WO2013118531A1 - パーティクルボード - Google Patents

パーティクルボード Download PDFInfo

- Publication number

- WO2013118531A1 WO2013118531A1 PCT/JP2013/050296 JP2013050296W WO2013118531A1 WO 2013118531 A1 WO2013118531 A1 WO 2013118531A1 JP 2013050296 W JP2013050296 W JP 2013050296W WO 2013118531 A1 WO2013118531 A1 WO 2013118531A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- particle board

- particles

- plant

- surface layer

- fiber

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B27—WORKING OR PRESERVING WOOD OR SIMILAR MATERIAL; NAILING OR STAPLING MACHINES IN GENERAL

- B27N—MANUFACTURE BY DRY PROCESSES OF ARTICLES, WITH OR WITHOUT ORGANIC BINDING AGENTS, MADE FROM PARTICLES OR FIBRES CONSISTING OF WOOD OR OTHER LIGNOCELLULOSIC OR LIKE ORGANIC MATERIAL

- B27N3/00—Manufacture of substantially flat articles, e.g. boards, from particles or fibres

- B27N3/02—Manufacture of substantially flat articles, e.g. boards, from particles or fibres from particles

Definitions

- the present invention relates to a particle board.

- a fiber board manufactured by hot-pressing a resin composite long fiber mat in which an adhesive is uniformly dispersed on long fibers is also used as an interior building material (for example, see Patent Document 2).

- the fiber board generally has better dimensional stability against moisture absorption and desorption than the particle board.

- fiber boards generally have poor surface smoothness compared to particle boards. For this reason, even if particle board can be applied as an alternative material for plywood in interior building materials, fiberboard may not be applied.

- the present invention has been made in view of the circumstances as described above, and an object thereof is to provide a particle board having surface smoothness and small dimensional fluctuation due to moisture absorption and desorption.

- the particle board of the present invention is a particle board formed by hot-press molding a mixture of plant-based particles and an adhesive, and at least the surface layer includes plant-based fibers.

- the average fiber length of the plant-based fibers in the surface layer is 0.3 to 3.0 times the average length of the particles in the surface layer.

- the plant fiber content in the surface layer is preferably 10% by weight to 30% by weight with respect to the surface layer particles.

- the plant fiber is cut between a pair of cutting blades.

- the adhesive is preferably an isocyanate resin adhesive or a phenol resin adhesive.

- the adhesive further contains a melamine resin adhesive.

- the plant fiber is preferably a non-wood fiber.

- the surface layer includes plant fibers having a predetermined average fiber length.

- the particle board of this embodiment is formed into a plate shape with a constant area and thickness by hot pressing a mixture of plant-based particles and an adhesive. And at least the surface layer contains plant fibers together with particles.

- Such particle boards can be used as interior building materials and flooring materials such as door panels, sliding doors, and partitions.

- the surface layer refers to a layer having the outer surface (front surface and back surface) of the particle board.

- the layer deposits a mixture containing particles before hot pressing and an adhesive on the molding belt, which will be described later, separately from other mixtures, and forms a plate with a certain area and thickness by hot pressing. It is formed.

- the particle board has a multilayer structure, that is, when each layer is formed in a plate shape with a constant area and thickness and each layer is laminated, the outermost layer is the surface layer.

- FIG. 1 shows a cross-sectional view of a multilayered particle board.

- the surface layer 2 is a layer on the front surface side and a layer on the back surface side of the particle board 1.

- the central layer is the core layer 3.

- the plant layer 4 is included in the surface layer 2, and the plant fiber 4 is not included in the core layer 3.

- the particle board has a single layer structure, that is, when it is composed of a single layer, the single layer is the surface layer.

- particles used in a conventionally known particle board can be used.

- plant materials including wood such as conifers such as pine, cedar and cypress, broad-leaved trees such as lawan, capol, and poplar, and kenaf core are used as raw materials.

- the plant-based material can be crushed or cut by a crusher or cutting machine such as a hammer mill, drum flaker, ring flaker, etc. to make chips into chips. Chips (fine pieces) or wood chips (coarse pieces) crushed into a wood powder shape can also be used.

