JP5490701B2 - 圧延機及びその動作方法 - Google Patents

圧延機及びその動作方法 Download PDFInfo

- Publication number

- JP5490701B2 JP5490701B2 JP2010526200A JP2010526200A JP5490701B2 JP 5490701 B2 JP5490701 B2 JP 5490701B2 JP 2010526200 A JP2010526200 A JP 2010526200A JP 2010526200 A JP2010526200 A JP 2010526200A JP 5490701 B2 JP5490701 B2 JP 5490701B2

- Authority

- JP

- Japan

- Prior art keywords

- flatness

- roll gap

- rolled product

- rolling mill

- roll

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000005096 rolling process Methods 0.000 title claims description 38

- 238000011017 operating method Methods 0.000 title 1

- 238000001514 detection method Methods 0.000 claims description 22

- 239000000463 material Substances 0.000 claims description 7

- 238000000034 method Methods 0.000 claims description 7

- 238000006073 displacement reaction Methods 0.000 claims description 6

- 238000005461 lubrication Methods 0.000 claims description 3

- 230000003287 optical effect Effects 0.000 claims description 3

- 230000014759 maintenance of location Effects 0.000 description 8

- 238000005452 bending Methods 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 230000006641 stabilisation Effects 0.000 description 1

- 238000011105 stabilization Methods 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B37/00—Control devices or methods specially adapted for metal-rolling mills or the work produced thereby

- B21B37/28—Control of flatness or profile during rolling of strip, sheets or plates

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B37/00—Control devices or methods specially adapted for metal-rolling mills or the work produced thereby

- B21B37/28—Control of flatness or profile during rolling of strip, sheets or plates

- B21B37/30—Control of flatness or profile during rolling of strip, sheets or plates using roll camber control

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B37/00—Control devices or methods specially adapted for metal-rolling mills or the work produced thereby

- B21B37/28—Control of flatness or profile during rolling of strip, sheets or plates

- B21B37/30—Control of flatness or profile during rolling of strip, sheets or plates using roll camber control

- B21B37/32—Control of flatness or profile during rolling of strip, sheets or plates using roll camber control by cooling, heating or lubricating the rolls

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B37/00—Control devices or methods specially adapted for metal-rolling mills or the work produced thereby

- B21B37/28—Control of flatness or profile during rolling of strip, sheets or plates

- B21B37/38—Control of flatness or profile during rolling of strip, sheets or plates using roll bending

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B37/00—Control devices or methods specially adapted for metal-rolling mills or the work produced thereby

- B21B37/28—Control of flatness or profile during rolling of strip, sheets or plates

- B21B37/40—Control of flatness or profile during rolling of strip, sheets or plates using axial shifting of the rolls

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B37/00—Control devices or methods specially adapted for metal-rolling mills or the work produced thereby

- B21B37/28—Control of flatness or profile during rolling of strip, sheets or plates

- B21B37/42—Control of flatness or profile during rolling of strip, sheets or plates using a combination of roll bending and axial shifting of the rolls

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B37/00—Control devices or methods specially adapted for metal-rolling mills or the work produced thereby

- B21B37/28—Control of flatness or profile during rolling of strip, sheets or plates

- B21B37/44—Control of flatness or profile during rolling of strip, sheets or plates using heating, lubricating or water-spray cooling of the product

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B38/00—Methods or devices for measuring, detecting or monitoring specially adapted for metal-rolling mills, e.g. position detection, inspection of the product

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B38/00—Methods or devices for measuring, detecting or monitoring specially adapted for metal-rolling mills, e.g. position detection, inspection of the product

- B21B38/02—Methods or devices for measuring, detecting or monitoring specially adapted for metal-rolling mills, e.g. position detection, inspection of the product for measuring flatness or profile of strips

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Control Of Metal Rolling (AREA)

- Metal Rolling (AREA)

- Casting Or Compression Moulding Of Plastics Or The Like (AREA)

Description

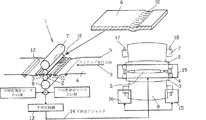

2,3 ワークロール(対)

