WO2013111332A1 - テレフタル酸カリウム塩からの有用化学品の製造法 - Google Patents

テレフタル酸カリウム塩からの有用化学品の製造法 Download PDFInfo

- Publication number

- WO2013111332A1 WO2013111332A1 PCT/JP2012/051854 JP2012051854W WO2013111332A1 WO 2013111332 A1 WO2013111332 A1 WO 2013111332A1 JP 2012051854 W JP2012051854 W JP 2012051854W WO 2013111332 A1 WO2013111332 A1 WO 2013111332A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- terephthalate

- terephthalic acid

- acid

- seq

- solid

- Prior art date

Links

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 90

- LRUDDHYVRFQYCN-UHFFFAOYSA-L dipotassium;terephthalate Chemical compound [K+].[K+].[O-]C(=O)C1=CC=C(C([O-])=O)C=C1 LRUDDHYVRFQYCN-UHFFFAOYSA-L 0.000 title claims abstract description 64

- 239000000126 substance Substances 0.000 title claims abstract description 28

- KKEYFWRCBNTPAC-UHFFFAOYSA-N terephthalic acid group Chemical group C(C1=CC=C(C(=O)O)C=C1)(=O)O KKEYFWRCBNTPAC-UHFFFAOYSA-N 0.000 claims abstract description 691

- LYCAIKOWRPUZTN-UHFFFAOYSA-N Ethylene glycol Chemical compound OCCO LYCAIKOWRPUZTN-UHFFFAOYSA-N 0.000 claims abstract description 313

- KWYUFKZDYYNOTN-UHFFFAOYSA-M Potassium hydroxide Chemical compound [OH-].[K+] KWYUFKZDYYNOTN-UHFFFAOYSA-M 0.000 claims abstract description 255

- YQUVCSBJEUQKSH-UHFFFAOYSA-N 3,4-dihydroxybenzoic acid Chemical compound OC(=O)C1=CC=C(O)C(O)=C1 YQUVCSBJEUQKSH-UHFFFAOYSA-N 0.000 claims abstract description 202

- LRHPLDYGYMQRHN-UHFFFAOYSA-N N-Butanol Chemical compound CCCCO LRHPLDYGYMQRHN-UHFFFAOYSA-N 0.000 claims abstract description 197

- LNTHITQWFMADLM-UHFFFAOYSA-N gallic acid Chemical compound OC(=O)C1=CC(O)=C(O)C(O)=C1 LNTHITQWFMADLM-UHFFFAOYSA-N 0.000 claims abstract description 143

- 244000005700 microbiome Species 0.000 claims abstract description 117

- 229910052700 potassium Inorganic materials 0.000 claims abstract description 74

- 239000011591 potassium Substances 0.000 claims abstract description 74

- 235000004515 gallic acid Nutrition 0.000 claims abstract description 72

- 229940074391 gallic acid Drugs 0.000 claims abstract description 72

- 239000002904 solvent Substances 0.000 claims abstract description 55

- 229920000728 polyester Polymers 0.000 claims abstract description 51

- ZLMJMSJWJFRBEC-UHFFFAOYSA-N Potassium Chemical compound [K] ZLMJMSJWJFRBEC-UHFFFAOYSA-N 0.000 claims abstract description 34

- 238000010438 heat treatment Methods 0.000 claims abstract description 26

- 150000003503 terephthalic acid derivatives Chemical class 0.000 claims abstract description 15

- KKEYFWRCBNTPAC-UHFFFAOYSA-L terephthalate(2-) Chemical compound [O-]C(=O)C1=CC=C(C([O-])=O)C=C1 KKEYFWRCBNTPAC-UHFFFAOYSA-L 0.000 claims description 203

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 claims description 183

- 108090000623 proteins and genes Proteins 0.000 claims description 176

- 102000004169 proteins and genes Human genes 0.000 claims description 136

- 238000000034 method Methods 0.000 claims description 89

- 239000000243 solution Substances 0.000 claims description 81

- 239000007787 solid Substances 0.000 claims description 80

- 150000001413 amino acids Chemical class 0.000 claims description 75

- -1 Polyethylene Polymers 0.000 claims description 71

- 238000006243 chemical reaction Methods 0.000 claims description 71

- 239000002699 waste material Substances 0.000 claims description 69

- 239000007810 chemical reaction solvent Substances 0.000 claims description 63

- 229920000139 polyethylene terephthalate Polymers 0.000 claims description 51

- 239000005020 polyethylene terephthalate Substances 0.000 claims description 51

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 42

- 241000588724 Escherichia coli Species 0.000 claims description 40

- 239000007788 liquid Substances 0.000 claims description 34

- 229920002215 polytrimethylene terephthalate Polymers 0.000 claims description 34

- 229920001707 polybutylene terephthalate Polymers 0.000 claims description 33

- 238000000926 separation method Methods 0.000 claims description 33

- 238000012691 depolymerization reaction Methods 0.000 claims description 32

- 239000007864 aqueous solution Substances 0.000 claims description 30

- 230000000694 effects Effects 0.000 claims description 28

- 239000002253 acid Substances 0.000 claims description 27

- 230000008569 process Effects 0.000 claims description 22

- 150000003839 salts Chemical class 0.000 claims description 21

- 238000007667 floating Methods 0.000 claims description 18

- 108091022889 lactaldehyde reductase Proteins 0.000 claims description 17

- 108010057617 Lactaldehyde dehydrogenase Proteins 0.000 claims description 16

- 239000012736 aqueous medium Substances 0.000 claims description 14

- 230000000295 complement effect Effects 0.000 claims description 13

- 238000001035 drying Methods 0.000 claims description 10

- WGCNASOHLSPBMP-UHFFFAOYSA-N hydroxyacetaldehyde Natural products OCC=O WGCNASOHLSPBMP-UHFFFAOYSA-N 0.000 claims description 10

- 150000002009 diols Chemical class 0.000 claims description 9

- 238000001291 vacuum drying Methods 0.000 claims description 9

- FWMNVWWHGCHHJJ-SKKKGAJSSA-N 4-amino-1-[(2r)-6-amino-2-[[(2r)-2-[[(2r)-2-[[(2r)-2-amino-3-phenylpropanoyl]amino]-3-phenylpropanoyl]amino]-4-methylpentanoyl]amino]hexanoyl]piperidine-4-carboxylic acid Chemical compound C([C@H](C(=O)N[C@H](CC(C)C)C(=O)N[C@H](CCCCN)C(=O)N1CCC(N)(CC1)C(O)=O)NC(=O)[C@H](N)CC=1C=CC=CC=1)C1=CC=CC=C1 FWMNVWWHGCHHJJ-SKKKGAJSSA-N 0.000 claims description 8

- 239000004698 Polyethylene Substances 0.000 claims description 8

- 150000002334 glycols Chemical class 0.000 claims description 8

- 229920000573 polyethylene Polymers 0.000 claims description 8

- 239000000843 powder Substances 0.000 claims description 8

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 claims description 7

- 239000005977 Ethylene Substances 0.000 claims description 7

- 238000011426 transformation method Methods 0.000 claims description 7

- 230000002708 enhancing effect Effects 0.000 claims description 6

- 102000040811 transporter activity Human genes 0.000 claims description 4

- 108091092194 transporter activity Proteins 0.000 claims description 4

- 239000000725 suspension Substances 0.000 claims description 3

- 230000010189 intracellular transport Effects 0.000 claims description 2

- 125000003275 alpha amino acid group Chemical group 0.000 claims 14

- 238000006116 polymerization reaction Methods 0.000 claims 2

- 238000002360 preparation method Methods 0.000 claims 1

- 239000002994 raw material Substances 0.000 abstract description 34

- 101710088194 Dehydrogenase Proteins 0.000 abstract description 19

- 108010082309 4-hydroxybenzoate 3-monooxygenase Proteins 0.000 abstract description 11

- 108010088582 Terephthalate 1,2-dioxygenase Proteins 0.000 abstract description 3

- 108020004414 DNA Proteins 0.000 description 167

- 235000018102 proteins Nutrition 0.000 description 114

- 210000004027 cell Anatomy 0.000 description 38

- 239000002585 base Substances 0.000 description 37

- 102000004020 Oxygenases Human genes 0.000 description 34

- 108090000417 Oxygenases Proteins 0.000 description 34

- 239000013612 plasmid Substances 0.000 description 31

- WQZGKKKJIJFFOK-GASJEMHNSA-N Glucose Natural products OC[C@H]1OC(O)[C@H](O)[C@@H](O)[C@@H]1O WQZGKKKJIJFFOK-GASJEMHNSA-N 0.000 description 29

- 239000008103 glucose Substances 0.000 description 29

- 108010078791 Carrier Proteins Proteins 0.000 description 25

- 239000002609 medium Substances 0.000 description 25

- 102000004316 Oxidoreductases Human genes 0.000 description 23

- 108090000854 Oxidoreductases Proteins 0.000 description 23

- 239000000047 product Substances 0.000 description 23

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 description 21

- 239000013615 primer Substances 0.000 description 21

- 239000000203 mixture Substances 0.000 description 20

- 238000010276 construction Methods 0.000 description 19

- 230000007423 decrease Effects 0.000 description 19

- FJKROLUGYXJWQN-UHFFFAOYSA-N 4-hydroxybenzoic acid Chemical compound OC(=O)C1=CC=C(O)C=C1 FJKROLUGYXJWQN-UHFFFAOYSA-N 0.000 description 18

- 241000589518 Comamonas testosteroni Species 0.000 description 18

- 241001646716 Escherichia coli K-12 Species 0.000 description 18

- 238000010367 cloning Methods 0.000 description 18

- 238000012258 culturing Methods 0.000 description 18

- PWKNBLFSJAVFAB-UHFFFAOYSA-N 1-fluoro-2-nitrobenzene Chemical compound [O-][N+](=O)C1=CC=CC=C1F PWKNBLFSJAVFAB-UHFFFAOYSA-N 0.000 description 16

- 235000001014 amino acid Nutrition 0.000 description 16

- 239000012634 fragment Substances 0.000 description 16

- VIQSRHWJEKERKR-UHFFFAOYSA-L disodium;terephthalate Chemical compound [Na+].[Na+].[O-]C(=O)C1=CC=C(C([O-])=O)C=C1 VIQSRHWJEKERKR-UHFFFAOYSA-L 0.000 description 15

