EP0803446A2 - Ensemble d'emballage ainsi qu'un procédé et un dispositif pour le réaliser - Google Patents

Ensemble d'emballage ainsi qu'un procédé et un dispositif pour le réaliser Download PDFInfo

- Publication number

- EP0803446A2 EP0803446A2 EP97105082A EP97105082A EP0803446A2 EP 0803446 A2 EP0803446 A2 EP 0803446A2 EP 97105082 A EP97105082 A EP 97105082A EP 97105082 A EP97105082 A EP 97105082A EP 0803446 A2 EP0803446 A2 EP 0803446A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- objects

- group

- banderole

- band

- unit

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B25/00—Packaging other articles presenting special problems

- B65B25/14—Packaging paper or like sheets, envelopes, or newspapers, in flat, folded, or rolled form

- B65B25/146—Packaging paper or like sheets, envelopes, or newspapers, in flat, folded, or rolled form packaging rolled-up articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B11/00—Wrapping, e.g. partially or wholly enclosing, articles or quantities of material, in strips, sheets or blanks, of flexible material

- B65B11/58—Applying two or more wrappers, e.g. in succession

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D71/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans or pop bottles; Bales of material

- B65D71/50—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans or pop bottles; Bales of material comprising a plurality of articles held together only partially by packaging elements formed otherwise than by folding a blank

Definitions

- the invention relates to a pack of several objects, in particular individual packs, which are arranged side by side in at least one layer. Furthermore, the invention relates to a method and a device for producing such packaging.

- Bundles are a widespread form of packaging for groups of individual items, in particular (small) packs, such as food packaging, cigarette packaging, paper tissue packaging, etc.

- the small or individual packs are grouped together in organized groups, usually in layers .

- the group of small or individual packs is surrounded by a large container, for example made of cardboard or corrugated cardboard. As a result, the usual packaging of containers is expensive.

- the invention is based on the object of proposing novel packagings which require significantly less material. Furthermore, it is about measures for a rational or industrial production of such packaging.

- the packaging according to the invention is characterized in that the group of objects or individual packs are combined to form a unit by at least one strip-shaped band that runs around the outside and encompasses the layer or layers of the objects or individual packs.

- the items or individual packaging are provided with their own wrapping made of paper, cardboard or (plastic) foil.

- the unit of a group of such individual packs is created by at least one banderole which comprises the layer or the group.

- the container For better cohesion of the container, further simple packaging measures are provided according to the invention, which consolidate the relative position of the individual packs within the group.

- objects or individual packs can be connected to one another by means of glue points or glue points, in the case of a layer composed of individual packs, especially the individual packs positioned inside the same, which have no direct contact with the banderole.

- the glue is preferably a known pressure sensitive adhesive which enables the individual packs to be easily detached from one another when the container is divided.

- the group of individual packs can be surrounded by at least one further, second banderole, which extends transversely to the first banderole, that is to say it surrounds it in a crossing manner.

- a container packaging according to the invention with two crossing banderoles for packaging cylindrical objects is particularly advantageous.

- two rolls are combined to form a packaging unit by means of a (film) wrapping.

- These are grouped in several layers, preferably two rows of the rollers or the packaging units lying in one layer next to one another in the axial direction of the rollers.

- the banderoles are arranged and dimensioned so that they partially cover the two adjacent rows in the middle.

- the banderoles each extend almost over the full width or length of the group.

- a package is particularly advantageous in which the crossing (two) banderoles are positioned so that the inner banderole runs transversely axially to the aligned cylindrical objects or the packaging units formed from them, while the outer, crossing banderole with two (upper and lower) Legs do not run parallel to the axes of the cylindrical objects.

- the banderoles are expediently placed around the group of objects with increased tension, so that the banderoles partially nestle in a wave-like manner on the external cylindrical objects.

- the group of objects is first conveyed in one direction through the vertical plane of a blank for the banderole provided therein and then in the transverse direction through the vertical plane of a second banderole, the banderoles successively being U-shaped to the group of objects.

- the banderole is completely wrapped around the group of objects by additional folding members.

- the ends of the banderoles are connected to one another, in particular by sealing (in the case of plastic films) or by gluing.

- a device is provided with at least two conveyor tracks arranged at right angles to one another for the groups of objects, namely packing tracks.

- folding units are positioned in a fixed position, each of which has cut-outs for the banderoles and places them around the groups of objects.

- FIG. 1 to 3 show a particularly economical embodiment of a packaging unit.

- This consists of cuboidal individual packs 10 and 11.

- the individual packs 10 and 11 are formed in a group, in the present case with three rows 12, 13, 14. Within the rows 12, 13, 14, the individual packs 10, 11 are aligned so that a regular formation, namely a layer of individual packs 10, 11 is formed.

