WO2014196609A1 - Corps de boîtier isolant et réfrigérateur - Google Patents

Corps de boîtier isolant et réfrigérateur Download PDFInfo

- Publication number

- WO2014196609A1 WO2014196609A1 PCT/JP2014/065001 JP2014065001W WO2014196609A1 WO 2014196609 A1 WO2014196609 A1 WO 2014196609A1 JP 2014065001 W JP2014065001 W JP 2014065001W WO 2014196609 A1 WO2014196609 A1 WO 2014196609A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- heat insulating

- insulating material

- box

- vacuum heat

- refrigerator

- Prior art date

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D23/00—General constructional features

- F25D23/06—Walls

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D23/00—General constructional features

- F25D23/06—Walls

- F25D23/062—Walls defining a cabinet

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D2201/00—Insulation

- F25D2201/10—Insulation with respect to heat

- F25D2201/14—Insulation with respect to heat using subatmospheric pressure

Definitions

- the present invention relates to a heat insulating box with a vacuum heat insulating material, a refrigerator with a vacuum heat insulating material, a showcase, a hot water storage device, a device with a vacuum heat insulating material, and the like.

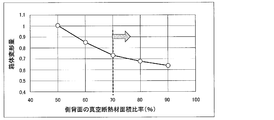

- a technology has been proposed in which a vacuum heat insulating material is arranged in addition to a hard urethane foam in a heat insulating box body in which an outer box and an inner box are formed. And a vacuum heat insulating material, and an invention of a heat insulating box body in which the coverage of the vacuum heat insulating material is defined with respect to the outer box surface area has been proposed (see Patent Document 1).

- a rail member that supports a drawer-type case is fixed to an inner box with a screw or the like (see Patent Document 3).

- the rail member is fixed to the drawer door of the drawer-type storage chamber with a screw or the like. (See Patent Document 4)

- the vacuum heat insulating material has a heat insulating performance of, for example, 6 times or more that of a conventional hard urethane foam. For this reason, from the viewpoint of energy saving and the like, in addition to the hard urethane foam, a vacuum heat insulating material has also been disposed in the space formed between the outer box and the inner box. In recent years, as the demand for energy saving increases, the amount of vacuum heat insulating material disposed in the heat insulating box, such as the heat insulating box described in Patent Document 1, has also increased.

- the conventional heat insulation box has been manufactured based on the technical idea that the hard urethane foam mainly has a heat insulation function, and the vacuum heat insulation material assists the heat insulation function of the hard urethane foam.

- the conventional heat insulation box body is obtained by filling the space between the inner box and the outer box with rigid urethane foam at a predetermined density, but the strength of the box body is reduced.

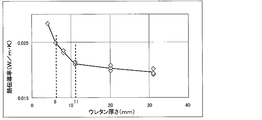

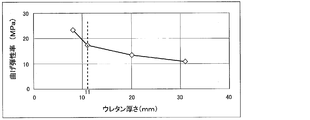

- the thickness of the urethane decreases, the density of the urethane increases and the heat insulation performance decreases, so that the heat insulation performance is satisfied and the necessary box strength is obtained. It was difficult.

- the heat insulation performance of the wall surface and box body and the strength of the box body and wall are secured by rigid urethane foam, and the wall thickness of the heat insulation box body If the thickness of the rigid urethane foam is reduced in order to reduce the thickness, the heat insulation performance of the heat insulation box is insufficient or the strength is insufficient, and it is difficult to reduce the wall thickness.

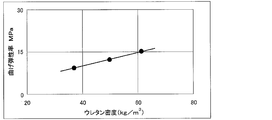

- the heat insulation box of patent document 1 since the usage-amount (coverage rate) of a vacuum heat insulating material is increased, the bending elastic modulus (rigidity of a hard urethane foam) of hard urethane foam is enlarged. It seems that the wall thickness can be reduced to some extent from the strength aspect of the heat insulation box.

- the heat insulation box described in Patent Document 1 is manufactured based on the technical idea that the hard urethane foam is mainly responsible for the heat insulation function, and the vacuum heat insulating material assists the heat insulation function of the hard urethane foam.

- the foam mainly performs a heat insulating function, and the vacuum heat insulating material assists the heat insulating function of the hard urethane foam, and the heat insulating performance of the heat insulating box and the strength of the wall surface are ensured by the hard urethane foam.

- the bending elastic modulus and density of the rigid urethane foam are set to be equal to or less than predetermined values (flexural modulus of 10 MPa or less, density of 60 kg / m 3 or less). ing.

- Patent Document 2 discloses that as a measure against the strength of a heat insulating box provided with a vacuum heat insulating material, a plastic material or the like is formed on the outer packaging material of the vacuum heat insulating material into a desired shape by vacuum forming, pressure forming, etc.

- a vacuum heat insulating material, an inner box, and an outer box formed into a concavo-convex shape ensuring strength by filling a core material is used.

- the inner box and the outer box are fitted with a concave and convex shape that is substantially the same as the concave and convex shape of the outer packaging material of the vacuum heat insulating material to give strength to the inner box and the outer box.

- the vacuum heat insulating material also needs to be molded into an irregular shape to ensure strength

- the core material enclosed in the outer packaging material also needs to have a shape that conforms to the irregular shape of the outer packaging material. It is necessary to use a granular material having the property, and the cost is increased as compared with a fiber-based core material such as glass fiber, and the heat insulation performance may be deteriorated. Further, the back surface of the room (the storage space for stored items in the heat insulation box) has an uneven shape, the shape is complicated, and the design is poor.

- the urethane inlet provided in the width direction end portion (or the vertical end portion) of the back surface of the heat insulating box is a vacuum heat insulating material. Therefore, the vacuum heat insulating material cannot be increased in the width direction (or the vertical direction), and it is difficult to improve the heat insulating performance.

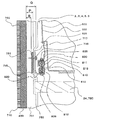

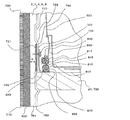

- a rail member or a door frame that supports a case of a drawer-type storage chamber is insulated with a heat insulating wall (an inner box, or an urethane box between an inner box and an outer box). Material, or a reinforcing member provided between the inner box and the outer box).

- a vacuum heat insulating material is disposed between the outer box and the inner box, if the thickness of the heat insulating material between the vacuum heat insulating material and the inner box is thin, the thickness of the vacuum heat insulating material may vary. There is a risk that the fixing screw of the rail member or the door frame may damage or break the outer packaging material of the vacuum heat insulating material, thereby reducing the heat insulating performance and reliability of the vacuum heat insulating material.

- the length of the screw portion of the screw could not be shortened to a predetermined length or less.

- another member that is held or fixed to a heat insulating wall having a vacuum heat insulating material by a screw or a fitting structure for example, a heavy weight support member that supports a heavy object such as a rail member or a door frame that supports a case, or

- a vibration-affected member that is affected by vibration during operation such as a cooler that generates cool air to cool the storage room or a fan that blows cool air into the storage room

- the attachment site has sufficient mounting strength.

- the wall thickness of the fixing member such as a screw is difficult to reduce to a predetermined length (for example, 15 mm) or less because of the mounting strength of the screw. It was difficult to increase the internal volume.

- the present invention has been made to solve the above-mentioned problems, and has as its main purpose to ensure the heat insulation performance and strength of the heat insulation box.

- an object is to obtain a heat insulating box, a refrigerator, a hot water storage device, a device having a high temperature part or a low temperature part, etc., capable of reducing the thickness of the heat insulating wall or the heat insulating material.

- the purpose is to obtain a heat insulating box, refrigerator, hot water storage device, equipment, etc.

- the heat insulating wall or the heat insulating material is made thinner.

- the purpose is to obtain a heat insulating box, refrigerator, hot water storage device, equipment, etc.

