WO2015122263A1 - 梱包箱 - Google Patents

梱包箱 Download PDFInfo

- Publication number

- WO2015122263A1 WO2015122263A1 PCT/JP2015/052001 JP2015052001W WO2015122263A1 WO 2015122263 A1 WO2015122263 A1 WO 2015122263A1 JP 2015052001 W JP2015052001 W JP 2015052001W WO 2015122263 A1 WO2015122263 A1 WO 2015122263A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- packaging box

- upper lid

- box

- box according

- lower box

- Prior art date

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/42—Details of containers or of foldable or erectable container blanks

- B65D5/64—Lids

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/20—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper by folding-up portions connected to a central panel from all sides to form a container body, e.g. of tray-like form

- B65D5/22—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper by folding-up portions connected to a central panel from all sides to form a container body, e.g. of tray-like form held erect by extensions of one or more sides being doubled-over to enclose extensions of adjacent sides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/42—Details of containers or of foldable or erectable container blanks

- B65D5/4208—Means facilitating suspending, lifting, handling, or the like of containers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/42—Details of containers or of foldable or erectable container blanks

- B65D5/64—Lids

- B65D5/68—Telescope flanged lids

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/42—Details of containers or of foldable or erectable container blanks

- B65D5/72—Contents-dispensing means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/08—Containers or packages with special means for dispensing contents for dispensing thin flat articles in succession

- B65D83/0805—Containers or packages with special means for dispensing contents for dispensing thin flat articles in succession through an aperture in a wall

- B65D83/0811—Containers or packages with special means for dispensing contents for dispensing thin flat articles in succession through an aperture in a wall with means for assisting dispensing

- B65D83/0841—Containers or packages with special means for dispensing contents for dispensing thin flat articles in succession through an aperture in a wall with means for assisting dispensing and for cutting interconnected articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D85/00—Containers, packaging elements or packages, specially adapted for particular articles or materials

- B65D85/67—Containers, packaging elements or packages, specially adapted for particular articles or materials for web or tape-like material

- B65D85/671—Containers, packaging elements or packages, specially adapted for particular articles or materials for web or tape-like material wound in flat spiral form

- B65D85/672—Containers, packaging elements or packages, specially adapted for particular articles or materials for web or tape-like material wound in flat spiral form on cores

Definitions

- the present invention relates to a packaging box having an upper lid and a lower box made of corrugated cardboard and containing a film having a width of about 0.5 to 2 m wound around a longitudinal axis, that is, a raw material or the like. It is about.

- this film is a film mainly affixed to a glass window etc. by manual work, and what is called a scattering prevention film, a thermal insulation film, an ultraviolet cut film, etc. are contained. These films are unpacked at a construction site or the like, then manually cut to a desired width and length, and pasted on a glass window or the like.

- Such a packaging box using corrugated cardboard has a problem that it is weak in strength and is easily bent in the vicinity of the central portion because it is particularly long in the longitudinal direction. Further, when a packaging box containing such a raw fabric is transported, it is easily bent when placed on a pallet for transportation and protruding from the pallet. That is, in a packing box with a long length in the longitudinal direction, the weight may be concentrated on the end, and when the corner of the pallet hits a place other than the end of the packing box, that part is pressed and bent. easy. Moreover, it is easy to bend similarly when a packaging box is piled up in two steps or more and a position shifts.

- an object of the present invention is a packaging box comprising an upper lid part and a lower box part made of cardboard, which accommodates articles therein, wherein the upper lid part is the entire interior of the lower box part And a side plate portion extending vertically downward from each side of the top plate portion and substantially covering the side surface of the lower box portion, the top plate portion having a center of gravity of the top plate portion.

- An object of the present invention is to provide a packaging box in which at least a pair of perforation portions are provided at point-symmetric positions, and the perforation portions are configured to be bendable.

- a packaging box is a packaging box comprising an upper lid part and a lower box part made of cardboard, each containing an article therein, wherein the upper lid part is a part of the lower box part. It consists of a top plate part that covers the entire interior and a side plate part that extends vertically downward from each side of the top plate part and substantially covers the side surface of the lower box part, and the top plate part has a center of gravity of the top plate part At least a pair of perforation portions are provided at a point-symmetrical position about the perforation, and the perforation portions are configured to be bendable.

- the operator can put a finger into the hole and lift the upper lid in a state where the perforation portion is bent, so that the work efficiency at the time of unpacking can be improved. Moreover, since the hole of this part is not only used for an operator putting a finger, but also acts as an air hole, the unpacking operation can be performed more easily. Moreover, the packaging box of this invention is comprised so that the said perforation part can be bend

- the packing box of the present invention is configured to have a portion that curves outward from the top plate surface of the upper lid portion with the perforation portion being bent.

- the folded portion is separated from the center to the outside inside the lower box, so that the folded portion can be prevented from coming into contact with the raw material of the contents.

- the contents can be handled safely.

- the packaging box according to the present invention has a structure further including a pair of notches at the same position from both ends of the upper lid portion on both side plates in the longitudinal direction.

- the shape of the notch can be determined in various shapes, and for example, it is composed of a portion inclined upward at a predetermined angle from the center side in the longitudinal direction and an arc portion connected to the inclined portion. Can do.

- the efficiency improvement of unpacking work can be aimed at by providing at least one notch part. By doing in this way, it can be set as the structure which considered the operation

- it is also possible to reduce the manufacturing cost of an upper cover part by setting it as the structure which provides such a notch part of at least one place.

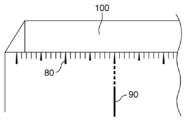

- the packing box of the present invention is configured such that a scale indicating the length along the longitudinal direction is provided on the upper side of the side plate portion in the longitudinal direction of the lower box portion.

