EP0243572A1 - Escalier roulant à vitesse variable - Google Patents

Escalier roulant à vitesse variable Download PDFInfo

- Publication number

- EP0243572A1 EP0243572A1 EP87100103A EP87100103A EP0243572A1 EP 0243572 A1 EP0243572 A1 EP 0243572A1 EP 87100103 A EP87100103 A EP 87100103A EP 87100103 A EP87100103 A EP 87100103A EP 0243572 A1 EP0243572 A1 EP 0243572A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- roller

- escalator

- running

- tread

- rollers

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66B—ELEVATORS; ESCALATORS OR MOVING WALKWAYS

- B66B23/00—Component parts of escalators or moving walkways

- B66B23/14—Guiding means for carrying surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66B—ELEVATORS; ESCALATORS OR MOVING WALKWAYS

- B66B21/00—Kinds or types of escalators or moving walkways

- B66B21/02—Escalators

- B66B21/04—Escalators linear type

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66B—ELEVATORS; ESCALATORS OR MOVING WALKWAYS

- B66B23/00—Component parts of escalators or moving walkways

- B66B23/08—Carrying surfaces

- B66B23/12—Steps

Definitions

- the invention relates to an escalator with variable travel speeds, the treads together with articulated elements form an endless step belt running on rollers, which is deflected at the upper and lower ends of the escalator and driven by a drive unit provided with drivers.

- the major disadvantage of this escalator is that the passenger must enter and exit the escalator at a high step belt speed, while the travel speed in the inclined walking area is reduced after the steps are formed. With comparatively the same starting speed, the passenger therefore needs a longer travel time in such an escalator than in a conventional escalator. The greater the delivery head, the greater the time lost for the passenger. In the return area that cannot be entered, the step belt speed is the same as for the inlets and outlets.

- the invention has for its object to propose an escalator in which the journey time for the passengers is reduced at a constant approach speed and in which the total number of steps is reduced compared to a conventional escalator and the risk of injury to passengers who may fall is reduced.

- the advantages achieved by the invention are essentially to be seen in the fact that the travel time for the individual passenger, especially in the case of high-lift escalators, for example in subway stations, is markedly reduced, that the total number of steps can be reduced by up to 40%, which results in a reduction in the manufacturing price and that the risk of injury for passengers who may fall on the escalator is greatly reduced by the round front edge of the step.

- Further advantages of the invention are that no step chains On the two outer sides of the steps, it is necessary that no deflection shaft is required at the bottom and no drive shaft is required at the top, and that a precise lateral guidance of the step belt is guaranteed by the self-contained and profiled inner raceway and the associated, inevitably guided rollers.

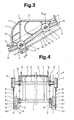

- each step 1 has a support body 2, a step level 3 and a front part 4.

- Two roller axes 5, 6 are fixedly arranged on a connecting carrier 2.1 of the supporting body 2.

- Guide rollers 7 running on ball bearings are attached to the two ends of the longer roller axis 5 and guide rollers 8 running on ball bearings are also attached to the two ends of the shorter roller axis 6.

- the guide rollers 7 run in the guide track 9 while the guide rollers 8 move on the guide rail 10.

- the individual stages are connected to one another by articulated rods 13, ball bearings (16) mounted on the roller axis 5, 6 forming the pivot bearings of the articulated rod 13.

- Step 1 is assembled from several parts in the exemplary embodiment shown.

- a step plane 3 grooved in the direction of travel and a front part 4 which has a convex curvature and is also grooved in the direction of travel are firmly constructed.

- two continuous roller axes, a longer roller axis 5 and a shorter roller axis 6 are firmly connected, the roller axes being accommodated on both sides of the step in a recess of a connecting carrier 2.1 of the support body 2.

- rollers 7, 8 are mounted on ball bearings.

- roller shaft 6 At the end of the roller shaft 6 there is additionally a pivotally mounted support 12 which carries two counter pressure rollers 11 which cooperate with the roller 8. Also on the roller axles 5, 6, articulated rods 13 are supported on ball bearings 16, with which each step 1 is connected to an adjacent step 1 and is thus joined to form the endless step belt.

- the rollers 7 provided on the longer roller axes 5 are guided in the endlessly closed outer guide track 9, which has a U-shaped cross section, while the rollers 8 provided on the shorter roller axes 6 run on the likewise endlessly closed inner guide rail 10.

- the U-shaped exterior Guide track 9 engages around the roller 7 and prevents this roller from lifting off.

- the inner guide rail 10 has an upper running surface 10.1, a lower running surface 10.2 and a fastening flange 10.3.

- the roller 8 is always held on the upper running surface 10.1 by the counter pressure roller running on the lower running surface 10.2 of the guide rail 10. Since the lower running surface 10.2 of the guide rail 10 can have a guide profile and the running surface 11.1 of the counter-pressure roller 11 can have a matching counter-profile, it is possible to precisely guide the steps 1 with the counter-pressure rollers 11 laterally.

- the U-shaped outer guideway 9 is fastened with a fastening flange 9.1 to a supporting structure 15 of the supporting structure of the escalator.

- the guide rail 10 is flanged to the same supporting structure 15 with its fastening flange 10.3. The mutual distances between the two guideways 9, 10 change during an entire revolution, but do not overlap.

- the tread levels 3 of the treads 1 always assume a horizontal position in the accessible lead, on the other hand this results in higher and lower driving speeds for the step belt.

- the movable step belt is covered on both sides by a vertically arranged, fixed base plate 14 that adjoins lateral balustrades.

- the type of escalator described above works as follows:

- the endless step belt is driven by a drive unit, not shown, in the upper part of the inclined running area between the step belt.

- the drive unit can, for example, have a chain-like drive element which acts on one of the roller axles of individual steps and which advantageously simultaneously drives the forward run and the return run of the step belt.

- Each individual step 1 of the step belt which is endlessly closed by the articulated rods 13 is guided by four rollers 7, 8 in four likewise endlessly closed guideways 9, 10.

- rollers 7 arranged on the longer roller axles 5 of the step 1 run in the two outer guide tracks 9, which have a U-shaped cross section, while the rollers 8 arranged on the shorter roller axles 6 run on the upper guide tracks 10.1 of the inner guide rails 10 and from the counter pressure rollers 11 running on the lower guideways 10.2 of the inner guide rails 10 are held on their guideways.

- the inner and outer guideways 9, 10 are spaced apart from one another over an entire revolution so that the step level 3 of each step 1 is in a horizontal position in the accessible lead.

- the two guideways run at a correspondingly large distance from one another, so that steps 1 and fold the articulated rods 13 against each other, the treads 1 pushing together and forming a continuous horizontal tread plane over approximately three treads 1.

- the distance between the two guideways 9, 10 gradually decreases in order to have the smallest distance in the inclined running area.

- the treads pushed together in the horizontal running area are pulled apart again and assume an almost extended position together with the articulated rods 13 in the inclined running area.

- the drive unit provided in the upper part of the inclined running area of the step belt is thus used in the area of high driving speed. Since the sloping forward and the sloping return have the same driving speed, the drive unit can also intervene in both runs at the same time.

- a precise lateral step guidance is achieved in that the lower running surface 10.2 of the guide rail 10 has, for example, a triangular profile, on whose obtuse apex angle the counter pressure rollers connected to the steps are guided and centered.

- the step band of the escalator according to the invention differs in some points from a conventional escalator.

- the individual steps are not articulated on two endless step chains arranged on both sides of the step belt, which serve as a pulling element, but are directly connected to one another by articulated rods.

- a positively guided folding movement occurs between the steps and the articulated rods through constant guidance of the rollers in the two endlessly closed guideways.

- the step body is designed in such a way that the distance between two adjacent steps, which is increased by the connecting articulated rods, is bridged by a convex rounding of the step front part.

- the continuous, closed track system for the rollers of the step belt also occurs here.

- a drive unit arranged at the upper deflection point at least one drive unit provided in the inclined step band area between the step band occurs.

Landscapes

- Escalators And Moving Walkways (AREA)

- Electric Propulsion And Braking For Vehicles (AREA)

- Steps, Ramps, And Handrails (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT87100103T ATE55758T1 (de) | 1986-02-07 | 1987-01-07 | Fahrtreppe mit veraenderlichen fahrgeschwindigkeiten. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH49486 | 1986-02-07 | ||

| CH494/86 | 1986-04-15 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0243572A1 true EP0243572A1 (fr) | 1987-11-04 |

| EP0243572B1 EP0243572B1 (fr) | 1990-08-22 |

Family

ID=4188290

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP87100103A Expired - Lifetime EP0243572B1 (fr) | 1986-02-07 | 1987-01-07 | Escalier roulant à vitesse variable |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0243572B1 (fr) |

| JP (1) | JP2587823B2 (fr) |

| AT (1) | ATE55758T1 (fr) |

| DE (1) | DE3764391D1 (fr) |

| MX (1) | MX160538A (fr) |

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2624492A1 (fr) * | 1987-12-14 | 1989-06-16 | Orenstein & Koppel Ag | Profile de rail de roulement pour les galets d'un trottoir roulant |

| EP0685421A1 (fr) * | 1993-12-20 | 1995-12-06 | Masao Kubota | Machine de transport reliee |

| EP1468952A1 (fr) * | 2002-01-21 | 2004-10-20 | Mitsubishi Denki Kabushiki Kaisha | Escalier mecanique a grande vitesse, a partie inclinee |

| EP1331195A3 (fr) * | 2002-01-23 | 2004-12-22 | Mitsubishi Denki Kabushiki Kaisha | Escalier roulant avec section incliné à haute vitesse |

| EP1331196A3 (fr) * | 2002-01-23 | 2004-12-22 | Mitsubishi Denki Kabushiki Kaisha | Marches pour escalier roulant avec section incliné à haute vitesse |

| EP1331194A3 (fr) * | 2002-01-23 | 2004-12-22 | Mitsubishi Denki Kabushiki Kaisha | Escalier roulant avec section incliné à haute vitesse |

| US7104386B2 (en) | 2002-01-21 | 2006-09-12 | Mitsubishi Denki Kabushiki Kaisha | Sloped part high-speed escalator |

| JP2016204112A (ja) * | 2015-04-22 | 2016-12-08 | 三菱電機ビルテクノサービス株式会社 | エスカレータの踏段装置 |

| CN108408556A (zh) * | 2017-02-09 | 2018-08-17 | 奥的斯电梯公司 | 人员输送机、输送带和人员输送机的输送元件 |

| CN110388061A (zh) * | 2019-07-26 | 2019-10-29 | 深圳市建工集团股份有限公司 | 结构及建筑找坡定型收面方法 |

| EP3736240A1 (fr) * | 2019-05-06 | 2020-11-11 | thyssenkrupp Elevator Innovation Center, S.A. | Système de transport d'un escalier roulant |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2540965B2 (ja) * | 1990-01-16 | 1996-10-09 | 三菱電機株式会社 | 中間高速エスカレ―タ― |

| JP2004262614A (ja) * | 2003-03-03 | 2004-09-24 | Mitsubishi Electric Corp | エスカレータ |

| WO2011138844A1 (fr) * | 2010-12-21 | 2011-11-10 | Teramoto Katsuya | Dispositif d'accélération et escalier mécanique à accélération équipé de ce dispositif |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB245869A (en) * | 1924-10-24 | 1926-01-21 | Never Stop Transit Ltd | Improvements in or relating to vehicles adapted to travel on inclined tracks |

| FR724088A (fr) * | 1931-09-14 | 1932-04-21 | Transporteur accélérateur et ralentisseur pour personnes | |

| DE1481725A1 (de) * | 1967-03-15 | 1969-03-27 | Walter Wimmer | Fahrtreppe |

| FR2340269A1 (fr) * | 1976-02-03 | 1977-09-02 | Kone Oy | Escalier mecanique |

| US4411352A (en) * | 1981-04-04 | 1983-10-25 | Otis Elevator Company | Racetrack escalator |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5211515A (en) * | 1975-07-16 | 1977-01-28 | Agency Of Ind Science & Technol | Circuit of controlling at constant the speed of an electric car |

-

1987

- 1987-01-07 AT AT87100103T patent/ATE55758T1/de not_active IP Right Cessation

- 1987-01-07 DE DE8787100103T patent/DE3764391D1/de not_active Expired - Fee Related

- 1987-01-07 EP EP87100103A patent/EP0243572B1/fr not_active Expired - Lifetime

- 1987-01-22 MX MX5004A patent/MX160538A/es unknown

- 1987-02-02 JP JP62022272A patent/JP2587823B2/ja not_active Expired - Fee Related

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB245869A (en) * | 1924-10-24 | 1926-01-21 | Never Stop Transit Ltd | Improvements in or relating to vehicles adapted to travel on inclined tracks |

| FR724088A (fr) * | 1931-09-14 | 1932-04-21 | Transporteur accélérateur et ralentisseur pour personnes | |

| DE1481725A1 (de) * | 1967-03-15 | 1969-03-27 | Walter Wimmer | Fahrtreppe |

| FR2340269A1 (fr) * | 1976-02-03 | 1977-09-02 | Kone Oy | Escalier mecanique |

| US4411352A (en) * | 1981-04-04 | 1983-10-25 | Otis Elevator Company | Racetrack escalator |

Cited By (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2624492A1 (fr) * | 1987-12-14 | 1989-06-16 | Orenstein & Koppel Ag | Profile de rail de roulement pour les galets d'un trottoir roulant |

| EP0685421A1 (fr) * | 1993-12-20 | 1995-12-06 | Masao Kubota | Machine de transport reliee |

| EP0685421A4 (fr) * | 1993-12-20 | 1996-12-18 | Masao Kubota | Machine de transport reliee. |

| US7104386B2 (en) | 2002-01-21 | 2006-09-12 | Mitsubishi Denki Kabushiki Kaisha | Sloped part high-speed escalator |

| EP1468952A1 (fr) * | 2002-01-21 | 2004-10-20 | Mitsubishi Denki Kabushiki Kaisha | Escalier mecanique a grande vitesse, a partie inclinee |

| EP1468952A4 (fr) * | 2002-01-21 | 2007-05-09 | Mitsubishi Electric Corp | Escalier mecanique a grande vitesse, a partie inclinee |

| EP1852385A2 (fr) * | 2002-01-23 | 2007-11-07 | Mitsubishi Denki Kabushiki Kaisha | Escalateur doté d'une section inclinée à haute vitesse |

| EP1331194A3 (fr) * | 2002-01-23 | 2004-12-22 | Mitsubishi Denki Kabushiki Kaisha | Escalier roulant avec section incliné à haute vitesse |

| US7124875B2 (en) | 2002-01-23 | 2006-10-24 | Mitsubishi Denki Kabushiki Kaisha | Escalator with high speed inclined section |

| EP1331196A3 (fr) * | 2002-01-23 | 2004-12-22 | Mitsubishi Denki Kabushiki Kaisha | Marches pour escalier roulant avec section incliné à haute vitesse |

| EP1331195A3 (fr) * | 2002-01-23 | 2004-12-22 | Mitsubishi Denki Kabushiki Kaisha | Escalier roulant avec section incliné à haute vitesse |

| EP2258651A1 (fr) * | 2002-01-23 | 2010-12-08 | Mitsubishi Denki K.K. | Escalier roulant avec section incliné à haute vitesse |

| EP1852385A3 (fr) * | 2002-01-23 | 2013-07-03 | Mitsubishi Denki Kabushiki Kaisha | Escalateur doté d'une section inclinée à haute vitesse |

| JP2016204112A (ja) * | 2015-04-22 | 2016-12-08 | 三菱電機ビルテクノサービス株式会社 | エスカレータの踏段装置 |

| CN108408556A (zh) * | 2017-02-09 | 2018-08-17 | 奥的斯电梯公司 | 人员输送机、输送带和人员输送机的输送元件 |

| EP3736240A1 (fr) * | 2019-05-06 | 2020-11-11 | thyssenkrupp Elevator Innovation Center, S.A. | Système de transport d'un escalier roulant |

| WO2020225178A1 (fr) * | 2019-05-06 | 2020-11-12 | Thyssenkrupp Elevator Innovation Center S.A. | Système de transport d'un escalier roulant |

| CN113795451A (zh) * | 2019-05-06 | 2021-12-14 | Tk 电梯创新中心股份公司 | 自动扶梯的输送系统 |

| CN110388061A (zh) * | 2019-07-26 | 2019-10-29 | 深圳市建工集团股份有限公司 | 结构及建筑找坡定型收面方法 |

| CN110388061B (zh) * | 2019-07-26 | 2021-07-06 | 深圳市建工集团股份有限公司 | 结构及建筑找坡定型收面方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| JPS62185692A (ja) | 1987-08-14 |

| EP0243572B1 (fr) | 1990-08-22 |

| JP2587823B2 (ja) | 1997-03-05 |

| DE3764391D1 (de) | 1990-09-27 |

| MX160538A (es) | 1990-03-20 |

| ATE55758T1 (de) | 1990-09-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3437369C2 (fr) | ||

| DE10308417B4 (de) | Rollsteig | |

| DE4101111C2 (fr) | ||

| DE952556C (de) | Rolltreppe | |

| EP0243572B1 (fr) | Escalier roulant à vitesse variable | |

| DE60004893T2 (de) | Beschleunigungsfahrsteig | |

| CH637901A5 (de) | Beschleunig- und verzoegerbarer handlauf. | |

| DE3431610A1 (de) | Rolltreppe | |

| DE2809861A1 (de) | Endlostransportband | |

| DE112009005321B4 (de) | Personenbeförderungseinrichtung mit bewegbaren lateralen Paneelelementen | |

| DE3441845C2 (fr) | ||

| DE2434009A1 (de) | Lift | |

| DE60106969T2 (de) | Rolltreppe zur bewegung um kurven | |

| DE2222263A1 (de) | Fussgaengerfoerderanlage | |

| DE3218253C2 (fr) | ||

| EP1102718B1 (fr) | Procede et dispositif pour guider une chaine au niveau des roues dentees d'un engin de manutention continue | |

| DE10230799B4 (de) | Fahrschachttür | |

| DE3819522C2 (fr) | ||

| DE2325967A1 (de) | Bogenfoermige rolltreppenanlage | |

| DE10125686B4 (de) | Stufenbefestigung an der Stufenkette einer Fahrtreppe | |

| DE2419957C3 (de) | Vorrichtung zum Unterstfitzen eines Lastträgers | |

| DE2414629A1 (de) | Foerdervorrichtung, insbesondere rollsteig, mit variabler geschwindigkeit | |

| DE2343425C3 (de) | Fahrsteig zum Befördern von Personen | |

| DE102005039755B3 (de) | Transporteinrichtung | |

| DE19522939C2 (de) | Treppengängiges Fahrzeug |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT CH DE FR GB IT LI |

|

| 17P | Request for examination filed |

Effective date: 19880331 |

|

| 17Q | First examination report despatched |

Effective date: 19890413 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE FR GB IT LI |

|

| REF | Corresponds to: |

Ref document number: 55758 Country of ref document: AT Date of ref document: 19900915 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3764391 Country of ref document: DE Date of ref document: 19900927 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| ET | Fr: translation filed | ||

| ITF | It: translation for a ep patent filed |

Owner name: MODIANO & ASSOCIATI S.R.L. |

|

| ITTA | It: last paid annual fee | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20030102 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: D6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040107 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20041229 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20050106 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20050111 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20050418 Year of fee payment: 19 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060131 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060131 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060131 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20060131 Year of fee payment: 20 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060801 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20060107 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20060929 |