- the particle size is the same as the conventional one.

- a material having a length of 1 to 50 mm, a thickness of 0.1 to 5 mm, and a width of 0.5 to 10 mm can be used.

- a particle board having high strength and high rigidity can be obtained.

- the particles constituting the surface layer desirably have an average length of 3 to 8 mm, particularly 3 to 4 mm.

- particles in the average length of 3 to 8 mm are used to disperse the plant fibers more evenly. Can do.

- particles having a length within a certain range can be obtained by classification using a known classifier such as a vibrating screen.

- the plant fiber used in this embodiment has an average fiber length of 0.3 to 3.0 times the average length of the particles constituting the surface of the particle board. Plant fibers having such an average fiber length tend to be more uniformly dispersed with respect to the particles constituting the surface layer. For this reason, in addition to the surface smoothness inherent to the particle board, the particle board of the present embodiment can have a small size expansion and contraction (size variation) due to moisture absorption and desorption. From the viewpoint of further reducing the expansion and contraction of dimensions due to moisture absorption and desorption, the average fiber length of the plant fiber is 1.0 to 2.6 times the average length of the particles constituting the surface of the particle board.

- the fiber length is long, the dispersibility of the fiber is deteriorated, and the effect of suppressing dimensional fluctuation due to moisture absorption and desorption is lowered.

- the average fiber length of the plant fiber is less than 0.3 times the average length of the particles constituting the surface layer of the particle board, the effect of suppressing the dimensional fluctuation due to moisture absorption / release is not sufficient.

- when exceeding 3.0 times when mixing so that the particles after adhesive dispersion

- Such plant fibers having a predetermined average fiber length can be obtained by performing a conventionally known defibrating method for a long time on the long fibers.

- a predetermined length is obtained by tearing a fiber bundle made of long plant fibers using a defibrator or the like.

- the weak part in the fiber bundle is torn off, and the torn part becomes the end of the plant fiber.

- the fiber bundle can be cut into a predetermined length by a cutting machine.

- a cutting machine the apparatus which cut

- FIG. 2 is an explanatory view of the cutting of the fiber bundle by the cutting machine.

- the cutting machine 5 in FIG. 2 includes a flat blade-shaped cutting blade 6 (guillotine blade) that moves linearly along the cutting line.

- the cutting blade 6 can be moved up and down.

- the distal end portion of the cutting blade 6 has a smaller thickness toward the distal end, and the blade tip is formed in a V shape in a sectional view.

- the cutting machine 5 also includes a fiber bundle mounting table 8 that supports the fiber bundle 7 and a cutting blade 9.

- the cutting blade 9 is fixed to the fiber bundle mounting table 8 as a fixed blade.

- the fiber bundle 7 can be cut between the pair of cutting blades 6 and 9 by supporting the fiber bundle 7 with the fiber bundle mounting table 8 and the cutting blade 9 and lowering the cutting blade 6 from above the fiber bundle 7. .

- part peeled in the cut cross section of the plant fiber 4 is easy to osmose

- FIG. it becomes easy to adhere the rigid part of the plant fiber 4 to the particles by using the plant fiber 4 cut as described above.

- the adhesiveness between the rigid portion of the plant fiber 4 and the particles is strengthened, and the effect of suppressing the variation in dimensions due to the strength of the particle board and moisture absorption / release can be further enhanced.

- Plant fiber has a low bulk density as a volume compared to particles. For this reason, in order to easily achieve uniform dispersion of plant fibers with respect to particles, when mixing particles and plant fibers, plant fibers should be less in weight ratio than particles. It is desirable to mix. From this viewpoint, the content of the plant fiber in the surface layer portion is preferably 30% by weight or less with respect to the particles constituting the surface layer. Moreover, it is preferable that the content rate of a plant-type fiber is 10 weight% or more with respect to the particle which comprises a surface layer from a viewpoint of improving the suppression effect of the dimensional variation by moisture absorption / release. More preferably, it is 15 wt% or more and 25 wt% or less.

- Wood fiber can be used as a raw material for plant fiber, but non-wood fiber is desirable in consideration of ease of processing, adhesive permeability, the effect of suppressing dimensional fluctuation of particle board due to moisture absorption and release, etc. .

- bast fibers include jute, kenaf, flax, cannabis and the like.

- stem fiber include bamboo, rice straw, wheat straw, sugarcane bagasse and straw.

- leaf fibers include Manila hemp and sisal hemp. Two or more of these can be used in combination.

- an adhesive used in a conventionally known particle board can be used.

- isocyanate resin adhesives such as MDI (diphenylmethane diisocyanate), TDI (tolylene diisocyanate), MDI prepolymer, and TDI prepolymer can be used.

- a urea resin adhesive, a melamine resin adhesive, a urea / melamine cocondensation resin adhesive, a phenol resin adhesive, or the like can be used. Two or more of these can be used in combination. Among them, isocyanate resin adhesives and phenol resin adhesives have good compatibility with plant fibers and easily penetrate into the fibers.

- an isocyanate resin adhesive or a phenol resin adhesive it is possible to enhance the adhesion between the particles and the plant fiber, and to further enhance the effect of suppressing the dimensional fluctuation due to the strength of the particle board and moisture absorption / release.

- the melamine resin adhesive easily spreads on the surface of the particles and plant fibers, and can effectively bond the particles and the plant fibers. For this reason, it is desirable to use an isocyanate resin adhesive or a phenol resin adhesive in combination with a melamine resin adhesive.

- Such an adhesive can be used, for example, within a range of 5 wt% to 30 wt% with respect to the particles. By using an adhesive in a proportion within such a range, particles, particles and plant fibers, or plant fibers can be effectively bonded.

- the particle board of the present embodiment can be manufactured by hot pressing a mixture of particles, plant-based fibers, and an adhesive. More specifically, fragmentation of plant material and cutting of long-fiber plant fiber, drying of small pieces and plant fiber, addition of adhesive, mesh passing process, mat molding (forming), hot pressing, finishing A method performed through the steps can be given as an example. In such a particle board manufacturing method, it is not necessary to use a special device such as a card machine that mats long fibers used in the manufacture of fiber boards and a device that disperses the long fibers with air.

- the above-described crushing machine or cutting machine is used for fragmenting the plant material that becomes particles of the surface layer 2 and the core layer 3.

- the particles constituting the surface layer 2 particles having an average length of 3 to 8 mm can be preferably used.

- the particles constituting the core layer 3 particles having an average length longer than that of the surface layer 2 can be used.

- the surface layer 2 becomes dense and the core layer 3 becomes rough. Therefore, the smoothness of the surface can be increased, the overall density can be lowered, and the bending strength can be increased.

- the cutting machine 5 shown in FIG. 2 is used for cutting the long plant fiber.

- the adhesiveness between the rigid portion of the plant fiber 4 and the particles is strengthened, and the effect of suppressing the dimensional fluctuation due to the strength of the particle board 1 and moisture absorption / release can be further enhanced.

- Drying of the small pieces and the plant fibers 4 is an effective process for suppressing puncture during hot pressing.

- the addition of the adhesive can be performed in a state where the particles and the plant fiber 4 are stirred.

- the adhesive is sprayed while stirring the particles and the plant fibers 4 in a drum blender.

- the plant fiber 4 is desirably mixed so as to be 10 wt% or more and 30 wt% or less with respect to the particles of the surface layer 2.

- distribution of the plant fiber 4 with respect to a particle can be implement

- a core layer forming mixture in which particles and an adhesive are mixed to form the core layer 3 of the particle board 1 is also prepared in the same manner as the surface layer forming mixture except that the plant fiber 4 is not mixed.

- the surface layer-forming mixture and the core layer-forming mixture may contain other additives such as a water repellent and ammonium sulfide within the range not impairing the effects of the present invention.

- the prepared mixture for surface layer formation is passed through a mesh having a predetermined opening.

- This step is effective for making the dispersed state of the plant fiber 4 more uniform, and can be performed as necessary.

- the aggregates can be removed or reduced by defibrating the fine aggregates of the plant fibers 4.

