EP0572352A1 - Parking automatique à étages multiples - Google Patents

Parking automatique à étages multiples Download PDFInfo

- Publication number

- EP0572352A1 EP0572352A1 EP93810351A EP93810351A EP0572352A1 EP 0572352 A1 EP0572352 A1 EP 0572352A1 EP 93810351 A EP93810351 A EP 93810351A EP 93810351 A EP93810351 A EP 93810351A EP 0572352 A1 EP0572352 A1 EP 0572352A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- parking

- transport

- entrance

- parking garage

- inner shaft

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 230000005855 radiation Effects 0.000 claims description 2

- 238000010276 construction Methods 0.000 abstract description 7

- 230000007306 turnover Effects 0.000 abstract description 4

- 238000000034 method Methods 0.000 description 3

- 235000004443 Ricinus communis Nutrition 0.000 description 1

- 240000000528 Ricinus communis Species 0.000 description 1

- 208000012886 Vertigo Diseases 0.000 description 1

- 238000009435 building construction Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000000151 deposition Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 230000002787 reinforcement Effects 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

- 238000009423 ventilation Methods 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04H—BUILDINGS OR LIKE STRUCTURES FOR PARTICULAR PURPOSES; SWIMMING OR SPLASH BATHS OR POOLS; MASTS; FENCING; TENTS OR CANOPIES, IN GENERAL

- E04H6/00—Buildings for parking cars, rolling-stock, aircraft, vessels or like vehicles, e.g. garages

- E04H6/08—Garages for many vehicles

- E04H6/12—Garages for many vehicles with mechanical means for shifting or lifting vehicles

- E04H6/18—Garages for many vehicles with mechanical means for shifting or lifting vehicles with means for transport in vertical direction only or independently in vertical and horizontal directions

- E04H6/28—Garages for many vehicles with mechanical means for shifting or lifting vehicles with means for transport in vertical direction only or independently in vertical and horizontal directions characterised by use of turntables or rotary rings for horizontal transport

- E04H6/282—Garages for many vehicles with mechanical means for shifting or lifting vehicles with means for transport in vertical direction only or independently in vertical and horizontal directions characterised by use of turntables or rotary rings for horizontal transport turntables, rotary elevators or the like on which the cars are not permanently parked

Definitions

- Such a parking garage is e.g. known from the Swiss patent CH-A5-649 340.

- parking garages or underground garages are known in which vehicles can be parked close to one another on several parking levels. In such parking garages or underground garages, it is common for the vehicles to be driven under their own power via suitable access routes to the respective parking lot.

- This type of parking is associated with various disadvantages: On the one hand, the access and departure routes take up a considerable amount of additional space, so that fewer parking spaces can be identified with the same construction volume. On the other hand, because of the exhaust gases, extensive ventilation systems are required, which make the park system extremely expensive and also take up more space. In addition, such systems must be publicly accessible, which on the one hand endangers the parked cars with regard to theft or damage, but on the other hand also endangers people, especially women.

- Such a parking garage is described in the publication cited at the beginning.

- a large number of parking boxes or individual parking spaces are arranged in a radiation pattern around a cylindrical shaft on different parking levels.

- An elevator device with a rotatable lifting platform is provided in the shaft, which has two rotating positions for receiving vehicles. By vertically shifting or rotating the platform around a central axis, all parking boxes can be reached with the turning stations.

- the two rotary stations are arranged parallel to each other on both sides of the central axis and shifted in their longitudinal direction against each other, so that their longitudinal axis deviates significantly from the radial direction.

- the parking boxes of each parking level are arranged inclined to each other so that their longitudinal axes can be aligned with the longitudinal axes of the turning stations.

- the parking boxes on each level are divided into two halves, whereby each of the halves can only be controlled from one turning station due to the different inclination.

- the construction of the parking garage is relatively complex.

- the distribution of vehicles is comparatively slow because there can only be two turning spaces and only one turning space is available for half of the parking boxes on one level. No further details are given about the transshipment device required for reloading vehicles between the turning stations and the parking boxes.

- Another automatic parking garage is known from the document DE-A1-38 31 463.