- Another object of the present invention is to obtain a heat-insulating box, a refrigerator, a hot water storage device, equipment, and the like that are highly reliable and have a large internal volume.

- the thickness of the heat insulation wall is reduced, and the size of the outer shape of the heat insulation box such as a cylinder, a square tube, or a box having a front opening (for example, the outer diameter)

- the purpose is to obtain a compact heat insulating box, refrigerator, hot water storage device, equipment, etc. with reduced width, depth, height, etc.

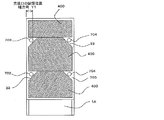

- the refrigerator of the present invention is formed of an outer box and an inner box, and a box having a back wall and a side wall;

- a storage chamber having an opening on the front surface formed by partitioning the box body with a partition wall;

- a drawer-type case that is housed in the storage chamber and pulled out via a rail member provided on the side wall of the storage chamber;

- a vacuum insulating material disposed between the inner box and the outer box, the core material being formed of a fiber-based material made of inorganic fiber or organic fiber, and forming the side wall provided with the rail member;

- the refrigerator of the present invention is formed of an outer box and an inner box, and has a top wall, a back wall, a side wall, and a box body having a bottom wall, A storage chamber having an opening on the front surface formed by partitioning the box body with a partition wall; A drawer-type case that is housed in the storage chamber and pulled out via a rail member provided on the partition wall that forms the bottom or top surface of the storage chamber; A vacuum heat insulating material disposed in the partition wall in which the core material is formed of a fiber-based material made of inorganic fiber or organic fiber, and the rail member is provided; In the partition wall at a position facing the rail member, a heat insulating material that is filled, applied, or arranged between the outer member forming the partition wall and the vacuum heat insulating material, With The thickness of the heat insulating material at a position facing the rail member is smaller than 10 mm, and the density of the heat insulating material is larger than 60 kg / m 3 .

- the heat insulation box of the present invention is formed of an outer box and an inner box, and is a box having a back wall and a side wall, provided in the box, and having a storage chamber having an opening on the front surface,

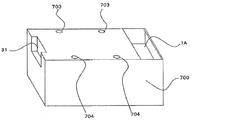

- a vacuum heat insulating material provided on the outer box side in the back wall; Provided at the width direction end or the vertical direction end of the back wall, and an injection port for injecting a stock solution of foam heat insulating material into the back wall, and

- the vacuum heat insulating material is provided with a notch such as a notch or an opening so as not to interfere with the inlet at a portion facing the inlet.

- the thickness of the foam heat insulating material after injection is smaller than 10 mm.

- the heat insulating box having the above configuration is applied to a device such as a refrigerator, so that the wall thickness of the box can be reduced, so that the volume of the storage space or the storage chamber can be increased without increasing the outer shape of the box. Can be increased.

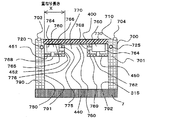

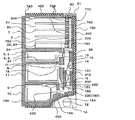

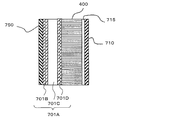

- FIG. 1 It is a schematic diagram of another cross-sectional shape of the heat insulation box side wall after a hard urethane foam foams. It is principal part sectional drawing of the rail attachment part vicinity of the refrigerator showing embodiment of this invention. It is principal part sectional drawing of the rail attachment part vicinity of another refrigerator showing embodiment of this invention. It is principal part sectional drawing of the rail attachment part vicinity of another refrigerator showing embodiment of this invention. It is principal part sectional drawing of the rail attachment part vicinity of another refrigerator showing embodiment of this invention.

- Embodiment 1 (refrigerator) 1 is a front view of a refrigerator representing Embodiment 1 of the present invention

- FIG. 2 is a side sectional view of the refrigerator illustrating Embodiment 1 of the present invention

- the refrigerator 1 includes a refrigerator compartment 2 which is a double door (or openable) storage room at the top.

- an ice making room 3 and a switching room 4 which are storage rooms are arranged in parallel on the left and right.

- a freezer room 6 serving as a storage room is provided at the bottom of the refrigerator 1

- a vegetable room 5 serving as a storage room is provided above the freezer room 6.

- the vegetable compartment 5 is provided above the freezing compartment 6 below the ice making compartment 3 and the switching compartment 4 arranged in parallel on the left and right.

- the refrigerator compartment 2 which is a storage room, has a storage product storage space for storing storage products (food, beverages, etc.), and the storage product storage space has a plurality of resins on which the storage products are placed.

- a shelf 80 made of glass or glass is provided below this storage space (under the shelf in the cabinet), containers 2X and 2Y having a substantially sealed structure are provided, and a chilled chamber 2X controlled to a chilled temperature range of about + 3 ° C to -3 ° C, Alternatively, it is used as a vegetable room 2Y controlled in a temperature range of the vegetable room maintained at about + 3 ° C. to + 5 ° C.

- the substantially sealed containers 2X and 2Y may be used as an egg compartment for storing eggs. Further, the containers 2X and 2Y having a substantially sealed structure have, for example, a pull-out structure, and a stored product can be taken in and out by pulling out the container.

- a container having a substantially sealed structure can be configured by providing a detachable lid on the upper surface opening of the container having an upper surface opening having an upper surface.

- the lid may be provided on the container, may be provided on a shelf 80 or a partition wall provided on the top of the container, or the shelf or the partition wall itself on the top of the container may be used as the lid.

- the arrangement of the respective chambers is not limited to the present embodiment, and the ice making chamber 3 and the switching chamber 4 are arranged in parallel on the left and right below the refrigerating chamber 2 provided in the upper stage.

- An ice making room arranged in parallel with the so-called vegetable room 5 in the freezing room 6 below the arranged ice making room 3 and switching room 4 and above the vegetable room 5 provided in the lower stage.

- the mid freezer type in which the freezing chamber 6 is disposed is closer to the low temperature chamber (for example, the ice making chamber 3, the switching chamber 4, the freezing chamber 6), so that a heat insulating material between the low temperature chambers is provided. Since it is unnecessary and there are few heat leaks, an energy-saving and low-cost refrigerator can be provided.

- the front side opening of the refrigerating room 2 which is a storage room is provided with a double door type refrigerating room door 7 which can be freely opened and closed.

- This refrigerating room door 7 has a refrigerating room door left 7A and a refrigerating room door 7A.

- Two doors on the right side of the room door 7B constitute a Kannon type door.

- a single-piece rotary door may be used instead of the Kannon door.

- the ice making room 3, the switching room 4, the vegetable room 5, and the freezing room 6, which are other storage rooms have a drawer type ice making room door 8 and a switching room that can freely open and close the opening of the ice making room 3.

- a drawer-type freezer compartment door 11 that can freely open and close the opening is provided.

- a rail member is attached to the inner box 750 forming the storage room, such as a screw.

- the door and door frame are fixed or held by the rail fixing member 735 or the fitting structure, and the door frame fixed or held on the door inner plate slides on the rail member directly or via a roller. The case placed on can be pulled out.

- an operation switch (room for setting the temperature in the storage chamber) is provided on either the left or right refrigerator door left 7A or the right refrigerator door right 7B of the refrigerator room 2 as a storage room.

- a selection switch 60a, a temperature zone changeover switch 60b, a quick freeze switch 60c, an ice making changeover switch 60d, a mist supply switch 60e) and an operation panel 60 for displaying temperature information such as the inside temperature and the set temperature are provided.

- Operation information of the switch, display information on the liquid crystal display unit, temperature information in the storage chamber, and the like are controlled by the control device 30 configured by a control board mounted with a microcomputer or the like provided on the upper back of the refrigerator (the back of the refrigerator compartment). .

- a compressor 12 is disposed in the machine room 1A provided at the lowermost back of the refrigerator 1.

