JP4588885B2 - プラズマ処理システム及びプラズマ処理方法並びにガス注入器 - Google Patents

プラズマ処理システム及びプラズマ処理方法並びにガス注入器 Download PDFInfo

- Publication number

- JP4588885B2 JP4588885B2 JP2000592857A JP2000592857A JP4588885B2 JP 4588885 B2 JP4588885 B2 JP 4588885B2 JP 2000592857 A JP2000592857 A JP 2000592857A JP 2000592857 A JP2000592857 A JP 2000592857A JP 4588885 B2 JP4588885 B2 JP 4588885B2

- Authority

- JP

- Japan

- Prior art keywords

- gas

- gas injector

- substrate

- injector

- chamber

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000012545 processing Methods 0.000 title claims description 74

- 238000003672 processing method Methods 0.000 title 1

- 239000000758 substrate Substances 0.000 claims description 136

- 238000000034 method Methods 0.000 claims description 108

- 230000008569 process Effects 0.000 claims description 89

- 238000002347 injection Methods 0.000 claims description 44

- 239000007924 injection Substances 0.000 claims description 44

- 229910021420 polycrystalline silicon Inorganic materials 0.000 claims description 24

- 229920005591 polysilicon Polymers 0.000 claims description 24

- 239000000460 chlorine Substances 0.000 claims description 12

- 239000004065 semiconductor Substances 0.000 claims description 10

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 claims description 9

- 238000001020 plasma etching Methods 0.000 claims description 9

- 229910052801 chlorine Inorganic materials 0.000 claims description 8

- 230000001154 acute effect Effects 0.000 claims description 7

- 229910052782 aluminium Inorganic materials 0.000 claims description 7

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 7

- 238000005229 chemical vapour deposition Methods 0.000 claims description 6

- ZAMOUSCENKQFHK-UHFFFAOYSA-N Chlorine atom Chemical compound [Cl] ZAMOUSCENKQFHK-UHFFFAOYSA-N 0.000 claims description 4

- 229910052731 fluorine Inorganic materials 0.000 claims description 4

- 229910052794 bromium Inorganic materials 0.000 claims description 3

- 239000003989 dielectric material Substances 0.000 claims description 3

- 239000011737 fluorine Substances 0.000 claims description 3

- WKBOTKDWSSQWDR-UHFFFAOYSA-N Bromine atom Chemical compound [Br] WKBOTKDWSSQWDR-UHFFFAOYSA-N 0.000 claims 2

- YCKRFDGAMUMZLT-UHFFFAOYSA-N Fluorine atom Chemical compound [F] YCKRFDGAMUMZLT-UHFFFAOYSA-N 0.000 claims 2

- GDTBXPJZTBHREO-UHFFFAOYSA-N bromine Substances BrBr GDTBXPJZTBHREO-UHFFFAOYSA-N 0.000 claims 2

- 229910052814 silicon oxide Inorganic materials 0.000 claims 2

- 238000007789 sealing Methods 0.000 claims 1

- 239000007789 gas Substances 0.000 description 276

- 235000012431 wafers Nutrition 0.000 description 33

- 238000000151 deposition Methods 0.000 description 16

- 230000008021 deposition Effects 0.000 description 16

- 238000005530 etching Methods 0.000 description 14

- 238000009616 inductively coupled plasma Methods 0.000 description 12

- 230000005684 electric field Effects 0.000 description 9

- 150000002500 ions Chemical class 0.000 description 9

- 238000013461 design Methods 0.000 description 8

- 230000000694 effects Effects 0.000 description 8

- 239000000376 reactant Substances 0.000 description 7

- 239000006185 dispersion Substances 0.000 description 6

- 239000000463 material Substances 0.000 description 6

- 239000006227 byproduct Substances 0.000 description 5

- 238000009826 distribution Methods 0.000 description 5

- 238000005268 plasma chemical vapour deposition Methods 0.000 description 5

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 4

- 238000009792 diffusion process Methods 0.000 description 4

- 230000002093 peripheral effect Effects 0.000 description 4

- 235000012239 silicon dioxide Nutrition 0.000 description 4

- 230000015572 biosynthetic process Effects 0.000 description 3

- 125000001309 chloro group Chemical group Cl* 0.000 description 3

- 230000004907 flux Effects 0.000 description 3

- 229910052751 metal Inorganic materials 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

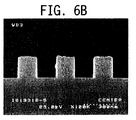

- 238000001878 scanning electron micrograph Methods 0.000 description 3

- 229910052710 silicon Inorganic materials 0.000 description 3

- 239000010703 silicon Substances 0.000 description 3

- 239000000377 silicon dioxide Substances 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- 125000003821 2-(trimethylsilyl)ethoxymethyl group Chemical group [H]C([H])([H])[Si](C([H])([H])[H])(C([H])([H])[H])C([H])([H])C(OC([H])([H])[*])([H])[H] 0.000 description 2

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- 230000002411 adverse Effects 0.000 description 2

- 238000013459 approach Methods 0.000 description 2

- 238000011109 contamination Methods 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- 230000008878 coupling Effects 0.000 description 2

- 238000010168 coupling process Methods 0.000 description 2

- 238000005859 coupling reaction Methods 0.000 description 2

- 238000000354 decomposition reaction Methods 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 238000010494 dissociation reaction Methods 0.000 description 2

- 230000005593 dissociations Effects 0.000 description 2

- 239000010408 film Substances 0.000 description 2

- 229910052736 halogen Inorganic materials 0.000 description 2

- 150000002367 halogens Chemical class 0.000 description 2

- 238000007654 immersion Methods 0.000 description 2

- 238000002513 implantation Methods 0.000 description 2

- 239000011261 inert gas Substances 0.000 description 2

- 229920002120 photoresistant polymer Polymers 0.000 description 2

- 229920000642 polymer Polymers 0.000 description 2

- -1 quartz Chemical compound 0.000 description 2

- 238000004626 scanning electron microscopy Methods 0.000 description 2

- 239000007921 spray Substances 0.000 description 2

- 238000009827 uniform distribution Methods 0.000 description 2

- BSYNRYMUTXBXSQ-UHFFFAOYSA-N Aspirin Chemical compound CC(=O)OC1=CC=CC=C1C(O)=O BSYNRYMUTXBXSQ-UHFFFAOYSA-N 0.000 description 1

- PXGOKWXKJXAPGV-UHFFFAOYSA-N Fluorine Chemical compound FF PXGOKWXKJXAPGV-UHFFFAOYSA-N 0.000 description 1

- 230000003213 activating effect Effects 0.000 description 1

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 1

- 229910021417 amorphous silicon Inorganic materials 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 239000012159 carrier gas Substances 0.000 description 1

- 238000005266 casting Methods 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 239000007806 chemical reaction intermediate Substances 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 230000001627 detrimental effect Effects 0.000 description 1

- 230000009977 dual effect Effects 0.000 description 1

- 230000005520 electrodynamics Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000002360 explosive Substances 0.000 description 1

- 150000008282 halocarbons Chemical class 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 150000002431 hydrogen Chemical class 0.000 description 1

- 239000007943 implant Substances 0.000 description 1

- 239000000543 intermediate Substances 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 150000004767 nitrides Chemical class 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 238000009828 non-uniform distribution Methods 0.000 description 1

- 238000005457 optimization Methods 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 230000008092 positive effect Effects 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 239000010453 quartz Substances 0.000 description 1

- 239000012048 reactive intermediate Substances 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 238000005245 sintering Methods 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

- 238000000427 thin-film deposition Methods 0.000 description 1

Images

Classifications

-

- H01L21/205—

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

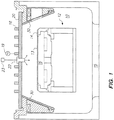

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/32431—Constructional details of the reactor

- H01J37/3244—Gas supply means

Landscapes

- Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Plasma & Fusion (AREA)

- Chemical & Material Sciences (AREA)

- Analytical Chemistry (AREA)

- Drying Of Semiconductors (AREA)

- Physical Or Chemical Processes And Apparatus (AREA)

- Chemical Vapour Deposition (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US09/223,273 US6230651B1 (en) | 1998-12-30 | 1998-12-30 | Gas injection system for plasma processing |

| US09/223,273 | 1998-12-30 | ||

| PCT/US1999/027917 WO2000041212A1 (en) | 1998-12-30 | 1999-12-07 | Gas injection system for plasma processing |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2002534797A JP2002534797A (ja) | 2002-10-15 |

| JP2002534797A5 JP2002534797A5 (enExample) | 2007-04-05 |

| JP4588885B2 true JP4588885B2 (ja) | 2010-12-01 |

Family

ID=22835796

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2000592857A Expired - Lifetime JP4588885B2 (ja) | 1998-12-30 | 1999-12-07 | プラズマ処理システム及びプラズマ処理方法並びにガス注入器 |

Country Status (7)

| Country | Link |

|---|---|

| US (3) | US6230651B1 (enExample) |

| EP (1) | EP1145277B1 (enExample) |

| JP (1) | JP4588885B2 (enExample) |

| KR (1) | KR100665646B1 (enExample) |

| IL (1) | IL144001A (enExample) |

| TW (1) | TW548680B (enExample) |

| WO (1) | WO2000041212A1 (enExample) |

Families Citing this family (114)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6129808A (en) * | 1998-03-31 | 2000-10-10 | Lam Research Corporation | Low contamination high density plasma etch chambers and methods for making the same |

| US6230651B1 (en) * | 1998-12-30 | 2001-05-15 | Lam Research Corporation | Gas injection system for plasma processing |

| US6432259B1 (en) | 1999-12-14 | 2002-08-13 | Applied Materials, Inc. | Plasma reactor cooled ceiling with an array of thermally isolated plasma heated mini-gas distribution plates |

| US6451161B1 (en) * | 2000-04-10 | 2002-09-17 | Nano-Architect Research Corporation | Method and apparatus for generating high-density uniform plasma |

| US6403491B1 (en) * | 2000-11-01 | 2002-06-11 | Applied Materials, Inc. | Etch method using a dielectric etch chamber with expanded process window |

| US6797639B2 (en) * | 2000-11-01 | 2004-09-28 | Applied Materials Inc. | Dielectric etch chamber with expanded process window |

| KR100413145B1 (ko) * | 2001-01-11 | 2003-12-31 | 삼성전자주식회사 | 가스 인젝터 및 이를 갖는 식각 장치 |

| US6852167B2 (en) * | 2001-03-01 | 2005-02-08 | Micron Technology, Inc. | Methods, systems, and apparatus for uniform chemical-vapor depositions |

