JP5345708B2 - バルブの軸洩れ低減構造 - Google Patents

バルブの軸洩れ低減構造 Download PDFInfo

- Publication number

- JP5345708B2 JP5345708B2 JP2011552235A JP2011552235A JP5345708B2 JP 5345708 B2 JP5345708 B2 JP 5345708B2 JP 2011552235 A JP2011552235 A JP 2011552235A JP 2011552235 A JP2011552235 A JP 2011552235A JP 5345708 B2 JP5345708 B2 JP 5345708B2

- Authority

- JP

- Japan

- Prior art keywords

- valve

- shaft

- fluid passage

- bearing

- valve shaft

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K1/00—Lift valves or globe valves, i.e. cut-off apparatus with closure members having at least a component of their opening and closing motion perpendicular to the closing faces

- F16K1/16—Lift valves or globe valves, i.e. cut-off apparatus with closure members having at least a component of their opening and closing motion perpendicular to the closing faces with pivoted closure-members

- F16K1/18—Lift valves or globe valves, i.e. cut-off apparatus with closure members having at least a component of their opening and closing motion perpendicular to the closing faces with pivoted closure-members with pivoted discs or flaps

- F16K1/22—Lift valves or globe valves, i.e. cut-off apparatus with closure members having at least a component of their opening and closing motion perpendicular to the closing faces with pivoted closure-members with pivoted discs or flaps with axis of rotation crossing the valve member, e.g. butterfly valves

- F16K1/226—Shaping or arrangements of the sealing

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K1/00—Lift valves or globe valves, i.e. cut-off apparatus with closure members having at least a component of their opening and closing motion perpendicular to the closing faces

- F16K1/16—Lift valves or globe valves, i.e. cut-off apparatus with closure members having at least a component of their opening and closing motion perpendicular to the closing faces with pivoted closure-members

- F16K1/18—Lift valves or globe valves, i.e. cut-off apparatus with closure members having at least a component of their opening and closing motion perpendicular to the closing faces with pivoted closure-members with pivoted discs or flaps

- F16K1/22—Lift valves or globe valves, i.e. cut-off apparatus with closure members having at least a component of their opening and closing motion perpendicular to the closing faces with pivoted closure-members with pivoted discs or flaps with axis of rotation crossing the valve member, e.g. butterfly valves

- F16K1/226—Shaping or arrangements of the sealing

- F16K1/2268—Sealing means for the axis of rotation

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D9/00—Controlling engines by throttling air or fuel-and-air induction conduits or exhaust conduits

- F02D9/08—Throttle valves specially adapted therefor; Arrangements of such valves in conduits

- F02D9/10—Throttle valves specially adapted therefor; Arrangements of such valves in conduits having pivotally-mounted flaps

- F02D9/1035—Details of the valve housing

- F02D9/106—Sealing of the valve shaft in the housing, e.g. details of the bearings

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M26/00—Engine-pertinent apparatus for adding exhaust gases to combustion-air, main fuel or fuel-air mixture, e.g. by exhaust gas recirculation [EGR] systems

- F02M26/52—Systems for actuating EGR valves

- F02M26/53—Systems for actuating EGR valves using electric actuators, e.g. solenoids

- F02M26/54—Rotary actuators, e.g. step motors

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M26/00—Engine-pertinent apparatus for adding exhaust gases to combustion-air, main fuel or fuel-air mixture, e.g. by exhaust gas recirculation [EGR] systems

- F02M26/65—Constructional details of EGR valves

- F02M26/70—Flap valves; Rotary valves; Sliding valves; Resilient valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M26/00—Engine-pertinent apparatus for adding exhaust gases to combustion-air, main fuel or fuel-air mixture, e.g. by exhaust gas recirculation [EGR] systems

- F02M26/65—Constructional details of EGR valves

- F02M26/74—Protection from damage, e.g. shielding means

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Health & Medical Sciences (AREA)

- Toxicology (AREA)

- Details Of Valves (AREA)

- Exhaust-Gas Circulating Devices (AREA)

- Lift Valve (AREA)

Description

実施の形態1.

