EP1628713B1 - Capuche pour vetement de protection - Google Patents

Capuche pour vetement de protection Download PDFInfo

- Publication number

- EP1628713B1 EP1628713B1 EP04731824A EP04731824A EP1628713B1 EP 1628713 B1 EP1628713 B1 EP 1628713B1 EP 04731824 A EP04731824 A EP 04731824A EP 04731824 A EP04731824 A EP 04731824A EP 1628713 B1 EP1628713 B1 EP 1628713B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- hood

- hem

- clothing item

- sealing elements

- less

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000001681 protective effect Effects 0.000 title claims abstract description 33

- 238000007789 sealing Methods 0.000 claims abstract description 72

- 230000007704 transition Effects 0.000 claims abstract description 12

- ZCFFYALKHPIRKJ-UHFFFAOYSA-N 3-[18-(2-carboxylatoethyl)-8,13-bis(ethenyl)-3,7,12,17-tetramethyl-22,23-dihydroporphyrin-21,24-diium-2-yl]propanoate Chemical compound N1C(C=C2C(=C(C)C(=CC=3C(C)=C(CCC(O)=O)C(N=3)=C3)N2)C=C)=C(C)C(C=C)=C1C=C1C(C)=C(CCC(O)=O)C3=N1 ZCFFYALKHPIRKJ-UHFFFAOYSA-N 0.000 claims abstract 15

- 239000000463 material Substances 0.000 claims description 20

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 14

- 239000007789 gas Substances 0.000 claims description 6

- 230000004888 barrier function Effects 0.000 claims description 4

- 239000002575 chemical warfare agent Substances 0.000 claims description 3

- 239000007788 liquid Substances 0.000 claims description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 3

- 238000003466 welding Methods 0.000 claims description 2

- 238000010276 construction Methods 0.000 claims 2

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical class C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 claims 2

- 210000003041 ligament Anatomy 0.000 claims 1

- 230000029058 respiratory gaseous exchange Effects 0.000 abstract 4

- 230000002093 peripheral effect Effects 0.000 abstract 2

- 230000000007 visual effect Effects 0.000 description 14

- 230000000241 respiratory effect Effects 0.000 description 8

- 239000000835 fiber Substances 0.000 description 7

- 231100000614 poison Toxicity 0.000 description 5

- 239000003440 toxic substance Substances 0.000 description 4

- 229920001971 elastomer Polymers 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- 230000000274 adsorptive effect Effects 0.000 description 2

- QKSKPIVNLNLAAV-UHFFFAOYSA-N bis(2-chloroethyl) sulfide Chemical compound ClCCSCCCl QKSKPIVNLNLAAV-UHFFFAOYSA-N 0.000 description 2

- 239000003795 chemical substances by application Substances 0.000 description 2

- 229920000642 polymer Polymers 0.000 description 2

- 229920002635 polyurethane Polymers 0.000 description 2

- 239000004814 polyurethane Substances 0.000 description 2

- 239000005060 rubber Substances 0.000 description 2

- 239000003053 toxin Substances 0.000 description 2

- 231100000765 toxin Toxicity 0.000 description 2

- 108700012359 toxins Proteins 0.000 description 2

- UNUVUYPEOAILGM-UHFFFAOYSA-N C=CC1(CC2)CC2CC1 Chemical compound C=CC1(CC2)CC2CC1 UNUVUYPEOAILGM-UHFFFAOYSA-N 0.000 description 1

- 229920000049 Carbon (fiber) Polymers 0.000 description 1

- 244000043261 Hevea brasiliensis Species 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- 229920002334 Spandex Polymers 0.000 description 1

- 230000006750 UV protection Effects 0.000 description 1

- 230000037374 absorbed through the skin Effects 0.000 description 1

- 238000004026 adhesive bonding Methods 0.000 description 1

- 210000001124 body fluid Anatomy 0.000 description 1

- 239000010839 body fluid Substances 0.000 description 1

- 230000001934 delay Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 150000001993 dienes Chemical class 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000000806 elastomer Substances 0.000 description 1

- 229920000126 latex Polymers 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000000178 monomer Substances 0.000 description 1

- 229920003052 natural elastomer Polymers 0.000 description 1

- 229920001194 natural rubber Polymers 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000002574 poison Substances 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 238000006116 polymerization reaction Methods 0.000 description 1

- 230000004224 protection Effects 0.000 description 1

- 239000005871 repellent Substances 0.000 description 1

- 210000002345 respiratory system Anatomy 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

