EP1628713B1 - Hood for protective garment - Google Patents

Hood for protective garment Download PDFInfo

- Publication number

- EP1628713B1 EP1628713B1 EP04731824A EP04731824A EP1628713B1 EP 1628713 B1 EP1628713 B1 EP 1628713B1 EP 04731824 A EP04731824 A EP 04731824A EP 04731824 A EP04731824 A EP 04731824A EP 1628713 B1 EP1628713 B1 EP 1628713B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- hood

- hem

- clothing item

- sealing elements

- less

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000001681 protective effect Effects 0.000 title claims abstract description 33

- 238000007789 sealing Methods 0.000 claims abstract description 72

- 230000007704 transition Effects 0.000 claims abstract description 12

- ZCFFYALKHPIRKJ-UHFFFAOYSA-N 3-[18-(2-carboxylatoethyl)-8,13-bis(ethenyl)-3,7,12,17-tetramethyl-22,23-dihydroporphyrin-21,24-diium-2-yl]propanoate Chemical compound N1C(C=C2C(=C(C)C(=CC=3C(C)=C(CCC(O)=O)C(N=3)=C3)N2)C=C)=C(C)C(C=C)=C1C=C1C(C)=C(CCC(O)=O)C3=N1 ZCFFYALKHPIRKJ-UHFFFAOYSA-N 0.000 claims abstract 15

- 239000000463 material Substances 0.000 claims description 20

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 14

- 239000007789 gas Substances 0.000 claims description 6

- 230000004888 barrier function Effects 0.000 claims description 4

- 239000002575 chemical warfare agent Substances 0.000 claims description 3

- 239000007788 liquid Substances 0.000 claims description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 3

- 238000003466 welding Methods 0.000 claims description 2

- 238000010276 construction Methods 0.000 claims 2

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical class C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 claims 2

- 210000003041 ligament Anatomy 0.000 claims 1

- 230000029058 respiratory gaseous exchange Effects 0.000 abstract 4

- 230000002093 peripheral effect Effects 0.000 abstract 2

- 230000000007 visual effect Effects 0.000 description 14

- 230000000241 respiratory effect Effects 0.000 description 8

- 239000000835 fiber Substances 0.000 description 7

- 231100000614 poison Toxicity 0.000 description 5

- 239000003440 toxic substance Substances 0.000 description 4

- 229920001971 elastomer Polymers 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- 230000000274 adsorptive effect Effects 0.000 description 2

- QKSKPIVNLNLAAV-UHFFFAOYSA-N bis(2-chloroethyl) sulfide Chemical compound ClCCSCCCl QKSKPIVNLNLAAV-UHFFFAOYSA-N 0.000 description 2

- 239000003795 chemical substances by application Substances 0.000 description 2

- 229920000642 polymer Polymers 0.000 description 2

- 229920002635 polyurethane Polymers 0.000 description 2

- 239000004814 polyurethane Substances 0.000 description 2

- 239000005060 rubber Substances 0.000 description 2

- 239000003053 toxin Substances 0.000 description 2

- 231100000765 toxin Toxicity 0.000 description 2

- 108700012359 toxins Proteins 0.000 description 2

- UNUVUYPEOAILGM-UHFFFAOYSA-N C=CC1(CC2)CC2CC1 Chemical compound C=CC1(CC2)CC2CC1 UNUVUYPEOAILGM-UHFFFAOYSA-N 0.000 description 1

- 229920000049 Carbon (fiber) Polymers 0.000 description 1

- 244000043261 Hevea brasiliensis Species 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- 229920002334 Spandex Polymers 0.000 description 1

- 230000006750 UV protection Effects 0.000 description 1

- 230000037374 absorbed through the skin Effects 0.000 description 1

- 238000004026 adhesive bonding Methods 0.000 description 1

- 210000001124 body fluid Anatomy 0.000 description 1

- 239000010839 body fluid Substances 0.000 description 1

- 230000001934 delay Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 150000001993 dienes Chemical class 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000000806 elastomer Substances 0.000 description 1

- 229920000126 latex Polymers 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000000178 monomer Substances 0.000 description 1

- 229920003052 natural elastomer Polymers 0.000 description 1

- 229920001194 natural rubber Polymers 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000002574 poison Substances 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 238000006116 polymerization reaction Methods 0.000 description 1

- 230000004224 protection Effects 0.000 description 1

- 239000005871 repellent Substances 0.000 description 1

- 210000002345 respiratory system Anatomy 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

- 238000009958 sewing Methods 0.000 description 1

- 238000001179 sorption measurement Methods 0.000 description 1

- 210000004243 sweat Anatomy 0.000 description 1

- 229920003051 synthetic elastomer Polymers 0.000 description 1

- 231100000331 toxic Toxicity 0.000 description 1

- 230000002588 toxic effect Effects 0.000 description 1

- 125000000391 vinyl group Chemical group [H]C([*])=C([H])[H] 0.000 description 1

- 229920002554 vinyl polymer Polymers 0.000 description 1

- 238000009941 weaving Methods 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A62—LIFE-SAVING; FIRE-FIGHTING

- A62B—DEVICES, APPARATUS OR METHODS FOR LIFE-SAVING

- A62B17/00—Protective clothing affording protection against heat or harmful chemical agents or for use at high altitudes

- A62B17/006—Protective clothing affording protection against heat or harmful chemical agents or for use at high altitudes against contamination from chemicals, toxic or hostile environments; ABC suits

Definitions

- the present invention relates to a hood, in particular for clothing for protective or military purposes, such as NBC protective suits or the like, according to the preamble of claim 1. Furthermore, the present invention relates to clothing, in particular for protection or military purposes, such as ABC Protective suits or the like, which are equipped with such a hood.

- the present invention relates to garments, in particular for protective or military purposes, such as ABC protective suits or the like, according to the preamble of claim 17.

- the present invention also relates to the use of an elastic seam for sealing the transition between a part of a Garment, in particular a hood, on the one hand and another item of clothing or equipment, in particular a respirator, on the other hand according to the preamble of claim 19.

- hood of such ABC protective suits may comprise a circumferential, in particular elastic, seam for forming a visual field opening intended to receive the respiratory mask, the hem of the hood being intended to be applied to the respirator in use (see, for example, GB 2 078 491).

- An object of the present invention is now to provide a garment, preferably for protective or military purposes, such as ABC protective suit or the like, or a hood for such a garment, which at least largely avoids the problems described above.

- an object of the present invention is to design the transition between garment or hood on the one hand and respirator on the other hand in such a garment or in such a hood on the other hand, that this transition is at least largely sealed.

- the present invention is thus a hood, in particular for a garment, preferably for protective or military purposes, such as ABC protective suit or the like, wherein the hood has a circumferential elastic seam to form a visual field opening, wherein the visual field opening is provided for receiving a respirator mask and wherein the hem in the state of use rests against the respirator mask, wherein on the side facing in the field of view opening of the hem (ie on the side facing the respirator in use state side of the field opening of the seam) at least one circumferential sealing element for sealing Concerning the respiratory mask is provided.

- a basic idea of the present invention therefore consists in equipping the seam of the previously described hood forming the visual field opening on the side of the hem pointing in the visual field opening (that is to say the side of the seam pointing towards the respiratory mask in use) with at least one circumferential sealing element. This means that in use, so when wearing the respirator, a seal the transition between the hood or hem on the one hand and respirator on the other hand is achieved or the sealing of this transition is significantly improved.

- the sealing element In use, d. H. when wearing the respirator, the sealing element rests on the respirator, and it creates a tight and frictional connection with the underlying respirator.

- circumferential as it is understood according to the invention with respect to the seam and the sealing element, is understood in the context of the present invention both in its narrower sense as well as in a further meaning.

- the term “circumferential” may refer to both a state where the seam or sealing element forms a closed ring or circle, but also a state where the seam and the sealing element have two loose ends (eg, when the hood has a closure or a closable opening), wherein the two loose ends of the seam and the sealing element can then be superimposed or at least substantially brought together at the ends.

- circumferential sealing element is at least substantially continuous, d. H. without channels and openings, so that it can rest sealingly on the respirator.

- the sealing element is formed at least substantially linearly adjacent to the respirator mask and / or the sealing element is formed projecting or projecting from the hem.

- Fig. 1 shows an inventive garment 2, preferably for protective and / or military purposes, such as an ABC protective suit or the like, which is equipped with a hood 1 according to the invention.

- the hood 1 has a circumferential elastic seam 3 for forming a visual field opening 4.

- the visual field opening 4 is provided for receiving a respiratory mask 5.

- the hem 3 applies in the use state of the respirator 5.

- FIG. 3B shows the area marked separately in FIG. 3A as a schematic enlargement, the hem 3 resting against the respiratory mask 5 being flipped upward in the direction of the arrow in FIG. 3B, so that according to the invention for sealing engagement with the respiratory mask 5 provided sealing element 6, which is provided on the facing in the face opening 4 side of the hem or on the in use state to the respirator 5 facing side of the hem comes to light.

- the sealing element 6 provided according to the invention is applied to the respiratory mask 5 at least substantially in a line.

- the sealing element 6 is applied to the respiratory mask 5 at least substantially in a line.

- FIG. 3B it is designed accordingly.

- FIG. 6 is an enlarged cross-sectional view along the dashed line VI shown in FIG.

- FIG. 6 are in use, d. H. when wearing a respirator 5, the sealing elements 6 at least substantially linearly on the respirator 5 together with the seam 3, wherein the seam 3 presses the sealing elements 6 to the respirator 5. Due to the at least substantially linear concerns of the sealing elements 6, the contact pressure is significantly increased and achieved an excellent seal.

- FIG. 4A it may be advantageous to provide a plurality of sealing elements 6 on the seam 3, preferably at least two sealing elements 6.

- the individual sealing elements 6 can be arranged at least substantially parallel to one another.

- the sealing element 6 may be formed protruding from the seam 3.

- a substantially linear abutment is achieved in the use state, which is associated with a higher contact pressure and with a higher seal.

- the sealing element 6 provided according to the invention is designed as a sealing ring, sealing lip or sealing projection. In general, an elevation or increase on the seam 3 is created in this way.

- the sealing element 6 may be attached to the seam 3, in particular be permanently connected to the seam 3, preferably by sewing, weaving, gluing, stapling, welding or the like; such an embodiment is shown in Fig. 4B.

- the sealing element 6 but also be part of the seam 3, in particular, the sealing element 6 and the seam 3 may be integrally formed; such an embodiment is shown in Fig. 4C.

- the sealing element provided according to the invention may be thread-shaped, band-shaped, cord-shaped or strip-shaped or web-like or else honeycomb-shaped.

- the sealing element 6 consists of an elastically deformable material. Care should be taken in particular that the elasticity of the sealing element 6 corresponds at least substantially to the elasticity of the seam 3 or even exceeds it.

- the sealing element 6 has a relative elastic extensibility or elongation, based on its initial length, of at least 20%, in particular at least 30%, preferably at least 50%, preferably at least 70%, particularly preferably at least 85% or more.

- the modulus of elasticity of elasticity of the material constituting the sealing element 6 at 25 ° C is at most 10 8 N ⁇ m -2 , in particular at most 10 7 N ⁇ m -2 , preferably at most 5 ⁇ 10 6 N ⁇ M -2 , and is preferably in the range of 5 ⁇ 10 5 N ⁇ m -2 to 9 ⁇ 10 6 N ⁇ m -2 .

- the cross-sectional thickness d of the sealing element 6 shown in FIG. 4B is at least 1/4, in particular at least 1/3, preferably at least 2/3, particularly preferably at least 3/4, that in 4B corresponds to the illustrated cross-sectional thickness D of the seam 3.

- the sealing element 6 should protrude to at least 0.1 mm, in particular to at least 0.25 mm, preferably to at least 0.4 mm, preferably to at least 0.6 mm, particularly preferably to 1 mm and more, from the seam (3) or be formed protruding. As a result, a particularly good sealing effect can be achieved.

- the sealing element 6 provided according to the invention for example, all types of rubbers, latices, elastic plastics, etc. may be considered, provided that they are suitable for use in the context of the present invention.

- these materials should advantageously have a certain heat and UV resistance and, moreover, also have a certain resistance to aggressive media, in particular warfare agents, but also to body fluids, in particular sweat.

- the material is water-repellent.

- Suitable materials according to the invention are for. B. certain types of so-called elastofibres (see R ⁇ MPP Chemielexikon, 10th Edition, Volume 2, 1997, pages 1104 to 1106, keyword “elastofibers", Georg Thieme Verlag Stuttgart / New York); These are man-made fibers that are extremely elastic and largely return to their original state after the tensile force has been removed.

- the most important representatives are elastane, fibers of high polymers which are at least 85 wt .-% of segmented Polyurethane, and elastomers, fibers consisting of synthetic polyisoprene or high polymers, which are formed by polymerization of one or more dienes, optionally with the addition of one or more vinyl monomers.

- the rubber fibers made of natural rubber Elastodiene is often vulcanized. Elastic properties are also possessed by a bicomponent fiber made of polyamide and polyurethane. For further details, reference may be made to the aforementioned reference. The dimensions of such fibers are to be adapted accordingly for the purposes of the invention. Such fibers can be sewn to the hem material, for example.

- the hood 1 according to the invention including the visual field opening 4, in particular at the lateral part of the visual field opening 4, can have a closure 7 (eg in the form of a hook-and-loop fastener or a zipper).

- a closure 7 eg in the form of a hook-and-loop fastener or a zipper.

- the closure 7 can be arranged at any point of the visual field opening 4 (eg laterally or also centrally with respect to the visual field opening 4); in practice, however, it has proved to be particularly practical for reasons of practicality, wearing comfort and better sealability when the closure 7 is attached to the lateral part of the visual field opening 4.

- the hood 1 may be removable from the rest of the garment 2 (eg via a hook-and-loop fastener or zipper); Care must also be taken in this embodiment that the remaining garment 2 and the hood 1 are at least substantially connectable to each other. Similarly, it is possible that the hood 1 is part of the garment 2, in particular hereby sewn or even integrally formed therewith.

- the hood according to the invention 1 above the visual field opening 4 at least one loop, tab or the like 8 has.

- this makes it possible to adjust the visual field opening 4 or the hood 1, in particular if the hood 1 is worn in conjunction with a helmet or another headgear that is still seated on the hood 1.

- the hood 1 on its inside completely or partially is lined with an inner material which comprises an adsorptive material, in particular activated carbon (for example in the form of activated carbon particles or activated carbon fibers).

- an adsorptive material in particular activated carbon (for example in the form of activated carbon particles or activated carbon fibers).

- the inner material comprises a water vapor permeable, at least substantially gas or air impermeable barrier layer, which prevents or at least delays the passage of harmful gases or liquids, in particular chemical warfare agents.

- Such inner materials which are configured with an adsorption layer and / or a barrier layer, are known as such from the prior art.

- all or part of the garment 2 may be provided with such inner material.

- Another object of the present invention according to another aspect of the present invention is a garment, in particular for protective or military purposes, such as an ABC protective suit or the like, according to the preamble of claim 17.

- the above statements apply to the invention Hood or to the garment according to the invention accordingly.

- the subject of the present invention is therefore also a garment, in particular for protective or military purposes, such as an ABC protective suit or the like, the garment having at least one opening for a body part (eg hand, arm, foot, leg or head ) with a circumferential elastic seam for forming this opening, wherein the opening for receiving a further item of clothing in particular with a smooth surface structure (eg protective glove etc.) and / or for receiving a piece of equipment (eg respiratory mask, etc.) is provided and in the state of use the hem is in contact with the further item of clothing and / or the piece of equipment, at least one circumferential one on the side of the seam facing the further item of clothing and / or the item of equipment, preferably on the side of the seam pointing in the opening Sealing element for sealing concern to the other Be modeu or piece of equipment is provided.

- a body part eg hand, arm, foot, leg or head

- a circumferential elastic seam for forming this opening

- Another basic idea of the present invention is to seal the transition between the openings provided on garments for body parts on the one hand and other garments or equipment on the other hand by providing the corresponding opening with a seam which has at least one sealing element on the corresponding side having previously described type.

- another object of the present invention is the use of an elastic seam for sealing the transition between a part of a garment, in particular a hood, on the one hand and another garment and / or a piece of equipment, in particular a respirator, on the other hand, wherein on the other Garment or the equipment counterpart facing side of the seam at least one circumferential sealing element is provided for sealing concern to the further garment or to the equipment item.