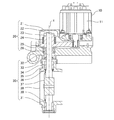

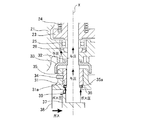

図1に示すEGRバルブは、バルブ開閉の回転駆動力を発生させるアクチュエータ部10と、アクチュエータ部10の駆動力をロッド(弁軸)32に伝達するギア部20と、高温の排ガスが流通する管(不図示)に介装され、バタフライ弁状のバルブ(弁体)37を開閉して排ガスの流通を制御するバルブ部30とからなる。

また、ロッド32にはバルブ37が固定されており、このバルブ37がロッド32と一体に回転して、ガス通路38に設けられたバルブシート39に当接してガスの流通を止める。

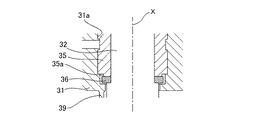

ガス通路38を流通するガス、及びバルブ37とバルブシート39の隙間から洩れ出るガスは、ロッド32の外周面に沿って軸方向上向きに軸洩れするが、プレート36がロッド32の外周面に圧入されているため、プレート36の内周面とロッド32の外周面に隙間がなく、この部分から軸洩れすることもない。

そこで、ブッシュ35の軸方向下側の端部外径をプレート36の外径より小さくなるように縮径して、縮径端部35aを形成する。これにより、ブッシュ35に対してプレート36が回転して当接面が磨耗したとしても、段差がなく均一に磨耗するようになるので、ブッシュ35とプレート36の磨耗部分が噛み込んだり引っ掛かったりしにくい構造になっている。

Claims (3)

- 内部に設けた流体通路に連通する貫通穴を形成したハウジングと、

前記貫通穴から前記流体通路に挿入され、回転中心軸を中心にして回転する弁軸と、

前記弁軸と一体に回転して、前記流体通路を開閉する弁体と、

前記弁軸の前記流体通路挿入側とは反対側で当該弁軸を回転自在に軸支するベアリングと、

前記貫通穴内に設けられ、前記ベアリングより前記流体通路側で前記弁軸を回転自在に軸支する軸受け部と、

前記ベアリングを、回転中心軸方向の前記流体通路とは反対側に荷重するワッシャと、

前記弁軸の外周面に圧入され、与圧によって前記軸受け部の前記流体通路側の面に当接しながら回転する、切れ目のない環状の軸シール部とを備え、

前記軸シール部は、前記ワッシャに荷重された前記ベアリングにより前記弁軸に作用する前記回転中心軸方向の前記流体通路とは反対側の与圧によって、前記軸受け部の前記流体通路側の面に当接すると共に、前記貫通穴を通じて前記流体通路から流れ出る流体の圧力が当該軸シール部に与圧として作用して前記軸受け部の前記流体通路側の面に当接することを特徴とするバルブの軸洩れ低減構造。 - 軸受け部と軸シール部の当接面それぞれに、表面処理を施すことを特徴とする請求項1記載のバルブの軸洩れ低減構造。

- 軸受け部の軸シール部に当接する端面の外径を、当該軸シール部の外径より小さくすることを特徴とする請求項1記載のバルブの軸洩れ低減構造。

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/JP2010/001047 WO2011101903A1 (ja) | 2010-02-18 | 2010-02-18 | バルブの軸洩れ低減構造 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JPWO2011101903A1 JPWO2011101903A1 (ja) | 2013-06-17 |

| JP5345708B2 true JP5345708B2 (ja) | 2013-11-20 |

Family

ID=44482530

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2011552235A Active JP5345708B2 (ja) | 2010-02-18 | 2010-02-18 | バルブの軸洩れ低減構造 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20120193562A1 (ja) |

| JP (1) | JP5345708B2 (ja) |

| KR (1) | KR101310453B1 (ja) |

| CN (1) | CN102575623B (ja) |

| DE (1) | DE112010005282B4 (ja) |

| WO (1) | WO2011101903A1 (ja) |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5924247B2 (ja) * | 2012-11-27 | 2016-05-25 | 株式会社デンソー | バルブ装置 |

| KR101362058B1 (ko) * | 2012-12-17 | 2014-02-12 | 기아자동차 주식회사 | 차량용 배기 가스 재순환 밸브 |