- the refrigerator 1 is provided with a refrigeration cycle, and the compressor 12 is a component that constitutes the refrigeration cycle and is disposed in the machine room 1A, and has an action of compressing a refrigerant in the refrigeration cycle.

- the refrigerant compressed by the compressor 12 is condensed in a condenser (not shown).

- the condensed refrigerant is decompressed in a capillary tube (not shown) or an expansion valve (not shown) which is a decompression device.

- the cooler 13 is a component that constitutes the refrigeration cycle of the refrigerator and is disposed in the cooler chamber 131.

- the refrigerant decompressed by the decompression device evaporates in the cooler 13, and the gas around the cooler 13 is cooled by the endothermic action during the evaporation.

- the cool air circulation fan 14 is disposed in the cooler chamber 131 in the vicinity of the cooler 13, and cools the cool air around the cooler 13 as a cool air path (for example, the switching chamber cool air path 16 or the refrigerating room cool air wind). It is for ventilating to each room (refrigeration room 2, ice making room 3, switching room 4, vegetable room 5, freezing room 6) which is a storage room of refrigerator 1 via way 50 etc.).

- a defrosting heater 150 (a defrosting glass tube heater, which is a defrosting means for defrosting the cooler 13, for example, in a quartz glass tube. And a carbon heater using carbon fibers that emit light having a wavelength of 0.2 ⁇ m to 4 ⁇ m that is transmitted through the quartz glass tube.

- a heater roof 151 is provided above the defrosting heater 150 between the cooler 13 and the defrosting heater 150 so that the defrosting water falling from the cooler 13 does not directly hit the defrosting heater 150. ing.

- the frost in the cooler 13 can be efficiently melted by radiant heat transfer, so the surface temperature is low (about 70 ° C to 80 ° C). If a flammable refrigerant (such as isobutane, which is a hydrocarbon refrigerant) is used as the refrigerant used in the refrigeration cycle, the risk of ignition is reduced even if refrigerant leakage occurs. it can. Moreover, since the frost of the cooler 13 can be efficiently melted by radiant heat transfer as compared with the nichrome wire heater, the frost formed on the cooler 13 gradually melts, and the frost quickly falls into a lump. Therefore, since the falling sound when falling on the heater roof 151 can be reduced, a refrigerator with low noise and good defrosting efficiency can be provided.

- a black medium heater such as a carbon heater

- the defrosting heater 150 may be a stowage type heater integrally incorporated in the cooler 13.

- a glass tube type heater and a bite type heater may be used in combination.

- the defrost water generated in the cooler 13 or the defrost water dropped on the heater roof 151 falls in the cooler chamber and is provided outside the refrigerator (for example, a machine) from the defrost water discharge port provided below the cooler chamber 131. It is discharged to an evaporating dish or the like provided in the chamber 1A.

- the switching chamber damper 15 that is an air volume adjusting means adjusts the amount of cool air blown to the switching chamber 4 that is a storage chamber by the cool air circulation fan 14, and controls the temperature in the switching chamber 4 to a predetermined temperature, This is for switching the set temperature of the switching chamber 4.

- the cold air cooled by the cooler 13 is blown into the switching chamber 4 through the switching chamber cold air passage 16 which is a cold air passage.

- the switching chamber cold air passage 16 is arranged downstream of the switching chamber damper 15.

- the cold room damper 55 as the air volume adjusting means also adjusts the amount of cold air blown to the cold room 2 as the storage room by the cold air circulation fan 14 and controls the temperature in the cold room 2 to a predetermined temperature. Or for changing the set temperature of the refrigerator compartment 2.

- the cold air cooled by the cooler 13 is blown into the refrigerating chamber 2 through the refrigerating chamber cold air passage 50 which is a cold air passage.

- the switching room 4 which is a storage room, is a room (storage) in which the temperature in the storage room can be selected from a plurality of stages between a freezing temperature zone ( ⁇ 17 ° C. or lower) and a vegetable room temperature zone (3 to 10 ° C.).

- the temperature in the storage room is selected or switched by operating the operation panel 60 installed in either the refrigerator compartment door left 7A or the refrigerator compartment door right 7B of the refrigerator 1.

- a switching chamber thermistor 19 (see FIG. 3), which is a first temperature detecting means for detecting the air temperature in the switching chamber 4, is installed on, for example, the back wall surface of the switching chamber 4.

- a thermopile which is a second temperature detecting means for directly detecting the surface temperature of the stored material put into the switching chamber 4 which is a storage chamber, on the top surface (center portion, front surface portion, rear surface portion, etc.) 22 (see FIG. 3 or an infrared sensor) is installed.

- the air passage that sends the cold air from the cooler chamber 131 to the switching chamber 4 is provided with a switching chamber damper 15 that is an air volume adjusting device that can block the air flow by controlling the air volume and blocking the air passage.

- the temperature of the switching chamber 4 is adjusted to be in the selected temperature range by opening and closing the switching chamber damper 15 by the detection temperature of the switching chamber thermistor 19 (or the detection temperature of the thermopile 22) as the temperature detection means. Or controlled by the control device 30 so as to fall within the set temperature range. Further, the thermopile 22 serving as the second temperature detecting means directly detects the temperature of the food that is stored in the switching chamber 4.

- the machine room 1A is provided at the lowermost part of the back surface of the refrigerator 1 is shown, it may be provided at the upper part of the back surface (for example, the uppermost part of the back surface).

- Electrostatic atomization which is a mist device that supplies mist to be sterilized or humidified in the storage chamber, for example, to the partition wall 51 (back wall, heat insulating wall) on the back side (back side) of the refrigerator compartment 2, for example.

- An apparatus 200 is provided.

- a cooling member for example, a cooling plate

- the rear partition wall 51 or the cooler chamber wall that forms the front wall of the cooler chamber 131 in which the cooler 13, the cool air circulation fan 14, and the like are arranged is provided so as to contact or penetrate.

- the partition wall 51 may be the back wall 730, the side wall 790, the top wall 740, the bottom wall 780, and the partition wall 24 between the storage rooms.

- This cooling member (for example, a cooling plate) is stored in the cold air in the cold air flow paths 50 and 760, which are cold air paths provided on the back side, the side surface, and the top and bottom of the partition wall 51, or stored in the partition wall 51.

- a low-temperature storage room for example, a freezing room, ice making room, switching room, etc. that is cooler than the storage room

- a low-temperature storage room for example, a freezing room, ice making room, switching room, etc. that is cooler than the storage room

- the electrostatic atomizer 200 will be described here, another sterilizer, sterilizer, humidifier, or the like may be used as long as it can be sterilized, sterilized, or humidified in the storage chamber.

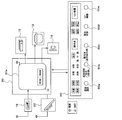

- FIG. 3 is a block diagram of the control device 30 of the refrigerator 1 representing the first embodiment of the present invention.

- the control device 30 is equipped with a microcomputer 30a (microcomputer) and controls the temperature of each storage chamber of the refrigerator 1, the rotational speed control of the compressor 12 and the cool air circulation fan 14, and the switching chamber damper according to a program stored in advance. 15. Opening / closing control of the refrigerator compartment damper 55, voltage application control to the mist device (electrostatic atomizer) 200, and the like are performed.

- the operation panel 60 includes, for example, the switches shown below.

- a room selection switch 60a for selecting a storage room such as a refrigerator room, a freezer room, a switching room

- a temperature zone changeover switch 60b for changing the temperature zone (refrigeration, freezing, chilled, soft freezing, etc.) of a storage room such as a changeover room or switching between rapid cooling, strong / medium / weak, etc .

- Instantaneous freezing switch 60c that freezes and stores the storage chamber through a supercooled state (flash freezing is also called supercooled freezing);

- ice making, ice making changeover switch 60d for selecting transparent ice, normal, rapid, stop, etc .