- the group or layer is surrounded on the outside by a strip-shaped band 15 running all around. This preferably consists of a (tensile) plastic.

- the band 15 holds the group of individual packs 10, 11 together under tension in the formation shown, so that the bundle pack thus formed can be put into circulation.

- glue points 16 are attached between mutually facing sides or walls of adjacent individual packs 10, 11.

- the glue points 16 have the effect that the group or layer from the individual packs 10, 11 is additionally held together in the formation.

- the glue dots 16 preferably consist of a pressure sensitive adhesive, which enables the individual packs 10, 11 to be easily separated without damaging them when the packaging is released.

- all the individual packs 10, 11 can be mutually connected by one or more glue points 16. However, it can be sufficient if only the internal ones Individual packs 11, which are not directly covered by the band 15, are connected to one another by glue points 16 and, if appropriate, to the adjacent external individual packs 10.

- the individual packs 10 located outside the layer can additionally be connected to the band 15 by means of glue points or other glue connections.

- FIG. 5 A likewise economically constructed container packaging with increased protection of the packed objects is shown in FIG. 5 and in FIG. 6.

- individual objects are combined into a pack and held together by banderoles 17 and 18 which cross each other.

- a first band 17 lies directly against the objects and surrounds the group formed from them.

- the second banderole 18 is positioned transversely to this, accordingly crosses the first banderole 17, 18 at the bottom and top of the packaging.

- These two banderoles 17, 18 result in optimal cohesion with little use of material.

- the bands 17, 18 are dimensioned such that they cover approximately half the dimension of the group formed from the objects with a central arrangement.

- the packaging is constructed on the same principle.

- An inner band 19 extends here over almost the full width of the bundle or group of individual items.

- a transverse banderole 20 is dimensioned so that it covers the almost full length of the group of objects to be wrapped.

- the container is only provided with slot-like or slit-shaped openings on upright edges.

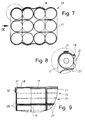

- the bundle of banderoles 17, 18; 19, 20 according to FIGS. 5 and 6 is particularly suitable for cylindrical objects, in the present case paper rolls 21. These can be rolls of household paper, toilet paper or the like.

- the cylindrical objects namely paper rolls 21, are also formed in rows 22 and 23. Within a row 22, 23, the paper rolls 21 are axially parallel to one another. From row 22 to row 23, the cylindrical objects are therefore arranged coaxially.

- the package here consists of two adjacent rows 22, 23. These each form a layer 24 or 25.

- the smaller container according to FIG. 5 consists of three layers 24 formed in this way one above the other. 6 consists of four layers arranged one above the other.

- the number of cylindrical objects within a row 22, 23 can also be different - depending on the size of the container.

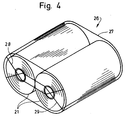

- FIG. 4 Another special feature is realized in these examples of packaging.

- two cylindrical objects paper rolls 21

- the two paper rolls 21 are arranged axially parallel to one another and surrounded by an outer covering 27, for example a plastic film. This is designed so that the two paper rolls 21 are completely enveloped.

- the wrapping 27 is folded in an envelope-like manner, forming trapezoidal folding tabs 28, 29 that partially overlap one another.

- 5 and 6 consist of such packing units 26, the paper rolls 21 of a packing unit 26 being adjacent to one another within a layer 24, 25. This creates approximately oval objects in cross-section, which are grouped in rows and layers.

- the inner band 17 is positioned so that it bears against the cylindrical outer surfaces of the objects (paper rolls 21) or the pack units 26.

- the band 17 in the embodiment according to FIG. 5 is dimensioned such that it covers approximately half the length of the adjacent objects or paper rolls 21.

- the transverse banderole 18, which is also arranged in the center, is dimensioned such that, in the present case, it grasps the paper rolls 21 of the pack units 26 lying next to one another (FIG. 7).

- the banderole 18 is under tension and is therefore nestled in a wave shape in the area of the top and bottom of the packaging (FIG. 7).

- the bands 17..20 are formed from a finite blank, preferably made of plastic, which in turn is separated from a material web 30.

- the bands 17..20 are placed under tension around the group of objects. Protruding end tabs are connected to one another to form a fin seam 31, 32, in particular by thermal sealing.

- the fin seam 31, 32 is folded against the banderole 15, 17..20 and expediently connected to the banderole in this position by light stitching.

- FIGS. 10 ff. A machine as shown in important details in FIGS. 10 ff. Is suitable for attaching the bands 17, 18 or 19, 20.

- the exemplary embodiment shows the attachment of (narrow) banderoles 17 and 18.

- Item groups 33 in particular groups of cylindrical items, such as paper rolls 21, are conveyed through the machine on a packing track 34.

