EP0664984A2 - Coulisse de tiroir séquentielle ou similaire - Google Patents

Coulisse de tiroir séquentielle ou similaire Download PDFInfo

- Publication number

- EP0664984A2 EP0664984A2 EP94120260A EP94120260A EP0664984A2 EP 0664984 A2 EP0664984 A2 EP 0664984A2 EP 94120260 A EP94120260 A EP 94120260A EP 94120260 A EP94120260 A EP 94120260A EP 0664984 A2 EP0664984 A2 EP 0664984A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- rail

- pull

- differential

- drawer

- coupling part

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47B—TABLES; DESKS; OFFICE FURNITURE; CABINETS; DRAWERS; GENERAL DETAILS OF FURNITURE

- A47B88/00—Drawers for tables, cabinets or like furniture; Guides for drawers

- A47B88/40—Sliding drawers; Slides or guides therefor

- A47B88/49—Sliding drawers; Slides or guides therefor with double extensible guides or parts

- A47B88/493—Sliding drawers; Slides or guides therefor with double extensible guides or parts with rollers, ball bearings, wheels, or the like

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47B—TABLES; DESKS; OFFICE FURNITURE; CABINETS; DRAWERS; GENERAL DETAILS OF FURNITURE

- A47B88/00—Drawers for tables, cabinets or like furniture; Guides for drawers

- A47B88/40—Sliding drawers; Slides or guides therefor

- A47B88/453—Actuated drawers

- A47B88/46—Actuated drawers operated by mechanically-stored energy, e.g. by springs

- A47B88/467—Actuated drawers operated by mechanically-stored energy, e.g. by springs self-closing

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47B—TABLES; DESKS; OFFICE FURNITURE; CABINETS; DRAWERS; GENERAL DETAILS OF FURNITURE

- A47B2210/00—General construction of drawers, guides and guide devices

- A47B2210/0002—Guide construction for drawers

- A47B2210/0064—Guide sequencing or synchronisation

- A47B2210/007—Three slide synchronisation

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47B—TABLES; DESKS; OFFICE FURNITURE; CABINETS; DRAWERS; GENERAL DETAILS OF FURNITURE

- A47B2210/00—General construction of drawers, guides and guide devices

- A47B2210/0002—Guide construction for drawers

- A47B2210/0064—Guide sequencing or synchronisation

- A47B2210/0072—Coordinating mechanisms for sequential drawer slides, e.g. by cable

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47B—TABLES; DESKS; OFFICE FURNITURE; CABINETS; DRAWERS; GENERAL DETAILS OF FURNITURE

- A47B2210/00—General construction of drawers, guides and guide devices

- A47B2210/0002—Guide construction for drawers

- A47B2210/0064—Guide sequencing or synchronisation

- A47B2210/0083—Drawer symmetric movement on opposite telescopic rails

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47B—TABLES; DESKS; OFFICE FURNITURE; CABINETS; DRAWERS; GENERAL DETAILS OF FURNITURE

- A47B2210/00—General construction of drawers, guides and guide devices

- A47B2210/02—Drawers with hollow lateral walls in two parts

Definitions

- the invention relates to a differential pull-out for drawers or the like.

- a mounting rail to be fastened to a furniture body With a mounting rail to be fastened to a furniture body, a pull-out rail to be fastened to the drawer and a middle rail arranged in between on each side of the drawer, the weight of the drawers between the rails by means of rollers od.

- a deflection roller is arranged, and a control cable, which is attached to the mounting rail and on the pull-out rail, is guided over the deflection rollers.

- Various full pull-outs for drawers are known in which the drawer can be completely pulled out of the furniture body and is nevertheless held by the rails of the full pull-out.

- a device is provided to ensure that the rails run differentially with respect to one another.

- This device can consist, for example, of a gearwheel mounted on the central rail, which meshes with toothed racks on the pull-out rail and the mounting rail.

- a simplified version would be the arrangement of a friction wheel on the middle rail.

- a particularly precise guidance of the middle rail is achieved by a control cable which is fastened to the mounting rail and the pull-out rail and which runs on both sides of the middle rail and is guided at the front and rear ends via band guides of the middle rail.

