EP1293144B1 - Plattenförmiges Aufnahmegehäuse für Gebrauchs- und/oder Verbrauchsgegenstände - Google Patents

Plattenförmiges Aufnahmegehäuse für Gebrauchs- und/oder Verbrauchsgegenstände Download PDFInfo

- Publication number

- EP1293144B1 EP1293144B1 EP02028246A EP02028246A EP1293144B1 EP 1293144 B1 EP1293144 B1 EP 1293144B1 EP 02028246 A EP02028246 A EP 02028246A EP 02028246 A EP02028246 A EP 02028246A EP 1293144 B1 EP1293144 B1 EP 1293144B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- plate

- cover plate

- base

- webs

- housing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 229920003023 plastic Polymers 0.000 claims description 12

- 239000004033 plastic Substances 0.000 claims description 12

- 239000000853 adhesive Substances 0.000 claims description 7

- 230000001070 adhesive effect Effects 0.000 claims description 7

- 238000013461 design Methods 0.000 claims description 7

- 238000007373 indentation Methods 0.000 claims description 7

- 229910052751 metal Inorganic materials 0.000 claims description 4

- 239000002184 metal Substances 0.000 claims description 4

- 230000003746 surface roughness Effects 0.000 claims description 3

- 230000000717 retained effect Effects 0.000 claims 2

- 239000011521 glass Substances 0.000 claims 1

- 235000010585 Ammi visnaga Nutrition 0.000 description 21

- 244000153158 Ammi visnaga Species 0.000 description 21

- 238000003780 insertion Methods 0.000 description 9

- 230000037431 insertion Effects 0.000 description 9

- 238000012549 training Methods 0.000 description 8

- 230000003203 everyday effect Effects 0.000 description 7

- 239000000463 material Substances 0.000 description 7

- 238000003466 welding Methods 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 5

- 230000004308 accommodation Effects 0.000 description 4

- 230000015572 biosynthetic process Effects 0.000 description 4

- 238000001746 injection moulding Methods 0.000 description 4

- 239000010410 layer Substances 0.000 description 4

- 229940112822 chewing gum Drugs 0.000 description 3

- 235000015218 chewing gum Nutrition 0.000 description 3

- 238000011161 development Methods 0.000 description 3

- 230000018109 developmental process Effects 0.000 description 3

- 238000000034 method Methods 0.000 description 3

- 238000003860 storage Methods 0.000 description 3

- DJQYKWDYUQPOOE-OGRLCSSISA-N (2s,3s)-2-[4-[(1s)-1-amino-3-methylbutyl]triazol-1-yl]-1-[4-[4-[4-[(2s,3s)-2-[4-[(1s)-1-amino-3-methylbutyl]triazol-1-yl]-3-methylpentanoyl]piperazin-1-yl]-6-[2-[2-(2-prop-2-ynoxyethoxy)ethoxy]ethylamino]-1,3,5-triazin-2-yl]piperazin-1-yl]-3-methylpentan- Chemical compound Cl.N1([C@@H]([C@@H](C)CC)C(=O)N2CCN(CC2)C=2N=C(NCCOCCOCCOCC#C)N=C(N=2)N2CCN(CC2)C(=O)[C@H]([C@@H](C)CC)N2N=NC(=C2)[C@@H](N)CC(C)C)C=C([C@@H](N)CC(C)C)N=N1 DJQYKWDYUQPOOE-OGRLCSSISA-N 0.000 description 2

- 230000002354 daily effect Effects 0.000 description 2

- 238000002347 injection Methods 0.000 description 2

- 239000007924 injection Substances 0.000 description 2

- 238000005259 measurement Methods 0.000 description 2

- 239000000243 solution Substances 0.000 description 2

- 230000003313 weakening effect Effects 0.000 description 2

- 238000004026 adhesive bonding Methods 0.000 description 1

- 239000012790 adhesive layer Substances 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 230000005489 elastic deformation Effects 0.000 description 1

- 238000004049 embossing Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 239000006260 foam Substances 0.000 description 1

- 210000001061 forehead Anatomy 0.000 description 1

- 239000003292 glue Substances 0.000 description 1

- 210000000056 organ Anatomy 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A45—HAND OR TRAVELLING ARTICLES

- A45D—HAIRDRESSING OR SHAVING EQUIPMENT; EQUIPMENT FOR COSMETICS OR COSMETIC TREATMENTS, e.g. FOR MANICURING OR PEDICURING

- A45D29/00—Manicuring or pedicuring implements

- A45D29/18—Manicure or pedicure sets, e.g. combinations without case, etui, or the like

- A45D29/20—Boxes, cases, etuis or the like specially adapted therefor

-

- A—HUMAN NECESSITIES

- A45—HAND OR TRAVELLING ARTICLES

- A45C—PURSES; LUGGAGE; HAND CARRIED BAGS

- A45C11/00—Receptacles for purposes not provided for in groups A45C1/00-A45C9/00

-

- A—HUMAN NECESSITIES

- A45—HAND OR TRAVELLING ARTICLES

- A45C—PURSES; LUGGAGE; HAND CARRIED BAGS

- A45C11/00—Receptacles for purposes not provided for in groups A45C1/00-A45C9/00

- A45C11/18—Ticket-holders or the like

- A45C11/182—Credit card holders

-

- A—HUMAN NECESSITIES

- A45—HAND OR TRAVELLING ARTICLES

- A45C—PURSES; LUGGAGE; HAND CARRIED BAGS

- A45C11/00—Receptacles for purposes not provided for in groups A45C1/00-A45C9/00

- A45C11/32—Bags or wallets for holding keys

- A45C11/325—Spare-key holders

- A45C11/326—Card-like holders

Definitions

- a plate-shaped housing made of plastic, especially for Credit and check cards known which is preferably a rectangular layout as well has a receiving chamber which of a base plate, one running parallel to this Cover plate and side walls, which are perpendicular to the base plate or cover plate run, is bounded. There is a receiving opening in one of the side walls, through which the credit or check card is inserted into the receiving chamber.

- the per se advantageous small external dimensions of such receiving housings, in particular a small thickness enables an extremely space-saving accommodation of the receiving housing, like this e.g. when accommodating in a wallet is required. This However, the advantage can only be for an object to be inserted into the receiving housing, for example, for a credit or check card.

- a key and holder combination is known from WO 93/22948 A, in which the plate-shaped Receiving housing a base plate and one with this via an articulated connection has pivotally connected cover plate, the base plate and / or the cover plate has one or more receiving chambers formed at least over part of its thickness for a key.

- the key is about one in a corner area the base plate arranged pivotally connected to the base plate.

- the key and stop combination has the disadvantage that because of the arrangement of the only a limited number of receiving chambers for the connection of the key required can be arranged in the receiving housing.

- a plate-shaped receiving housing which is a base plate with several, separated from each other by webs arranged distributed over an inner surface Storage compartments for storing items of daily use, such as a safety pin, a pair of scissors.

- the receiving chambers are from the outside accessible by lifting a cover that can be placed on the base plate.

- the bridges serve primarily for spatial separation into several reception chambers, and should by this is a mixing of the utensils which can essentially be freely inserted into the receiving chamber be prevented.

- GB 2 146 623 A is a receptacle housing for holding a wide variety of objects shown. These items can be, for example, by multi-function tools, e.g. a ruler, a lamp, a radio, a clock, a compass, a calculator, a thermometer, a comb needle.

- multi-function tools e.g. a ruler, a lamp, a radio, a clock, a compass, a calculator, a thermometer, a comb needle.

- the disadvantage of this training is that Objects can easily slide out of the corresponding receiving chambers and so that a loss of objects is possible.

- DE 38 27 536 C shows a key plastic container in a flat design, which has a carrier plate which has receiving grooves which are dovetail-shaped are formed and in which an object, for example, a key via corresponding Side surfaces is slidably supported.

- the material weakening is disadvantageous the carrier plate.

- a pistol with a pistol grip is known, which with the barrel the gun is connected in one piece and forms a central position for a receptacle, which is formed by the handle of the gun and a base plate and a pivotable to this Has cover plate.

- DE 38 34 303 A which has a container part and a pivotable articulated thereon Lid.

- the inside of the container and the lid are covered with foam mats provided, which have recesses which differ in shape from the shape of the Commodities are adapted.

- the object of the invention is to provide a plate-shaped housing, which while maintaining the advantageous small external dimensions and thereby space-saving accommodation, a good holding of the objects in the receiving housing allows.

- the object of the invention is indicated by that in the characterizing part of claims 1 and 2 Features solved.

- the surprising advantage of this is that the large number of thin, rib-like distributed between the cover and base plate over at least one inner surface Webs a support structure is formed and the structure stable by the support structure of the extremely flat design plate-shaped receiving housing also at extremely thin wall thicknesses of the base or cover plate and the webs can be achieved can.

- Dimensional stability gives the advantage of the higher number of receptacles that can be accommodated by the receiving housing Items.

- each one is simple Receiving chamber can be adapted to the respective object with the least effort can.

- a further embodiment according to claim 5 favors the establishment of the connection between base and cover plate by welding processes, for example ultrasonic welding processes.

- the embodiment according to claim 9 is also advantageous, since the object is in its in the receiving chamber inserted or projecting position positively over the receiving housing is supported and an automatic detachment of the object from the receiving chamber is avoided.

- the training variant according to claim 10 is also favorable, in which the commodities and / or consumables can be gripped even better Friction of the holder of the commodities and / or consumables in the Admission chambers can be enlarged.

- Another advantage is a training variant according to claim 17, through which the Swivel plate itself can be locked in the housing and / or at the same time Locking for sharp or pointed utensils allows, which for reasons security must be secured against automatic loosening.

- the functionality of the receiving housing is expanded.

- An embodiment according to claim 25 is also advantageous, since this results in an undisturbed insertion is possible even with slight tilting of the object.

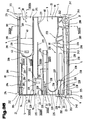

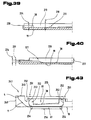

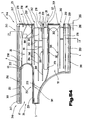

- FIGS. 1 and 2 one is known from the prior art Embodiment of a plate-shaped housing 1 made of metal or plastic shown, which is a rectangular plan with a width 2 and one to the right Angle measured length 3 has.

- the width 2 distances two parallel to each other extending longitudinal side surfaces 4, which are perpendicular to each other by the length 3 spaced transverse side surfaces 5 run.

- the plate-shaped receiving housing 1 has a base plate 6 and a cover plate 7, which are detachably or non-detachably connected to each other are.

- the longitudinal side surfaces 4 and transverse side surfaces 5 also preferably run perpendicular to the base plate 6 and to the cover plate 7.

- Transverse side surfaces 5 extend inside receiving chambers 8, in which objects, arranged in particular commodities 9, but also consumer items are.

- a longitudinal side surface 4 is with a top 10 extending at right angles to this Cover plate 7 connected via an inclined surface 11, which from the longitudinal side surface 4 in Direction of the top 10 and the second longitudinal side surface 4 by an angle of inclination 12 runs inclined.

- the second longitudinal side surface 4 and / or the transverse side faces 5 or at least parts of the longitudinal side faces 4 or transverse side faces 5 are inclined to the base and / or cover plate 6 and 7 and the inclined surface 11 train.

- the inclined surface 11 or a region of the base plate assigned to it 6 and / or the cover plate 7 has a scale 13, in particular a length scale 14 on.

- the receiving chamber 8 extends adjacent to the inclined surface 11 for a knife 15 forming the utility object 9, a knife blade 16 from the base plate 6 and the cover plate 7 in the direction perpendicular to the top 10 is delimited.

- a knife handle 17 is in a connecting surface 18 of the base plate 6 with the cover plate 7 facing away from one of the top 10 and parallel to this extending underside 19 of the base plate 6 projecting recess groove 20 is arranged and thus only bounded in the direction of the bottom 19 by the base plate 6. Consequently the receiving chamber 8 for the commodity 9, i.e. for the knife 15, of the Base plate 6 and at least in some areas from the cover plate running parallel to this 7 bounded.

- the knife handle 17 has a grip surface 21 which is approximately parallel and runs flat with the top 10.

- Receiving chamber 8 arranged for a file 22, for example. This is towards the top 10 and the bottom 19 delimited by the cover plate 7 and the base plate 6, wherein a receiving opening 23 for the file 22, through which this in the receiving chamber 8 can be inserted, is arranged in the transverse side surface 5.

- the cover plate 7 has a rectangular recess 24, which from the transverse side surface 5 in the direction of this protrudes opposite transverse side surface 5 and in which a file handle 25 is arranged is that it is accessible via the recess 24 from the outside. This enables easy Handle the file 22 and thus easy insertion and export of the same with respect to the Receiving chamber 8.

- a portion of the receiving chamber 8 is thereby over the recess 24, as is also available for receiving the knife handle 17 and also in the base plate 6 can be arranged made accessible.

- the receiving chamber 8 for extends adjacent to the receiving chamber 8 of the file 22 a pair of scissors 26 which extend from the transverse side surface 5 in the direction of the latter Transverse side surface 5 extends.

- a scissor handle 27 of the scissors 26 and a circular arc running recess 24 of the cover plate 7 is in the direction of the top 10 of a Swivel plate 28 covers, the receiving opening 23 for the scissors 26 from the Base plate 6 and the cover plate 7 bounded in the direction of the bottom 19 and the top 10 becomes.

- the swivel plate 28 is in a corner region 29 of the receiving housing 1 via a pivot pin 30 running perpendicular to the top 10 or bottom 19, which is preferably cylindrical, mounted in a swivel mount 31. This is designed, for example, as a curved slide track 32.

- the pivot pin 30 can in the swivel mount 31 by means of a locking ring against axial movement be secured.

- Adjacent to the receiving chamber 8 of the scissors 26 run parallel to one another and to Longitudinal side surface 4 two receiving chambers 8, which for receiving tweezers 33 and serve a toothpick 34. These are each via a receiving opening 23 of the transverse side surface 5 insertable into the receiving chambers 8. It is also possible in the field of Transverse side surface 5 for both the handle of the tweezers 33 and the toothpick 34 Form recess 24, as provided for the file handle 25.

- the top 10 is from the bottom 19 by a thickness 35 of the preferably rectangular receiving housing 1 spaced and is between 1.5 mm and 5 mm, preferably 4.0 to 4.3 mm.

- the length 3 must not be less than 70 mm and no greater than 90 mm and forms, as the width 2, a multiple of the thickness 35 of the receiving housing 1, which creates an accommodation in conventional compartments, such as those in wallets, briefcases or schedule folders are provided.

- the thickness 35 of the receiving housing 1 with increasing length 3 less the thickness 35 of the receiving housing 1 according to the ratio of thickness 35 (D) less than or equal to [1/18 times (70 - length 3) + 5] reduced. It is possible that all Receiving openings 23 of the receiving chambers 8 on a transverse side surface 5 or longitudinal side surface 4 are arranged.

- a plane of symmetry of the commodity running parallel to the base plate 6 and / or cover plate 7 9 and / or the consumable and / or the receiving chamber 8 is opposite to a parallel to the base plate 6 and / or cover plate 7 Plane of symmetry of the known receiving housing 1, which bisects the thickness 35, in Base plate 6 and / or cover plate 7 offset in the vertical direction. Furthermore, the Pivot plate 28 or part of base plate 6 and / or cover plate 7 cannot be pivoted, but relatively adjustable and / or relative to at least one receiving chamber 8 in a plane receiving the base plate 6 and / or cover plate 7 or be pivoted.

- a cross-sectional dimension can at least a part of a receiving chamber 8 with low tolerance to a cross-sectional shape of the Utility item 9 and / or the consumer item, which over it can also be held in the receiving chamber 8 via friction.

- a peripheral end edge of the utility item 9 and / or the consumer item, which delimits the outer contour of the same is approximately perpendicular to the base plate 6 and / or cover plate 7 aligned.

- the commodity 9 and / or consumer item has a grip part projecting over its outer circumference, such as, for example the file handle 25 of the file 22, which is arranged in the recess 24 and also can be held in the recess 24 by friction.

- the well-known housing 1, as already mentioned, is formed in two parts, the base plate 6 and / or Cover plate 7 can be formed by a one-piece, flat blank.

- the cover plate 7 from the base plate 6 via one, especially the receiving chambers 8 to keep the central part spaced apart from one another and via a connecting means, in particular to connect an adhesive or weld seam.

- the swivel plate 28 can in the area of a curved end face a protruding locking projection have, which in a locking recess of a commodity 9, such as the Scissors 26, engages and secures them against automatic solution.

- a commodity 9 such as the Scissors 26

- Known receiving housing 1 is formed as a one-piece component, for example as an injection molded part be, the receiving chambers 8 for the commodities 9 and / or Consumables are shaped by means of a slide during the injection molding process.

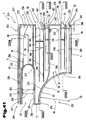

- the base plate 6 has a rectangular circumferential, the long side surfaces 4 and transverse side surfaces 5 forming envelope surface 36, which both the connecting surface 18 and also bounded by a base plate thickness 37 of this underside 19 distanced from this.

- Has groove bottom 38 which from the connecting surface 18 by a groove depth 39 in Direction of the bottom 19 is spaced.

- the recess groove 20, which is used to receive the Knife handle 17 shown in FIG.

- Recess groove 20 has one at right angles to the longitudinal side surface 4 measured groove width 40, which two facing each other and parallel to the long side surface 4 extending groove side surfaces 41 spaced apart.

- the recess groove 20 forms in the area of the transverse side face 5 a gradation 42, which is a partial area of the Receiving opening 23 forms.

- Recess groove 20 has an arc surface 43, preferably running in the shape of a circular arc, which connects the two groove side surfaces 41 running parallel to one another.

- the receiving opening is located on the transverse side surface 5 opposite the step 42 23 for the file 22 shown in FIG. 1.

- This also has a gradation 42 and a recess groove 20.

- the recess groove 20 runs at right angles to the transverse side surface 5 and has in one of the transverse side surface 5 in the direction of this opposite Transverse side surface 5 spaced by a partial length 44, a shoulder 45, whereby the groove depth 39 in the area of the transverse side surface 5 is greater than a partial groove depth 46 one from the shoulder 45 in the direction of an end face 47 extending portion 48 of the groove 20.

- Parallel a further deepening groove 20 runs to this deepening groove 20, which is for receiving any other commodity 9 or consumer item.

- the guide surface 53 has an area adjacent to the swivel mount 31 Longitudinal side surface 4 a stop surface 54 running parallel to this, which a parallel has to the transverse side surface 5 extending end surface 55 which from the center 52 around a distance 56 measured parallel to the longitudinal side surface 4 is spaced, which is smaller is as the radius 51.

- the center point 52 is located on a curved center line 57 of the swivel mount 31, which has a curved slide track 32 for the swivel pin 30 - as can be seen in FIG. 1 - and one perpendicular to the base surface 49 in the direction the underside 19 has a measured depth 58 which is less than one of the base area 49 and the underside 19 bounded base height 59.

- the swivel mount 31 is designed in the form of a cylindrical blind bore.

- the recess groove 20 for the scissors 26 shown in FIG. 1 has two facing each other Flank surfaces 60, which do not run parallel to the longitudinal side surfaces 4, but instead the outer shape of the scissors 26 are reproduced.

- the cover plate 7 has a slot-shaped opening running parallel to the longitudinal side surface 4 61, which extends from the transverse side face 5 in the direction of this and parallel extends transverse side surface 5 by an opening depth 62 and the recess 24 formed.

- the slot-shaped opening 61 is through an arcuate end face 63, which is distanced from the transverse side surface 5 by the opening depth 62. From the end face 63 extends opposite to the slot-shaped opening 61 the recess groove 20, which runs parallel to the longitudinal side surface 4.

- the slit-shaped Opening 61 and the recess groove 20 of the cover plate 7 correspond to the recess groove 20 and the connecting surface 18 of the base plate 6 and each form a partial area the receiving chamber 8 for the knife 15 shown in Fig.

- the slot-shaped opening 61 thereby breaks through both the connecting surface 18 as well as the top 10.

- the transverse side surface 5 and Longitudinal side surface 4 are connected in the corner area 29 via a guide profile 64. This is composed of an approximately perpendicular to the connecting surface 18 Guide surface 65, which is in a radius of curvature 66 around the center shown in FIG. 3 52 runs.

- the radius of curvature 66 is larger than that by a distance 67 3 shows the radius 51 of the guide surface 53 of the base plate 6.

- transverse side surface having the slot-shaped opening 61 5 opposite transverse side surface 5 are the recess grooves 20 for that shown in Fig. 1 File 22, tweezers 33, toothpicks 34 and another tool shown.

- the Recess grooves 20 have the recesses 24, which the top 10 partially break through and serve for better gripping of the tools or their handles.

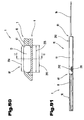

- the pivot plate 28 is for the receiving housing known from the prior art 1 in perspective or a partial area of the same in section shown. From this it can be seen how the pivot plate 28 is guided in the guide arrangement 71 becomes. This is formed by the guide surface 65 and the annular surface 72, which in of the cover plate 7 are arranged, the guide surface 65 being perpendicular to the upper side 10 and the annular surface 72 extends parallel to the top 10. By the distance 67 is a Cover area of the annular surface 72 and an upper surface 73 of the swivel plate 28 is formed, whereby movement of the pivot plate 28 in the direction of the top 10 is prevented becomes.

- the base plate 6 has the guide surface 53 already described, which is the connecting surface 18 protrudes in the direction of the top 10 of the cover plate 7 by the height 50. It runs along an inner ring surface 74 which is perpendicular to one parallel to the top 73 extending inside 75 of the pivot plate 28 is arranged and this in the direction overhanging the connecting surface 18.

- An annular collar 76 is thereby formed, which is guided in the guide arrangement 71, a movement of the swivel plate 28 is prevented in the direction of the base plate 6.

- the collar 76 has a web 77, which with an inner surface 78 and the stop surface 54 shown in FIG. 3 a stop formed. Located on an outer ring surface 79 which limits the collar 76 to the outside the outer ring surface 79 opposite the collar 76 in the region of the collar 76 outstanding extension 80, which with the recess 70 shown in Fig. 4 a locking formed.

- FIGS. 7 to 15 are now in the base plate 6 of the Well-known receiving housing 1 arranged recess grooves 20 with corresponding dimensions shown.

- One of the long side surface forming the recess groove 20 4 adjacent knife recess groove 81 has one parallel to the width 2 measured groove width 82, which is 12.83 mm.

- One parallel to the long side surface 4 extending groove side 83 is from a longitudinal side surface 4 by a distance 84 of 37.3 mm spaced.

- the width 2 is preferably 54 mm, the length 3 is preferably 82 mm.

- Knife recess groove 81 protrudes from the transverse side surface 5 in the direction of that facing away from it Transverse side face 5 by a depth, a circular end face 85, which delimits the knife recess groove 81 in the direction of the transverse side surface 5, preferably runs in a circular arc and a center of the circular arc End face 85 is spaced from transverse side face 5 by a distance 86 of 35 mm.

- Another depression groove 20 forms a needle depression groove 89 which extends from the transverse side surface 5 angularly in the direction of this transverse side surface 5 facing away from the Longitudinal side surface 4 runs.

- a center line 90 of the needle groove 89 therefore closes with an auxiliary line running at right angles to the transverse side surface 5, an angle 91 of 3.5 ° on.

- the receiving opening 23 of the needle recess groove lying in the region of the transverse side surface 5 89 is spaced from the long side surface 4 by a distance 92 of 5.17 mm, wherein the needle recess groove 89 has a length 93 of 33 mm. It also owns As can be seen in FIG.

- a further deepening groove 20 forming file deepening groove 96 is provided with a groove side surface 97 from the longitudinal side surface 4 by a distance 98 of 35.5 mm and has a groove width 99 of 7 mm parallel to this measured. She also has one from the transverse side surface 5 in the direction of the transverse side surface 5 facing away from it, groove length 100 of 58.5 mm measured parallel to the longitudinal side surface 4.

- the file recess groove 96 has - as can be seen in FIG.

- a further tool groove 105 is arranged, which of the transverse side surface 5 runs in the direction of the transverse side surface 5 facing away from it and has an arcuate end portion, the center of which is from the transverse side surface 5 is spaced from the transverse side surface 5 by a groove length 106, which 52 mm is.

- a groove side surface 107 of the tool groove 105 is from the longitudinal side surface 4 spaced apart by a distance 108 of 24.5 mm and has a groove width 109 of 2.2 mm on.

- it has one of the connecting surface 18 in the direction of the bottom 19 measured groove depth 110 of 1.1 mm.

- Another scissor groove 111 forming another groove 20 has a groove side surface 112, which runs parallel to the longitudinal side surface 4 and from this by one Distance 113 of 13.5 mm from the long side surface 4 is spaced.

- An end region 114 the scissor recess groove 111 has an arcuate end face 115, whose center point is spaced 116 from the transverse side surface 5 at a distance 116 of 75 mm is.

- a groove side surface 117 which faces away from the groove side surface 112 extends circular arc-shaped end face 115 in the direction of the transverse side face 5 parallel to the groove side face 112 runs up to a distance 118 of 42.59 mm.

- a groove base 123 of the scissor recess groove 111 is as can be seen in FIG. 12 - from the connecting surface 18 in the direction of the underside 19 a groove depth 124 spaced 1.2 mm apart.

- the groove base 125 of the tool recess groove 105 already described is - as in FIG. 11 can be seen - from the connecting surface 18 in the direction of the underside 19 in a groove depth 126 spaced from 1.1 mm.

- a tweezer groove 127 extends from the transverse side surface 5 by a groove length 128 of 47 mm, which is identical to that of the recess groove 20 of the toothpick 34 shown in FIG. 1.

- the groove width 129 is 3.3 mm and that in FIG.

- the groove depth 130 shown in FIG. 13 is 0.6 mm.

- the swivel mount 31 is in the form of a curved one Long hole formed and has a curved center line 131, which in a radius 132 from a center point 133.

- the center point 133 lies around one Distance 134 in the direction of the longitudinal side surface 4 and transverse side surface 5 of 3.5 mm. Of this extends the radius 51, which delimits the guide surface 53 and is 29 mm.

- the pivot mount 31 has a groove width 135 of 2.5 mm and a groove depth 136 of 2.2 mm.

- the cover plate 7 is now from the stand the receiving housing 1 known in the art is shown in detail. It goes like this described - the slot-shaped opening 61 parallel to the longitudinal side surface 4, at right angles to the transverse side surface 5, from this in the direction of that arranged adjacent to it Transverse side surface 5.

- the slot-shaped opening 61 which forms the recess 24, has an arcuate end face 63, the center of which is at a distance 137 from 35 mm is distanced from the transverse side surface 5.

- An end face 138 that extends from the face 63 in the direction of the transverse side surface 5 extending groove 20 which the Knife depression groove 81, in particular for the knife blade 16 shown in FIG.

- An opening width is 146 in the area the top 10 about 11.5 mm.

- the knife recess groove 81 runs adjacent File deepening groove 96 into a groove length 147 measured from the transverse side surface 5 of 58.5 mm.

- the file recess groove 96 has the shoulder 45 which - as can be seen in FIG. 19 - Is spaced from the transverse side surface 5 by a length 148 of 20 mm.

- the tool groove 105 has a groove width 157, which is measured parallel to the transverse side surface 5, and which is 2.2 mm. Furthermore, it projects from the transverse side surface 5 in the direction of the transverse side surface 5 facing away from it in front, wherein it is semicircular in an end region and a center point in a distance 158 of 52 mm from the transverse side surface 5.

- a groove depth 159 the tool groove 105 is - as can be seen in FIG. 20 - from the connecting surface 18 in Direction of the top 10 1.1 mm. There is also a bevel in this recess groove 20 151 present at the top 10.

- Guide surface 65 which runs in the form of a circular arc and which extends from the center 52 in the radius of curvature 66 runs from 29 mm.

- the center point 52 is at a distance 160, which is 3.5 mm, spaced from the longitudinal side surface 4 and transverse side surface 5, respectively.

- the end face 68 which is concentric with the guide surface 65, has the end face radius 69, which is also measured at the center 52 and is 28 mm.

- Both the tweezer recess groove 127 and the recess groove 20 for the toothpicks 34 shown in FIG. 1 extend from the transverse side surface 5 into one Length 168 of 47 mm parallel to the long side surface 4.

- the recesses 24 of these two Deepening grooves 20 are analogous to the versions already described, as is the bevel 151.

- a groove depth 169 of these two recess grooves 20 is - as in FIG. 21 visible - 0.6 mm.

- the width 2 of the cover plate 7 is approximately 52.8 mm, the length 3 in about 82 mm.

- the scissor-groove 111 has - as can be seen in Fig. 22 - one Groove depth 170 of 1 mm.

- the swivel plate 28 is now for the from Known prior art receptacle housing 1 shown with detailed measurements.

- the outer ring surface 79 extends in a radius 171 of 29 mm around a center point 172. This is at a distance 173 from mutually perpendicular end faces 174, which is 3.5 mm.

- the inner radius 175 becomes the center 172 measured, which distances the inner ring surface 74.

- the pivot pin 30 is in one Intersection of the distance 173 and a distance 176, which is 8 mm, arranged and lies eccentrically to the center 172.

- a distance between an inner edge 177 of the inner ring surface 74 is from the end face 174 31.05 mm.

- Outer distance 178 which is measured from the face 174, limits the outer ring surface 79 and is 32.77 mm.

- a distance 179 that is parallel from the face 174 is measured to the outer distance 178 and delimits the outermost point of the extension 80, is approximately 33.05 mm.

- the top 73 of the swivel plate 28 has a step 180, which creates an annular surface 181 is formed, which runs at a depth 182 of 0.7 mm.

- a surface 183 the pivot pin 30 is spaced from the top 73 by a height 184 of approximately 3.4 mm.

- the pivot pin 30 has a pin diameter 185 of 2.3 mm.

- the collar 76 projects beyond the inner side 75, which runs parallel to the upper side 73, by a height 186 of 1 mm.

- the top 73 is spaced from the inside 75 by a thickness 187 of 1.2 mm.

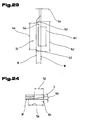

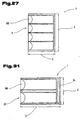

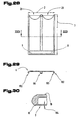

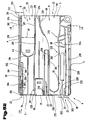

- FIGS. 27 to 31 further training variants of the are shown receiving housing 1 shown in the prior art.

- the base plate 6 can be formed with a box-shaped central web 191 are and limited by two side webs 192 which are spaced apart by the width 2 become.

- the side webs 192 each have a shoulder 193 running parallel to the length 3 on which of the top 10, which in this case is predetermined by the base plate 6 is projected in the direction of the bottom 19 by a heel depth 194.

- 193 is

- a cover plate 7 designed as a film is arranged.

- FIG. 31 A further known embodiment of a receiving housing 1 can be seen in FIG. 31, in which the chewing gum 190 are arranged parallel to the length 3 and in an end area facing away from the receiving openings 23, for example a toothpick 34 is arranged, which runs parallel to the width 2 of the receiving housing 1.

- Chamber webs 201 for the needle recess groove 89 are sectionally formed by partial webs 204 limited, which run at an angle to the transverse side surface 5 towards each other and from are spaced from one another by the groove width 94 measured parallel to the transverse side surface 5. This is smaller than a diameter of a one to be inserted into the needle recess groove 89 Needle 205.

- curvature webs 257 run opposite one another Connect longitudinal webs 258 to the opening 61, of which that of the longitudinal side surface 4 or

- the groove bottom 38 of the knife recess groove arranged in the cover plate 7 81 is inclined to the upper side 10 in some areas.

- the cover plate 7 is located in the opposite direction to the longitudinal side surface 4 arranged file recess groove 96.

- This has a recess 24, which from web-shaped trained centering receptacles 259 is limited.

- Following the web-shaped Centering receptacles 259 extend longitudinal webs 260 parallel to the longitudinal side surface 4 and is at a depth 261 from the recess end face delimiting the recess 24 262, which extends from the transverse side surface 5 in the direction of the second transverse side surface facing away from this 5, in which the opening 61 for the knife 15, in particular for the knife handle 17 is located, is arranged at right angles to the longitudinal webs 260 Crossbar 263 arranged.

- the recess end face 262 is from the transverse side face 5 by an end face depth 265 distanced in the direction of the further transverse side surface 5.

- the next recess groove 20, which is arranged in the cover plate 7, is the tweezer recess groove 127. This also has the recess 24, which with the The recess end face 262 is spaced apart from the transverse side face 5 by the end face depth 265 is.

- the tweezer recess groove 127 is also through the web-like centering receptacle 259 circumscribed. Furthermore, it is through a longitudinal web 260 of the file recess groove 96 and through delimits a longitudinal web 266 of the scissor recess groove 111.

- the web-shaped centering fixtures 259 have an upper surface 267, which extends from a surface parallel to the upper surface 10 Base 268 is spaced by a height 269.

- the centering fixtures also run 259 to a depth 270, in the connection of which, for example, the longitudinal webs 260 extend which are spaced from the base surface 268 by a web height 271.

- the Web height 271 is greater than the height 269.

- the recess 24 Extend tweezer recess groove 127 limiting web-shaped centering receptacles 259 there are further connecting webs 301 parallel to the longitudinal side surfaces 4. Further connecting webs 301 are in the area of the scissor groove 111 and the ballpoint pen groove 203 arranged.

- the connection between the base plate 6 and the cover plate 7 is such that, for example in the area of the gap width 298 between the longitudinal web 219 and the inside surface 295 of the connecting web 294 of the longitudinal web 251 of the cover plate 7 in a form-fitting manner on the Connecting web 294 rests.

- Receiving housing 1 is that an inner height 311, that is the free dimension perpendicular to the basic or cover plate 6, 7 between the mutually facing inner surfaces of the base or Cover plate 6, 7 equal to or greater than a thickness of the object to be picked up, in particular Commodity 9 is.

- the webs in particular the chamber web, can thereby 201, the stop web 206, the longitudinal webs 219, 226, the curvature webs 231 and / or the centering webs 220, which are perpendicular to these inner surfaces of the base or cover plate 6, 7 protrude, each from the cover plate 7 in the direction of the base plate 6 or from the Base plate 6 extend in the direction of the cover plate 7 over the entire inner height 311 or only over part of the inner height 311, so that when the basic or cover plate 6, 7 lying side by side each from the base plate 6 to the cover plate 7 extend or together a continuous web from the base plate 6 to the cover plate 7 train.

- connecting webs 294, 301 are assigned.

- This Connecting webs 294, 301 have a considerably smaller width 314 than the thickness 313 of the Webs, e.g. the curvature webs 231 and / or the centering webs 220, the longitudinal webs 219, 226, the stop webs 206 and the chamber webs 201.

- the top 10 of the cover plate 7 with a corresponding electroplated or otherwise applied or glued on coating be provided, e.g. can be designed reflective to serve as a mirror.

- the upper side 10 or the opposite side Bottom 19 of the base plate 6 to be at least partially provided with solar cells in order an energy store provided in the plate for further applications, e.g. one VHF receivers or position transmitters or signal lights or To be able to operate.

- the plate-shaped receiving housing 1 can be produced from any materials, but in particular made of plastic in the course of an injection molding process or injection or embossing process respectively. A production is also made of other materials, such as Aluminum, wood, cardboard or other materials possible.

- the plate-shaped housing 1 with additional Holding organs such as projecting holding lugs or the like.

- additional Holding organs such as projecting holding lugs or the like.

- For receiving and holding be provided by credit cards, identification cards or possibly also cash can.

Landscapes

- Purses, Travelling Bags, Baskets, Or Suitcases (AREA)

- Packaging Of Annular Or Rod-Shaped Articles, Wearing Apparel, Cassettes, Or The Like (AREA)

- Packaging For Recording Disks (AREA)

- Accommodation For Nursing Or Treatment Tables (AREA)

- Supports Or Holders For Household Use (AREA)

- Thermotherapy And Cooling Therapy Devices (AREA)

- Packages (AREA)

- Details Of Rigid Or Semi-Rigid Containers (AREA)

- Non-Silver Salt Photosensitive Materials And Non-Silver Salt Photography (AREA)

- Catching Or Destruction (AREA)

- Pens And Brushes (AREA)

- Magnetic Record Carriers (AREA)

- Laminated Bodies (AREA)

- Details Of Measuring And Other Instruments (AREA)

- Sheet Holders (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT02028246T ATE277538T1 (de) | 1995-11-30 | 1996-12-02 | Plattenförmiges aufnahmegehäuse für gebrauchs- und/oder verbrauchsgegenstände |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT0196195A AT404237B (de) | 1995-11-30 | 1995-11-30 | Plattenförmiges aufnahmegehäuse für gebrauchs- und/oder verbrauchsgegenstände |

| AT196195 | 1995-11-30 | ||

| EP96939748A EP0957704B2 (de) | 1995-11-30 | 1996-12-02 | Plattenförmiges aufnahmegehäuse für gebrauchs- und/oder verbrauchsgegenstände |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96939748A Division EP0957704B2 (de) | 1995-11-30 | 1996-12-02 | Plattenförmiges aufnahmegehäuse für gebrauchs- und/oder verbrauchsgegenstände |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1293144A2 EP1293144A2 (de) | 2003-03-19 |

| EP1293144A3 EP1293144A3 (de) | 2003-03-26 |

| EP1293144B1 true EP1293144B1 (de) | 2004-09-29 |

Family

ID=3524803

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP02028246A Expired - Lifetime EP1293144B1 (de) | 1995-11-30 | 1996-12-02 | Plattenförmiges Aufnahmegehäuse für Gebrauchs- und/oder Verbrauchsgegenstände |

| EP96939748A Expired - Lifetime EP0957704B2 (de) | 1995-11-30 | 1996-12-02 | Plattenförmiges aufnahmegehäuse für gebrauchs- und/oder verbrauchsgegenstände |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96939748A Expired - Lifetime EP0957704B2 (de) | 1995-11-30 | 1996-12-02 | Plattenförmiges aufnahmegehäuse für gebrauchs- und/oder verbrauchsgegenstände |

Country Status (9)

| Country | Link |

|---|---|

| US (4) | US6044967A (enExample) |

| EP (2) | EP1293144B1 (enExample) |

| JP (1) | JP4098360B2 (enExample) |

| CN (1) | CN1161059C (enExample) |

| AT (3) | AT404237B (enExample) |

| AU (1) | AU7685396A (enExample) |

| DE (3) | DE59610769D1 (enExample) |

| ES (2) | ES2230442T3 (enExample) |

| WO (1) | WO1997019856A2 (enExample) |

Families Citing this family (84)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT408053B (de) * | 1998-05-18 | 2001-08-27 | Painsith Hermann Dipl Ing | Funktionsteileträger, insbesondere taschenmesser oder plattenförmiges aufnahmegehäuse |

| CN1275744C (zh) | 1997-08-08 | 2006-09-20 | 维科托里诺克斯股份公司 | 功能件存放盒和小刀 |

| US7466556B2 (en) * | 1999-08-04 | 2008-12-16 | Super Talent Electronics, Inc. | Single chip USB packages with swivel cover |

| US7872871B2 (en) * | 2000-01-06 | 2011-01-18 | Super Talent Electronics, Inc. | Molding methods to manufacture single-chip chip-on-board USB device |

| US7535719B2 (en) * | 1999-08-04 | 2009-05-19 | Super Talent Electronics, Inc. | Single chip USB packages with contact-pins cover |

| US7447037B2 (en) * | 1999-08-04 | 2008-11-04 | Super Talent Electronics, Inc. | Single chip USB packages by various assembly methods |

| US7830666B2 (en) | 2000-01-06 | 2010-11-09 | Super Talent Electronics, Inc. | Manufacturing process for single-chip MMC/SD flash memory device with molded asymmetric circuit board |

| US8625270B2 (en) | 1999-08-04 | 2014-01-07 | Super Talent Technology, Corp. | USB flash drive with deploying and retracting functionalities using retractable cover/cap |

| US8141240B2 (en) | 1999-08-04 | 2012-03-27 | Super Talent Electronics, Inc. | Manufacturing method for micro-SD flash memory card |

| US8102662B2 (en) * | 2007-07-05 | 2012-01-24 | Super Talent Electronics, Inc. | USB package with bistable sliding mechanism |

| JP2003515370A (ja) * | 1999-12-02 | 2003-05-07 | ビクトリノクス アクチェンゲゼルシャフト | 機能部品支持体、特に工具カードまたはポケットナイフ |

| AT410644B8 (de) * | 1999-12-02 | 2003-07-25 | Victorinox Ag | Taschenmesser |

| AT414328B (de) * | 1999-12-02 | 2007-09-15 | Victorinox Ag | Werkzeugkarte |

| US7297024B2 (en) * | 2003-09-11 | 2007-11-20 | Super Talent Electronics, Inc. | Universal-serial-bus (USB) flash-memory device with metal wrap formed over plastic housing |

| US20080286990A1 (en) * | 2003-12-02 | 2008-11-20 | Super Talent Electronics, Inc. | Direct Package Mold Process For Single Chip SD Flash Cards |

| US6460698B1 (en) * | 2000-11-27 | 2002-10-08 | Jenn Liang Wang | Planer tool casing |

| US6571940B2 (en) * | 2001-06-01 | 2003-06-03 | Chris M. Newman | Flat article holder |

| AT500390B1 (de) * | 2002-10-30 | 2008-12-15 | Victorinox Ag | Taschenwerkzeug |

| US20050156333A1 (en) * | 2003-09-11 | 2005-07-21 | Super Talent Electronics Inc. | Narrow Universal-Serial-Bus (USB) Flash-Memory Card with Straight Sides using a Ball-Grid-Array (BGA) Chip |

| US7094074B2 (en) * | 2003-09-11 | 2006-08-22 | Super Talent Electronics, Inc. | Manufacturing methods for ultra-slim USB flash-memory card with supporting dividers or underside ribs |

| WO2005043429A2 (en) * | 2003-10-23 | 2005-05-12 | Kyp (Holdings) Plc | Device for use as a bookmark or for promotional purposes |

| US8102657B2 (en) * | 2003-12-02 | 2012-01-24 | Super Talent Electronics, Inc. | Single shot molding method for COB USB/EUSB devices with contact pad ribs |

| US7872873B2 (en) | 2003-12-02 | 2011-01-18 | Super Talent Electronics, Inc. | Extended COB-USB with dual-personality contacts |

| US8998620B2 (en) * | 2003-12-02 | 2015-04-07 | Super Talent Technology, Corp. | Molding method for COB-EUSB devices and metal housing package |

| US7440286B2 (en) * | 2005-04-21 | 2008-10-21 | Super Talent Electronics, Inc. | Extended USB dual-personality card reader |

| US9630740B2 (en) * | 2004-04-06 | 2017-04-25 | Wm. Wrigley Jr. Company | Comestible product dispensers and methods of making and using same |

| US20070134371A1 (en) * | 2005-12-12 | 2007-06-14 | Jason Billig | Comestible product dispensers and methods of making and using same |

| USD519828S1 (en) | 2004-04-06 | 2006-05-02 | Wm. Wrigley Jr. Company | Comestible product dispenser |

| US8061586B2 (en) * | 2004-04-06 | 2011-11-22 | Wm. Wrigley Jr. Company | Comestible product dispensers and methods of making and using same |

| USD516422S1 (en) | 2004-04-06 | 2006-03-07 | Wm. Wrigley Jr. Company | Dispenser for a comestible product |

| US7527189B2 (en) * | 2004-04-06 | 2009-05-05 | Wm. Wrigley Jr. Company | Comestible product dispensers and methods of making and using same |

| US20080195817A1 (en) * | 2004-07-08 | 2008-08-14 | Super Talent Electronics, Inc. | SD Flash Memory Card Manufacturing Using Rigid-Flex PCB |

| USD517390S1 (en) * | 2004-08-16 | 2006-03-21 | Tsung-Kai Cheng | Tool card |

| US20060245815A1 (en) * | 2005-05-02 | 2006-11-02 | Chakmakian Gregory A | Wallet card writing instrument |

| US20090308782A1 (en) * | 2007-03-29 | 2009-12-17 | Grist Elizabeth A | Attractive implement kit for personal care usage |

| US8254134B2 (en) | 2007-05-03 | 2012-08-28 | Super Talent Electronics, Inc. | Molded memory card with write protection switch assembly |

| US20090000038A1 (en) * | 2007-05-31 | 2009-01-01 | Padden Stephen J | Plier tool combination |

| US7789680B2 (en) * | 2007-07-05 | 2010-09-07 | Super Talent Electronics, Inc. | USB device with connected cap |

| US8102658B2 (en) * | 2007-07-05 | 2012-01-24 | Super Talent Electronics, Inc. | Micro-SD to secure digital adaptor card and manufacturing method |

| US20090199941A1 (en) * | 2008-02-13 | 2009-08-13 | Toner Machining Technologies, Inc. | Combination Wallet Tool |

| US20090199940A1 (en) * | 2008-02-13 | 2009-08-13 | Toner Machining Technologies, Inc. | Combination Wallet Tool |

| US7984804B2 (en) * | 2008-12-12 | 2011-07-26 | Lebauer Ian F | Portable protective container for electronic devices in conjunction with a multifunction pocket tool |

| USD671814S1 (en) * | 2010-08-05 | 2012-12-04 | Ningbo Power Stationery & Promotion Industry Co., Ltd | Mini toolkit with screwdrivers and flashlight |

| US8967377B2 (en) * | 2012-02-07 | 2015-03-03 | Ian F Lebauer | Protective case for portable electronic device with foldable lens cover and storage compartments |

| USD690931S1 (en) | 2012-04-18 | 2013-10-08 | HUMN Design, LLC | Wallet |

| US9125464B2 (en) | 2012-04-19 | 2015-09-08 | Human Design, Llc | Low profile wallet |

| USD673055S1 (en) | 2012-05-14 | 2012-12-25 | Frank Anthony Cappello | Fluid dispensing apparatus |

| US9092076B2 (en) * | 2013-01-31 | 2015-07-28 | Mastercard International Incorporated | Electronic transaction card with stylus |

| USD745274S1 (en) | 2013-03-13 | 2015-12-15 | HUMN Design, LLC | Wallet |

| USD710179S1 (en) | 2013-09-09 | 2014-08-05 | Fiskars Brands, Inc. | Card tool set |

| US20150240524A1 (en) * | 2014-02-26 | 2015-08-27 | Craig Olroyd | Credit card-sized slim tool set |

| AT515835B1 (de) | 2014-05-28 | 2016-09-15 | Painsith Hermann Dipl Ing | Taschenwerkzeug |

| WO2016046041A1 (de) * | 2014-09-23 | 2016-03-31 | Victorinox Ag | Unterschale für eine kommunikationsvorrichtung sowie damit ausgestattete kommunikationsvorrichtung |

| US10791808B2 (en) | 2015-05-07 | 2020-10-06 | Daniel Kane | Compact wallet |

| CN106308126B (zh) * | 2016-11-19 | 2018-12-28 | 林丽利 | 一种拆卸旋转式多层文件架 |

| US20190166974A1 (en) * | 2017-12-05 | 2019-06-06 | Mark Davidov | Disposable Portable Pocket Fluid/Floss Dispenser |

| USD877594S1 (en) * | 2018-06-08 | 2020-03-10 | Nite Ize, Inc. | Pocket tool |

| US11206910B2 (en) * | 2018-08-01 | 2021-12-28 | Mark Davidov | Disposable portable pocket fluid/floss dispenser |

| USD878891S1 (en) * | 2018-10-11 | 2020-03-24 | Ultimate Survival Tips Llc | Tool card |

| USD881671S1 (en) * | 2018-12-18 | 2020-04-21 | Wen-Chun Kao | Keychain tool |

| US11571050B2 (en) | 2019-10-22 | 2023-02-07 | Dango Products, Llc | Wallet |

| US11653729B2 (en) | 2019-10-22 | 2023-05-23 | Dango Products, Llc | Wallet with card holding mechanisms |

| US11439214B2 (en) | 2019-01-17 | 2022-09-13 | Dango Products, Llc | Wallet |

| USD893975S1 (en) * | 2019-01-17 | 2020-08-25 | Dango, Inc. | Separable tool and clip combination |

| US11903466B2 (en) | 2019-01-17 | 2024-02-20 | Dango Products, Llc | Wallet with card holding mechanisms |

| US11178947B2 (en) | 2019-01-17 | 2021-11-23 | Dango Products, Llc | Wallet with card holding mechanisms |

| USD887708S1 (en) | 2019-02-08 | 2020-06-23 | Thuan Tran | Wallet |

| US11369186B1 (en) * | 2019-07-16 | 2022-06-28 | Full Coverage Security Solutions, LLC | Credit card/identity card holder |

| USD934560S1 (en) | 2020-04-21 | 2021-11-02 | Dango Products, Llc | Wallet |

| USD951632S1 (en) | 2020-10-07 | 2022-05-17 | Dango Products, Llc | Wallet |

| USD972841S1 (en) | 2020-10-12 | 2022-12-20 | Dango Products, Llc | Wallet |

| USD967626S1 (en) | 2020-10-28 | 2022-10-25 | Dango Products, Llc | Wallet |

| KR102284738B1 (ko) * | 2021-03-19 | 2021-08-03 | 윤승수 | 칼 수납 장치 |

| USD979239S1 (en) | 2021-04-09 | 2023-02-28 | Dango Products, Llc | Wallet |

| USD1072474S1 (en) | 2021-07-16 | 2025-04-29 | Ctb Holdings Llc | Wallet |

| USD1031495S1 (en) | 2021-09-03 | 2024-06-18 | Dango Products, Llc | Money clip |

| US11425976B1 (en) | 2021-09-29 | 2022-08-30 | Dango Products, Llc | Money clip |

| US12484671B2 (en) | 2021-09-29 | 2025-12-02 | Ctb Holdings Llc | Money clip |

| USD1030312S1 (en) | 2021-10-13 | 2024-06-11 | The Ridge Wallet Llc | Wallet-mounted wireless device holder |

| USD1098741S1 (en) | 2021-10-29 | 2025-10-21 | The Ridge Wallet Llc | Wallet |

| USD1065827S1 (en) | 2021-10-29 | 2025-03-11 | The Ridge Wallet Llc | Wallet |

| USD1088516S1 (en) | 2022-08-12 | 2025-08-19 | Ctb Holdings Llc | Wallet |

| USD1096144S1 (en) | 2023-01-24 | 2025-10-07 | The Ridge Wallet Llc | Wallet |

| US12119174B1 (en) | 2024-01-26 | 2024-10-15 | The Ridge Wallet Llc | Magnetic plate(s) |

Family Cites Families (50)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB599405A (en) | 1945-09-18 | 1948-03-11 | Julius Manus Macmicking | Improvements in holders for attachment to or for use as pockets |

| US464405A (en) | 1891-12-01 | Pocket match-safe | ||

| FR739628A (enExample) | ||||

| US2749923A (en) | 1956-06-12 | Toilet article | ||

| US973930A (en) | 1910-03-05 | 1910-10-25 | John W Fink | Match-box. |

| US1590492A (en) | 1924-05-05 | 1926-06-29 | Benson Anthony Frederick | Pocket case |

| FR613245A (fr) | 1925-08-18 | 1926-11-12 | Nécessaire de couture de poche | |

| US1731287A (en) | 1928-06-19 | 1929-10-15 | Barnowitz Harry | Combination toilet implement |

| FR739682A (fr) * | 1932-06-06 | 1933-01-16 | Nécessaire de toilette pour dames | |

| US2080248A (en) | 1935-11-22 | 1937-05-11 | Howard M Ballou | Comb |

| US2122226A (en) | 1937-05-17 | 1938-06-28 | Walter A Wyman | Combination comb and instrument case |

| US2412056A (en) | 1944-09-15 | 1946-12-03 | Mosch Alfred | Utensil holder |

| US2474570A (en) | 1945-03-24 | 1949-06-28 | Emile V Boudreaux | Combination comb and file |

| US2443099A (en) | 1946-03-23 | 1948-06-08 | Roy J Delhaye | Combination comb and carrying case |

| US2491753A (en) | 1946-09-25 | 1949-12-20 | Felmore Company Inc | Comb |

| US2630212A (en) | 1946-10-12 | 1953-03-03 | Mosch Alfred | General utility compact |

| US2511278A (en) | 1949-06-06 | 1950-06-13 | Ronald G Lyle | Combination sheath and nail file |

| US3212546A (en) | 1963-10-14 | 1965-10-19 | Stanley L Lind | Key holder |

| US3461469A (en) | 1966-06-24 | 1969-08-19 | Jessie Morrision | Multipurpose tools and wallet holders therefor |

| US3478683A (en) | 1967-06-05 | 1969-11-18 | Arnold R Hopkins | Safety credit card construction |

| US3563254A (en) | 1969-05-26 | 1971-02-16 | Mary A Gallagher | Combination comb and nail treatment device |

| US3832775A (en) | 1972-08-21 | 1974-09-03 | Salm Inc Arthur | Foldable implement and method of manufacture thereof |

| DE2416752C3 (de) * | 1974-04-05 | 1978-09-07 | Pfeiffer, Michael, 8012 Ottobrunn | Kassette zur Aufnahme von Münzen |

| US4037716A (en) | 1976-06-21 | 1977-07-26 | Marks John D | Card key and/or coin holder |

| US4300610A (en) | 1980-01-31 | 1981-11-17 | Bermas Plastics Company, Inc. | Card-like holder |

| US4331194A (en) | 1980-09-18 | 1982-05-25 | Lederer Richard J | Key holder |

| DE3234778A1 (de) * | 1982-03-24 | 1983-10-06 | Gerhard Ritter | Schutzhuelle fuer eine scheckkarte, automatenkarte, und dergleichen |

| US4562923A (en) * | 1983-03-11 | 1986-01-07 | Pola Chemical Industries Inc. | Cosmetics case |

| US4457425A (en) | 1983-04-21 | 1984-07-03 | Phelon Magnagrip Co., Inc. | Magnetic holder for keys and the like and method of manufacturing the same |

| GB2146623A (en) * | 1983-09-21 | 1985-04-24 | Ching Huei Lin | Pocket-size container for tools, etc |

| US4909054A (en) | 1985-07-08 | 1990-03-20 | Fox Robert M | Key shank with rectangular slot and keycase |

| JPH07121631B2 (ja) * | 1987-09-07 | 1995-12-25 | 三菱電機株式会社 | 記憶媒体内蔵カード用プラスチックパッケージ |

| JPH0199226U (enExample) * | 1987-12-24 | 1989-07-03 | ||

| US4946030A (en) | 1988-06-20 | 1990-08-07 | Guridi Jose J S | Emergency key holder card |

| SU1706513A1 (ru) | 1988-07-11 | 1992-01-23 | Институт Микробиологии Ан Узсср | Способ получени бактериальной закваски дл лечебно-диетических молочных продуктов |

| DE3827536C1 (en) * | 1988-08-13 | 1989-11-23 | Proline Handels- Und Marketing Gmbh, 8500 Nuernberg, De | Plastic container with key in flat construction |

| DE3834303A1 (de) | 1988-10-08 | 1990-04-12 | Grundig Emv | Aufnahme-wiedergabegeraet, insbesondere telefonanrufbeantworter |

| DE8813333U1 (de) | 1988-10-22 | 1989-01-12 | Müller, Bernd C. W. | Pflegeset insbesondere für den Reisebedarf |

| NL8802679A (nl) * | 1988-11-02 | 1990-06-01 | Acodeq Trading Co | Inrichting voor het opbergen van kaarten. |

| US4934528A (en) | 1989-02-09 | 1990-06-19 | Mocap | Mirror pouch |

| JPH03113621U (enExample) | 1989-10-26 | 1991-11-20 | ||

| US5022247A (en) | 1989-11-24 | 1991-06-11 | Beck J Frederick | Holder for spare set of keys |

| FR2656779B1 (fr) * | 1990-01-09 | 1992-04-17 | Passot Innovation | Boitier pour le stockage des pieces, jetons, cartes, etiquettes.. ou articles similaires pouvant etre associes a un anneau porte-cle. |

| US4979619A (en) * | 1990-01-22 | 1990-12-25 | Hager Alan C | Protective case for collectible sports cards |

| IT1260819B (it) * | 1992-05-13 | 1996-04-22 | Silca Spa | Combinazione di chiave e relativa custodia |

| FR2700929B3 (fr) * | 1992-10-30 | 1995-04-14 | Mediana Sa | Porte-cartes pour au moins une carte magnétique. |

| US5328026A (en) * | 1993-06-11 | 1994-07-12 | Newman Chris M | Flat multiple tool holder |

| WO1994029083A2 (en) * | 1993-06-11 | 1994-12-22 | Newman Chris M | Flat multiple tool holder |

| US5467871A (en) * | 1994-09-06 | 1995-11-21 | Defield; Norman | Key chain note holder with transparent housing |

| US5621936A (en) * | 1994-09-30 | 1997-04-22 | Penaligon; Janet L. | Multi-purpose hand tool |

-

1995

- 1995-11-30 AT AT0196195A patent/AT404237B/de not_active IP Right Cessation

-

1996

- 1996-12-02 EP EP02028246A patent/EP1293144B1/de not_active Expired - Lifetime

- 1996-12-02 EP EP96939748A patent/EP0957704B2/de not_active Expired - Lifetime

- 1996-12-02 DE DE59610769T patent/DE59610769D1/de not_active Expired - Lifetime

- 1996-12-02 DE DE29624203U patent/DE29624203U1/de not_active Expired - Lifetime

- 1996-12-02 AT AT02028246T patent/ATE277538T1/de active

- 1996-12-02 AT AT96939748T patent/ATE251398T1/de not_active IP Right Cessation

- 1996-12-02 JP JP51999297A patent/JP4098360B2/ja not_active Expired - Lifetime

- 1996-12-02 US US09/077,482 patent/US6044967A/en not_active Expired - Lifetime

- 1996-12-02 ES ES02028246T patent/ES2230442T3/es not_active Expired - Lifetime

- 1996-12-02 DE DE59611104T patent/DE59611104D1/de not_active Expired - Lifetime

- 1996-12-02 ES ES96939748T patent/ES2208767T5/es not_active Expired - Lifetime

- 1996-12-02 CN CNB961996722A patent/CN1161059C/zh not_active Expired - Lifetime

- 1996-12-02 WO PCT/AT1996/000238 patent/WO1997019856A2/de not_active Ceased

- 1996-12-02 AU AU76853/96A patent/AU7685396A/en not_active Abandoned

-

1999

- 1999-12-13 US US09/460,268 patent/US6257405B1/en not_active Expired - Lifetime

-

2001

- 2001-06-22 US US09/851,783 patent/US6527112B2/en not_active Expired - Lifetime

-

2002

- 2002-10-07 US US10/265,103 patent/US7631752B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2000501003A (ja) | 2000-02-02 |

| US6527112B2 (en) | 2003-03-04 |

| CN1207653A (zh) | 1999-02-10 |

| ES2208767T5 (es) | 2007-03-16 |

| US20010047946A1 (en) | 2001-12-06 |

| WO1997019856A3 (de) | 1997-07-31 |

| US20030038043A1 (en) | 2003-02-27 |

| EP0957704B1 (de) | 2003-10-08 |

| EP1293144A2 (de) | 2003-03-19 |

| DE59611104D1 (de) | 2004-11-04 |

| ATE277538T1 (de) | 2004-10-15 |

| JP4098360B2 (ja) | 2008-06-11 |

| ES2230442T3 (es) | 2005-05-01 |

| US6044967A (en) | 2000-04-04 |

| CN1161059C (zh) | 2004-08-11 |

| DE59610769D1 (de) | 2003-11-13 |

| ES2208767T3 (es) | 2004-06-16 |

| AT404237B (de) | 1998-09-25 |

| EP0957704B2 (de) | 2006-07-05 |

| US6257405B1 (en) | 2001-07-10 |

| EP0957704A2 (de) | 1999-11-24 |

| DE29624203U1 (de) | 2001-04-26 |

| ATA196195A (de) | 1998-02-15 |

| EP1293144A3 (de) | 2003-03-26 |

| AU7685396A (en) | 1997-06-19 |

| US7631752B2 (en) | 2009-12-15 |

| HK1017592A1 (en) | 1999-11-26 |

| ATE251398T1 (de) | 2003-10-15 |

| WO1997019856A2 (de) | 1997-06-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1293144B1 (de) | Plattenförmiges Aufnahmegehäuse für Gebrauchs- und/oder Verbrauchsgegenstände | |

| DE19881229B4 (de) | Funktionsteileträger, insbesondere Taschenmesser | |

| DE3822372C2 (de) | Rasierapparat | |

| EP0842014B1 (de) | Mehrzweck-handgerät für bürogebrauch | |

| DE19964440B4 (de) | Funktionsteileträger, insbesondere Werkzeugkarte | |

| DE8717386U1 (de) | Verkaufsregalteiler | |

| DE3707410A1 (de) | Verkaufsregalteiler | |

| DE8909551U1 (de) | Dose, insbesondere Pillendose | |

| EP0384449B1 (de) | Behälter | |

| DE3827536C1 (en) | Plastic container with key in flat construction | |

| EP0505697B1 (de) | Rückenschildhalter für Briefordner | |

| AT408053B (de) | Funktionsteileträger, insbesondere taschenmesser oder plattenförmiges aufnahmegehäuse | |

| DE19623904C2 (de) | Halter für Wendetafeln od. dgl. | |

| DE19520645A1 (de) | Vorrichtung zum Verpacken von Kraftfahrzeug-Scheiben | |

| EP0122380B1 (de) | Skalenleiste | |

| AT414328B (de) | Werkzeugkarte | |

| AT9250U1 (de) | Linealschutzhülle | |

| EP0554556A1 (de) | Folientasche | |

| DE8710273U1 (de) | Tastenknopf | |

| DE9404377U1 (de) | Verbindungsbeschlag | |

| DE20213321U1 (de) | Vorrichtung zur Aufbewahrung von Stiftschlüsseln | |

| DE29607662U1 (de) | Behälter zur Aufbewahrung und Abgabe von blattförmigen Artikeln | |

| DE8907308U1 (de) | Präsentationslade für ringförmige Schmuckstücke | |

| WO2009040125A2 (de) | Plattenförmiges aufnahmegehäuse, insbesondere werkzeugkarte | |

| DE9412113U1 (de) | Aufbewahrungs- und Verkaufsbehältnis |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| 17P | Request for examination filed |

Effective date: 20021216 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 0957704 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT CH DE ES FR GB IT LI PT |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT CH DE ES FR GB IT LI PT |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| AKX | Designation fees paid |

Designated state(s): AT CH DE ES FR GB IT LI PT |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 0957704 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE ES FR GB IT LI PT |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59611104 Country of ref document: DE Date of ref document: 20041104 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: ABP PATENT NETWORK SWISS GMBH |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20050115 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2230442 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| ET | Fr: translation filed | ||

| 26N | No opposition filed |

Effective date: 20050630 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Owner name: VICTORINOX AG Free format text: VICTORINOX AG#SCHMIEDGASSE 57#6438 IBACH (CH) $ HERMANN PAINSITH#WULFENGASSE 6#9020 KLAGENFURT (AT) -TRANSFER TO- VICTORINOX AG#SCHMIEDGASSE 57#6438 IBACH (CH) $ HERMANN PAINSITH#WULFENGASSE 6#9020 KLAGENFURT (AT) |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050228 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: ABP PATENT NETWORK AG, CH |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20151214 Year of fee payment: 20 Ref country code: GB Payment date: 20151204 Year of fee payment: 20 Ref country code: DE Payment date: 20151203 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20151204 Year of fee payment: 20 Ref country code: AT Payment date: 20151207 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20151207 Year of fee payment: 20 Ref country code: IT Payment date: 20151223 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PCAR Free format text: NEW ADDRESS: OTHMARSTRASSE 8, 8008 ZUERICH (CH) |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59611104 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20161201 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK07 Ref document number: 277538 Country of ref document: AT Kind code of ref document: T Effective date: 20161202 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20161201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20161203 |