| DE102013013387A1 (de) * | 2013-03-10 | 2014-09-11 | Kohlhage Automotive GmbH & Co. KG | Lagerung für eine Welle, insbesondere bei einer Ventileinheit, mit einer solchen Lagerung ausgestattete Ventileinheit und Verfahren zur Herstellung |

| DE102013107111A1 (de) * | 2013-07-05 | 2015-01-08 | Pierburg Gmbh | Aktor zum Antrieb einer Ventileinheit einer Verbrennungskraftmaschine |

| JP6177114B2 (ja) * | 2013-12-03 | 2017-08-09 | 三菱電機株式会社 | 排気ガス再循環バルブ |

| JP5847857B2 (ja) * | 2014-01-14 | 2016-01-27 | 本田技研工業株式会社 | 内燃機関のバルブの基準位置学習装置 |

| JP6324870B2 (ja) * | 2014-10-08 | 2018-05-16 | 東京エレクトロン株式会社 | ガス供給機構及び半導体製造装置 |

| JP6062129B2 (ja) * | 2014-10-31 | 2017-01-18 | 三菱電機株式会社 | 流体制御バルブ |

| DE102014226598A1 (de) * | 2014-12-19 | 2016-06-23 | Mahle International Gmbh | Ventileinrichtung zur Strömungsregelung von Abgas in einem Abgaskanal |

| DE102015111461B4 (de) * | 2015-05-07 | 2020-02-06 | BorgWarner Esslingen GmbH | Abgasrückführventil und Verfahren zur Verbesserung eines solchen Ventils |

| DE102015111460B4 (de) * | 2015-05-07 | 2020-02-06 | BorgWarner Esslingen GmbH | Ventil |

| JP2017160889A (ja) * | 2016-03-11 | 2017-09-14 | マツダ株式会社 | エンジンの排気装置 |

| KR101836254B1 (ko) * | 2016-03-16 | 2018-03-08 | 현대자동차 주식회사 | 차량용 배기가스 재순환 밸브장치 |

| JP6597477B2 (ja) * | 2016-05-24 | 2019-10-30 | 株式会社デンソー | バルブ装置 |

| KR20190043004A (ko) * | 2017-10-17 | 2019-04-25 | 현대자동차주식회사 | Egr밸브 |

| DE102017127793A1 (de) * | 2017-11-24 | 2019-05-29 | Pierburg Gmbh | Abgasventil für eine Verbrennungskraftmaschine |

| DE102020103420A1 (de) * | 2020-02-11 | 2021-08-12 | Friedrich Boysen GmbH & Co KG. | Klappeneinrichtung |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS55106342U (ja) * | 1979-01-19 | 1980-07-25 | ||

| JPH0394485U (ja) * | 1990-01-16 | 1991-09-26 | ||

| JP2001221346A (ja) * | 2000-02-09 | 2001-08-17 | Kubota Corp | バタフライ弁の軸封構造 |

| JP2001234759A (ja) * | 2000-02-22 | 2001-08-31 | Mikuni Corp | スロットルボディのシャフト支持構造 |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2900995A (en) * | 1953-04-20 | 1959-08-25 | Rockwell Mfg Co | Jacketed valve |

| US2917271A (en) * | 1954-08-24 | 1959-12-15 | George W Banks | High pressure metering valve |

| US3326516A (en) * | 1964-03-17 | 1967-06-20 | Texsteam Corp | High pressure plug valve |

| US3753569A (en) * | 1971-03-23 | 1973-08-21 | A Bonomi | Pressure valve for fluids |

| US3851853A (en) * | 1973-04-23 | 1974-12-03 | Hoke Inc | Valve |

| DE2529641C3 (de) * | 1975-07-03 | 1982-01-21 | Fördertechnik Streicher GmbH, 7988 Wangen | Hahn mit axial nachstellbarem Kegelküken |

| US4249555A (en) * | 1977-12-30 | 1981-02-10 | Domer Scaramucci | Fire safe disc valve |

| JPS63147538U (ja) * | 1987-03-19 | 1988-09-28 | ||

| US5630571A (en) * | 1995-10-16 | 1997-05-20 | General Motors Corporation | Exhaust flow control valve |

