

- B21H5/00—Making gear wheels, racks, spline shafts or worms

- B21H5/02—Making gear wheels, racks, spline shafts or worms with cylindrical outline, e.g. by means of die rolls

- B21H5/022—Finishing gear teeth with cylindrical outline, e.g. burnishing

Definitions

- the invention relates to a device for smoothing of gears according to the preamble of the main claim.

- the object of the invention is a device for smoothing gears to make available that is simple and inexpensive and easy on different diameters of gears to be smoothed adjustable and to be maintained.

- This design allows a complete separation of the clamping a gear to be smoothed from the function of its coaxial Alignment to the longitudinal direction of the oscillation axis of the clamping device and also of the technical design of the clamping device itself and is simple and manageable and thereby very economical to produce and easy to maintain.

- the first carriage is designed as a frame and on Guide rails stored on a machine table and the second Carriage disposed within the frame of the first carriage and stored on the same guide rails, wherein the pressure cylinder is arranged on the frame of the first carriage and over a Push rod moves the second slide within the frame, allowing the arranged on the second carriage pair of smoothing in Direction to the single, set on the first slide level below Move clamping of the gear to be smoothed solve.

- a positioning cylinder is articulated, whose free End either on the first slide or on the second slide can, so that the entire clamping unit in the clamped state a gear to be smoothed along the guide rails so positioned can be that the rotation axis of a gear to be smoothed runs coaxially with a central axis of its clamping device.

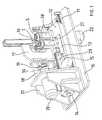

- the device for smoothing gears It consists of a machine table 10, mounted on the two parallel guide rails 11 are on which a frame-shaped carriage 12 for a by a motor 22 driven smoothing wheel 5 is slidably disposed, and within of the carriage 12, another carriage 13 for a driven Pair of smoothing wheels 5, wherein on the carriage 12 for the driven Smoothing 5 a pressing cylinder 14 is arranged, the slide 13th for the driven pair of smoothing wheels 5 in the direction of the driven Smoothing presses 5, wherein between the pair of polishing wheels 5 and the individual smoothing wheel 5 a smoothing gear 1 as a workpiece during operation is kept clamped under a high radial pressure.

- axial the gear 1 to be smoothed by a clamping device 16 is radial movably clamped, which is arranged on a C-shaped bracket 17, which in turn via spring assemblies 18 and an eccentric 19 at a holding frame 21 is fixed so that it has an eccentric drive 20 a vertical oscillation of the axially clamped only, radially quasi floating gear 1 allows.

- a contact pressure of about 150 to 500 kg for floating clamping of the gear to be smoothed 1 can be applied.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Jigs For Machine Tools (AREA)

- Retarders (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

- Gear Processing (AREA)

- Gear Transmission (AREA)

- Treatment Of Fiber Materials (AREA)

Priority Applications (7)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE502004006188T DE502004006188D1 (de) | 2004-03-01 | 2004-03-01 | Vorrichtung zum Glätten von Zahnrädern |

| EP04003106A EP1582277B1 (fr) | 2004-03-01 | 2004-03-01 | Dispositif de lissage des roues dentées |

| PL04003106T PL1582277T3 (pl) | 2004-03-01 | 2004-03-01 | Urządzenie do wygładzania kół zębatych |

| ES04003106T ES2301890T3 (es) | 2004-03-01 | 2004-03-01 | Dispositivo de alisado de ruedas dentadas. |

| AT04003106T ATE385865T1 (de) | 2004-03-01 | 2004-03-01 | Vorrichtung zum glätten von zahnrädern |

| CA002465452A CA2465452C (fr) | 2004-02-12 | 2004-04-27 | Dispositif de lissage de roues d'engrenage |

| US10/846,213 US7004826B2 (en) | 2004-03-01 | 2004-05-10 | Device for smoothing gear wheels |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP04003106A EP1582277B1 (fr) | 2004-03-01 | 2004-03-01 | Dispositif de lissage des roues dentées |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1582277A1 true EP1582277A1 (fr) | 2005-10-05 |

| EP1582277B1 EP1582277B1 (fr) | 2008-02-13 |

Family

ID=34833581

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04003106A Expired - Lifetime EP1582277B1 (fr) | 2004-02-12 | 2004-03-01 | Dispositif de lissage des roues dentées |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US7004826B2 (fr) |

| EP (1) | EP1582277B1 (fr) |

| AT (1) | ATE385865T1 (fr) |

| CA (1) | CA2465452C (fr) |

| DE (1) | DE502004006188D1 (fr) |

| ES (1) | ES2301890T3 (fr) |

| PL (1) | PL1582277T3 (fr) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2022576A1 (fr) * | 2007-08-03 | 2009-02-11 | Wolfgang Linnenbrink | Procédé de travail destiné à l'amélioration du fonctionnement de roues dentées et dispositif de lissage destiné à la réalisation du procédé |

| DE102017126988A1 (de) | 2017-11-16 | 2019-05-16 | Profiroll Technologies Gmbh | Werkzeug, Maschine und Verfahren zum Glattwalzen von verzahnten Werkstücken |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7169023B2 (en) * | 2004-06-08 | 2007-01-30 | Asmo Co., Ltd. | Method and apparatus for manufacturing hourglass worm rolling die |

