EP0854221A2 - Dispositif pour l'étalement et l'essorage de tricots tubulaires - Google Patents

Dispositif pour l'étalement et l'essorage de tricots tubulaires Download PDFInfo

- Publication number

- EP0854221A2 EP0854221A2 EP97119994A EP97119994A EP0854221A2 EP 0854221 A2 EP0854221 A2 EP 0854221A2 EP 97119994 A EP97119994 A EP 97119994A EP 97119994 A EP97119994 A EP 97119994A EP 0854221 A2 EP0854221 A2 EP 0854221A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- rollers

- squeeze

- roller

- spreading

- spreader

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06B—TREATING TEXTILE MATERIALS USING LIQUIDS, GASES OR VAPOURS

- D06B15/00—Removing liquids, gases or vapours from textile materials in association with treatment of the materials by liquids, gases or vapours

- D06B15/02—Removing liquids, gases or vapours from textile materials in association with treatment of the materials by liquids, gases or vapours by squeezing rollers

- D06B15/025—Removing liquids, gases or vapours from textile materials in association with treatment of the materials by liquids, gases or vapours by squeezing rollers for tubular fabrics

Definitions

- the invention relates to a device for holding and squeezing in particular Hose knitted fabric with the features of the preamble of claim 1 and claim 3.

- Such a device is intended for the treatment liquor gently and without To leave bow markings squeezed out of the tubular knitted fabric.

- Such a squeezing device is known from DE 41 23 477 C2, according to this Device the tubular knitted fabric between a rotatable and in diameter adjustable inner nip roller system and a rotatable outer one Nip roller system is performed.

- the structural structure of the interior Squeeze roller system corresponds to that of a circular spreader according to DE 37 32 754 C1.

- the device according to DE 41 23 477 C2 at the free ends Supports instead of longitudinal guide elements, one pair of squeeze rollers arranged.

- Each pinch roller pair of the inner system together with a pinch roller forms the external system, a so-called partial crusher.

- a rotary drive between the squeeze rollers of each pair of squeeze rollers Squeeze roller controlled by the outer system.

- the treatment fleet is this way largely squeezed from the tubular knitted fabric.

- the goods are replaced by a Spreader device kept wide in cross section, the spreader device is provided below and above with roller heads, which are stored in assigned fixing rollers.

- the roller heads serve to fix the position of the spreader device and to motorized width adjustment by a lifting device, with which the storage of the lower Roller head is connected.

- This system has the disadvantage that the goods are squeezed out by the Crushers must pass the upper roller head, causing it to become irregular Pressure loads between the roller head and the fixing roller can occur, which can be disadvantageous can affect the uniformity of the quality of the goods.

- the object of the invention is to provide a rotary crusher of the type mentioned at the outset to further develop that the tubular knitted fabric after squeezing no further, for the Uniformity of product quality is exposed to harmful pressure loads.

- this object is achieved in that the spreading device 8 is fixed in its horizontal position solely by the squeezing mechanisms 13 and that the inner tube 19b of the carrier 19 via a rotary bearing 22 with support rollers 9th is connected, wherein for the vertical position adjustment of the device 8, the support rollers 9 in Fixing rollers 10 of a lifting device 17 are mounted.

- the Spreading device 8 is fixed in its horizontal position solely by the squeezing mechanisms 13 and is carried, and that at least in the upper region of the outer tube 19a of the carrier 19th a piston-cylinder unit with a piston rod is arranged, which in the direction of Double arrow 18 is effective.

- the free end of the piston rod is articulated with the top Supports 20a of the spreader 8 connected. This allows the Width adjustment of the spreading device 8 take place.

- the goods 1 runs between the support rollers 9 and Fixing rollers 10 and is from the spreader 8 with the help of Spreading rollers 12 spread and guided by individual crushing units 13 such that the Liquor can drain down into a collecting container (not shown).

- the goods 1 After squeezing, the goods 1 pass through an upper spreader head 15 consisting of a pair of support rollers 16 and a pair of fixing rollers 14, and after passing through the Spreader head 15 in a flat spread shape by a driven roller arrangement (not shown), which is provided in the upper region of the frame 5.