| US5577709A (en) * | 1995-10-17 | 1996-11-26 | Henry Valve Company | Stem seal configuration for ball valves |

| CN2577055Y (zh) * | 2002-07-22 | 2003-10-01 | 王建敏 | 无摩擦硬密封蝶阀 |

| CN1629524A (zh) * | 2003-12-15 | 2005-06-22 | 王加新 | 适应陶瓷或金属或工程塑料制造的对称蝶阀 |

| JP2005233023A (ja) | 2004-02-18 | 2005-09-02 | Denso Corp | 排気ガス再循環装置 |

| JP4621557B2 (ja) * | 2005-07-22 | 2011-01-26 | 大豊工業株式会社 | バルブアセンブリ |

-

2010

- 2010-02-18 WO PCT/JP2010/001047 patent/WO2011101903A1/ja not_active Ceased

- 2010-02-18 US US13/498,608 patent/US20120193562A1/en not_active Abandoned

- 2010-02-18 CN CN201080046961.6A patent/CN102575623B/zh active Active

- 2010-02-18 DE DE112010005282.4T patent/DE112010005282B4/de active Active

- 2010-02-18 JP JP2011552235A patent/JP5345708B2/ja active Active

- 2010-02-18 KR KR1020127009328A patent/KR101310453B1/ko not_active Expired - Fee Related

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS55106342U (ja) * | 1979-01-19 | 1980-07-25 | ||

| JPH0394485U (ja) * | 1990-01-16 | 1991-09-26 | ||

| JP2001221346A (ja) * | 2000-02-09 | 2001-08-17 | Kubota Corp | バタフライ弁の軸封構造 |

| JP2001234759A (ja) * | 2000-02-22 | 2001-08-31 | Mikuni Corp | スロットルボディのシャフト支持構造 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR101310453B1 (ko) | 2013-09-24 |

| WO2011101903A1 (ja) | 2011-08-25 |

| JPWO2011101903A1 (ja) | 2013-06-17 |

| CN102575623B (zh) | 2015-06-17 |

| KR20120065404A (ko) | 2012-06-20 |

| DE112010005282T5 (de) | 2013-02-07 |

| DE112010005282B4 (de) | 2015-02-19 |

| US20120193562A1 (en) | 2012-08-02 |

| CN102575623A (zh) | 2012-07-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5345708B2 (ja) | バルブの軸洩れ低減構造 | |

| CN102959294B (zh) | 流体控制阀 | |

| JP6062129B2 (ja) | 流体制御バルブ | |

| CN104838112B (zh) | 用于内燃机的活门装置 | |

| CN109312669B (zh) | 用于内燃机的废气活门装置 | |

| JP5304825B2 (ja) | Egrバルブ | |

| JP5355792B2 (ja) | ステップタイプバルブ | |

| US20140252259A1 (en) | Butterfly valve | |

| KR20150082560A (ko) | 개선된 시일링을 가지는 오버몰딩된 전동식 밸브 | |

| US20110139132A1 (en) | Exhaust gas recirculation valve thrust collar | |

| JP2020128711A (ja) | 冷却水制御弁装置 | |

| JP5924247B2 (ja) | バルブ装置 | |

| JP2011196464A (ja) | ボール弁型バルブ装置 | |

| JP2016501336A (ja) | 内燃機関のフラップ装置 | |

| JP6247458B2 (ja) | 車両用排気ガス再循環バルブ | |

| JP5335167B2 (ja) | バルブの軸シール構造 | |

| JP2012107572A (ja) | Egrバルブ | |

| JP5664599B2 (ja) | バルブ装置 | |

| JP5185725B2 (ja) | 蒸気タービン用蒸気弁 | |

| JP2005256765A (ja) | 内燃機関の排気制御装置 | |

| JP2012052637A (ja) | 流体制御弁 | |

| EP2065573B1 (en) | Gasket for a valve of an internal combustion engine | |

| JP2012127207A (ja) | バタフライバルブ | |

| JP2017160880A (ja) | 排気管開閉弁装置 | |

| JP2016048050A (ja) | Egr装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20120605 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130612 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130814 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5345708 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313111 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |