WO2011142159A1 - ウェーハの面取り装置 - Google Patents

ウェーハの面取り装置 Download PDFInfo

- Publication number

- WO2011142159A1 WO2011142159A1 PCT/JP2011/054445 JP2011054445W WO2011142159A1 WO 2011142159 A1 WO2011142159 A1 WO 2011142159A1 JP 2011054445 W JP2011054445 W JP 2011054445W WO 2011142159 A1 WO2011142159 A1 WO 2011142159A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- wafer

- processing

- chamfering

- moving

- processing table

- Prior art date

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B9/00—Machines or devices designed for grinding edges or bevels on work or for removing burrs; Accessories therefor

- B24B9/02—Machines or devices designed for grinding edges or bevels on work or for removing burrs; Accessories therefor characterised by a special design with respect to properties of materials specific to articles to be ground

- B24B9/06—Machines or devices designed for grinding edges or bevels on work or for removing burrs; Accessories therefor characterised by a special design with respect to properties of materials specific to articles to be ground of non-metallic inorganic material, e.g. stone, ceramics, porcelain

- B24B9/065—Machines or devices designed for grinding edges or bevels on work or for removing burrs; Accessories therefor characterised by a special design with respect to properties of materials specific to articles to be ground of non-metallic inorganic material, e.g. stone, ceramics, porcelain of thin, brittle parts, e.g. semiconductors, wafers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B47/00—Drives or gearings; Equipment therefor

- B24B47/22—Equipment for exact control of the position of the grinding tool or work at the start of the grinding operation

- B24B47/225—Equipment for exact control of the position of the grinding tool or work at the start of the grinding operation for bevelling optical work, e.g. lenses

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02002—Preparing wafers

- H01L21/02005—Preparing bulk and homogeneous wafers

- H01L21/02008—Multistep processes

- H01L21/0201—Specific process step

- H01L21/02021—Edge treatment, chamfering

Definitions

- the present invention relates to a wafer chamfering apparatus that performs chamfering processing on the outer periphery of a wafer such as silicon used as a material of a semiconductor element.

- Disc-like thin plate materials used as substrates for integrated circuits such as various crystal wafers and other semiconductor device wafers

- other disc-like thin plate materials made of hard materials including metal materials such as silicon (Si) single crystal, gallium arsenide (GaAs), Quartz, quartz, sapphire, ferrite, silicon carbide (SiC), etc. (collectively these are simply referred to as wafers) are thinly cut out from the ingot by a slicing machine, and then the edges (periphery) are ground. And chamfered to a predetermined shape and a predetermined surface roughness.

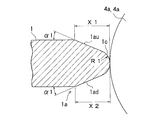

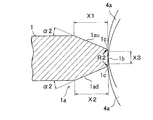

- a V-shaped or U-shaped notch 1n for indicating a reference position in the circumferential direction is formed on the wafer 1 to be chamfered, and this is also chamfered.

- the edge 1a of the wafer 1 has an upper slope 1au inclined by an angle ⁇ 1 (about 22 °) with respect to the upper plane and a lower angle inclined by an angle ⁇ 1 (about 22 °) with respect to the lower plane.

- the cross section is formed into a cross-sectional shape (a substantially triangular shape as a whole) including the inclined surface 1ad and an arc 1c having a radius R1 that smoothly connects the inclined surface 1ad.

- the horizontal length of the upper slope 1au is referred to as “chamfer width X1”

- the horizontal length of the lower slope 1ad is referred to as “chamfer width X2”.

- the edge 1a of the wafer 1 has an upper slope 1au inclined by an angle ⁇ 2 with respect to the upper plane, a lower slope 1ad inclined by an angle ⁇ 2 with respect to the lower plane, and an end face of the edge 1a.

- the horizontal length of the upper slope 1au is referred to as “chamfer width X1”

- the horizontal length of the lower slope 1ad is referred to as “chamfer width X2”

- the length of the face width of the peripheral edge 1b is referred to as “chamfer width X3”.

- the conventional chamfering apparatus is provided with one processing section 40 having one processing table 41 on which the wafer 1 is placed and grindstones 42 and 43 for chamfering the wafer 1 (see FIGS. 16 and 17). ).

- the chamfering apparatus includes, in addition to the processing unit 40, two cassettes 12 for storing the wafer 1 before processing, the thickness of the wafer 1 before processing, and the center of the wafer 1 and the notch 1n.

- the wafer 1 taken out from the cassette 12 by the carry-in arm 48 on which the wafer 1 can be placed and conveyed is conveyed to the pre-setting unit 45, where the thickness is measured and the circumferential direction is roughly set.

- the wafer 1 is transferred to the upper part of the processing table 41 by the loading arm 48 and transferred from the loading arm 48 to the processing and conveying unit 44.

- the processing conveyance unit 44 supports the wafer 1 with two rollers and one positioning piece, and can move up and down.

- the center of the wafer 1 and the center of the processing table 41 coincide with each other, and the circumference of the wafer 1

- the direction position is accurately positioned and placed on the processing table 41.

- the processing unit 40 had a grindstone 42 for grinding the edge 1a of the circumferential portion of the wafer 1 and a grindstone 43 for grinding the notch 1n.

- the processing unit 40 may be provided with two types of coarse grinding and fine grinding for each of the edge grindstone 42 and the notch grindstone 43.

- the wafer 1 is adsorbed and fixed to the processing table 41 with a negative pressure or the like, rotates along with the processing table 41, and the edge 1 a is chamfered by pressing the rotating grindstone 42. Further, the grindstone 43 is pressed against the notch 1n of the wafer 1 while the processing table 41 is stationary, and chamfering is performed.

- the processed wafer 1 is sandwiched by a cleaning transfer unit 46 having four rollers, transferred from the processing table 41 to the cleaning unit 47, and cleaned by the cleaning unit 47.

- the wafer 1 is transferred from the cleaning unit 47 to the post-measurement unit 50 by the cleaning transfer unit 46.

- the wafer 1 whose shape and dimensions have been measured by the post-measurement unit 50 is placed on the carry-out arm 49, transferred to the cassette 13, and stored.

- the time for taking out the wafer 1 from the cassette 12, the time for setting the circumferential position of the wafer 1 before processing, and the time for chamfering the wafer 1 by the processing unit 40 were processed. Comparing the time for cleaning the wafer 1, the time for measuring the shape and dimension of the cleaned wafer 1, and the time for storing the processed wafer 1 in the cassette 13, the chamfering time is generally the longest. Therefore, the throughput (processing amount per unit time) of the wafer chamfering apparatus is affected by the length of the chamfering process.

- Patent Document 1 describes a wafer chamfering apparatus in which a plurality of processing units are provided to improve throughput. 16 and 17 are cited from FIGS. 1 and 2 of Patent Document 1.

- FIG. This chamfering apparatus has a plurality of processing units 40, and each processing unit 40 includes a processing table 41 and units of grindstones 42 and 43 having different processing characteristics (wafer processing locations, roughness, etc.).

- the processing / conveying unit 44 has a movable range in which the wafer 1 can be supplied from the pre-setting unit 45 to each processing unit 40.

- the cleaning / conveying unit 46 can also transport the wafer 1 from each processing unit 40 to the cleaning unit 47. It has a movable range.

- Other configurations are substantially the same as those of the conventional chamfering apparatus.

- the wafer 1 whose thickness is measured by the pre-setting unit 45 and whose circumferential position is roughly set is transferred to the processing unit 40 by the carry-in arm 48 and the processing transfer unit 44, and is chamfered.

- the next wafer 1 that has been measured and set by the previous setting unit 45 while the previous wafer 1 is chamfered by the processing unit 40 is transferred to another processing unit 40 by the carry-in arm 48 and the processing transfer unit 44. Carried in and chamfered.

- the wafers 1 are sequentially supplied to the plurality of processing units 40, and the wafers 1 are chamfered in parallel by the plurality of processing units 40, and the processed wafers 1 are sequentially processed. By transporting to the cleaning unit 47, the throughput could be increased.

- a disk-shaped resin bond grindstone or rubber that is rotated after rough grinding is performed on a single wafer with a grindstone with grooves that match the required cross-sectional shape of the wafer.

- a grindstone with grooves that match the required cross-sectional shape of the wafer.

- each processing unit 40 is provided with a set of a plurality of types of grindstones 42 and 43. It is necessary to provide a number of grindstones obtained by multiplying the number of types of grindstones 42 and 43 and a device for precisely moving the position of the grindstone, which increases the cost and size of the device. Further, since the entire chamfering apparatus has a plurality of grindstones having the same processing characteristics (for example, the grindstone 42), the quality of the wafer 1 varies when the degree of wear differs between the grindstones 42 having the same processing characteristics. In addition, it took time and effort to manage the plurality of grindstones 42.

- machining finish dimensions such as diameter and chamfering width are input so that chamfering accuracy does not vary with the grindstone 42 having the same machining characteristics of the other machining unit 40. It was necessary to adjust the setting of the control unit. Further, once the chamfering process is started, the spindle motor that rotates the grindstones 42 and 43 normally keeps operating even when the grindstones 42 and 43 are not processing the wafer 1. As a result, the amount of waste of electric power and cooling water has increased, leading to an increase in running cost.

- the present invention has been made in order to solve the above-described problems, and chamfering a wafer in parallel with a plurality of processing tables to improve throughput and reduce the total number of grindstones, thereby reducing the cost and size of the entire apparatus. It is an object of the present invention to provide a wafer chamfering apparatus which can be reduced and easily maintained. Another problem is that when chamfering a single wafer, most of the processing before chamfering, chamfering, and processing after chamfering can be performed on one processing table and its vicinity. An object of the present invention is to provide a wafer chamfering apparatus capable of reducing the overall cost and size.

- a wafer chamfering apparatus includes a plurality of processing tables for placing a wafer and a plurality of grindstones having different processing characteristics respectively corresponding to a plurality of types of processing steps for chamfering the peripheral edge of the wafer. And a grindstone moving means for moving the grindstones between the processing tables. The grindstones chamfer the wafer by approaching one processing table, and then sequentially move to the other processing tables. Then, the plurality of wafers are chamfered in parallel by the plurality of grindstones by repeating the processing.

- the position of the grindstone is precisely moved in the moving direction between the processing tables. It is characterized by that.

- a wafer chamfering apparatus detects a plurality of processing tables for placing a wafer, a grindstone for chamfering the peripheral end surface of the wafer, and a wafer shape or placement position before chamfering the wafer. Therefore, the pre-processing sensor has at least one pre-processing sensor for measuring different measurement objects and a pre-processing sensor moving means for moving the pre-processing sensor between the processing tables.

- the shape or placement position of the wafer is detected at a position held above the processing table or a position placed on each processing table. Examples of the measurement target of the pre-processing sensor include the diameter, thickness, center position, and notch position of the wafer.

- the pre-processing sensor moving means may be provided for each pre-processing sensor, and a unit for moving several pre-processing sensors by one pre-processing sensor moving means. You may form as.

- a wafer chamfering apparatus includes a plurality of processing tables for placing a wafer, a grindstone for chamfering the peripheral end surface of the wafer, and a shape of the wafer after chamfering the wafer.

- One or more post-processing sensors for measuring different measurement objects, and post-processing sensor moving means for moving the post-processing sensors between the processing tables, wherein the post-processing sensor is configured to transfer the wafer to each processing table.

- the shape of the wafer is measured at a position held above or a position placed on each processing table.

- the post-processing sensor moving means may be provided for each post-processing sensor, or several post-processing sensors are integrated into one post-processing sensor movement. You may form so that it may move by a means.

- a wafer chamfering apparatus includes a plurality of processing tables for placing a wafer, a grindstone for chamfering the peripheral end surface of the wafer, a wafer cleaning mechanism for cleaning the wafer after chamfering the wafer, A wafer drying mechanism for drying the wafer after cleaning, and a post-processing mechanism moving means for moving the wafer cleaning mechanism and the wafer drying mechanism between the processing tables.

- the wafer is washed or dried at a position where the wafer is held above each processing table or a position where the wafer is placed on each processing table.

- the wafer cleaning mechanism and the wafer drying mechanism may be provided with different post-processing mechanism moving means, and the wafer cleaning mechanism and the wafer drying mechanism are moved by one post-processing mechanism moving means. It may be formed as a unit.

- the wafer is held above the processing table and cleaned by the wafer cleaning mechanism, and at the same time the processing table is cleaned, and then the wafer is dried by the wafer drying mechanism and at the same time the processing table is dried. It is characterized by making it.

- any of the pre-processing sensor, the post-processing sensor, the wafer cleaning mechanism, or the wafer drying mechanism is provided between a cassette for storing the wafer before and after chamfering and each processing table. And provided on an arm for transporting the wafer.

- the eighth invention is characterized in that the plurality of processing tables are linearly arranged.

- the processing table is moved in a horizontal orthogonal direction with respect to any of the movement directions of the grindstone moving means, the pre-processing sensor moving means, the post-processing sensor moving means, or the post-processing mechanism moving means.

- a processing table approaching / separating means and a processing table rotating means for rotating the processing table are provided.

- a plurality of processing tables for placing a wafer for placing a wafer, a plurality of grindstones having different processing characteristics respectively corresponding to a plurality of types of processing steps for chamfering the peripheral edge of the wafer, And a grindstone moving means for moving the grindstone between the processing tables.

- the grindstones each approach the one processing table to chamfer the wafer, and then sequentially move to another processing table for processing. By repeating this, the plurality of wafers can be chamfered in parallel by the plurality of grindstones, thereby increasing the throughput of the chamfering apparatus.

- the number of grindstones in the entire chamfering device can be suppressed, the cost of the grindstone can be reduced and the management burden of the grindstone can be reduced. Further, in the chamfering apparatus, it is necessary to continue to rotate the grindstone even during play time when the wafer is not chamfered and to use cooling water for the spindle motor. In the chamfering apparatus according to the first invention, the number of grindstones is required. Since the time of play of each grindstone is reduced and waste of electric power and cooling water can be reduced.

- the position of the grindstone is precisely moved in the moving direction between the processing tables, so that 1

- One grindstone moving means can serve as both a large movement between processing tables and a precise movement at the time of chamfering a wafer, and the cost of the grindstone moving means in the chamfering apparatus can be reduced.

- one or more pre-processing sensors for measuring different measurement objects to detect the shape or placement position of the wafer before chamfering the wafer, and the pre-processing sensor between the processing tables.

- a pre-processing sensor moving means for moving the wafer at a position where the pre-processing sensor holds the wafer above each processing table or a position on each processing table.

- one or more post-processing sensors that measure different measurement objects to detect the shape of the wafer after chamfering the wafer, and post-processing that moves the post-processing sensor between the processing tables.

- a sensor moving means, and the post-processing sensor measures the shape of the wafer at a position where the wafer is held above each processing table or placed on each processing table. Since it is not necessary to provide an independent space for the measurement, the chamfering device can be saved, and the time required for moving the wafer can be omitted to improve the throughput.

- a wafer cleaning mechanism for cleaning the wafer after chamfering the wafer, a wafer drying mechanism for drying the wafer after cleaning, and the wafer cleaning mechanism and the wafer drying mechanism are moved between the processing tables.

- a post-processing mechanism moving means wherein the wafer cleaning mechanism or the wafer drying mechanism cleans or dries the wafer at a position where the wafer is held above each processing table or placed on each processing table.

- the wafer is held above the processing table and cleaned by the wafer cleaning mechanism, and at the same time the processing table is cleaned, and then the wafer is dried by the wafer drying mechanism and at the same time the processing table.

- the wafer drying mechanism By drying the substrate, it is not necessary to provide a special time for cleaning and drying the processing table, and sufficient cleaning and drying time can be secured and the throughput of the chamfering processing apparatus can be improved.

- any one of the pre-processing sensor, the post-processing sensor, the wafer cleaning mechanism, or the wafer drying mechanism is provided with a cassette for storing the wafer before and after chamfering, and each processing table.

- this arm also serves as a pre-processing sensor moving means, a post-processing sensor moving means, or a post-processing mechanism moving means, and reduces the cost of the entire chamfering apparatus. In addition, space can be saved.

- a chamfering device with little dead space can be obtained by arranging the plurality of processing tables in a straight line.

- the processing table is arranged in a direction perpendicular to the moving direction of any one of the grinding wheel moving means, the pre-processing sensor moving means, the post-processing sensor moving means, or the post-processing mechanism moving means.

- It is front explanatory drawing which shows the same chamfering apparatus.

- It is side explanatory drawing which shows the chamfering process using an edge rough grindstone.

- It is an isometric view enlarged view which shows the chamfering process using an edge fine grinding wheel.

- It is a front view which shows the grindstone support apparatus of an edge fine grinding grindstone.

- FIG. It is a perspective explanatory view showing a chamfering device of Patent Document 1.