- the parking boxes are arranged radially;

- a combined lifting and rotating device is also provided for the distribution of the vehicles, although this is only available for a single transport station poses.

- the transport lift is loaded and unloaded by means of an auxiliary vehicle on which the vehicle to be parked is placed. Since the transport lift can only bring or pick up one vehicle at a time, such a parking garage does not meet the requirements for quick parking and unloading.

- the use of auxiliary trolleys also requires special devices for guiding the trolley in all parking boxes, which causes considerable technical effort.

- a transfer device which travels along the side of the vehicle and pulls the vehicle into the lift on one of the front wheels or pushes it out of the lift into a parking box. Because of the external position of the transfer device, additional space is required. In addition, this transfer device only attacks on one side of the vehicle, which leads to an uneven load on the chassis.

- the task is solved in a parking garage of the type mentioned in that (c) the transport surfaces as well as the parking boxes and the at least one entrance and exit are arranged radially starting from the central axis.

- the essence of the invention is to align and arrange the individual parking boxes strictly radially on the parking levels and the lift mechanism.

- the storage silo can be set up particularly easily because the parking boxes do not have to be arranged in an inclined manner in a special way.

- several transport areas preferably four, can be provided for the vehicles because the star-shaped arrangement creates more space.

- the individual parking boxes can be approached from all transport areas in the same way, since the structure is highly symmetrical and all boxes are equivalent to one another.

- the connection between a transport surface and a parking box is particularly simple because the opposite edges are at a particularly small distance from one another due to the radial alignment.

- the transport surfaces can be moved in different ways: According to a first preferred embodiment of the invention, the transport surfaces are arranged on a common transport platform and are moved or rotated together vertically by vertical movement or rotation of the transport platform.

- the transport surfaces can be moved vertically independently of one another by means of assigned individual lifts, the individual lifts being arranged on a common turntable which can be rotated about the central axis.

- a further preferred embodiment of the invention is characterized in that on each of the transport surfaces a pulling device working in the radial direction for pulling a vehicle out of the at least one driveway or a parking box onto the transport surface or for pushing a vehicle down from the transport surface into the at least one an exit or a parking box is arranged.

- Such a pulling device makes it possible to make do with a minimum of mechanically movable parts in the parking garage, because neither any pallets, containers or other movable platforms with the correspondingly necessary rails or guides have to be provided in a multitude corresponding to the parking boxes, nor the vehicles themselves on such Transport vehicles must be positioned.

- the pulling device rather moves the vehicle to be parked on its own wheels and thus effectively avoids unnecessary technical effort.

- guides for the wheels of an entering vehicle are provided in the at least one entrance, such that when entering the at least one entrance, a vehicle is forcibly aligned in the radial direction in such a way that it can be securely gripped by the pulling device on one of the transport surfaces when this transport surface is brought into connection with the at least one entrance.

- each vehicle is aligned to the pulling device in the same way and can then be pulled onto the transport platform without problems.

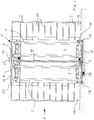

- FIG. 1 the internal structure of an automatic parking garage according to a first preferred embodiment of the invention is shown in longitudinal section.

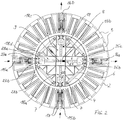

- the associated plan view at the lowest parking level is shown in FIG. 2, the same parts being provided with the same reference numerals.

- the exemplary embodiment relates to a building construction, i.e. a multi-storey building that extends upwards from the flat ground.

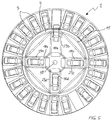

- the parking garage (as in the example in FIG. 3) as an underground car park sunk into the floor.

- the multi-storey car park 1 essentially comprises a storage silo 2 with an annular floor plan, which on a plurality of parking levels 20 contains a large number of parking boxes 3 stacked side by side and one above the other, each of which can accommodate a vehicle for parking.

- the parking boxes 3 are elongated and are arranged with their longitudinal axis radially to a central axis 21 of the building. They surround you in a star shape cylindrical inner shaft 4, in which a conveyor device 5 for transporting the vehicles from an entrance 15 to the parking boxes 3 or from the parking boxes 3 to an exit 16 is accommodated.