- 239000000463 material Substances 0.000 description 15

- 238000003756 stirring Methods 0.000 description 15

- 241000894006 Bacteria Species 0.000 description 14

- BSABBBMNWQWLLU-UHFFFAOYSA-N lactaldehyde Chemical compound CC(O)C=O BSABBBMNWQWLLU-UHFFFAOYSA-N 0.000 description 14

- GPSDUZXPYCFOSQ-UHFFFAOYSA-N m-toluic acid Chemical compound CC1=CC=CC(C(O)=O)=C1 GPSDUZXPYCFOSQ-UHFFFAOYSA-N 0.000 description 14

- 108091008146 restriction endonucleases Proteins 0.000 description 14

- 125000003178 carboxy group Chemical group [H]OC(*)=O 0.000 description 12

- 238000004064 recycling Methods 0.000 description 12

- 229920006395 saturated elastomer Polymers 0.000 description 12

- 102000004190 Enzymes Human genes 0.000 description 11

- 108090000790 Enzymes Proteins 0.000 description 11

- 108020004511 Recombinant DNA Proteins 0.000 description 11

- 150000001875 compounds Chemical class 0.000 description 11

- FFPQSNUAVYJZDH-UHFFFAOYSA-N diazanium;terephthalate Chemical compound [NH4+].[NH4+].[O-]C(=O)C1=CC=C(C([O-])=O)C=C1 FFPQSNUAVYJZDH-UHFFFAOYSA-N 0.000 description 11

- 238000005516 engineering process Methods 0.000 description 11

- 230000004060 metabolic process Effects 0.000 description 11

- 239000000523 sample Substances 0.000 description 11

- 239000011734 sodium Substances 0.000 description 11

- 229910052708 sodium Inorganic materials 0.000 description 11

- 239000013604 expression vector Substances 0.000 description 10

- 230000035772 mutation Effects 0.000 description 10

- 229940090248 4-hydroxybenzoic acid Drugs 0.000 description 9

- VHUUQVKOLVNVRT-UHFFFAOYSA-N Ammonium hydroxide Chemical compound [NH4+].[OH-] VHUUQVKOLVNVRT-UHFFFAOYSA-N 0.000 description 9

- 108020001019 DNA Primers Proteins 0.000 description 9

- 239000003155 DNA primer Substances 0.000 description 9

- 108010074633 Mixed Function Oxygenases Proteins 0.000 description 9

- 235000011114 ammonium hydroxide Nutrition 0.000 description 9

- 238000004458 analytical method Methods 0.000 description 9

- 239000001963 growth medium Substances 0.000 description 9

- 238000004128 high performance liquid chromatography Methods 0.000 description 9

- 230000014759 maintenance of location Effects 0.000 description 9

- 239000013598 vector Substances 0.000 description 9

- DHMQDGOQFOQNFH-UHFFFAOYSA-N Glycine Chemical group NCC(O)=O DHMQDGOQFOQNFH-UHFFFAOYSA-N 0.000 description 8

- 102000008109 Mixed Function Oxygenases Human genes 0.000 description 8

- KZSNJWFQEVHDMF-UHFFFAOYSA-N Valine Natural products CC(C)C(N)C(O)=O KZSNJWFQEVHDMF-UHFFFAOYSA-N 0.000 description 8

- 239000000706 filtrate Substances 0.000 description 8

- 239000002773 nucleotide Substances 0.000 description 8

- 125000003729 nucleotide group Chemical group 0.000 description 8

- 229920003023 plastic Polymers 0.000 description 8

- 239000004033 plastic Substances 0.000 description 8

- 229910001414 potassium ion Inorganic materials 0.000 description 8

- 238000005070 sampling Methods 0.000 description 8

- 239000004474 valine Substances 0.000 description 8

- 239000003643 water by type Substances 0.000 description 8

- NPYPAHLBTDXSSS-UHFFFAOYSA-N Potassium ion Chemical compound [K+] NPYPAHLBTDXSSS-UHFFFAOYSA-N 0.000 description 7

- 238000002835 absorbance Methods 0.000 description 7

- 238000007792 addition Methods 0.000 description 7

- 229910021529 ammonia Inorganic materials 0.000 description 7

- 230000001976 improved effect Effects 0.000 description 7

- 239000000411 inducer Substances 0.000 description 7

- 229910001220 stainless steel Inorganic materials 0.000 description 7

- 239000010935 stainless steel Substances 0.000 description 7

- VTYYLEPIZMXCLO-UHFFFAOYSA-L Calcium carbonate Chemical compound [Ca+2].[O-]C([O-])=O VTYYLEPIZMXCLO-UHFFFAOYSA-L 0.000 description 6

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 6

- 108700039691 Genetic Promoter Regions Proteins 0.000 description 6

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 6

- 241000316848 Rhodococcus <scale insect> Species 0.000 description 6

- QAOWNCQODCNURD-UHFFFAOYSA-N Sulfuric acid Chemical compound OS(O)(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-N 0.000 description 6

- 101150081631 aldA gene Proteins 0.000 description 6

- 229910052783 alkali metal Inorganic materials 0.000 description 6

- 238000001914 filtration Methods 0.000 description 6

- 101150030625 fucO gene Proteins 0.000 description 6

- 230000001965 increasing effect Effects 0.000 description 6

- 238000000746 purification Methods 0.000 description 6

- 239000000758 substrate Substances 0.000 description 6

- NLXLAEXVIDQMFP-UHFFFAOYSA-N Ammonium chloride Substances [NH4+].[Cl-] NLXLAEXVIDQMFP-UHFFFAOYSA-N 0.000 description 5

- KZSNJWFQEVHDMF-BYPYZUCNSA-N L-valine Chemical group CC(C)[C@H](N)C(O)=O KZSNJWFQEVHDMF-BYPYZUCNSA-N 0.000 description 5

- ROHFNLRQFUQHCH-UHFFFAOYSA-N Leucine Natural products CC(C)CC(N)C(O)=O ROHFNLRQFUQHCH-UHFFFAOYSA-N 0.000 description 5

- 239000003513 alkali Substances 0.000 description 5

- 150000008044 alkali metal hydroxides Chemical class 0.000 description 5

- BFNBIHQBYMNNAN-UHFFFAOYSA-N ammonium sulfate Chemical compound N.N.OS(O)(=O)=O BFNBIHQBYMNNAN-UHFFFAOYSA-N 0.000 description 5

- 229910052921 ammonium sulfate Inorganic materials 0.000 description 5

- 235000011130 ammonium sulphate Nutrition 0.000 description 5

- 239000013611 chromosomal DNA Substances 0.000 description 5

- KTVIXTQDYHMGHF-UHFFFAOYSA-L cobalt(2+) sulfate Chemical compound [Co+2].[O-]S([O-])(=O)=O KTVIXTQDYHMGHF-UHFFFAOYSA-L 0.000 description 5

- 210000004748 cultured cell Anatomy 0.000 description 5

- 239000000284 extract Substances 0.000 description 5

- 125000001909 leucine group Chemical group [H]N(*)C(C(*)=O)C([H])([H])C(C([H])([H])[H])C([H])([H])[H] 0.000 description 5

- 230000000813 microbial effect Effects 0.000 description 5

- COLNVLDHVKWLRT-UHFFFAOYSA-N phenylalanine Natural products OC(=O)C(N)CC1=CC=CC=C1 COLNVLDHVKWLRT-UHFFFAOYSA-N 0.000 description 5

- COLNVLDHVKWLRT-QMMMGPOBSA-N phenylalanine group Chemical group N[C@@H](CC1=CC=CC=C1)C(=O)O COLNVLDHVKWLRT-QMMMGPOBSA-N 0.000 description 5

- 230000032258 transport Effects 0.000 description 5

- OUYCCCASQSFEME-UHFFFAOYSA-N tyrosine Natural products OC(=O)C(N)CC1=CC=C(O)C=C1 OUYCCCASQSFEME-UHFFFAOYSA-N 0.000 description 5

- 125000001493 tyrosinyl group Chemical group [H]OC1=C([H])C([H])=C(C([H])=C1[H])C([H])([H])C([H])(N([H])[H])C(*)=O 0.000 description 5

- 101710111736 1,2-dihydroxy-3,5-cyclohexadiene-1,4-dicarboxylate dehydrogenase Proteins 0.000 description 4

- 101100070555 Arabidopsis thaliana HSFA4C gene Proteins 0.000 description 4

- 101100523550 Arabidopsis thaliana RABF2A gene Proteins 0.000 description 4

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 4

- 241000589519 Comamonas Species 0.000 description 4

- 102000016680 Dioxygenases Human genes 0.000 description 4

- 108010028143 Dioxygenases Proteins 0.000 description 4

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 4

- 239000004471 Glycine Chemical group 0.000 description 4

- AEMRFAOFKBGASW-UHFFFAOYSA-N Glycolic acid Chemical compound OCC(O)=O AEMRFAOFKBGASW-UHFFFAOYSA-N 0.000 description 4

- 239000004743 Polypropylene Substances 0.000 description 4

- 241000589516 Pseudomonas Species 0.000 description 4

- 101100198283 Scheffersomyces stipitis (strain ATCC 58785 / CBS 6054 / NBRC 10063 / NRRL Y-11545) DHG2 gene Proteins 0.000 description 4

- FAPWRFPIFSIZLT-UHFFFAOYSA-M Sodium chloride Chemical compound [Na+].[Cl-] FAPWRFPIFSIZLT-UHFFFAOYSA-M 0.000 description 4

- 235000004279 alanine Nutrition 0.000 description 4

- 238000011088 calibration curve Methods 0.000 description 4

- 229910052799 carbon Inorganic materials 0.000 description 4

- 238000004817 gas chromatography Methods 0.000 description 4

- 238000009396 hybridization Methods 0.000 description 4

- 238000005259 measurement Methods 0.000 description 4

- 229910052751 metal Inorganic materials 0.000 description 4

- 239000002184 metal Substances 0.000 description 4

- 238000010369 molecular cloning Methods 0.000 description 4

- 229910000402 monopotassium phosphate Inorganic materials 0.000 description 4

- 235000019796 monopotassium phosphate Nutrition 0.000 description 4

- 108020004707 nucleic acids Proteins 0.000 description 4

- 150000007523 nucleic acids Chemical class 0.000 description 4

- 102000039446 nucleic acids Human genes 0.000 description 4

- PJNZPQUBCPKICU-UHFFFAOYSA-N phosphoric acid;potassium Chemical compound [K].OP(O)(O)=O PJNZPQUBCPKICU-UHFFFAOYSA-N 0.000 description 4