- the groups of objects 33 are formed in such a way that the axes of the cylindrical objects (paper rolls 21) point in the region of a feed line 35 in the direction of conveyance.

- the packing web 34 or its feed conveyor line 35 consists of an endless conveyor, for example a belt or a chain conveyor.

- the object groups 33 are transported at a distance from one another.

- the groups of items 33 are held together by fixed side guides 36 of the packaging web 34.

- the group of objects 33 runs against a stop which is also a side guide 37 for a transverse conveyor line 38 of the package conveyor.

- the object group 33 is transported in the direction transverse to the feed line 35.

- a slide 39 is provided, which moves the group of objects 33 to the end of the cross conveyor line 38, namely until it abuts against a further side guide 40 of a discharge line 41 of the packing line 34 which acts as a stop.

- the discharge line 41 in turn runs transversely to the cross conveyor line 38 and thus parallel to the Feed conveyor line 35, in the present example in the same conveying direction.

- a band 17, 18 is attached each time the direction of the object group 33 changes.

- the inner band 17 is attached.

- a banding unit 42 is attached in the area of the transverse conveyor line.

- a blank for the banderole 17 is kept available in an upright plane transverse to the conveying direction of the group of articles 33. Due to the conveying movement of the object group 33, the banderole 17 is applied to the object group 33 in a U-shape.

- the material web 30 is drawn off from a bobbin 43.

- the material web 30 reaches the area of the banding unit 42 via deflection rollers and compensating pendulums.

- This has suction belts 44 for transporting the material web 30 or the cutting of the banding 17, which cover the material web 30 or banding in the area of a horizontal conveying path above the packaging line 34 and after deflecting in the downward direction to the packing web 34.

- the suction belts 44 are preceded by a cutting unit with a knife roller 45 designed in the usual way. In the area of the latter, the bands 17 are separated from the material web 30.

- Preference rollers 46 are arranged in front of the cutter roller 45.

- the banding 17 In the area of the banding unit 42, the banding 17 is kept ready in a vertical plane.

- the band 17 wraps around the group of objects 33 in a U-shape.

- the paper rolls 21 point with their longitudinal axes transverse to the conveying direction.

- the (inner) sleeve 17 bears against the outer surfaces of the paper rolls 21 or the pack units 26.

- This U-shaped folding process is favored by an upper guide 48 and an underpass 49 in the movement path of the group of objects 33.

- Top guide 48 and underpass 49 act like a folding mouthpiece.

- the upper guide 48 is arranged in a funnel shape.

- the group of objects 33 is held by movable members before being wrapped by the banding 17.

- a plate 50 which can be moved up and down is provided on the upper side. This causes the objects, namely paper rolls 21 or packing units 26, to be aligned on the upper side.

- the plate 50 is raised slightly when the group of articles is pushed off by the slide 39.

- a stop plate 51 is arranged on the front side in the direction of movement. This causes the upright formation from the objects to be maintained.

- the cylindrical objects are therefore supported on all sides in the area of the cylindrical surfaces, so that the formation shown is preserved.

- the stop plate 51 is displaceable transversely to the direction of movement of the group of objects, and is therefore pulled out of the movement path of the group of objects 33 when it is pushed through the slide 39 through the banding unit 42.

- the article group 33 arrives with the banderole 17 in the initial area of the discharge line 41.

- a support plate 52 is arranged above the article group.

- End flaps 53, 54 of the band 17 are located on a rear side in the direction of movement of the article group 33.

- These end flaps 53, 54 are placed against the back of the group of articles, namely by folding and sealing members 55, 56.

- These are made up of an upper and a lower one Position moved downwards or upwards with entrainment of the end flaps 53, 54 and bearing against the object group 33.

- the bar and strip-like folding and sealing members are heated in thermoplastic plastic films and seal the ends of the band 17 together to form the fin seam 31 ( Fig. 14).

- the lower folding and sealing member 56 is moved upward, so that it places the fin seam 31 formed on the wall of the band 17, namely on the upper end tab 53.

- the group of objects 33 provided with the band 17 is fed to a second band unit 58 in the region of the line 41.

- the outer or second banderole 18 is kept ready and placed around the object group 33 in the same way as the banderole 17.

- the packaging is finished after leaving the banderole unit 58.

- the banding unit 58 is supplied with material via a bobbin 59.

- a material web 60 for the band 18 is drawn off from this, analogously to the band 17.

- the band units 42, 58 are designed in a special way. As can be seen in particular from FIGS. 14 and 16, the material web 30, 60 is fed from above through the suction belts 44 to the packaging web 34.

- the suction belts 44 are two parallel individual belts arranged at a distance from one another, which together transport the material web 30, 60 or the blank for the sleeve 17, 18.