- an upper spreader head 15 consisting of a pair of support rollers 16 and a pair of fixing rollers 14, and after passing through the Spreader head 15 in a flat spread shape by a driven roller arrangement (not shown), which is provided in the upper region of the frame 5.

- a support and lifting device 17, not shown, for the Circular crushing mechanism provided in the lower part of the frame 5 .

- the lifting device 17 can be in the direction of the double arrow 18 raise or lower the lower spreader head 11. So that the lower one Spreader head 11 carrying device 17 the lower telescopic inner tube 19b of the central support 19, on which the supports 20b are articulated, in height adjust.

- a spreading roller 12 is located at each of the free ends of the supports 20a, 20b, 21 appropriate.

- the central support 19 consists of an outer tube 19a and one in the outer tube 19a telescopic inner tube 19b.

- the free end of the outer tube 19a is with the upper spreader head 15 and the free end of the inner tube 19b with the lower Spreader head 11 is connected via a respective pivot bearing 22.

- the spreader and Crimping device is thus held rotatably between the two spreader heads 11, 15.

- the inner squeeze rollers 26 of the individual squeeze mechanisms 13 are stationary and on the Telescopic tube 19a of the central support 19 in corresponding roller mounts 24, 25 pivoted.

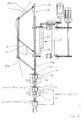

- the arrangement of the individual squeeze rollers 26 with the associated rotary drive Squeeze roller 23 is also shown in Figure 1.

- the tubular knitted fabric to be squeezed 1 is on the one hand via the spreading rollers 12 and on the other hand by one adjustable pinch gap performed in each pinch mechanism 13.

- the pinch gap and therefore also the squeezing force F acting on the tubular knitted fabric 1 is by means of the respective Pinch roller 23 carrying piston-cylinder unit 27 adjustable.

- the individual squeeze rollers 23 are at their free ends with the piston rod of the piston-cylinder unit 27 connected.

- the piston-cylinder units 27 act both as Support member for the squeeze rollers 23 and as a means for generating the required Crushing force F.

- the piston-cylinder units acting on the upper and lower ends of the nip roller 23 27 are in a known manner with a rotationally driven pair of bearing rings 28 connected.

- the pair of bearing rings is accommodated in a frame 5.

- Cross members 5b are connected to the vertical supports 5a of the frame 5, which Take up bearing rollers 30 that support the rotationally driven bearing rings 28, 29.

- the drive of the bearing rings by drive motors 2 and 3 is not intended here in detail be discussed, since the drive principle already in the previously known DE 41 23 477 C2 has been described in detail.

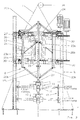

- FIG. 2 shows a first embodiment of the device according to the invention.

- the arrangement corresponds to the arrangement according to FIG. 1, but an upper one Spreader head is not provided.

- the horizontal fixation of the spreading device 8 is largely taken over by the squeeze mechanisms 13.

- the weight of the spreader is by a stationary roller head attached below the spreader 8 31 taken over, which is mounted in fixing rollers 32.

- the roller head 31 is via a rotary bearing 22 with the outer tube 19a of the carrier 19, on which the supports 20b, 21 are articulated, connected.

- the inner tube 19b of the carrier 19, on which the supports 20a are articulated, is by a rod 36 guided within the central gene carrier 19, which is not in detail is shown, connected to the lower spreader head 11, the part of the already mentioned Motorized adjustment or lifting device 17, through which the width adjustment of the Spreader 8 takes place.

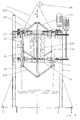

- FIG. 3 shows an embodiment modified from FIG. 2, with an overview here because of the squeezing mechanisms and the spreading rollers are folded into one level. However, you are evenly distributed all around and multiple, as in Figures 1a and 1b shown.

- an additional roller head 31 for receiving the Own weight of the spreading device 8 is dispensed with.

- the central spreader 8 is by the Squeezers 13 fixed in the horizontal position and by the weight of the spreader a slight inclination (V position) of the squeeze rollers 23a, 26a at an angle ⁇ also taken over by the crushing machines.

- the spreader 8 hangs freely in the outer nip rollers 23a.

- a roller head for fixation and for taking up the Dead weight of the spreader 8 is no longer necessary.

