JP5126040B2 - マグネットピース成形用金型およびマグネットピースの製造方法 - Google Patents

マグネットピース成形用金型およびマグネットピースの製造方法 Download PDFInfo

- Publication number

- JP5126040B2 JP5126040B2 JP2008315118A JP2008315118A JP5126040B2 JP 5126040 B2 JP5126040 B2 JP 5126040B2 JP 2008315118 A JP2008315118 A JP 2008315118A JP 2008315118 A JP2008315118 A JP 2008315118A JP 5126040 B2 JP5126040 B2 JP 5126040B2

- Authority

- JP

- Japan

- Prior art keywords

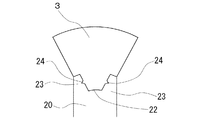

- magnet piece

- mold

- cavity

- ejector

- magnet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000000465 moulding Methods 0.000 title claims description 25

- 238000004519 manufacturing process Methods 0.000 title claims description 7

- 239000000463 material Substances 0.000 claims description 14

- 229920005989 resin Polymers 0.000 claims description 14

- 239000011347 resin Substances 0.000 claims description 14

- 230000002093 peripheral effect Effects 0.000 claims description 7

- 238000001816 cooling Methods 0.000 claims description 2

- 230000000694 effects Effects 0.000 description 6

- 239000000843 powder Substances 0.000 description 5

- 238000010586 diagram Methods 0.000 description 3

- -1 for example Substances 0.000 description 3

- QLZJUIZVJLSNDD-UHFFFAOYSA-N 2-(2-methylidenebutanoyloxy)ethyl 2-methylidenebutanoate Chemical compound CCC(=C)C(=O)OCCOC(=O)C(=C)CC QLZJUIZVJLSNDD-UHFFFAOYSA-N 0.000 description 2

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical group [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 2

- 239000011230 binding agent Substances 0.000 description 2

- 230000005489 elastic deformation Effects 0.000 description 2

- 229920006244 ethylene-ethyl acrylate Polymers 0.000 description 2

- 239000005042 ethylene-ethyl acrylate Substances 0.000 description 2

- 230000004907 flux Effects 0.000 description 2

- 238000012423 maintenance Methods 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- 239000004952 Polyamide Substances 0.000 description 1

- 239000004698 Polyethylene Substances 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- 238000007792 addition Methods 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 238000012217 deletion Methods 0.000 description 1

- 230000037430 deletion Effects 0.000 description 1

- 239000003822 epoxy resin Substances 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 229920000647 polyepoxide Polymers 0.000 description 1

- 229920000573 polyethylene Polymers 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 238000005086 pumping Methods 0.000 description 1

- 229910052761 rare earth metal Inorganic materials 0.000 description 1

- 150000002910 rare earth metals Chemical class 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 238000009966 trimming Methods 0.000 description 1

- 229910000859 α-Fe Inorganic materials 0.000 description 1

Images

Landscapes

- Magnetic Brush Developing In Electrophotography (AREA)

- Manufacturing Cores, Coils, And Magnets (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008315118A JP5126040B2 (ja) | 2008-12-11 | 2008-12-11 | マグネットピース成形用金型およびマグネットピースの製造方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008315118A JP5126040B2 (ja) | 2008-12-11 | 2008-12-11 | マグネットピース成形用金型およびマグネットピースの製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2010141062A JP2010141062A (ja) | 2010-06-24 |

| JP2010141062A5 JP2010141062A5 (enExample) | 2011-09-15 |

| JP5126040B2 true JP5126040B2 (ja) | 2013-01-23 |

Family

ID=42350952

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008315118A Expired - Fee Related JP5126040B2 (ja) | 2008-12-11 | 2008-12-11 | マグネットピース成形用金型およびマグネットピースの製造方法 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5126040B2 (enExample) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5825795B2 (ja) * | 2011-02-03 | 2015-12-02 | キヤノン株式会社 | 現像装置、及びマグネットローラ |

| JP5936753B2 (ja) * | 2015-06-01 | 2016-06-22 | キヤノン株式会社 | 現像装置、及びマグネットローラ |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0715126B2 (ja) * | 1987-05-18 | 1995-02-22 | 本田技研工業株式会社 | 焼結成形品の圧粉成型方法 |

| JP3869024B2 (ja) * | 1994-09-13 | 2007-01-17 | 株式会社カネカ | 射出成形マグネットロールの製造方法及び製造装置 |

| JPH08142108A (ja) * | 1994-11-24 | 1996-06-04 | Hitachi Metals Ltd | マグネットロール用永久磁石部材の製造方法 |

| JPH09125103A (ja) * | 1995-11-07 | 1997-05-13 | Honda Motor Co Ltd | Ti合金の圧粉成形方法とその装置 |

| JP3441593B2 (ja) * | 1996-03-28 | 2003-09-02 | 株式会社リコー | 現像装置 |

| JPH1067030A (ja) * | 1996-06-17 | 1998-03-10 | Kanegafuchi Chem Ind Co Ltd | マグネットロールの成形装置及び成形方法 |

| JP3308187B2 (ja) * | 1997-03-27 | 2002-07-29 | 株式会社ブリヂストン | マグネットローラの製造方法 |

| JPH1177783A (ja) * | 1997-09-08 | 1999-03-23 | Kanegafuchi Chem Ind Co Ltd | マグネットロールの成形装置及び成形方法 |

| JPH11224815A (ja) * | 1998-02-04 | 1999-08-17 | Bridgestone Corp | マグネットローラ成形用金型及び該金型を用いたマグネットローラの製造方法 |

| JPH11224814A (ja) * | 1998-02-04 | 1999-08-17 | Bridgestone Corp | マグネットローラ成形用金型及び該金型を用いたマグネットローラの製造方法 |

| JP3485485B2 (ja) * | 1998-12-28 | 2004-01-13 | 住友特殊金属株式会社 | 粉体プレス装置、パンチ及び粉体プレス方法 |

| JP2002365915A (ja) * | 2001-06-05 | 2002-12-20 | Ricoh Co Ltd | 現像ローラ及びその製造方法並びに現像装置、画像形成装置 |

| JP3936231B2 (ja) * | 2002-04-22 | 2007-06-27 | 鈴鹿富士ゼロックス株式会社 | 射出成形金型 |

| JP3989284B2 (ja) * | 2002-04-22 | 2007-10-10 | 株式会社リコー | マグネットブロック、現像ローラ、現像装置及び画像形成装置 |

| JP2007105992A (ja) * | 2005-10-13 | 2007-04-26 | Bridgestone Corp | マグネットローラの製造方法 |

| JP4920984B2 (ja) * | 2006-02-03 | 2012-04-18 | 株式会社リコー | マグネットローラ、現像剤担持体、現像装置、プロセスカートリッジ、画像形成装置 |

| JP4949883B2 (ja) * | 2007-02-14 | 2012-06-13 | 株式会社リコー | 現像剤担持体、現像装置、プロセスカートリッジ及び画像形成装置 |

-

2008

- 2008-12-11 JP JP2008315118A patent/JP5126040B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2010141062A (ja) | 2010-06-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2009066858A (ja) | 樹脂成形品、樹脂成形品の成形方法、及び成形用金型 | |

| JP5126040B2 (ja) | マグネットピース成形用金型およびマグネットピースの製造方法 | |

| CN111231238B (zh) | 注塑成型模具 | |

| JP6138863B2 (ja) | 射出成形方法、及び射出成形装置 | |

| JP2007136809A (ja) | 樹脂成形金型 | |

| JP5471170B2 (ja) | 長尺成形品用金型および長尺成形品の製造方法 | |

| JP2005178066A (ja) | 射出成形方法及びこの成形方法により成形された成形品 | |

| JP2010110893A (ja) | 射出成形用金型 | |

| JP5351196B2 (ja) | シールリング | |

| JP6400401B2 (ja) | 成形用金型、及び成形方法 | |

| JP2010162782A (ja) | 長尺成形品用金型 | |

| JP2018134780A (ja) | 摺動部材の製造方法 | |

| JP2011071148A (ja) | 多数個取り金型、マグネットピースの製造方法およびマグネットロールの製造方法 | |

| JP4727341B2 (ja) | シールリングの成形方法および成形用金型 | |

| JP4040963B2 (ja) | 射出成形金型 | |

| JP6058458B2 (ja) | ダイカスト鋳造用金型 | |

| JP3869024B2 (ja) | 射出成形マグネットロールの製造方法及び製造装置 | |

| JP4590135B2 (ja) | 成形用金型 | |

| JP6572384B2 (ja) | 射出成形装置 | |

| JP5892009B2 (ja) | コイル装置及びその製造方法 | |

| JP2011201103A (ja) | レンズ成形方法 | |

| JP6314003B2 (ja) | 射出成形用金型、及び成形品 | |

| JP2010141062A5 (enExample) | ||

| US10406736B1 (en) | Method for manufacturing sliding component | |

| JP4134180B2 (ja) | 射出成形用金型及び射出成形方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A712 Effective date: 20100630 |

|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A711 Effective date: 20101007 |

|

| RD03 | Notification of appointment of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7423 Effective date: 20101007 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110801 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110801 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120719 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120731 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120912 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20121002 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20121015 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 Ref document number: 5126040 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20151109 Year of fee payment: 3 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| LAPS | Cancellation because of no payment of annual fees |