- the suction belts 44 end with an upright belt leg 61 above the movement path of the object groups 33, namely above the plate 50 or the top guide 48 in the region of the banding unit 42 or 58.

- a vertical conveyor 62 which here also consists of two parallel suction belts 63, 64. These can be moved up and down as a unit.

- Each suction belt is guided over upper deflection rollers 65, which are each attached to an upright support arm 66. These in turn are connected to a lower common support frame 67 for both suction belts 63, 64.

- Lower guide rollers for the suction belts 63, 64 are also mounted on the support frame 67, namely drive rollers 68. These sit on a common drive shaft 69 which are driven by a belt 70.

- the suction belts 63, 64 of the vertical conveyor 62 are a continuation of the suction belts 44 with regard to the transport of the material web 30, 60 or the banderoles 17, 18.

- the vertical conveyor 62 can be moved up and down as a unit, in the present case by a pivotable lever 71

- the carrying frame 67 is slidably mounted on two upright guide rods 72, 73 for carrying out exact vertical movements.

- the deflection rollers 65 of the vertical conveyor 62 enter the area between the suction belts 44 of the vertical belt leg 61 which are spaced apart from one another. There is an overlap of the funding bodies.

- the vertical conveyor 62 takes over the front end of the material web 30, 60 or the banderole 17, 18 and transports it downwards in the vertical plane. Simultaneously with the transport movement through the suction belts 63, 64, the vertical conveyor 62 is moved downward as a whole to a position below the movement path of the object groups 33, namely to a position as shown in solid lines in FIG. 16. This keeps the blank for the band 17, 18 free in the vertical plane.

- the group of objects 33 can now be pushed through the "curtain" formed by the band 17, 18 to form the U-shaped fold.

- the downward movement of the vertical conveyor 62 is primarily necessary because the suction belts 63, 64 are at a smaller distance from one another than the width of the group of articles 33.

- the vertical conveyor 62 After pushing through the item group 33, taking the banderole 17, 18 with it, the vertical conveyor 62 returns to the upper starting position (FIG. 16) in order to pick up the beginning of the material web 30, 60 or the banderole 17, 18.

- the banderole unit 42, 58 also includes the folding and sealing members 55, 56 already mentioned. These carry out the folding and sealing and thus the completion of the banderole on the back of the group of objects 33 in the manner described.

- a further development of the packagings according to FIGS. 5 and 6 is to connect the bands 17, 18, on the one hand, and 19, 20, on the other hand, that cross each other in the area of the intersection.

- a plurality of parallel sealing seams 74 and 75 are provided in the region of mutually overlapping surfaces of the banderoles, so that the banderole 17 is connected to the banderole 18 and the banderole 19 is connected to the banderole 20.

- the sealing seams 74 and 75 are expediently located in the area of depressions between adjacent cylindrical objects. Said sealing seams 74, 75 can be produced by sealing elements from outside with low pressure after completion of the packaging for connecting the two layers of the bands 17..20.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Packages (AREA)

- Supplying Of Containers To The Packaging Station (AREA)

- Basic Packing Technique (AREA)

- Auxiliary Devices For And Details Of Packaging Control (AREA)

- Containers And Plastic Fillers For Packaging (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19616153A DE19616153A1 (de) | 1996-04-23 | 1996-04-23 | Gebindeverpackung sowie Verfahren und Vorrichtung zum Herstellen derselben |

| DE19616153 | 1996-04-23 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0803446A2 true EP0803446A2 (fr) | 1997-10-29 |

| EP0803446A3 EP0803446A3 (fr) | 1998-04-15 |

| EP0803446B1 EP0803446B1 (fr) | 2003-09-10 |

Family

ID=7792182

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97105082A Expired - Lifetime EP0803446B1 (fr) | 1996-04-23 | 1997-03-26 | Ensemble d'emballage ainsi qu'un procédé et un dispositif pour le réaliser |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US6021890A (fr) |

| EP (1) | EP0803446B1 (fr) |

| AT (1) | ATE249373T1 (fr) |

| DE (2) | DE19616153A1 (fr) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2013004341A1 (fr) * | 2011-07-05 | 2013-01-10 | Khs Gmbh | Emballage multiple et son procédé de réalisation |

| WO2013004339A1 (fr) * | 2011-07-05 | 2013-01-10 | Khs Gmbh | Emballage multiple et procédé de réalisation d'un tel emballage multiple |

| EP2635505A4 (fr) * | 2010-11-04 | 2014-06-25 | Georgia Pacific Consumer Prod | Systèmes, procédés et appareil faisant intervenir un emballage |

| WO2018114560A3 (fr) * | 2016-12-23 | 2018-09-07 | Sig Technology Ag | Système d'emballage et procédé de production d'une unité d'emballage, et unité d'emballage constituée d'enveloppes d'emballage et d'un emballage extérieur |