| US6758909B2 (en) * | 2001-06-05 | 2004-07-06 | Honeywell International Inc. | Gas port sealing for CVD/CVI furnace hearth plates |

| US6548416B2 (en) * | 2001-07-24 | 2003-04-15 | Axcelis Technolgoies, Inc. | Plasma ashing process |

| EP1421606A4 (en) * | 2001-08-06 | 2008-03-05 | Genitech Co Ltd | PLASMA ACTIVE ATOMIC LAYER (PEALD) DEPOSITION APPARATUS AND METHOD OF FORMING THIN FILM USING SAID APPARATUS |

| US20030070620A1 (en) * | 2001-10-15 | 2003-04-17 | Cooperberg David J. | Tunable multi-zone gas injection system |

| US7160577B2 (en) | 2002-05-02 | 2007-01-09 | Micron Technology, Inc. | Methods for atomic-layer deposition of aluminum oxides in integrated circuits |

| JP4338355B2 (ja) * | 2002-05-10 | 2009-10-07 | 東京エレクトロン株式会社 | プラズマ処理装置 |

| US7861667B2 (en) * | 2002-05-23 | 2011-01-04 | Lam Research Corporation | Multi-part electrode for a semiconductor processing plasma reactor and method of replacing a portion of a multi-part electrode |

| DE10392996T5 (de) * | 2002-08-08 | 2005-07-21 | Trikon Technologies Limited, Newport | Verbesserungen für Duschköpfe |

| US7270713B2 (en) * | 2003-01-07 | 2007-09-18 | Applied Materials, Inc. | Tunable gas distribution plate assembly |

| WO2004088729A1 (en) * | 2003-03-26 | 2004-10-14 | Tokyo Electron Limited | Chemical processing system and method |

| US6942753B2 (en) * | 2003-04-16 | 2005-09-13 | Applied Materials, Inc. | Gas distribution plate assembly for large area plasma enhanced chemical vapor deposition |

| KR20060011887A (ko) * | 2003-05-30 | 2006-02-03 | 에비자 테크놀로지, 인크. | 가스 분산 시스템 |

| US7083903B2 (en) * | 2003-06-17 | 2006-08-01 | Lam Research Corporation | Methods of etching photoresist on substrates |

| JP2005072446A (ja) * | 2003-08-27 | 2005-03-17 | Chi Mei Electronics Corp | プラズマ処理装置及び基板の表面処理装置 |

| KR100859265B1 (ko) * | 2003-12-30 | 2008-09-18 | 동부일렉트로닉스 주식회사 | 반도체 제조 설비의 공정 가스 유입관 구조 |

| KR101025323B1 (ko) * | 2004-01-13 | 2011-03-29 | 가부시키가이샤 아루박 | 에칭 장치 및 에칭 방법 |

| US20070066038A1 (en) | 2004-04-30 | 2007-03-22 | Lam Research Corporation | Fast gas switching plasma processing apparatus |

| US7708859B2 (en) * | 2004-04-30 | 2010-05-04 | Lam Research Corporation | Gas distribution system having fast gas switching capabilities |

| US20060021703A1 (en) * | 2004-07-29 | 2006-02-02 | Applied Materials, Inc. | Dual gas faceplate for a showerhead in a semiconductor wafer processing system |

| US7081421B2 (en) | 2004-08-26 | 2006-07-25 | Micron Technology, Inc. | Lanthanide oxide dielectric layer |

| US7494939B2 (en) | 2004-08-31 | 2009-02-24 | Micron Technology, Inc. | Methods for forming a lanthanum-metal oxide dielectric layer |

| US20060051965A1 (en) * | 2004-09-07 | 2006-03-09 | Lam Research Corporation | Methods of etching photoresist on substrates |

| US7235501B2 (en) | 2004-12-13 | 2007-06-26 | Micron Technology, Inc. | Lanthanum hafnium oxide dielectrics |

| KR20060076346A (ko) * | 2004-12-29 | 2006-07-04 | 주식회사 하이닉스반도체 | 반도체 제조용 고밀도 플라즈마 화학기상증착 장치 |

| JP3984638B2 (ja) * | 2005-03-30 | 2007-10-03 | 松下電器産業株式会社 | 伝送線路対及び伝送線路群 |

| US7662729B2 (en) | 2005-04-28 | 2010-02-16 | Micron Technology, Inc. | Atomic layer deposition of a ruthenium layer to a lanthanide oxide dielectric layer |

| KR100522166B1 (ko) * | 2005-05-26 | 2005-10-18 | 한국기계연구원 | 플라즈마 반응장치 |

| US7927948B2 (en) | 2005-07-20 | 2011-04-19 | Micron Technology, Inc. | Devices with nanocrystals and methods of formation |

| US20070032081A1 (en) * | 2005-08-08 | 2007-02-08 | Jeremy Chang | Edge ring assembly with dielectric spacer ring |

| JP4628900B2 (ja) * | 2005-08-24 | 2011-02-09 | 株式会社日立ハイテクノロジーズ | プラズマ処理装置 |

| US7703479B2 (en) * | 2005-10-17 | 2010-04-27 | The University Of Kentucky Research Foundation | Plasma actuator |