- 238000009958 sewing Methods 0.000 description 1

- 238000001179 sorption measurement Methods 0.000 description 1

- 210000004243 sweat Anatomy 0.000 description 1

- 229920003051 synthetic elastomer Polymers 0.000 description 1

- 231100000331 toxic Toxicity 0.000 description 1

- 230000002588 toxic effect Effects 0.000 description 1

- 125000000391 vinyl group Chemical group [H]C([*])=C([H])[H] 0.000 description 1

- 229920002554 vinyl polymer Polymers 0.000 description 1

- 238000009941 weaving Methods 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A62—LIFE-SAVING; FIRE-FIGHTING

- A62B—DEVICES, APPARATUS OR METHODS FOR LIFE-SAVING

- A62B17/00—Protective clothing affording protection against heat or harmful chemical agents or for use at high altitudes

- A62B17/006—Protective clothing affording protection against heat or harmful chemical agents or for use at high altitudes against contamination from chemicals, toxic or hostile environments; ABC suits

Definitions

- the present invention relates to a hood, in particular for clothing for protective or military purposes, such as NBC protective suits or the like, according to the preamble of claim 1. Furthermore, the present invention relates to clothing, in particular for protection or military purposes, such as ABC Protective suits or the like, which are equipped with such a hood.

- the present invention relates to garments, in particular for protective or military purposes, such as ABC protective suits or the like, according to the preamble of claim 17.

- the present invention also relates to the use of an elastic seam for sealing the transition between a part of a Garment, in particular a hood, on the one hand and another item of clothing or equipment, in particular a respirator, on the other hand according to the preamble of claim 19.

- hood of such ABC protective suits may comprise a circumferential, in particular elastic, seam for forming a visual field opening intended to receive the respiratory mask, the hem of the hood being intended to be applied to the respirator in use (see, for example, GB 2 078 491).

- An object of the present invention is now to provide a garment, preferably for protective or military purposes, such as ABC protective suit or the like, or a hood for such a garment, which at least largely avoids the problems described above.

- an object of the present invention is to design the transition between garment or hood on the one hand and respirator on the other hand in such a garment or in such a hood on the other hand, that this transition is at least largely sealed.

- the present invention is thus a hood, in particular for a garment, preferably for protective or military purposes, such as ABC protective suit or the like, wherein the hood has a circumferential elastic seam to form a visual field opening, wherein the visual field opening is provided for receiving a respirator mask and wherein the hem in the state of use rests against the respirator mask, wherein on the side facing in the field of view opening of the hem (ie on the side facing the respirator in use state side of the field opening of the seam) at least one circumferential sealing element for sealing Concerning the respiratory mask is provided.

- a basic idea of the present invention therefore consists in equipping the seam of the previously described hood forming the visual field opening on the side of the hem pointing in the visual field opening (that is to say the side of the seam pointing towards the respiratory mask in use) with at least one circumferential sealing element. This means that in use, so when wearing the respirator, a seal the transition between the hood or hem on the one hand and respirator on the other hand is achieved or the sealing of this transition is significantly improved.

- the sealing element In use, d. H. when wearing the respirator, the sealing element rests on the respirator, and it creates a tight and frictional connection with the underlying respirator.

- circumferential as it is understood according to the invention with respect to the seam and the sealing element, is understood in the context of the present invention both in its narrower sense as well as in a further meaning.

- the term “circumferential” may refer to both a state where the seam or sealing element forms a closed ring or circle, but also a state where the seam and the sealing element have two loose ends (eg, when the hood has a closure or a closable opening), wherein the two loose ends of the seam and the sealing element can then be superimposed or at least substantially brought together at the ends.

- circumferential sealing element is at least substantially continuous, d. H. without channels and openings, so that it can rest sealingly on the respirator.

- the sealing element is formed at least substantially linearly adjacent to the respirator mask and / or the sealing element is formed projecting or projecting from the hem.

- Fig. 1 shows an inventive garment 2, preferably for protective and / or military purposes, such as an ABC protective suit or the like, which is equipped with a hood 1 according to the invention.

- the hood 1 has a circumferential elastic seam 3 for forming a visual field opening 4.

- the visual field opening 4 is provided for receiving a respiratory mask 5.

- the hem 3 applies in the use state of the respirator 5.

- FIG. 3B shows the area marked separately in FIG. 3A as a schematic enlargement, the hem 3 resting against the respiratory mask 5 being flipped upward in the direction of the arrow in FIG. 3B, so that according to the invention for sealing engagement with the respiratory mask 5 provided sealing element 6, which is provided on the facing in the face opening 4 side of the hem or on the in use state to the respirator 5 facing side of the hem comes to light.

- the sealing element 6 provided according to the invention is applied to the respiratory mask 5 at least substantially in a line.

- the sealing element 6 is applied to the respiratory mask 5 at least substantially in a line.

- FIG. 3B it is designed accordingly.

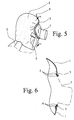

- FIG. 6 is an enlarged cross-sectional view along the dashed line VI shown in FIG.

- FIG. 6 are in use, d. H. when wearing a respirator 5, the sealing elements 6 at least substantially linearly on the respirator 5 together with the seam 3, wherein the seam 3 presses the sealing elements 6 to the respirator 5. Due to the at least substantially linear concerns of the sealing elements 6, the contact pressure is significantly increased and achieved an excellent seal.

- FIG. 4A it may be advantageous to provide a plurality of sealing elements 6 on the seam 3, preferably at least two sealing elements 6.

- the individual sealing elements 6 can be arranged at least substantially parallel to one another.

- the sealing element 6 may be formed protruding from the seam 3.

- a substantially linear abutment is achieved in the use state, which is associated with a higher contact pressure and with a higher seal.

- the sealing element 6 provided according to the invention is designed as a sealing ring, sealing lip or sealing projection. In general, an elevation or increase on the seam 3 is created in this way.

- the sealing element 6 may be attached to the seam 3, in particular be permanently connected to the seam 3, preferably by sewing, weaving, gluing, stapling, welding or the like; such an embodiment is shown in Fig. 4B.

- the sealing element 6 but also be part of the seam 3, in particular, the sealing element 6 and the seam 3 may be integrally formed; such an embodiment is shown in Fig. 4C.

- the sealing element provided according to the invention may be thread-shaped, band-shaped, cord-shaped or strip-shaped or web-like or else honeycomb-shaped.

- the sealing element 6 consists of an elastically deformable material. Care should be taken in particular that the elasticity of the sealing element 6 corresponds at least substantially to the elasticity of the seam 3 or even exceeds it.

- the sealing element 6 has a relative elastic extensibility or elongation, based on its initial length, of at least 20%, in particular at least 30%, preferably at least 50%, preferably at least 70%, particularly preferably at least 85% or more.

- the modulus of elasticity of elasticity of the material constituting the sealing element 6 at 25 ° C is at most 10 8 N ⁇ m -2 , in particular at most 10 7 N ⁇ m -2 , preferably at most 5 ⁇ 10 6 N ⁇ M -2 , and is preferably in the range of 5 ⁇ 10 5 N ⁇ m -2 to 9 ⁇ 10 6 N ⁇ m -2 .

- the cross-sectional thickness d of the sealing element 6 shown in FIG. 4B is at least 1/4, in particular at least 1/3, preferably at least 2/3, particularly preferably at least 3/4, that in 4B corresponds to the illustrated cross-sectional thickness D of the seam 3.

- the sealing element 6 should protrude to at least 0.1 mm, in particular to at least 0.25 mm, preferably to at least 0.4 mm, preferably to at least 0.6 mm, particularly preferably to 1 mm and more, from the seam (3) or be formed protruding. As a result, a particularly good sealing effect can be achieved.

- the sealing element 6 provided according to the invention for example, all types of rubbers, latices, elastic plastics, etc. may be considered, provided that they are suitable for use in the context of the present invention.

- these materials should advantageously have a certain heat and UV resistance and, moreover, also have a certain resistance to aggressive media, in particular warfare agents, but also to body fluids, in particular sweat.

- the material is water-repellent.

- Suitable materials according to the invention are for. B. certain types of so-called elastofibres (see R ⁇ MPP Chemielexikon, 10th Edition, Volume 2, 1997, pages 1104 to 1106, keyword “elastofibers", Georg Thieme Verlag Stuttgart / New York); These are man-made fibers that are extremely elastic and largely return to their original state after the tensile force has been removed.

- the most important representatives are elastane, fibers of high polymers which are at least 85 wt .-% of segmented Polyurethane, and elastomers, fibers consisting of synthetic polyisoprene or high polymers, which are formed by polymerization of one or more dienes, optionally with the addition of one or more vinyl monomers.

- the rubber fibers made of natural rubber Elastodiene is often vulcanized. Elastic properties are also possessed by a bicomponent fiber made of polyamide and polyurethane. For further details, reference may be made to the aforementioned reference. The dimensions of such fibers are to be adapted accordingly for the purposes of the invention. Such fibers can be sewn to the hem material, for example.

- the hood 1 according to the invention including the visual field opening 4, in particular at the lateral part of the visual field opening 4, can have a closure 7 (eg in the form of a hook-and-loop fastener or a zipper).

- a closure 7 eg in the form of a hook-and-loop fastener or a zipper.

- the closure 7 can be arranged at any point of the visual field opening 4 (eg laterally or also centrally with respect to the visual field opening 4); in practice, however, it has proved to be particularly practical for reasons of practicality, wearing comfort and better sealability when the closure 7 is attached to the lateral part of the visual field opening 4.

- the hood 1 may be removable from the rest of the garment 2 (eg via a hook-and-loop fastener or zipper); Care must also be taken in this embodiment that the remaining garment 2 and the hood 1 are at least substantially connectable to each other. Similarly, it is possible that the hood 1 is part of the garment 2, in particular hereby sewn or even integrally formed therewith.

- the hood according to the invention 1 above the visual field opening 4 at least one loop, tab or the like 8 has.

- this makes it possible to adjust the visual field opening 4 or the hood 1, in particular if the hood 1 is worn in conjunction with a helmet or another headgear that is still seated on the hood 1.

- the hood 1 on its inside completely or partially is lined with an inner material which comprises an adsorptive material, in particular activated carbon (for example in the form of activated carbon particles or activated carbon fibers).

- an adsorptive material in particular activated carbon (for example in the form of activated carbon particles or activated carbon fibers).

- the inner material comprises a water vapor permeable, at least substantially gas or air impermeable barrier layer, which prevents or at least delays the passage of harmful gases or liquids, in particular chemical warfare agents.

- Such inner materials which are configured with an adsorption layer and / or a barrier layer, are known as such from the prior art.

- all or part of the garment 2 may be provided with such inner material.

- Another object of the present invention according to another aspect of the present invention is a garment, in particular for protective or military purposes, such as an ABC protective suit or the like, according to the preamble of claim 17.

- the above statements apply to the invention Hood or to the garment according to the invention accordingly.

- the subject of the present invention is therefore also a garment, in particular for protective or military purposes, such as an ABC protective suit or the like, the garment having at least one opening for a body part (eg hand, arm, foot, leg or head ) with a circumferential elastic seam for forming this opening, wherein the opening for receiving a further item of clothing in particular with a smooth surface structure (eg protective glove etc.) and / or for receiving a piece of equipment (eg respiratory mask, etc.) is provided and in the state of use the hem is in contact with the further item of clothing and / or the piece of equipment, at least one circumferential one on the side of the seam facing the further item of clothing and / or the item of equipment, preferably on the side of the seam pointing in the opening Sealing element for sealing concern to the other Be modeu or piece of equipment is provided.

- a body part eg hand, arm, foot, leg or head

- a circumferential elastic seam for forming this opening

- Another basic idea of the present invention is to seal the transition between the openings provided on garments for body parts on the one hand and other garments or equipment on the other hand by providing the corresponding opening with a seam which has at least one sealing element on the corresponding side having previously described type.

- another object of the present invention is the use of an elastic seam for sealing the transition between a part of a garment, in particular a hood, on the one hand and another garment and / or a piece of equipment, in particular a respirator, on the other hand, wherein on the other Garment or the equipment counterpart facing side of the seam at least one circumferential sealing element is provided for sealing concern to the further garment or to the equipment item.

Landscapes

- Health & Medical Sciences (AREA)

- Toxicology (AREA)

- General Health & Medical Sciences (AREA)

- Business, Economics & Management (AREA)

- Emergency Management (AREA)

- Respiratory Apparatuses And Protective Means (AREA)

- Professional, Industrial, Or Sporting Protective Garments (AREA)

- Outer Garments And Coats (AREA)

Claims (20)

- Capuche (1), en particulier pour un vêtement (2), de préférence pour usage de protection et/ou militaire, tel qu'une combinaison de protection ABC ou similaire, la capuche (1) présentant un ourlet élastique périphérique (3) pour former une ouverture de champ de vision (4), l'ouverture de champ de vision (4) étant prévue pour recevoir un masque de protection respiratoire (5) et l'ourlet (3) s'appliquant dans l'état d'utilisation contre le masque de protection respiratoire (5),

caractérisée en ce que

du côté de l'ourlet (3) tourné vers l'ouverture de champ de vision (4) est prévue une pluralité d'éléments d'étanchéité (6) périphériques connectés de manière durable à l'ourlet (3), en forme de fibres élastomères pour l'application étanche contre le masque de protection respiratoire (5). - Capuche selon la revendication 1, caractérisée en ce que les éléments d'étanchéité (6) sont réalisés de manière à s'appliquer au moins sous forme sensiblement linéaire contre le masque de protection respiratoire (5) et/ou en ce que les éléments d'étanchéité (6) sont réalisés de manière à faire saillie ou à dépasser de l'ourlet (3).

- Capuche selon la revendication 1 ou 2, caractérisée en ce que les éléments d'étanchéité (6) sont fixés sur l'ourlet (3) par couture, tissage, collage, brochage, soudage ou similaire.

- Capuche selon l'une quelconque des revendications précédentes, caractérisée en ce que les éléments d'étanchéité (6) sont réalisés sous forme d'anneau d'étanchéité, de lèvre d'étanchéité ou de saillie d'étanchéité.

- Capuche selon l'une quelconque des revendications précédentes, caractérisée en ce que les éléments d'étanchéité (6) sont réalisés en forme de fils, de bandes, de cordons ou en forme de rubans et/ou en forme de nervures et/ou en nid d'abeilles.

- Capuche selon l'une quelconque des revendications précédentes, caractérisée en ce que les éléments d'étanchéité (6) individuels sont disposés essentiellement parallèlement les uns aux autres et/ou en ce que les éléments d'étanchéité (6) individuels constituent une structure en nid d'abeilles.

- Capuche selon l'une quelconque des revendications précédentes, caractérisée en ce que l'élasticité des éléments d'étanchéité (6) correspond au moins essentiellement à l'élasticité de l'ourlet (3).

- Capuche selon l'une quelconque des revendications précédentes, caractérisée en ce que l'épaisseur en section transversale d des éléments d'étanchéité (6) vaut au moins 1/4, notamment au moins 1/3, de préférence au moins 2/3, particulièrement préférablement au moins 3/4 de l'épaisseur en section transversale D de l'ourlet (3) et/ou les éléments d'étanchéité (6) sont réalisés de manière à faire saillie et/ou à dépasser d'au moins 0,1 mm, notamment d'au moins 0,25 mm, de préférence d'au moins 0,4 mm, de préférence d'au moins 0,6 mm et particulièrement préférablement d'au moins 1 mm et plus de l'ourlet (3).

- Capuche selon l'une quelconque des revendications précédentes, caractérisée en ce que les éléments d'étanchéité (6) présentent une capacité d'extension élastique relative par rapport à leur longueur initiale, d'au moins 20%, notamment d'au moins 30%, de préférence d'au moins 50%, de préférence d'au moins 70%, particulièrement préférablement d'au moins 85% ou plus, et/ou en ce que le module d'élasticité en extension du matériau constituant les éléments d'étanchéité (6) à 25°C vaut au maximum 108N/m2, notamment au maximum 107N/m2, de préférence au maximum 5.106N/m2, et se situe de préférence dans la plage de 5.105N/m2 à 9.106N/m2.

- Capuche selon l'une quelconque des revendications précédentes, caractérisée en ce que la capuche (1) y compris l'ouverture de champ de vision (4), notamment au niveau de la partie latérale de l'ouverture de champ de vision (4), présente une fermeture (7), notamment sous forme de fermeture de type velcro ou de fermeture à glissière, et/ou en ce que la capuche (1) est réalisée de manière amovible par rapport au reste du vêtement (2).

- Capuche selon l'une quelconque des revendications précédentes, caractérisée en ce que la capuche (1) est doublée au niveau de son côté intérieur, complètement ou en partie, d'un matériau intérieur, le matériau intérieur comprenant un matériau adsorbant, notamment du charbon actif, de préférence sous forme de grains de charbon actif ou de billes de charbon actif et/ou de fibres de charbon actif, et/ou comprend une couche barrière perméable à la vapeur d'eau, au moins essentiellement imperméable au gaz et/ou à l'air, qui empêche ou au moins retarde le passage de gaz toxiques ou de liquides toxiques, notamment des agents de combat chimiques.

- Capuche selon l'une quelconque des revendications précédentes, caractérisée en ce que la capuche (1) présente, au-dessus de l'ouverture du champ de vision (4), au moins une boucle, une languette ou similaire (8).

- Vêtement (2), de préférence pour usage de protection et/ou militaire, tel qu'une combinaison de protection ABC ou similaire, présentant une capuche (1) selon l'une quelconque des revendications précédentes.

- Vêtement selon la revendication 13, caractérisé en ce que la capuche (1) est connectée de manière durable au reste du vêtement (2), notamment par couture, tissage, collage, brochage ou similaire, ou en ce que la capuche (1) et le reste du vêtement (2) sont réalisés d'une seule pièce ou en ce que la capuche (1) est réalisée de manière amovible par rapport au reste du vêtement (2), notamment au moyen d'une fermeture à glissière ou de type velcro.

- Vêtement selon la revendication 13 ou 14, caractérisé en ce que le vêtement (2) est doublé sur son côté intérieur complètement ou en partie d'un matériau intérieur, le matériau intérieur comprenant un matériau adsorbant, notamment du charbon actif, de préférence sous forme de grains de charbon actif ou de billes de charbon actif et/ou de fibres de charbon actif, et/ou comprend une couche barrière perméable à la vapeur d'eau, au moins essentiellement imperméable au gaz et/ou à l'air, qui empêche ou au moins retarde le passage de gaz toxiques ou de liquides toxiques, notamment des agents de combat chimiques.

- Vêtement (2), notamment pour usage de protection et/ou militaire, tel qu'une combinaison de protection ABC ou similaire, le vêtement (2) présentant au moins une ouverture (4) pour une partie corporelle, telle qu'une main, un bras, un pied, une jambe ou la tête, avec un ourlet élastique périphérique (3) pour former cette ouverture (4), l'ouverture (4) étant prévue pour recevoir un autre vêtement notamment avec une structure superficielle lisse et/ou pour recevoir un objet d'équipement (5) et l'ourlet (3) s'appliquant dans l'état d'utilisation contre le vêtement supplémentaire et/ou l'objet d'équipement (5),

caractérisé en ce que

du côté de l'ourlet tourné vers le vêtement supplémentaire et/ou l'objet d'équipement (5), de préférence du côté de l'ourlet (3) tourné vers l'ouverture (4), est prévue une pluralité d'éléments d'étanchéité (6) périphériques connectés de manière durable à l'ourlet (3), en forme de fibres élastomères pour l'application étanche contre le vêtement supplémentaire et/ou l'objet d'équipement (5). - Vêtement selon la revendication 16, caractérisé par les caractéristiques de la partie caractérisante d'une ou plusieurs des revendications 1 à 15.

- Utilisation d'un ourlet élastique (3) pour l'étanchéité de la transition entre une partie d'un vêtement (2), notamment une capuche (1), d'une part, et un autre vêtement et/ou un objet d'équipement (5), notamment un masque de protection respiratoire, d'autre part,

caractérisée en ce que

l'on prévoit, du côté de l'ourlet (3) tourné vers le vêtement supplémentaire et/ou l'objet d'équipement (5), une pluralité d'éléments d'étanchéité (6) périphériques connectés de manière durable à l'ourlet (3), en forme de fibres élastomères pour l'application étanche contre le vêtement supplémentaire et/ou l'objet d'équipement (5). - Utilisation selon la revendication 18, pour l'étanchéité de la transition entre une capuche (1) d'un vêtement (2), de préférence pour usage de protection et/ou militaire, tel qu'une combinaison de protection ABC ou similaire, et un masque de protection respiratoire (5).

- Utilisation selon la revendication 18 ou 19, caractérisée par les caractéristiques de la partie caractérisante d'une ou plusieurs des revendications 1 à 15.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10325057 | 2003-06-02 | ||

| DE10327994A DE10327994B4 (de) | 2003-06-02 | 2003-06-21 | Kapuze für Schutzbekleidung und Bekleidungsstück mit Kapuze |

| PCT/EP2004/004932 WO2004105880A1 (fr) | 2003-06-02 | 2004-05-08 | Capuche pour vetement de protection |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1628713A1 EP1628713A1 (fr) | 2006-03-01 |

| EP1628713B1 true EP1628713B1 (fr) | 2007-01-03 |

Family

ID=33491658

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04731824A Expired - Lifetime EP1628713B1 (fr) | 2003-06-02 | 2004-05-08 | Capuche pour vetement de protection |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP1628713B1 (fr) |

| JP (1) | JP4257663B2 (fr) |

| AT (1) | ATE350112T1 (fr) |

| CA (1) | CA2524465C (fr) |

| DE (1) | DE502004002558D1 (fr) |

| WO (1) | WO2004105880A1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2009124748A1 (fr) * | 2008-04-10 | 2009-10-15 | BLüCHER GMBH | Article vestimentaire de protection fonctionnelle |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102007020626A1 (de) | 2007-04-30 | 2008-11-06 | BLüCHER GMBH | Bekleidungsstück mit Kapuze und Schutzmaske |

| JP2010133772A (ja) * | 2008-12-03 | 2010-06-17 | Eikan Shoji Kk | 防護服 |

| DE102014106193B4 (de) | 2014-04-15 | 2020-07-16 | BLüCHER GMBH | Balaklava und CBRN-Schutzanzug |

| CA3049006C (fr) * | 2017-01-06 | 2021-03-30 | W. L. Gore & Associates, Inc. | Capuche comprenant une barriere contre les particules |

| JP2018126364A (ja) * | 2017-02-09 | 2018-08-16 | 東洋紡株式会社 | 防護服 |

| US11806557B2 (en) * | 2018-12-06 | 2023-11-07 | Dupont Safety & Construction, Inc. | Protective garment having improved hood elastomeric interface |

| WO2021047789A1 (fr) | 2019-09-09 | 2021-03-18 | BLüCHER GMBH | Couvre-chef, en particulier capuche ou cagoule, pour vêtement de protection |

| CN112121323B (zh) * | 2020-10-17 | 2024-07-19 | 北京仰生恒泰科技有限责任公司 | 一种动态密封呼吸防护面罩 |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2005072A (en) * | 1934-10-15 | 1935-06-18 | William H Lea | Breathing mask |

| US2086325A (en) * | 1935-07-11 | 1937-07-06 | Frankel Nathan | Detachable and adjustable cap for garments |

| DE2718864C2 (de) * | 1977-04-28 | 1982-04-01 | Auergesellschaft Gmbh, 1000 Berlin | Gasdichte Verbindung zwischen zwei unterschiedlichen Teilen des Atem- bzw. Körperschutzes |

| DE7715247U1 (de) * | 1977-05-13 | 1977-08-25 | Denso-Chemie Wedekind Kg, 5090 Leverkusen | Bandartiges Dichtungsprofil aus elastomerem Material |

| GB2078491B (en) * | 1980-06-25 | 1984-01-11 | Wood Harris & Co Ltd | Protective garments |

| DE3272496D1 (en) * | 1981-01-15 | 1986-09-18 | Keith Bellas Simpson | Protective clothing |

| JPS57156036A (en) * | 1981-03-20 | 1982-09-27 | Toyobo Co Ltd | Protecting material against poisonous chemical material |

| DE8710165U1 (de) * | 1987-07-24 | 1987-10-01 | Güldener, Fritz, 6957 Elztal | Schutzanzug |

| DE3815720A1 (de) | 1988-05-07 | 1989-11-16 | Hasso Von Bluecher | Wasserdampfdurchlaessiges, wasserdichtes material und verfahren zu seiner herstellung |

| DE3924033A1 (de) * | 1989-07-21 | 1991-02-28 | Ruiter Ernest De | Schutzmaterial |

| DE3939373C2 (de) | 1989-11-29 | 1998-04-09 | Hasso Von Bluecher | Material für Schutzanzüge und Verfahren zur Herstellung des Materials |

| FR2686795B1 (fr) * | 1992-01-30 | 1996-07-05 | Intertechnique Sa | Equipement individuel respiratoire et de protection en ambiance contaminee. |

| DE19519869C2 (de) | 1995-05-31 | 2001-02-08 | Kaercher Gmbh & Co Alfred | Dekontaminierbares Schutzmaterial sowie daraus hergestellter ABC- Schutzanzug |

| DE19829975B4 (de) | 1998-07-04 | 2006-11-30 | BLüCHER GMBH | Schutzmaterial gegen chemische Gifte und Verfahren zu seiner Herstellung sowie seine Verwendung |

| DE19834688A1 (de) * | 1998-07-31 | 2000-02-03 | Bayerische Motoren Werke Ag | Verfahren zum Herstellen eines Dichtungsprofiles |

| DE19842274B4 (de) | 1998-09-16 | 2006-11-09 | BLüCHER GMBH | Laminiertes, wasser-und luftdichtes wasserdampfdurchlässiges Verbundmaterial |

| US6829784B2 (en) * | 2001-08-17 | 2004-12-14 | Tayco | Firefighting hood with dual bib |

| DE10240548C5 (de) | 2002-08-29 | 2011-06-16 | BLüCHER GMBH | Adsorptionsmaterial, Verfahren zu seiner Herstellung und seine Verwendung |

-

2004

- 2004-05-08 DE DE502004002558T patent/DE502004002558D1/de not_active Expired - Lifetime

- 2004-05-08 CA CA 2524465 patent/CA2524465C/fr not_active Expired - Fee Related

- 2004-05-08 WO PCT/EP2004/004932 patent/WO2004105880A1/fr active IP Right Grant

- 2004-05-08 AT AT04731824T patent/ATE350112T1/de not_active IP Right Cessation

- 2004-05-08 EP EP04731824A patent/EP1628713B1/fr not_active Expired - Lifetime

- 2004-05-08 JP JP2006508166A patent/JP4257663B2/ja not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2009124748A1 (fr) * | 2008-04-10 | 2009-10-15 | BLüCHER GMBH | Article vestimentaire de protection fonctionnelle |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2004105880A1 (fr) | 2004-12-09 |

| DE502004002558D1 (de) | 2007-02-15 |

| JP4257663B2 (ja) | 2009-04-22 |

| CA2524465C (fr) | 2008-08-05 |

| ATE350112T1 (de) | 2007-01-15 |

| CA2524465A1 (fr) | 2004-12-09 |

| JP2006526436A (ja) | 2006-11-24 |

| EP1628713A1 (fr) | 2006-03-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE10327994B4 (de) | Kapuze für Schutzbekleidung und Bekleidungsstück mit Kapuze | |

| EP1788899B1 (fr) | Piece vestimentaire et systeme pour relier de maniere etanche des pieces vestimentaires | |

| EP1308186B1 (fr) | Vêtement de protection contre les substances chimiques et biologiques qui sont nocives à la santé | |

| EP1495784B1 (fr) | Combinaison de vêtement de protection deux pièces avec une section connexion | |

| DE3048276A1 (de) | Atemschutzhaube, insbesondere fuer den fluchtfall | |

| EP1628713B1 (fr) | Capuche pour vetement de protection | |

| EP3996818B1 (fr) | Couvre-chef, en particulier capuche ou cagoule, pour vêtement de protection | |

| DE202020101737U1 (de) | Einsatzschutzanzug | |

| DE4029939A1 (de) | Ventil fuer staubschutzmasken | |

| EP3131643B1 (fr) | Cagoule et vêtement de protection nrbc | |

| DE20308642U1 (de) | Kapuze für Schutzbekleidung | |

| EP2768585B1 (fr) | Capuchon pour un vêtement ou comme part d'un vêtement | |

| DE202020103171U1 (de) | Atemschutzmaske | |

| DE202020101910U1 (de) | Gesichtsschutzmaske | |

| DE202007007996U1 (de) | Bekleidungsstück mit Kapuze und Schutzmaske | |

| EP2142260B1 (fr) | Pièce de vêtement à capuche et masque protecteur | |

| DE102008035683A1 (de) | Kapuze | |

| DE102014220272B4 (de) | Atemschutz-Halbmaske | |

| DE102020110727B4 (de) | Gesichtsmaske | |

| DE202012003807U1 (de) | Kapuze für ein Kleidungsstück oder als Bestandteil eines Kleidungsstücks | |

| DE202020102814U1 (de) | Schutzmaske | |

| DE102021000815A1 (de) | Atemmaske | |

| DE20311788U1 (de) | Zweiteiliger Schutzanzug mit Verbindungsabschnitt | |

| WO2021198293A1 (fr) | Respirateur | |

| DE202020102260U1 (de) | Gesichtsmaske |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20051013 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REF | Corresponds to: |

Ref document number: 502004002558 Country of ref document: DE Date of ref document: 20070215 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070403 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070403 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070414 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070604 |

|

| LTIE | Lt: invalidation of european patent or patent extension |

Effective date: 20070103 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 |

|

| 26N | No opposition filed |

Effective date: 20071005 |

|

| BERE | Be: lapsed |

Owner name: BLUCHER G.M.B.H. Effective date: 20070531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070404 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070508 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080531 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070508 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070704 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502004002558 Country of ref document: DE Representative=s name: VON ROHR PATENTANWAELTE PARTNERSCHAFT MBB, DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20200522 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20200527 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20210601 Year of fee payment: 18 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20210508 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210508 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210531 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502004002558 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221201 |