- a mist supply switch 60e electrostatic spray selection

- mist device 200 for energizing the mist device 200 to supply mist (electrostatic spray) into the storage chamber.

- a temperature detection sensor for detecting the temperature in the storage room for example, the switching room 4

- the switching chamber thermistor 19 as the first temperature detection means and the thermopile 22 as the second temperature detection means.

- the detected temperature of the switching chamber thermistor 19 which is the first temperature detecting means for detecting the temperature of the air in the storage chamber (for example, the switching chamber 4) is input to the microcomputer 30a constituting the control device 30, and the microcomputer 30a (for example, In the microcomputer 30a, temperature determination is performed by comparing with a predetermined value, and control is performed so that the temperature falls within a predetermined temperature range.

- thermopile 22 which is a second temperature detecting means for directly detecting the surface temperature of food in the storage room (for example, the switching room 4) is input to the microcomputer 30a, and the microcomputer 30a (for example, in the microcomputer 30a) And calculating the surface temperature of the food or the like, and then performing predetermined temperature control such as quick freezing control or supercooling freezing control.

- the control device 30 performs various controls such as temperature control in each storage room (refrigeration room 2, ice making room 3, switching room 4, vegetable room 5, freezing room 6) and energization control of the electrostatic atomizer 200.

- the set temperature, food (surface) temperature of each storage room, and each storage room are installed on the operation panel 60 (display panel) or server or portable terminal provided on either the left of the refrigerator door 7A or the right of the refrigerator door 7B.

- the operation status of the electrostatic atomizer 200 is displayed.

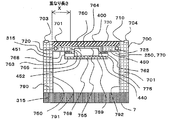

- FIG. 4 is a cross-sectional view of the refrigerator representing the first embodiment of the present invention.

- the figure is a cross-sectional view of the refrigerator 1 cut along a plane perpendicular to the vertical direction of the refrigerator 1. 4, parts that are the same as those in FIGS. 1 to 3 are given the same reference numerals, and descriptions thereof are omitted.

- a heat insulating box 700 constituting the refrigerator 1 is composed of an outer box 710 and an inner box 750, and a vacuum heat insulating material 400 is disposed between the outer box 710 and the inner box 750.

- the vacuum heat insulating material 400 is provided on the back surface of the refrigerator 1 and is directly attached to the outer box 710 via a second adhesive which is a second interposed member such as hot melt or double-sided tape.

- the vacuum heat insulating material 400 is directly attached to a part of the inner box 750 (for example, a substantially central portion in the left-right direction of the wall surface forming the back of the inner box 750) with an adhesive,

- the left and right end portions (corner portions) in the vicinity of the side wall 790 excluding the central portion are formed with convex portions 450 that protrude to the front side from the rear wall 730, and the vacuum heat insulating material 400 is only a predetermined length from the convex portion 450.

- an adhesive that is a first interposed member (for example, a foam heat insulating material having self-adhesive properties such as hard urethane may be used) is filled between the inner box 750 and the vacuum heat insulating material 400,

- the vacuum heat insulating material 400 is provided between the inner box 750 and the outer box 710 via an adhesive (for example, hard urethane) that is a first interposed member. Therefore, the vacuum heat insulating material 400 is bonded, fixed, or fixed to the inner box 750 or the outer box 710 by the first and second interposed members.

- the back shape of the inner box 750 is formed as a concave groove-shaped concave portion 440 (also referred to as a first concave portion) having a substantially central portion extending vertically.

- the vacuum heat insulating material 400 is directly attached to the outer box 710 and the inner box 750 via an adhesive.

- the rear shape of the inner box 750 is such that the width direction (left and right direction) end side is the front opening side compared to the width direction (left and right direction) substantially central portion.

- the back surface shape of the inner box 750 has a concave portion 440 that has a concave groove shape with a substantially central portion in the left-right direction recessed toward the outer box side (rear side of the refrigerator) as compared to the left and right end portions.

- 440 is provided in the vertical direction of the refrigerator in the storage room (for example, the refrigerator compartment 2). That is, the concave portion 440 is formed by the side surface 452 of the convex portion 450 and the rear wall 730, and the inner box 750 that forms the inner surface (storage chamber side) of the rear wall 730 and the outer box 710 that forms the outer surface of the rear wall 730.

- a plate-like vacuum heat insulating material 400 is provided between the two.

- a plate-like vacuum heat insulating material 400 is also provided between the inner box 750 that forms the inner surface (the storage chamber side) of the side wall 790 and the outer box 710 that forms the outer surface of the side wall 790. May be.

- the cold air passage 760 provided in the back wall 730 or the recess 440 is provided on the first air passage component 762 that is a cover member having design properties, and on the back side (inner box 750 side) of the first air passage component 762,

- the second air passage component 764 having heat insulation properties is disposed in the recess 440.

- the first air path component 762 or the second air path component 764 as the cover member has an attachment portion (engagement portion), and the attachment portion (engagement) provided on the convex portion 450 or the back wall 730.

- the cover member 760 is attached to the convex portion 450 or the back wall 730 by fitting into the portion) or engaging the attachment portions with a fixing member such as a screw.

- the vacuum heat insulating material 400 is disposed between the outer box 710 and the inner box 750 on the center side in the width direction (the range of the overlap length X).

- the space between the vacuum heat insulating material 400 and the inner box 750 is filled with an adhesive (self-adhesive foam heat insulating material 701, for example, hard urethane) as a first interposed member.

- an adhesive self-adhesive foam heat insulating material 701, for example, hard urethane

- the heat insulating material 701 for example, hard urethane

- the heat insulation performance and the box strength may be improved by enlarging the vacuum heat insulating material 400 in the width direction and increasing the arrangement area of the vacuum heat insulating material 400 in the width direction, but the cost increases. Therefore, if the heat insulation performance and strength are equal to or higher than the predetermined values, a portion where the vacuum heat insulating material 400 is not provided may be set.

- the vacuum heat insulating material 400 is directly attached to the outer box 710 via a second adhesive which is a second interposed member, and the inner box 750 is the first interposed member. It is pasted via an adhesive having self-adhesive properties and foaming properties such as urethane. (For example, a hard urethane foam as an adhesive is filled between the vacuum heat insulating material 400 and the inner box 750.)

- heat insulation mainly for heat insulation such as urethane in a portion where the vacuum heat insulating material is disposed in the width direction of the rear surface of the storage room as in the past (for example, Patent Document 2).

- heat insulation such as urethane is provided in the vertical direction on the left and right end sides (width direction end portions side). Since the convex portion 450 composed of the material 701 is formed, the torsional strength and the bending strength of the box body are improved by forming the convex portion 450.

- the convex portion 450 is provided so as to at least partially overlap the arrangement portion of the vacuum heat insulating material 400 in the width direction of the rear surface of the storage chamber (so as to overlap by the overlap length X).

- the rigid urethane foam filled in the convex portion 450 is also applied to a part between the vacuum heat insulating material 400 and the inner box 750 on the end side in the width direction (left-right direction) of the vacuum heat insulating material 400.

- the thickness of the rigid urethane foam filled between the vacuum heat insulating material 400 at the position facing the convex portion 450 and the inner box 750 is set to the vacuum heat insulating material 400 at the position facing the concave portion 440, Since the thickness of the hard urethane foam filled in the inner box 750 can be made larger, the adhesion area of the hard urethane foam to the vacuum heat insulating material 400 can be increased, and the hard foam of the vacuum heat insulating material 400 portion can be increased. Because it can increase the thickness of the tongue forms the bonding strength between the rigid urethane foam and vacuum insulation material 400 in the convex portion 450 is increased.

- the strength of the box body can be greatly improved.

- the convex part 450 since the thickness of a hard urethane foam can be enlarged, even if there exists a part in which the vacuum heat insulating material 400 is not provided, heat insulation performance improves.

- the vacuum heat insulating material, the inner box, and the outer box into a complicated shape in order to ensure the box strength as in the conventional patent document 2, and the vacuum heat insulating material.

- Organic and inorganic fiber core materials such as cotton-like core materials and non-woven core materials

- Refrigerators, showcases, water heaters, devices equipped with vacuum heat insulating materials, and the like can be obtained.

- the back of the box is deformed to form irregularities in the storage chamber, or the storage box door (for example, refrigerated) provided on the front of the storage chamber (for example, the refrigeration chamber 2) is deformed, for example.

- the chamber door 7) is not tilted, and one of the left and right doors (7A, 7B) is not tilted to cause misalignment, so that the storage chamber door can be opened and closed smoothly.

- the appearance (designability) is good.

- the opening and closing doors provided on the inner wall of the storage room for example, the ice making room 3, the switching room 4, the vegetable room 5, the freezing room 6 and the like

- the left and right side walls and the rail member for the drawer case are provided. Since the installation height does not differ from side to side and does not tilt, the case can be inserted and removed smoothly, and a highly reliable and easy-to-use refrigerator and equipment can be obtained.

- the vacuum heat insulating material 400 when the vacuum heat insulating material 400 is flat, in the state where the vacuum heat insulating material 400 is mounted on the back of the refrigerator 1, it is easy to bend in the left-right direction (width direction) and the front-rear direction, and to be twisted easily. Also in this state, when mounted on a device such as a refrigerator, a convex portion 450 provided with a heat insulating material such as urethane is formed in the vertical direction on the left and right end portions of the back surface, and the vacuum heat insulating material 400 is placed inside the convex portion 450.

- a convex portion 450 provided with a heat insulating material such as urethane is formed in the vertical direction on the left and right end portions of the back surface, and the vacuum heat insulating material 400 is placed inside the convex portion 450.

- the inner box 750, the vacuum heat insulating material 400, and the outer box 710 are integrally bonded by the convex portion 450, the bending strength of the box 700 (particularly the bending strength in the front-rear direction) is formed. ) And torsional strength can be improved. Therefore, it is possible to prevent the opening of the storage chamber having the front surface from being bent and deforming, or to cause a cold air leak due to a displacement of the seal member of the opening, etc. Equipment with energy-saving heat insulation box, refrigerator, and vacuum heat insulating material can be obtained.

- a foam heat insulating material such as urethane mainly for heat insulation and an adhesive not mainly intended for heat insulation (for example, heat insulation is mainly used).

- the provided part (concave part 440) does not need a predetermined thickness as a heat insulating material for obtaining heat insulating performance, compared with a part provided with a heat insulating material such as urethane mainly for heat insulation, and has a predetermined adhesive strength.

- the portion used for the main purpose of bonding may have a considerably small thickness of the adhesive

- Main purpose of insulation It can significantly reduce the thickness of the urethane against sites used Te. Accordingly, the wall thickness can be reduced by the difference in the thickness of the adhesive, and thus the internal volume of the storage chamber can be increased, and a convenient refrigerator and equipment can be obtained.

- the pipe 720 which is a lead wire housing member in which a lead wire such as a driving power line such as a control wiring or a compressor or a fan is housed extends in a vertical direction in a heat insulating material 701 such as urethane forming the convex portion 450. It is embedded and provided. Control wiring for performing opening / closing control of various dampers in the pipe 720, operation control of the compressor 12, the cool air circulation fan 14 and the like, and a power line for supplying power to the compressor 12, the cool air circulation fan 14, and the like Etc. are accommodated.

- Lead wires such as control wires and power lines pass through the pipe 720 to the compressor 12 disposed in the machine room 1A provided in the lower part (or upper part) of the refrigerator 1, and to the back, bottom and top surfaces of the refrigerator 1.

- a control device (control board or the like) 30 provided, a cool air circulation fan 14 provided in the cooler room 131, a switching room damper 15 provided in the cold air passage, a cold room damper 55, a storage room (for example, a cold room) 2) is connected to an operation panel 60 provided on an open / close door (for example, the refrigerator compartment door 7) provided so as to cover the front surface.

- the width in the left-right direction of the vacuum heat insulating material 400 provided on the back surface of the refrigerator 1 is smaller than the width between the storage chamber inner wall surfaces 791, 792 of the side wall 790 of the refrigerator 1.

- the filling ports (injection ports) 703 and 704 of a heat insulating material such as urethane provided in a plurality are not blocked, and the filling flow path of the heat insulating material such as urethane filled from the filling ports 703 and 704 is blocked. There is no such thing.

- the width in the left-right direction of the vacuum heat insulating material 400 provided on the rear surface of the refrigerator 1 is the width between the storage chamber inner walls of the side wall 790 of the refrigerator 1 (between the storage chamber inner wall left 791 and the storage chamber inner wall right 792). If the distance is equal to or smaller than (distance), it will not block the filling port or flow path of the heat insulating material such as urethane, so the urethane heat insulating material will be filled without interruption, so there will be no decrease in heat insulation performance.

- the distance is equal to or smaller than (distance)

- the vacuum heat insulating material 400 is equivalent to the arrangement position of the filling ports 703 and 704 of the heat insulating material such as urethane provided at the left and right end portions on the back side of the refrigerator 1 or the center side of the filling ports 703 and 704 (inward direction) ), The filling ports 703 and 704 of the urethane heat insulating material are not blocked by the vacuum heat insulating material 400, so that urethane filled from the filling ports 703 and 704, etc.

- the filling port of the heat insulating material such as urethane

- the filling port of the heat insulating material such as urethane

- urethane filled from 703 and 704 may obstruct or obstruct the flow of the vacuum heat insulating material 400 in the side wall 790, the convex portion 450, or between the vacuum heat insulating material 400 and the inner box 750.

- the side wall or the like is poorly filled with a heat insulating material such as urethane and the heat insulating performance is lowered.

- the vacuum heat insulating material 400 is filled on the left side (one side) so as not to protrude outward from the filling ports 703 and 704 of a heat insulating material such as urethane provided at the left and right end portions on the back side of the refrigerator 1.

- Insulating material such as urethane filled from the filling ports 703 and 704 is disposed within the range inside the port 703 and the right side (the other side) filling port 704, so that the heat insulating material inside the heat insulation box (between the inner box 750 and the outer box 710, For example, it does not hinder or disturb the filling into the side wall 790, the convex portion 450, between the vacuum heat insulating material 400 and the inner box 750, between the vacuum heat insulating material 400 and the outer box 710, etc.

- a high-performance heat insulation box or refrigerator in which the heat insulation performance does not deteriorate is obtained.

- the width of the vacuum heat insulating material 400 protrudes outside the filling ports 703 and 704 of heat insulating material such as urethane provided at the left and right end portions on the back side of the refrigerator 1 (the end position in the width direction of the vacuum heat insulating material 400 is In the case where the filling ports 703 and 704 such as urethane provided at the left and right end portions on the rear side of the refrigerator 1 are disposed outside the placement position), the filling ports 703 and 704 are closed with the vacuum heat insulating material 400.

- heat insulating material such as urethane provided at the left and right end portions on the back side of the refrigerator 1

- the vacuum heat insulating material 400 does not block at least a part of the filling ports 703 and 704, and a notch portion such as a notch or an opening is formed in the portion of the vacuum heat insulating material 400 facing the filling ports 703 and 704. 33 may be provided.

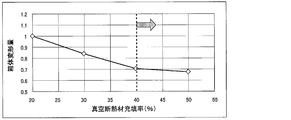

- the width of the vacuum heat insulating material 400 can be increased, so that the area of the vacuum heat insulating material 400 can be increased, and the vacuum heat insulating material with respect to the outer surface area of the heat insulating box or the back wall of the heat insulating box.

- the ratio (coverage ratio) of the arrangement area can be increased. Therefore, it is possible to improve the heat insulation performance. (For example, see FIGS. 12 and 22)

- a heat insulating material 701 such as urethane is filled between the inner box 750 and the outer box 710 forming the convex portion (or between the inner box 750 and the vacuum heat insulating material 400) or another part (urethane)

- the heat insulating material other than the heat insulating material is arranged to improve the strength of the heat insulating box 700.

- the inside of the convex portion 450 (for example, vacuum) Between the heat insulating material 400 and the inner box 750, near the end in the width direction of the vacuum heat insulating material 400, or near the convex portion 450, for example, outside the convex portion 450 (for example, inside the inner box 750 or outside the inner box 750). ) May be provided with a reinforcing member.

- This reinforcing member may be less affected by a member having poor thermal conductivity (for example, a resin member made of resin) than that made of metal, for example. Even if it is made of metal (aluminum, aluminum alloy, etc.), it is possible to suppress the loss of heat insulation performance, and the shape is rod-shaped (round bar or square bar) or pipe-shaped. Also good. Moreover, the structure which provides a rib etc. in the inner box 750 may be sufficient, and what can improve box strength, such as the twist strength of the heat insulation box 700, and bending strength, is sufficient.

- a member having poor thermal conductivity for example, a resin member made of resin

- the structure which provides a rib etc. in the inner box 750 may be sufficient, and what can improve box strength, such as the twist strength of

- the pipe 720 and the refrigerant pipe 725 in which the lead wires such as the control wiring and the power line are accommodated as a reinforcing member, and if the pipe 720 and the refrigerant pipe 725 are used as a reinforcing member, the reinforcement is separately performed.

- the reinforcing member can be disposed in the convex portion 450 or in the space between the inner box 750 and the outer box 710, and the design is improved because the reinforcing member is not directly visible to the user. Therefore, it is possible to obtain a heat insulating box, a refrigerator, and a device that are low in cost, highly reliable, and excellent in design.

- the concave portion 440 which is a portion where the inner box 750 and the vacuum heat insulating material 400 are directly attached via an adhesive (may be a self-adhesive foam heat insulating material), is a peripheral wall formed around the concave portion 440. Since it is recessed with respect to the convex portion 450 provided at the corner portion (for example, the side wall 790, the ceiling wall 740, or the partition wall 24), this concave portion may be used as the cold air passage 760.

- the cold air passage 760 corresponds to the refrigerator compartment cold air passage 50

- the cold air passage 760 is (When the storage room is the vegetable room 5, the cold air path 760 corresponds to the vegetable room cold air path).

- the opening portion of the second air passage component 764 having a U-shaped (or concave shape) opening portion is disposed so as to open to the storage chamber side, and the air passage cover

- the first air path component 762 is arranged so as to cover the U-shaped opening of the second air path component 764 and the opening of the second air path component 764 is closed by the first air path component 762.

- a cold air passage 760 in a sealed space can be formed.

- Both the first air path component 762 and the second air path component 764 are made of a heat insulating member such as polystyrene foam or resin, but the second air path component 764 disposed in the concave portion 440 is an air path rear surface member on the back side. 765, a side surface side air passage side member 766.

- An inner box 750 that forms a recess 440 is disposed on the back side of the member on the back side of the second air path component 764 (air path back member 765).

- the vacuum heat insulating material 400 is provided via an inner box 750 that forms the back wall 730 and an adhesive, and on the side surface side of the member on the side surface of the second air path component 764 (air path side surface member 766).

- a convex portion 450 formed by the inner box 750 is provided, and a heat insulating material 701 such as urethane is provided in the convex portion 450.

- the air path back surface member 765 and the air path side surface member 766 constituting the second air path component 764 can ensure heat insulating performance even if they do not have heat insulating properties.

- the heat insulation performance is ensured on the back side of the cold air passage 760 by the vacuum heat insulating material 400 disposed in the back wall 730, and the heat insulation performance is secured on the side surface side of the cold air passage 760 by the heat insulation material 701 in the convex portion 450.

- the air path back surface member 765 and the air path side surface member 766 constituting the second air path component 764 may be heat insulating materials such as polystyrene foam, they are made of resin or metal that does not have heat insulating performance.

- the member constituting the second air passage component 764 may be a heat insulating material such as a polystyrene foam having heat insulation properties, but even if it is a member made of resin or metal that does not have heat insulation properties, Adhesion of dew or the like to parts or the like forming the path 760 or dew generation due to dew generation can be suppressed.

- the first air passage component 762 is made of, for example, a heat insulating member having heat insulating properties such as foamed polystyrene or a resin, and suppresses the dew so that dew does not adhere to or occurs on the storage chamber side. Yes.

- the first air passage component 762 has a protruding portion (extension) having a width greater than the width in the left-right direction of the recess 440 or the width in the left-right direction of the U-shaped opening of the second air passage component 764.

- the protrusion (extension part) 763 closes the opening or recess 440 of the second air passage component 764 in a substantially sealed state to form a cold air passage 760, and the protrusion

- the first air path component 762 can be detachably fixed to the convex portion 450 or the second air path component 764.

- the first air passage component 762 only needs to close the opening of the second air passage component 764 to secure the cold air passage, so that only the opening of the second air passage component can be closed, and the recess 440 is also included.

- the attachment manufacture of the 1st air path component 762 will improve, and the design property will also improve.

- the cold air path components (for example, the first air path component 762 or the second air path component 764) forming the cold air path 760 can be used as a reinforcing member for improving the strength of the box.

- the box strength or the box rigidity for example, the torsion strength or the bending strength

- the first wind path component 762 or the second wind path component 764 is used as a reinforcing member to strengthen the box strength ( The box rigidity may be increased.

- the first air path component or the second air path component 764 is made of resin, it may be made to have a predetermined thickness so that the box strength can be obtained.

- the torsional strength and the bending strength may be improved by providing ribs in the width direction or the vertical direction in the first airway component 762 or the second airway component 764. If the strength or rigidity of the heat insulating box 700 is not a problem, the second air passage component 764 is omitted, and the recess 440 is directly used as the back wall and side wall of the cold air passage 760, and the opening of the recess 440 It is also possible to provide the first air path component 762 so as to cover the air.

- the second air channel component 764 is not required, so that the heat insulating box 700 and the refrigerator 1 having a simple structure and low cost can be obtained. can get.

- the first air path component 762 is provided so as to cover the concave portion 440, and the protruding portion (extending portion) 763 of the first air path component 762 may be detachably fixed to the convex portion 450. By directly fixing the (extension part) 763 to the convex part 450, the strength of the box is also improved.

- the recess 440 can be used as the cold air path 760.

- the first air passage component 762 may be used as a reinforcing member with increased rigidity by increasing the plate thickness or by providing a rib, and the heat insulation box strength can be improved.

- the cold air passage 760 is provided with one or a plurality of cold air supply ports (cold air outlets) 768 for supplying cold air into the storage room (for example, the refrigerator room 2 or the vegetable room 5).

- One or a plurality (at least one) of the cold air supply port (cold air outlet) 768 is provided in the first air channel component 762 or the second air channel component 764 so that the storage chamber can be efficiently cooled.

- the cold air supply port 768 is a side air outlet that blows out sideways in the storage chamber, a front air outlet that blows out forward, a side front oblique air outlet that can be blown in a diagonal direction between the side and the front, or an upper side and a front side.

- the upper front oblique blower outlet that can be blown in an oblique direction

- the lower front oblique blower outlet that can be blown in the downward and forward oblique directions

- the side upper oblique blower outlet that can be blown in the lateral and upward oblique directions

- a lateral lower oblique outlet is provided that can blow out laterally and obliquely downward.

- the vacuum heat insulating material 400 is provided on the back wall 730 of the heat insulating box 700 or the back surface of the refrigerator 1

- the side wall 790, the top wall 740, and the bottom wall 780 of the heat insulating box 700 are described.

- it may be provided on the side, top or bottom of the refrigerator 1.

- you may provide the vacuum heat insulating material 400 in the storage chamber door (For example, the refrigerator compartment door 7, the freezer compartment door 11, etc.) which covers the front opening of a storage chamber, In this case, the improvement of the heat insulation performance can be aimed at further.

- a cold air supply passage (cold air outlet) 768 is provided on a side surface (side surface of the first air passage component 762 which is the front cover) of the cold air passage 760.

- the cold air supply port 768 is provided with a protruding portion (extending portion) 763 of the first air passage component 762 on the end surface 451 on the front surface side of the convex portion 450.

- the size of the opening of the cold air supply port (cold air outlet) 768 is set.

- the front side of the convex part 450 with respect to the front side end face 769 of the first air path component 762 that is a cover.

- the side end face 451 is recessed on the back side (rear side), and a recessed portion (space between the protruding portion (extension portion) 763 and the side wall 790) 770 recessed on the back side can be effectively used as a storage space.

- the step 775 can be used to provide a cold air supply port (cold air outlet) 768, and by providing the step 775, the side of the step 775 (the side of the cold air supply 768) and the side wall 790. Since a storage space for storing stored items such as food can be provided in the space 770 between the first air passage part 762 and the extension part 763, the step part 775 can be formed. By providing a cold air supply port (cold air outlet) 768 in 775, stored items such as food stored or stored in a storage space which is a space 770 on the side of the stepped portion 775 can be efficiently cooled.

- FIG. 5 is a cross-sectional view of another refrigerator representing the first embodiment of the present invention, and is a cross-sectional view when the refrigerator is cut along a plane perpendicular to the vertical direction of the refrigerator 1.

- the same components as those in FIGS. 1 to 4 are denoted by the same reference numerals, and description thereof is omitted.

- the recess 440 is used as a cold air passage 760 in the same manner as in FIG. 4. That is, the concave portion 440 is formed by the side surface 452 of the convex portion 450 and the rear wall 730, and the inner box 750 that forms the inner surface (storage chamber side) of the rear wall 730 and the outer box 710 that forms the outer surface of the rear wall 730. Between the two, a plate-like vacuum heat insulating material 400 is provided. Here, although not shown, a plate-like vacuum heat insulating material 400 is also provided between the inner box 750 that forms the inner surface (the storage chamber side) of the side wall 790 and the outer box 710 that forms the outer surface of the side wall 790. May be.

- the cold air passage 760 provided in the back wall 730 or the recess 440 is provided on the first air passage component 762 that is a cover member having design properties, and on the back side (inner box 750 side) of the first air passage component 762,

- the second air passage component 764 having heat insulation properties is disposed in the recess 440.

- the first air path component 762 or the second air path component 764 as the cover member has an attachment portion (engagement portion), and the attachment portion (engagement) provided on the convex portion 450 or the back wall 730.

- the mounting portion is attached to the convex portion 450 or the back wall 730 by fitting into the portion) or engaging the mounting portions with a fixing member such as a screw.

- the cold air channel 760 is a cover provided so as to cover the storage chamber side opening of the second air channel component 764 or the storage chamber side opening of the recess 440 that is at least partially or entirely housed in the recess 440.

- the first air passage component 762 includes a concave portion 440 or a second air passage component 764, and the first air passage component 762 is the end surface 451 on the front surface side of the convex portion 450 or the air passage side surface of the second air passage component 764.

- the member 766 is fixed or held.

- the size of the stepped portion 775 formed by the extending portion 763 of the first airway component 762 is small, the stepped portion on the side surface formed by the extending portion 763 of the first airway component 762 Since it is difficult to provide the cold air supply port 768 in 775, the cold air supply port (cold air outlet) 768 is provided only on the front surface side of the first air passage component 762.

- the thickness of the protruding portion (extending portion) 763 of the first air passage component 762 can be reduced, the size of the stepped portion 775 can be reduced. Accordingly, the length in the depth direction in the storage chamber can be increased by the amount that the stepped portion 775 is reduced, and the storage capacity in the storage chamber can be increased.

- the shape of the first air passage component 762 that is a cover may be a plate shape as shown in FIGS. 4 and 5, but is a curved surface shape (for example, an arc shape or an arch shape) protruding toward the storage chamber. May be.

- the opening direction of the cold air supply port 768 can be provided not only in the front surface direction in the storage chamber but also in the curved portion, so that the cold air supply port 768 can be provided in an oblique direction. Since the degree of freedom of the position where the storage space is provided is improved, the storage chamber can be evenly cooled.

- the first air path component 762 may be fixed or held on the front end face 451 of the convex portion 450 or the second air path component 764.

- the assembly of the first air passage component 762 and the second air passage component 764 is stored or disposed in the recess 440 in a state in which the air passage component 764 is fixed to or held in advance with the first air passage component 762.

- the protruding portion (extending portion) 763 of the first air path component 762 may be fixed or held on the convex portion 450 (for example, the end surface 451 on the front surface side).

- the second air passage component 764 can be attached to the convex portion 450 in the storage chamber in a state in which the second air passage component 764 is fixed or held to the first air passage component 762 to form the cold air passage 760.

- the first air passage component 762 and the second air passage component 764 can constitute an assembly of the cold air passage 760, so that the cold air passage is detachable. 760 assemblies can be easily installed in a storage chamber (eg, convex portion 450).

- an adhesive which may be a foam heat insulating material having self-adhesiveness

- a first interposed member whose main purpose is adhesion is interposed between the vacuum heat insulating material 400 and the inner box 750.

- the cold air flow path 760 (first air flow path component)

- the second air passage component 764 or the assembly of the first air passage component and the second air passage component is attached to the recess 440

- the vacuum heat insulating material 400 may be damaged by screws or the like for fixing.

- the cold air passage 760 is attached to the convex portion 450, the cold air passage 760 is not attached to the concave portion 440 or the inner box 750 at a position facing the vacuum heat insulating material 400.

- Well Runode, reduction and less heat-insulating main body degradation of high heat insulating performance eliminates reliability hurt like outer cover material of the vacuum heat insulating material 400, refrigerators, appliance is obtained.

- the cold air duct 760 if the first air duct component 762 is attached to the convex portion 450 so as to cover the recess 440, the cool air duct 760 is formed without providing the second air duct component 764. Therefore, it is possible to obtain a heat-insulated box or a refrigerator that has a small number of parts, is easy to assemble at low cost, and is highly reliable.

- FIG. 6 is a cross-sectional view of another refrigerator representing the first embodiment of the present invention, and is a cross-sectional view when the refrigerator is cut along a plane perpendicular to the vertical direction of the refrigerator 1.

- the same parts as those in FIGS. 1 to 5 are denoted by the same reference numerals, and description thereof is omitted.

- a concave portion 440 is formed by the side surface 452 of the convex portion 450 and the rear wall 730, and an inner box 750 that forms the inner surface (storage chamber side) of the rear wall 730 and an outer surface that forms the outer surface of the rear wall 730.

- a plate-like vacuum heat insulating material 400 is provided between the box 710 and the box 710.

- a plate-like vacuum heat insulating material 400 is also provided between the inner box 750 that forms the inner surface (the storage chamber side) of the side wall 790 and the outer box 710 that forms the outer surface of the side wall 790. Yes.

- the cold air passage 760 provided in the back wall 730 or the recess 440 is provided on the first air passage component 762 that is a cover member having design properties, and on the back side (inner box 750 side) of the first air passage component 762,

- the second air passage component 764 having heat insulation properties is disposed in the recess 440.