4 ロール間隙

5 圧延製品

6 ストリップ

7,8 バックアップロール(対)

9 圧延方向

10 滞留部

11 検出装置(センサ)

12 平坦度測定ローラ

13 制御ユニット

14 制御信号

15〜19 平坦度アジャスタ

Claims (5)

- 少なくとも2つのワークロール(2,3)と、

複数のバックアップロール(7,8)と

を備えて成り、前記ワークロール(2,3)の間に圧延製品(5)が通過するロール間隙(4)が設定された圧延機(1)において、

前記ロール間隙(4)の手前で前記圧延製品(5)の圧延材料の滞留部を検出するために、少なくとも1つの検出装置(11)を設けるとともに、該検出装置(11)からの信号に基づき前記圧延製品の平坦度の調整のためのアジャスタを制御する制御ユニット(13)を設け、かつ、

平坦度を調整する前記アジャスタを、前記ワークロール(2,3)及び/又は前記バックアップロール(7,8)の傾斜、前記ワークロール(2,3)、中間ロール及び/又は前記バックアップロール(7,8)の曲がり、前記ワークロール(2,3)及び/又は中間ロールの連続可変クラウン(CVC)変位における軸方向変位並びに前記ストリップ(6)及び/又は前記ワークロール(2,3)の最小潤滑量若しくは温度を調整するよう構成し、かつ、

前記検出装置(11)を、前記ロール間隙(4)の手前において前記圧延製品(5)の圧延材料の滞留部を検出する光学式又は機械式の検出装置として構成したことを特徴とする圧延機。 - 前記ロール間隙(4)の後方に、前記制御ユニット(13)へ信号を送出する平坦度検出装置(12)を設けるとともに、前記検出装置(11)及び前記平坦度検出装置(12)からの信号に基づき、前記圧延製品(5)の平坦度を調整するアジャスタ(15,16,17,18,19)を前記制御ユニット(13)によって制御するよう構成したことを特徴とする請求項1記載の圧延機。

- 少なくとも2つのワークロール(2,3)を備えて成り、前記ワークロール(2,3)の間に圧延製品(5)が通過するロール間隙(4)が設定された請求項1又は2記載の圧延機(1)の動作方法において、

前記ロール間隙(4)の手前で前記圧延製品(5)の滞留部を検出するとともに、この検出された滞留部に応じて、前記圧延製品(5)の平坦度の調整を行う少なくとも1つのアジャスタを制御することを特徴とする圧延機の動作方法。 - 前記圧延製品の平坦度の調整を、更に、前記ロール間隙の後方における前記圧延製品の平坦度を示す平坦度検出信号に基づいて行うことを特徴とする請求項3記載の圧延機の動作方法。

- 前記圧延製品の滞留部を、前記ロール間隙(4)の手前で光学的又は機械的に検出することを特徴とする請求項3又は4記載の圧延機の動作方法。

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102007046189.7 | 2007-09-26 | ||

| DE102007046189 | 2007-09-26 | ||

| DE102008015828.3 | 2008-03-27 | ||

| DE102008015828A DE102008015828A1 (de) | 2007-09-26 | 2008-03-27 | Walzvorrichtung und Verfahren für deren Betrieb |

| PCT/EP2008/007981 WO2009043501A1 (de) | 2007-09-26 | 2008-09-22 | Walzvorrichtung und verfahren für deren betrieb |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2010540250A JP2010540250A (ja) | 2010-12-24 |

| JP2010540250A5 JP2010540250A5 (ja) | 2012-12-20 |

| JP5490701B2 true JP5490701B2 (ja) | 2014-05-14 |

Family

ID=40384509

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2010526200A Active JP5490701B2 (ja) | 2007-09-26 | 2008-09-22 | 圧延機及びその動作方法 |