- 229920001155 polypropylene Polymers 0.000 description 4

- 101150076874 rha-1 gene Proteins 0.000 description 4

- 239000012047 saturated solution Substances 0.000 description 4

- 229910001415 sodium ion Inorganic materials 0.000 description 4

- LPXPTNMVRIOKMN-UHFFFAOYSA-M sodium nitrite Chemical compound [Na+].[O-]N=O LPXPTNMVRIOKMN-UHFFFAOYSA-M 0.000 description 4

- 230000005030 transcription termination Effects 0.000 description 4

- TVKBBTQJNQDZRU-UHFFFAOYSA-N 2,4-dioxopentanedioic acid Chemical compound OC(=O)C(=O)CC(=O)C(O)=O TVKBBTQJNQDZRU-UHFFFAOYSA-N 0.000 description 3

- WEVYAHXRMPXWCK-UHFFFAOYSA-N Acetonitrile Chemical compound CC#N WEVYAHXRMPXWCK-UHFFFAOYSA-N 0.000 description 3

- 241001485655 Corynebacterium glutamicum ATCC 13032 Species 0.000 description 3

- QNAYBMKLOCPYGJ-REOHCLBHSA-N L-alanine Chemical group C[C@H](N)C(O)=O QNAYBMKLOCPYGJ-REOHCLBHSA-N 0.000 description 3

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 3

- 239000003963 antioxidant agent Substances 0.000 description 3

- 235000006708 antioxidants Nutrition 0.000 description 3

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 3

- 229910000019 calcium carbonate Inorganic materials 0.000 description 3

- 238000005119 centrifugation Methods 0.000 description 3

- 239000003638 chemical reducing agent Substances 0.000 description 3

- KRKNYBCHXYNGOX-UHFFFAOYSA-N citric acid Chemical compound OC(=O)CC(O)(C(O)=O)CC(O)=O KRKNYBCHXYNGOX-UHFFFAOYSA-N 0.000 description 3

- JZCCFEFSEZPSOG-UHFFFAOYSA-L copper(II) sulfate pentahydrate Chemical compound O.O.O.O.O.[Cu+2].[O-]S([O-])(=O)=O JZCCFEFSEZPSOG-UHFFFAOYSA-L 0.000 description 3

- 238000012217 deletion Methods 0.000 description 3

- 230000037430 deletion Effects 0.000 description 3

- 239000011521 glass Substances 0.000 description 3

- 150000004688 heptahydrates Chemical class 0.000 description 3

- 230000003100 immobilizing effect Effects 0.000 description 3

- 239000000395 magnesium oxide Substances 0.000 description 3

- CPLXHLVBOLITMK-UHFFFAOYSA-N magnesium oxide Inorganic materials [Mg]=O CPLXHLVBOLITMK-UHFFFAOYSA-N 0.000 description 3

- WRUGWIBCXHJTDG-UHFFFAOYSA-L magnesium sulfate heptahydrate Chemical compound O.O.O.O.O.O.O.[Mg+2].[O-]S([O-])(=O)=O WRUGWIBCXHJTDG-UHFFFAOYSA-L 0.000 description 3

- 229940061634 magnesium sulfate heptahydrate Drugs 0.000 description 3

- AXZKOIWUVFPNLO-UHFFFAOYSA-N magnesium;oxygen(2-) Chemical compound [O-2].[Mg+2] AXZKOIWUVFPNLO-UHFFFAOYSA-N 0.000 description 3

- CDUFCUKTJFSWPL-UHFFFAOYSA-L manganese(II) sulfate tetrahydrate Chemical compound O.O.O.O.[Mn+2].[O-]S([O-])(=O)=O CDUFCUKTJFSWPL-UHFFFAOYSA-L 0.000 description 3

- 238000002156 mixing Methods 0.000 description 3

- 239000007800 oxidant agent Substances 0.000 description 3

- 239000001301 oxygen Substances 0.000 description 3

- 229910052760 oxygen Inorganic materials 0.000 description 3

- 238000011084 recovery Methods 0.000 description 3

- 230000010076 replication Effects 0.000 description 3

- 238000011160 research Methods 0.000 description 3

- 230000035897 transcription Effects 0.000 description 3

- 238000013518 transcription Methods 0.000 description 3

- 230000009466 transformation Effects 0.000 description 3

- 125000002987 valine group Chemical group [H]N([H])C([H])(C(*)=O)C([H])(C([H])([H])[H])C([H])([H])[H] 0.000 description 3

- 238000005406 washing Methods 0.000 description 3

- RZLVQBNCHSJZPX-UHFFFAOYSA-L zinc sulfate heptahydrate Chemical compound O.O.O.O.O.O.O.[Zn+2].[O-]S([O-])(=O)=O RZLVQBNCHSJZPX-UHFFFAOYSA-L 0.000 description 3

- YBJHBAHKTGYVGT-ZKWXMUAHSA-N (+)-Biotin Chemical compound N1C(=O)N[C@@H]2[C@H](CCCCC(=O)O)SC[C@@H]21 YBJHBAHKTGYVGT-ZKWXMUAHSA-N 0.000 description 2

- CDOWNLMZVKJRSC-UHFFFAOYSA-N 2-hydroxyterephthalic acid Chemical compound OC(=O)C1=CC=C(C(O)=O)C(O)=C1 CDOWNLMZVKJRSC-UHFFFAOYSA-N 0.000 description 2

- VRMXCPVFSJVVCA-UHFFFAOYSA-N 2-oxo-2H-pyran-4,6-dicarboxylic acid Chemical compound OC(=O)C=1C=C(C(O)=O)OC(=O)C=1 VRMXCPVFSJVVCA-UHFFFAOYSA-N 0.000 description 2

- 229920001817 Agar Polymers 0.000 description 2

- CIWBSHSKHKDKBQ-JLAZNSOCSA-N Ascorbic acid Chemical compound OC[C@H](O)[C@H]1OC(=O)C(O)=C1O CIWBSHSKHKDKBQ-JLAZNSOCSA-N 0.000 description 2

- 241001061264 Astragalus Species 0.000 description 2

- 241001453380 Burkholderia Species 0.000 description 2

- BHPQYMZQTOCNFJ-UHFFFAOYSA-N Calcium cation Chemical compound [Ca+2] BHPQYMZQTOCNFJ-UHFFFAOYSA-N 0.000 description 2

- YASYEJJMZJALEJ-UHFFFAOYSA-N Citric acid monohydrate Chemical compound O.OC(=O)CC(O)(C(O)=O)CC(O)=O YASYEJJMZJALEJ-UHFFFAOYSA-N 0.000 description 2

- 241000186216 Corynebacterium Species 0.000 description 2

- QXNVGIXVLWOKEQ-UHFFFAOYSA-N Disodium Chemical class [Na][Na] QXNVGIXVLWOKEQ-UHFFFAOYSA-N 0.000 description 2

- VEXZGXHMUGYJMC-UHFFFAOYSA-N Hydrochloric acid Chemical compound Cl VEXZGXHMUGYJMC-UHFFFAOYSA-N 0.000 description 2

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 description 2

- 229910021578 Iron(III) chloride Inorganic materials 0.000 description 2

- CSNNHWWHGAXBCP-UHFFFAOYSA-L Magnesium sulfate Chemical compound [Mg+2].[O-][S+2]([O-])([O-])[O-] CSNNHWWHGAXBCP-UHFFFAOYSA-L 0.000 description 2

- 108091028043 Nucleic acid sequence Proteins 0.000 description 2

- 241000589776 Pseudomonas putida Species 0.000 description 2

- 241000232299 Ralstonia Species 0.000 description 2

- XSQUKJJJFZCRTK-UHFFFAOYSA-N Urea Chemical compound NC(N)=O XSQUKJJJFZCRTK-UHFFFAOYSA-N 0.000 description 2

- 238000005273 aeration Methods 0.000 description 2

- 239000008272 agar Substances 0.000 description 2

- 229910052782 aluminium Inorganic materials 0.000 description 2

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 2

- AVKUERGKIZMTKX-NJBDSQKTSA-N ampicillin Chemical compound C1([C@@H](N)C(=O)N[C@H]2[C@H]3SC([C@@H](N3C2=O)C(O)=O)(C)C)=CC=CC=C1 AVKUERGKIZMTKX-NJBDSQKTSA-N 0.000 description 2

- 229960000723 ampicillin Drugs 0.000 description 2

- 230000003078 antioxidant effect Effects 0.000 description 2

- 235000006533 astragalus Nutrition 0.000 description 2

- 230000001580 bacterial effect Effects 0.000 description 2

- KGBXLFKZBHKPEV-UHFFFAOYSA-N boric acid Chemical compound OB(O)O KGBXLFKZBHKPEV-UHFFFAOYSA-N 0.000 description 2

- 239000004327 boric acid Substances 0.000 description 2

- 239000000872 buffer Substances 0.000 description 2

- WERYXYBDKMZEQL-UHFFFAOYSA-N butane-1,4-diol Chemical compound OCCCCO WERYXYBDKMZEQL-UHFFFAOYSA-N 0.000 description 2

- LLSDKQJKOVVTOJ-UHFFFAOYSA-L calcium chloride dihydrate Chemical compound O.O.[Cl-].[Cl-].[Ca+2] LLSDKQJKOVVTOJ-UHFFFAOYSA-L 0.000 description 2

- 229940052299 calcium chloride dihydrate Drugs 0.000 description 2

- 229910001424 calcium ion Inorganic materials 0.000 description 2

- 229940041514 candida albicans extract Drugs 0.000 description 2

- 210000000349 chromosome Anatomy 0.000 description 2

- 229960002303 citric acid monohydrate Drugs 0.000 description 2

- 229910000361 cobalt sulfate Inorganic materials 0.000 description 2

- 229940044175 cobalt sulfate Drugs 0.000 description 2

- 238000002425 crystallisation Methods 0.000 description 2

- 238000005520 cutting process Methods 0.000 description 2

- 238000013461 design Methods 0.000 description 2

- KCIDZIIHRGYJAE-YGFYJFDDSA-L dipotassium;[(2r,3r,4s,5r,6r)-3,4,5-trihydroxy-6-(hydroxymethyl)oxan-2-yl] phosphate Chemical compound [K+].[K+].OC[C@H]1O[C@H](OP([O-])([O-])=O)[C@H](O)[C@@H](O)[C@H]1O KCIDZIIHRGYJAE-YGFYJFDDSA-L 0.000 description 2

- 238000004090 dissolution Methods 0.000 description 2

- 239000012153 distilled water Substances 0.000 description 2

- 239000013613 expression plasmid Substances 0.000 description 2

- 239000011888 foil Substances 0.000 description 2

- 239000012535 impurity Substances 0.000 description 2

- 238000003780 insertion Methods 0.000 description 2

- 230000037431 insertion Effects 0.000 description 2

- 229910000358 iron sulfate Inorganic materials 0.000 description 2

- RBTARNINKXHZNM-UHFFFAOYSA-K iron trichloride Chemical compound Cl[Fe](Cl)Cl RBTARNINKXHZNM-UHFFFAOYSA-K 0.000 description 2

- BAUYGSIQEAFULO-UHFFFAOYSA-L iron(2+) sulfate (anhydrous) Chemical compound [Fe+2].[O-]S([O-])(=O)=O BAUYGSIQEAFULO-UHFFFAOYSA-L 0.000 description 2

- RUTXIHLAWFEWGM-UHFFFAOYSA-H iron(3+) sulfate Chemical compound [Fe+3].[Fe+3].[O-]S([O-])(=O)=O.[O-]S([O-])(=O)=O.[O-]S([O-])(=O)=O RUTXIHLAWFEWGM-UHFFFAOYSA-H 0.000 description 2

- 229910000360 iron(III) sulfate Inorganic materials 0.000 description 2

- 238000002955 isolation Methods 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 229910052757 nitrogen Inorganic materials 0.000 description 2

- 235000015097 nutrients Nutrition 0.000 description 2

- 239000008363 phosphate buffer Substances 0.000 description 2

- XAEFZNCEHLXOMS-UHFFFAOYSA-M potassium benzoate Chemical compound [K+].[O-]C(=O)C1=CC=CC=C1 XAEFZNCEHLXOMS-UHFFFAOYSA-M 0.000 description 2

- 239000011347 resin Substances 0.000 description 2

- 229920005989 resin Polymers 0.000 description 2

- 238000005185 salting out Methods 0.000 description 2

- 239000011780 sodium chloride Substances 0.000 description 2

- 235000010288 sodium nitrite Nutrition 0.000 description 2

- GEHJYWRUCIMESM-UHFFFAOYSA-L sodium sulfite Chemical compound [Na+].[Na+].[O-]S([O-])=O GEHJYWRUCIMESM-UHFFFAOYSA-L 0.000 description 2

- 235000019345 sodium thiosulphate Nutrition 0.000 description 2

- 239000002689 soil Substances 0.000 description 2

- 238000006467 substitution reaction Methods 0.000 description 2

- 238000003786 synthesis reaction Methods 0.000 description 2

- 210000004233 talus Anatomy 0.000 description 2

- 238000012546 transfer Methods 0.000 description 2

- 238000013519 translation Methods 0.000 description 2

- 229940088594 vitamin Drugs 0.000 description 2

- 239000011782 vitamin Substances 0.000 description 2

- 235000013343 vitamin Nutrition 0.000 description 2

- 229930003231 vitamin Natural products 0.000 description 2

- 239000012138 yeast extract Substances 0.000 description 2

- DNIAPMSPPWPWGF-VKHMYHEASA-N (+)-propylene glycol Chemical compound C[C@H](O)CO DNIAPMSPPWPWGF-VKHMYHEASA-N 0.000 description 1

- BJEPYKJPYRNKOW-REOHCLBHSA-N (S)-malic acid Chemical compound OC(=O)[C@@H](O)CC(O)=O BJEPYKJPYRNKOW-REOHCLBHSA-N 0.000 description 1

- YPFDHNVEDLHUCE-UHFFFAOYSA-N 1,3-propanediol Substances OCCCO YPFDHNVEDLHUCE-UHFFFAOYSA-N 0.000 description 1

- PAWQVTBBRAZDMG-UHFFFAOYSA-N 2-(3-bromo-2-fluorophenyl)acetic acid Chemical compound OC(=O)CC1=CC=CC(Br)=C1F PAWQVTBBRAZDMG-UHFFFAOYSA-N 0.000 description 1

- BKFXSOCDAQACQM-UHFFFAOYSA-N 3-chlorophthalic acid Chemical compound OC(=O)C1=CC=CC(Cl)=C1C(O)=O BKFXSOCDAQACQM-UHFFFAOYSA-N 0.000 description 1

- QGZKDVFQNNGYKY-UHFFFAOYSA-O Ammonium Chemical compound [NH4+] QGZKDVFQNNGYKY-UHFFFAOYSA-O 0.000 description 1

- BTBUEUYNUDRHOZ-UHFFFAOYSA-N Borate Chemical compound [O-]B([O-])[O-] BTBUEUYNUDRHOZ-UHFFFAOYSA-N 0.000 description 1

- 108020004705 Codon Proteins 0.000 description 1

- 229920000742 Cotton Polymers 0.000 description 1

- 230000004544 DNA amplification Effects 0.000 description 1

- 108010014303 DNA-directed DNA polymerase Proteins 0.000 description 1

- 102000016928 DNA-directed DNA polymerase Human genes 0.000 description 1

- 241000196324 Embryophyta Species 0.000 description 1

- 241000588722 Escherichia Species 0.000 description 1

- 241000672609 Escherichia coli BL21 Species 0.000 description 1

- 101900203280 Escherichia coli Lactaldehyde dehydrogenase Proteins 0.000 description 1

- 229930091371 Fructose Natural products 0.000 description 1

- 239000005715 Fructose Substances 0.000 description 1

- RFSUNEUAIZKAJO-ARQDHWQXSA-N Fructose Chemical compound OC[C@H]1O[C@](O)(CO)[C@@H](O)[C@@H]1O RFSUNEUAIZKAJO-ARQDHWQXSA-N 0.000 description 1

- 108700007698 Genetic Terminator Regions Proteins 0.000 description 1

- 241000238631 Hexapoda Species 0.000 description 1

- XUJNEKJLAYXESH-REOHCLBHSA-N L-Cysteine Chemical compound SC[C@H](N)C(O)=O XUJNEKJLAYXESH-REOHCLBHSA-N 0.000 description 1

- HBBGRARXTFLTSG-UHFFFAOYSA-N Lithium ion Chemical compound [Li+] HBBGRARXTFLTSG-UHFFFAOYSA-N 0.000 description 1

- 240000002853 Nelumbo nucifera Species 0.000 description 1

- 235000006508 Nelumbo nucifera Nutrition 0.000 description 1

- 235000006510 Nelumbo pentapetala Nutrition 0.000 description 1

- CTQNGGLPUBDAKN-UHFFFAOYSA-N O-Xylene Chemical compound CC1=CC=CC=C1C CTQNGGLPUBDAKN-UHFFFAOYSA-N 0.000 description 1

- 239000001888 Peptone Substances 0.000 description 1

- 108010080698 Peptones Proteins 0.000 description 1

- 241000512220 Polaromonas Species 0.000 description 1

- 239000004793 Polystyrene Substances 0.000 description 1

- 108010001267 Protein Subunits Proteins 0.000 description 1

- 102000002067 Protein Subunits Human genes 0.000 description 1

- 241000589517 Pseudomonas aeruginosa Species 0.000 description 1

- 241000320117 Pseudomonas putida KT2440 Species 0.000 description 1

- 108020005091 Replication Origin Proteins 0.000 description 1

- 241001459443 Rhodococcus jostii RHA1 Species 0.000 description 1

- 240000004808 Saccharomyces cerevisiae Species 0.000 description 1

- 238000012300 Sequence Analysis Methods 0.000 description 1

- DWAQJAXMDSEUJJ-UHFFFAOYSA-M Sodium bisulfite Chemical compound [Na+].OS([O-])=O DWAQJAXMDSEUJJ-UHFFFAOYSA-M 0.000 description 1

- FKNQFGJONOIPTF-UHFFFAOYSA-N Sodium cation Chemical compound [Na+] FKNQFGJONOIPTF-UHFFFAOYSA-N 0.000 description 1

- 108091081024 Start codon Proteins 0.000 description 1

- KDYFGRWQOYBRFD-UHFFFAOYSA-N Succinic acid Natural products OC(=O)CCC(O)=O KDYFGRWQOYBRFD-UHFFFAOYSA-N 0.000 description 1

- CZMRCDWAGMRECN-UGDNZRGBSA-N Sucrose Chemical compound O[C@H]1[C@H](O)[C@@H](CO)O[C@@]1(CO)O[C@@H]1[C@H](O)[C@@H](O)[C@H](O)[C@@H](CO)O1 CZMRCDWAGMRECN-UGDNZRGBSA-N 0.000 description 1

- 229930006000 Sucrose Natural products 0.000 description 1

- 108010006785 Taq Polymerase Proteins 0.000 description 1

- BZHJMEDXRYGGRV-UHFFFAOYSA-N Vinyl chloride Chemical compound ClC=C BZHJMEDXRYGGRV-UHFFFAOYSA-N 0.000 description 1

- 244000131415 Zanthoxylum piperitum Species 0.000 description 1

- 235000008853 Zanthoxylum piperitum Nutrition 0.000 description 1

- 240000008042 Zea mays Species 0.000 description 1

- 235000005824 Zea mays ssp. parviglumis Nutrition 0.000 description 1

- 235000002017 Zea mays subsp mays Nutrition 0.000 description 1

- AZFNGPAYDKGCRB-XCPIVNJJSA-M [(1s,2s)-2-amino-1,2-diphenylethyl]-(4-methylphenyl)sulfonylazanide;chlororuthenium(1+);1-methyl-4-propan-2-ylbenzene Chemical compound [Ru+]Cl.CC(C)C1=CC=C(C)C=C1.C1=CC(C)=CC=C1S(=O)(=O)[N-][C@@H](C=1C=CC=CC=1)[C@@H](N)C1=CC=CC=C1 AZFNGPAYDKGCRB-XCPIVNJJSA-M 0.000 description 1

- 238000010306 acid treatment Methods 0.000 description 1

- 125000003295 alanine group Chemical group N[C@@H](C)C(=O)* 0.000 description 1

- 150000001298 alcohols Chemical class 0.000 description 1

- 150000001299 aldehydes Chemical class 0.000 description 1

- 239000000783 alginic acid Substances 0.000 description 1

- 235000010443 alginic acid Nutrition 0.000 description 1

- 229920000615 alginic acid Polymers 0.000 description 1

- 229960001126 alginic acid Drugs 0.000 description 1

- 150000001340 alkali metals Chemical class 0.000 description 1

- 239000012670 alkaline solution Substances 0.000 description 1

- BJEPYKJPYRNKOW-UHFFFAOYSA-N alpha-hydroxysuccinic acid Natural products OC(=O)C(O)CC(O)=O BJEPYKJPYRNKOW-UHFFFAOYSA-N 0.000 description 1

- 235000019270 ammonium chloride Nutrition 0.000 description 1

- 230000003321 amplification Effects 0.000 description 1

- 210000004102 animal cell Anatomy 0.000 description 1

- 239000003125 aqueous solvent Substances 0.000 description 1

- 235000010323 ascorbic acid Nutrition 0.000 description 1

- 229960005070 ascorbic acid Drugs 0.000 description 1

- 239000011668 ascorbic acid Substances 0.000 description 1

- LFYJSSARVMHQJB-QIXNEVBVSA-N bakuchiol Chemical compound CC(C)=CCC[C@@](C)(C=C)\C=C\C1=CC=C(O)C=C1 LFYJSSARVMHQJB-QIXNEVBVSA-N 0.000 description 1

- 230000037429 base substitution Effects 0.000 description 1

- WQZGKKKJIJFFOK-VFUOTHLCSA-N beta-D-glucose Chemical compound OC[C@H]1O[C@@H](O)[C@H](O)[C@@H](O)[C@@H]1O WQZGKKKJIJFFOK-VFUOTHLCSA-N 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000011616 biotin Substances 0.000 description 1

- 229960002685 biotin Drugs 0.000 description 1

- 235000020958 biotin Nutrition 0.000 description 1

- 239000007853 buffer solution Substances 0.000 description 1

- KDYFGRWQOYBRFD-NUQCWPJISA-N butanedioic acid Chemical compound O[14C](=O)CC[14C](O)=O KDYFGRWQOYBRFD-NUQCWPJISA-N 0.000 description 1

- 159000000007 calcium salts Chemical class 0.000 description 1

- 238000004364 calculation method Methods 0.000 description 1

- 239000004202 carbamide Substances 0.000 description 1

- 150000001732 carboxylic acid derivatives Chemical class 0.000 description 1

- 239000000679 carrageenan Substances 0.000 description 1

- 235000010418 carrageenan Nutrition 0.000 description 1

- 229920001525 carrageenan Polymers 0.000 description 1

- 229940113118 carrageenan Drugs 0.000 description 1

- 230000015556 catabolic process Effects 0.000 description 1

- 238000003163 cell fusion method Methods 0.000 description 1

- 210000000170 cell membrane Anatomy 0.000 description 1

- 238000012824 chemical production Methods 0.000 description 1

- 239000003153 chemical reaction reagent Substances 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 229960004106 citric acid Drugs 0.000 description 1

- MEYVLGVRTYSQHI-UHFFFAOYSA-L cobalt(2+) sulfate heptahydrate Chemical compound O.O.O.O.O.O.O.[Co+2].[O-]S([O-])(=O)=O MEYVLGVRTYSQHI-UHFFFAOYSA-L 0.000 description 1

- 239000000571 coke Substances 0.000 description 1

- 238000004440 column chromatography Methods 0.000 description 1

- 238000011109 contamination Methods 0.000 description 1

- 235000005822 corn Nutrition 0.000 description 1

- 230000008025 crystallization Effects 0.000 description 1

- 235000018417 cysteine Nutrition 0.000 description 1

- XUJNEKJLAYXESH-UHFFFAOYSA-N cysteine Natural products SCC(N)C(O)=O XUJNEKJLAYXESH-UHFFFAOYSA-N 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 238000006731 degradation reaction Methods 0.000 description 1

- 238000006297 dehydration reaction Methods 0.000 description 1

- RCRBCNZJGBTYDI-UHFFFAOYSA-L dilithium;terephthalate Chemical compound [Li+].[Li+].[O-]C(=O)C1=CC=C(C([O-])=O)C=C1 RCRBCNZJGBTYDI-UHFFFAOYSA-L 0.000 description 1

- ZPWVASYFFYYZEW-UHFFFAOYSA-L dipotassium hydrogen phosphate Chemical compound [K+].[K+].OP([O-])([O-])=O ZPWVASYFFYYZEW-UHFFFAOYSA-L 0.000 description 1

- 229910000396 dipotassium phosphate Inorganic materials 0.000 description 1

- 235000019797 dipotassium phosphate Nutrition 0.000 description 1

- BNIILDVGGAEEIG-UHFFFAOYSA-L disodium hydrogen phosphate Chemical compound [Na+].[Na+].OP([O-])([O-])=O BNIILDVGGAEEIG-UHFFFAOYSA-L 0.000 description 1

- 238000004821 distillation Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 239000003814 drug Substances 0.000 description 1

- 238000004520 electroporation Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 238000006911 enzymatic reaction Methods 0.000 description 1

- FYIBGDKNYYMMAG-UHFFFAOYSA-N ethane-1,2-diol;terephthalic acid Chemical compound OCCO.OC(=O)C1=CC=C(C(O)=O)C=C1 FYIBGDKNYYMMAG-UHFFFAOYSA-N 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 235000013305 food Nutrition 0.000 description 1

- 108020001507 fusion proteins Proteins 0.000 description 1

- 102000037865 fusion proteins Human genes 0.000 description 1

- 238000001502 gel electrophoresis Methods 0.000 description 1

- 230000002068 genetic effect Effects 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 230000012010 growth Effects 0.000 description 1

- 229940093915 gynecological organic acid Drugs 0.000 description 1

- 229910052736 halogen Inorganic materials 0.000 description 1

- 150000002367 halogens Chemical class 0.000 description 1

- 230000006801 homologous recombination Effects 0.000 description 1

- 238000002744 homologous recombination Methods 0.000 description 1

- 230000001939 inductive effect Effects 0.000 description 1

- 238000009776 industrial production Methods 0.000 description 1

- 230000002401 inhibitory effect Effects 0.000 description 1

- 229910017053 inorganic salt Inorganic materials 0.000 description 1

- 239000003456 ion exchange resin Substances 0.000 description 1

- 229920003303 ion-exchange polymer Polymers 0.000 description 1

- 150000002500 ions Chemical class 0.000 description 1

- SURQXAFEQWPFPV-UHFFFAOYSA-L iron(2+) sulfate heptahydrate Chemical compound O.O.O.O.O.O.O.[Fe+2].[O-]S([O-])(=O)=O SURQXAFEQWPFPV-UHFFFAOYSA-L 0.000 description 1

- 229910001416 lithium ion Inorganic materials 0.000 description 1

- 229910052943 magnesium sulfate Inorganic materials 0.000 description 1

- 235000019341 magnesium sulphate Nutrition 0.000 description 1

- 239000001630 malic acid Substances 0.000 description 1

- 235000011090 malic acid Nutrition 0.000 description 1

- 235000013372 meat Nutrition 0.000 description 1

- 230000002503 metabolic effect Effects 0.000 description 1

- 229910021645 metal ion Inorganic materials 0.000 description 1

- 239000011259 mixed solution Substances 0.000 description 1

- 235000013379 molasses Nutrition 0.000 description 1

- 150000002823 nitrates Chemical class 0.000 description 1

- 239000002736 nonionic surfactant Substances 0.000 description 1

- 238000003199 nucleic acid amplification method Methods 0.000 description 1

- 150000007524 organic acids Chemical class 0.000 description 1

- 235000005985 organic acids Nutrition 0.000 description 1

- 239000003960 organic solvent Substances 0.000 description 1

- 238000010979 pH adjustment Methods 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 235000019319 peptone Nutrition 0.000 description 1

- 230000035699 permeability Effects 0.000 description 1

- 150000007965 phenolic acids Chemical class 0.000 description 1

- 235000009048 phenolic acids Nutrition 0.000 description 1

- 239000013600 plasmid vector Substances 0.000 description 1

- 229920002223 polystyrene Polymers 0.000 description 1

- 229920000166 polytrimethylene carbonate Polymers 0.000 description 1

- 239000004304 potassium nitrite Substances 0.000 description 1

- 235000010289 potassium nitrite Nutrition 0.000 description 1

- 239000002244 precipitate Substances 0.000 description 1

- 238000001556 precipitation Methods 0.000 description 1

- 230000001737 promoting effect Effects 0.000 description 1

- 238000010188 recombinant method Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 238000012827 research and development Methods 0.000 description 1

- 239000013605 shuttle vector Substances 0.000 description 1

- 239000002002 slurry Substances 0.000 description 1

- 239000001509 sodium citrate Substances 0.000 description 1

- NLJMYIDDQXHKNR-UHFFFAOYSA-K sodium citrate Chemical compound O.O.[Na+].[Na+].[Na+].[O-]C(=O)CC(O)(CC([O-])=O)C([O-])=O NLJMYIDDQXHKNR-UHFFFAOYSA-K 0.000 description 1

- 235000010267 sodium hydrogen sulphite Nutrition 0.000 description 1

- KKCBUQHMOMHUOY-UHFFFAOYSA-N sodium oxide Chemical compound [O-2].[Na+].[Na+] KKCBUQHMOMHUOY-UHFFFAOYSA-N 0.000 description 1

- 229910001948 sodium oxide Inorganic materials 0.000 description 1

- 159000000000 sodium salts Chemical class 0.000 description 1

- 235000010265 sodium sulphite Nutrition 0.000 description 1

- AKHNMLFCWUSKQB-UHFFFAOYSA-L sodium thiosulfate Chemical compound [Na+].[Na+].[O-]S([O-])(=O)=S AKHNMLFCWUSKQB-UHFFFAOYSA-L 0.000 description 1

- 239000006104 solid solution Substances 0.000 description 1

- 239000007858 starting material Substances 0.000 description 1

- 239000004575 stone Substances 0.000 description 1

- 239000005720 sucrose Substances 0.000 description 1

- 235000000346 sugar Nutrition 0.000 description 1

- 150000008163 sugars Chemical class 0.000 description 1

- LSNNMFCWUKXFEE-UHFFFAOYSA-L sulfite Chemical class [O-]S([O-])=O LSNNMFCWUKXFEE-UHFFFAOYSA-L 0.000 description 1