- the conveyor 5 itself consists of a transport platform 6, which comprises a total of four transport surfaces 18a to 18d, starting from the central axis 21 and rotated by 90 ° with respect to one another, on which vehicles can be transported (in FIG. 1, the transport platform 6 is twice, namely in their lower and upper limit, shown).

- the transport surfaces 18a-d are connected to one another by lattice-like struts and thus form a stable platform which is mounted and guided displaceably on a plurality of guide columns 7 in the vertical direction.

- the guide columns 7 are arranged in pairs on both sides on the outer edge of a transport surface 18a-d.

- the (in the example of FIGS. 1 and 2) a total of eight guide columns 7 (two per transport surface 18a-d) are rigidly fixed with their lower end on a turntable 11, and with their upper end under a bearing plate 26.

- the turntable 11 is in turn rotatably mounted on the bottom of the inner shaft 4 by means of rollers 12 running on rails.

- the turntable 11 is driven by a (for example electrical) turntable drive 13, the drive gear of which engages in an opposing ring gear.

- the rotary table drive 13 can - as shown in Fig.

- the ring gear 1 - be arranged stationary in a recess in the bottom of the inner shaft 4; in this case, the ring gear is attached to the underside of the turntable 11. However, it can also directly on the turntable because of a possible floor sump 11 attached; the ring gear is provided on the bottom of the inner shaft 4 in this case.

- the transport platform 6 with its transport surfaces 18a-d can be moved both vertically and rotated about the central axis, so that each of the parking boxes 3 can be reached with each of the transport surfaces 18a-d.

- the vertical movement along the guide columns 7 is preferably accomplished by a lift unit 8 placed in the middle between the transport surfaces 18a-d on the transport platform.

- the lift unit 8 contains an electrically driven cable winch 9 with a cable drum on which a support cable 10 can be wound, which is attached at its other end to the transport platform 6 and is guided in the manner of a pulley block via a deflection roller arranged under the bearing plate 26.

- the guide columns 7 are hollow on the inside, they can accommodate such free-running counterweights in a space-saving manner, which are then connected to the transport platform 6 by means of corresponding cables running over deflection rollers attached to the upper end of the guide columns 7.

- a pulling device 19 is provided on each of the transport surfaces 18a-d, which pulls the vehicle to be transported out of one of the entrances 15a, b or a parking box 3 onto the adjoining transport surface, or from the transport surface in pushes exits 16a, b or into a parking box 3.

- the pulling or pushing happens completely automatically without the help of a driver.

- Each pulling device 19 comprises a slide 22 which is slidably arranged on a guide rail 24 running in the longitudinal direction of the transport surface 18a-d.

- the carriage 22 has, on its side facing the parking boxes 3 or entrances and exits 15a, b or 16a, b, two mutually parallel, tangentially displaceable gripping arms 23a, b, which are provided with rollers 25a, b at their hook-shaped ends are.

- the gripper arms 23a, b are first moved towards one another transversely to the longitudinal axis of the transport surface 18a-d until they are so close together that the carriage 22 can be securely pushed with them between the front wheels of the vehicle to be pulled.

- the carriage 22 is then pushed with the gripping arms 23a, b pushed together under the vehicle until the gripping arms 23a, b can reach behind the front wheels of the vehicle with their hook-shaped ends.

- the gripper arms 23a, b are then moved apart, so that the rollers 25a, b attached to the inside of their ends lie against the tread of the front wheels.

- the gripping arms 23a, b pull the vehicle on the front wheels out of the parking box or driveway onto the abutting transport surface 18a-d.

- the carriage 22 itself pushes the vehicle on its front wheels. So that the wheels can roll freely in this case, 22 corresponding rollers 28a, b are provided on the outside of the carriage

- guides 17 are attached to the floor in pairs for each wheel side, at least in the box-like entrances 15a, b, with the aid of which even an inexperienced driver can be installed Align vehicle in the driveway with the pulling device.

- Such guides 17 can also - as shown in FIG. 2 - in the individual parking boxes 3 for safety are provided, but are generally not necessary there.