- the desired width when cutting while pulling out the film from the raw material stored inside, the desired width can be grasped and the position of the cutter can be easily determined.

- the packing box of the present invention is configured so that at least the upper side in the longitudinal direction of the lower box is formed by folding cardboard.

- the strength in the longitudinal direction of the lower box can be improved, and since the cut surface of the cardboard is not exposed, scattering of paper dust can be suppressed. Further, when the film is taken out from the original fabric, the movement of the film on the upper side becomes smooth, and the efficiency of the film taking-out operation can be improved.

- the present invention it is possible to improve the strength of a packaging box made of cardboard and having a long length in the longitudinal direction. Moreover, the work efficiency at the time of unpacking of an operator can be improved. Furthermore, the efficiency at the time of taking out a film from the raw material of a content can also be improved, and scattering of the paper powder from the corrugated cardboard which is material can be suppressed. Further, the desired length of the film to be taken out can be easily specified, and the efficiency of the taking out operation can be improved.

- FIG. 1 It is a perspective view which shows the use condition of the packaging box concerning this invention. It is a perspective view of the upper cover part of the packaging box concerning this invention. It is a perspective view of the lower box part of the packaging box concerning this invention. It is a perspective view of the modification of the upper cover part of the packaging box concerning this invention. It is an expanded view of an upper cover part. It is an expanded view of a lower box part. It is sectional drawing which shows the state which accommodated the original fabric of the contents in the packaging box concerning this invention. It is a perspective view which shows the state which pulls out a film from the accommodated original fabric. It is a top view which shows the example of the form of the perforation part provided in an upper cover part.

- FIG. 1 It is a perspective view which shows the example of the form of the notch provided in the longitudinal direction lower side of the side-plate part of an upper cover part. It is a perspective view which shows the example of the form of the scale provided in the side surface of a lower box part. It is a perspective view which shows the modification which provides a slit further when providing the scale. It is a perspective view which shows another embodiment of the packaging box concerning this invention. It is an expanded view which shows another embodiment of the lower box part of the packaging box concerning this invention. It is an expanded view which shows another embodiment of the upper cover part of the packaging box concerning this invention.

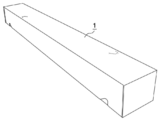

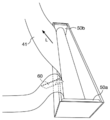

- FIG. 1A is a perspective view exemplarily showing an entire use state of a packaging box 1 made of corrugated cardboard as a material according to an embodiment of the present invention.

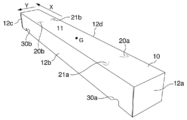

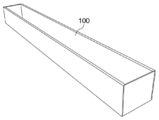

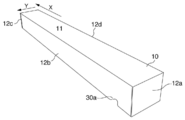

- FIG. 1B is a perspective view showing an example of the upper lid portion 10 constituting the packing box 1 and FIG. 1C is an example of the lower box portion 100 similarly constituting the packing box 1.

- the upper lid portion 10 has a rectangular top plate portion 11 having a long side extending in the longitudinal direction X and a short side extending in the short side direction Y perpendicular thereto, and the side plate portions 12a and 12b vertically downward from the respective sides. 12c and 12d are provided so as to substantially cover the corresponding side surfaces of the lower box 100, respectively.

- the top plate portion 11 is provided with a pair of perforated portions 20 a and 20 b at positions that are point-symmetric with respect to the center of gravity G of the upper lid portion 10.

- the worker presses the perforated portions 20a and 20b to bend the inside of the box, put a finger on the hole formed thereby, and lift the upper lid 10.

- the hole is not limited to just putting a finger on it, but also acts as an air hole, so that the efficiency of the unpacking operation is further improved.

- the perforation may be bent outside the box.

- the perforated parts 20a and 20b are arranged so as to be point-symmetric with respect to the center of gravity G as shown in FIG. Further, it is generally known that in such unpacking work, it is generally effective to arrange the perforation portion corresponding to the operator's dominant arm, that is, the right arm in the back. . Therefore, as shown in FIG. 1B, another pair of perforated portions 21a and 21b may be provided. As a result, the work position of the worker can be made arbitrary with respect to the packaging box.

- the perforation can be arbitrarily defined as long as one or two fingers can be inserted into the hole formed by bending.

- the position of the perforation is not limited to the form as shown in FIG. 1B, and may be provided at an arbitrary position unrelated to the center of gravity G.

- the number of perforations is not limited to the contents of work or the convenience of the operator. It can be arbitrarily set in consideration.

- the perforated part is not limited to bendable configuration, and may be cut off. Further, this portion may not be configured as a perforation, but may be provided with a hole through which an operator's finger can be simply inserted. Details of the perforation will be described later.

- the upper lid portion 10 is provided with cutout portions 30a and 30b at predetermined positions from both end portions of the side plate portions 12b and 12d along the long side. Thereby, when unpacking the packing box, one worker stands at each end, and the work efficiency of the work of lifting by placing the hand on the upper lid is improved.

- the position and shape of the cut portion are arbitrarily determined, but the positions from both ends are preferably equal.

- the size of the notch is preferably about the size of a palm.

- the shape is basically a triangle with the lower side of the side plate portion as the base, and the triangle is appropriately deformed. As an example, as shown in FIG.

- the notch 30a may be provided on one side of the side plate and in the vicinity of one end surface.

- the work at the site is often performed by only one person, and considering such work, it is possible to sufficiently improve the work efficiency with only one notch, and manufacturing the top cover itself. Cost can also be reduced.

- FIG. 2A is a development view of the upper lid portion 10

- FIG. 2B is a development view of the lower box portion 100.

- Both can be formed by bending a single cardboard.

- 2A the short side of the upper lid portion 10 is formed by folding.

- 2B the long side of the lower box portion 100 is also configured by folding. From these configurations, the structural strength of both the upper lid and the lower box can be improved.