- RVUXIPACAZKWHU-UHFFFAOYSA-N sulfuric acid;heptahydrate Chemical compound O.O.O.O.O.O.O.OS(O)(=O)=O RVUXIPACAZKWHU-UHFFFAOYSA-N 0.000 description 1

- 239000006228 supernatant Substances 0.000 description 1

- 150000003504 terephthalic acids Chemical class 0.000 description 1

- 229940101691 thiamine 10 mg Drugs 0.000 description 1

- DPJRMOMPQZCRJU-UHFFFAOYSA-M thiamine hydrochloride Chemical compound Cl.[Cl-].CC1=C(CCO)SC=[N+]1CC1=CN=C(C)N=C1N DPJRMOMPQZCRJU-UHFFFAOYSA-M 0.000 description 1

- 229960000344 thiamine hydrochloride Drugs 0.000 description 1

- 235000019190 thiamine hydrochloride Nutrition 0.000 description 1

- 239000011747 thiamine hydrochloride Substances 0.000 description 1

- 150000004764 thiosulfuric acid derivatives Chemical class 0.000 description 1

- 101150102505 tphB gene Proteins 0.000 description 1

- 230000005758 transcription activity Effects 0.000 description 1

- 239000012137 tryptone Substances 0.000 description 1

- 238000009281 ultraviolet germicidal irradiation Methods 0.000 description 1

- 230000004580 weight loss Effects 0.000 description 1

- 239000008096 xylene Substances 0.000 description 1

- UHVMMEOXYDMDKI-JKYCWFKZSA-L zinc;1-(5-cyanopyridin-2-yl)-3-[(1s,2s)-2-(6-fluoro-2-hydroxy-3-propanoylphenyl)cyclopropyl]urea;diacetate Chemical compound [Zn+2].CC([O-])=O.CC([O-])=O.CCC(=O)C1=CC=C(F)C([C@H]2[C@H](C2)NC(=O)NC=2N=CC(=CC=2)C#N)=C1O UHVMMEOXYDMDKI-JKYCWFKZSA-L 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12P—FERMENTATION OR ENZYME-USING PROCESSES TO SYNTHESISE A DESIRED CHEMICAL COMPOUND OR COMPOSITION OR TO SEPARATE OPTICAL ISOMERS FROM A RACEMIC MIXTURE

- C12P7/00—Preparation of oxygen-containing organic compounds

- C12P7/40—Preparation of oxygen-containing organic compounds containing a carboxyl group including Peroxycarboxylic acids

- C12P7/44—Polycarboxylic acids

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12P—FERMENTATION OR ENZYME-USING PROCESSES TO SYNTHESISE A DESIRED CHEMICAL COMPOUND OR COMPOSITION OR TO SEPARATE OPTICAL ISOMERS FROM A RACEMIC MIXTURE

- C12P7/00—Preparation of oxygen-containing organic compounds

- C12P7/40—Preparation of oxygen-containing organic compounds containing a carboxyl group including Peroxycarboxylic acids

- C12P7/42—Hydroxy-carboxylic acids

Definitions

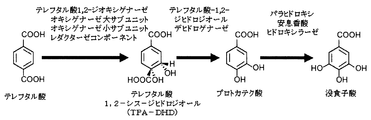

- the present invention uses a terephthalic acid potassium salt as a raw material and a microorganism expressing terephthalic acid 1,2-dioxygenase to produce terephthalic acid-1,2-cis-dihydrodiol (hereinafter referred to as TPA-DHD as necessary). And a method of converting TPA-DHD into protocatechuic acid or gallic acid, and a method of obtaining a raw material potassium terephthalate by depolymerization of waste polyester.

- terephthalic acid potassium salt means at least one terephthalic acid such as terephthalic acid dipotassium salt, terephthalic acid 1-potassium 4-sodium salt and terephthalic acid 1-potassium 4-ammonium salt.

- a carboxyl group residue forms a salt with potassium ion.

- Terephthalic acid is mainly produced in large quantities as a raw material for terephthalic acid-based polyesters such as polyethylene terephthalate (hereinafter abbreviated as PET), polytrimethylene terephthalate (hereinafter abbreviated as PTT), and polybutylene terephthalate (hereinafter abbreviated as PBT). It is an inexpensive chemical product. Since terephthalic acid is inexpensive, technologies for producing useful chemicals such as TPA-DHD, 2-pyrone-4,6-dicarboxylic acid, protocatechuic acid, and gallic acid using terephthalic acid as a raw material using microorganisms have also been developed. (References 1 to 5). It is known that 2-hydroxyterephthalic acid, which is a raw material for pharmaceuticals and resin materials, can be produced by dehydration reaction of TPA-DHD (Patent Documents 1 and 2).

- terephthalate having excellent water solubility to the medium instead of terephthalic acid itself. Since sodium hydroxide is cheaper than potassium hydroxide, sodium salt of terephthalic acid has been used as a raw material so far, but useful chemicals were produced using microorganisms using potassium salt of terephthalic acid as a raw material. There are no reports and reports that the use of terephthalic acid potassium salt is superior to terephthalic acid sodium salt in terms of productivity of the target compound.

- terephthalic acid-based polyester Regarding the recycling of terephthalic acid-based polyester, a number of recycling technologies have been developed and commercialized, especially focusing on the recycling of discarded PET bottles. However, the recycling cost is high, and more profitable recycling technology is required. Thus, in the manufacture of chemicals using terephthalic acid as a raw material, using terephthalic acid derived from waste polyester as a raw material is an important research and development issue because it leads to the solution of environmental problems and the reduction of manufacturing costs.

- Patent Literature 6 to 11 As a recycling method for waste polyester, in addition to the material recycling method for obtaining the original polyester, the chemical recycling method for chemically depolymerizing polyester to obtain terephthalic acid, bis-2-hydroxyethyl terephthalate, etc. (Patent Literature) 6 to 11) are known. It is known that depolymerization can be achieved by heating a polyester such as PET in an ethylene glycol reaction solvent or an alcohol reaction solvent containing an alkali metal hydroxide such as sodium hydroxide. In this case, sodium hydroxide is generally used as the alkali metal hydroxide because sodium hydroxide is inexpensive.

- Non-Patent Document 1 Although it is known that PET can be depolymerized in an ethylene glycol solvent containing potassium hydroxide (Non-Patent Document 1), the result of comparing the differences in PET depolymerization between potassium hydroxide and sodium hydroxide in an ethylene glycol solvent Has not been reported. Furthermore, after depolymerizing PET, PTT or PBT in an ethylene glycol reaction solvent containing potassium hydroxide to obtain potassium terephthalate, the microorganism is used to convert the potassium terephthalate into another useful chemical. There is no report on the recycling technology of waste polyester to be converted.

- Patent Document 12 An experimental example in which waste PET is depolymerized in a 1-butanol reaction solvent containing sodium hydroxide and terephthalic acid is obtained by addition of sulfuric acid has been reported (Patent Document 12). A 1-butanol reaction containing potassium hydroxide is reported. There have been no reports of cases in which waste PET is depolymerized in a solvent, and cases in which the difference between potassium hydroxide and sodium hydroxide in a depolymerization reaction of polyester in a 1-butanol reaction solvent containing an alkali is compared.

- E Escherichia coli

- K-12 strain which is often used in the basic research field and industrial production field, is obtained by using ethylene glycol with lactaldehyde reductase and lactaldehyde dehydrogenase. It is known that it can be converted to glycolic acid, and it has also been reported that the introduction of mutations into lactaldehyde reductase improves the metabolic ability of ethylene glycol (Non-Patent Documents 2 to 4).

- An object of the present invention is to produce TPA-DHD using an alkali metal terephthalate as a raw material and to improve the productivity of these compounds when converting the produced TPA-DHD into protocatechuic acid using a microorganism. And a method for obtaining the alkali metal terephthalate by depolymerization of waste polyester.

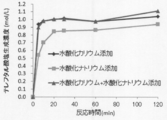

- the inventors of the present invention have studied the productivity of protocatechuic acid by recombinant Escherichia coli in the process of depolymerizing PET, a terephthalic acid polyester, in an alkaline solution to obtain terephthalate.

- terephthalic acid potassium salt terephthalic acid dipotassium salt, 1-potassium 4-ammonium salt or terephthalic acid 1-potassium 4-sodium salt

- protocatechuic acid was used instead of terephthalic acid disodium salt.

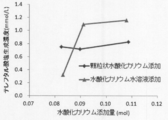

- the solubility of the terephthalate salt as a raw material is low, the amount of liquid introduced from the raw material tank increases, and the production amount of the target compound per culture tank decreases. Therefore, it is preferable to use terephthalate having high water solubility as a raw material. Therefore, when the solubility of terephthalic acid disodium salt, terephthalic acid 1-potassium 4-sodium salt and terephthalic acid dipotassium salt in water at 30 ° C. was examined, the solubility of terephthalic acid dipotassium salt was about 1.0 ⁇ M.

- terephthalic acid potassium salts such as terephthalic acid dipotassium salt and terephthalic acid 1-potassium 4-sodium salt were found to be superior to terephthalic acid disodium salt in the production of target compounds by microorganisms such as Escherichia coli. .

- the solubility of ammonium terephthalate in water at 30 ° C was investigated.

- the solubility of acid 1-potassium 4-ammonium salt is about 0.85 M

- the solubility of terephthalic acid 1-sodium 4-ammonium salt is about 0.61 M

- the solubility of terephthalic acid diammonium salt is about 0.51 M. It has been found that potassium 4-ammonium salt has high water solubility.

- terephthalic acid 1-potassium 4-ammonium salt it has been found that the productivity of the target compound by microorganisms such as Escherichia coli is excellent, and the problem of the present invention has been solved.

- the present inventors have found that by changing the depolymerization reaction solvent from ethylene glycol to 1-butanol, the depolymerization reaction temperature can be lowered and the terephthalate recovery efficiency is unexpectedly excellent. Furthermore, in the depolymerization reaction in 1-butanol, it has been unexpectedly found that the use of potassium hydroxide as the alkali metal hydroxide is superior to sodium hydroxide in that the depolymerization efficiency of terephthalate is superior. It was.

- the present invention relates to the following (1) to (24).