- a control cable which is fastened to the mounting rail and the pull-out rail and which runs on both sides of the middle rail and is guided at the front and rear ends via band guides of the middle rail.

- control cable has two free ends which can be coupled in a manner known per se by a receiving part and an insertion part which have rack-like profiles, the receiving part or the insertion part being able to be coupled to the mounting rail and in that two Further coupling parts which can be coupled to one another via rack-like profiles are provided, one of which is designed as a cable coupling part fastened to the control cable and one as a rail coupling part fastened to the pull-out rail.

- a known pull-in device for the drawer is arranged on the mounting rail or on the pull-out rail, which comprises a spring-loaded driver, which can be moved in a linear guideway and can be locked at the two ends of the guideway and that the central rail has a pin or the like, which the driver engages in the rear entry area of the differential pull-out.

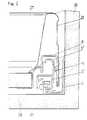

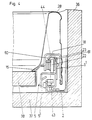

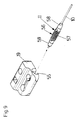

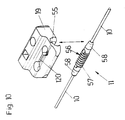

- Fig. 1 shows a diagram and pulled apart the parts of the differential pull-out and the drawer frame; 2 shows a vertical section through one side of the drawer; 3 shows a diagram of the central rail; 4 shows a vertical section through the drawer frame and the differential pull-out in the rear area; 5 shows a diagram of a pull-out rail with adapter; Fig. 6 shows diagrammatically and pulled apart the rear rollers and the rear adapter; 7 shows a diagram of the control cable and the two clutches; 8 shows a diagram of the cable coupling; FIG. 9 shows a diagram of the coupling which connects the control cable to the pull-out rail, the coupling being indicated from the front; FIG. 10 shows the same diagram as FIG.

- FIG. 12 shows the same view as FIG. 11 of a further exemplary embodiment of a fastening device for the front panel and FIGS. 13 to 15 show side views of the fastening device according to FIG. 12.

- the drawer is formed by the two metal drawer frames 28 of the front panel 39, the drawer base 38 and the rear wall 27.

- the mounting rail 2 is fastened to the body side wall 36 in the usual manner via a fastening web 40.

- the drawer bottom 38 rests on a horizontal web 41 of the pull-out rail 15.

- In the horizontal web 41 there are tabs 42 with a pinecone profile that can be expressed from the horizontal web 41 and can be pressed into a groove or the like of the drawer base 38 and thus anchor the drawer base 38 on the pull-out rail 15.

- the central rail 5 is located between the pull-out rail 15 and the mounting rail 2.

- the central rail 5 has a lower profile 5 ', in which there is a carriage 3 in which rollers are mounted.

- the middle rail 5 is therefore guided in relation to the mounting rail 2 via the rollers mounted in the carriage 3.

- the middle rail 5 is provided with an upper, partially U-shaped profile 5 ′′.

- the rollers 22, 23, which are mounted on the rear adapter 18 of the pull-out rail 15, run on the catwalks 43, 44 of this profile 5 ′′.

- the catwalk 45 of the pull-out rail 15 runs on the roller 6 mounted on the lower profile 5 'of the central rail 5.

- the central rail 5 has a front and a rear cable pulley 9 for the control cable 10, which is mounted on the cable pulleys 9 of the central rail 5.

- the control cable 10 which is formed, for example, by a wire or plastic cable, has a snap-type cable coupling 8.

- the cable coupling 8 consists of two coupling parts, namely a receiving part 12 and an insertion part 13, which are connected to the cable ends of the control cable 10.

- the receiving part 12 is designed as a housing. It has two rack-like profiles 46 on the inside. The side walls are provided with openings 47, which give the housing of the receiving part 12 a certain elasticity.

- the insertion part 13 has a finger-like projecting web 48, which is also provided with rack-like profiles 49, which correspond to the rack-like profiles 46 of the receiving part 12. The web 48 can be inserted into the housing of the receiving part 12 until the control cable 10 is tensioned.

- the teeth 50, 51 of the rack-like profiles 46, 49 are designed like pine cones and counter to one another in order to facilitate the insertion of the web 48 of the insertion part 13 into the housing of the receiving part 12.

- the receiving part 12 is provided with a U-shaped recess 52.

- the insertion part 13 has a side hook 53 with which it can be inserted into an opening 14 in the mounting rail 2.