| CN108098075B (zh) * | 2016-11-24 | 2019-07-19 | 丹阳市华清机车配件有限公司 | 一种闭门器用齿条柱塞铣齿装置及其工作方法 |

| CN108772781A (zh) * | 2018-06-13 | 2018-11-09 | 何磊 | 一种小型轴承套内壁打磨用定位装置 |

| CN109277919B (zh) * | 2018-11-14 | 2024-03-22 | 漳浦金盛智能科技有限公司 | 打磨机 |

| CN112318254A (zh) * | 2020-10-27 | 2021-02-05 | 韦熙斌 | 一种金属材料加工用链轮去毛刺装置 |

| CN113664618A (zh) * | 2021-07-09 | 2021-11-19 | 林元霞 | 一种竹节打磨方法 |

| CN113618564A (zh) * | 2021-07-09 | 2021-11-09 | 林元霞 | 一种原竹竹节打磨设备 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2352557A (en) * | 1939-09-12 | 1944-06-27 | Fellows Gear Shaper Co | Gear finishing apparatus |

| DE914365C (de) * | 1944-01-07 | 1954-07-01 | Daimler Benz Ag | Verfahren zum Herstellen von Zahnraedern |

| EP0366074A2 (fr) * | 1988-10-28 | 1990-05-02 | Isuzu Jidosha Kabushiki Kaisha | Dispositif de correction d'imperfections de la surface de la dent d'une roue d'engrenage |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1024435A (en) * | 1911-09-21 | 1912-04-23 | Joseph Bissell | Grinding pen-nibs. |

| US1576806A (en) * | 1922-11-06 | 1926-03-16 | Pratt & Whitney Co | Method of burnishing gears |

| US1658899A (en) * | 1924-01-11 | 1928-02-14 | William E Hoke | Method of and apparatus for wearing in gears |

| US1599818A (en) * | 1924-01-11 | 1926-09-14 | William E Hoke | Apparatus for finishing gears |

| US1707555A (en) * | 1926-03-23 | 1929-04-02 | Jones Brothers Company | Apparatus for grinding corrugated rolls and bedplates |

| US1712095A (en) * | 1927-08-11 | 1929-05-07 | Lees Bradner Co | Machine and method for profiling gear teeth |

| US1912216A (en) * | 1929-03-01 | 1933-05-30 | Detroit Trust Company | Method and apparatus for lapping gears |

| US1990239A (en) * | 1932-08-13 | 1935-02-05 | Fellows Gear Shaper Co | Gear finishing machine |

| US2060803A (en) * | 1933-08-14 | 1936-11-17 | Falk Corp | Means for treating gears |

| US2139290A (en) * | 1933-09-23 | 1938-12-06 | Fellows Gear Shaper Co | Apparatus and method for lapping gears |

| US2105896A (en) * | 1935-01-04 | 1938-01-18 | Fellows Gear Shaper Co | Method and means for honing gears, and for truing the honing means |

| US2389549A (en) * | 1941-02-04 | 1945-11-20 | Fellows Gear Shaper Co | Machine for honing tooth grooves of gear finishing tools |

| US3139707A (en) * | 1962-10-17 | 1964-07-07 | United Aircraft Prod | Metallic omicron-ring polishing machine |

| US3391495A (en) * | 1966-10-03 | 1968-07-09 | John A. Maurer | Method and apparatus for producing gears of extreme accuracy |

| US4067218A (en) * | 1976-12-16 | 1978-01-10 | Bibbens William H | Apparatus and method and means for removing surface defects from a workpiece |

| US4414780A (en) | 1981-08-21 | 1983-11-15 | Jorgensen Arne R | Gear burnishing and honing machine |

| US4583271A (en) * | 1983-04-28 | 1986-04-22 | Illinois Tool Works Inc. | Method and apparatus for burnishing splines and gears using synchronously rotated gears |

| US6561869B2 (en) * | 1999-12-10 | 2003-05-13 | Denso Corporation | Gear grinding machine and gear grinding method |

-

2004

- 2004-03-01 PL PL04003106T patent/PL1582277T3/pl unknown

- 2004-03-01 ES ES04003106T patent/ES2301890T3/es not_active Expired - Lifetime

- 2004-03-01 EP EP04003106A patent/EP1582277B1/fr not_active Expired - Lifetime

- 2004-03-01 DE DE502004006188T patent/DE502004006188D1/de not_active Expired - Lifetime

- 2004-03-01 AT AT04003106T patent/ATE385865T1/de not_active IP Right Cessation

- 2004-04-27 CA CA002465452A patent/CA2465452C/fr not_active Expired - Fee Related

- 2004-05-10 US US10/846,213 patent/US7004826B2/en not_active Expired - Fee Related

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2352557A (en) * | 1939-09-12 | 1944-06-27 | Fellows Gear Shaper Co | Gear finishing apparatus |

| DE914365C (de) * | 1944-01-07 | 1954-07-01 | Daimler Benz Ag | Verfahren zum Herstellen von Zahnraedern |

| EP0366074A2 (fr) * | 1988-10-28 | 1990-05-02 | Isuzu Jidosha Kabushiki Kaisha | Dispositif de correction d'imperfections de la surface de la dent d'une roue d'engrenage |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2022576A1 (fr) * | 2007-08-03 | 2009-02-11 | Wolfgang Linnenbrink | Procédé de travail destiné à l'amélioration du fonctionnement de roues dentées et dispositif de lissage destiné à la réalisation du procédé |

| US8069566B2 (en) | 2007-08-03 | 2011-12-06 | Wolfgang Linnenbrink | Operating method for improving the running behavior of gearwheels and burnishing device for performing the method |

| DE102017126988A1 (de) | 2017-11-16 | 2019-05-16 | Profiroll Technologies Gmbh | Werkzeug, Maschine und Verfahren zum Glattwalzen von verzahnten Werkstücken |

Also Published As

| Publication number | Publication date |

|---|---|

| CA2465452A1 (fr) | 2005-08-12 |

| ATE385865T1 (de) | 2008-03-15 |

| DE502004006188D1 (de) | 2008-03-27 |

| CA2465452C (fr) | 2009-09-01 |

| US20050181714A1 (en) | 2005-08-18 |

| ES2301890T3 (es) | 2008-07-01 |

| PL1582277T3 (pl) | 2008-07-31 |

| EP1582277B1 (fr) | 2008-02-13 |

| US7004826B2 (en) | 2006-02-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE4010445A1 (de) | Rohrbiegemaschine | |

| EP1600227A1 (fr) | Machine à forger | |

| EP1582277B1 (fr) | Dispositif de lissage des roues dentées | |

| EP1797994A1 (fr) | Dispositif ébarbeur | |

| DE625218C (de) | Vorrichtung zum fortlaufenden selbsttaetigen Entgraten von Rohren an beiden Enden durh Fraesen | |

| DE609717C (de) | Maschine zum Hobeln von in der Kokille gegossenen, pyramidenstumpffoermigen Stahlguss-Vierkantbloecken | |

| DE2718502C3 (de) | Kopiervorrichtung für Kurbelwellenfräsmaschinen | |

| DE100339C (fr) | ||

| DE347937C (de) | Nach dem Abwaelzverfahren, vorzugsweise mittels Rollbogen-Bandgetriebe arbeitende Kegelraederverzahnungsmaschine | |

| DE1919249A1 (de) | Vorrichtung zum spanlosen Bearbeiten von Zahnraedern | |

| DE467155C (de) | Selbsttaetige Werkzeugmaschine | |

| DE3346613C2 (fr) | ||

| DE45396C (de) | Bohrbank | |

| DE452993C (de) | Vorrichtung zum Ausrichten des Satzbetts und Druckzylinders einer Druckpresse | |

| DE561231C (de) | Verfahren zum Einlaufen mit oder ohne Schleifmittel von Zahnraedern mit abgeschraegtem Radkoerper, wie z. B. Kegelraedern und Hyperboloidraedern | |

| DE466913C (de) | Mehrspindelige Revolverdrehbank | |

| DE693448C (de) | Maschine zum Hobeln von Zahnraedern mit gerader oder schraeger Verzahnung mittels zahnstangenfoermigen Werkzeugs | |

| AT24437B (de) | Nachstellvorrichtung für das querverschiebliche Einzelwerkzeug einer Revolverdrehbank. | |

| DE235515C (fr) | ||

| DE54067C (de) | Selbsttätige Maschine zum Fräsen faconnirter Knöpfe | |

| DE647643C (de) | Vorschubvorrichtung fuer achsig verschiebbare Arbeitsspindeln an selbsttaetigen Drehbaenken | |

| DE110609C (fr) | ||

| DE1652187C (de) | Schleifmaschine mit einer Ausgleichsvorrichtung für den beim Abrichten der Schleifscheibe entstehenden Schleifscheibenschwund | |

| DE324761C (de) | Vorrichtung zum Hobeln von runden Werkstuecken, insbesondere von Stirnraedern | |

| DE3227093A1 (de) | Rohrschneidemaschine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20050426 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 502004006188 Country of ref document: DE Date of ref document: 20080327 Kind code of ref document: P |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20080320 Year of fee payment: 5 Ref country code: ES Payment date: 20080326 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20080318 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20080319 Year of fee payment: 5 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2301890 Country of ref document: ES Kind code of ref document: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080213 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20080321 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080213 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080213 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080213 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080331 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080213 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080213 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080513 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080714 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080213 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20081114 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080213 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080513 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CZ Payment date: 20090220 Year of fee payment: 6 Ref country code: PL Payment date: 20090326 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080213 |

|

| BERE | Be: lapsed |

Owner name: LINNENBRINK, WOLFGANG Effective date: 20090331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090301 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20090301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090331 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090301 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20090302 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20100331 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080814 Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090302 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080213 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20100521 Year of fee payment: 7 Ref country code: IT Payment date: 20100327 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080514 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100301 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: LAPE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20111130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111001 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110331 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502004006188 Country of ref document: DE Effective date: 20111001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100301 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110301 |