| US20090087967A1 (en) * | 2005-11-14 | 2009-04-02 | Todd Michael A | Precursors and processes for low temperature selective epitaxial growth |

| KR100707983B1 (ko) * | 2005-11-28 | 2007-04-16 | 주식회사 에이이티 | 산화막의 원자층 에칭방법 |

| US7679024B2 (en) * | 2005-12-23 | 2010-03-16 | Lam Research Corporation | Highly efficient gas distribution arrangement for plasma tube of a plasma processing chamber |

| US7562638B2 (en) * | 2005-12-23 | 2009-07-21 | Lam Research Corporation | Methods and arrangement for implementing highly efficient plasma traps |

| US7554053B2 (en) * | 2005-12-23 | 2009-06-30 | Lam Research Corporation | Corrugated plasma trap arrangement for creating a highly efficient downstream microwave plasma system |

| US8088248B2 (en) * | 2006-01-11 | 2012-01-03 | Lam Research Corporation | Gas switching section including valves having different flow coefficients for gas distribution system |

| US7685965B1 (en) * | 2006-01-26 | 2010-03-30 | Lam Research Corporation | Apparatus for shielding process chamber port |

| JP4833778B2 (ja) * | 2006-02-13 | 2011-12-07 | 東京エレクトロン株式会社 | 基板処理装置及び基板処理方法 |

| JP4674177B2 (ja) * | 2006-03-15 | 2011-04-20 | 株式会社日立ハイテクノロジーズ | プラズマ処理装置 |

| US20070249173A1 (en) * | 2006-04-21 | 2007-10-25 | Applied Materials, Inc. | Plasma etch process using etch uniformity control by using compositionally independent gas feed |

| US8187415B2 (en) * | 2006-04-21 | 2012-05-29 | Applied Materials, Inc. | Plasma etch reactor with distribution of etch gases across a wafer surface and a polymer oxidizing gas in an independently fed center gas zone |

| US7540971B2 (en) * | 2006-04-28 | 2009-06-02 | Applied Materials, Inc. | Plasma etch process using polymerizing etch gases across a wafer surface and additional polymer managing or controlling gases in independently fed gas zones with time and spatial modulation of gas content |

| US20070254483A1 (en) * | 2006-04-28 | 2007-11-01 | Applied Materials, Inc. | Plasma etch process using polymerizing etch gases and an inert diluent gas in independent gas injection zones to improve etch profile or etch rate uniformity |

| US8231799B2 (en) * | 2006-04-28 | 2012-07-31 | Applied Materials, Inc. | Plasma reactor apparatus with multiple gas injection zones having time-changing separate configurable gas compositions for each zone |

| US7431859B2 (en) * | 2006-04-28 | 2008-10-07 | Applied Materials, Inc. | Plasma etch process using polymerizing etch gases with different etch and polymer-deposition rates in different radial gas injection zones with time modulation |

| US7541292B2 (en) * | 2006-04-28 | 2009-06-02 | Applied Materials, Inc. | Plasma etch process with separately fed carbon-lean and carbon-rich polymerizing etch gases in independent inner and outer gas injection zones |

| JP5337482B2 (ja) * | 2006-05-09 | 2013-11-06 | 株式会社アルバック | 薄膜製造装置 |

| US7605063B2 (en) * | 2006-05-10 | 2009-10-20 | Lam Research Corporation | Photoresist stripping chamber and methods of etching photoresist on substrates |

| KR100748872B1 (ko) * | 2006-06-09 | 2007-08-13 | 에이피티씨 주식회사 | 가스 공급 인젝터를 포함하는 플라즈마 공정 장비 |

| US7928366B2 (en) * | 2006-10-06 | 2011-04-19 | Lam Research Corporation | Methods of and apparatus for accessing a process chamber using a dual zone gas injector with improved optical access |

| WO2008005539A2 (en) * | 2006-07-07 | 2008-01-10 | Accretech Usa, Inc. | Apparatus for cleaning a wafer substrate |

| US7972471B2 (en) * | 2007-06-29 | 2011-07-05 | Lam Research Corporation | Inductively coupled dual zone processing chamber with single planar antenna |

| KR20090018290A (ko) * | 2007-08-17 | 2009-02-20 | 에이에스엠지니텍코리아 주식회사 | 증착 장치 |

| US20090221149A1 (en) * | 2008-02-28 | 2009-09-03 | Hammond Iv Edward P | Multiple port gas injection system utilized in a semiconductor processing system |

| JP5223377B2 (ja) | 2008-02-29 | 2013-06-26 | 東京エレクトロン株式会社 | プラズマ処理装置用の電極、プラズマ処理装置及びプラズマ処理方法 |

| JP5230225B2 (ja) * | 2008-03-06 | 2013-07-10 | 東京エレクトロン株式会社 | 蓋部品、処理ガス拡散供給装置、及び基板処理装置 |

| CN102187741B (zh) * | 2008-10-31 | 2014-08-06 | 朗姆研究公司 | 等离子体处理腔室的下电极组件 |

| KR200475462Y1 (ko) * | 2009-03-27 | 2014-12-03 | 램 리써치 코포레이션 | 플라즈마 처리 장치의 교체 가능한 상부 챔버 섹션 |

| US8415884B2 (en) * | 2009-09-08 | 2013-04-09 | Tokyo Electron Limited | Stable surface wave plasma source |