- the part including the aggregates becomes a weak body part having lower adhesiveness than the peripheral part.

- the dimensional stability against moisture absorption / release may be affected. Therefore, by reducing aggregates in the surface layer forming mixture as much as possible, it is possible to suppress the occurrence of local swelling when the particle board 1 absorbs water. Moreover, the dimensional stability with respect to moisture absorption / release can be improved.

- the mesh has a large number of openings that penetrate the front and back.

- Examples of the shape of the opening include a circular hole (circular) and a square hole (square), but are not particularly limited.

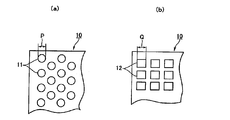

- FIG. 3 shows a schematic diagram of the main part of the mesh.

- FIG. 3A shows a mesh 10 having a circular hole 11

- FIG. 3B shows a mesh 10 having a square hole 12.

- the inner dimension of the opening is an opening.

- the diameter P of the circular hole 11 is an opening

- the length Q of one side of the square hole 12 is an opening.

- the average length of the particles on the surface layer 2 is reduced. It is desirable to use a mesh 10 having an opening of 0.75 times or more and 2.0 times or less. In addition, the influence on this effect by the difference in the shape of the opening part of the mesh 10 is small.

- Examples of the material of the mesh 10 include metal materials such as stainless steel, zinc, copper, brass, and iron, and synthetic resin materials such as nylon, but are not particularly limited. Moreover, as a shape, although a net-like thing, a punching metal, etc. can be mentioned, it is not specifically limited.

- a method of classifying by the self-weight of the surface layer forming mixture may be used, but a method of forcibly classifying by the external load is more suitable for the particles and the plant fibers 4. It is preferable because it is easy to maintain a dispersed state.

- the apparatus for forcibly classifying include a sieve such as a vibration sieve, an in-plane sieve and a centrifugal dispersion sieve, a crusher, and a pulverizer. Among them, the centrifugal force dispersion sieve is preferable because the dispersion state of the mixture after treatment is good and the treatment speed is high.

- a surface layer forming mixture is laminated on a molding belt, then a core layer forming mixture is laminated thereon, and then another surface layer forming mixture is laminated thereon to obtain a mat. Can do.

- the mat thus obtained is preferably pre-compressed at room temperature or the like.

- the quality of the particle board 1 can be stabilized by pre-compressing in consideration of the shape of the target particle board 1 before or after lamination on a molding table, a steel belt, etc., and then hot pressing.

- the hot pressure conditions moisture content, temperature, pressing pressure, time, etc.

- the hot pressure conditions can be factors that determine the characteristics of the particle board 1, such as the surface state and bending strength.

- the surface temperature and pressure of the hot platen or steel belt at the time of hot pressing depends on the type of adhesive, but can be set to, for example, a surface temperature of 180 to 220 ° C. and a pressure of 3 to 5 MPa.

- Examples of the hot-pressure forming press method include a continuous press using a steel belt, a flat press such as a batch-type multi-stage press and a single-stage press. Especially, when productivity is considered, continuous press is preferable.

- the target particle board 1 can be manufactured through finishing processes such as trimming and surface finishing with a sander.

- fine particles are used for the surface layer 2, and larger particles are used for the core layer 3.

- the overall density can be lowered and the bending strength can be increased.

- surface smoothness can be improved.

- the particle board since the effect of suppressing dimensional fluctuation due to moisture absorption and release can be effectively obtained without mixing plant fibers in a layer other than the surface layer 2 (core layer 3), the particle board has good dimensional stability. 1 can be manufactured at low cost.

- plant fibers can be mixed in layers other than the surface layer.

- the average fiber length of the plant-based fibers in the layers other than the surface layer can be 0.3 to 3.0 times the average length of the particles in the layer.

- the effect of suppressing the dimensional fluctuation due to the strength of the particle board and moisture absorption / release can be further enhanced.

- the adhesive is also dispersed or dissolved in water and supplied.

- a particle board having a three-layer structure was manufactured by the following procedure. Blender with particles processed from wood (demolition material for construction waste) to an average length of 3.5 mm and plant fibers cut from jute to the length shown in Table 1-2 using the cutting method shown in Table 1-2 The adhesive was sprayed while stirring. Even after spraying the adhesive, the particles were stirred together to prepare a surface layer forming mixture.

- Plant fibers were used in the proportions shown in Table 1-2 with respect to the surface particles.

- the adhesive shown in Table 1-2 was used in the ratio shown in Table 1-2 with respect to the surface particles.

- the phenol resin adhesive used was a type having a molecular weight of 500 or less and good impregnation properties.

- the system using “a pair of cutting blades” as a cutting method of plant fiber shown in Table 1-2 is a method in which a fiber bundle is sandwiched between a pair of cutting blades 6 and 9 of a cutting machine 5 as shown in FIG. This refers to a method of cutting to a predetermined length.

- the method using the “defibner” refers to a method in which a fiber bundle is torn to a predetermined length.

- This three-layer structure was hot-press molded under the conditions of 200 ° C., 3 MPa, and 5 minutes to obtain a particle board having a length and width of 300 ⁇ 300 mm and a thickness of 12 mm.

- the prepared mixture for surface layer formation was evaluated for uniform mixing properties. Judgment criteria are as follows. The presence or absence of lumps was confirmed visually. Occurrence of no lump that makes particle board production impossible: ⁇ (pass) Occurrence of dust that makes it impossible to manufacture particleboard: ⁇ (Failure)

- the dimensional change rate was measured about the obtained particle board, and the dimensional variability by moisture absorption / release was evaluated.

- the dimensional change rate is a change rate of a dimensional value that has changed from becoming constant in a 40 ° C., 90% RH environment until becoming constant in a 40 ° C., 30% RH environment.

- the rate of dimensional change of the plywood under the same conditions is 0.2%.

- the dimensional change rate of the conventional particle board (particle board which does not use plant fiber: Comparative Example 3) under the same conditions is 0.40%.

- the dimensional change rate of the particle board is 0.25% or less, it is evaluated that the dimensional variability due to moisture absorption and desorption is similar to that of the plywood. ⁇ ”. If the rate of dimensional change was greater than 0.25% and less than or equal to 0.35%, it was evaluated as “B” because it was slightly inferior to plywood but better than conventional particle boards. When the dimensional change rate was larger than 0.35%, it was evaluated as “x” by evaluating that it was the same level as the conventional particle board.

- Example 1-9 The particle boards manufactured under the manufacturing conditions of Example 1-9 all had better dimensional variability due to moisture absorption / release than the plywood, and it was confirmed that the size expansion / contraction due to moisture absorption / release was small. Further, when the surface of the particle board was visually observed, it was confirmed that all had good surface smoothness.

- Comparative Example 1 uses plant fibers that are less than 0.3 times the average length of the surface particles.

- the dimensional variability due to moisture absorption / release of the obtained particle board was similar to that of the conventional particle board (Comparative Example 3).

- Comparative Example 2 plant fibers exceeding 3.0 times the average length of the surface particles are used. Under these production conditions, the particle board could not be produced due to the occurrence of lumps in the surface layer forming mixture.

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Wood Science & Technology (AREA)

- Forests & Forestry (AREA)

- Dry Formation Of Fiberboard And The Like (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IN6492DEN2014 IN2014DN06492A (enExample) | 2012-02-08 | 2013-01-10 | |

| CN201380008633.0A CN104105579A (zh) | 2012-02-08 | 2013-01-10 | 碎料板 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012025182A JP2013159095A (ja) | 2012-02-08 | 2012-02-08 | パーティクルボード |

| JP2012-025182 | 2012-02-08 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2013118531A1 true WO2013118531A1 (ja) | 2013-08-15 |

Family

ID=48947300

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2013/050296 Ceased WO2013118531A1 (ja) | 2012-02-08 | 2013-01-10 | パーティクルボード |

Country Status (4)

| Country | Link |

|---|---|

| JP (1) | JP2013159095A (enExample) |

| CN (1) | CN104105579A (enExample) |

| IN (1) | IN2014DN06492A (enExample) |

| WO (1) | WO2013118531A1 (enExample) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104227819B (zh) * | 2014-08-15 | 2016-05-18 | 东营正和木业有限公司 | 芦苇纤维刨花板的制备方法 |

| CN107813485B (zh) * | 2017-11-01 | 2020-08-04 | 郑州峰泰纳米材料有限公司 | 一种密胺泡沫与纤维混纺制备工艺 |

| JP6964251B2 (ja) * | 2017-11-14 | 2021-11-10 | パナソニックIpマネジメント株式会社 | バイオマス組成物及びバイオマス成形体 |

| CN110666903A (zh) * | 2019-11-12 | 2020-01-10 | 石家庄华杰木业有限公司 | 芯板及填充层应用的浸渍胶膜纸饰面细木工板及制作方法 |

| WO2025028661A1 (ja) * | 2023-08-03 | 2025-02-06 | 大建工業株式会社 | パーティクルボード及びパーティクルボードの製造方法 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH06297417A (ja) * | 1993-04-13 | 1994-10-25 | Sumitomo Ringyo Kk | 高強度パーティクルボード及びその製造方法 |

| JP2006116854A (ja) * | 2004-10-22 | 2006-05-11 | Eidai Co Ltd | パーティクルボード |

Family Cites Families (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS60219007A (ja) * | 1984-04-16 | 1985-11-01 | Daiken Trade & Ind Co Ltd | 木質人造板材 |

| JPH04219203A (ja) * | 1990-12-20 | 1992-08-10 | Mitsui Toatsu Chem Inc | 植物繊維板 |

| CN1055694A (zh) * | 1991-05-22 | 1991-10-30 | 湖南省澧县刨花板厂 | 一种有竹纤维的人造刨花板 |

| CN1120487A (zh) * | 1994-10-13 | 1996-04-17 | 汪林 | 纤维面刨花板的生产工艺 |

| JPH08267418A (ja) * | 1995-03-31 | 1996-10-15 | Eidai Co Ltd | 成型木質板 |

| JPH08332611A (ja) * | 1995-06-07 | 1996-12-17 | Dantani Plywood Co Ltd | パーティクルボード |

| JPH10178909A (ja) * | 1996-12-25 | 1998-07-07 | Tosuko Kk | 多孔質植物育成用鉢体 |

| JPH11138513A (ja) * | 1997-11-10 | 1999-05-25 | Mitsui Chem Inc | 木質ボードの製造方法 |

| JP3642214B2 (ja) * | 1999-03-03 | 2005-04-27 | 松下電工株式会社 | 長繊維複合ボード及びその製造方法 |

| JP4154792B2 (ja) * | 1999-03-19 | 2008-09-24 | 松下電工株式会社 | 造作部材 |

| JP3235726B2 (ja) * | 2000-02-17 | 2001-12-04 | 倉敷紡績株式会社 | ケナフを含む繊維、糸及びそれらの製造方法 |

| JP2001293706A (ja) * | 2000-04-14 | 2001-10-23 | Matsushita Electric Works Ltd | パーティクルボード |

| JP4085582B2 (ja) * | 2001-02-23 | 2008-05-14 | 松下電工株式会社 | 繊維板の製造方法 |

| JP2003119662A (ja) * | 2001-10-16 | 2003-04-23 | Chubu Pile Kogyosho:Kk | 繊維用断裁装置 |

| JP4125065B2 (ja) * | 2002-07-22 | 2008-07-23 | 日清紡績株式会社 | バナナ繊維及びその製法、それを用いた混紡糸、並びに繊維構造物 |

| CN2595919Y (zh) * | 2002-11-20 | 2003-12-31 | 杜依泓 | 三层结构木质复合板材 |

| CN1255273C (zh) * | 2002-11-20 | 2006-05-10 | 杜官本 | 三层结构木质复合板材及其制造方法 |

| JP2004175013A (ja) * | 2002-11-28 | 2004-06-24 | Aikosha:Kk | 木材チップボード及びその製造方法 |

| CN100503191C (zh) * | 2004-12-28 | 2009-06-24 | 中国林业科学研究院木材工业研究所 | 一种木基棉花秸秆复合人造板的制造方法 |

| JP2008155531A (ja) * | 2006-12-25 | 2008-07-10 | Matsushita Electric Works Ltd | 植物細片含有成形品の製造方法 |

| CN101069974A (zh) * | 2007-06-13 | 2007-11-14 | 韩健 | 一种竹材碎料利用的方法及其制品 |

| JP2009172929A (ja) * | 2008-01-25 | 2009-08-06 | Panasonic Electric Works Co Ltd | 長繊維板の製造方法 |

| JP5491141B2 (ja) * | 2008-11-21 | 2014-05-14 | パナソニック株式会社 | 床材 |

| JP2011152679A (ja) * | 2010-01-26 | 2011-08-11 | Panasonic Electric Works Co Ltd | 木質ボードの製造方法及び木質ボード |

-

2012

- 2012-02-08 JP JP2012025182A patent/JP2013159095A/ja active Pending

-

2013

- 2013-01-10 IN IN6492DEN2014 patent/IN2014DN06492A/en unknown

- 2013-01-10 WO PCT/JP2013/050296 patent/WO2013118531A1/ja not_active Ceased

- 2013-01-10 CN CN201380008633.0A patent/CN104105579A/zh active Pending

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH06297417A (ja) * | 1993-04-13 | 1994-10-25 | Sumitomo Ringyo Kk | 高強度パーティクルボード及びその製造方法 |

| JP2006116854A (ja) * | 2004-10-22 | 2006-05-11 | Eidai Co Ltd | パーティクルボード |

Also Published As

| Publication number | Publication date |

|---|---|

| CN104105579A (zh) | 2014-10-15 |

| IN2014DN06492A (enExample) | 2015-06-12 |

| JP2013159095A (ja) | 2013-08-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN114746236B (zh) | 纤维板中木质纤维素纤维的回收 | |

| Lee et al. | Mechanical and physical properties of agro-based fiberboard | |

| JP2003311717A (ja) | 木質繊維板 | |

| JP2003311718A (ja) | 木質繊維板の製造方法 | |

| WO2013118531A1 (ja) | パーティクルボード | |

| KR102425845B1 (ko) | 섬유재 초지 조성물, 준불연성 섬유판재의 제조 방법 및 준불연성 섬유판재 | |

| CN1631632A (zh) | 麦(稻)秸秆碎料板工业化生产制作方法 | |

| CN112020412B (zh) | 纤维板和形成纤维板的方法 | |

| JP2017177087A (ja) | 天然繊維質材料の解繊物を製造する方法及び同解繊物と綿状繊維との複合綿状解繊物を製造する方法 | |

| CN108015876A (zh) | 一种刨花板的生产方法 | |

| WO2008145379A1 (de) | Mehrschichtige werkstoffplatte, insbesondere aus hanf | |

| JP2017154300A (ja) | パーティクルボード | |

| JP3399394B2 (ja) | 繊維板の製造方法及び長繊維複合ボードの製造方法 | |

| JP5934908B2 (ja) | パーティクルボードの製造方法 | |

| JP2018103482A (ja) | 木質ボードの製造方法 | |

| WO2015118814A1 (ja) | 木質ボードの製造方法 | |

| EP2666604B1 (de) | Leichte Holzwerkstoffplatte, und Verfahren zur Herstellung | |

| EP3461940B1 (de) | Verfahren zur herstellung von faserwerkstoffen sowie die nach diesen verfahren erhältlichen faserwerkstoffe und deren verwendung | |

| JP5914825B2 (ja) | 繊維ボード | |

| JP2014205268A (ja) | 木質ボードの製造方法 | |

| JP5975378B2 (ja) | 繊維板 | |

| JP6504634B2 (ja) | 木質ボード | |

| JP3911070B2 (ja) | 繊維板及び繊維板の製造方法 | |

| JP6985657B2 (ja) | 木質複合板の製造方法 | |

| JP2022512000A (ja) | 資材 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 13747202 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 13747202 Country of ref document: EP Kind code of ref document: A1 |