- a process for producing terephthalic acid 1,2-cis-dihydrodiol by reacting with terephthalic acid in an aqueous medium containing terephthalic acid salt to produce terephthalic acid 1,2-cis-dihydrodiol, wherein the terephthalic acid salt comprises The method further comprises 0.5 times or more and 2 times or less of potassium in terms of mole relative to all terephthalic acid contained in terephthalate.

- A DNA encoding a protein comprising the amino acid sequence shown in SEQ ID NO: 2.

- B conversion from terephthalic acid to terephthalic acid 1,2-cis-dihydrodiol, including a sequence in which one or several amino acids are deleted, substituted and / or added in the amino acid sequence shown in SEQ ID NO: 2 DNA encoding a protein having a function related to.

- C DNA consisting of the base sequence shown in SEQ ID NO: 1.

- (D) hybridizes under stringent conditions with DNA comprising a sequence complementary to all or part of the base sequence shown in SEQ ID NO: 1, and from terephthalic acid to terephthalic acid 1,2-cis-dihydro DNA encoding a protein having a function related to conversion to a diol.

- (E) DNA encoding a protein comprising the amino acid sequence shown in SEQ ID NO: 4.

- terephthalic acid selected from the group consisting of dipotassium terephthalate, 1-potassium 4-sodium terephthalate, and 1-potassium 4-ammonium terephthalate as the aqueous medium containing the terephthalate

- the microorganism described in (1) is a microorganism in which the intracellular transport ability of terephthalic acid is enhanced by introducing the DNA shown in (m), (n), (o) or (p) below.

- N DNA encoding a protein comprising a sequence in which one or several amino acids are deleted, substituted and / or added in the amino acid sequence shown in SEQ ID NO: 8 and having terephthalic acid transporter activity.

- O DNA consisting of the base sequence represented by SEQ ID NO: 7.

- P DNA that hybridizes under stringent conditions with DNA consisting of a sequence complementary to all or part of the base sequence shown in SEQ ID NO: 7 and encodes a protein having terephthalic acid transporter activity .

- the microorganism further has a DNA shown in (q), (r), (s) or (t) below, and has the ability to produce protocatechuic acid from terephthalic acid, from (1) (4) characterized in that terephthalic acid 1,2-cis-dihydrodiol is produced from terephthalate by the method described in any one of (4), and terephthalic acid 1,2-cis-dihydrodiol is further converted into protocatechuic acid.

- a production method of protocatechuic acid. (Q) DNA encoding a protein comprising the amino acid sequence represented by SEQ ID NO: 10.

- (R) includes a sequence in which one or several amino acids are deleted, substituted and / or added in the amino acid sequence shown in SEQ ID NO: 10, and converts 1,2-cis-dihydrodiol terephthalate to protocatechuic acid DNA encoding a protein having activity.

- the microorganism further has the DNA shown in (q), (r), (s) or (t) and the DNA shown in (u), (v), (w) or (x),

- a process for producing gallic acid characterized in that the acid 1,2-cis-dihydrodiol is converted into gallic acid.

- U DNA encoding a protein comprising the amino acid sequence represented by SEQ ID NO: 12.

- (V) a DNA encoding a protein comprising a sequence in which one or several amino acids are deleted, substituted and / or added in the amino acid sequence shown in SEQ ID NO: 12 and having an activity of converting protocatechuic acid to gallic acid .

- (X) a protein that hybridizes under stringent conditions with DNA consisting of a sequence complementary to all or part of the base sequence shown in SEQ ID NO: 11 and has an activity of converting protocatechuic acid to gallic acid DNA encoding (8)

- the above (q), (r), (s ) Or (t) in addition to the DNA shown in (u), (v), (w) or (x) above, treatment of the microorganism or the culture obtained by the transformation method

- a method for producing gallic acid comprising converting terephthalic acid 1,2-cis-dihydrodiol into gallic acid using a product.

- the terephthalic acid 1,2-cis-dihydrodiol according to any one of (1) to (4), further comprising the step of obtaining the terephthalate salt by the following steps (A) to (D): Manufacturing method.

- step (B) Of the solid foreign substances contained in the depolymerization reaction solution of the waste obtained in step (A), a process of removing solid foreign substances floating in the solution by a floating sorting method, (C) A step of recovering solids in the solution other than the suspended solid foreign matter by a solid-liquid separation method from the solution subjected to the treatment in the step (B), (D) The solid collected in step (C) is subjected to a heat drying treatment, a vacuum drying treatment or a centrifugal separation treatment to reduce the content of glycols in the solid, and the remaining solid is treated with terephthalate.

- Step (10) of obtaining an acid salt The step of recovering the ethylene glycol reaction solvent after recovering the solid by the solid-liquid separation method in the step (C), and using the solvent as the ethylene glycol reaction solvent in the step (A)

- (12) The ethylene glycol reaction solvent after recovering the solid matter by the solid-liquid separation method in the step (C) is recovered, and the solvent is used as the ethylene glycol reaction solvent in the step (A).

- the method for producing protocatechuic acid according to (11), wherein a terephthalate obtained by repeatedly using the solvent without discarding is used.

- the ethylene glycol reaction solvent after recovering the solid by the solid-liquid separation method in the step (C) is recovered, and the solvent is used as the ethylene glycol reaction solvent in the step (A).

- the method for producing gallic acid according to (13), wherein terephthalate obtained by repeatedly using the solvent without discarding is used.

- a butanol reaction solvent containing potassium hydroxide or 1-butanol containing both potassium hydroxide and sodium hydroxide

- step (F) Of the solid foreign matters contained in the waste depolymerization reaction solution obtained in step (E), a step of removing solid foreign matters floating in the solution by a floating sorting method, (G) A step of recovering solids in the solution other than the suspended solid foreign matters from the solution subjected to the treatment in the step (F) by a solid-liquid separation method, (H) The solid matter recovered in step (G) is subjected to heat drying treatment, vacuum drying treatment or centrifugal separation treatment to reduce the contents of 1-butanol and glycols in the solid matter and remain.

- Step (19) of obtaining a solid as a terephthalate salt The 1-butanol reaction solvent after recovering the solid by the solid-liquid separation method in the step (G) is recovered, and the solvent is recovered as 1-butanol in the step (E).

- a process for producing diols (20) The method for producing protocatechuic acid according to (5) or (6), further comprising the step of obtaining the terephthalate by the steps (E) to (H).

- the 1-butanol reaction solvent after recovering the solid by the solid-liquid separation method in the step (G) is recovered, and the solvent is used as the 1-butanol reaction solvent in the step (E).

- the method for producing protocatechuic acid according to (20), wherein a terephthalate obtained by repeatedly using a glycol reaction solvent without being discarded is used.

- the 1-butanol reaction solvent after the solid is recovered by the solid-liquid separation method in the step (G) is recovered, and the solvent is used as the 1-butanol reaction solvent in the step (E).

- TPA- DHD when terephthalate containing 0.5 to 2 times the amount of potassium is used as a raw material with respect to the total terephthalic acid contained in the terephthalate in terms of mole, TPA- DHD can be manufactured efficiently. Moreover, according to the present invention, the obtained TPA-DHD can be efficiently converted into protocatechuic acid or gallic acid. Furthermore, terephthalic acid potassium salt suitable as a raw material for terephthalic acid derivatives by microorganisms can be efficiently prepared by depolymerization of waste polyester.

- terephthalic acid salt As a form of terephthalic acid used as a raw material for compound production by microorganisms, terephthalic acid salt is generally preferable because terephthalic acid salt has higher water solubility than terephthalic acid itself.

- the terephthalate used for such purposes include terephthalic acid dipotassium salt, terephthalic acid 1-potassium 4-sodium salt, terephthalic acid 1-potassium 4-ammonium salt, terephthalic acid disodium salt, terephthalic acid 1-sodium 4 -Ammonium salts and diammonium terephthalic acid salts.

- the terephthalic acid dipotassium salt is a salt in which the carboxyl groups at the 1-position and 4-position of terephthalic acid are ion-bonded to potassium ions.

- the terephthalic acid 1-potassium 4-sodium salt is a salt in which the carboxyl group residue at the 1-position of terephthalic acid is ion-bonded with potassium ion, and the carboxyl group residue at the 4-position of terephthalic acid is ion-bonded with sodium ion. is there.

- the terephthalic acid 1-potassium 4-ammonium salt is a salt in which the carboxyl group residue at the 1-position of terephthalic acid is ion-bonded with potassium ion and the carboxyl group residue at the 4-position of terephthalic acid is ion-bonded with ammonium ion. is there.

- the terephthalic acid disodium salt is a salt in which the carboxyl group residues at positions 1 and 4 of terephthalic acid are ion-bonded to sodium ions.

- the terephthalic acid 1-sodium 4-ammonium salt is a salt in which the carboxyl group residue at the 1-position of terephthalic acid is ion-bonded with sodium ions and the carboxyl group residue at the 4-position of terephthalic acid is ion-bonded with ammonium ions. is there.

- the diammonium terephthalate is a salt in which the carboxyl groups at the 1st and 4th positions of terephthalic acid are ion-bonded to ammonium ions.

- Each terephthalic acid powder has a molar ratio of twice as much potassium hydroxide, a molar ratio of 1 time of potassium hydroxide and 1 time of sodium hydroxide, a molar ratio of 1 time of potassium hydroxide and 1 Aqueous ammonia solution containing twice the amount of ammonia, 2 times the molar amount of sodium hydroxide, an aqueous ammonia solution containing the molar amount of 1 time sodium hydroxide and 1 time amount of ammonia, and a molar amount of 2 times the amount of ammonia After adding an aqueous ammonia solution containing water to an appropriate amount of water, the solution of each terephthalate is stir

- the terephthalic acid salt used in the present invention is a terephthalic acid salt containing 0.5 times or more and 2 times or less of potassium in terms of moles based on the total terephthalic acid contained in the terephthalate. More preferably, it is a terephthalate salt containing 0.6 times or more and 2 times or less of potassium in terms of moles relative to the total terephthalic acid contained in the terephthalate.

- potassium defined as 0.5 to 2 times the amount of all terephthalic acid contained in terephthalate is potassium derived from potassium terephthalate, that is, carboxyl of terephthalic acid. This is the amount of potassium that forms an ionic bond with the base residue.

- potassium (ion) derived from potassium terephthalate may be contained in the aqueous solvent in an amount of 0.5 to 2 times the amount of all terephthalic acid in terms of mole.