- the insertion part 13 can thus be anchored to the mounting rail 2 via the hook 53.

- guide pins 54 are formed on the insertion part 13, which also protrude into the opening 14 and improve the fit of the hook 53 in the opening 14.

- a special coupling is also provided.

- This consists of an outer rail coupling part 19 and an inner cable coupling part 11.

- the outer rail coupling part 19 is fastened to the pull-out rail 15 by means of screws or rivets 20 which protrude through fastening holes. It includes the inner cable coupling part 11 like pliers.

- the inner cable coupling part 11 is torpedo-shaped and can be pressed into a trough-shaped recess 55 of the outer rail coupling part 19.

- a slot-like opening 120 is provided, which widens in a circle at both ends. This increases the elasticity of the rail coupling part 19 made of plastic.

- the rack-like profile 56 On the wall of the trough-shaped recess, two rack-like profiles are provided, which correspond to the rack-like profile 56 of the cable coupling part 11.

- the teeth 57 of the rack-like profile 56 are designed annular.

- the cross section of the teeth 57 is either like a pine cone or the cross section corresponds to an isosceles triangle.

- the teeth 57 can be rounded on the outer edge.

- the cable coupling part 11 is approximately cylindrical or torpedo-shaped and has a frustoconical end section 58 on both sides.

- the rail coupling part 19 In order to connect the coupling parts 11, 19 to one another, the rail coupling part 19, as shown in FIG. 9, can be pushed onto the cable coupling part 11 from the front or, as shown in FIG.

- a roller 6 is mounted on tabs 59 by means of a rent 7.

- the runway 45 of the pull-out rail 15 runs on the roller 6.

- Three adapters 16, 17, 18 are attached to the running rail 15.

- two rollers 22, 23 are supported by rivets 21.

- the rollers 22, 23 are guided in the upper profile 5 ′′ of the middle rail 5 and are located inside the adapter 18. They are mounted one behind the other.

- the front roller 22 is narrower than the rear roller 23 and is supported on the web 43 of the upper profile 5 ′′ of the center rail 5 when the drawer is moved.

- the web 44 of the profile 5 ′′ of the central rail 5 is U-shaped with a lateral limiting web 60. Between this limiting web 60 and the vertical web 61, which runs at the top with the same slope as the limiting web 60, the roller 23 is fed properly. This ensures lateral guidance of the pull-out rail 15 and thus the drawer. Since the roller 22 is supported on the lower horizontal web 43 and the roller 23 on the upper horizontal web 44, there is no change in the direction of rotation of the rollers 22, 23 during pulling out or pushing in of the drawer and thus smooth running of the drawer is achieved.

- a headstock 4 made of plastic material is attached at the front end of the lower profile 5 'of the center rail 5.

- the headstock 4 has an opening 62 in which the roller 6 is mounted.

- the roller 6 is supported on a rivet 7, which is held in flanges 67.

- the headstock 4, which overlaps the front end of the lower profile 5 'of the central rail 5, is provided with a rail web 63 which has a straight section 63' and a front, downwardly bent section 63 ''.

- All three adapters 16, 17, 18 have retaining webs 64 projecting downwards.

- the drawer frames 28 are double-walled with an outer wall 65 and an inner wall 66.

- the outer wall 65 has, at its lower edge, a retaining web 67 which is angled inwards and upward, with which it can be suspended in the retaining webs 64 of the adapters 16, 17, 18.

- the inner wall 66 has a horizontal web 68 which rests on the drawer base 38 when the drawer is mounted and a vertical side web 69 which rests on the side of the drawer base 38.

- the transition from the horizontal web 68 to the inner wall 66 is rounded.

- drawer frame 28 is neither welded or grooved to the adapters 16, 17, 18, nor to the pull-out rail 15, drawer frames made of any material can be hung into the adapters 16, 17, 18, from plastic frames to aluminum frames to steel frames made of a stainless steel material.

- the furniture manufacturer is therefore given the possibility of equipping drawers with very different prices with the differential pull-out according to the invention.

- the foremost adapter 16 is provided with a holding plate 70 to which a supporting part 32, 33 of a fastening device 30, 31 for the front panel 39 can be screwed.

- the front panel 39 is pressed onto the dowels 71 of the front panel fastening 30 when the drawer is assembled.