| KR200478069Y1 (ko) * | 2009-09-10 | 2015-08-24 | 램 리써치 코포레이션 | 플라즈마 처리 장치의 교체가능한 상부 체임버 부품 |

| JP5808750B2 (ja) * | 2009-11-30 | 2015-11-10 | ラム リサーチ コーポレーションLam Research Corporation | 傾斜側壁を備える静電チャック |

| DE202010015933U1 (de) | 2009-12-01 | 2011-03-31 | Lam Research Corp.(N.D.Ges.D.Staates Delaware), Fremont | Eine Randringanordnung für Plasmaätzkammern |

| US20110278260A1 (en) | 2010-05-14 | 2011-11-17 | Applied Materials, Inc. | Inductive plasma source with metallic shower head using b-field concentrator |

| US9171702B2 (en) | 2010-06-30 | 2015-10-27 | Lam Research Corporation | Consumable isolation ring for movable substrate support assembly of a plasma processing chamber |

| US8485128B2 (en) | 2010-06-30 | 2013-07-16 | Lam Research Corporation | Movable ground ring for a plasma processing chamber |

| US8826855B2 (en) | 2010-06-30 | 2014-09-09 | Lam Research Corporation | C-shaped confinement ring for a plasma processing chamber |

| US9728429B2 (en) | 2010-07-27 | 2017-08-08 | Lam Research Corporation | Parasitic plasma prevention in plasma processing chambers |

| US10658161B2 (en) * | 2010-10-15 | 2020-05-19 | Applied Materials, Inc. | Method and apparatus for reducing particle defects in plasma etch chambers |

| US8133349B1 (en) | 2010-11-03 | 2012-03-13 | Lam Research Corporation | Rapid and uniform gas switching for a plasma etch process |

| US8288174B1 (en) | 2011-03-24 | 2012-10-16 | Tokyo Electron Limited | Electrostatic post exposure bake apparatus and method |

| US9245717B2 (en) | 2011-05-31 | 2016-01-26 | Lam Research Corporation | Gas distribution system for ceramic showerhead of plasma etch reactor |

| US8562785B2 (en) | 2011-05-31 | 2013-10-22 | Lam Research Corporation | Gas distribution showerhead for inductively coupled plasma etch reactor |

| US9947512B2 (en) * | 2011-10-25 | 2018-04-17 | Lam Research Corporation | Window and mounting arrangement for twist-and-lock gas injector assembly of inductively coupled plasma chamber |

| US9679751B2 (en) | 2012-03-15 | 2017-06-13 | Lam Research Corporation | Chamber filler kit for plasma etch chamber useful for fast gas switching |

| US10174422B2 (en) * | 2012-10-25 | 2019-01-08 | Applied Materials, Inc. | Apparatus for selective gas injection and extraction |

| WO2014119177A1 (ja) * | 2013-01-30 | 2014-08-07 | 京セラ株式会社 | ガスノズルおよびこれを用いたプラズマ装置 |

| US9314854B2 (en) | 2013-01-30 | 2016-04-19 | Lam Research Corporation | Ductile mode drilling methods for brittle components of plasma processing apparatuses |

| US8893702B2 (en) | 2013-02-20 | 2014-11-25 | Lam Research Corporation | Ductile mode machining methods for hard and brittle components of plasma processing apparatuses |

| US9536710B2 (en) * | 2013-02-25 | 2017-01-03 | Applied Materials, Inc. | Tunable gas delivery assembly with internal diffuser and angular injection |

| KR102104018B1 (ko) * | 2013-03-12 | 2020-04-23 | 어플라이드 머티어리얼스, 인코포레이티드 | 방위각 및 방사상 분배 제어되는 다중-구역 가스 주입 조립체 |

| US10163606B2 (en) | 2013-03-15 | 2018-12-25 | Applied Materials, Inc. | Plasma reactor with highly symmetrical four-fold gas injection |

| US9449797B2 (en) | 2013-05-07 | 2016-09-20 | Lam Research Corporation | Component of a plasma processing apparatus having a protective in situ formed layer on a plasma exposed surface |

| US9275869B2 (en) * | 2013-08-02 | 2016-03-01 | Lam Research Corporation | Fast-gas switching for etching |

| US9123661B2 (en) | 2013-08-07 | 2015-09-01 | Lam Research Corporation | Silicon containing confinement ring for plasma processing apparatus and method of forming thereof |

| US10553398B2 (en) * | 2013-09-06 | 2020-02-04 | Applied Materials, Inc. | Power deposition control in inductively coupled plasma (ICP) reactors |

| US10249511B2 (en) * | 2014-06-27 | 2019-04-02 | Lam Research Corporation | Ceramic showerhead including central gas injector for tunable convective-diffusive gas flow in semiconductor substrate processing apparatus |

| JP6499835B2 (ja) * | 2014-07-24 | 2019-04-10 | 株式会社日立ハイテクノロジーズ | プラズマ処理装置およびプラズマ処理方法 |

| US10465288B2 (en) * | 2014-08-15 | 2019-11-05 | Applied Materials, Inc. | Nozzle for uniform plasma processing |

| US9966270B2 (en) * | 2015-03-31 | 2018-05-08 | Lam Research Corporation | Gas reaction trajectory control through tunable plasma dissociation for wafer by-product distribution and etch feature profile uniformity |

| KR101633721B1 (ko) * | 2015-11-27 | 2016-06-27 | (주)이엠아이티 | 수직 다중 기둥 구조를 갖는 rf 안테나 |

| US9716005B1 (en) | 2016-03-18 | 2017-07-25 | Applied Materials, Inc. | Plasma poisoning to enable selective deposition |

| KR102553629B1 (ko) * | 2016-06-17 | 2023-07-11 | 삼성전자주식회사 | 플라즈마 처리 장치 |

| US20190032211A1 (en) * | 2017-07-28 | 2019-01-31 | Lam Research Corporation | Monolithic ceramic gas distribution plate |

| US11670490B2 (en) * | 2017-09-29 | 2023-06-06 | Taiwan Semiconductor Manufacturing Co., Ltd. | Integrated circuit fabrication system with adjustable gas injector |

| US10840066B2 (en) | 2018-06-13 | 2020-11-17 | Taiwan Semiconductor Manufacturing Co., Ltd. | Adjustable fastening device for plasma gas injectors |

| CN110223904A (zh) * | 2019-07-19 | 2019-09-10 | 江苏鲁汶仪器有限公司 | 一种具有法拉第屏蔽装置的等离子体处理系统 |

| CN111081525B (zh) * | 2019-12-31 | 2021-06-08 | 江苏鲁汶仪器有限公司 | 一种阻挡工艺腔室等离子体反流保护进气结构的装置 |

| WO2021206950A1 (en) * | 2020-04-06 | 2021-10-14 | Lam Research Corporation | Ceramic additive manufacturing techniques for gas injectors |

| CN113707527B (zh) * | 2020-05-21 | 2022-07-29 | 江苏鲁汶仪器有限公司 | 一种阻挡等离子体反流的分离式进气结构 |

| TWI767244B (zh) * | 2020-05-29 | 2022-06-11 | 朗曦科技股份有限公司 | 半導體製程腔體之氣體噴頭 |

| KR20220021206A (ko) * | 2020-08-13 | 2022-02-22 | 삼성전자주식회사 | 플라즈마 처리 장치 |

| US20230317423A1 (en) * | 2020-10-30 | 2023-10-05 | Lam Research Corporation | Magnesium aluminum oxynitride component for use in a plasma processing chamber |

| JP7543176B2 (ja) * | 2021-03-08 | 2024-09-02 | 株式会社アルバック | プラズマ処理装置およびそのメンテナンス方法 |

| JP7791677B2 (ja) * | 2021-09-16 | 2025-12-24 | 株式会社Screenホールディングス | 基板処理装置および基板処理方法 |

| KR102887338B1 (ko) * | 2022-06-22 | 2025-11-14 | 나이스 스타 코퍼레이션 | 스월 모션 사이드 가스 피드가 구비된 플라즈마 챔버 |

Family Cites Families (66)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS51144183A (en) | 1975-06-06 | 1976-12-10 | Hitachi Ltd | Semiconductor element containing surface protection film |

| DE2608417C3 (de) * | 1976-03-01 | 1981-02-12 | Degussa Ag, 6000 Frankfurt | Verfahren und vorrichtung zur herstellung von russ |

| US4270999A (en) | 1979-09-28 | 1981-06-02 | International Business Machines Corporation | Method and apparatus for gas feed control in a dry etching process |

| JPS59150417A (ja) | 1983-02-08 | 1984-08-28 | Toshiba Corp | 気相成長方法およびその装置 |

| US4691662A (en) | 1983-02-28 | 1987-09-08 | Michigan State University | Dual plasma microwave apparatus and method for treating a surface |

| JPS6077429A (ja) * | 1983-10-04 | 1985-05-02 | Asahi Glass Co Ltd | ドライエツチング方法 |

| JPS61100935A (ja) | 1984-10-23 | 1986-05-19 | Fujitsu Ltd | ドライエツチング装置 |

| US4614639A (en) | 1985-04-26 | 1986-09-30 | Tegal Corporation | Compound flow plasma reactor |

| US4612077A (en) | 1985-07-29 | 1986-09-16 | The Perkin-Elmer Corporation | Electrode for plasma etching system |

| US5160543A (en) | 1985-12-20 | 1992-11-03 | Canon Kabushiki Kaisha | Device for forming a deposited film |

| DE3885833T2 (de) | 1987-09-22 | 1994-03-24 | Nippon Electric Co | Chemischer Dampfabscheidungsapparat für die Herstellung von hochqualitativen epitaktischen Schichten mit gleichmässiger Dichte. |

| US4980204A (en) | 1987-11-27 | 1990-12-25 | Fujitsu Limited | Metal organic chemical vapor deposition method with controlled gas flow rate |

| US4996077A (en) | 1988-10-07 | 1991-02-26 | Texas Instruments Incorporated | Distributed ECR remote plasma processing and apparatus |

| US4943345A (en) | 1989-03-23 | 1990-07-24 | Board Of Trustees Operating Michigan State University | Plasma reactor apparatus and method for treating a substrate |

| US5104634A (en) * | 1989-04-20 | 1992-04-14 | Hercules Incorporated | Process for forming diamond coating using a silent discharge plasma jet process |

| US5134965A (en) | 1989-06-16 | 1992-08-04 | Hitachi, Ltd. | Processing apparatus and method for plasma processing |

| US5164040A (en) | 1989-08-21 | 1992-11-17 | Martin Marietta Energy Systems, Inc. | Method and apparatus for rapidly growing films on substrates using pulsed supersonic jets |

| JPH04355917A (ja) * | 1990-10-12 | 1992-12-09 | Seiko Epson Corp | 半導体装置の製造装置 |

| US5252132A (en) * | 1990-11-22 | 1993-10-12 | Mitsubishi Denki Kabushiki Kaisha | Apparatus for producing semiconductor film |

| JP2839720B2 (ja) | 1990-12-19 | 1998-12-16 | 株式会社東芝 | 熱処理装置 |

| US5531834A (en) | 1993-07-13 | 1996-07-02 | Tokyo Electron Kabushiki Kaisha | Plasma film forming method and apparatus and plasma processing apparatus |

| US5614055A (en) | 1993-08-27 | 1997-03-25 | Applied Materials, Inc. | High density plasma CVD and etching reactor |

| KR100264445B1 (ko) * | 1993-10-04 | 2000-11-01 | 히가시 데쓰로 | 플라즈마처리장치 |

| TW293983B (enExample) | 1993-12-17 | 1996-12-21 | Tokyo Electron Co Ltd | |

| US5680013A (en) * | 1994-03-15 | 1997-10-21 | Applied Materials, Inc. | Ceramic protection for heated metal surfaces of plasma processing chamber exposed to chemically aggressive gaseous environment therein and method of protecting such heated metal surfaces |

| US5589002A (en) * | 1994-03-24 | 1996-12-31 | Applied Materials, Inc. | Gas distribution plate for semiconductor wafer processing apparatus with means for inhibiting arcing |

| US5522934A (en) | 1994-04-26 | 1996-06-04 | Tokyo Electron Limited | Plasma processing apparatus using vertical gas inlets one on top of another |

| US5425810A (en) * | 1994-05-11 | 1995-06-20 | Internation Business Machines Corporation | Removable gas injectors for use in chemical vapor deposition of aluminium oxide |

| US5426810A (en) * | 1994-05-23 | 1995-06-27 | Americo | Abrasive pad holder |

| GB9410567D0 (en) | 1994-05-26 | 1994-07-13 | Philips Electronics Uk Ltd | Plasma treatment and apparatus in electronic device manufacture |

| US5540800A (en) | 1994-06-23 | 1996-07-30 | Applied Materials, Inc. | Inductively coupled high density plasma reactor for plasma assisted materials processing |

| US5580385A (en) | 1994-06-30 | 1996-12-03 | Texas Instruments, Incorporated | Structure and method for incorporating an inductively coupled plasma source in a plasma processing chamber |

| US5643394A (en) | 1994-09-16 | 1997-07-01 | Applied Materials, Inc. | Gas injection slit nozzle for a plasma process reactor |

| US5746875A (en) | 1994-09-16 | 1998-05-05 | Applied Materials, Inc. | Gas injection slit nozzle for a plasma process reactor |

| JP3699142B2 (ja) | 1994-09-30 | 2005-09-28 | アネルバ株式会社 | 薄膜形成装置 |

| TW285746B (enExample) * | 1994-10-26 | 1996-09-11 | Matsushita Electric Industrial Co Ltd | |

| DE4440323A1 (de) * | 1994-11-11 | 1996-05-15 | Sulzer Metco Ag | Düse für einen Brennerkopf eines Plasmaspritzgeräts |

| JPH08158072A (ja) | 1994-12-02 | 1996-06-18 | Nippon Soken Inc | ドライエッチング装置 |

| US5685942A (en) | 1994-12-05 | 1997-11-11 | Tokyo Electron Limited | Plasma processing apparatus and method |

| JPH0945624A (ja) | 1995-07-27 | 1997-02-14 | Tokyo Electron Ltd | 枚葉式の熱処理装置 |

| JP3150056B2 (ja) * | 1995-10-19 | 2001-03-26 | 東京エレクトロン株式会社 | プラズマ処理装置 |

| US5792269A (en) * | 1995-10-31 | 1998-08-11 | Applied Materials, Inc. | Gas distribution for CVD systems |

| US5772771A (en) | 1995-12-13 | 1998-06-30 | Applied Materials, Inc. | Deposition chamber for improved deposition thickness uniformity |

| US6070551A (en) * | 1996-05-13 | 2000-06-06 | Applied Materials, Inc. | Deposition chamber and method for depositing low dielectric constant films |

| US6013155A (en) * | 1996-06-28 | 2000-01-11 | Lam Research Corporation | Gas injection system for plasma processing |

| US5885358A (en) | 1996-07-09 | 1999-03-23 | Applied Materials, Inc. | Gas injection slit nozzle for a plasma process reactor |

| US6170428B1 (en) | 1996-07-15 | 2001-01-09 | Applied Materials, Inc. | Symmetric tunable inductively coupled HDP-CVD reactor |

| US6090210A (en) | 1996-07-24 | 2000-07-18 | Applied Materials, Inc. | Multi-zone gas flow control in a process chamber |

| JP3220394B2 (ja) * | 1996-09-27 | 2001-10-22 | 東京エレクトロン株式会社 | プラズマ処理装置 |

| TW415970B (en) * | 1997-01-08 | 2000-12-21 | Ebara Corp | Vapor-phase film growth apparatus and gas ejection head |

