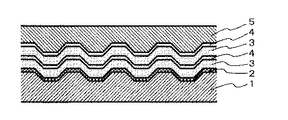

JP2004039136A - 光学多層記録媒体成形用透明スタンパおよび光学多層記録媒体の製造方法 - Google Patents

光学多層記録媒体成形用透明スタンパおよび光学多層記録媒体の製造方法 Download PDFInfo

- Publication number

- JP2004039136A JP2004039136A JP2002196096A JP2002196096A JP2004039136A JP 2004039136 A JP2004039136 A JP 2004039136A JP 2002196096 A JP2002196096 A JP 2002196096A JP 2002196096 A JP2002196096 A JP 2002196096A JP 2004039136 A JP2004039136 A JP 2004039136A

- Authority

- JP

- Japan

- Prior art keywords

- stamper

- recording medium

- layer

- optical multilayer

- light

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 230000003287 optical effect Effects 0.000 title claims abstract description 35

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 22

- 238000000034 method Methods 0.000 title claims abstract description 16

- 229920005989 resin Polymers 0.000 claims abstract description 56

- 239000011347 resin Substances 0.000 claims abstract description 56

- 229920005672 polyolefin resin Polymers 0.000 claims abstract description 22

- 239000000758 substrate Substances 0.000 claims abstract description 20

- 238000010030 laminating Methods 0.000 claims abstract 2

- 238000000465 moulding Methods 0.000 claims description 12

- 239000010408 film Substances 0.000 description 13

- 238000010586 diagram Methods 0.000 description 11

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 10

- 239000002184 metal Substances 0.000 description 9

- 229910052751 metal Inorganic materials 0.000 description 9

- 239000004417 polycarbonate Substances 0.000 description 7

- 239000011521 glass Substances 0.000 description 6

- 229920000515 polycarbonate Polymers 0.000 description 6

- 229910052759 nickel Inorganic materials 0.000 description 5

- 239000003795 chemical substances by application Substances 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000005530 etching Methods 0.000 description 2

- 230000009477 glass transition Effects 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 239000002994 raw material Substances 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 239000012780 transparent material Substances 0.000 description 2

- 229920000089 Cyclic olefin copolymer Polymers 0.000 description 1

- 229920000297 Rayon Polymers 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- 150000007513 acids Chemical class 0.000 description 1

- -1 alkalis Substances 0.000 description 1

- 101150059062 apln gene Proteins 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 238000002425 crystallisation Methods 0.000 description 1

- 230000008025 crystallization Effects 0.000 description 1

- 239000000428 dust Substances 0.000 description 1

- 239000003999 initiator Substances 0.000 description 1

- 238000007689 inspection Methods 0.000 description 1

- 230000001678 irradiating effect Effects 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 239000012778 molding material Substances 0.000 description 1

- 239000003495 polar organic solvent Substances 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 239000011342 resin composition Substances 0.000 description 1

- 230000009291 secondary effect Effects 0.000 description 1

- 230000035945 sensitivity Effects 0.000 description 1

- 239000007779 soft material Substances 0.000 description 1

- 238000004528 spin coating Methods 0.000 description 1

- 238000004544 sputter deposition Methods 0.000 description 1

- 229920001169 thermoplastic Polymers 0.000 description 1

- 239000004416 thermosoftening plastic Substances 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

- 238000007740 vapor deposition Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D17/00—Producing carriers of records containing fine grooves or impressions, e.g. disc records for needle playback, cylinder records; Producing record discs from master stencils

- B29D17/005—Producing optically read record carriers, e.g. optical discs

-

- G—PHYSICS

- G11—INFORMATION STORAGE

- G11B—INFORMATION STORAGE BASED ON RELATIVE MOVEMENT BETWEEN RECORD CARRIER AND TRANSDUCER

- G11B7/00—Recording or reproducing by optical means, e.g. recording using a thermal beam of optical radiation by modifying optical properties or the physical structure, reproducing using an optical beam at lower power by sensing optical properties; Record carriers therefor

- G11B7/24—Record carriers characterised by shape, structure or physical properties, or by the selection of the material

-

- G—PHYSICS

- G11—INFORMATION STORAGE

- G11B—INFORMATION STORAGE BASED ON RELATIVE MOVEMENT BETWEEN RECORD CARRIER AND TRANSDUCER

- G11B7/00—Recording or reproducing by optical means, e.g. recording using a thermal beam of optical radiation by modifying optical properties or the physical structure, reproducing using an optical beam at lower power by sensing optical properties; Record carriers therefor

- G11B7/24—Record carriers characterised by shape, structure or physical properties, or by the selection of the material

- G11B7/26—Apparatus or processes specially adapted for the manufacture of record carriers

- G11B7/261—Preparing a master, e.g. exposing photoresist, electroforming

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Manufacturing Optical Record Carriers (AREA)

- Casting Or Compression Moulding Of Plastics Or The Like (AREA)

- Optical Record Carriers And Manufacture Thereof (AREA)

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002196096A JP2004039136A (ja) | 2002-07-04 | 2002-07-04 | 光学多層記録媒体成形用透明スタンパおよび光学多層記録媒体の製造方法 |

| US10/446,930 US20040004300A1 (en) | 2002-07-04 | 2003-05-29 | Transparent stamper for molding optical multi-layer recording medium and process for producing optical multi-layer recording medium |

| EP03013748A EP1378898B1 (en) | 2002-07-04 | 2003-06-17 | Transparent stamper for molding optical multi-layer recording medium and process for producing optical multi-layer recording medium |

| DE60309782T DE60309782T2 (de) | 2002-07-04 | 2003-06-17 | Durchsichtige Prägeplatte für das Prägen von mehrschichtigen optischen Aufzeichnungsmedien und Verfahren zur Herstellung eines mehrschichtigen optischen Aufzeichnungsmediums |

| CNA031485057A CN1469364A (zh) | 2002-07-04 | 2003-06-27 | 模压光学多层记录介质的透明压模及该记录介质的制造方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002196096A JP2004039136A (ja) | 2002-07-04 | 2002-07-04 | 光学多層記録媒体成形用透明スタンパおよび光学多層記録媒体の製造方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2004039136A true JP2004039136A (ja) | 2004-02-05 |

| JP2004039136A5 JP2004039136A5 (enExample) | 2005-10-20 |

Family

ID=29720299

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2002196096A Pending JP2004039136A (ja) | 2002-07-04 | 2002-07-04 | 光学多層記録媒体成形用透明スタンパおよび光学多層記録媒体の製造方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20040004300A1 (enExample) |

| EP (1) | EP1378898B1 (enExample) |

| JP (1) | JP2004039136A (enExample) |

| CN (1) | CN1469364A (enExample) |

| DE (1) | DE60309782T2 (enExample) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2006313077A (ja) * | 2005-05-06 | 2006-11-16 | Ricoh Co Ltd | 光学積層体検査方法,光学積層体製造方法および光学積層体検査装置ならびに光学積層体製造装置 |

| JPWO2006092987A1 (ja) * | 2005-02-28 | 2008-08-07 | 日本ゼオン株式会社 | 硬化性樹脂成形体の製造方法、及び硬化樹脂成形体 |

| WO2009101883A1 (ja) * | 2008-02-13 | 2009-08-20 | Konica Minolta Opto, Inc. | ハイブリッド光学素子集合体の製造方法 |

| KR101317267B1 (ko) | 2009-09-22 | 2013-10-14 | 에이에스엠엘 네델란즈 비.브이. | 임프린트 리소그래피 방법 및 장치 |

| JP2013233807A (ja) * | 2005-06-10 | 2013-11-21 | Obducat Ab | 環状オレフィン共重合体を含んでなるインプリントスタンプ |

| US9196288B2 (en) | 2006-09-26 | 2015-11-24 | Mitsubishi Kagaku Media Co., Ltd. | Process and apparatus for producing optical recording medium |

| WO2016051928A1 (ja) * | 2014-10-04 | 2016-04-07 | 富山県 | インプリント用テンプレート及びその製造方法 |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2005048253A1 (ja) * | 2003-11-12 | 2005-05-26 | Mitsubishi Kagaku Media Co., Ltd. | 光記録媒体の製造方法及び光透過性スタンパ |

| DE102004025314A1 (de) * | 2004-05-19 | 2005-12-29 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Verfahren zur Herstellung eines optischen Speichermediums und optisches Speichermedium |

| WO2006009161A1 (ja) * | 2004-07-21 | 2006-01-26 | Matsushita Electric Industrial Co., Ltd. | 多層情報記録媒体及びその製造方法 |

| DE602006011185D1 (de) * | 2005-08-30 | 2010-01-28 | Panasonic Corp | Mehrschichteninformation-aufzeichnungsmedium und verfahren zum herstellen dieses mehrschichteninformation-aufzeichnungsmediums und bildschirm, aus denen sich dieses gerät zur herstellung des mehrschichteninformation-aufzeichnungsmedium zusammensetzt |

| JP2007133970A (ja) * | 2005-11-10 | 2007-05-31 | Canon Inc | 光記録媒体およびその製造方法 |

| WO2007058309A2 (ja) * | 2005-11-18 | 2007-05-24 | Mitsubishi Kagaku Media Co., Ltd. | 光記録媒体の製造方法及び製造装置 |

| JP4529895B2 (ja) * | 2005-12-22 | 2010-08-25 | ソニー株式会社 | 光ディスクの製造方法 |

| DE102007007323A1 (de) | 2007-02-14 | 2008-08-21 | Singulus Technologies Ag | Verfahren zur Herstellung optischer Datenträger mit mehreren Informationsschichten |

| JP2008269720A (ja) * | 2007-04-23 | 2008-11-06 | Canon Inc | 透光性スタンパ、透光性スタンパの製造方法及び多層光記録媒体の製造方法 |

| CN101256354B (zh) * | 2008-04-14 | 2012-05-23 | 友达光电股份有限公司 | 压模及其制造方法 |

| JP4829360B2 (ja) * | 2010-04-27 | 2011-12-07 | 株式会社東芝 | スタンパーの製造方法 |

| US10034519B2 (en) | 2016-06-16 | 2018-07-31 | Adidas Ag | UV curable lattice microstructure for footwear |

| US10779609B2 (en) | 2017-04-24 | 2020-09-22 | Nike, Inc. | Apparel and sporting equipment with an UV radiation curable material and method of manufacturing thereof |

| US11136475B2 (en) | 2017-04-24 | 2021-10-05 | Nike, Inc. | Articles and components with UV radiation curable elastomeric materials and methods of making the same |

| EP3576919B1 (en) | 2017-04-24 | 2020-06-17 | NIKE Innovate C.V. | Transparent tooling mold and process for uv radiation curable rubber |

| CN110913716B (zh) | 2017-04-24 | 2022-03-18 | 耐克创新有限合伙公司 | 具有粘附至纺织品的uv辐射可固化材料的物品及制造该物品的方法 |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0823941B2 (ja) * | 1988-11-08 | 1996-03-06 | パイオニア株式会社 | 光学式情報記録担体及びその製造方法 |

| US5175030A (en) * | 1989-02-10 | 1992-12-29 | Minnesota Mining And Manufacturing Company | Microstructure-bearing composite plastic articles and method of making |

-

2002

- 2002-07-04 JP JP2002196096A patent/JP2004039136A/ja active Pending

-

2003

- 2003-05-29 US US10/446,930 patent/US20040004300A1/en not_active Abandoned

- 2003-06-17 DE DE60309782T patent/DE60309782T2/de not_active Revoked

- 2003-06-17 EP EP03013748A patent/EP1378898B1/en not_active Revoked

- 2003-06-27 CN CNA031485057A patent/CN1469364A/zh active Pending

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPWO2006092987A1 (ja) * | 2005-02-28 | 2008-08-07 | 日本ゼオン株式会社 | 硬化性樹脂成形体の製造方法、及び硬化樹脂成形体 |

| US7695668B2 (en) | 2005-02-28 | 2010-04-13 | Zeon Corporation | Process for producing molded object of curable resin and molded cured resin |

| JP4678026B2 (ja) * | 2005-02-28 | 2011-04-27 | 日本ゼオン株式会社 | 硬化性樹脂成形体の製造方法 |

| JP2006313077A (ja) * | 2005-05-06 | 2006-11-16 | Ricoh Co Ltd | 光学積層体検査方法,光学積層体製造方法および光学積層体検査装置ならびに光学積層体製造装置 |

| JP2013233807A (ja) * | 2005-06-10 | 2013-11-21 | Obducat Ab | 環状オレフィン共重合体を含んでなるインプリントスタンプ |

| US9196288B2 (en) | 2006-09-26 | 2015-11-24 | Mitsubishi Kagaku Media Co., Ltd. | Process and apparatus for producing optical recording medium |

| WO2009101883A1 (ja) * | 2008-02-13 | 2009-08-20 | Konica Minolta Opto, Inc. | ハイブリッド光学素子集合体の製造方法 |

| KR101317267B1 (ko) | 2009-09-22 | 2013-10-14 | 에이에스엠엘 네델란즈 비.브이. | 임프린트 리소그래피 방법 및 장치 |

| US8889055B2 (en) | 2009-09-22 | 2014-11-18 | Asml Netherlands B.V. | Imprint lithography method |

| WO2016051928A1 (ja) * | 2014-10-04 | 2016-04-07 | 富山県 | インプリント用テンプレート及びその製造方法 |

| JPWO2016051928A1 (ja) * | 2014-10-04 | 2017-09-28 | 富山県 | インプリント用テンプレート及びその製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1378898A1 (en) | 2004-01-07 |

| EP1378898B1 (en) | 2006-11-22 |

| DE60309782T2 (de) | 2007-03-01 |

| CN1469364A (zh) | 2004-01-21 |

| DE60309782D1 (de) | 2007-01-04 |

| US20040004300A1 (en) | 2004-01-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2004039136A (ja) | 光学多層記録媒体成形用透明スタンパおよび光学多層記録媒体の製造方法 | |

| JP3763763B2 (ja) | 光情報記録媒体の製造方法 | |

| US20030179693A1 (en) | Single-sided double layer optical disc, and method and apparatus for manufacturing the same | |

| JPH10283682A (ja) | 光ディスク及び光ディスク製造方法 | |

| US6800224B2 (en) | Production process of optical disc and optical disc produced thereby | |

| CN1608291A (zh) | 多层光记录介质的制造方法及多层光记录介质 | |

| JP2008269720A (ja) | 透光性スタンパ、透光性スタンパの製造方法及び多層光記録媒体の製造方法 | |

| JPH0997452A (ja) | 多層光学記録媒体の製造方法 | |

| JP4360269B2 (ja) | 多層光ディスクの製造方法 | |

| JP2000036135A (ja) | 多層情報記録媒体の製造方法 | |

| JP4088884B2 (ja) | 光ディスクの製造方法 | |

| WO2003056553A1 (en) | Multi-layered optical recording medium and multi-layered optical recording medium manufacturing method | |

| JP4516414B2 (ja) | 光ディスクの製造方法および光ディスク | |

| JP2000298879A (ja) | 光記録媒体 | |

| JPWO2004090882A1 (ja) | 光記録媒体とその製造方法 | |

| KR100962743B1 (ko) | 광학 기록 매체 및 그 제조 방법 | |

| TW200832392A (en) | Method and apparatus for manufacturing optical recording medium | |

| JP2009020975A (ja) | 多層光記録媒体及びその製造方法 | |

| JP3671484B2 (ja) | 光学記録媒体 | |

| JP4433632B2 (ja) | 光記録媒体の製造方法 | |

| JPH08306085A (ja) | 多層構造光学記録媒体の製造方法 | |

| CN101374650A (zh) | 制备多层光记录介质的方法和压模以及制造该压模的方法 | |

| JP2007226939A (ja) | 多層光記録媒体の製造方法 | |

| JP2007305251A (ja) | 多層光記録媒体の製造方法 | |

| JP2007287253A (ja) | 光ディスクの製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050628 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20050628 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20061227 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20070605 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20080325 |