Landscapes

- Health & Medical Sciences (AREA)

- Toxicology (AREA)

- General Health & Medical Sciences (AREA)

- Business, Economics & Management (AREA)

- Emergency Management (AREA)

- Respiratory Apparatuses And Protective Means (AREA)

- Professional, Industrial, Or Sporting Protective Garments (AREA)

- Outer Garments And Coats (AREA)

Abstract

Description

Die vorliegende Erfindung betrifft eine Kapuze, insbesondere für Bekleidungsstücke für Schutz- bzw. militärische Zwecke, wie ABC-Schutzanzüge oder dergleichen, nach dem Oberbegriff des Anspruchs 1. Weiterhin betrifft die vorliegende Erfindung Bekleidungsstücke, insbesondere für Schutz- bzw. militärische Zwecke, wie ABC-Schutzanzüge oder dergleichen, die mit einer derartigen Kapuze ausgestattet sind.The present invention relates to a hood, in particular for clothing for protective or military purposes, such as NBC protective suits or the like, according to the preamble of

Des weiteren betrifft die vorliegende Erfindung Bekleidungsstücke, insbesondere für Schutz- bzw. militärische Zwecke, wie ABC-Schutzanzüge oder dergleichen, nach dem Oberbegriff des Anspruchs 17. Schließlich betrifft die vorliegende Erfindung auch die Verwendung eines elastischen Saums zum Abdichten des Übergangs zwischen einem Teil eines Bekleidungsstückes, insbesondere einer Kapuze, einerseits und einem weiteren Bekleidungsstück oder Ausrüstungsgegenstand, insbesondere einer Atemschutzmaske, andererseits nach dem Oberbegriff des Anspruchs 19.Furthermore, the present invention relates to garments, in particular for protective or military purposes, such as ABC protective suits or the like, according to the preamble of claim 17. Finally, the present invention also relates to the use of an elastic seam for sealing the transition between a part of a Garment, in particular a hood, on the one hand and another item of clothing or equipment, in particular a respirator, on the other hand according to the preamble of claim 19.

Personen, die mit giftigen Stoffen in Kontakt kommen, welche über die Atemwege resorbiert werden können, müssen sich gegenüber diesen Giftstoffen durch das Tragen einer Atemschutzmaske schützen. Wenn darüber hinaus die Gefahr besteht, daß die giftigen Stoffe auch über die Haut aufgenommen bzw. resorbiert werden können, oder wenn dies ausrüstungstechnisch erforderlich ist, müssen diese Personen (z. B. Soldaten, Feuerwehrleute, Polizisten, Angehörige von Sondereinheiten wie der GSG 9 etc.) zusätzlich Schutzkleidung, insbesondere ABC-Schutzanzüge, tragen, die einen Kontakt der Giftstoffe mit der Haut bzw. dem Körper vermeiden und in der Regel mit einer Kapuze ausgestattet sind. Die Kapuze solcher ABC-Schutzanzüge kann einen umlaufenden, insbesondere elastischen Saum zur Bildung einer Gesichtsfeldöffnung, die zur Aufnahme der Atemschutzmaske vorgesehen ist, aufweisen, wobei sich der Saum der Kapuze im Gebrauchszustand an die Atemschutzmaske anlegen soll (siehe z.B. GB 2 078 491).Persons in contact with toxic substances that can be absorbed through the respiratory tract must protect themselves against these toxins by wearing a respirator. Moreover, if there is a risk that the toxic substances may also be absorbed or absorbed through the skin, or if this is technically necessary, these persons (eg soldiers, firefighters, police officers, members of special units such as GSG 9 etc.) in addition wear protective clothing, in particular NBC protective suits, which avoid contact of the toxins with the skin or the body and are usually equipped with a hood. The hood of such ABC protective suits may comprise a circumferential, in particular elastic, seam for forming a visual field opening intended to receive the respiratory mask, the hem of the hood being intended to be applied to the respirator in use (see, for example,

Die führt aber oftmals zu Problemen, da der Übergang von Kapuze bzw. Saum einerseits und Atemschutzmaske andererseits in den meisten Fällen nicht ausreichend abgedichtet ist. Dies kann folglich dazu führen, daß giftige bzw. gefährliche Stoffe durch den nicht ausreichend abgedichteten Übergang zwischen Kapuze bzw. Saum einerseits und Atemschutzmaske andererseits gelangen können und folglich der Träger eines derartigen Schutzanzuges mit diesem Stoffen in Kontakt kommt oder diese Stoffe sogar unter den Rand der Atemschutzmaske gelangen können, so daß sie schließlich inhaliert werden. Dies ist insbesondere für den Träger eines solchen Schutzanzuges gefährlich, wenn er sogenannten Hautgiften ausgesetzt ist, wie z. B. Senfgas (Bis-(2-chlorethyl)sulfid, auch Lost genannt).However, this often leads to problems, as the transition from hood or hem on the one hand and respirator on the other hand, in most cases is not sufficiently sealed. This can consequently lead to toxic or dangerous substances can pass through the insufficiently sealed transition between the hood or hem on the one hand and respirator on the other hand, and consequently the wearer of such a protective suit comes into contact with these substances or even these substances under the edge of the Respirator can get so that they are finally inhaled. This is particularly dangerous for the wearer of such a protective suit when exposed to so-called skin poisons, such as. B. Mustard gas (bis (2-chloroethyl) sulfide, also called Lost).

Eine Aufgabe der vorliegenden Erfindung besteht nunmehr darin, ein Bekleidungsstück, vorzugsweise für Schutz- bzw. militärische Zwecke, wie ABC-Schutzanzug oder dergleichen, bzw. eine Kapuze für ein derartiges Bekleidungsstück bereitzustellen, welches die zuvor geschilderten Probleme zumindest weitgehend vermeidet. Insbesondere besteht eine Aufgabe der vorliegenden Erfindung darin, bei einem derartigen Bekleidungsstück bzw. bei einer derartigen Kapuze den Übergang zwischen Bekleidungsstück bzw. Kapuze einerseits und Atemschutzmaske andererseits derart auszugestalten, daß dieser Übergang zumindest weitgehend abgedichtet ist.An object of the present invention is now to provide a garment, preferably for protective or military purposes, such as ABC protective suit or the like, or a hood for such a garment, which at least largely avoids the problems described above. In particular, an object of the present invention is to design the transition between garment or hood on the one hand and respirator on the other hand in such a garment or in such a hood on the other hand, that this transition is at least largely sealed.

Die zuvor geschilderte Aufgabe wird vorschlagsgemäß durch eine Kapuze gemäß Anspruch 1 bzw. ein Bekleidungsstück nach Anspruch 17 gelöst. Weitere, vorteilhafte Weiterbildungen und Ausgestaltungen sind Gegenstand der Unteransprüche.The above-described object is, as proposed, achieved by a hood according to

Gegenstand der vorliegenden Erfindung gemäß einem ersten Aspekt ist somit eine Kapuze, insbesondere für ein Bekleidungsstück, vorzugsweise für Schutz- bzw. militärische Zwecke, wie ABC-Schutzanzug oder dergleichen, wobei die Kapuze einen umlaufenden elastischen Saum zur Bildung einer Gesichtsfeldöffnung aufweist, wobei die Gesichtsfeldöffnung zur Aufnahme einer Atemschutzmaske vorgesehen ist und wobei sich der Saum im Gebrauchszustand an die Atemschutzmaske anliegt, wobei auf der in die Gesichtsfeldöffnung weisenden Seite des Saums (d. h. auf der im Gebrauchszustand zu der Atemschutzmaske weisenden Seite der Gesichtsfeldöffnung des Saums) mindestens ein umlaufendes Dichtelement zum abdichtenden Anliegen an die Atemschutzmaske vorgesehen ist.The present invention according to a first aspect is thus a hood, in particular for a garment, preferably for protective or military purposes, such as ABC protective suit or the like, wherein the hood has a circumferential elastic seam to form a visual field opening, wherein the visual field opening is provided for receiving a respirator mask and wherein the hem in the state of use rests against the respirator mask, wherein on the side facing in the field of view opening of the hem (ie on the side facing the respirator in use state side of the field opening of the seam) at least one circumferential sealing element for sealing Concerning the respiratory mask is provided.

Eine grundlegende Idee der vorliegenden Erfindung besteht somit darin, den die Gesichtsfeldöffnung bildenden Saum der zuvor beschriebenen Kapuze auf der in die Gesichtsfeldöffnung weisenden Seite des Saums (d. h. auf der Gebrauchszustand zu der Atemschutzmaske weisenden Seite des Saums) mit mindestens einem umlaufenden Dichtelement auszurüsten. Dies führt dazu, daß im Gebrauchszustand, also beim Tragen der Atemschutzmaske, eine Abdichtung des Übergangs zwischen Kapuze bzw. Saum einerseits und Atemschutzmaske andererseits erzielt wird bzw. die Abdichtung dieses Übergangs signifikant verbessert wird.A basic idea of the present invention therefore consists in equipping the seam of the previously described hood forming the visual field opening on the side of the hem pointing in the visual field opening (that is to say the side of the seam pointing towards the respiratory mask in use) with at least one circumferential sealing element. This means that in use, so when wearing the respirator, a seal the transition between the hood or hem on the one hand and respirator on the other hand is achieved or the sealing of this transition is significantly improved.

Im Gebrauchszustand, d. h. beim Tragen der Atemschutzmaske, liegt das Dichtelement auf der Atemschutzmaske auf, und es entsteht eine dichte und reibschlüssige Verbindung mit der unterliegenden Atemschutzmaske.In use, d. H. when wearing the respirator, the sealing element rests on the respirator, and it creates a tight and frictional connection with the underlying respirator.

Der Begriff "umlaufend", wie er erfindungsgemäß in bezug auf den Saum und das Dichtelement verstanden wird, wird im Sinne der vorliegenden Erfindung sowohl in seiner engeren Bedeutung wie auch in einer weiteren Bedeutung verstanden. Daher kann der Begriff "umlaufend" sowohl einen Zustand bezeichnen, bei dem der Saum oder das Dichtelement einen geschlossenen Ring oder Kreis bilden, aber auch einen Zustand, bei dem der Saum und das Dichtelement zwei lose Enden aufweist (z. B. wenn die Kapuze einen Verschluß bzw. eine verschließbare Öffnung aufweist), wobei die beiden losen Enden des Saums und des Dichtelements dann übereinandergelegt oder an den Enden zumindest im wesentlichen zusammengeführt werden können. Auch dies wird erfindungsgemäß noch unter dem Begriff "umlaufend" verstanden. Entscheidend ist, daß das umlaufende Dichtelement zumindest im wesentlichen durchgängig ausgebildet ist, d. h. ohne Kanäle und Öffnungen, so daß es abdichtend an die Atemschutzmaske anliegen kann.The term "circumferential", as it is understood according to the invention with respect to the seam and the sealing element, is understood in the context of the present invention both in its narrower sense as well as in a further meaning. Thus, the term "circumferential" may refer to both a state where the seam or sealing element forms a closed ring or circle, but also a state where the seam and the sealing element have two loose ends (eg, when the hood has a closure or a closable opening), wherein the two loose ends of the seam and the sealing element can then be superimposed or at least substantially brought together at the ends. Again, this is understood by the term "circumferential" according to the invention. It is crucial that the circumferential sealing element is at least substantially continuous, d. H. without channels and openings, so that it can rest sealingly on the respirator.

Besonders vorteilhaft ist es, wenn das Dichtelement zumindest im wesentlichen linienförmig an die Atemschutzmaske anliegend ausgebildet ist und/oder das Dichtelement vom Saum abragend bzw. vorspringend ausgebildet ist. Durch das zumindest im wesentlichen linienförmige Anliegen an die Atemschutzmaske im Gebrauchszustand wird ein höherer Anpreßdruck erzielt und folglich eine verbesserte Abdichtung. Zur Erzielung eines zumindest im wesentlichen linienförmigen Anliegens des Dichtelements an die Atemschutzmaske ist das Dichtelement entsprechend auszubilden.It is particularly advantageous if the sealing element is formed at least substantially linearly adjacent to the respirator mask and / or the sealing element is formed projecting or projecting from the hem. By the at least substantially linear concerns to the respirator in use, a higher contact pressure is achieved, and thus an improved seal. To achieve at least substantially line-shaped concern of the sealing element to the respirator, the sealing element is to be formed accordingly.

Weitere Vorteile, Eigenschaften, Aspekte und Merkmale der vorliegenden Erfindung ergeben sich aus der folgenden Beschreibung eines in der Zeichnung dargestellten, bevorzugten Ausführungsbeispiels. Es zeigt:

- Fig. 1

- eine schematische Darstellung eines erfindungsgemäßen Bekleidungsstückes, das mit einer erfindungsgemäßen Kapuze ausgestattet ist;

- Fig. 2

- eine schematische Darstellung einer erfindungsgemäßen Kapuze im Gebrauchszustand;

- Fig. 3A

- eine Vergrößerungsdarstellung des in Fig. 2 durch Strichelung markierten Bereichs der erfindungsgemäßen Kapuze im Gebrauchszustand;

- Fig. 3B

- eine Vergrößerungsdarstellung des in Fig. 3B durch Strichelung markierten Bereichs bzw. des in Fig. 3A entsprechend markierten Ausschnitts;

- Fig. 4A

- eine schematische Draufsicht auf den erfindungsgemäß mit Dichtelementen ausgestatteten Saum;

- Fig. 4B, C

- einen schematischen Querschnitt durch einen erfindungsgemäß mit Dichtelementen ausgestatteten Saum gemäß zweier Ausführungsformen;

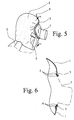

- Fig. 5

- eine Seitenansicht der erfindungsgemäßen Kapuze im Gebrauchszustand; und

- Fig. 6

- eine vergrößerte Querschnittsdarstellung entlang der in Fig. 5 dargestellten Linie VI.

- Fig. 1

- a schematic representation of a garment according to the invention, which is equipped with a hood according to the invention;

- Fig. 2

- a schematic representation of a hood according to the invention in use;

- Fig. 3A

- an enlargement of the marked in Figure 2 by Strichelung area of the hood according to the invention in use.

- Fig. 3B

- an enlargement of the marked in Fig. 3B by Strichelung area or of the marked in Fig. 3A corresponding section;

- Fig. 4A

- a schematic plan view of the present invention equipped with sealing elements seam;

- Fig. 4B, C

- a schematic cross section through an inventively equipped with sealing elements seam according to two embodiments;

- Fig. 5

- a side view of the hood according to the invention in use; and

- Fig. 6

- an enlarged cross-sectional view along the line VI shown in Fig. 5.

Fig. 1 zeigt ein erfindungsgemäßes Bekleidungsstück 2, vorzugsweise für Schutz- und/oder militärische Zwecke, wie einen ABC-Schutzanzug oder dergleichen, der mit einer erfindungsgemäßen Kapuze 1 ausgestattet ist. Die Kapuze 1 weist einen umlaufenden elastischen Saum 3 zur Bildung einer Gesichtsfeldöffnung 4 auf. Wie aus Fig. 2 und Fig. 3A ersichtlich, ist die Gesichtsfeldöffnung 4 zur Aufnahme einer Atemschutzmaske 5 vorgesehen. Dabei legt sich der Saum 3 im Gebrauchszustand an die Atemschutzmaske 5 an.Fig. 1 shows an

Fig. 3B zeigt den in Fig. 3A gesondert markierten Bereich als schematische Vergrößerung, wobei der an die Atemschutzmaske 5 anliegende Saum 3 in der Darstellung der Fig. 3B in Pfeilrichtung nach oben geklappt ist, so daß das erfindungsgemäß zum abdichtenden Anliegen an die Atemschutzmaske 5 vorgesehene Dichtelement 6, das auf der in die Gesichtsfelsöffnung 4 weisenden Seite des Saums bzw. auf der im Gebrauchszustand zu der Atemschutzmaske 5 weisenden Seite des Saums vorgesehen ist, zum Vorschein kommt.FIG. 3B shows the area marked separately in FIG. 3A as a schematic enlargement, the

Gemäß einer besonderen Ausführungsform liegt das erfindungsgemäß vorgesehene Dichtelement 6 zumindest im wesentlichen linienförmig an die Atemschutzmaske 5 an. Zu diesem Zweck ist es, wie Fig. 3B zeigt, entsprechend ausgebildet. Die Vorteile des zumindest im wesentlichen linienförmigen Anliegens wurden zuvor im allgemeinen Beschreibungsteil geschildert.According to a particular embodiment, the sealing

Die Wirkungsweise des erfindungsgemäß vorgesehenen Dichtelements 6 ist in Fig. 6 in Verbindung mit Fig. 5 veranschaulicht Fig. 6 ist eine vergrößerte Querschnittsdarstellung entlang der in Fig. 5 dargestellten gestrichelten Linie VI. Wie aus Fig. 6 ersichtlich, liegen im Gebrauchszustand, d. h. beim Tragen einer Atemschutzmaske 5, die Dichtelemente 6 zumindest im wesentlichen linienförmig an der Atemschutzmaske 5 zusammen mit dem Saum 3 an, wobei der Saum 3 die Dichtelemente 6 an die Atemschutzmaske 5 andrückt. Durch das zumindest im wesentlichen linienförmige Anliegen der Dichtelemente 6 wird der Anpreßdruck signifikant erhöht und eine ausgezeichnete Abdichtung erreicht.The mode of operation of the sealing

Wie aus Fig. 4A ersichtlich, kann es vorteilhaft sein, eine Mehrzahl von Dichtelementen 6 auf dem Saum 3 vorzusehen, vorzugsweise mindestens zwei Dichtelemente 6. Dabei sind verschiedene Ausgestaltungen in bezug auf die Anordnung der Dichtelemente möglich. Wie Fig. 4A zeigt, können die einzelnen Dichtelemente 6 zumindest im wesentlichen parallel zueinander angeordnet sein. Darüber hinaus besteht beispielsweise auch die Möglichkeit, die einzelnen Dichtelemente so anzuordnen, daß sie eine wabenartige Struktur ausbilden (nicht dargestellt). Entscheidend allein ist, daß im Gebrauchszustand eine dichte Verbindung zwischen Saum 3 und Atemschutzmaske 5 erreicht wird.As can be seen from FIG. 4A, it may be advantageous to provide a plurality of sealing

Wie die Querschnittsdarstellung 4B und 4C zeigen, kann das Dichtelement 6 vom Saum 3 abragend bzw. vorspringend ausgebildet sein. Hierdurch wird anstelle einer flächigen Auflage bzw. anstelle eines flächigen Anliegens ein im wesentlichen linienförmiges Anliegen im Gebrauchszustand erreicht, was mit einem höherem Anpreßdruck und mit einer höheren Abdichtung verbunden ist.As the cross-sectional representation 4B and 4C show, the sealing

Insbesondere ist das erfindungsgemäß vorgesehene Dichtelement 6 als Dichtring, Dichtlippe oder Dichtvorsprung ausgebildet. Im allgemeinen wird auf diese Weise eine Erhebung bzw. Erhöhung auf dem Saum 3 geschaffen.In particular, the sealing

Das Dichtelement 6 kann an dem Saum 3 befestigt sein, insbesondere dauerhaft mit dem Saum 3 verbunden sein, vorzugsweise durch Vernähen, Verweben, Verkleben, Verheften, Verschweißen oder dergleichen; eine derartige Ausführungsform ist in Fig. 4B dargestellt. Gemäß einer anderen Ausführungsform kann das Dichtelement 6 aber auch Bestandteil des Saums 3 sein, insbesondere können das Dichtelement 6 und der Saum 3 einstückig ausgebildet sein; eine solche Ausführungsform ist in Fig. 4C dargestellt.The sealing

Was das erfindungsgemäß vorgesehene Dichtelement anbelangt, so kann dieses faden-, band-, schnur- oder streifenförmig oder aber stegartig oder aber wabenförmig ausgebildet sein.As far as the sealing element provided according to the invention is concerned, it may be thread-shaped, band-shaped, cord-shaped or strip-shaped or web-like or else honeycomb-shaped.

Im allgemeinen besteht das Dichtelement 6 aus einem elastisch verformbaren Material. Dabei sollte insbesondere darauf geachtet werden, daß die Elastizität des Dichtelements 6 zumindest im wesentlichen der Elastizität des Saums 3 entspricht oder diese sogar übersteigt.In general, the sealing

Gemäß einer besonderen Ausführungsform der vorliegenden Erfindung weist das Dichtelement 6 eine relative elastische Dehnbarkeit bzw. Dehnung, bezogen auf seine Ausgangslänge, von mindestens 20 %, insbesondere mindestens 30 %, vorzugsweise mindestens 50 %, bevorzugt mindestens 70 %, besonders bevorzugt mindestens 85 % oder mehr, auf. Gemäß einer besonderen Ausführungsform der vorliegenden Erfindung beträgt der Dehnelastizitätsmodul des Materials, aus dem das Dichtelement 6 besteht, bei 25 °C höchstens 108 N · m-2, insbesondere höchstens 107 N · m-2, vorzugsweise höchstens 5 · 106 N · m-2, und liegt vorzugsweise im Bereich von 5 · 105 N · m-2 bis 9 · 106 N · m-2.According to a particular embodiment of the present invention, the sealing

Gemäß einer weiteren Ausführungsform der vorliegenden Erfindung kann es vorteilhaft sein, wenn die in Fig. 4B dargestellte Querschnittsdicke d des Dichtelements 6 mindestens 1/4, insbesondere mindestens 1/3, vorzugsweise mindestens 2/3, besonders bevorzugt mindestens 3/4, der in Fig. 4B dargestellten Querschnittsdicke D des Saums 3 entspricht. Insbesondere sollte das Dichtelement 6 zu mindestens 0,1 mm, insbesondere zu mindestens 0,25 mm, vorzugsweise zu mindestens 0,4 mm, bevorzugt zu mindestens 0,6 mm, besonders bevorzugt zu 1 mm und mehr, vom Saum (3) abragend bzw. vorspringend ausgebildet sein. Hierdurch läßt sich eine besonders gute Dichtwirkung erzielen.According to a further embodiment of the present invention, it may be advantageous if the cross-sectional thickness d of the sealing

Was das Material anbelangt, aus dem das erfindungsgemäße vorgesehene Dichtelement 6 besteht, so kommen beispielsweise alle Arten von Gummen, Latices, elastischen Kunststoffen etc. in Betracht, sofern sie sich zur Verwendung im Rahmen der vorliegenden Erfindung eignen. Insbesondere sollten diese Materialien vorteilhafterweise eine gewisse Wärme- und UV-Beständigkeit aufweisen und darüber hinaus auch eine gewisse Beständigkeit gegenüber aggressiven Medien, insbesondere Kampfstoffen, aber auch gegen Körperflüssigkeiten, insbesondere Schweiß, aufweisen. Darüber hinaus ist es von Vorteil, wenn das Material wasserabweisend ausgebildet ist.As regards the material of which the

Beispiele für erfindungsgemäß geeignete Materialien sind z. B. bestimmte Arten sogenannter Elastofasern (siehe RÖMPP-Chemielexikon, 10. Auflage, Band 2, 1997, Seiten 1104 bis 1106, Stichwort "Elastofasern", Georg Thieme Verlag Stuttgart/New York); hierbei handelt es sich um Chemiefasern, die extrem dehnbar sind und nach Aufhebung der Zugkraft weitgehend in den ursprünglichen Zustand zurückkehren. Die wichtigsten Vertreter sind Elastan, Fasern aus Hochpolymeren die zu mindestens 85 Gew.-% aus segmentiertem Polyurethan bestehen, und Elastodien, Fasern, die aus synthetischem Polyisopren oder aus Hochpolymeren bestehen, die durch Polymerisation eines oder mehrerer Diene, gegebenenfalls unter Zusatz eines oder mehrerer Vinylmonomerer, entstanden sind. Zur zweiten Gruppe kann man auch die Gummifasern aus Naturkautschuk zählen. Elastodiene werden häufig vulkanisiert. Elastische Eigenschaften besitzt auch eine Bikomponentenfaser aus Polyamid und Polyurethan. Auf weitere Einzelheiten kann auf die vorgenannte Literaturstelle verwiesen werden. Die Dimensionen derartiger Fasern sind für die erfindungsgemäßen Zwecke entsprechend anzupassen. Derartige Fasern können beispielsweise mit dem Saummaterial vernäht werden.Examples of suitable materials according to the invention are for. B. certain types of so-called elastofibres (see RÖMPP Chemielexikon, 10th Edition,

Wie beispielsweise in Fig. 1 und Fig. 2 dargestellt, kann die erfindungsgemäße Kapuze 1 einschließlich der Gesichtsfeldöffnung 4, insbesondere am seitlichen Teil der Gesichtsfeldöffnung 4, einen Verschluß 7 aufweisen (z. B. in Form eines Klettverschlusses oder eines Reißverschlusses). Hierdurch wird einerseits das Aufsetzen der Maske erleichtert; zum anderen steigert dies den Tragekomfort, da in Situationen, wo die Atemschutzmaske nicht benötigt wird, die Kapuze geöffnet werden kann. Es sollte aber sichergestellt sein, daß sich der Kapuzenverschluß 7 zumindest im wesentlichen dicht verschließen läßt. Grundsätzlich kann der Verschluß 7 an einer beliebigen Stelle der Gesichtsfeldöffnung 4 angeordnet sein (z. B. seitlich oder aber auch mittig in bezug auf die Gesichtsfeldöffnung 4); in der Praxis hat es sich aber insbesondere aus Gründen der Praktikabilität, des Tragekomforts und der besseren Abdichtbarkeit bewährt, wenn der Verschluß 7 am seitlichen Teil der Gesichtsfeldöffnung 4 angebracht ist.As shown, for example, in Figures 1 and 2, the

Was die Kapuze 1 anbelangt, so kann diese vom restlichen Bekleidungsstück 2 abnehmbar ausgebildet sein (z. B. über einen Klettverschluß oder einen Reißverschluß); auch bei dieser Ausführungsform muß darauf geachtet werden, daß das restliche Bekleidungsstück 2 und die Kapuze 1 zumindest im wesentlichen dicht miteinander verbindbar sind. Gleichermaßen ist es möglich, daß die Kapuze 1 Bestandteil des Bekleidungsstückes 2 ist, insbesondere hiermit vernäht ist oder sogar einstückig hiermit ausgebildet ist.As far as the

Gemäß einer weiteren Ausführungsform kann es - wie beispielsweise in Fig. 1 und Fig. 2 dargestellt - vorgesehen sein, daß die erfindungsgemäße Kapuze 1 oberhalb der Gesichtsfeldöffnung 4 mindestens eine Schlaufe, Lasche oder dergleichen 8 aufweist. Dies ermöglicht insbesondere ein Justieren der Gesichtsfeldöffnung 4 bzw. der Kapuze 1, insbesondere wenn die Kapuze 1 in Verbindung mit einem Helm oder einer anderen Kopfbedeckung getragen wird, die noch auf der Kapuze 1 aufsitzt.According to a further embodiment, it may be provided, as shown for example in FIGS. 1 and 2, that the hood according to the

Um ein Durchschlagen von giftigen Stoffen, insbesondere Kampfstoffen, durch die Kapuze 1 zu ermöglichen und/oder aber auch um eine Beseitigung gegebenenfalls in die Kapuze 1 eingedrungener giftiger Stoffe zu gewährleisten, kann es vorgesehen sein, daß die Kapuze 1 an ihrer Innenseite vollständig oder teilweise mit einem Innenmaterial ausgekleidet ist, welches ein adsorptionsfähiges Material, insbesondere Aktivkohle (z. B. in Form von Aktivkohlekömem bzw. -kügelchen oder Aktivkohlefasern), umfaßt. Alternativ oder in Kombination mit einem solchen adsorptionsfähigen Material kann es vorgesehen sein, daß das Innenmaterial eine wasserdampfdurchlässige, zumindest im wesentlichen gas- bzw. luftundurchlässige Sperrschicht umfaßt, welche den Durchtritt von schädlichen Gasen oder Flüssigkeiten, insbesondere chemischen Kampfstoffen, verhindert oder zumindest verzögert. Derartige Innenmaterialien, die mit einer Adsorptionsschicht und/oder einer Sperrschicht ausgestaltet sind, sind aus dem Stand der Technik als solche bekannt. Diesbezüglich kann beispielsweise verwiesen werden auf die DE 198 29 975 A1, die DE 39 39 373 A1, die DE 38 15 720 A1, die DE 195 19 869 A1, die DE 198 42 274 A1 und die DE 102 40 548, deren jeweilige Offenbarung hiermit durch Bezugnahme eingeschlossen ist.In order to allow a penetration of toxic substances, in particular warfare agents, through the

Gemäß einer besonderen Ausführungsform kann das gesamte Bekleidungsstück 2, insgesamt oder teilweise, mit einem derartigen Innenmaterial ausgestattet sein.According to a particular embodiment, all or part of the

Ein weiterer Gegenstand der vorliegenden Erfindung gemäß einem weiteren Aspekt der vorliegenden Erfindung ist ein Bekleidungsstück, insbesondere für Schutz- bzw. militärische Zwecke, wie beispielsweise ein ABC-Schutzanzug oder dergleichen, nach dem Oberbegriff des Anspruchs 17. Hier gelten die obigen Ausführungen zu der erfindungsgemäßen Kapuze bzw. zu dem erfindungsgemäßen Bekleidungsstück entsprechend.Another object of the present invention according to another aspect of the present invention is a garment, in particular for protective or military purposes, such as an ABC protective suit or the like, according to the preamble of claim 17. Here, the above statements apply to the invention Hood or to the garment according to the invention accordingly.

Gegenstand der vorliegenden Erfindung ist somit auch ein Bekleidungsstück, insbesondere für Schutz- bzw. militärische Zwecke, wie ein ABC-Schutzanzug oder dergleichen, wobei das Bekleidungsstück mindestens eine Öffnung für ein Körperteil (z. B. Hand, Arm, Fuß, Bein oder Kopf) mit einem umlaufenden elastischen Saum zur Bildung dieser Öffnung aufweist, wobei die Öffnung zur Aufnahme eines weiteren Bekleidungsstückes insbesondere mit glatter Oberflächenstruktur (z. B. Schutzhandschuh etc.) und/oder zur Aufnahme eines Ausrüstungsgegenstandes (z. B. Atemschutzmaske etc.) vorgesehen ist und sich der Saum im Gebrauchszustand an das weitere Bekleidungsstück und/oder den Ausrüstungsgegenstand anliegt, wobei auf der im Gebrauchszustand dem weiteren Bekleidungsstück und/oder dem Ausrüstungsgegenstand zugewandten Seite des Saums, vorzugsweise auf der in die Öffnung weisenden Seite des Saums, mindestens ein umlaufendes Dichtelement zum abdichtenden Anliegen an das weitere Bekleidungsstück bzw. an den Ausrüstungsgegenstand vorgesehen ist. Für weitere Einzelheiten kann auf obige Ausführungen in bezug auf die erfindungsgemäße Kapuze bzw. das erfindungsgemäße Bekleidungsstück verwiesen werden, die hier entsprechend gelten.The subject of the present invention is therefore also a garment, in particular for protective or military purposes, such as an ABC protective suit or the like, the garment having at least one opening for a body part (eg hand, arm, foot, leg or head ) with a circumferential elastic seam for forming this opening, wherein the opening for receiving a further item of clothing in particular with a smooth surface structure (eg protective glove etc.) and / or for receiving a piece of equipment (eg respiratory mask, etc.) is provided and in the state of use the hem is in contact with the further item of clothing and / or the piece of equipment, at least one circumferential one on the side of the seam facing the further item of clothing and / or the item of equipment, preferably on the side of the seam pointing in the opening Sealing element for sealing concern to the other Bekleidu or piece of equipment is provided. For further details, reference may be made to the above statements with respect to the hood according to the invention or the item of clothing according to the invention, which apply accordingly here.

Eine weitere grundliegende Idee der vorliegenden Erfindung besteht somit darin, den Übergang zwischen den bei Bekleidungsstücken für Körperteile vorgesehenen Öffnungen einerseits und weiteren Bekleidungsstücken oder Ausrüstungsgegenständen andererseits dadurch abzudichten, daß die entsprechende Öffnung mit einem Saum versehen ist, die auf der entsprechenden Seite mindestens ein Dichtelement der zuvor beschriebenen Art aufweist.Thus, another basic idea of the present invention is to seal the transition between the openings provided on garments for body parts on the one hand and other garments or equipment on the other hand by providing the corresponding opening with a seam which has at least one sealing element on the corresponding side having previously described type.

Schließlich ist ein weiterer Gegenstand der vorliegenden Erfindung die Verwendung eines elastischen Saums zum Abdichten des Übergangs zwischen einem Teil eines Bekleidungsstückes, insbesondere einer Kapuze, einerseits und einem weiteren Bekleidungsstück und/oder einem Ausrüstungsgegenstand, insbesondere einer Atemschutzmaske, andererseits, wobei auf der zu dem weiteren Bekleidungsstück bzw. zu dem Ausrüstungsgegenstück weisenden Seite des Saums mindestens ein umlaufendes Dichtelement zum abdichtenden Anliegen an das weitere Bekleidungsstück bzw. an den Ausrüstungsgegenstand vorgesehen ist. Die Ausführungen in bezug auf die erfindungsgemäße Kapuze bzw. das erfindungsgemäße Bekleidungsstück gelten in bezug auf die erfindungsgemäße Verwendung entsprechend.Finally, another object of the present invention is the use of an elastic seam for sealing the transition between a part of a garment, in particular a hood, on the one hand and another garment and / or a piece of equipment, in particular a respirator, on the other hand, wherein on the other Garment or the equipment counterpart facing side of the seam at least one circumferential sealing element is provided for sealing concern to the further garment or to the equipment item. The statements relating to the inventive Hood or garment according to the invention apply correspondingly with respect to the use according to the invention.

Weitere Ausgestaltungen, Abwandlungen und Variationen der vorliegenden Erfindung sind für den Fachmann beim Lesen der Beschreibung ohne weiteres erkennbar und realisierbar, ohne daß er dabei den Rahmen der vorliegenden Erfindung verläßt.Further embodiments, modifications and variations of the present invention will be readily apparent to those skilled in the art upon reading the description and practicable without departing from the scope of the present invention.

Claims (20)

- Hood (1), in particular for a clothing item (2), preferably for protective and/or military purposes, such as an NBC protective suit or the like, the hood (1) comprising an orbital elastic hem (3) to form a face opening (4), the face opening (4) being provided to receive a respirator (5) and the hem (3) abutting the respirator (5) in the use state,

characterized in that

the side of hem (3) that faces into the face opening (4) is provided with a multiplicity of orbital sealing elements (6) which are durably conjoined with the hem (3) and are in the form of elastofibres for closeout abutment of the respirator (5). - Hood according to Claim 1, characterized in that the sealing elements (6) abut the respirator (5) at least essentially linearly, and/or in that the sealing elements (6) project and/or protrude from the hem (3).

- Hood according to Claim 1 or 2, characterized in that the sealing elements (6) are secured to the hem (3) by stitching, interweaving, adhering, stapling, welding or the like.

- Hood according to any one of the preceding claims, characterized in that the sealing elements (6) are configured as a sealing ring, as a sealing lip or as a sealing protrusion.

- Hood according to any one of the preceding claims, characterized in that the sealing elements (6) are thread, ligament, string or strip shaped and/or webbed and/or honeycomb shaped.

- Hood according to any one of the preceding claims, characterized in that the individual sealing elements (6) are in an at least essentially parallel arrangement and/or in that the individual sealing elements (6) form a honeycomblike construction.

- Hood according to any one of the preceding claims, characterized in that the elasticity of the sealing elements (6) corresponds at least essentially to the elasticity of the hem (3).

- Hood according to any one of the preceding claims, characterized in that the cross-sectional thickness d of the sealing elements (6) is not less than 1/4, in particular not less than 1/3, preferably not less than 2/3 and more preferably not less than 3/4 of the cross-sectional thickness D of the hem (3), and/or the sealing elements (6) project and/or protrude from the hem (3) by not less than 0.1 mm, in particular not less than 0.25 mm, preferably not less than 0.4 mm, more preferably not less than 0.6 mm and even more preferably to an extent of 1 mm or more.

- Hood according to any one of the preceding claims, characterized in that the sealing elements (6) have a relative elastic extensibility, based on their original length, of not less than 20%, in particular not less than 30%, preferably not less than 50%, more preferably not less than 70% and even more preferably not less than 85% or more, and/or in that the material of which the sealing elements (6) consist has a 25°C modulus of elasticity in stretching which is not more than 108 N·m-2, in particular not more than 107 N·m-2, preferably not more than 5·106 N·m-2, and is preferably in the range from 5·105 N·m-2 to 9·106 N·m-2.

- Hood according to any one of the preceding claims, characterized in that the hood (1) including the face opening (4) comprises, in particular on the side portion of face opening (4), a fastener (7), in particular in the form of a touch and close fastener or zip fastener, and/or in that the hood (1) is detachable from the rest of clothing item (2).

- Hood according to any one of the preceding claims, characterized in that the hood (1) is fully or partially lined on its inside surface with an inside material, the inside material comprising an adsorption-capable material, in particular activated carbon, preferably in the form of activated carbon granules or spherules and/or activated carbon fibres, and/or a water vapour pervious, at least essentially gas and/or air impervious barrier layer which prevents or at least retards the passage of harmful gases or liquids, in particular chemical warfare agents.

- Hood according to any one of the preceding claims, characterized in that the hood (1) comprises at least one loop, tab or the like (8) above the face opening (4).

- Clothing item (2), preferably for protective and/or military purposes, such as an NBC protective suit or the like, comprising a hood (1) according to any one of the preceding claims.

- Clothing item according to Claim 13, characterized in that the hood (1) is durably joined to the rest of clothing item (2), in particular by stitching, interweaving, adhering, stapling or the like, or in that the hood (1) and the rest of clothing item (2) form a one-piece construction, or in that the hood (1) is detachable from the rest of clothing item (2), in particular by means of a zip fastener or of a touch and close fastener.

- Clothing item according to Claim 13 or 14, characterized in that the clothing item (2) is fully or partially lined on its inside surface with an inside material, the inside material comprising an adsorption-capable material, in particular activated carbon, preferably in the form of activated carbon granules or spherules and/or activated carbon fibres, and/or a water vapour pervious, at least essentially gas and/or air impervious barrier layer which prevents or at least retards the passage of harmful gases or liquids, in particular chemical warfare agents.

- Clothing item (2), in particular for protective and/or military purposes, such as an NBC protective suit or the like, the clothing item (2) comprising at least one opening (4) for a body part, such as a hand, arm, foot, leg or head, having an orbital elastic hem (3) to form this opening (4), the opening (4) being provided to receive a further clothing item in particular having a smooth surface texture and/or to receive an outfit article (5) and the hem (3) abutting the further clothing item and/or the outfit article (5) in the use state,

characterized in that

the side of the hem that faces the further clothing item and/or the outfit article (5), preferably the side of hem (3) which faces into the opening (4), is provided with a multiplicity of orbital sealing elements (6) which are durably conjoined with the hem (3) and are in the form of elastofibres for closeout abutment of the further clothing item and/or outfit article (5). - Clothing item according to Claim 16, characterized by the features of the characterizing portion of one or more of Claims 1 to 15.

- Use of an elastic hem (3) for closing out the transition between a portion of a clothing item (2), in particular a hood (1), on the one hand and a further clothing item and/or outfit article (5), in particular a respirator, on the other,

characterized in that

the side of hem (3) that faces the further clothing item and/or the outfit article (5) is provided with a multiplicity of orbital sealing elements (6) which are durably conjoined with the hem (3) and are in the form of elastofibres for closeout abutment of the further clothing item and/or outfit article (5). - Use according to Claim 18 for closing out the transition of a hood (1) of a clothing item (2), preferably for protective and/or military purposes, such as an NBC protective suit or the like, and of a respirator (5).

- Use according to Claim 18 or 19, characterized by the features of the characterizing portion of one or more of Claims 1 to 15.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10325057 | 2003-06-02 | ||

| DE10327994A DE10327994B4 (en) | 2003-06-02 | 2003-06-21 | Protective hood outer wear for atomic, biological and chemical warfare has seal between facial seam and respirator |

| PCT/EP2004/004932 WO2004105880A1 (en) | 2003-06-02 | 2004-05-08 | Hood for protective garment |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1628713A1 EP1628713A1 (en) | 2006-03-01 |

| EP1628713B1 true EP1628713B1 (en) | 2007-01-03 |

Family

ID=33491658

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04731824A Expired - Lifetime EP1628713B1 (en) | 2003-06-02 | 2004-05-08 | Hood for protective garment |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP1628713B1 (en) |

| JP (1) | JP4257663B2 (en) |

| AT (1) | ATE350112T1 (en) |

| CA (1) | CA2524465C (en) |

| DE (1) | DE502004002558D1 (en) |

| WO (1) | WO2004105880A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2009124748A1 (en) * | 2008-04-10 | 2009-10-15 | BLüCHER GMBH | Functional protective clothing unit |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102007020626A1 (en) | 2007-04-30 | 2008-11-06 | BLüCHER GMBH | Garment with hood and protective mask |

| JP2010133772A (en) * | 2008-12-03 | 2010-06-17 | Eikan Shoji Kk | Protective clothing |

| DE202014102072U1 (en) | 2014-04-15 | 2015-08-13 | BLüCHER GMBH | Balaklava and CBRN protective suit |

| CN110709139A (en) * | 2017-01-06 | 2020-01-17 | W.L.戈尔及同仁股份有限公司 | Shroud including particle barrier |

| JP2018126364A (en) * | 2017-02-09 | 2018-08-16 | 東洋紡株式会社 | Protective suit |

| US11806557B2 (en) * | 2018-12-06 | 2023-11-07 | Dupont Safety & Construction, Inc. | Protective garment having improved hood elastomeric interface |

| WO2021047789A1 (en) | 2019-09-09 | 2021-03-18 | BLüCHER GMBH | Head covering, in particualr a hood or balaclava, for use as protective clothing |

| CN112121323B (en) * | 2020-10-17 | 2024-07-19 | 北京仰生恒泰科技有限责任公司 | Dynamic sealing respiratory protection mask |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2005072A (en) * | 1934-10-15 | 1935-06-18 | William H Lea | Breathing mask |

| US2086325A (en) * | 1935-07-11 | 1937-07-06 | Frankel Nathan | Detachable and adjustable cap for garments |

| DE2718864C2 (en) * | 1977-04-28 | 1982-04-01 | Auergesellschaft Gmbh, 1000 Berlin | Gas-tight connection between two different parts of the respiratory or body protection |

| DE7715247U1 (en) * | 1977-05-13 | 1977-08-25 | Denso-Chemie Wedekind Kg, 5090 Leverkusen | Band-like sealing profile made of elastomeric material |

| GB2078491B (en) * | 1980-06-25 | 1984-01-11 | Wood Harris & Co Ltd | Protective garments |

| EP0057517B1 (en) * | 1981-01-15 | 1986-08-13 | Keith Bellas Simpson | Protective clothing |

| JPS57156036A (en) * | 1981-03-20 | 1982-09-27 | Toyobo Co Ltd | Protecting material against poisonous chemical material |

| DE8710165U1 (en) * | 1987-07-24 | 1987-10-01 | Güldener, Fritz, 6957 Elztal | protective suit |

| DE3815720A1 (en) | 1988-05-07 | 1989-11-16 | Hasso Von Bluecher | Material which is permeable to water vapour but impermeable to liquid water and its manufacture |

| DE3924033A1 (en) * | 1989-07-21 | 1991-02-28 | Ruiter Ernest De | Chemical warfare agent resistant liner - which is separately worn below outer combat garments |

| DE3939373C2 (en) | 1989-11-29 | 1998-04-09 | Hasso Von Bluecher | Protective suit material and process for making the material |

| FR2686795B1 (en) * | 1992-01-30 | 1996-07-05 | Intertechnique Sa | INDIVIDUAL RESPIRATORY AND PROTECTIVE EQUIPMENT IN CONTAMINATED ATMOSPHERE. |

| DE19519869C2 (en) | 1995-05-31 | 2001-02-08 | Kaercher Gmbh & Co Alfred | Protective material that can be decontaminated and ABC protective suit made from it |

| DE19829975B4 (en) | 1998-07-04 | 2006-11-30 | BLüCHER GMBH | Protective material against chemical poisons and process for its preparation and its use |

| DE19834688A1 (en) * | 1998-07-31 | 2000-02-03 | Bayerische Motoren Werke Ag | Texturing of seal profile used around vehicle access openings is achieved using, e.g., laser to inscribe transverse fish scale pattern preventing undesirable slip-stick noises |

| DE19842274B4 (en) | 1998-09-16 | 2006-11-09 | BLüCHER GMBH | Laminated, water and airtight water vapor permeable composite material |

| US6829784B2 (en) * | 2001-08-17 | 2004-12-14 | Tayco | Firefighting hood with dual bib |

| DE10240548C5 (en) | 2002-08-29 | 2011-06-16 | BLüCHER GMBH | Adsorption material, process for its preparation and its use |

-

2004

- 2004-05-08 EP EP04731824A patent/EP1628713B1/en not_active Expired - Lifetime

- 2004-05-08 AT AT04731824T patent/ATE350112T1/en not_active IP Right Cessation

- 2004-05-08 DE DE502004002558T patent/DE502004002558D1/en not_active Expired - Lifetime

- 2004-05-08 CA CA 2524465 patent/CA2524465C/en not_active Expired - Fee Related

- 2004-05-08 WO PCT/EP2004/004932 patent/WO2004105880A1/en active IP Right Grant

- 2004-05-08 JP JP2006508166A patent/JP4257663B2/en not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2009124748A1 (en) * | 2008-04-10 | 2009-10-15 | BLüCHER GMBH | Functional protective clothing unit |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1628713A1 (en) | 2006-03-01 |

| CA2524465C (en) | 2008-08-05 |

| JP2006526436A (en) | 2006-11-24 |

| JP4257663B2 (en) | 2009-04-22 |

| WO2004105880A1 (en) | 2004-12-09 |

| ATE350112T1 (en) | 2007-01-15 |

| DE502004002558D1 (en) | 2007-02-15 |

| CA2524465A1 (en) | 2004-12-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE10327994B4 (en) | Protective hood outer wear for atomic, biological and chemical warfare has seal between facial seam and respirator | |

| EP1788899B1 (en) | Piece of garment and system for sealingly joining pieces of garment | |

| EP1308186B1 (en) | Protective clothing against chemical and biological substances that are detrimental to health | |

| DE3048276A1 (en) | RESPIRATORY COVER, ESPECIALLY FOR THE REFUGEE | |

| EP1495784A2 (en) | Two piece combination protective suit with connection section | |

| EP1628713B1 (en) | Hood for protective garment | |

| EP3996818B1 (en) | Head covering, in particualr a hood or balaclava, for use as protective clothing | |

| DE202020101737U1 (en) | Protective suit | |

| DE4029939A1 (en) | Valve for breathing protection mask - has two flexible tongues which form seal with transverse rib | |

| EP3131643B1 (en) | Balaclava and cbrn protective suit | |

| DE20308642U1 (en) | Hood, for protective clothing, e.g. used for military purposes etc, e.g. NBC protective suit, has surrounding elastic edge, to create face opening to receive gas mask | |

| EP2768585B1 (en) | Hood for a piece of clothing or as a part of a clothing | |

| DE202020103171U1 (en) | Respirator | |

| DE202020101910U1 (en) | Face mask | |

| DE202007007996U1 (en) | Garment with hood and protective mask | |

| EP2142260B1 (en) | Piece of clothing having a hood and protective mask | |

| DE102008035683A1 (en) | Hood for use with respiratory mask in piece of clothing i.e. overall, has connection element i.e. hook and loop fastener element, arranged at clamping field and provided for connection with respirator mask | |

| DE102020110727B4 (en) | face mask | |

| DE202012003807U1 (en) | Hood for a garment or as part of a garment | |

| DE202020102814U1 (en) | Protective mask | |

| DE102021000815A1 (en) | breathing mask | |

| DE20311788U1 (en) | Two-piece safety- or military protective clothing has surrounding connecting section on upper part for sealed connection to lower part | |

| WO2021198293A1 (en) | Respirator | |

| DE202020102260U1 (en) | Face mask | |

| AT500584B1 (en) | Mask sealing frame comprises a cut out for a gas mask and a seal with a U or V shaped sealing lip |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20051013 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REF | Corresponds to: |

Ref document number: 502004002558 Country of ref document: DE Date of ref document: 20070215 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070403 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070403 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070414 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070604 |

|

| LTIE | Lt: invalidation of european patent or patent extension |

Effective date: 20070103 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 |

|

| 26N | No opposition filed |

Effective date: 20071005 |

|

| BERE | Be: lapsed |

Owner name: BLUCHER G.M.B.H. Effective date: 20070531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070404 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070508 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080531 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070508 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070103 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070704 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502004002558 Country of ref document: DE Representative=s name: VON ROHR PATENTANWAELTE PARTNERSCHAFT MBB, DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| REG | Reference to a national code |