- the first air passage component 762 or the second air passage component 764 that is the cover member has an attachment portion (engagement portion) and is fitted into the attachment portion (engagement portion) provided on the back wall.

- the attachment portions are attached to the back wall 730 by engaging the fixing members such as screws.

- a space 770 is provided between a side portion (side surface) 766 of the cold air passage 760 and a side surface (side portion) 452 of the convex portion 450, and this space 770 can be used as a storage space. It is possible to increase the storage volume of storage items (for example, the refrigerator compartment 2).

- the second air passage component 764 constituting the cold air passage 760 has a U-shaped cross section with an opening in the cold air flow direction (for example, the vertical direction of the refrigerator 1). It is installed in the storage chamber of the refrigerator 1 so that the letter-shaped opening faces the back side of the refrigerator 1 (arranged in the recess 440 on the back of the storage chamber).

- the first air passage component 762 is fixed to the convex portion 450 in a state of being pressed by the first air passage component 762 so that the U-shaped opening of the second air passage component 764 is in contact with the inner box 750 that forms the recess 440.

- the cold air path 760 is configured by the second air path component 764 and the inner box 750 by being held.

- the second air passage component 764 is not necessary, and therefore the first air passage component.

- the cold air path 760 can be configured by the 762 and the inner box, and a low-cost refrigerator and equipment can be obtained.

- the second air passage component 764 has an opening having a U-shaped cross section with respect to the flow direction of the cold air.

- the second air passage component 764 does not have to be U-shaped separately and only needs to be able to configure the cold air air passage. It is only necessary that the cross-sectional shape with respect to the flow direction is square or elliptical and a cold air passage is formed inside.

- the cross-sectional shape of the internal cold air passage may also be square or elliptical.

- a circular or elliptical cool air passage is more efficient because the flow resistance is smaller and more efficient, and the elliptical shape elongated in the width direction than the circular shape can reduce the length in the depth direction. The amount can be reduced and the storage volume can be increased.

- first air passage component 762 or the second air passage component 764 may be directly fixed to or held in the inner box 750 that forms the recess 440, but the cold air passage 760 may be formed as shown in FIG.

- the first air passage component 762 is provided with a protrusion (extension part) 763, and the protrusion 763 extends longer than that in the case of FIG. 4 so that the protrusion (extension part) 763 straddles the space 770. You may enable it to fix to the convex part 450. FIG. In this case, depending on the place where the protruding portion (extending portion) 763 is fixed, the storage volume of the space 770 may be reduced by the protruding portion 763.

- the top wall 740 or the bottom wall provided above and below the cold air passage 760 The projecting portion (extending portion) 763 extends to the vicinity of the partition wall 24 or the shelf 80 for partitioning between 780 or the storage chambers, and is fixed or held on the convex portion 450. Can be reduced (a situation in which a tall stored item cannot be stored by hitting the protruding portion (extending portion) 763) can be suppressed.

- the components (first air channel component or second air channel component) forming the cold air air passage 760 partition the vicinity of the top wall 740 or the bottom wall 780 provided between the upper and lower sides of the cold air air passage 760 or between the storage chambers. You may make it fix or hold

- FIG. (For example, when the protruding portion 763 is provided in the vertical center of the space 770 or below the approximate center, the stored item hits the protruding portion 763 and cannot be stored when a tall stored item is stored in the space 770.

- the stored items are stored in the space 770. Also, the protrusion 763 is less likely to get in the way, and the storage capacity can be increased.

- the first air passage component 762 that is a cover that covers at least a part of the back surface of the storage chamber includes at least a part of the cold air passage 760 or an air passage cover portion that covers at least a part of the cold air passage 760, A back cover part extending in the width direction (left-right direction or side wall 790 direction) from the air path cover part and covering at least a part of the back wall 730 or the recess 440, and connected to the back cover part or integrally formed with the back cover part You may make it provide the side surface cover part which covers at least one part of the side wall 790.

- the side cover portion may be attached by being fixed or held on the inner box 750 forming the side wall 790 or the convex portion 450. If it does in this way, since at least one part of the back wall 730, the side wall 790, and the convex part 450 can be covered with the 1st air path component 762 which is a cover, design property improves and assembly property also improves.

- the first air passage component 762 that is a cover that covers at least a part of the back surface of the storage chamber includes at least a part of the cold air passage 760 or an air passage cover portion that covers at least a part of the cold air passage 760, A back cover portion extending in the width direction (left-right direction or side wall 790 direction) from the air passage cover portion and covering at least a part of the back wall 730 or the recess 440, and connected to the air passage cover portion or integrally formed with the air passage cover portion.

- an upper and lower wall cover portion that covers at least a part of the partition wall 24 (including the ceiling wall 740 or the bottom wall 780) provided in the vertical direction of the back wall 730 may be provided.

- the upper and lower wall cover portions may be attached to the inner box 750 that forms the partition wall 24 (including the ceiling wall 740 or the bottom wall 780) provided in the vertical direction of the back wall 730.

- the partition wall 24 including the ceiling wall 740 or the bottom wall 780

- Cold air that has been generated by the cooler 13 and has flowed through the cold air passage 760 or the like is stored in the cold air passage 760 or a part that forms the cold air passage 760 (such as the first air passage component or the second air passage component).

- One or a plurality of cold air supply ports 768 for supplying the inside of the room are provided on the side surface or the front surface of the cold air passage 760. Is provided at a position where the stored items such as food in the storage room and the stored items can be cooled effectively.

- the vertical position of the cold air supply port on the side and the cold air supply port on the front surface may be the same.

- the height position of the cool air supply port 768 provided in the left and right side surfaces may be the same height, it is possible to cool from a position having a different height by disposing the height positions. Storing and storing items such as food can be cooled evenly and efficiently.

- the width dimension of the vacuum heat insulating material 400, the installation position in a heat insulation box or a refrigerator are equivalent to FIG.4 and FIG.5. That is, the width in the left-right direction of the vacuum heat insulating material 400 provided on the back wall 730 of the refrigerator 1 is, for example, smaller than the width between the storage chamber inner walls 791 and 792 of the side wall 790 of the refrigerator 1.

- the filling flow path of the heat insulating material such as urethane filled from the filling ports 703 and 704 of the urethane heat insulating material provided in is not blocked.

- the vacuum heat insulating material 400 is located outside the filling ports 703 and 704 of a heat insulating material such as urethane provided on the left and right end portions of the rear surface of the refrigerator 1 (for example, the openings of the filling ports 703 and 704 are not opened). Insulates or obstructs the flow of heat insulating material such as urethane flowing into the heat insulating box (for example, the side wall 790) from the unoccluded position or the opening of the filling ports 703 and 704 into the side wall 790 or the back wall 730. It is sufficient if it is arranged at a position where it does not.

- a heat insulating material such as urethane provided on the left and right end portions of the rear surface of the refrigerator 1 (for example, the openings of the filling ports 703 and 704 are not opened). Insulates or obstructs the flow of heat insulating material such as urethane flowing into the heat insulating box (for example, the side wall 790)

- filling is performed by placing the left and right filling ports (the left filling port 703 and the right filling port 704) on the center side (inside) in the width direction, and the filling ports 703 and 704 at positions where the vertical positions do not overlap.

- a heat insulating material such as urethane filled in the heat insulating box (the space 315 between the inner box 750 and the outer box 710, for example, in the side wall 790 or the back wall 730) from the ports 703 and 704 is formed in the heat insulating box (inner box 750).

- the space 315) between the outer box 710 and the outer box 710 is not obstructed or obstructed, so there is no insufficient filling or density of the heat insulating material, and a high performance heat insulating box or refrigerator that does not deteriorate the heat insulating performance. can get.