- the terephthalate any form of terephthalate powder, an aqueous solution in which terephthalate is dissolved, or a suspension of terephthalate in which terephthalate powder is mixed in a slurry state in the aqueous solution of terephthalate Even so, it can be used in the present invention.

- terephthalate includes any form of terephthalate.

- terephthalic acid containing at least one potassium terephthalate selected from the group consisting of dipotassium terephthalate, 1-potassium 4-sodium terephthalate, and 1-potassium 4-ammonium terephthalate is used.

- a terephthalic acid salt which is a salt and contains 0.5 times or more and 2 times or less of potassium in terms of mole relative to the total terephthalic acid contained in the terephthalic acid salt can be used.

- a terephthalate having a single component of terephthalate selected from dipotassium terephthalate, 1-potassium 4-sodium terephthalate and 1-potassium 4-ammonium terephthalate may be used.

- the terephthalate used in the present invention satisfies the above potassium content, in addition to the potassium terephthalate, disodium terephthalate, 1-sodium 4-ammonium terephthalate, diammonium terephthalate, etc. May be included.

- terephthalic acid 1-potassium 4-sodium salt and terephthalic acid disodium salt when using a mixture of two types of terephthalic acid salt, terephthalic acid 1-potassium 4-sodium salt and terephthalic acid disodium salt, the molar ratio of terephthalic acid 1-potassium 4-sodium salt to terephthalic acid disodium salt is It is possible to use terephthalate containing at least one amount.

- terephthalic acid dipotassium salt contains at least 1/3 times the molar ratio of terephthalic acid disodium salt. Terephthalate can be used.

- a mixture of three or more types of terephthalate can also be used.

- the mixture is 0.5 times or more and 2 times in terms of moles based on the total terephthalic acid contained in the terephthalate.

- the following potassium must be included.

- one or more types of potassium terephthalate selected from the group consisting of dipotassium terephthalate, 1-potassium 4-sodium terephthalate, 1-potassium 4-ammonium terephthalate, and disodium terephthalate

- a terephthalate containing two or more terephthalates selected from the group consisting of 1-sodium 4-ammonium terephthalate and diammonium terephthalate can be used.

- aqueous solution prepared by mixing terephthalic acid dipotassium salt, terephthalic acid disodium salt and terephthalic acid diammonium salt in a molar ratio of 1: 2: 1.

- the aqueous solution contains 0.5 times the amount of potassium relative to the total terephthalic acid, and 0.5 mol of potassium hydroxide, 1.0 mol of sodium hydroxide and 0.5 mol of ammonia are added to water and dissolved with respect to 1 mol of terephthalic acid. Can also be obtained.

- terephthalic acid dipotassium salt or 1-terephthalic acid salt obtained by depolymerizing waste polyester in ethylene glycol solvent or 1-butanol solvent containing potassium hydroxide or a mixture of potassium hydroxide and sodium hydroxide.

- a terephthalate salt containing potassium 4-sodium salt can be used as a raw material for producing a compound by a microorganism.

- terephthalate obtained by depolymerization of waste polyester since the price per mole is lower than sodium hydroxide or aqueous sodium hydroxide than potassium hydroxide, high-purity terephthalic acid and sodium hydroxide or ammonia are used for the terephthalate obtained by depolymerization of waste polyester.

- terephthalate produced by adding water may lower the manufacturing cost.

- Specific examples thereof include, for example, terephthalic acid salt obtained by mixing terephthalic acid dipotassium salt obtained by depolymerization of waste polyester, high-purity terephthalic acid, and aqueous ammonia in a molar ratio of 6: 4: 8, respectively.

- aqueous solution of terephthalate thus obtained is equivalent to an aqueous solution prepared by mixing terephthalic acid dipotassium salt and terephthalic acid diammonium salt in a molar ratio of 6: 4.

- potassium terephthalate When potassium terephthalate is prepared from waste polyester using the method disclosed in the present invention, in addition to potassium ions, sodium ions, ammonium ions, other metal ions such as calcium ions and lithium ions may be mixed as foreign substances. is there.

- terephthalic acid is used as long as it is a terephthalate containing 0.5 to 2 times the amount of potassium in terms of moles relative to the total terephthalic acid contained in the terephthalate.

- a terephthalate such as calcium salt or lithium terephthalate may be mixed if its content is low.

- TPA-DHD a process for producing TPA-DHD, protocatechuic acid and gallic acid from terephthalic acid

- terephthalic acid is oxidized by terephthalic acid 1,2-dioxygenase and converted to TPA-DHD.

- TPA-DHD can be converted to protocatechuic acid by TPA-DHD dehydrogenase.

- parahydroxybenzoic acid hydroxylase or improved parahydroxybenzoic acid hydroxylase for example, leucine at position 199 or leucine at position 200 of parahydroxybenzoic acid hydroxylase is replaced with valine or glycine, and positions 385 or 386)

- Protocatechuic acid can be converted to gallic acid by a mutant in which the tyrosine is substituted with phenylalanine, valine or alanine.

- the terephthalic acid 1,2-dioxygenase used in the present invention comprises an oxygenase component and a reductase component.

- the oxygenase component consists of two large and small subunits.

- Examples of the oxygenase large subunit protein include a protein having an amino acid sequence derived from the Comamonas testeroni 72W2 strain represented by SEQ ID NO: 2. This strain was received on January 24, 2012 by an independent administrative agency, National Institute for Product Evaluation and Patent Microorganisms Depositary Center (NPMD) (2-5-8 Kazusa-Kamashita, Kisarazu City, Chiba Prefecture 292-0818, Japan) NITE ABP-1209 is deposited internationally and can be sold.

- NPMD National Institute for Product Evaluation and Patent Microorganisms Depositary Center

- the oxygenase large subunit protein used in the present invention includes an amino acid sequence in which one or several amino acids are deleted, substituted or added in the amino acid sequence of SEQ ID NO: 2, and terephthalic acid to TPA-DHD. Proteins having a function related to the conversion to can be mentioned.

- the protein comprises an amino acid sequence having 75% or more identity, preferably 90% or more, particularly preferably 95% or more identity with the amino acid sequence of SEQ ID NO: 2, and terephthalic acid to TPA-DHD. Proteins having a function related to the conversion of can be mentioned.

- function related to the conversion from terephthalic acid to TPA-DHD means terephthalic acid together with terephthalic acid 1,2-dioxygenase / oxygenase small subunit protein and terephthalic acid 1,2-dioxygenase / reductase protein. Means a function capable of producing TPA-DHD when reacted with.

- terephthalic acid 1,2-dioxygenase / oxygenase small subunit protein examples include a protein having the amino acid sequence derived from the above-mentioned Comamonas testosteroni 72W2 strain represented by SEQ ID NO: 4. Further, the terephthalic acid 1,2-dioxygenase / oxygenase small subunit protein used in the present invention is an amino acid sequence of SEQ ID NO: 4 from an amino acid sequence in which one or several amino acids are deleted, substituted or added. And a protein having a function related to the conversion from terephthalic acid to TPA-DHD.

- the protein comprises an amino acid sequence having 75% or more identity, preferably 90% or more, particularly preferably 95% or more identity with the amino acid sequence of SEQ ID NO: 4, and terephthalic acid to TPA-DHD.

- proteins having a function related to the conversion of can be mentioned.

- “function related to the conversion from terephthalic acid to TPA-DHD” means terephthalic acid together with terephthalic acid 1,2-dioxygenase / oxygenase large subunit protein and terephthalic acid 1,2-dioxygenase / reductase protein.

- Examples of the terephthalic acid 1,2-dioxygenase reductase protein used in the present invention include a protein having the amino acid sequence derived from the above-mentioned Comamonas testosteroni 72W2 strain represented by SEQ ID NO: 6.

- the terephthalic acid 1,2-dioxygenase / reductase protein used in the present invention comprises an amino acid sequence in which one or several amino acids are deleted, substituted or added in the amino acid sequence of SEQ ID NO: 6, and Examples thereof include proteins having a function related to the conversion of terephthalic acid to TPA-DHD.

- the protein comprises an amino acid sequence having 75% or more identity, preferably 90% or more, particularly preferably 95% or more identity with the amino acid sequence of SEQ ID NO: 6, and terephthalic acid to TPA-DHD Proteins having a function related to the conversion of can be mentioned.

- “functions related to the conversion from terephthalic acid to TPA-DHD” means terephthalic acid 1,2-dioxygenase / oxygenase large subunit protein and terephthalic acid 1,2-dioxygenase / oxygenase small subunit protein In addition, it means a function capable of producing TPA-DHD when reacted with terephthalic acid.

- the terephthalic acid transporter protein used in the present invention examples include a protein having an amino acid sequence derived from Rhodococcus jostii RHA1 strain represented by SEQ ID NO: 8.

- the terephthalic acid transporter protein used in the present invention is composed of an amino acid sequence in which one or several amino acids are deleted, substituted or added in the amino acid sequence of SEQ ID NO: 8, and transports terephthalic acid into cells.

- a protein having an ability can be mentioned.

- the protein comprises an amino acid sequence having 75% or more identity, preferably 90% or more, particularly preferably 95% or more identity with the amino acid sequence of SEQ ID NO: 8, and transports terephthalic acid into cells.

- TPA-DHD dehydrogenase protein used in the present invention examples include a protein having an amino acid sequence derived from the above-mentioned Comamonas testosteroni 72W2 strain represented by SEQ ID NO: 10.

- the TPA-DHD dehydrogenase protein used in the present invention includes an amino acid sequence in which one or several amino acids are deleted, substituted or added in the amino acid sequence of SEQ ID NO: 10, and TPA-DHD is converted to protocatechuic acid.

- proteins having the activity of converting to The protein comprises an amino acid sequence having 75% or more identity, preferably 90% or more, particularly preferably 95% or more identity with the amino acid sequence of SEQ ID NO: 10, and TPA-DHD is converted to protocatechuic acid.

- a protein having an activity to convert can be mentioned.

- Examples of the parahydroxybenzoic acid hydroxylase used in the present invention include, for example, a Pseudomonas aeruginosa PAO strain GenBank (hereinafter referred to as GenBank GB) protein of GB accession number AAG03636, or Pseudomonas putida ( Pseudomonas putida ) a protein of GB accession number AAN69138 of the KT2440 strain, or a protein having an amino acid sequence derived from the Corynebacterium glutamicum ATCC13032 strain represented by SEQ ID NO: 12.