Families Citing this family (48)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BR9912394A (pt) | 1998-07-24 | 2001-04-24 | Pulsar Srl | Aparelho e método para transferência de itens |

| IT1320899B1 (it) * | 2000-02-25 | 2003-12-10 | Pulsar Srl | Impianto per il trattamento di articoli e apparato di convogliamentodegli articoli utilizzabile in detto impianto. |

| IT1317159B1 (it) * | 2000-04-04 | 2003-05-27 | Decopack S R L | Metodo per l'affardellamento di contenitori per alimenti inparticolare per bottiglie |

| DE10034093A1 (de) * | 2000-07-13 | 2002-01-24 | Bosch Gmbh Robert | Verfahren zum Herstellen einer Sammelpackung |

| DE60117911T2 (de) * | 2000-12-20 | 2006-12-21 | Tissue Machinery Co. S.P.A. | Verfahren und Vorrichtung zum Verpacken von Stapeln von Papier oder dergleichen in einer Umhüllungsfolie |

| ITBO20020392A1 (it) * | 2002-06-18 | 2003-12-18 | Tmc Spa | Metodo ed apparato per il confezionamento di pacchi di rotoli di carta con relativa impugnatura di presa |

| ITBO20030210A1 (it) * | 2003-04-10 | 2004-10-11 | Tissue Machinery Co Spa | Confezione di rotoli ottenuta con una macchina avvolgitrice |

| DE10317392A1 (de) * | 2003-04-15 | 2004-11-04 | Saint-Gobain Isover G+H Ag | Großgebinde für Transport und Lagerung von Dämmstoffelementen sowie Module aus Dämmstoffelementen hierfür |

| BE1015523A3 (fr) | 2003-05-22 | 2005-05-03 | Knauf Insulation S A | Paquets de rouleaux et leur procede de fabrication. |

| US20060191426A1 (en) * | 2003-06-03 | 2006-08-31 | Lee Timmerman | Bundled printed sheets |

| WO2004108428A2 (fr) * | 2003-06-03 | 2004-12-16 | Precision Press, Inc | Feuilles imprimees en liasse |

| US20050121348A1 (en) * | 2003-12-09 | 2005-06-09 | Clare Timothy P. | Package insert and stackable package for articles |

| ITBO20050618A1 (it) * | 2005-10-14 | 2007-04-15 | Tmc Tissue Machinery Company Spa | Sovra confezione per gruppi di prodotti in rotolo confezionati |

| US20070141208A1 (en) * | 2005-12-15 | 2007-06-21 | Kimberly-Clark Worldwide, Inc. | Carrier for consumable products |

| US7621397B2 (en) * | 2005-12-15 | 2009-11-24 | Kimberly-Clark Worldwide, Inc. | Packaging configurations for consumable products |

| US7721887B2 (en) * | 2005-12-15 | 2010-05-25 | Kimberly-Clark Worldwide, Inc. | Package for consumable products with separately sealed compartments |

| US8443974B2 (en) * | 2006-04-19 | 2013-05-21 | Zinus, Inc. | Rolled memory foam bedding article having a plurality of roll portions |

| US20080041755A1 (en) * | 2006-08-18 | 2008-02-21 | Kristine Gail Noschang | Package assembly with product feature display area |

| US7987984B2 (en) * | 2006-09-26 | 2011-08-02 | The Procter & Gamble Company | Method of marketing for absorbent paper products through branded print packaging |

| US20080078685A1 (en) * | 2006-09-29 | 2008-04-03 | Patterson Ryan M | Efficient tissue roll configurations |

| USD574721S1 (en) * | 2006-10-23 | 2008-08-12 | The Procter & Gamble Company | Package for rolls of paper towels |

| US20080245491A1 (en) * | 2007-02-23 | 2008-10-09 | Thorsten Knobloch | Array of sanitary tissue products |

| US9242775B2 (en) * | 2007-02-23 | 2016-01-26 | The Procter & Gamble Company | Array of sanitary tissue products |

| US9327888B2 (en) | 2007-02-23 | 2016-05-03 | The Procter & Gamble Company | Array of sanitary tissue products |

| US20080245693A1 (en) * | 2007-04-04 | 2008-10-09 | Kenneth Douglas Vinson | Sanitary tissue product roll |

| US20090056891A1 (en) * | 2007-08-31 | 2009-03-05 | Kevin Mitchell Wiwi | Array of paper towel products |

| US20100038265A1 (en) * | 2007-12-06 | 2010-02-18 | Noel Mathey Geoffroy | Display assembly of folded rolled paper products |

| CA2708270A1 (fr) * | 2007-12-06 | 2009-06-18 | The Procter & Gamble Company | Ensemble de presentation de produits papetiers enroules et plies |

| EP2096039A1 (fr) * | 2008-02-26 | 2009-09-02 | Nestec S.A. | Ensemble d'emballage renforcé |

| USD636273S1 (en) * | 2008-09-12 | 2011-04-19 | Kimberly-Clark Worldwide, Inc. | Double roll package |

| ATE493346T1 (de) * | 2009-01-13 | 2011-01-15 | Ursa Insulation Sa | Verpackung für mineralwolleprodukte, module zum formen einer solchen verpackung und herstellungsverfahren für eine solche verpackung |

| WO2012061570A1 (fr) * | 2010-11-05 | 2012-05-10 | Dsg International Limited | Emballage d'articles personnels par paquets entourés de bandes |

| US20130067864A1 (en) * | 2011-09-20 | 2013-03-21 | Michael Scott Dwyer | Packaging a Product Bundle |

| US9637252B2 (en) * | 2012-08-01 | 2017-05-02 | Right/Pointe, Llc | Sealant packaging and method |

| WO2015130305A1 (fr) * | 2014-02-28 | 2015-09-03 | Kimberly-Clark Worldwide, Inc. | Produits du type mouchoirs en papier emballés |

| WO2016172277A1 (fr) | 2015-04-24 | 2016-10-27 | 3M Innovative Properties Company | Compositions d'adhésif acrylique et rubans adhésifs acryliques permettant un retrait propre de surfaces délicates |

| DE102016105806A1 (de) * | 2016-03-30 | 2017-10-19 | Krones Ag | Verfahren und Vorrichtung zum Bilden von Behältniszusammenstellungen |

| DE102016105807A1 (de) * | 2016-03-30 | 2017-10-19 | Krones Ag | Verfahren und Vorrichtung zum Bilden von Behältniszusammenstellungen |

| WO2017189871A1 (fr) | 2016-04-28 | 2017-11-02 | H.B. Fuller Company | Palette à paquets empilés |

| US11059614B2 (en) * | 2016-08-29 | 2021-07-13 | Johns Manville | Insulation packaging system |

| CA3060180A1 (fr) | 2018-10-26 | 2020-04-26 | The Procter & Gamble Company | Rouleaux de papier hygienique |

| CA3060211C (fr) | 2018-10-26 | 2025-05-13 | The Procter & Gamble Company | Rouleaux de papier hygiénique |

| CA3060193C (fr) | 2018-10-26 | 2023-05-09 | The Procter & Gamble Company | Rouleaux d`essuie-tout |

| CA3060185A1 (fr) | 2018-10-26 | 2020-04-26 | The Procter & Gamble Company | Rouleaux de papier hygienique |

| DE102020101934A1 (de) | 2020-01-28 | 2021-07-29 | Krones Aktiengesellschaft | Verpackungseinheit, Verfahren zur Herstellung von Verpackungseinheiten und Verpackungsvorrichtung |

| DE112022004023T5 (de) * | 2021-10-22 | 2024-06-20 | Illinois Tool Works Inc. | Banderoliereinheit, verpackungsmaschine mit einer banderoliereinheit und verfahren zum banderolieren eines produkts oder einer produktgruppe |

| JP2024011993A (ja) * | 2022-07-15 | 2024-01-25 | 大王製紙株式会社 | 集合包装体 |

| US20240076077A1 (en) * | 2022-08-31 | 2024-03-07 | The Procter & Gamble Company | Sanitary tissue product packages and arrays comprising shoulder area ratio(s) |

Family Cites Families (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2062539A (en) * | 1934-05-03 | 1936-12-01 | Girdler Corp | Comestible package |

| US2566385A (en) * | 1947-01-22 | 1951-09-04 | Ernest W Van Patten | Packaged unit for article handling |

| US2741885A (en) * | 1952-12-08 | 1956-04-17 | Gen Mills Inc | Banding with thermoplastic |

| DE1586924A1 (de) * | 1967-04-12 | 1970-10-22 | Schwaben Nudelwerke B Birkel S | Versandpackung,insbesondere fuer Teigwaren |

| US3447675A (en) * | 1967-07-13 | 1969-06-03 | Reynolds Metals Co | Package construction and method of making the same or the like |

| US3460671A (en) * | 1967-08-02 | 1969-08-12 | Procter & Gamble | Package for cylindrical articles or objects |

| US3515272A (en) * | 1968-03-27 | 1970-06-02 | John C Von Gal | Container cluster |

| FR1590202A (fr) * | 1968-10-11 | 1970-04-13 | ||

| US3568591A (en) * | 1969-01-10 | 1971-03-09 | Ambassador College | Automatic tying apparatus |

| US4079566A (en) * | 1972-03-09 | 1978-03-21 | The Procter & Gamble Company | Method of forming unitized modular loads |

| US3902992A (en) * | 1973-05-04 | 1975-09-02 | Coors Co Adolph | Multi-container package |

| NL7414099A (nl) * | 1973-11-24 | 1975-05-27 | Kronseder Hermann | Werkwijze voor het verpakken van etiketten en met die werkwijze verkregen eenheid van ver- pakking. |

| US3906591A (en) * | 1974-07-30 | 1975-09-23 | Boiardi Products Corp | Bridging clip for metal or plastic banding |

| FR2286763A1 (fr) * | 1974-10-03 | 1976-04-30 | Unisabi Sa | Procede d'emballage d'un groupe de recipients |

| US4075815A (en) * | 1976-04-30 | 1978-02-28 | Franklin Electric Subsidiaries, Inc. | Automatic package wrapping machine |

| GB1589778A (en) * | 1976-10-29 | 1981-05-20 | Starpak Pty Ltd | Wrapping apparatus and a method of wrapping |

| FR2460862A1 (fr) * | 1979-07-09 | 1981-01-30 | Saint Gobain | Fardeau de rouleaux de materiaux compressibles |

| US4596330A (en) * | 1981-08-10 | 1986-06-24 | Benno Edward L | Multipackages, the packaging elements, and the method for making the multipackages |

| IT1169175B (it) * | 1983-02-23 | 1987-05-27 | Gambetti Mario Baumer | Macchina per imballare articoli in movimento continuo con un nastro di materiale termorestringibile |

| SE468711B (sv) * | 1987-01-02 | 1993-03-08 | Andersson Claes Goeran | Foerpackning, innefattande ett banderolliknande foerpackningshoelje, jaemte ett foerfarande och en anordning foer framstaellning av en dylik foerpackning |

| NZ225305A (en) * | 1987-07-10 | 1990-09-26 | Mead Corp | Container multipack: encircling elastic band |

| US4886167B1 (en) * | 1989-04-14 | 1991-06-11 | Compact,core-wound paper product | |

| DE4120925A1 (de) * | 1991-06-25 | 1993-01-07 | Hansa Anlagenbau Gmbh & Co Kg | Gebinde aus brennmaterialien in brikettform |

| TW201327B (fr) * | 1991-07-19 | 1993-03-01 | Minnesota Mining & Mfg | |

| DE4138138C2 (de) * | 1991-10-19 | 2003-06-12 | Focke & Co | Vorrichtung zum Herstellen von Großpackungen |

| IT1253890B (it) * | 1991-11-20 | 1995-08-31 | Gd Spa | Confezione multipla di prodotti singoli, in particolare di pacchetti di sigarette |

| EP0612661A1 (fr) * | 1993-02-25 | 1994-08-31 | ROSENBERG GmbH & Co. | Dispositif pour la fabrication d'un emballage de transport |

| JPH082548A (ja) * | 1994-06-21 | 1996-01-09 | Heisei Polymer Co Ltd | 結束テープ、結束方法および結束物 |

| DE9412648U1 (de) * | 1994-08-05 | 1994-09-29 | Merz Verpackungsmaschinen GmbH, 35423 Lich | Sammelpackung mit Stickpacks (Kleinstschlauchbeutel) |

-

1996

- 1996-04-23 DE DE19616153A patent/DE19616153A1/de not_active Withdrawn

-

1997

- 1997-03-26 DE DE59710708T patent/DE59710708D1/de not_active Expired - Fee Related

- 1997-03-26 EP EP97105082A patent/EP0803446B1/fr not_active Expired - Lifetime

- 1997-03-26 AT AT97105082T patent/ATE249373T1/de not_active IP Right Cessation

- 1997-04-07 US US08/838,439 patent/US6021890A/en not_active Expired - Fee Related

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2635505A4 (fr) * | 2010-11-04 | 2014-06-25 | Georgia Pacific Consumer Prod | Systèmes, procédés et appareil faisant intervenir un emballage |

| US9708085B2 (en) | 2010-11-04 | 2017-07-18 | Georgia-Pacific Consumer Products Lp | Systems, methods, and apparatus involving packaging |

| US9821923B2 (en) | 2010-11-04 | 2017-11-21 | Georgia-Pacific Consumer Products Lp | Method of packaging product units and a package of product units |

| US10427813B2 (en) | 2010-11-04 | 2019-10-01 | Gpcp Ip Holdings Llc | Methods of packaging products and packaging arrangements using a shrinkable protective cover to keep a graphic on a band formed, intact, and visible |

| WO2013004341A1 (fr) * | 2011-07-05 | 2013-01-10 | Khs Gmbh | Emballage multiple et son procédé de réalisation |

| WO2013004339A1 (fr) * | 2011-07-05 | 2013-01-10 | Khs Gmbh | Emballage multiple et procédé de réalisation d'un tel emballage multiple |

| CN103648915A (zh) * | 2011-07-05 | 2014-03-19 | Khs有限责任公司 | 装填件和用于制造这种装填件的方法 |

| WO2018114560A3 (fr) * | 2016-12-23 | 2018-09-07 | Sig Technology Ag | Système d'emballage et procédé de production d'une unité d'emballage, et unité d'emballage constituée d'enveloppes d'emballage et d'un emballage extérieur |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE249373T1 (de) | 2003-09-15 |

| EP0803446A3 (fr) | 1998-04-15 |

| DE19616153A1 (de) | 1997-10-30 |

| EP0803446B1 (fr) | 2003-09-10 |

| DE59710708D1 (de) | 2003-10-16 |

| US6021890A (en) | 2000-02-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0803446B1 (fr) | Ensemble d'emballage ainsi qu'un procédé et un dispositif pour le réaliser | |

| EP0424991B1 (fr) | Procédé et dispositif d'emballage d'objets | |

| EP2544958B1 (fr) | Paquet pour cigarettes | |

| DE19838076B4 (de) | Verfahren und Vorrichtung zum Herstellen von (Groß-)Packungen | |

| EP2477907B1 (fr) | Emballages, en particulier de cigarettes, et procédé et dispositif pour leur fabrication | |

| DE4035352C2 (de) | Vorrichtung zum Herstellen von Schachteln mit Klappdeckel und Kragen und zum Befüllen dieser Schachteln | |

| DE3789113T2 (de) | Packung mit einer banderolenartigen hülle sowie verfahren und anordnung zum herstellen einer derartigen packung. | |

| EP1067049B1 (fr) | Procédé et dispositif pour la fabrication de paquets | |

| DE102009058589A1 (de) | Aromatisierte Zigarettenpackung und Verpackungsmaschine zur Herstellung einer derartigen Zigarettenpackung | |

| DE4207759A1 (de) | Maschine zur verpackung von gegenstaenden mit waermeschrumpfbarem material | |

| EP0141351B1 (fr) | Dispositif pour envelopper des paquets dans une feuille étirable | |

| DE10310451A1 (de) | Verfahren und Vorrichtung zum Herstellen von Verpackungen aus wenigstens zwei Teilpackungen | |

| DE2322377A1 (de) | Verfahren zum verpacken von gegenstaenden und maschine zur durchfuehrung des verfahrens | |

| EP0854098B1 (fr) | Emballage pour un groupe de paquets de cigarettes et dispositif pour la fabrication de flans correspondants | |

| DE2507843B2 (de) | Verpackung für Eier mit einem Wellenband aus Karton o.dgl. und Verfahren zu seiner Herstellung | |

| DE10203459A1 (de) | Verfahren und Vorrichtung zum Herstellen von Gebindepackung für Zigaretten | |

| EP0174591A2 (fr) | Dispositif pour fabriquer des emballages, en particulier cartouches de cigarettes | |

| DE69205482T2 (de) | Verfahren zum Verpacken von Gegenständen. | |

| EP2371527B1 (fr) | Procédé et dispositif de fabrication de sachets (de tabac) | |

| DE4023025A1 (de) | Vorrichtung zum gruppenweisen verpacken von produkten in schachteln | |

| DE69100691T2 (de) | Verfahren und Vorrichtung zum selbsttätigen Einwickeln von zylindrischen Gegenständen, insbesondere Kunststoffspülen. | |

| DE60106034T2 (de) | Verfahren zum verpacken von zigaretten in weichpackungen sowie die erhaltene weichpackung | |

| EP0109353B1 (fr) | Procédé de fabrication d'un emballage en matière flexible | |

| DE69003154T2 (de) | Verfahren zum Verpacken von Büchern. | |

| DE4225876A1 (de) | Packaufnahme und Verfahren sowie Vorrichtung zur Herstellung mindestens einer Packaufnahme für langgestreckte Gegenstände |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE ES FR GB IT LI NL |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE FR GB IT NL |

|

| 17P | Request for examination filed |

Effective date: 19981006 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT BE CH DE ES FR GB IT LI NL |

|

| 17Q | First examination report despatched |

Effective date: 20020628 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB IT LI NL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20030910 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59710708 Country of ref document: DE Date of ref document: 20031016 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20031221 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20031215 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040326 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040331 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040331 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20040614 |

|

| BERE | Be: lapsed |

Owner name: *FOCKE & CO. G.M.B.H. & CO. Effective date: 20040331 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20080326 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20080311 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20080328 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20090321 Year of fee payment: 13 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20090326 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20091130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090326 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091123 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20101001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090326 |