Country Status (15)

| Country | Link |

|---|---|

| US (1) | US20110030433A1 (ja) |

| EP (1) | EP2195126B1 (ja) |

| JP (1) | JP5490701B2 (ja) |

| KR (1) | KR101185391B1 (ja) |

| CN (1) | CN101808759B (ja) |

| AU (1) | AU2008306213A1 (ja) |

| BR (1) | BRPI0817341A2 (ja) |

| CA (1) | CA2700752C (ja) |

| DE (1) | DE102008015828A1 (ja) |

| ES (1) | ES2394234T3 (ja) |

| MX (1) | MX2010003239A (ja) |

| RU (1) | RU2427437C1 (ja) |

| TW (1) | TWI346587B (ja) |

| WO (1) | WO2009043501A1 (ja) |

| ZA (1) | ZA201000566B (ja) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102009060243A1 (de) | 2009-12-23 | 2011-06-30 | SMS Siemag Aktiengesellschaft, 40237 | Planheitsbestimmung eines Metallbands durch Messung des Profils |

| AT513245B1 (de) * | 2012-12-11 | 2014-03-15 | Siemens Vai Metals Tech Gmbh | Planheitsmessung und Messung der Eigenspannungen für ein metallisches Flachprodukt |

| CN104785542B (zh) * | 2014-01-22 | 2016-10-05 | 宝山钢铁股份有限公司 | 一种粗轧机张力调节控制方法 |

| US9758044B2 (en) * | 2014-10-02 | 2017-09-12 | Ford Global Technologies, Llc | Bus leakage resistance estimation for electrical isolation testing and diagnostics |

| JP7067541B2 (ja) * | 2019-10-31 | 2022-05-16 | Jfeスチール株式会社 | 圧延機の制御方法および制御装置 |

Family Cites Families (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2883895A (en) * | 1954-10-15 | 1959-04-28 | Carl A Vossberg | Rolling mill thickness control system |

| JPS4612897B1 (ja) * | 1967-07-07 | 1971-04-02 | ||

| AT345237B (de) | 1976-12-28 | 1978-09-11 | Voest Ag | Vorrichtung zum walzen von band- oder tafelfoermigem walzgut |

| JPS5467550A (en) * | 1977-11-09 | 1979-05-31 | Mitsubishi Electric Corp | Shape control of rolled material |

| DE2911621A1 (de) * | 1978-03-31 | 1979-10-04 | Loewy Robertson Eng Co Ltd | Verfahren zum betreiben eines walzwerks zur erzeugung von metallbaendern |

| DE3038865C1 (de) * | 1980-10-15 | 1982-12-23 | SMS Schloemann-Siemag AG, 4000 Düsseldorf | Walzgeruest mit axial verschiebbaren Walzen |

| DE3240602A1 (de) | 1982-11-03 | 1984-06-14 | Betriebsforschungsinstitut VDEh - Institut für angewandte Forschung GmbH, 4000 Düsseldorf | Verfahren zum regeln der zugspannungsverteilung beim kaltwalzen von baendern |

| JPS60148608A (ja) * | 1984-01-11 | 1985-08-05 | Hitachi Ltd | 異周速圧延制御におけるセツトアツプ方法 |

| US4771622A (en) * | 1986-03-12 | 1988-09-20 | International Rolling Mill Consultants Inc. | Strip rolling mill apparatus |

| JPS6316805A (ja) * | 1986-07-07 | 1988-01-23 | Nippon Steel Corp | 圧延方法 |

| JPH0818058B2 (ja) * | 1987-06-12 | 1996-02-28 | 川崎製鉄株式会社 | 厚板圧延の自動板厚制御方法 |

| DE3823202A1 (de) * | 1988-07-08 | 1990-01-11 | Betr Forsch Inst Angew Forsch | Verfahren zum kaltwalzen von blechen und baendern |

| JPH0523723A (ja) * | 1991-07-24 | 1993-02-02 | Toshiba Corp | 平坦度測定装置及びこの平坦度測定装置を用いた連続圧延機の制御装置 |

| JP3056668B2 (ja) * | 1995-04-21 | 2000-06-26 | 新日本製鐵株式会社 | ストリップ連続鋳造熱間圧延熱処理設備およびストリップ連続鋳造熱間圧延熱処理方法 |