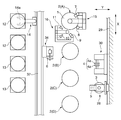

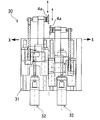

- this chamfering apparatus has a plurality of processing tables 2 on which a wafer 1 is placed, and has different processing characteristics (roughness, processing points of wafers, etc.) corresponding to a plurality of chamfering processes.

- a plurality of grindstones 3, 4, 5, 6 are provided, and each grindstone 3, 4, 5, 6 is movable between the processing tables 2.

- the sensors 7, 8 and 9, the cleaning mechanism 10, and the drying mechanism 11 that measure, clean, and dry the wafer 1 before and after the chamfering process are movable between the processing tables 2. . This will be described in detail below.

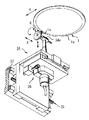

- this chamfering apparatus has two cassettes 12 and 12 for storing an unprocessed wafer 1 and four processing tables 2 (2A to 2D) for chamfering by placing the wafer 1 thereon. And two cassettes 13 and 13 for storing processed wafers 1. Further, the chamfering apparatus takes out the wafer 1 from the cassette 12 or stores it in the cassette 13 for transporting the wafer 1, and receives the wafer 1 from the cassette arm 14 and places it on each processing table 2. And a carry-out arm 16 for delivering the processed wafer 1 from the processing table 2 to the cassette arm 14.

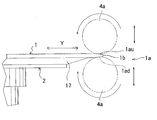

- this chamfering device includes a rough grinding wheel 3 for rough polishing of the edge 1a, a pair of disk grinding stones 4a, 4a for contouring processing (fine polishing) of the edge 1a, and a notch 1n.

- the four processing tables 2 are arranged in series on a substantially straight line.

- this arrangement direction is referred to as an X-axis direction.

- a stage 17 on which the wafer 1 is placed is provided on the processing table 2.

- This stage 17 has a smaller diameter than the wafer 1 and has a suction chuck for fixing the placed wafer 1 with a negative pressure.

- the processing table 2 is provided with a processing table rotating mechanism 18 using a motor, and the stage 17 is rotated during the chamfering processing of the wafer 1 so that the edge of the wafer 1 is rotated. 1a can be chamfered over the entire circumference.

- processing table 2 can be moved in a horizontal direction orthogonal to the X axis (hereinafter referred to as the Y axis direction) by a processing table approaching / separating mechanism 19 constituted by rails, ball screws, or the like. Chamfering can be performed by approaching and separating from each of the grinding wheels 3, 4, 5, 6.

- a cassette 12 for storing unprocessed wafers 1 and a cassette 13 for storing processed wafers 1 are also arranged along the X-axis direction.

- a cassette arm 14 is provided between the rows of the cassettes 12 and 13 and the row of the processing table 2.

- the cassette arm 14 has a substantially Y-shaped arm portion 14a for carrying the wafer 1 thereon.

- the cassette arm 14 is provided with a cassette arm X-axis moving mechanism 20 for moving in the X-axis direction, and a cassette arm Y for moving the arm portion 14a in the Y-axis direction.

- An axis moving mechanism 21, a cassette arm raising / lowering mechanism 22 that moves up and down, and a cassette arm turning mechanism 23 that turns horizontally are provided.

- the carry-in arm 15 is hung from the ceiling side in the vicinity of the processing table 2, and has an arm portion 15a protruding in the horizontal direction.

- An adsorption chuck 15b that adsorbs the wafer from above by pressure is provided, and the wafer 1 can be held.

- a direct drive motor 15c is provided immediately above the suction chuck 15b, and the held wafer 1 can be rotated in the circumferential direction to be measured and placed as described later.

- the carry-in arm 15 is provided with a carry-in arm moving mechanism 24 (FIG. 2) for moving in the X-axis direction and a carry-in arm raising / lowering mechanism (not shown) for raising and lowering the arm portion 15a.

- the unprocessed wafer 1 can be transferred to the processing table 2.

- an alignment sensor 7 that measures the diameter (D in FIG. 13) or the radius (same R), the center, and the position of the notch 1n of the wafer 1 in a pair of upper and lower sides at approximately the same height as the arm portion 15a. (The alignment sensor 7 is omitted in FIG. 2). As shown in FIG. 3, since the alignment sensor 7 is pivotably attached to the loading arm 15, when the wafer 1 is sucked or removed from the suction chuck 15 b, the alignment sensor 7 can be released so as not to come in contact with it. The wafer 1 can be measured by turning the alignment sensor 7 up and down the wafer 1 while the loading arm 15 holds the wafer 1.

- an alignment sensor elevating mechanism (not shown) for elevating the alignment sensor 7 with respect to the loading arm 15 is provided, and the height of the alignment sensor 7 can be adjusted when measuring the wafer 1.

- the carry-in arm 15 rotates the wafer 1 based on the circumferential placement angle of the wafer 1 set from the measurement result of the alignment sensor 7 and places it on the processing table 2 at a desired placement angle. At this time, the center of the wafer 1 coincides with the center of the stage 17 of the processing table 2.

- the carry-in arm 15 is provided with a pair of upper and lower thickness sensors 8 below the arm portion 15a. After the wafer 1 is placed on the processing table 2, the heights of the upper and lower surfaces of the wafer 1 are measured. The thickness of the wafer 1 is detected from the difference. Note that the thickness sensor 8 may be configured to measure the thickness of the wafer 1 while the carry-in arm 15 holds the wafer 1.

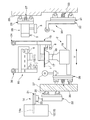

- the edge roughing grindstone 3 is a horizontal general-purpose grindstone in which grooves corresponding to the required cross-sectional shape of the wafer 1 are formed on the peripheral end surface.

- the processing table 2 is moved in the Y-axis direction by the processing table approaching / separating mechanism 19 while rotating at different rotational speeds in the opposite directions, and the edge 1a of the wafer 1 is pressed against the grindstone groove to roughen the edge 1a. I do.

- the notch roughing grindstone 5 is a general grindstone in which grooves corresponding to the required cross-sectional shape of the wafer 1 are formed on the peripheral end surface in the same manner as the edge roughing grindstone 3.

- the edge roughening grindstone 3 and the notch roughening grindstone 5 are attached to one grindstone support device 26 to chamfer the wafer 1.

- the grindstone support device 26 is attached to the upper part of the side wall 29 of the chamfering device, and has a rough grindstone moving mechanism 27 for moving in the X-axis direction and a rough grindstone lifting mechanism 28 for moving up and down.

- the rough grinding wheel moving mechanism 27 can be configured by using a ball screw including a screw shaft in the X-axis direction attached to the side wall 29 and a nut attached to the grinding wheel support device 26 as a driving force. it can.

- the rough grinding stone lifting mechanism 28 can also be configured using a ball screw.

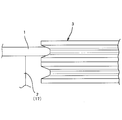

- the edge fine grinding wheel 4 is composed of a pair of vertical disk-shaped grinding wheels 4 a and 4 a that face each other in the vicinity, and rotate horizontally by rotating each of them vertically and in opposite directions.

- the chamfering process of the edge 1a is performed by pressing against the wafer 1 to be performed. Therefore, as shown in FIGS. 2, 7, and 8, the edge polishing wheel 4 is supported by the wheel support device 30, and each of the wheels 4a and 4a is attached to the wheel support device 30 via a spindle motor that rotates the wheel. It is attached.

- the edge precise grinding stone raising / lowering mechanisms 32 and 32 which raise / lower each grindstone 4a, 4a separately are provided, and each grindstone 4a, 4a is the same.

- the edge 1a of the wafer 1 can be chamfered while maintaining the height (FIG. 6).

- the upper and lower slopes 1au and 1au are arranged so that the wafers 1 are sandwiched from above and below by varying the heights of the grindstones 4a and 4a. It is possible to chamfer 1ad (FIG. 9). As shown in FIG.

- the grindstone support device 30 for attaching the edge fine grinding stone 4 is assembled to the lower portion of the side wall 29 of the chamfering device, and has an edge fine grinding stone moving mechanism 33 for moving in the X-axis direction.

- the edge precision grinding wheel moving mechanism 33 is configured by using a ball screw including a screw shaft in the X-axis direction attached to the side wall 29 and a nut attached to the grinding wheel support device 30 as a driving force. Can do.

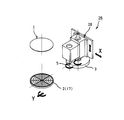

- the notch fine grinding wheel 6 is a thin disc-shaped grinding wheel formed of rubber containing an abrasive, and is installed vertically and is moved vertically close to the processing table while being rotated in the vertical direction. Using the movement of the machining table 2 in the Y-axis direction by the mechanism 19 and the movement of the notch fine grinding wheel 6 in the X-axis direction by a notch fine grinding wheel moving mechanism 35 described later, precise grinding is performed along the shape of the notch 1n. Do. As shown in FIG. 10, the notch fine grinding wheel 6 is supported by a grinding wheel support device 34, and is attached so as to rotate in the vertical direction by converting the rotation of a spindle motor that rotates the grinding wheel at a tip end portion 34a.

- the grindstone support device 34 for attaching the notch fine grinding wheel 6 is attached to the lower portion of the middle wall 37 of the chamfering device installed between the processing table 2 and the cassettes 12 and 13.

- a notch fine grinding wheel moving mechanism 35 for moving in the X-axis direction and a notch fine grinding wheel lifting mechanism 36 for lifting and lowering is attached to the notch fine grinding wheel moving mechanism 35 .

- the notch fine grinding wheel moving mechanism 35 uses a ball screw including a screw shaft in the X-axis direction attached to the inner wall 37 and a nut attached to the grinding wheel support device 34 as a driving force. be able to.

- the notch precision grinding stone lifting mechanism 36 can also be configured using a ball screw.

- the carry-out arm 16 is hung from the ceiling side on the side wall 29 side in the vicinity of the processing table 2, and has an arm portion 16 a protruding in the horizontal direction.

- a direct drive motor 16c is provided immediately above the suction chuck 16b, and the held wafer 1 can be rotated in the circumferential direction to be cleaned, dried and measured as described later.

- the carry-out arm 16 includes a carry-out arm moving mechanism 38 for moving in the X-axis direction, a carry-out arm raising / lowering mechanism (not shown) for raising and lowering the arm portion 16a, and a carry-out arm turning mechanism (not shown) for turning the arm portion 16a. ) Is provided, and the processed wafer 1 can be transferred from each processing table 2 to the cassette arm 14.

- the carry-out arm 16 includes a cleaning mechanism 10 including three upper and lower water nozzles 10a, 10b, and 10c that discharges cleaning liquid, and three upper and lower air nozzles 11a, 11b, and 11c that discharge drying air.

- a drying mechanism 11 comprising: When the wafer 1 is held by the arm portion 16a of the carry-out arm 16, the upper water nozzle 10a and the air nozzle 11a are installed so as to be inclined downward and above the wafer 1, and the upper surface of the wafer 1 is cleaned and dried. The water nozzle 10b and the air nozzle 11b in the middle stage are installed so as to be inclined upward and below the wafer 1, and the lower surface of the wafer 1 is cleaned and dried.

- the lower water nozzle 10c and the air nozzle 11c are installed so as to be inclined downward, and the stage 17 of the processing table 2 is washed and dried.

- the cleaning mechanism 10 and the drying mechanism 11 are arranged so that the stage 1 of the processing table 2 can be cleaned and dried while holding the wafer 1 above the processing table 2 and cleaning and drying the wafer 1.

- the wafer 1 may be cleaned and dried while the wafer 1 is placed on the processing table 2.

- the unloading arm 16 is provided with a post-process sensor 9 which is composed of a pair of upper and lower members and measures the radius of the wafer 1 and the shape of the notch 1n. After processing, the sensor 9 irradiates the laser from the upper member, and the laser received by the lower member is blocked by the wafer 1, thereby measuring the shapes of the peripheral end surface 1b and the notch 1n of the wafer 1, The radius of the wafer 1 is detected from the distance from the center. Since the post-processing sensor 9 is pivotally attached to the carry-out arm 16, in order to measure the shape of the wafer 1, first, the post-process sensor 9 is placed directly above the wafer 1 with the carry-out arm 16 holding the wafer 1. Escape from.

- the height of the arm portion 16a is raised to the height of the post-processing sensor 9, and the post-processing sensor 9 is swung and placed on the top and bottom of the wafer 1, whereby the shape of the wafer 1 can be measured.

- the post-processing sensor 9 is provided above the cleaning mechanism 10 or the drying mechanism 11 so as not to become dirty when the wafer 1 is cleaned or dried.

- the post-processing sensor 9 may be configured to measure the shape of the wafer 1 while the wafer 1 is placed on the processing table 2. If necessary, a camera may be mounted on the post-processing sensor 9 so that the chamfered widths X1, X2, and X3 of the edge 1a and the presence or absence of chipping (chips) can be measured.

- the chamfering process of the wafer 1 and the control of each part in this chamfering apparatus will be described.

- the first process, the second process, the third process, and the fourth process are sequentially repeated for one processing table 2 to efficiently chamfer the wafer 1 with the four processing tables 2. Can do.

- the unloading arm 16 adsorbs the processed wafer 1 and rotates it over the processing table 2, washing and drying the wafer 1 and the processing table 2, and processing.

- the rear sensor 9 measures the shape of the wafer 1 (see FIG. 11), delivers the wafer 1 from the carry-out arm 16 to the cassette arm 14, and stores it in the cassette 13 (see FIG. 2).

- the unprocessed wafer 1 is taken out from the cassette 12 by the cassette arm 14, and the carry-in arm 15 receives this (see FIG. 2) and places it on the processing table 2 at the correct placement position based on the measurement of the alignment sensor 7.

- the thickness of the wafer 1 is measured by the thickness sensor 8 (see FIG. 3).

- the grindstone moving mechanism 27 moves the grindstone support device 26 to the position of the machining table 2 in the X-axis direction, and the machining table approaching / separating mechanism 19 brings the machining table 2 close to the grindstone support device 26 so that the edge The edge 1a of the wafer 1 is chamfered with the rough grindstone 3, and then the notch 1n is chamfered with the notch rough grindstone 5 (see FIG. 5).

- the rough grindstone moving mechanism 27 can accurately move the edge.

- the edge precision grinding wheel moving mechanism 33 moves the grinding wheel support device 30 to the position of the processing table 2 in the X-axis direction, the processing table approaching / separating mechanism 19 brings the processing table 2 close to the grinding wheel support device 30,

- the edge 1a of the wafer 1 is chamfered with the edge polishing grindstone 4 (see FIGS. 6 and 7).

- the edge fine grinding stone moving mechanism 33 can precisely move the edge fine grinding stone 4.

- the notch precision grinding wheel moving mechanism 35 moves the grindstone support device 34 to the position of the processing table 2 in the X-axis direction, the processing table approaching / separating mechanism 19 brings the processing table 2 close to the grindstone support device 34,

- the notch 1n of the wafer 1 is chamfered with the notch fine grinding wheel 6 (see FIG. 10).

- the notch fine grinding stone moving mechanism 35 can precisely move the wafer.

- the construction times of the first process, the second process, the third process, and the fourth process are all about 80 to 120 seconds, and variations in the construction time are reduced.

- FIG. 12 is a timing chart for chamfering the wafer 1 with the chamfering apparatus.

- the vertical direction represents each processing table 2, and the horizontal direction represents elapsed time.

- the four processing tables 2 are distinguished as processing tables 2A, 2B, 2C, and 2D.

- the second step is then performed on the processing table 2A, and at the same time, the latter half of the first step is performed on the processing table 2B (t2).

- the third process is performed on the machining table 2A.

- the second process is performed on the machining table 2B.

- the latter half of the first process is performed on the machining table 2C. Is performed (t3).

- the fourth process is performed at the machining table 2A

- the third process is performed at the machining table 2B

- the second process is performed at the machining table 2C.

- the second half of the first step is performed on the processing table 2D (t4).

- each processing table 2 different processes depending on the grindstone and the like are performed in parallel.

- Each grindstone 3, 4, 5, 6, carry-in arm 15 and carry-out arm 16 approaches one processing table 2 to process or process the wafer 1, and then sequentially moves to another processing table 2 to process or process the wafer 1. Processing will be repeated.

- the grindstone support device 26 and the grindstone support device 30, and the carry-in arm 15 and the carry-out arm 16 may pass each other. , So that they can pass each other without contact (FIG. 2).

- a plurality of grindstones 3, 4, 5, 6, sensors 7, 8, 9 and cleaning mechanisms respectively corresponding to a plurality of types of processing steps (first to fourth steps) in chamfering the wafer 1 are provided.

- 10 and the drying mechanism 11 are each provided with a moving mechanism for moving between the processing tables 2, so that different processing steps can be performed simultaneously on the plurality of processing tables 2, and the throughput of the chamfering device is increased. Can do. Further, since the number of grindstones, sensors, cleaning mechanisms, and drying mechanisms in the entire chamfering device can be suppressed, the cost of the chamfering device can be reduced and the management burden of the grindstone can be reduced.

- each of the grinding stones 3, 4, 5, 6 is placed between the machining tables 2 (X axis).

- the grindstones 3, 4, 5, and 6 can be moved precisely in the X-axis direction during chamfering, thereby reducing the cost of the precision chamfering machine in the entire chamfering device. Can do.

- the sensors 7, 8 and 9, the cleaning mechanism 10 and the drying mechanism 11 perform measurement, cleaning and drying at a position where the wafer 1 is held above each processing table 2 or placed on each processing table 2.

- all processes associated with the chamfering process of the wafer 1 can be performed in the vicinity of one processing table 2, and it is not necessary to provide an independent space for measurement, cleaning and drying, thus saving the chamfering device.

- the time of the first process associated with the chamfering process can be shortened and the throughput can be improved.

- the unloading arm 16 holds the wafer 1 above the processing table 2, cleans the wafer 1 simultaneously with the cleaning mechanism 10, and simultaneously cleans the processing table 2, and then dries the wafer 1 with the drying mechanism 11 and simultaneously processes the processing table 2.

- the time required for the first step can be further shortened, and the throughput of the chamfering apparatus can be improved.

- an alignment sensor 7 and a thickness sensor 8 are provided on the loading arm 15 for transporting the unprocessed wafer 1 from the cassette 12 to each processing table 2, and the processed wafer 1 is transported from each processing table 2 to the cassette 13. Since the post-processing sensor 9, the cleaning mechanism 10 and the drying mechanism 11 are provided on the carry-out arm 16, it is necessary to provide a separate machine for moving the sensors 7, 8, 9, the cleaning mechanism 10 and the drying mechanism 11 in the X-axis direction Therefore, the cost of the entire chamfering device can be reduced and the space can be saved.

- the dead space is small (compared to a case where the processing tables 2 are arranged in an annular shape), and the chamfering device can be saved.

- the machining table 2 by providing the machining table 2 with the machining table approaching / separating mechanism 19 and the machining table rotating mechanism 18, the machining table 2 is moved closer to and away from the grindstones 3, 4, 5, 6 as required.

- the processing table 2 can be rotated to chamfer the entire circumference of the edge 1a of the wafer 1 and the notch 1n.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Inorganic Chemistry (AREA)

- Ceramic Engineering (AREA)

- Physics & Mathematics (AREA)

- Chemical & Material Sciences (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Grinding And Polishing Of Tertiary Curved Surfaces And Surfaces With Complex Shapes (AREA)

- Mechanical Treatment Of Semiconductor (AREA)

- Constituent Portions Of Griding Lathes, Driving, Sensing And Control (AREA)

Abstract

Description

この場合、上斜面1auの水平長さを「面取り幅X1」と呼び、下斜面1adの水平長さを「面取り幅X2」と呼ぶ。

また、図15に示すように、ウェーハ1のエッジ1aを、上平面に対して角度α2だけ傾斜した上斜面1auと、下平面に対して角度α2だけ傾斜した下斜面1adと、エッジ1aの端面を形成する垂直な周端面1bと、同じ半径R2を有する2つの円弧であって上斜面1auと周端面1bとの間および下斜面1adと周端面1bとの間を滑らかに接続する円弧1c、1cとからなる断面形状(ほぼ台形形状)に加工する場合がある。

この場合も、上斜面1auの水平長さを「面取り幅X1」、下斜面1adの水平長さを「面取り幅X2」、周端1bの面幅の長さを「面取り幅X3」とそれぞれ呼ぶ。

また、この面取り装置には、この加工部40のほかに、加工前のウェーハ1を格納する2つのカセット12と、加工前にウェーハ1の厚さを測定するとともにウェーハ1の中心とノッチ1nの方向(ウェーハの円周方向)とを設定する前設定部45と、加工したウェーハ1を洗浄する洗浄部47と、加工したウェーハの形状寸法を測定する後測定部50と、加工の完了したウェーハ1を格納するカセット13とが設けられていた。

また、加工テーブル41を静止させた状態でウェーハ1のノッチ1nに砥石43が押し当てられ、面取り加工される。

よって、ウェーハの面取り装置のスループット(単位時間あたりの処理量)は、面取り加工の時間の長さに影響されていた。

この面取り装置は複数の加工部40を有し、各加工部40に、加工テーブル41と、加工特性(ウェーハの加工箇所や粗さ等)の異なる砥石42、43のユニットとをそれぞれ備えている。

また、加工搬送部44は前設定部45から各加工部40にウェーハ1を供給できる可動範囲を有し、同様に洗浄搬送部46も、各加工部40から洗浄部47にウェーハ1を搬送できる可動範囲を有している。

その他の構成においては、前記従来の面取り装置と概ね同様である。

このように、特許文献1の面取り装置では、複数の加工部40に順次ウェーハ1を供給し、複数の加工部40で同時並行してウェーハ1を面取り加工し、加工の完了したウェーハ1を順次洗浄部47へ搬送することによって、スループットを大きくすることができた。

また、面取り装置全体で同一加工特性の砥石(たとえば砥石42)を複数有していたため、同一加工特性の砥石42の間で摩耗度合いに差が出た場合にはウェーハ1の品質にばらつきを生じることとなり、加えて、複数の砥石42を管理する手間がかかっていた。たとえば、一つの砥石42を交換する場合には、他の加工部40の同一加工特性の砥石42との間で面取り精度にばらつきが出ないように、直径や面取り幅等の加工仕上げ寸法を入力する制御部の設定を調整する必要があった。

さらに、砥石42、43を回転させるスピンドルモータは、一旦面取り加工を開始すると、通常、砥石42、43がウェーハ1を加工していない間も稼動させ続けておくため、加工部40を増やした分だけ電力と冷却水を浪費する量が増大し、ランニングコストの増加を招いていた。

また、他の課題は、一枚のウェーハを面取り加工する際に、面取り加工前の処理、面取り加工、面取り加工後の処理のほとんどを一つの加工テーブルおよびその近傍で行うことができて、装置全体のコストやサイズを低減させることのできるウェーハの面取り装置を提供することにある。

第1の発明に係るウェーハの面取り装置は、ウェーハを戴置する複数の加工テーブルと、上記ウェーハの周縁部を面取りするための複数種類の加工工程にそれぞれ対応した異なる加工特性を有する複数の砥石と、上記各砥石をそれぞれ上記加工テーブル間で移動させる砥石移動手段とを有し、上記各砥石が、それぞれ一つの加工テーブルに接近してウェーハを面取り加工し、次いで他の加工テーブルに順次移動して加工することを繰り返すことにより、複数の上記ウェーハを上記複数の砥石が同時並行して面取りすることを特徴とする。

加工前センサーの測定対象としては、例えば、ウェーハの直径、厚み、中心位置、ノッチ位置などをあげることができる。

面取り装置が上記加工前センサーを複数有する場合には、各加工前センサーごとに上記加工前センサー移動手段を設けてもよく、いくつかの加工前センサーを1つの加工前センサー移動手段によって移動するユニットとして形成してもよい。

面取り装置が上記加工後センサーを複数有する場合には、各加工後センサーごとに上記加工後センサー移動手段を設けてもよく、また、いくつかの加工後センサーを一体化して1つの加工後センサー移動手段によって移動するように形成してもよい。

このような面取り装置では、ウェーハ洗浄機構とウェーハ乾燥機構とに各別の後処理機構移動手段を設けてもよく、また、ウェーハ洗浄機構およびウェーハ乾燥機構が1つの後処理機構移動手段によって移動するユニットとして形成してもよい。

また、面取り装置では、ウェーハを面取り加工していない遊びの時間にも砥石を回転させ続け、スピンドルモータに冷却水を使用する必要があるが、第1の発明にかかる面取り装置では、砥石の数が抑えられるとともに各砥石の遊びの時間が少なくなるため、電力および冷却水の浪費を低減させることができる。

図1に示すように、この面取り装置は、ウェーハ1を戴置する複数の加工テーブル2を有し、また、複数の面取り工程にそれぞれ対応した異なる加工特性(粗さやウェーハの加工箇所など)を有する複数の砥石3、4、5、6を有するものであって、各砥石3、4、5、6が加工テーブル2の間で移動可能であることを特徴とする。

また同様に、面取り加工の前後にウェーハ1の測定、洗浄および乾燥を行うセンサー7、8、9、洗浄機構10、乾燥機構11が、加工テーブル2の間で移動可能であることを特徴とする。

以下で詳述する。

また、面取り装置には、ウェーハ1を搬送するために、ウェーハ1をカセット12から取り出しあるいはカセット13に格納するカセットアーム14と、このカセットアーム14からウェーハ1を受け取って各加工テーブル2に戴置する搬入アーム15と、加工されたウェーハ1を加工テーブル2からカセットアーム14に受け渡す搬出アーム16とが設けられている。

ウェーハ1の面取り加工のために、この面取り装置は、エッジ1aの粗研用の総形砥石3と、エッジ1aのコンタリング加工(精研)用の一対の円盤砥石4a、4aと、ノッチ1nの粗研用の総形砥石5と、ノッチ1nの精研用の砥石6とを有している。

図2に示すように、加工テーブル2の上部には、ウェーハ1が戴置されるステージ17が設けられている。このステージ17はウェーハ1よりも小径に形成され、戴置されたウェーハ1を負圧によって固定する吸着チャックを有している。

また、図2、図7に示すように、加工テーブル2には、モータを用いた加工テーブル回転機構18が設けられ、ウェーハ1の面取り加工の際にステージ17を回転させて、ウェーハ1のエッジ1aを全周に亘って面取り加工できるようになっている。さらに、加工テーブル2は、レールまたはボールねじ等で構成される加工テーブル接近離間機構19によって、X軸と直交する水平な方向(以下、Y軸方向という)に移動が可能であり、ウェーハ1を上記各砥石3、4、5、6と接近離間させて面取り加工することができる。

カセット12、13の列と加工テーブル2の列の間には、カセットアーム14が設けられている。このカセットアーム14は、ウェーハ1を乗せて搬送する略Y字状のアーム部14aを有している。さらに、カセットアーム14には、図2に示すように、X軸方向に移動するためのカセットアームX軸移動機構20が設けられるとともに、アーム部14aをY軸方向に移動するためのカセットアームY軸移動機構21、昇降させるカセットアーム昇降機構22および水平に旋回させるカセットアーム旋回機構23が設けられている。

搬入アーム15には、X軸方向に移動するための搬入アーム移動機構24(図2)およびアーム部15aを昇降させる搬入アーム昇降機構(図示せず)が設けられており、カセットアーム14から各加工テーブル2への未加工のウェーハ1の受け渡しを行うことができる。

図3に示すように、アラインメントセンサー7は搬入アーム15に対し旋回可能に取り付けられるため、ウェーハ1を吸着チャック15bと吸着または取り外しする際にはアラインメントセンサー7が接触しないように逃がすことができ、搬入アーム15がウェーハ1を保持した状態でアラインメントセンサー7をウェーハ1の上下に旋回させてウェーハ1を測定できる。また、搬入アーム15に対してアラインメントセンサー7を昇降させるアラインメントセンサー昇降機構(図示せず)が設けられ、ウェーハ1の測定に際してアラインメントセンサー7の高さを調整することができる。

搬入アーム15は、アラインメントセンサー7の測定結果から設定したウェーハ1の円周方向の戴置角度に基づいて、ウェーハ1を回転させて所望の戴置角度で加工テーブル2に戴置する。このとき、ウェーハ1の中心と加工テーブル2のステージ17の中心が一致するようにする。

なお、厚さセンサー8は、搬入アーム15がウェーハ1を保持した状態でウェーハ1の厚さを測定するように構成してもよい。

ノッチ粗研砥石5は、図5に示すように、エッジ粗研砥石3と同様にウェーハ1の要求される断面形状と一致する溝を周端面に刻設してある総形砥石であって、エッジ粗研砥石3と同じ向きに回転させたまま、加工テーブル接近離間機構19による加工テーブル2のY軸方向移動と、後述の粗研砥石移動機構27によるノッチ粗研砥石のX軸方向移動とを用いて、ノッチ1nの形状に沿わせて粗研を行う。

図2、図5に示すように、エッジ粗研砥石3およびノッチ粗研砥石5は、一つの砥石支持装置26に取り付けられて、ウェーハ1を面取り加工する。また、砥石支持装置26は面取り装置の側壁29上部に取り付けられ、X軸方向に移動するための粗研砥石移動機構27および昇降するための粗研砥石昇降機構28を有している。一例として、粗研砥石移動機構27は、側壁29に取り付けられるX軸方向のねじ軸と砥石支持装置26に取り付けられるナットとからなるボールねじを用いて、サーボモータを駆動力として構成することができる。同様に、粗研砥石昇降機構28も、ボールねじを用いて構成することができる。

このため、図2、図7、図8に示すように、エッジ精研砥石4は砥石支持装置30に支持され、各砥石4a、4aは砥石を回転させるスピンドルモータを介して砥石支持装置30に取り付けられている。また、砥石支持装置30全体を昇降させる支持装置昇降機構31を設けるとともに、各砥石4a、4aを各別に昇降させるエッジ精研砥石昇降機構32、32を設けており、各砥石4a、4aを同じ高さに維持してウェーハ1のエッジ1aを面取り加工する(図6)こともできるが、各砥石4a、4aの高さを異ならせて、ウェーハ1を上下から挟むようにして上斜面1auおよび下斜面1adの面取り加工をすることもできる(図9)。

また、図2に示すように、エッジ精研砥石4を取り付ける砥石支持装置30は面取り装置の側壁29下部に組み付けられ、X軸方向に移動するためのエッジ精研砥石移動機構33を有している。一例として、エッジ精研砥石移動機構33は、側壁29に取り付けられるX軸方向のねじ軸と砥石支持装置30に取り付けられるナットとからなるボールねじを用いて、サーボモータを駆動力として構成することができる。

図10に示すように、ノッチ精研砥石6は砥石支持装置34に支持され、砥石を回転させるスピンドルモータの回転を先端部34aで変換することで、垂直方向に回転するように取り付けられている。

また、図2、図10に示すように、ノッチ精研砥石6を取り付ける砥石支持装置34は、加工テーブル2とカセット12、13との間に設置される面取り装置の中壁37下部に取り付けられ、X軸方向に移動するためのノッチ精研砥石移動機構35および昇降するためのノッチ精研砥石昇降機構36を有している。一例として、ノッチ精研砥石移動機構35は、中壁37に取り付けられるX軸方向のねじ軸と砥石支持装置34に取り付けられるナットとからなるボールねじを用いて、サーボモータを駆動力として構成することができる。同様に、ノッチ精研砥石昇降機構36も、ボールねじを用いて構成することができる。

搬出アーム16には、X軸方向に移動するための搬出アーム移動機構38、アーム部16aを昇降させる搬出アーム昇降機構(図示せず)およびアーム部16aを旋回させる搬出アーム旋回機構(図示せず)が設けられており、各加工テーブル2からカセットアーム14への加工済みのウェーハ1の受け渡しを行うことができる。

本実施例では、ウェーハ1を加工テーブル2の上方に保持して、ウェーハ1の洗浄および乾燥を行いながら、加工テーブル2のステージ17の洗浄および乾燥を行えるように洗浄機構10と乾燥機構11とを構成したが、ウェーハ1を加工テーブル2に戴置した状態でウェーハ1の洗浄および乾燥を行うように構成してもよい。

加工後センサー9は搬出アーム16に対し旋回可能に取り付けられるため、ウェーハ1の形状を測定するには、まず、搬出アーム16がウェーハ1を保持した状態で加工後センサー9をウェーハ1の真上から逃がす。次いで、アーム部16aの高さを加工後センサー9の高さに上昇させ、加工後センサー9を旋回させてウェーハ1の上下に配置し、ウェーハ1の形状を測定できる。また、加工後センサー9は、洗浄機構10または乾燥機構11の上方に設けてあり、ウェーハ1の洗浄または乾燥の際に汚れないようになっている。このほかに、ウェーハ1を加工テーブル2に戴置した状態で、加工後センサー9がウェーハ1の形状を測定するように構成してもよい。

また、必要に応じて、加工後センサー9にカメラを搭載し、エッジ1aの面取り幅X1、X2、X3やチッピング(欠け)の有無を測定できるようにしてもよい。

この面取り装置では、1台の加工テーブル2につき第一工程、第二工程、第三工程、第四工程を順に繰り返すことにより、4台の加工テーブル2で効率的にウェーハ1を面取り加工することができる。

面取り加工において、ウェーハ1に対するエッジ粗研砥石3またはノッチ粗研砥石5の位置をX軸方向に移動させながら精密加工するときには、粗研砥石移動機構27によって精密に移動させることができる。

面取り加工において、ウェーハ1に対するエッジ精研砥石4の位置をX軸方向に移動させながら精密加工するときには、エッジ精研砥石移動機構33によって精密に移動させることができる。

面取り加工において、ウェーハ1に対するノッチ精研砥石6の位置をX軸方向に移動させながら精密加工するときには、ノッチ精研砥石移動機構35によって精密に移動させることができる。

この面取り装置においては、第一工程、第二工程、第三工程、第四工程の施工時間がいずれも80~120秒程となり、施工時間のばらつきが少なくなる。

以下では、4台の加工テーブル2を、加工テーブル2A、2B、2C、2Dとして区別する。

この面取り装置で、全ての加工テーブル2でウェーハ1が戴置されていない状態から面取り加工を開始すると、まず、加工テーブル2Aにおいて、第一工程の後半工程、すなわちカセット12のウェーハ1を取り出してから加工テーブル2A上で厚さを測定するまでの工程が行われる(t1)。

加工テーブル2A、2Bの動作がともに完了すると、次に、加工テーブル2Aで第三工程が行われると同時に、加工テーブル2Bで第二工程が行われ、加工テーブル2Cで第一工程の後半工程が行われる(t3)。

全ての加工テーブル2A~2Dで動作が完了すると、次に、加工テーブル2Aでは第一工程の全工程が行われて、ウェーハ1の面取り加工に伴う全工程を終了し、新たなウェーハ1の面取り加工を開始する。同時に、加工テーブル2Bで第四工程が行われ、加工テーブル2Cで第三工程が行われ、加工テーブル2Dで第二工程が行われる(t5)。

各砥石3、4、5、6、搬入アーム15および搬出アーム16は、それぞれ一つの加工テーブル2に接近してウェーハ1を加工または処理し、次いで他の加工テーブル2に順次移動して加工または処理することを繰り返すことになる。その加工テーブル2間の移動においては、砥石支持装置26と砥石支持装置30、ならびに搬入アーム15と搬出アーム16とがすれ違うことがあるが、その際にはそれぞれの昇降機構によって高さを異ならせ、これらが接触することなくすれ違えるようにする(図2)。

また、各加工テーブル2に、加工テーブル接近離間機構19と加工テーブル回転機構18とを設けたことにより、必要に応じて加工テーブル2を砥石3、4、5、6に接近離間させ、要求される断面形状に面取り加工するとともに、加工テーブル2を回転させて、ウェーハ1のエッジ1aの全周およびノッチ1nを面取りすることができる。

1a エッジ

1b 周端面

1n ノッチ

2 加工テーブル

3 (エッジ粗研)砥石

4 (エッジ精研)砥石

4a (円盤)砥石

5 (ノッチ粗研)砥石

6 (ノッチ精研)砥石

7 (アラインメント)センサー

8 (厚さ)センサー

9 (加工後)センサー

10 洗浄機構

10a~c 水ノズル

11 乾燥機構

11a~c エアーノズル

12 カセット

13 カセット

14 カセットアーム

14a アーム部

15 搬入アーム

15a アーム部

15b 吸着チャック

15c ダイレクトドライブモータ

16 搬出アーム

16a アーム部

16b 吸着チャック

16c ダイレクトドライブモータ

17 ステージ

18 加工テーブル回転機構

19 加工テーブル接近離間機構

20 カセットアームX軸移動機構

21 カセットアームY軸移動機構

22 カセットアーム昇降機構

23 カセットアーム旋回機構

24 搬入アーム移動機構

26 砥石支持装置

27 粗研砥石移動機構

28 粗研砥石昇降機構

30 砥石支持装置

31 支持装置昇降機構

32 エッジ精研砥石昇降機構

33 エッジ精研砥石移動機構

34 砥石支持装置

35 ノッチ精研砥石移動機構

36 ノッチ精研砥石昇降機構

38 搬出アーム移動機構

40 加工部

41 加工テーブル

42 砥石

43 砥石

45 前設定部

47 洗浄部

X、Y 水平方向

Claims (9)

- ウェーハを戴置する複数の加工テーブルと、

上記ウェーハの周縁部を面取りするための複数種類の加工工程にそれぞれ対応した異なる加工特性を有する複数の砥石と、

上記各砥石をそれぞれ上記加工テーブル間で移動させる砥石移動手段とを有し、

上記各砥石が、それぞれ一つの加工テーブルに接近してウェーハを面取り加工し、次いで他の加工テーブルに順次移動して加工することを繰り返すことにより、

複数の上記ウェーハを上記複数の砥石が同時並行して面取りすることを特徴とするウェーハの面取り装置。 - 上記砥石移動手段が、上記加工テーブルに戴置された上記ウェーハを面取りする際に、上記加工テーブル間の移動方向に上記砥石の位置を精密移動させることを特徴とする請求項1記載のウェーハの面取り装置。

- ウェーハを戴置する複数の加工テーブルと、

上記ウェーハの周端面を面取りする砥石と、

上記ウェーハの面取り前にウェーハの形状または戴置位置を検出するためにそれぞれ異なる測定対象を測定する1以上の加工前センサーと、

上記加工前センサーを上記加工テーブル間で移動させる加工前センサー移動手段とを有して、

上記加工前センサーが、上記ウェーハを各加工テーブルの上方に保持した位置または各加工テーブルに戴置した位置で上記ウェーハの形状または戴置位置を検出することを特徴とするウェーハの面取り装置。 - ウェーハを戴置する複数の加工テーブルと、

上記ウェーハの周端面を面取りするための砥石と、

上記ウェーハの面取り後にウェーハの形状を検出するためにそれぞれ異なる測定対象を測定する1以上の加工後センサーと、

上記加工後センサーを上記加工テーブル間で移動させる加工後センサー移動手段とを有して、

上記加工後センサーが、上記ウェーハを各加工テーブルの上方に保持した位置または各加工テーブルに戴置した位置で上記ウェーハの形状を測定することを特徴とするウェーハの面取り装置。 - ウェーハを戴置する複数の加工テーブルと、

上記ウェーハの周端面を面取りするための砥石と、

上記ウェーハの面取り後にウェーハを洗浄するウェーハ洗浄機構と、

洗浄後に上記ウェーハを乾燥させるウェーハ乾燥機構と、

上記ウェーハ洗浄機構およびウェーハ乾燥機構を上記加工テーブル間で移動させる後処理機構移動手段とを有して、

上記ウェーハ洗浄機構またはウェーハ乾燥機構が、上記ウェーハを各加工テーブルの上方に保持した位置または各加工テーブルに戴置した位置で上記ウェーハを洗浄または乾燥することを特徴とするウェーハの面取り装置。 - 上記ウェーハを上記加工テーブルの上方に保持して上記ウェーハ洗浄機構によって洗浄すると同時に上記加工テーブルを洗浄し、次いで上記ウェーハ乾燥機構によってウェーハを乾燥させると同時に上記加工テーブルを乾燥させることを特徴とする請求項5記載のウェーハの面取り装置。

- 上記加工前センサー、上記加工後センサー、上記ウェーハ洗浄機構、または上記ウェーハ乾燥機構のいずれかを、面取り加工の前後に上記ウェーハを格納するカセットと上記各加工テーブルとの間で上記ウェーハを搬送するアームに設けたことを特徴とする請求項3から6のいずれかに記載のウェーハの面取り装置。

- 上記複数の加工テーブルが直線状に配置されることを特徴とする請求項1から7のいずれかに記載のウェーハの面取り装置。

- 上記砥石移動手段、上記加工前センサー移動手段、上記加工後センサー移動手段、または上記後処理機構移動手段のいずれかの移動方向に対し水平直交方向に上記加工テーブルを移動させる加工テーブル接近離間手段と、

上記加工テーブルを回転させる加工テーブル回転手段とを設けたことを特徴とする請求項1から5のいずれかに記載のウェーハの面取り装置。

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201180022063.1A CN102869476B (zh) | 2010-05-11 | 2011-02-28 | 圆片的倒角装置 |

| KR1020127029505A KR101598657B1 (ko) | 2010-05-11 | 2011-02-28 | 웨이퍼의 모따기 장치 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010-109645 | 2010-05-11 | ||

| JP2010109645A JP5491273B2 (ja) | 2010-05-11 | 2010-05-11 | ウェーハの面取り装置 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2011142159A1 true WO2011142159A1 (ja) | 2011-11-17 |

Family

ID=44914218

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2011/054445 WO2011142159A1 (ja) | 2010-05-11 | 2011-02-28 | ウェーハの面取り装置 |

Country Status (5)

| Country | Link |

|---|---|

| JP (1) | JP5491273B2 (ja) |

| KR (1) | KR101598657B1 (ja) |

| CN (1) | CN102869476B (ja) |

| TW (1) | TWI499482B (ja) |

| WO (1) | WO2011142159A1 (ja) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109333222A (zh) * | 2018-11-01 | 2019-02-15 | 浙江中晶新材料研究有限公司 | 一种全自动硅片倒角加工设备及其加工工艺 |

| EP3581331A1 (en) | 2018-06-13 | 2019-12-18 | Phup Remszklo s.c. | Set of discs for grinding the edges of glass plates |

| WO2020158376A1 (ja) * | 2019-01-29 | 2020-08-06 | 信越半導体株式会社 | シリコンウェーハの製造方法およびシリコンウェーハ |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6099960B2 (ja) * | 2012-12-18 | 2017-03-22 | ダイトエレクトロン株式会社 | ウェーハの面取り加工方法およびウェーハの面取り装置 |

| JP6007889B2 (ja) * | 2013-12-03 | 2016-10-19 | 信越半導体株式会社 | 面取り加工装置及びノッチレスウェーハの製造方法 |

| JP6141814B2 (ja) * | 2014-10-30 | 2017-06-07 | 信越半導体株式会社 | 研磨装置 |

| KR101578713B1 (ko) * | 2015-06-22 | 2015-12-18 | 황정하 | 광학렌즈의 양면 모따기 장치 |

| JP6614978B2 (ja) * | 2016-01-14 | 2019-12-04 | 株式会社荏原製作所 | 研磨装置及び研磨方法 |

| JP6774263B2 (ja) * | 2016-08-19 | 2020-10-21 | 株式会社ディスコ | 切削装置 |

| CN106181681A (zh) * | 2016-08-31 | 2016-12-07 | 天通银厦新材料有限公司 | 一种蓝宝石加工用精确打磨装置 |

| JP7016032B2 (ja) | 2019-09-24 | 2022-02-04 | 日亜化学工業株式会社 | 半導体素子の製造方法 |

| CN114888983A (zh) * | 2022-05-31 | 2022-08-12 | 杭州中为光电技术有限公司 | 硅片自动倒角清洗一体化设备 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH06295891A (ja) * | 1992-11-20 | 1994-10-21 | Sumitomo Sitix Corp | 半導体ウエーハの外周面加工装置 |

| JPH1177501A (ja) * | 1997-09-05 | 1999-03-23 | Asahi Glass Co Ltd | ガラス板端部の加工方法 |

| JP2006110642A (ja) * | 2004-10-12 | 2006-04-27 | Shiraitekku:Kk | 研磨装置 |

| JP2008199071A (ja) * | 2008-05-22 | 2008-08-28 | Tokyo Seimitsu Co Ltd | ウェーハ面取り装置 |

| JP2009274174A (ja) * | 2008-05-14 | 2009-11-26 | Sintokogio Ltd | 板状部材の端面の加工方法 |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN2186135Y (zh) * | 1994-03-04 | 1994-12-28 | 廖胜钦 | 多轴式圆形玻璃磨斜边机 |

| JP2882458B2 (ja) | 1994-11-28 | 1999-04-12 | 株式会社東京精密 | ウェーハ面取り機 |

| ITMI991382A1 (it) * | 1999-06-21 | 2000-12-21 | Bavelloni Z Spa | Macchina automatica bilaterale per la lavorazione dei bordi di lastredi vetro materiali lapidei e simili |

| JP4323058B2 (ja) | 2000-04-24 | 2009-09-02 | エムテック株式会社 | ウェーハのノッチの研摩装置 |

| JP4013778B2 (ja) * | 2003-02-04 | 2007-11-28 | 坂東機工株式会社 | ガラス板の加工装置 |

| JP5112703B2 (ja) | 2007-01-18 | 2013-01-09 | ダイトエレクトロン株式会社 | ウェーハ面取り加工方法およびその装置 |

| KR100905094B1 (ko) * | 2007-08-01 | 2009-06-30 | 주식회사 에스에프에이 | 웨이퍼 연마장치 |

| JP5434014B2 (ja) * | 2008-08-22 | 2014-03-05 | 坂東機工株式会社 | ガラス板の加工方法及びガラス板加工装置 |

-

2010

- 2010-05-11 JP JP2010109645A patent/JP5491273B2/ja active Active

-

2011

- 2011-02-28 CN CN201180022063.1A patent/CN102869476B/zh active Active

- 2011-02-28 KR KR1020127029505A patent/KR101598657B1/ko active IP Right Grant

- 2011-02-28 WO PCT/JP2011/054445 patent/WO2011142159A1/ja active Application Filing

- 2011-05-04 TW TW100115556A patent/TWI499482B/zh active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH06295891A (ja) * | 1992-11-20 | 1994-10-21 | Sumitomo Sitix Corp | 半導体ウエーハの外周面加工装置 |

| JPH1177501A (ja) * | 1997-09-05 | 1999-03-23 | Asahi Glass Co Ltd | ガラス板端部の加工方法 |

| JP2006110642A (ja) * | 2004-10-12 | 2006-04-27 | Shiraitekku:Kk | 研磨装置 |

| JP2009274174A (ja) * | 2008-05-14 | 2009-11-26 | Sintokogio Ltd | 板状部材の端面の加工方法 |

| JP2008199071A (ja) * | 2008-05-22 | 2008-08-28 | Tokyo Seimitsu Co Ltd | ウェーハ面取り装置 |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3581331A1 (en) | 2018-06-13 | 2019-12-18 | Phup Remszklo s.c. | Set of discs for grinding the edges of glass plates |

| CN109333222A (zh) * | 2018-11-01 | 2019-02-15 | 浙江中晶新材料研究有限公司 | 一种全自动硅片倒角加工设备及其加工工艺 |

| WO2020158376A1 (ja) * | 2019-01-29 | 2020-08-06 | 信越半導体株式会社 | シリコンウェーハの製造方法およびシリコンウェーハ |

Also Published As

| Publication number | Publication date |

|---|---|

| TW201206636A (en) | 2012-02-16 |

| KR20130092401A (ko) | 2013-08-20 |

| JP5491273B2 (ja) | 2014-05-14 |

| TWI499482B (zh) | 2015-09-11 |

| JP2011235406A (ja) | 2011-11-24 |

| KR101598657B1 (ko) | 2016-02-29 |

| CN102869476A (zh) | 2013-01-09 |

| CN102869476B (zh) | 2015-08-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5491273B2 (ja) | ウェーハの面取り装置 | |

| JP6336772B2 (ja) | 研削研磨装置 | |

| JP2007173487A (ja) | ウエーハの加工方法および装置 | |

| TWI735649B (zh) | 磨削裝置 | |

| JP2011042003A (ja) | 保持テーブルおよび研削装置 | |

| JP2018058160A (ja) | 研削砥石のドレッシング方法 | |

| JP6552930B2 (ja) | 研削装置 | |

| JP6099960B2 (ja) | ウェーハの面取り加工方法およびウェーハの面取り装置 | |

| KR20200029527A (ko) | 연삭 장치, 연삭 방법 및 컴퓨터 기억 매체 | |

| JP2010199336A (ja) | ワーク加工方法およびワーク加工装置 | |

| JPWO2020153219A1 (ja) | 加工装置及び加工方法 | |

| JP6598668B2 (ja) | 研削装置 | |

| JP2009160705A (ja) | ウェーハの研削方法および研削加工装置 | |

| JP5261125B2 (ja) | チャックテーブルの原点高さ位置検出方法 | |

| JP2017204606A (ja) | ウエーハ製造方法 | |

| JP5926042B2 (ja) | 板状基板の割れ検知方法 | |

| JP7451043B2 (ja) | 被加工物の研削方法及び研削装置 | |

| JP2011125987A (ja) | 研削装置 | |

| JP7118558B2 (ja) | 被加工物の加工方法 | |

| JP2017019055A (ja) | チャックテーブル及びチャックテーブルを備えた加工装置 | |

| JP2016078132A (ja) | 加工装置 | |

| JP4477974B2 (ja) | 研磨装置 | |

| JP2014226767A (ja) | ウェーハ面取り装置及びウェーハ面取り方法 | |

| JP2014042959A (ja) | 研削装置 | |

| JP5512314B2 (ja) | 研削装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| WWE | Wipo information: entry into national phase |

Ref document number: 201180022063.1 Country of ref document: CN |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 11780417 Country of ref document: EP Kind code of ref document: A1 |

|

| DPE2 | Request for preliminary examination filed before expiration of 19th month from priority date (pct application filed from 20040101) | ||

| ENP | Entry into the national phase |

Ref document number: 20127029505 Country of ref document: KR Kind code of ref document: A |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 11780417 Country of ref document: EP Kind code of ref document: A1 |