- automatic sliding doors are also arranged in the entrances 15a, b, which close the entrances 15a, b to the inner shaft 4 until the parking driver has left his vehicle and the entrance box.

- foldable elements are provided at the outer end of each transport surface 18a-d in the manner of a bascule bridge, which, when the respective transport surface is to be connected to a parking box 3 for pulling out or pushing in a vehicle, are folded out in order to bridge the space between the transport surface and the parking level .

- the symmetrical and uniform arrangement of the parking boxes 3 makes it possible to create the storage silo from 2 prefabricated boxes or prefabricated parts, which reduces construction time and construction costs and enables a modular construction with corresponding expansion options.

- the individual lifts 29a, b make it possible to park or pick up vehicles at different parking levels 20 at a specific position of the turntable, which leads to a further increase in vehicle sales.

- the individual lifts 19a, b are here also guided in the vertical direction by means of guide columns 7, the guide columns 7 being arranged in pairs on both sides at the front and rear ends of the transport surface (FIG. 5).

- the transport surfaces can also be equipped with corresponding pulling devices, as have already been described above in connection with FIG. 2.

- FIG. 3 is an underground garage embedded in the floor.

- FIG. 5 shows the top view of the upper parking level (with entrances and exits 15a, b or 16a, b) of an underground parking garage according to FIG. 3, only two opposite individual lifts 29a, b with corresponding transport surfaces 18a, b provided.

- FIG. 5 shows the top view of the upper parking level (with entrances and exits 15a, b or 16a, b) of an underground parking garage according to FIG. 3, only two opposite individual lifts 29a, b with corresponding transport surfaces 18a, b provided.

- FIG. 5 shows the top view of the upper parking level (with entrances and exits 15a, b or 16a, b) of an underground parking garage according to FIG. 3, only two opposite individual lifts 29a, b with corresponding transport surfaces 18a, b provided.

- FIG. 5 shows the top view of the upper parking level (with entrances and exits 15a, b or 16a, b) of an underground parking garage according to FIG. 3, only two opposite individual lifts 29a, b with corresponding transport

- the invention results in an automatic parking garage which is space-saving, safe, easy to set up and can be operated with short turnover times.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Mechanical Engineering (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Warehouses Or Storage Devices (AREA)

- Soil Working Implements (AREA)

- Catching Or Destruction (AREA)

- Devices For Conveying Motion By Means Of Endless Flexible Members (AREA)

- Magnetically Actuated Valves (AREA)

- Liquid Crystal (AREA)

- Sanitary Device For Flush Toilet (AREA)

- Filling Or Emptying Of Bunkers, Hoppers, And Tanks (AREA)

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH1735/92 | 1992-05-29 | ||

| CH173592 | 1992-05-29 | ||

| CH3483/92 | 1992-11-11 | ||

| CH348392A CH686896A5 (de) | 1992-11-11 | 1992-11-11 | Automatisches Parkhaus. |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0572352A1 true EP0572352A1 (fr) | 1993-12-01 |

| EP0572352B1 EP0572352B1 (fr) | 1999-01-20 |

Family

ID=25688521

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93810351A Expired - Lifetime EP0572352B1 (fr) | 1992-05-29 | 1993-05-13 | Parking automatique à étages multiples |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US5478182A (fr) |

| EP (1) | EP0572352B1 (fr) |

| JP (1) | JPH0642219A (fr) |

| AT (1) | ATE176025T1 (fr) |

| CA (1) | CA2096982A1 (fr) |

| DE (1) | DE59309318D1 (fr) |

| NO (1) | NO304495B1 (fr) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1996008624A1 (fr) * | 1994-09-16 | 1996-03-21 | Friedrich Maurer Söhne Gmbh & Co. Kg | Installation de reception, de stockage intermediaire et de sortie d'objets mobiles |

| WO1996008643A1 (fr) * | 1994-09-16 | 1996-03-21 | Electric Power Research Institute, Inc. | Methode et systeme d'alimentation en gazole vaporise d'une chambre de combustion de turbine |

| DE4444257A1 (de) * | 1994-12-13 | 1996-06-20 | Rudi Strobel | Parkhaus für automatisches Einparken |