- Lifting device 17 is provided with fixing rollers 10, in which the roller head 11 is mounted, the roller head 11 being connected to the inner tube 19b of the carrier 19 via a rotary bearing 22 connected is.

- the circumference of the goods is 1 slightly smaller in the lower area of the crushing machine than above. This can be the even one Disturb transport of the goods, so that the differences in width by a corresponding opposite inclination of the spreading rollers 12 can be compensated for at an angle ⁇ .

- the tubular knitted fabric 1 is moved upwards via a roller 34 deducted without further, undesirable pressures acting on the goods.

- FIG. 4 shows a further embodiment of the device according to the invention, wherein again the crushers and spreading rollers are folded into one plane.

- This The arrangement essentially corresponds to the arrangement according to FIG. 3, but is dispensed with entirely on the spreader head 11 and the lifting device 17 for width adjustment of the Spreading device 8.

- the spreader 8 hangs freely in the outer nip rollers 23a.

- the spreader is a piston-cylinder unit in the outer tube 19a of the carrier 19 arranged, the piston rod 33 articulated with the upper supports 20a of the Spreader device 8 is connected.

- the supports 20a are more or pulled less up and thereby adjusted the width of the spreader 8.

- FIG. 5 again shows the squeezing mechanisms and the spreading rollers folded into one plane.

- the spreader at too high inclination of the squeeze rises under the pressure of the goods, which is of course not desired.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Treatment Of Fiber Materials (AREA)

- Knitting Machines (AREA)

- Auxiliary Weaving Apparatuses, Weavers' Tools, And Shuttles (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19701415A DE19701415C1 (de) | 1997-01-17 | 1997-01-17 | Vorrichtung zum Breithalten und Quetschen von Schlauch-Wirkware |

| DE19701415 | 1997-01-17 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0854221A2 true EP0854221A2 (fr) | 1998-07-22 |

| EP0854221A3 EP0854221A3 (fr) | 1999-10-06 |

| EP0854221B1 EP0854221B1 (fr) | 2002-12-18 |

Family

ID=7817586

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97119994A Expired - Lifetime EP0854221B1 (fr) | 1997-01-17 | 1997-11-14 | Dispositif pour l'étalement et l'essorage de tricots tubulaires |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US5884377A (fr) |

| EP (1) | EP0854221B1 (fr) |

| JP (1) | JP2941756B2 (fr) |

| AT (1) | ATE230041T1 (fr) |

| DE (2) | DE19701415C1 (fr) |

| ES (1) | ES2187715T3 (fr) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6363701B1 (en) * | 1999-12-23 | 2002-04-02 | Jimmy R. Jacumin | Fabric detwister cylinder apparatus |

| DE10153691C2 (de) | 2001-10-31 | 2003-09-18 | Dornier Gmbh Lindauer | Rundbreithalter zum Behandeln textilen Schlauchware |

| US6682117B2 (en) * | 2002-01-13 | 2004-01-27 | Mark C. Sloan | Exterior vehicle ashtray system |

| DE102004061991A1 (de) * | 2004-12-23 | 2006-07-13 | Lindauer Dornier Gesellschaft Mit Beschränkter Haftung | Rundbreithalter zum Behandeln texiler Schlauchware |

| US7951900B2 (en) * | 2005-06-17 | 2011-05-31 | Eastman Chemical Company | Dialysis filter housings comprising polyester compositions formed from 2,2,4,4-tetramethyl-1,3-cyclobutanediol and 1,4-cyclohexanedimethanol |

| DE102007059728A1 (de) | 2007-12-12 | 2009-06-18 | Lindauer Dornier Gmbh | Verfahren zum Färben eines Schlauches aus einem Textilmaterial und Färbemaschine zur Durchführung des Verfahrens |

| US8661632B2 (en) * | 2011-09-22 | 2014-03-04 | Ethicon, Inc. | Method and apparatus for pliabilizing knitted or woven materials |

| GR1008282B (el) * | 2013-07-18 | 2014-09-02 | Γεωργιος Γεωργιου Λαγογιαννης | Σταθεροποιητης συστροφης πλεξης |

| CN105852588A (zh) * | 2015-06-29 | 2016-08-17 | 邹钰 | 一种服装的三维立体扩撑塑形设备 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1262201B (de) * | 1961-07-21 | 1968-03-07 | Karlheinz Heitkamp | Vorrichtung zum Abquetschen von Schlauchware, insbesondere Trikotschlauchware |

| DE4123477A1 (de) * | 1991-07-16 | 1993-01-21 | Dornier Gmbh Lindauer | Verfahren zur vermeidung von bugmarkierungen in schlauch-wirkware und vorrichtung zur durchfuehrung des verfahrens |

| DE4334897C1 (de) * | 1993-10-13 | 1995-04-20 | Dornier Gmbh Lindauer | Kombinierte Ausbreit- und Quetschvorrichtung, insbesondere für Schlauch-Wirkware |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2045755A (en) * | 1932-03-17 | 1936-06-30 | Samcoe Holding Corp | Method of treating fabrics |

| US2294642A (en) * | 1941-05-20 | 1942-09-01 | American Viscose Corp | Apparatus for spreading and stretching fabrics in tubular form |

| GB940339A (en) * | 1961-08-15 | 1963-10-30 | Benteler Werke Ag | Apparatus for expanding a tubular web of knitted fabric |

| CH460687A (de) * | 1967-09-22 | 1968-08-15 | Maschb Gmbh Hossmann & Strauss | Vorrichtung zum Abquetschen von Schlauchware, insbesondere Trikot-Schlauchware |

| US3501818A (en) * | 1968-02-26 | 1970-03-24 | Gmbh Hossmann & Strauss Maschb | Squeezing arrangement for wet tubular webs |

| US3616502A (en) * | 1969-06-10 | 1971-11-02 | Aronoff Edward Israel | Apparatus for treating of tubular fabrics |

| DE3732754C1 (de) * | 1987-09-29 | 1989-04-20 | Dornier Gmbh Lindauer | Von aussen gehaltener Rundbreithalter fuer textile Schlauchware |

| DE4108191C2 (de) * | 1991-03-14 | 1994-10-27 | Dornier Gmbh Lindauer | Sperrvorrichtung für von außen gehaltenen Rundbreithalter |

| IT1270162B (it) * | 1994-06-03 | 1997-04-29 | Gian Franco Ferraro | Allargatore per tessuti tubolari |

-

1997

- 1997-01-17 DE DE19701415A patent/DE19701415C1/de not_active Expired - Fee Related

- 1997-11-14 ES ES97119994T patent/ES2187715T3/es not_active Expired - Lifetime

- 1997-11-14 DE DE59709008T patent/DE59709008D1/de not_active Expired - Fee Related

- 1997-11-14 AT AT97119994T patent/ATE230041T1/de not_active IP Right Cessation

- 1997-11-14 EP EP97119994A patent/EP0854221B1/fr not_active Expired - Lifetime

-

1998

- 1998-01-16 JP JP10006594A patent/JP2941756B2/ja not_active Expired - Fee Related

- 1998-01-20 US US09/009,711 patent/US5884377A/en not_active Expired - Fee Related

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1262201B (de) * | 1961-07-21 | 1968-03-07 | Karlheinz Heitkamp | Vorrichtung zum Abquetschen von Schlauchware, insbesondere Trikotschlauchware |

| DE4123477A1 (de) * | 1991-07-16 | 1993-01-21 | Dornier Gmbh Lindauer | Verfahren zur vermeidung von bugmarkierungen in schlauch-wirkware und vorrichtung zur durchfuehrung des verfahrens |

| DE4334897C1 (de) * | 1993-10-13 | 1995-04-20 | Dornier Gmbh Lindauer | Kombinierte Ausbreit- und Quetschvorrichtung, insbesondere für Schlauch-Wirkware |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0854221A3 (fr) | 1999-10-06 |

| EP0854221B1 (fr) | 2002-12-18 |

| ATE230041T1 (de) | 2003-01-15 |

| DE59709008D1 (de) | 2003-01-30 |

| ES2187715T3 (es) | 2003-06-16 |

| JP2941756B2 (ja) | 1999-08-30 |

| US5884377A (en) | 1999-03-23 |

| JPH111863A (ja) | 1999-01-06 |

| DE19701415C1 (de) | 1998-01-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2919105C2 (de) | Sechswalzengerüst mit seitlicher Abstützung jeder Arbeitswalze | |

| EP0285942A1 (fr) | Dispositif de guidage des rouleaux d'une calandre pratiquement verticale | |

| EP0854221B1 (fr) | Dispositif pour l'étalement et l'essorage de tricots tubulaires | |

| DE4334897C1 (de) | Kombinierte Ausbreit- und Quetschvorrichtung, insbesondere für Schlauch-Wirkware | |

| DE19513143A1 (de) | Wickelmaschine zum Aufwickeln einer laufenden Bahn, insbesondere einer Papierbahn, zu einer Rolle | |

| DE69101995T2 (de) | Anlage zum Richten. | |

| DE3016849A1 (de) | Vorrichtung zum oeffnen von textilen stoffen in strang- oder seilform | |

| DE2059283C2 (de) | Vorrichtung zum Führen von Bandmaterial | |

| EP0292429A1 (fr) | Métier à tisser avec un dispositif pour l'étirage en largeur d'un tissu | |

| DE1955265B2 (de) | Maschine zum Ausdrucken von Flüssigkeit aus Häuten, Leder o.dgl | |

| DE2637248C2 (de) | Vorrichtung zum Zwischenspeichern eines bandförmigen Druckträgers | |

| DE4401963C2 (de) | Einrichtung zum Herstellen einer Bahnverbindung | |

| DE2130467B2 (de) | Landwirtschaftliche ballenpresse mit durch laufrollen gefuehrtem presskolben | |

| DE4123477A1 (de) | Verfahren zur vermeidung von bugmarkierungen in schlauch-wirkware und vorrichtung zur durchfuehrung des verfahrens | |

| DE926297C (de) | Kettbaumhubwagen | |

| DE2124706B2 (de) | Rollenrichtmaschine für Werkstücke wie Träger o.dgl | |

| DE3213203A1 (de) | Wickelmaschine zum auf- und/oder abwickeln bahnfoermig gefuehrten gutes | |

| DE4408416A1 (de) | Vorrichtung zum Aufwickeln einer textilen Warenbahn | |

| DE2139307A1 (de) | Streckwerk mit starker verfeinerung zum verstrecken diskontinuierlicher textilfasern | |

| DE4033977C2 (de) | Spannvorrichtung für Kettfäden | |

| DE970383C (de) | Vorrichtung zum Abquetschen der Feuchtigkeit von Textilien | |

| DE2258893C3 (de) | Vorrichtung zum Bedrucken von Warenbahnen, wie Teppichen o.dgl. großer Breite mittels eines Siebdruckschablonenbandes | |

| DE1113357B (de) | Kalander zur Behandlung von durchlaufenden Materialbahnen, insbesondere aus Papier | |

| DE3146255C2 (de) | Vorrichtung zum Lagern und Spannen von Rundschablonen oder Siebzylindern | |

| DE2951336A1 (de) | Vorrichtung zum abrollen von materialbahnen von wechselnden vorratsrollen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE ES FR GB IT LI |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 19991130 |

|

| AKX | Designation fees paid |

Free format text: AT BE CH DE ES FR GB IT LI |

|

| 17Q | First examination report despatched |

Effective date: 20010905 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB IT LI |

|

| REF | Corresponds to: |

Ref document number: 230041 Country of ref document: AT Date of ref document: 20030115 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59709008 Country of ref document: DE Date of ref document: 20030130 Kind code of ref document: P Ref document number: 59709008 Country of ref document: DE Date of ref document: 20030130 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: R. A. EGLI & CO. PATENTANWAELTE |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20030320 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2187715 Country of ref document: ES Kind code of ref document: T3 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20030919 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20050927 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20050928 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20051018 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20051110 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20051125 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061114 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061130 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20061114 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20070731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061114 |

|

| BERE | Be: lapsed |

Owner name: *LINDAUER DORNIER G.M.B.H. Effective date: 20061130 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20061115 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061130 Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061115 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20081017 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20081112 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20090224 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091114 |