- the strength in the longitudinal direction has been improved, and when a heavy object is stored, the lower box part can be prevented from being bent at the center part, or a dent caused by an impact from the outside, It is possible to suppress dents in the center when lifted.

- the cutter can be stably attached to the side surface of the lower box portion described later.

- FIG. 3A is a cross-sectional view showing a use state when the original fabrics 40 and 41 as contents are stored in the packing box 1

- FIG. 3B is a perspective view showing a state when the contents are taken out.

- the original fabrics 40 and 41 are obtained by winding a film 41 around a shaft 40 having a predetermined radius, and are supported by a pair of plate bars 50 a and 50 b provided at both ends inside the lower box portion 100.

- the perforated portions 20a and 20b have a shape that does not contact the film 41 when the perforated portions 20a and 20b are bent and protruded into the lower box portion 100.

- the film 41 is a film that is manually attached to a glass window or the like, and includes a so-called scattering prevention film, a heat shielding film, an ultraviolet cut film, and the like. Then, as shown in FIG. 3B, at a construction site or the like, for example, it is taken out in the direction indicated by L, cut into a desired width or length, and attached to glass or the like. In addition, it is also possible to attach and fix the cutter 60 on the side surface of the lower box portion 100 and fix it by cutting it according to the operation of taking out the film 41, thereby obtaining a film having a desired width.

- FIG. 4 is a plan view showing an example of an aspect of the perforation portion 20a. It is desirable that the perforated portion is configured to be separated from the center line of the packaging box to the outside as a shape that does not contact the surface of the film stored when the perforated portion is bent and protruded inside. Specifically, as in (1), (3), and (6), there is a side that inclines outward from the center line of the top plate portion, and this inclination makes it possible to avoid contact. Further, as in (2), (4), and (5), it may be configured to have a portion that curves outward from the center line, thereby avoiding contact. It is desirable that these shapes have as few corners as possible.

- the shape as in (2), (5), and (7) does not have corners and is rounded as a whole. It can be pushed out neatly, and when it is bent outward, it is easy to work without breaking the bent part.

- (9) to (11) in FIG. 4 have a notch l at the center of the perforation, and a pair that protrudes into the lower box part away from this notch when pressed by the operator's finger.

- the bent pieces 20a1 and 20a2 are provided.

- FIG. 5 is a perspective view showing an example of the cutout portion 30a provided on the lower side of the side plate portion of the upper lid portion 10.

- the shape, position, number, etc. of the notch portions can be arbitrarily determined. However, this notch is for two workers for unpacking work to stand at both ends of the packaging box and lift the upper lid together. Therefore, it is desirable to be provided at each of both side plate portions at the same position from both ends of the upper lid portion.

- the size of the cut portion is preferably about the size of a palm because it is easy to put a hand. With such a configuration, the finger is moved along the straight line portion, the position of the finger is determined inside the arc portion, and the unpacking operation is performed.

- (1) shows that the cutout portion 30a has a straight portion inclined from the center of the packing box toward the end portion and an arc portion connected to the straight portion.

- the angle of the inclined portion can be optimally set according to the length of the long side of the upper lid portion, the physique of the operator, and the like. As an example, it is preferable to incline at an angle of 25 to 40 degrees with respect to the lower side, and more preferably within a range of 30 to 36 degrees.

- (4) to (6) are configured with the upper surface of the notch as a flat portion.

- the degree of freedom for determining the position of the operator's finger inside the notch can be improved.

- it can sufficiently cope with the difference in the palm size of the worker.

- Such a configuration is useful because there is a great demand for the raw material of the contents regardless of whether it is in Japan or abroad, and the worker's race is diverse and the physique is not uniform.

- FIG. 6A is a perspective view showing an example in the case where scales 70a and 70b indicating the length are provided on the upper side in the longitudinal direction of the lower box part 100.

- FIG. 6A By adopting such a configuration, when the film 41 is taken out from the inside of the packing box and cut at a desired position in the longitudinal direction of the lower box part 100, that is, the short direction of the film 41, the position is accurately and quickly obtained. Can be determined. Note that such a scale can be provided even in the case of a packaging box having a configuration in which only one notch is provided as shown in FIG.

- (1) shows an example in which graduations are added at predetermined intervals on the upper side in the longitudinal direction of the side plate portion of the lower box portion.

- the base point of the scale may take into account the thickness of the plastic bar 50a in advance.

- the scale is attached not only to one side plate portion 12b but also to the other side plate portion 12d so that the work is efficient based on the work procedure at the time of unpacking the packing box.

- FIG. 6A shows an example in which the scale 70b is also attached to the back surface of the side plate portion.

- the scale unit is not necessarily the same between the front surface and the back surface, and can be arbitrarily set according to the necessity in the work. For example, the front surface may be displayed in centimeters and the back surface may be displayed in inches.

- FIG. 6A shows an example in which the portion 80 with a predetermined interval of the attached scale is displayed in a different manner from the others.

- the length can be arbitrarily determined according to the work procedure, such as 5 centimeter increments or 10 centimeter increments.

- the slit blade 85 used when cutting the film with a desired width while taking out the film can be quickly and without error.

- the slit blade 85 may be configured by a clip portion 85a and a blade portion 85b for mounting on the upper side of the lower box portion.

- the blade 85b may be a simple pin.

- the slit blade 85 is preferably a clip-shaped main body that can be mounted on the upper side of the lower box portion 100 and provided with an upward blade. Using the slit blade having such a configuration, the film can be cut while being taken out.

- (4) is provided with a scale with a display of such a special mode at every predetermined interval on the inner side of the lower box part 100 as well.

- FIG. 6B shows a slit 90 provided at a predetermined position on the scale 80.

- a slit 90 provided at a predetermined position on the scale 80.

- Work efficiency can be improved by providing the slit 90 for attaching the cutter 60 in advance.

- the packaging box using a corrugated cardboard which has a rectangular top plate as shown to FIG. 1A was demonstrated as one embodiment, this invention is not limited to such an aspect.

- the contents of the box are not the original fabric, but take the form of a so-called single sheet in which sheets of about 0.5 to 2 m in length and 0.5 to 2 m in width are separated one by one, A box having a shape close to a square as shown in FIG. 7 is used. Even in this case, it is possible to improve the working efficiency by appropriately providing the notches 30a and 30b on the lower side of the upper lid.

- FIGS. 8 and 9 further arc-shaped or semi-circular cutout portions 31a to 31f, 32a, and 32b are provided on the short side of the upper lid portion. It is also possible to provide it at the leading edge of the folded flap and the leading edge of the folded flap on the long side of the lower box part so that a finger can be hooked.

- the shape and number of these notches can be set arbitrarily in consideration of the overall size, strength, shape, and ease of fingering of the box, but it is approximately semicircular with a size of about 1 to 2 fingers. It is conceivable to construct a substantially U-shape.

- a packaging box comprising an upper lid portion and a lower box portion made of corrugated cardboard for storing articles therein, wherein the upper lid portion covers the entire interior of the lower box portion and the top plate

- a side plate portion extending vertically downward from each side of the portion and substantially covering the side surface of the lower box portion, and the top plate portion has at least a pair of points symmetrical with respect to the center of gravity of the top plate portion.

- a packaging box wherein a perforation portion is provided, and the perforation portion is configured to be bendable.

- the perforation portion is configured so that the bent portion is separated from the center line of the top plate portion when bent toward the inside of the lower box portion.

- the packaging box according to (1) or (2). (4) Any one of (1) to (3), wherein the bent portion of the perforated portion has a side inclined outward from the center line of the top plate portion. Crab packing box. (5) Any one of (1) to (3), wherein the bent portion of the perforated portion has a portion that curves outward from the center line of the top plate portion. Crab packing box.

- the perforation part has a notch part perpendicular to the longitudinal direction of the upper lid part, and a pair of bends configured to protrude from the notch part into the lower box part when folded. It has a piece,

- the packaging box in any one of (1) to (5) characterized by the above-mentioned.

- a pair of the cutout portions of the upper lid portion are provided at the same position from both ends of the lower sides of the side plate portions in the longitudinal direction.

- each of the cutout portions has a flat portion parallel to the lower side.

- Each of the notch portions includes a linear portion that is inclined vertically upward at a predetermined angle toward the end portion, and an arc portion that is continuous with the linear portion (1) to ( 9) A packaging box according to any one of the above.

- the display of the length of the scale is shown in a mode different from the display of other lengths for each predetermined interval length, according to any one of (1) to (14),

- Packing box (17) The packing box according to any one of (1) to (16), wherein the scale is provided on both the front surface and the back surface of the side plate portion.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Cartons (AREA)

- Packaging Of Machine Parts And Wound Products (AREA)

- Packages (AREA)

Abstract

Description

例えば箱の内容物が原反ではなく、縦0.5~2m程度、横0.5~2m程度の大きさのシートが一枚ずつ分離しているいわゆる枚葉の形態を取る場合には、図7に示すような正方形に近い形状の箱を用いる。この場合でも上蓋の下辺に適宜切り欠き部30a、30bを設けて作業効率の向上を図ることが可能である。また上蓋の天板にミシン目部分や孔部分を設けてもよい。また、梱包箱の使用後の解体作業を容易にするため、図8や図9に示すように、更に円弧状や半円形状の切り欠き部31aから31f、32a、32bを、上蓋部短辺の折り返しフラップの先端縁や、下箱部長辺の折り返しフラップの先端縁に設け、指を掛けることができるようにすることも可能である。これらの切り欠き部の形状や数は、箱全体の大きさ、強度、形状や指のかけ易さなどを勘案して任意に設定できるが、指1~2本程度の大きさの略半円形や略U字形に構成することが考えられる。

(1)内部に物品を収容する、ダンボールで構成された上蓋部と下箱部とから成る梱包箱であって、前記上蓋部は前記下箱部の内部全体を覆う天板部と前記天板部の各辺から鉛直方向下向きに伸びて前記下箱部の側面を略覆う側板部とから成り、前記天板部には、前記天板部の重心についての点対称の位置に、少なくとも一対のミシン目部分を設け、前記ミシン目部分が折り曲げ可能に構成されていること、を特徴とする梱包箱。

(2)前記ミシン目部分は、前記下箱部の内部に向けて折り曲げ可能に構成されていること、を特徴とする(1)に記載の梱包箱。

(3)前記ミシン目部分は、前記下箱部の内部に向けて折り曲げた際に、折り曲げられた部分が前記天板部の中心線から離間するように構成されていること、を特徴とする(1)または(2)に記載の梱包箱。

(4)前記ミシン目部分の前記折り曲げられた部分は、前記天板部の中心線から外側に向かって傾斜する辺を有していること、を特徴とする(1)から(3)のいずれかに記載の梱包箱。

(5)前記ミシン目部分の前記折り曲げられた部分は、前記天板部の中心線から外側に向かって湾曲する部分を有していること、を特徴とする(1)から(3)のいずれかに記載の梱包箱。

(6)前記ミシン目部分は、前記上蓋部の長手方向に垂直な切り込み部を有し、折り曲げたときに前記切り込み部から離れて前記下箱部内部に突出するように構成された一対の折り曲げ片を有していること、を特徴とする(1)から(5)のいずれかに記載の梱包箱。

(7)前記上蓋部の長手方向の側板の下辺に少なくとも一つの切り欠き部が設けられていること、を特徴とする(1)から(6)のいずれかに記載の梱包箱。

(8)前記上蓋部の前記切り欠き部は、前記長手方向の双方の前記側板部の下辺であって双方の端部から等しい位置に一対設けられていること、を特徴とする(1)から(7)に記載の梱包箱。

(9)前記切り欠き部のそれぞれは、前記下辺と平行な平坦部分を有すること、を特徴とする(1)から(8)のいずれかに記載の梱包箱。

(10)前記切り欠き部のそれぞれは、前記端部に向かって所定角度で鉛直方向上向きに傾斜する直線部と前記直線部に連なる円弧部とを有すること、を特徴とする(1)から(9)のいずれかに記載の梱包箱。

(11)前記所定の角度は25度から40度の範囲であること、を特徴とする(1)から(10)のいずれかに記載の梱包箱。

(12)前記切り欠き部のそれぞれは、切り欠き部の長さを直径とする半円状であること、を特徴とする(1)から(11)に記載の梱包箱。

(13)前記切り欠き部の上部に、平坦部が設けられていること、を特徴とする(1)から(12)のいずれかに記載の梱包箱。

(14)前記下箱部の長手方向の側板部の上辺には、前記長手方向に沿った長さを示す目盛りが設けられていること、を特徴とする(1)から(13)のいずれかに記載の梱包箱

(15)前記目盛りは、双方の前記長手方向の側板部に設けられていること、を特徴とする(1)から(14)のいずれかに記載の梱包箱

(16)前記目盛りの長さの表示は、所定間隔の長さごとに、他の長さの表示と異なった態様で示されていること、を特徴とする(1)から(14)のいずれかに記載の梱包箱

(17)前記目盛りは、前記側板部の表面及び裏面の双方に設けられていること、を特徴とする(1)から(16)のいずれかに記載の梱包箱。

(18)前記目盛りの長さの表示が設けられている部分に、更にスリットを設けたこと、を特徴とする(1)から(17)のいずれかに記載の梱包箱。

(19)少なくとも前記下箱部の長手方向上辺は、ダンボールを折り返すことで形成されていること、を特徴とする(1)から(18)のいずれかに記載の梱包箱。

10 上蓋部

11 天板部

12a―12d 側板部

20a・20b ミシン目部

30a・30b 切り欠き部

100 下箱部

40・41 原反

50a・50b プラツバ

60 カッター

70a・70b・80 目盛り

85 スリット刃

85a クリップ部

85b 刃部

90 スリット

Claims (13)

- 内部に物品を収容する、ダンボールで構成された上蓋部と下箱部とから成る梱包箱であって、前記上蓋部は前記下箱部の内部全体を覆う天板部と前記天板部の各辺から鉛直方向下向きに伸びて前記下箱部の側面を略覆う側板部とから成り、前記上蓋部のいずれかの下辺に少なくとも一つの切り欠き部が設けられていること、を特徴とする梱包箱。

- 前記上蓋部の前記切り欠き部は、前記上蓋部の長手方向の双方の前記側板部の下辺であって双方の端部から等しい位置に一対設けられていること、を特徴とする請求項1に記載の梱包箱。

- 前記切り欠き部のそれぞれは、前記下辺と平行な平坦部分を有すること、を特徴とする請求項1または請求項2のいずれかの請求項に記載の梱包箱。

- 前記切り欠き部のそれぞれは、前記端部に向かって所定角度で鉛直方向上向きに傾斜する直線部と前記直線部に連なる円弧部とを有すること、を特徴とする請求項1から請求項3のいずれかの請求項に記載の梱包箱。

- 前記所定の角度は25度から40度の範囲であること、を特徴とする請求項1から請求項4のいずれかの請求項に記載の梱包箱。

- 前記切り欠き部のそれぞれは、切り欠き部の長さを直径とする半円状であること、を特徴とする請求項1から請求項5のいずれかの請求項に記載の梱包箱。

- 前記下箱部の長手方向上辺は、ダンボールを前記下箱部の内側に折り返すことで形成され、前記折り返しにより形成されるフラップの先端縁には、少なくとも一つの切り欠き部が設けられていること、を特徴とする請求項1から請求項6のいずれかの請求項に記載の梱包箱。

- 前記上蓋部の短手方向下辺は、ダンボールを前記上蓋部の内側に折り返すことで形成され、前記折り返しにより形成されるフラップの先端縁には、少なくとも一つの切り欠き部が設けられていること、を特徴とする請求項1から請求項7のいずれかの請求項に記載の梱包箱。

- 前記上蓋部の前記天板部には、少なくとも一つの、ミシン目部分が設けられていること、を特徴とする請求項1から請求項6のいずれかの請求項に記載の梱包箱。

- 前記上蓋部の前記天板部には、少なくとも一つの、孔部分が設けられていること、を特徴とする請求項1から請求項6のいずれかの請求項に記載の梱包箱。

- 前記ミシン目部分は、折り曲げ可能または切除可能に構成されていること、を特徴とする請求項9に記載の梱包箱。

- 前記ミシン目部分は、前記天板部の重心についての点対称の位置に、少なくとも一対設けられていること、を特徴とする請求項9または請求項11に記載の梱包箱。

- 前記下箱部の長手方向の側板部の上辺には、前記長手方向に沿った長さを示す目盛りが設けられていることを特徴とする、請求項1から請求項12のいずれかの請求項に記載の梱包箱。

Priority Applications (8)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020227010136A KR102509653B1 (ko) | 2014-02-14 | 2015-01-26 | 곤포 상자 |

| JP2015527701A JP5923220B2 (ja) | 2014-02-14 | 2015-01-26 | 梱包箱 |

| KR1020167021388A KR102381492B1 (ko) | 2014-02-14 | 2015-01-26 | 곤포 상자 |

| US15/118,647 US10093447B2 (en) | 2014-02-14 | 2015-01-26 | Packing box |

| CN201580008315.3A CN105980257B (zh) | 2014-02-14 | 2015-01-26 | 包装箱 |

| PH12016501542A PH12016501542A1 (en) | 2014-02-14 | 2016-08-04 | Packing box |

| PH12017500973A PH12017500973B1 (en) | 2014-02-14 | 2017-05-25 | Packing box |

| US16/116,398 US10549881B2 (en) | 2014-02-14 | 2018-08-29 | Packing box |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014-026283 | 2014-02-14 | ||

| JP2014026283 | 2014-02-14 |

Related Child Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US15/118,647 A-371-Of-International US10093447B2 (en) | 2014-02-14 | 2015-01-26 | Packing box |

| US16/116,398 Continuation US10549881B2 (en) | 2014-02-14 | 2018-08-29 | Packing box |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2015122263A1 true WO2015122263A1 (ja) | 2015-08-20 |

Family

ID=53800011

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2015/052001 WO2015122263A1 (ja) | 2014-02-14 | 2015-01-26 | 梱包箱 |

Country Status (8)

| Country | Link |

|---|---|

| US (2) | US10093447B2 (ja) |

| JP (2) | JP5923220B2 (ja) |

| KR (2) | KR102509653B1 (ja) |

| CN (2) | CN108328058B (ja) |

| HK (1) | HK1253943A1 (ja) |

| PH (2) | PH12016501542A1 (ja) |

| TW (2) | TWI701194B (ja) |

| WO (1) | WO2015122263A1 (ja) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2022114030A1 (ja) * | 2020-11-26 | 2022-06-02 | 大王製紙株式会社 | シート収納箱 |

| WO2022230212A1 (ja) * | 2021-04-27 | 2022-11-03 | 株式会社きもと | 梱包箱 |

| WO2022230211A1 (ja) * | 2021-04-27 | 2022-11-03 | 株式会社きもと | 梱包箱 |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108328058B (zh) | 2014-02-14 | 2019-11-22 | 理研科技株式会社 | 包装箱 |

| USD769115S1 (en) * | 2014-06-02 | 2016-10-18 | Riken Technos Corporation | Packaging box |

| US20220127067A1 (en) * | 2016-01-19 | 2022-04-28 | David Paul Goodrich | Slit paper expansion method and apparatus |

| USD861477S1 (en) * | 2017-10-02 | 2019-10-01 | Reynolds Consumer Products LLC | Container |

| USD873129S1 (en) * | 2017-12-07 | 2020-01-21 | The Procter & Gamble Company | Container |

| WO2024178479A1 (pt) * | 2023-02-27 | 2024-09-06 | Westrock, Celulose, Papel E Embalagens Ltda | Disposição construtiva em embalagem para pizza e similares |

Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5930826U (ja) * | 1982-05-29 | 1984-02-25 | ワイケイケイ株式会社 | 物品収納容器 |

| JPS6349316U (ja) * | 1986-09-17 | 1988-04-04 | ||

| JPH0185220U (ja) * | 1987-11-30 | 1989-06-06 | ||

| JPH11115930A (ja) * | 1997-10-16 | 1999-04-27 | Matsushita Electric Works Ltd | 包装箱及び包装箱の使用方法 |

| JP3059671U (ja) * | 1998-09-04 | 1999-07-13 | 株式会社ケルン | カルテ、レントゲンフィルム等整理保管用箱 |

| JP2000238742A (ja) * | 1999-02-22 | 2000-09-05 | Otsuka Hoso Kogyo Kk | 組立式2重壁箱 |

| JP2002037240A (ja) * | 2000-07-28 | 2002-02-06 | Dainippon Printing Co Ltd | 包装箱 |

| JP2002225854A (ja) * | 2001-01-25 | 2002-08-14 | Heart Kk | 紙製名刺箱 |

| JP2002240868A (ja) * | 2001-02-12 | 2002-08-28 | Tadatora Nagao | 魚尺付きク−ラ−ボックス |

| JP3095583U (ja) * | 2003-01-28 | 2003-08-08 | 福澤紙器工業有限会社 | 名刺用包装紙箱 |

| JP2004067209A (ja) * | 2002-08-08 | 2004-03-04 | Rengo Co Ltd | 包装箱 |

| US6708874B1 (en) * | 2002-05-28 | 2004-03-23 | Footstar Corporation | Carton with finger holes |

| JP2005329971A (ja) * | 2004-05-19 | 2005-12-02 | Toli Corp | ロール巻シート材の梱包容器 |

| JP2013124112A (ja) * | 2011-12-13 | 2013-06-24 | Riken Technos Corp | ラップフィルム収納箱 |

Family Cites Families (40)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US310241A (en) * | 1885-01-06 | Paper box | ||

| US2474783A (en) * | 1946-04-08 | 1949-06-28 | Minerva Wax Paper Company | Carton |

| US3018940A (en) * | 1959-10-29 | 1962-01-30 | Edwin F Deline | Carton |

| JPS52171526U (ja) * | 1976-06-15 | 1977-12-27 | ||

| US4127228A (en) * | 1977-08-04 | 1978-11-28 | Willamette Industries, Inc. | Asparagus box |

| JPS5827119U (ja) * | 1981-08-19 | 1983-02-21 | 株式会社東芝 | 包装箱 |

| JPH0621854Y2 (ja) * | 1988-10-14 | 1994-06-08 | ニチバン株式会社 | 偏平小袋包装物の箱詰包装体 |

| US5072876A (en) * | 1990-10-30 | 1991-12-17 | Riverwood International Corporation | Article carrier with side handles |

| JPH04128214U (ja) * | 1991-05-17 | 1992-11-24 | ハナマルキ株式会社 | 即席汁物用カツプ梱包箱 |

| JP2004102221A (ja) | 2002-07-18 | 2004-04-02 | Fuji Photo Film Co Ltd | ロール状感光材料の包装用コンテナ |

| JP2005231667A (ja) * | 2004-02-19 | 2005-09-02 | Rengo Co Ltd | 包装箱 |

| JP4427386B2 (ja) * | 2004-05-31 | 2010-03-03 | サントリーホールディングス株式会社 | 包装具 |

| JP2005350133A (ja) * | 2004-06-14 | 2005-12-22 | Century Foods Kk | ケーキ用容器 |

| RU2007107916A (ru) * | 2004-08-04 | 2008-09-10 | МИДВЕСТВАКО ПЭКЭДЖИНГ СИСТЕМЗ, ЭлЭлСи (US) | Коробка, состоящая из двух частей |

| JP4468793B2 (ja) * | 2004-11-22 | 2010-05-26 | レンゴー株式会社 | 包装箱 |

| AR053175A1 (es) * | 2005-03-18 | 2007-04-25 | Int Paper Co | Recipiente de carton con costuras y asa moldeadas por inyeccion y un metodo para fabricarlo |

| US7743915B2 (en) * | 2006-01-24 | 2010-06-29 | Meadwestvaco Corporation | Carton having adjustment indicia |

| US7798391B2 (en) * | 2006-03-27 | 2010-09-21 | Innovative Packaging Designs L.P. | Display ready container |

| US7377420B2 (en) * | 2006-03-31 | 2008-05-27 | Weyerhaeuser Company | Two piece bliss box with sloped bottom |

| US20080054055A1 (en) * | 2006-08-31 | 2008-03-06 | Holley John M | Carton with reinforced handle openings |

| US7780067B2 (en) * | 2006-08-31 | 2010-08-24 | Meadwestvaco Packaging Systems, Llc | Carton with reinforced handle openings |

| JP2008230670A (ja) | 2007-03-22 | 2008-10-02 | Nihon Soreuse:Kk | 梱包箱 |

| EP2165939B1 (en) * | 2007-06-15 | 2014-08-20 | Asahi Kasei Chemicals Corporation | Film storage box |

| CN201245334Y (zh) * | 2008-07-16 | 2009-05-27 | 英业达科技有限公司 | 包装箱 |

| KR20100008835U (ko) * | 2009-02-27 | 2010-09-06 | 박신영 | 포장박스 |

| CN201472750U (zh) * | 2009-09-15 | 2010-05-19 | 富士胶片株式会社 | 包装箱 |

| CN201512211U (zh) * | 2009-09-17 | 2010-06-23 | 厦门搜巡科技有限公司 | 具有测量功能的鞋盒 |

| CN201647429U (zh) * | 2010-01-19 | 2010-11-24 | 广东天章信息纸品有限公司 | 一种带刻度的卷式打印纸包装箱 |

| JP5409539B2 (ja) * | 2010-07-27 | 2014-02-05 | 京セラドキュメントソリューションズ株式会社 | 個装ケース |

| CN103201181A (zh) * | 2010-11-09 | 2013-07-10 | 株式会社吴羽 | 包装膜收置容器以及包装膜供给用具 |

| US9242759B2 (en) * | 2011-04-25 | 2016-01-26 | William Mitchell Scott | Container with grips |

| WO2012154763A2 (en) * | 2011-05-08 | 2012-11-15 | Scott William Mitchell | Container box |

| JP2013193782A (ja) | 2012-03-22 | 2013-09-30 | Mitsui Chemicals Tohcello Inc | ロール体梱包箱 |

| US9096343B2 (en) * | 2012-04-03 | 2015-08-04 | Innovative Packaging Designs L.P. | Display ready container |

| US20150136619A1 (en) * | 2012-05-07 | 2015-05-21 | William Mitchell Scott | Container with improved locking ports |

| CA2873059A1 (en) * | 2012-05-10 | 2013-11-14 | Marbles, Llc | Container box with grips |

| US9051075B2 (en) * | 2012-09-07 | 2015-06-09 | William M. Scott | Corrugated container box and blank |

| US8991686B2 (en) * | 2013-04-30 | 2015-03-31 | Menasha Corporation | Eye shield lens dispenser tray |

| CN203306470U (zh) * | 2013-07-01 | 2013-11-27 | 桐乡市濮院毛针织技术服务中心 | 一种盖合式羊毛衫用包装盒 |

| CN108328058B (zh) | 2014-02-14 | 2019-11-22 | 理研科技株式会社 | 包装箱 |

-

2015

- 2015-01-26 CN CN201810151077.7A patent/CN108328058B/zh active Active

- 2015-01-26 CN CN201580008315.3A patent/CN105980257B/zh active Active

- 2015-01-26 JP JP2015527701A patent/JP5923220B2/ja active Active

- 2015-01-26 KR KR1020227010136A patent/KR102509653B1/ko active IP Right Grant

- 2015-01-26 KR KR1020167021388A patent/KR102381492B1/ko active IP Right Grant

- 2015-01-26 US US15/118,647 patent/US10093447B2/en active Active

- 2015-01-26 WO PCT/JP2015/052001 patent/WO2015122263A1/ja active Application Filing

- 2015-02-06 TW TW108118433A patent/TWI701194B/zh active

- 2015-02-06 TW TW104104071A patent/TWI667175B/zh active

-

2016

- 2016-01-08 JP JP2016002966A patent/JP6795304B2/ja active Active

- 2016-08-04 PH PH12016501542A patent/PH12016501542A1/en unknown

-

2017

- 2017-05-25 PH PH12017500973A patent/PH12017500973B1/en unknown

-

2018

- 2018-08-29 US US16/116,398 patent/US10549881B2/en active Active

- 2018-10-12 HK HK18113093.9A patent/HK1253943A1/zh unknown

Patent Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5930826U (ja) * | 1982-05-29 | 1984-02-25 | ワイケイケイ株式会社 | 物品収納容器 |

| JPS6349316U (ja) * | 1986-09-17 | 1988-04-04 | ||

| JPH0185220U (ja) * | 1987-11-30 | 1989-06-06 | ||

| JPH11115930A (ja) * | 1997-10-16 | 1999-04-27 | Matsushita Electric Works Ltd | 包装箱及び包装箱の使用方法 |

| JP3059671U (ja) * | 1998-09-04 | 1999-07-13 | 株式会社ケルン | カルテ、レントゲンフィルム等整理保管用箱 |

| JP2000238742A (ja) * | 1999-02-22 | 2000-09-05 | Otsuka Hoso Kogyo Kk | 組立式2重壁箱 |

| JP2002037240A (ja) * | 2000-07-28 | 2002-02-06 | Dainippon Printing Co Ltd | 包装箱 |

| JP2002225854A (ja) * | 2001-01-25 | 2002-08-14 | Heart Kk | 紙製名刺箱 |

| JP2002240868A (ja) * | 2001-02-12 | 2002-08-28 | Tadatora Nagao | 魚尺付きク−ラ−ボックス |

| US6708874B1 (en) * | 2002-05-28 | 2004-03-23 | Footstar Corporation | Carton with finger holes |

| JP2004067209A (ja) * | 2002-08-08 | 2004-03-04 | Rengo Co Ltd | 包装箱 |

| JP3095583U (ja) * | 2003-01-28 | 2003-08-08 | 福澤紙器工業有限会社 | 名刺用包装紙箱 |

| JP2005329971A (ja) * | 2004-05-19 | 2005-12-02 | Toli Corp | ロール巻シート材の梱包容器 |

| JP2013124112A (ja) * | 2011-12-13 | 2013-06-24 | Riken Technos Corp | ラップフィルム収納箱 |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2022114030A1 (ja) * | 2020-11-26 | 2022-06-02 | 大王製紙株式会社 | シート収納箱 |

| WO2022230212A1 (ja) * | 2021-04-27 | 2022-11-03 | 株式会社きもと | 梱包箱 |

| WO2022230211A1 (ja) * | 2021-04-27 | 2022-11-03 | 株式会社きもと | 梱包箱 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20180370679A1 (en) | 2018-12-27 |

| TWI701194B (zh) | 2020-08-11 |

| KR20220042496A (ko) | 2022-04-05 |

| US10093447B2 (en) | 2018-10-09 |

| HK1253943A1 (zh) | 2019-07-05 |

| JP2016084182A (ja) | 2016-05-19 |

| KR20160122714A (ko) | 2016-10-24 |

| KR102509653B1 (ko) | 2023-03-14 |

| US20170050759A1 (en) | 2017-02-23 |

| CN108328058A (zh) | 2018-07-27 |

| CN105980257A (zh) | 2016-09-28 |

| CN105980257B (zh) | 2018-02-16 |

| JPWO2015122263A1 (ja) | 2017-03-30 |

| TW201540616A (zh) | 2015-11-01 |

| TW201936453A (zh) | 2019-09-16 |

| TWI667175B (zh) | 2019-08-01 |

| PH12016501542B1 (en) | 2017-02-06 |

| PH12017500973A1 (en) | 2017-10-02 |

| PH12017500973B1 (en) | 2017-10-02 |

| JP6795304B2 (ja) | 2020-12-02 |

| PH12016501542A1 (en) | 2017-02-06 |

| CN108328058B (zh) | 2019-11-22 |

| JP5923220B2 (ja) | 2016-05-24 |

| KR102381492B1 (ko) | 2022-03-31 |

| US10549881B2 (en) | 2020-02-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5923220B2 (ja) | 梱包箱 | |

| US7000962B2 (en) | Stick-on handle for boxes and containers | |

| JP2016084182A5 (ja) | ||

| JP2015101367A (ja) | 精密機器用梱包箱 | |

| JP2015127208A (ja) | 物品運送用梱包具 | |

| JP2006182453A (ja) | 家庭用薄葉紙収納箱 | |

| JP3125305U (ja) | 荷造り紐用収納ケース | |

| JP2015034043A (ja) | ラップフィルム収納箱 | |

| JP6285148B2 (ja) | 台座付き台紙 | |

| TWI538859B (zh) | The lining of the gift box | |

| JP6927511B2 (ja) | 物品支持構造体 | |

| JP5697824B2 (ja) | 容器取り出し用シート | |

| JP2016124561A (ja) | ロール製品用ケース | |

| JP7273406B2 (ja) | ハンガー用掛止部品 | |

| JP2011098760A (ja) | 収納部材 | |

| JP2020055616A (ja) | 搬送補助具及び梱包体 | |

| JP3164820U (ja) | 菓子用トレイ | |

| JP3115462U (ja) | 外装ケース | |

| JP2017039526A (ja) | 荷物運搬シート | |

| JP2022100747A (ja) | 物品陳列用ボード | |

| JP2021024596A (ja) | 包装箱 | |

| JP2014024564A (ja) | 梱包容器 | |

| JP2013166559A (ja) | キャリーケース | |

| JP2014077026A (ja) | 片面粘着テープ、片面粘着テープ巻回体及びテープ引き出し装置 | |

| JP2006219194A (ja) | 外装ケース |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| ENP | Entry into the national phase |

Ref document number: 2015527701 Country of ref document: JP Kind code of ref document: A |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 15749049 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 20167021388 Country of ref document: KR Kind code of ref document: A |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 12016501542 Country of ref document: PH |

|

| WWE | Wipo information: entry into national phase |

Ref document number: IDP00201605341 Country of ref document: ID Ref document number: 15118647 Country of ref document: US |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 15749049 Country of ref document: EP Kind code of ref document: A1 |