| DE19746390A1 (de) * | 1997-10-21 | 1999-04-22 | Siemens Ag | Fahrzeug-Hochregallager, insbesondere Parkhaus |

| CN102242572A (zh) * | 2010-05-14 | 2011-11-16 | 马邕勤 | 移动载车设备 |

| CN102345403A (zh) * | 2011-08-12 | 2012-02-08 | 鞍山钢制压力容器有限公司 | 一种液压升降大型立体自动停车库 |

| CN106013897A (zh) * | 2016-05-25 | 2016-10-12 | 北京宏地车港科技有限公司 | 一种机械立体停车库存取车方法及其系统 |

| CN106049940A (zh) * | 2016-08-05 | 2016-10-26 | 陈辉敏 | 一种新型立体停车库 |

Families Citing this family (38)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH684203A5 (de) * | 1993-07-15 | 1994-07-29 | Jacek Wagner | Zylinderförmiges Parkhaus mit einem zentralen zylinderförmigen Innenschacht und voneinander unabhängigen Autofördereinrichtungen. |

| US5864995A (en) * | 1994-03-17 | 1999-02-02 | Buch; Hermann S. | Storage structure in particular a multi-story car park |

| US5863172A (en) * | 1997-02-07 | 1999-01-26 | Computer Aided Systems, Inc. | Staging, tracking and retrieval system with a rotatable storage structure |

| US6212832B1 (en) * | 1997-05-30 | 2001-04-10 | Zhuangmei Gao | Silo structure of vehicle parking system |

| US5980185A (en) * | 1997-07-30 | 1999-11-09 | Vita Auto Stack, Inc. | Vehicle parking structure |

| US6004091A (en) * | 1998-01-21 | 1999-12-21 | Roth; Hans U. | Apparatus for conveying items to a selected receiving station |

| US5964562A (en) * | 1998-03-17 | 1999-10-12 | Computer Aided Systems, Inc. | Rotating elevator mechanism for article transfer in an automated storage system |

| US20040143490A1 (en) * | 1998-03-26 | 2004-07-22 | Kelly Michael D. | Auto storage facility |

| DE19942356A1 (de) * | 1999-09-04 | 2001-03-08 | Paul Stolzer | Übergabestation zum Ein- und Auslagern von Kraftfahrzeugen in einem Regallager |

| AU2001278658A1 (en) | 2000-07-20 | 2002-02-05 | Maurice Segal | Vehicle parking building and system |

| DE10105918A1 (de) * | 2001-02-09 | 2003-08-28 | Fraunhofer Ges Forschung | Vorrichtung zur Lagerung und Übergabe von Waren in Kleingebinden |

| US6641351B2 (en) | 2001-04-02 | 2003-11-04 | William S. Payne | Parking garage elevator system |

| DE10126193C1 (de) * | 2001-05-30 | 2002-10-10 | Daimler Chrysler Ag | Innerstädtisches PKW-Verkaufs-und Wartungs-Center mit minimalem Grundflächenbedarf |

| USD486237S1 (en) | 2001-05-31 | 2004-02-03 | Ardeena Kim Henry | Multi-story individual automobile accessible structure |

| US20040037678A1 (en) * | 2002-08-22 | 2004-02-26 | Bonin Pete J. | High throughput parking system |

| ATE448373T1 (de) * | 2003-09-25 | 2009-11-15 | Dion Stuart Frank | Lift für eine mehrstöckige lagerunssystem |

| WO2006018824A1 (fr) | 2004-08-19 | 2006-02-23 | Maurice Segal | Structure de stationnement de véhicules automatisée à étages |

| CN101429824A (zh) * | 2007-11-05 | 2009-05-13 | 深圳市中科利亨车库设备有限公司 | 一种多出入口集群塔式立体车库 |

| CN102535913B (zh) * | 2012-01-19 | 2013-11-20 | 黄晓 | 一种环状旋转式立体停车库 |

| US20140286744A1 (en) * | 2013-03-21 | 2014-09-25 | Unitronics Parking Solutions Ltd. | Vehicle centering system |

| BR102013028165B1 (pt) | 2013-10-31 | 2021-11-03 | Carmine Alexandre Cifelli | Estacionamento de veículos em múltiplos níveis e método de gestão de manobras |

| CN104727607B (zh) * | 2015-01-27 | 2017-01-11 | 北京工业大学 | 一种集约化城市地下停车系统 |

| CN104912370A (zh) * | 2015-06-18 | 2015-09-16 | 王均 | 一种立体停车场 |

| EP3196385A1 (fr) * | 2016-01-21 | 2017-07-26 | DPG Deutsche Parken GmbH | Parc de stationnement pour vehicules automobiles, en particulier parking a etage et procede de construction d'un parc de stationnement |

| CN106168075B (zh) * | 2016-08-18 | 2020-01-31 | 唐锋 | 垂直升降密集型立体车库布置方法 |

| SG11201909500YA (en) * | 2017-04-11 | 2019-11-28 | Kappe Intermediair B V | Compact multi-tier parking garage and method for storing vehicles in such a parking garage |

| USD872642S1 (en) * | 2017-09-06 | 2020-01-14 | Heatherwick Studio, Ltd. | Sculpture, scale model sculpture, sculpture replica, and/or other replicas |

| GB2590267A (en) | 2018-07-12 | 2021-06-23 | Walmart Apollo Llc | Autonomous storage and retrieval tower |

| US20200017299A1 (en) | 2018-07-12 | 2020-01-16 | Walmart Apollo, Llc | Automated storage retrieval system connection and communication protocol |

| WO2020014615A1 (fr) | 2018-07-12 | 2020-01-16 | Walmart Apollo, Llc | Système et procédé de reconnaissance et d'attribution de produits au niveau d'un dispositif de stockage et de récupération automatisés |

| GB2590268A (en) | 2018-07-12 | 2021-06-23 | Walmart Apollo Llc | Autonomous storage and retrieval tower |

| WO2020028799A1 (fr) * | 2018-08-02 | 2020-02-06 | Walmart Apollo, Llc | Systèmes et procédés de stockage et de récupération d'objets |

| WO2020092790A2 (fr) | 2018-10-31 | 2020-05-07 | Walmart Apollo, Llc | Systèmes et procédés de stockage et de récupération d'objets |

| WO2022075812A1 (fr) * | 2020-10-08 | 2022-04-14 | 정성인 | Dispositif d'ascenseur pour véhicule destiné au stationnement vertical de ménages individuels dans un bâtiment collectif, système de stationnement d'attente et système de charge de véhicule électrique l'utilisant |

| US20220396921A1 (en) * | 2021-06-09 | 2022-12-15 | Frank Asamoah Frimpong | Freestanding kojo helipad for vtol flying cars |

| CA3222217A1 (fr) * | 2021-06-11 | 2022-12-15 | Gary J. BEEMAN | Systemes d'amarrage de vehicule de plaisance et procedes associes |

| WO2022263512A1 (fr) * | 2021-06-15 | 2022-12-22 | Urban Air Port Limited | Structure d'aérodrome et sa construction |

| KR102673049B1 (ko) * | 2022-07-12 | 2024-06-07 | 심창보 | 한 번에 4개의 물품 입ㆍ출고가 가능한 승하강용 원형상의 물류타워 시스템 및 한 번에 4개의 물품 입ㆍ출고가 가능한 승하강용 원형상의 물류타워 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE848248C (de) * | 1951-05-30 | 1952-09-01 | Rolf Zombeck | Parkgaragengebaeude |

| EP0306058A2 (fr) * | 1987-09-04 | 1989-03-08 | Hans Höfner | Bâtiment pour le stationnement des véhicules |

| DE3810116A1 (de) * | 1988-03-25 | 1989-10-12 | Kern Johann | Verfahren zum versetzen von leute oder ladungen aus einem geschoss in das andere mit hilfe von hubvorrichtungen und vorrichtungen zur verwirklichung des verfahrens |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4023687A (en) * | 1964-10-19 | 1977-05-17 | Salloum Charles R | Container handling structure |

| US3497087A (en) * | 1968-01-19 | 1970-02-24 | Lawrence Vita | Automatic vehicle parking system |

| US4264257A (en) * | 1979-07-16 | 1981-04-28 | Venus Products, Inc. | Automated parking system and subassemblies therefor |

| CH649340A5 (en) * | 1984-07-06 | 1985-05-15 | Edoardo Giuseppe Bianca | Apparatus for parking vehicles on a number of storeys |

| US4640214A (en) * | 1985-01-18 | 1987-02-03 | Bruns John H | Modular multi-storage building |

| GB8620486D0 (en) * | 1986-08-22 | 1986-10-01 | Knakrick E | Car park unit |

| DE3831463A1 (de) * | 1988-09-16 | 1990-03-22 | Fredenhagen Kg | Vorrichtung zum insbesondere verteilen und lagern von guetern |

| IL88806A (en) * | 1988-12-26 | 1991-04-15 | Shahar Moshe | Automatic multi-level parking garage |

| IT1233780B (it) * | 1989-04-28 | 1992-04-17 | Toschi Ing Luigi | Dispositivo per il trasferimento in piano di autoveicoli utilizzato sumontacarichi asserviti ad autorimesse pluripiano |

| IT1241433B (it) * | 1990-03-09 | 1994-01-17 | Soilmec Spa | Parcheggio interrato circolare od a raggio variabile. |

| CA2017054C (fr) * | 1990-05-16 | 1999-08-10 | Jack S. Wilson | Systeme automatique de stockage-destockage |

-

1993

- 1993-05-13 AT AT93810351T patent/ATE176025T1/de not_active IP Right Cessation

- 1993-05-13 DE DE59309318T patent/DE59309318D1/de not_active Expired - Fee Related

- 1993-05-13 EP EP93810351A patent/EP0572352B1/fr not_active Expired - Lifetime

- 1993-05-26 CA CA002096982A patent/CA2096982A1/fr not_active Abandoned

- 1993-05-27 US US08/067,787 patent/US5478182A/en not_active Expired - Fee Related

- 1993-05-28 NO NO931953A patent/NO304495B1/no not_active IP Right Cessation

- 1993-05-31 JP JP5129230A patent/JPH0642219A/ja active Pending

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE848248C (de) * | 1951-05-30 | 1952-09-01 | Rolf Zombeck | Parkgaragengebaeude |

| EP0306058A2 (fr) * | 1987-09-04 | 1989-03-08 | Hans Höfner | Bâtiment pour le stationnement des véhicules |

| DE3810116A1 (de) * | 1988-03-25 | 1989-10-12 | Kern Johann | Verfahren zum versetzen von leute oder ladungen aus einem geschoss in das andere mit hilfe von hubvorrichtungen und vorrichtungen zur verwirklichung des verfahrens |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1996008624A1 (fr) * | 1994-09-16 | 1996-03-21 | Friedrich Maurer Söhne Gmbh & Co. Kg | Installation de reception, de stockage intermediaire et de sortie d'objets mobiles |

| WO1996008643A1 (fr) * | 1994-09-16 | 1996-03-21 | Electric Power Research Institute, Inc. | Methode et systeme d'alimentation en gazole vaporise d'une chambre de combustion de turbine |

| US5915908A (en) * | 1994-09-16 | 1999-06-29 | Friedrich Maurer & Sohne Gmbh & Co. KG | System for accommodating, temporarily storing and output of movable objects |

| DE4444257A1 (de) * | 1994-12-13 | 1996-06-20 | Rudi Strobel | Parkhaus für automatisches Einparken |

| DE19746390A1 (de) * | 1997-10-21 | 1999-04-22 | Siemens Ag | Fahrzeug-Hochregallager, insbesondere Parkhaus |

| CN102242572A (zh) * | 2010-05-14 | 2011-11-16 | 马邕勤 | 移动载车设备 |

| CN102345403A (zh) * | 2011-08-12 | 2012-02-08 | 鞍山钢制压力容器有限公司 | 一种液压升降大型立体自动停车库 |

| CN106013897A (zh) * | 2016-05-25 | 2016-10-12 | 北京宏地车港科技有限公司 | 一种机械立体停车库存取车方法及其系统 |

| CN106049940A (zh) * | 2016-08-05 | 2016-10-26 | 陈辉敏 | 一种新型立体停车库 |

| CN106049940B (zh) * | 2016-08-05 | 2018-05-22 | 陈辉敏 | 一种立体停车库 |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE176025T1 (de) | 1999-02-15 |

| NO931953L (no) | 1993-11-30 |

| JPH0642219A (ja) | 1994-02-15 |

| EP0572352B1 (fr) | 1999-01-20 |

| US5478182A (en) | 1995-12-26 |

| NO931953D0 (no) | 1993-05-28 |

| CA2096982A1 (fr) | 1993-11-30 |

| DE59309318D1 (de) | 1999-03-04 |

| NO304495B1 (no) | 1998-12-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0572352B1 (fr) | Parking automatique à étages multiples | |

| DE3740586C2 (de) | Hochgarage | |

| EP0628124B1 (fr) | Dispositif de stockage d'objets dans un bloc d'entreposage | |

| EP3429947B1 (fr) | Système composé d'un transtockeur et d'un système de transport et de transfert pour le stockage et le déstockage ou le transfert de conteneurs standard entreposés dans des entrepôts à rayonnages hauts | |

| EP0309487B1 (fr) | Parc de stockage, notamment parc de stationnement | |

| EP0733144A1 (fr) | Installation de reception de stockage intermediaire et de sortie d'objets mobiles | |

| DE1997892U (de) | Vorrichtung zum speichern von fahrzuegen u. dgl. | |

| DE3739158A1 (de) | Lagersystem mit einer foerdereinrichtung, insbesondere parksystem fuer fahrzeuge | |

| AT406069B (de) | Parkeinrichtung | |

| EP1802830A1 (fr) | Dispositif mobile entierement automatise et procede correspondant de garage rapide, economique et peu encombrant de vehicules prives | |

| DE3943039A1 (de) | Parkeinrichtung | |

| EP0964970B1 (fr) | Installation pour stationner des vehicules a moteur de facon peu encombrante | |

| WO2017220285A1 (fr) | Entrepôt à haut rayonnage comprenant, à l'intérieur, des transstockeurs destinés à stocker et déstocker ou transférer des marchandises entreposées | |

| DE3831463C2 (fr) | ||

| EP0653532A1 (fr) | Installation automatique de parking pour véhicules | |

| DE3839550A1 (de) | Anlage zum auskleiden der innenwand einer umhuellung mit ziegelsteinen | |

| DE3902080A1 (de) | Parkhaus | |

| US2936082A (en) | Parking device | |

| DE69105503T2 (de) | Lagerungs und Rückholsystem. | |

| DE2305792C2 (de) | Lageranlage | |

| CH686896A5 (de) | Automatisches Parkhaus. | |

| DE4130141A1 (de) | Verfahren und vorrichtung zum ein- und ausparken von fahrzeugen o. dgl. schweren lagerguetern | |

| DE4133672A1 (de) | Drehbuehnenvorrichtung | |

| DE4444257A1 (de) | Parkhaus für automatisches Einparken | |

| EP0714469B1 (fr) | Dispositif de transport et de stockage commandes d'articles mobiles |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL PT SE |

|

| 17P | Request for examination filed |

Effective date: 19940526 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: SCHENK INTERSERVICE AG |

|

| 17Q | First examination report despatched |

Effective date: 19950302 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: RONDO SYSTEM AG |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: RONDO HOLDINGS AG |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19990120 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19990120 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 19990120 Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990120 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990120 Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19990120 Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19990120 |

|

| REF | Corresponds to: |

Ref document number: 176025 Country of ref document: AT Date of ref document: 19990215 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59309318 Country of ref document: DE Date of ref document: 19990304 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19990420 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19990512 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990513 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19990526 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990531 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19990611 Year of fee payment: 7 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: HUG INTERLIZENZ AG |

|

| EN | Fr: translation not filed | ||

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 19990120 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| BERE | Be: lapsed |

Owner name: RONDO HOLDINGS A.G. Effective date: 19990531 |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000513 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000531 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000531 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010301 |