| DE19704447A1 (de) * | 1997-02-06 | 1998-08-13 | Schloemann Siemag Ag | Planheitsmeßrolle |

| DE19713004C2 (de) * | 1997-03-27 | 2002-10-24 | Siemens Ag | Verfahren und Einrichtung zur Voreinstellung der Planheit eines Walzbandes |

| JP2000167609A (ja) * | 1998-12-02 | 2000-06-20 | Nippon Steel Corp | 冷間タンデム圧延機の圧延方法と圧延機 |

| US6230532B1 (en) * | 1999-03-31 | 2001-05-15 | Kawasaki Steel Corporation | Method and apparatus for controlling sheet shape in sheet rolling |

| IT1310879B1 (it) * | 1999-07-20 | 2002-02-22 | Danieli Off Mecc | Gabbia di laminazione per prodotti piani e metodo peril controllo della planarita' di detti prodotti |

| US6158260A (en) * | 1999-09-15 | 2000-12-12 | Danieli Technology, Inc. | Universal roll crossing system |

| AUPQ779900A0 (en) * | 2000-05-26 | 2000-06-22 | Bhp Steel (Jla) Pty Limited | Hot rolling thin strip |

| US6668626B2 (en) * | 2001-03-01 | 2003-12-30 | Abb Ab | System and a method for measuring and determining flatness |

| DE10352546A1 (de) * | 2003-09-04 | 2005-03-31 | Sms Demag Ag | Verfahren und Vorrichtung zum Aufbringen einer regelbaren Zugspannungsverteilung, insbesondere in den Kantenbereichen kaltgewalzter Metallbänder |

| DE102004032634A1 (de) * | 2004-07-06 | 2006-02-16 | Sms Demag Ag | Verfahren und Einrichtung zum Messen und Regeln der Planheit und/oder der Bandspannungen eines Edelstahlbandes oder einer Edelstahlfolie beim Kaltwalzen in einem Vielwalzengerüst, insbesondere in einem 20-Walzen-Sendizimir-Walzwerk |

| JP4049765B2 (ja) * | 2004-07-09 | 2008-02-20 | 株式会社日立製作所 | 熱間圧延ミルのクラウン制御装置およびその制御方法 |

| AT501314B1 (de) * | 2004-10-13 | 2012-03-15 | Voest Alpine Ind Anlagen | Verfahren und vorrichtung zum kontinuierlichen herstellen eines dünnen metallbandes |

| SE529074C2 (sv) * | 2005-06-08 | 2007-04-24 | Abb Ab | Förfarande och anordning för optimering av planhetsstyrning vid valsning av ett band |

| DE102005042020A1 (de) * | 2005-09-02 | 2007-03-08 | Sms Demag Ag | Verfahren zum Schmieren und Kühlen von Walzen und Metallband beim Walzen, insbesondere beim Kaltwalzen, von Metallbändern |

| JP4556856B2 (ja) * | 2005-12-02 | 2010-10-06 | 株式会社Ihi | 圧延装置 |

-

2008

- 2008-03-27 DE DE102008015828A patent/DE102008015828A1/de not_active Withdrawn

- 2008-09-22 BR BRPI0817341 patent/BRPI0817341A2/pt not_active IP Right Cessation

- 2008-09-22 CA CA2700752A patent/CA2700752C/en not_active Expired - Fee Related

- 2008-09-22 CN CN2008801088633A patent/CN101808759B/zh active Active

- 2008-09-22 AU AU2008306213A patent/AU2008306213A1/en not_active Abandoned

- 2008-09-22 RU RU2010116170/02A patent/RU2427437C1/ru active

- 2008-09-22 JP JP2010526200A patent/JP5490701B2/ja active Active

- 2008-09-22 EP EP08802476A patent/EP2195126B1/de active Active

- 2008-09-22 WO PCT/EP2008/007981 patent/WO2009043501A1/de active Application Filing

- 2008-09-22 US US12/733,935 patent/US20110030433A1/en not_active Abandoned

- 2008-09-22 MX MX2010003239A patent/MX2010003239A/es active IP Right Grant

- 2008-09-22 KR KR1020107004152A patent/KR101185391B1/ko active IP Right Grant

- 2008-09-22 ES ES08802476T patent/ES2394234T3/es active Active

- 2008-09-24 TW TW097136621A patent/TWI346587B/zh not_active IP Right Cessation

-

2010

- 2010-01-26 ZA ZA201000566A patent/ZA201000566B/xx unknown

Also Published As

| Publication number | Publication date |

|---|---|

| CN101808759B (zh) | 2012-11-28 |

| ZA201000566B (en) | 2010-09-29 |

| CN101808759A (zh) | 2010-08-18 |

| BRPI0817341A2 (pt) | 2015-03-31 |

| MX2010003239A (es) | 2010-04-21 |

| US20110030433A1 (en) | 2011-02-10 |

| KR101185391B1 (ko) | 2012-09-25 |

| TW200914159A (en) | 2009-04-01 |

| DE102008015828A1 (de) | 2009-04-02 |

| KR20100039893A (ko) | 2010-04-16 |

| WO2009043501A1 (de) | 2009-04-09 |

| JP2010540250A (ja) | 2010-12-24 |

| CA2700752A1 (en) | 2009-04-09 |

| ES2394234T3 (es) | 2013-01-23 |

| AU2008306213A1 (en) | 2009-04-09 |

| EP2195126A1 (de) | 2010-06-16 |

| TWI346587B (en) | 2011-08-11 |

| CA2700752C (en) | 2012-07-24 |

| RU2427437C1 (ru) | 2011-08-27 |

| EP2195126B1 (de) | 2012-11-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US9211573B2 (en) | Hot rolling equipment and hot rolling method | |

| JP5490701B2 (ja) | 圧延機及びその動作方法 | |

| US8539804B2 (en) | Method and device for controlling a roll gap | |

| JP4214150B2 (ja) | 金属板材の圧延方法および圧延装置 | |

| JP2010540250A5 (ja) | ||

| US7854155B2 (en) | Method and rolling mill for improving the running-out of a rolled metal strip whose trailing end is moving at rolling speed | |

| JP4267609B2 (ja) | 金属板材の圧延方法および圧延装置 | |

| JP4505550B2 (ja) | 金属板材の圧延方法および圧延装置 | |

| JP4268582B2 (ja) | 板厚制御方法及び板厚・形状非干渉制御方法 | |

| JP4288888B2 (ja) | タンデム圧延機におけるストリップの蛇行制御装置及び蛇行制御方法 | |

| JP2004243376A (ja) | タンデム圧延機におけるストリップの蛇行制御装置及び蛇行制御方法 | |

| JP2006082118A (ja) | 金属板材の圧延方法および圧延装置 | |

| JP2002210512A (ja) | 板圧延における圧下位置設定方法 | |

| WO2024042936A1 (ja) | 冷間圧延方法及び冷間圧延設備 | |

| US20240198402A1 (en) | Roll steering control systems and methods for tandem mills | |

| KR20080037010A (ko) | 열간 압연 시의 두께 제어 방법 | |

| JPH0890030A (ja) | 圧延材の板幅制御方法 | |

| JPH0441010A (ja) | 冷間圧延におけるエッジドロップ制御方法 | |

| JP2005161373A (ja) | 冷間タンデム圧延機の形状制御方法 | |

| JP2001269708A (ja) | 熱間圧延機のレベリング制御方法及び装置 | |

| JP3350294B2 (ja) | タンデムミルの制御方法および制御装置 | |

| JP2005152942A (ja) | 冷延板材の形状検知方法及び多段圧延機における形状制御方法 | |

| JP2500133B2 (ja) | 圧延機のエッジドロップ制御方法 | |

| JPH0839123A (ja) | 熱間圧延における絞り込み防止方法 | |

| JPH09206815A (ja) | 冷間圧延におけるエッジドロップ制御方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120625 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120717 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20121016 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20121023 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20121030 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20121031 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130205 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20130502 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20130513 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130524 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20130716 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20131114 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20131121 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20140128 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20140226 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5490701 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |