JP2010514933A - 冷間成形用の耐食性工具 - Google Patents

冷間成形用の耐食性工具 Download PDFInfo

- Publication number

- JP2010514933A JP2010514933A JP2009543985A JP2009543985A JP2010514933A JP 2010514933 A JP2010514933 A JP 2010514933A JP 2009543985 A JP2009543985 A JP 2009543985A JP 2009543985 A JP2009543985 A JP 2009543985A JP 2010514933 A JP2010514933 A JP 2010514933A

- Authority

- JP

- Japan

- Prior art keywords

- less

- cemented carbide

- weight

- carbide

- tools

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000005260 corrosion Methods 0.000 title abstract description 13

- 230000007797 corrosion Effects 0.000 title abstract description 13

- 238000004519 manufacturing process Methods 0.000 claims abstract description 12

- 229910052804 chromium Inorganic materials 0.000 claims abstract description 7

- 229910052750 molybdenum Inorganic materials 0.000 claims abstract description 7

- 229910052759 nickel Inorganic materials 0.000 claims abstract description 7

- 238000010409 ironing Methods 0.000 claims description 14

- 235000013361 beverage Nutrition 0.000 claims description 7

- 229910000831 Steel Inorganic materials 0.000 claims description 6

- 239000010959 steel Substances 0.000 claims description 6

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 5

- 229910052799 carbon Inorganic materials 0.000 claims description 5

- 239000010419 fine particle Substances 0.000 claims description 4

- 239000002245 particle Substances 0.000 claims description 4

- 229910052782 aluminium Inorganic materials 0.000 claims description 3

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 3

- 239000000443 aerosol Substances 0.000 claims description 2

- 229910000531 Co alloy Inorganic materials 0.000 claims 3

- 229910000599 Cr alloy Inorganic materials 0.000 claims 3

- 229910001182 Mo alloy Inorganic materials 0.000 claims 3

- 229910000990 Ni alloy Inorganic materials 0.000 claims 3

- 239000000463 material Substances 0.000 abstract description 14

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 abstract description 9

- 239000000203 mixture Substances 0.000 abstract description 6

- 239000011651 chromium Substances 0.000 abstract description 5

- MTPVUVINMAGMJL-UHFFFAOYSA-N trimethyl(1,1,2,2,2-pentafluoroethyl)silane Chemical compound C[Si](C)(C)C(F)(F)C(F)(F)F MTPVUVINMAGMJL-UHFFFAOYSA-N 0.000 abstract description 3

- UONOETXJSWQNOL-UHFFFAOYSA-N tungsten carbide Chemical compound [W+]#[C-] UONOETXJSWQNOL-UHFFFAOYSA-N 0.000 abstract description 3

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 abstract description 2

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 abstract description 2

- 239000011733 molybdenum Substances 0.000 abstract description 2

- 229910017052 cobalt Inorganic materials 0.000 abstract 1

- 239000010941 cobalt Substances 0.000 abstract 1

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 abstract 1

- 239000011230 binding agent Substances 0.000 description 10

- 229910052751 metal Inorganic materials 0.000 description 6

- 239000002184 metal Substances 0.000 description 6

- 238000000034 method Methods 0.000 description 6

- 230000006872 improvement Effects 0.000 description 4

- 239000000314 lubricant Substances 0.000 description 4

- 230000008569 process Effects 0.000 description 4

- 239000002131 composite material Substances 0.000 description 3

- 238000007654 immersion Methods 0.000 description 3

- 238000000465 moulding Methods 0.000 description 3

- 239000000843 powder Substances 0.000 description 3

- 230000008859 change Effects 0.000 description 2

- 239000002826 coolant Substances 0.000 description 2

- 238000002386 leaching Methods 0.000 description 2

- 238000003754 machining Methods 0.000 description 2

- 150000002739 metals Chemical class 0.000 description 2

- 238000010951 particle size reduction Methods 0.000 description 2

- 229910052581 Si3N4 Inorganic materials 0.000 description 1

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 229910010293 ceramic material Inorganic materials 0.000 description 1

- 239000012612 commercial material Substances 0.000 description 1

- 239000008367 deionised water Substances 0.000 description 1

- 229910021641 deionized water Inorganic materials 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

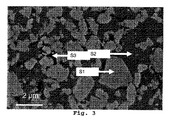

- 238000000445 field-emission scanning electron microscopy Methods 0.000 description 1

- 238000009472 formulation Methods 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 238000005461 lubrication Methods 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 150000001247 metal acetylides Chemical class 0.000 description 1

- 238000005555 metalworking Methods 0.000 description 1

- 238000001000 micrograph Methods 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 238000004080 punching Methods 0.000 description 1

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 description 1

- 238000005245 sintering Methods 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

- 238000001238 wet grinding Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D22/00—Shaping without cutting, by stamping, spinning, or deep-drawing

- B21D22/20—Deep-drawing

- B21D22/28—Deep-drawing of cylindrical articles using consecutive dies

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D37/00—Tools as parts of machines covered by this subclass

- B21D37/01—Selection of materials

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C29/00—Alloys based on carbides, oxides, nitrides, borides, or silicides, e.g. cermets, or other metal compounds, e.g. oxynitrides, sulfides

- C22C29/02—Alloys based on carbides, oxides, nitrides, borides, or silicides, e.g. cermets, or other metal compounds, e.g. oxynitrides, sulfides based on carbides or carbonitrides

- C22C29/06—Alloys based on carbides, oxides, nitrides, borides, or silicides, e.g. cermets, or other metal compounds, e.g. oxynitrides, sulfides based on carbides or carbonitrides based on carbides, but not containing other metal compounds

- C22C29/08—Alloys based on carbides, oxides, nitrides, borides, or silicides, e.g. cermets, or other metal compounds, e.g. oxynitrides, sulfides based on carbides or carbonitrides based on carbides, but not containing other metal compounds based on tungsten carbide

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F5/00—Manufacture of workpieces or articles from metallic powder characterised by the special shape of the product

- B22F2005/002—Tools other than cutting tools

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/12—All metal or with adjacent metals

- Y10T428/12493—Composite; i.e., plural, adjacent, spatially distinct metal components [e.g., layers, joint, etc.]

- Y10T428/12535—Composite; i.e., plural, adjacent, spatially distinct metal components [e.g., layers, joint, etc.] with additional, spatially distinct nonmetal component

- Y10T428/12576—Boride, carbide or nitride component

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Powder Metallurgy (AREA)

- Shaping Metal By Deep-Drawing, Or The Like (AREA)

- Mounting, Exchange, And Manufacturing Of Dies (AREA)

- Cutting Tools, Boring Holders, And Turrets (AREA)

- Metal Extraction Processes (AREA)

- Chemical Vapour Deposition (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| SE0602813A SE0602813L (sv) | 2006-12-27 | 2006-12-27 | Korrosionsresistent verktyg för kallbearbetningsoperationer |

| PCT/SE2007/050956 WO2008079082A1 (en) | 2006-12-27 | 2007-12-07 | Corrosion resistant tool for coldforming operations |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010514933A true JP2010514933A (ja) | 2010-05-06 |

| JP2010514933A5 JP2010514933A5 (enExample) | 2010-12-16 |

Family

ID=39301126

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009543985A Pending JP2010514933A (ja) | 2006-12-27 | 2007-12-07 | 冷間成形用の耐食性工具 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US8057571B2 (enExample) |

| EP (1) | EP1939314A3 (enExample) |

| JP (1) | JP2010514933A (enExample) |

| CN (2) | CN101573194B (enExample) |

| RU (1) | RU2454289C2 (enExample) |

| SE (1) | SE0602813L (enExample) |

| WO (1) | WO2008079082A1 (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2013544963A (ja) * | 2010-10-08 | 2013-12-19 | サンドビック インテレクチュアル プロパティー アクティエボラーグ | 超硬合金 |

| JP2022523664A (ja) * | 2019-01-24 | 2022-04-26 | ハイペリオン マテリアルズ アンド テクノロジーズ (スウェーデン) アクティエボラーグ | 軽量超硬合金 |

Families Citing this family (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2575506T3 (es) * | 2010-10-07 | 2016-06-29 | Sandvik Intellectual Property Ab | Punzón de carburo cementado |

| CN102061418A (zh) * | 2010-12-20 | 2011-05-18 | 中南大学 | 一种用于输油泵阀座的硬质合金材料及其制备方法 |

| CN102350466B (zh) * | 2011-10-18 | 2014-11-05 | 无锡市金杨新型电源有限公司 | 一种电池壳冲压装置 |

| CN102424970A (zh) * | 2011-12-05 | 2012-04-25 | 嘉鱼县海鑫合金制造有限公司 | 粉末冶金法制备耐磨件表面硬质合金覆层的工艺 |

| CN102389969B (zh) * | 2011-12-05 | 2013-10-09 | 北京工商大学 | 一种用于冷冲压模具的粉末冶金材料及其模具成形方法 |

| CN103160723B (zh) * | 2011-12-15 | 2015-10-28 | 株洲钻石切削刀具股份有限公司 | 一种用于钢材通用加工刀具的硬质合金及其涂层刀片 |

| CN103160724B (zh) * | 2011-12-15 | 2015-11-04 | 株洲钻石切削刀具股份有限公司 | 一种用于铸铁车削加工的硬质合金及其硬质合金涂层刀片 |

| CN103449111B (zh) * | 2013-09-12 | 2015-07-15 | 河南省煤科院耐磨技术有限公司 | 一种耐磨转载机凸槽的加工方法 |

| JP6306217B2 (ja) * | 2014-06-09 | 2018-04-04 | サンドビック インテレクチュアル プロパティー アクティエボラーグ | 超硬合金せぎり工具 |

| SG11201704721UA (en) * | 2014-12-30 | 2017-07-28 | Sandvik Intellectual Property | Light weight cemented carbide for flow erosion components |

| KR102235612B1 (ko) | 2015-01-29 | 2021-04-02 | 삼성전자주식회사 | 일-함수 금속을 갖는 반도체 소자 및 그 형성 방법 |

| CN105624512A (zh) * | 2016-01-29 | 2016-06-01 | 柳州市安龙机械设备有限公司 | 复合轧辊 |

| PT3475458T (pt) * | 2016-06-23 | 2020-04-09 | Hyperion Materials & Tech Sweden Ab | Ferramenta de linha de processo de carboneto cementado resistente a corrosão e fadiga |

| RU2627531C1 (ru) * | 2016-09-23 | 2017-08-08 | Юлия Алексеевна Щепочкина | Твердый сплав |

| JP6898450B2 (ja) * | 2016-12-20 | 2021-07-07 | サンドビック インテレクチュアル プロパティー アクティエボラーグ | 切削工具 |

| CN106964772B (zh) * | 2017-05-18 | 2019-05-28 | 江门富祥电子材料有限公司 | 一种孔径可控钽粉的制备方法 |

| CN107641770B (zh) * | 2017-09-27 | 2018-09-14 | 济南大学 | 硬质合金叶片材料及其制造工艺 |

| CN109161773A (zh) * | 2018-09-21 | 2019-01-08 | 成都理工大学 | 一种高熵合金粘结相硬质合金的制备方法 |

| JP7272353B2 (ja) * | 2018-11-01 | 2023-05-12 | 住友電気工業株式会社 | 超硬合金、切削工具および超硬合金の製造方法 |

| CN110527889B (zh) * | 2019-09-05 | 2021-11-23 | 无锡精蓉创材料科技有限公司 | 一种用于生产深腔焊劈刀的材料及其制备工艺 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07292426A (ja) * | 1994-04-22 | 1995-11-07 | Toshiba Tungaloy Co Ltd | 板状wc含有超硬合金の製法 |

| JP2001526974A (ja) * | 1997-12-22 | 2001-12-25 | サンドビック アクティエボラーグ(プブル) | 改良されたボールペン用ポイントボール |

| JP2006328540A (ja) * | 2005-05-27 | 2006-12-07 | Sandvik Intellectual Property Ab | 超硬合金および引抜きダイス |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3215510A (en) * | 1963-10-02 | 1965-11-02 | Gen Electric | Alloy |

| JPS5922779B2 (ja) * | 1979-02-28 | 1984-05-29 | 東洋製罐株式会社 | ドロ−・アイアニング缶成形用超硬工具 |

| JPS60125348A (ja) * | 1983-12-08 | 1985-07-04 | Hitachi Choko Kk | 工具材料 |

| US5095730A (en) | 1988-03-30 | 1992-03-17 | Advanced Composite Materials Corporation | Whisker reinforced ceramic material working tools |

| SU1569055A1 (ru) * | 1988-08-30 | 1990-06-07 | Институт сверхтвердых материалов АН УССР | Матрица дл выт жки |

| CN1036803A (zh) * | 1989-04-28 | 1989-11-01 | 株洲硬质合金厂 | 含钕的硬质合金 |

| JPH03258424A (ja) * | 1990-03-08 | 1991-11-18 | Mitsubishi Materials Corp | 炭化タングステン基超硬合金製アルミニウム缶成形金型 |

| US5396788A (en) | 1992-09-04 | 1995-03-14 | Golden Technologies Company, Inc. | Can tooling components |

| US5736658A (en) * | 1994-09-30 | 1998-04-07 | Valenite Inc. | Low density, nonmagnetic and corrosion resistant cemented carbides |

| JP3414102B2 (ja) | 1996-02-05 | 2003-06-09 | 三菱マテリアル株式会社 | 硬質層積層被覆切削工具 |

| US5750247A (en) | 1996-03-15 | 1998-05-12 | Kennametal, Inc. | Coated cutting tool having an outer layer of TiC |

| RU2150344C1 (ru) * | 1999-06-17 | 2000-06-10 | Государственный космический научно-производственный центр им. М.В. Хруничева | Способ изготовления полых деталей из листовой заготовки |

| CN1321210C (zh) * | 2002-10-30 | 2007-06-13 | 株洲硬质合金集团有限公司 | 钨钴钛硬质合金的制备方法 |

-

2006

- 2006-12-27 SE SE0602813A patent/SE0602813L/xx not_active Application Discontinuation

-

2007

- 2007-12-06 EP EP07122540A patent/EP1939314A3/en not_active Withdrawn

- 2007-12-07 WO PCT/SE2007/050956 patent/WO2008079082A1/en not_active Ceased

- 2007-12-07 JP JP2009543985A patent/JP2010514933A/ja active Pending

- 2007-12-07 CN CN2007800487595A patent/CN101573194B/zh not_active Expired - Fee Related

- 2007-12-07 RU RU2009128642/02A patent/RU2454289C2/ru not_active IP Right Cessation

- 2007-12-10 CN CN2007800484968A patent/CN101573193B/zh not_active Expired - Fee Related

- 2007-12-20 US US12/003,202 patent/US8057571B2/en not_active Expired - Fee Related

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07292426A (ja) * | 1994-04-22 | 1995-11-07 | Toshiba Tungaloy Co Ltd | 板状wc含有超硬合金の製法 |

| JP2001526974A (ja) * | 1997-12-22 | 2001-12-25 | サンドビック アクティエボラーグ(プブル) | 改良されたボールペン用ポイントボール |

| JP2006328540A (ja) * | 2005-05-27 | 2006-12-07 | Sandvik Intellectual Property Ab | 超硬合金および引抜きダイス |

| JP2006328539A (ja) * | 2005-05-27 | 2006-12-07 | Sandvik Intellectual Property Ab | 超硬合金および工具 |

Non-Patent Citations (1)

| Title |

|---|

| JPN6013053675; 社団法人日本金属学会 編: 改訂5版 金属便覧 , 19900331, p.974-975, 丸善株式会社 * |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2013544963A (ja) * | 2010-10-08 | 2013-12-19 | サンドビック インテレクチュアル プロパティー アクティエボラーグ | 超硬合金 |

| US9453271B2 (en) | 2010-10-08 | 2016-09-27 | Sandvik Intellectual Property Ab | Cemented carbide |

| JP2022523664A (ja) * | 2019-01-24 | 2022-04-26 | ハイペリオン マテリアルズ アンド テクノロジーズ (スウェーデン) アクティエボラーグ | 軽量超硬合金 |

| JP7544719B2 (ja) | 2019-01-24 | 2024-09-03 | ハイペリオン マテリアルズ アンド テクノロジーズ (スウェーデン) アクティエボラーグ | 軽量超硬合金 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN101573193B (zh) | 2011-11-23 |

| CN101573193A (zh) | 2009-11-04 |

| RU2009128642A (ru) | 2011-02-10 |

| RU2454289C2 (ru) | 2012-06-27 |

| WO2008079082A1 (en) | 2008-07-03 |

| CN101573194A (zh) | 2009-11-04 |

| US20080202191A1 (en) | 2008-08-28 |

| SE0602813L (sv) | 2008-06-28 |

| EP1939314A3 (en) | 2012-04-11 |

| EP1939314A2 (en) | 2008-07-02 |

| CN101573194B (zh) | 2012-09-26 |

| US8057571B2 (en) | 2011-11-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2010514933A (ja) | 冷間成形用の耐食性工具 | |

| JP6703757B2 (ja) | サーメット、及び切削工具 | |

| JP2010514934A (ja) | 冷間成形用パンチ | |

| JP4773416B2 (ja) | 焼結体の製造方法、該方法に用いる粉末混合物、該方法により製造された焼結体 | |

| KR102027858B1 (ko) | 초경 합금 펀치 | |

| US12378644B2 (en) | Hard metal cemented carbide | |

| US7713327B2 (en) | Tool for coldforming operations with improved performance | |

| JP2001181777A (ja) | 超高圧発生装置用シリンダーコアおよびアンビルコア | |

| JPH10130771A (ja) | 耐摩耗性硬質焼結合金 | |

| JP7209216B2 (ja) | 耐塑性変形性、耐チッピング性にすぐれたwc基超硬合金製切削工具および表面被覆wc基超硬合金製切削工具 | |

| JP2000336450A (ja) | チタン基炭窒化物合金 | |

| JP7441418B2 (ja) | 耐塑性変形性、耐欠損性にすぐれたwc基超硬合金製切削工具および表面被覆wc基超硬合金製切削工具 | |

| JP2020132935A (ja) | 耐欠損性にすぐれたwc基超硬合金製切削工具および表面被覆wc基超硬合金製切削工具 | |

| JP7133712B2 (ja) | 伸線ダイス | |

| JP2001294968A (ja) | 非鉄金属材料の塑性加工用超硬合金 | |

| JP2001277008A (ja) | 切削工具用サーメットおよびその製造方法 | |

| CN111500915A (zh) | 刀具材料及其制备方法 | |

| JP2001335877A (ja) | 内面溝付伝熱管製造用プラグ | |

| MXPA06005933A (en) | Tool for coldforming operations with improved performance |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20101027 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20101027 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20121023 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20130122 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20130129 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20131105 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20140129 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20140205 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140501 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20140610 |