| US6077357A (en) * | 1997-05-29 | 2000-06-20 | Applied Materials, Inc. | Orientless wafer processing on an electrostatic chuck |

| US6042687A (en) | 1997-06-30 | 2000-03-28 | Lam Research Corporation | Method and apparatus for improving etch and deposition uniformity in plasma semiconductor processing |

| TW416100B (en) | 1997-07-02 | 2000-12-21 | Applied Materials Inc | Control of oxygen to silane ratio in a seasoning process to improve particle performance in an HDP-CVD system |

| US6007330A (en) | 1998-03-12 | 1999-12-28 | Cosmos Factory, Inc. | Liquid precursor delivery system |

| US6194038B1 (en) | 1998-03-20 | 2001-02-27 | Applied Materials, Inc. | Method for deposition of a conformal layer on a substrate |

| US6294466B1 (en) | 1998-05-01 | 2001-09-25 | Applied Materials, Inc. | HDP-CVD apparatus and process for depositing titanium films for semiconductor devices |

| US6143078A (en) | 1998-11-13 | 2000-11-07 | Applied Materials, Inc. | Gas distribution system for a CVD processing chamber |

| US6230651B1 (en) | 1998-12-30 | 2001-05-15 | Lam Research Corporation | Gas injection system for plasma processing |

| US6263829B1 (en) | 1999-01-22 | 2001-07-24 | Applied Materials, Inc. | Process chamber having improved gas distributor and method of manufacture |

| US6052176A (en) | 1999-03-31 | 2000-04-18 | Lam Research Corporation | Processing chamber with optical window cleaned using process gas |

| US6257168B1 (en) * | 1999-06-30 | 2001-07-10 | Lam Research Corporation | Elevated stationary uniformity ring design |

| US6287643B1 (en) | 1999-09-30 | 2001-09-11 | Novellus Systems, Inc. | Apparatus and method for injecting and modifying gas concentration of a meta-stable or atomic species in a downstream plasma reactor |

| US20030155079A1 (en) | 1999-11-15 | 2003-08-21 | Andrew D. Bailey | Plasma processing system with dynamic gas distribution control |

| US6486069B1 (en) * | 1999-12-03 | 2002-11-26 | Tegal Corporation | Cobalt silicide etch process and apparatus |

| US6450117B1 (en) | 2000-08-07 | 2002-09-17 | Applied Materials, Inc. | Directing a flow of gas in a substrate processing chamber |

| US6403491B1 (en) * | 2000-11-01 | 2002-06-11 | Applied Materials, Inc. | Etch method using a dielectric etch chamber with expanded process window |

-

1998

- 1998-12-30 US US09/223,273 patent/US6230651B1/en not_active Expired - Lifetime

-

1999

- 1999-12-07 WO PCT/US1999/027917 patent/WO2000041212A1/en not_active Ceased

- 1999-12-07 KR KR1020017008435A patent/KR100665646B1/ko not_active Expired - Lifetime

- 1999-12-07 EP EP99967134A patent/EP1145277B1/en not_active Expired - Lifetime

- 1999-12-07 JP JP2000592857A patent/JP4588885B2/ja not_active Expired - Lifetime

- 1999-12-07 IL IL14400199A patent/IL144001A/xx not_active IP Right Cessation

-

2000

- 2000-01-28 TW TW088123167A patent/TW548680B/zh not_active IP Right Cessation

-

2001

- 2001-02-21 US US09/788,365 patent/US7785417B2/en not_active Expired - Fee Related

-

2010

- 2010-08-20 US US12/805,865 patent/US8025731B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2002534797A (ja) | 2002-10-15 |

| US20010010257A1 (en) | 2001-08-02 |

| IL144001A0 (en) | 2002-04-21 |

| KR100665646B1 (ko) | 2007-01-09 |

| US20100327085A1 (en) | 2010-12-30 |

| WO2000041212A1 (en) | 2000-07-13 |

| US7785417B2 (en) | 2010-08-31 |

| KR20010101359A (ko) | 2001-11-14 |

| TW548680B (en) | 2003-08-21 |

| US6230651B1 (en) | 2001-05-15 |

| US8025731B2 (en) | 2011-09-27 |

| EP1145277A1 (en) | 2001-10-17 |

| IL144001A (en) | 2005-12-18 |

| EP1145277B1 (en) | 2012-02-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4588885B2 (ja) | プラズマ処理システム及びプラズマ処理方法並びにガス注入器 | |

| US6013155A (en) | Gas injection system for plasma processing | |

| JP5364054B2 (ja) | 調整可能なマルチゾーンガス噴射システム | |

| US6042687A (en) | Method and apparatus for improving etch and deposition uniformity in plasma semiconductor processing | |

| US5976308A (en) | High density plasma CVD and etching reactor | |

| US6417111B2 (en) | Plasma processing apparatus | |

| US6270862B1 (en) | Method for high density plasma chemical vapor deposition of dielectric films | |

| US6306244B1 (en) | Apparatus for reducing polymer deposition on substrate support |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20061205 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20061205 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100204 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100212 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100510 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100607 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100729 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20100820 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20100909 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4588885 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130917 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| EXPY | Cancellation because of completion of term |