- the fastening device 30 is fully mounted on the pull-out rail 15.

- a holding part 34 is fastened to the front panel 39 and the supporting part 33 is fastened to the holding plate 70 by means of a screw 72.

- Both the support part 33 of the fastening device 31 and the support part 32 of the fastening device 30 are provided with a lateral guide wall 73 which bears against a corresponding guide wall 74 of the holding plate 70.

- the support part 32 of the fastening device 30 has a slot 75 which is open to the rear and through which the fastening screw 72 projects, which can be screwed into a nut thread 76 in the holding plate 70.

- the fastening device 30 has a holding part 80 which is fastened to the front panel 39 with dowels 71.

- the support part 32 which is stamped from a steel sheet, has a tab 76 which projects at a right angle from the support part 32.

- the support part 32 has a horizontal web 77, each with a slot 78 open to the rear. Pins 79 of the holding part 80 are guided in the slots 78.

- the holding part 80 is provided with a recess 81.

- An adjustment screw 82 for the lateral adjustment of the front panel 39 is also mounted in the holding part 80. When the fitting is mounted, the upper edge 83 of the support part 32 protrudes into an annular groove 84 of the adjusting screw 82, so that the holding part 81 is moved laterally with respect to the supporting part 32 by turning the adjusting screw 82.

- the flange 76 of the supporting part 32 projects into the recess 81 of the holding part 80.

- a compression spring 85 is mounted in the recess 81 and is supported on the one hand on the web 86 of the holding part 80 and on the other hand on the tab 76 of the supporting part 32.

- the holding part 80 is pressed backwards by the compression spring 6 and thus the front panel 39 is drawn to the front edges of the drawer frames 28.

- the drawer If the drawer is pushed into the furniture body with too much momentum, the front panel 39 strikes the front edges of the side walls 36 of the furniture body. However, the drawer can continue to move with the drawer frames 28, the pull-out rails 15 and the supporting parts 32 against the pressure of the compression springs 85 relative to the holding parts 80, so that a damping effect occurs and the hold of the dowels 71 in the front panel 39 is not excessively stressed. If the run-in energy is destroyed, the drawer frames 28 are over the supporting part 32 and the holding plates 70 pressed by the compression springs 85 on the front panel 28.

- the fastening device 30 When assembling the drawer, the fastening device 30 according to the invention is completely mounted in the drawer frame 28.

- the holding part 80 is pressed by the compression spring 85 into the rear end position.

- the outer wall 65 of the front panel 28 is provided in the area of the fastening device 30, 33 with a recess 87, which enables tools to be accessed on the fastening device 30, 33.

- the recess 87 is covered by a removable cover plate 29.

- the holding part 80 is pressed out of the drawer frame 28 somewhat by means of a press ram which engages in the recess 81 and bears against the web 89 of the holding part 80, the stop face 88 being just in front of the end face of the drawer frame 28

- the front panel 39 can be pressed onto the dowels 71 of the holding part 80. If the front panel 39 is anchored on the dowels 71 of the holding part 80, the ram is pulled out of the recess 81 and the compression spring 85 presses the holding part 80 into the drawer frame 28 so that the front panel 39 fits snugly against the end face of the drawer frame 17.

- the fastening device 31 has a support part 33, which in turn is fastened to the holding plate 70 of the adapter 16 by means of a screw 72.

- a rocker arm 90 is mounted on the support part 33.

- the support part 33 again has an angled tab 76 at the back, on which the spring 85 is supported.

- the angled tab 76 is provided with a cross slot 91 through protrudes a rod 92 which carries the spring 85 and which acts directly on the rocker arm 90.

- the support part 33 is fastened by means of the screw 72, which projects through a vertical slot 93 in the support part 32 and which can be screwed into the holding plate 70.

- the tilt segment 90 has an upper notch 93 and a lower notch 94.

- the locking bolt 95 which is supported at its rear end by means of a punched slot 96 on the rod 92 and which has a locking web 97 at the front, which engages in the notch 93 of the rocker arm 90 when the front panel 39 is fastened.

- the holding part 34 is attached directly to the front panel 39.

- the adjusting screw 82 for the lateral adjustment is stored in it.

- the support part 32 has an upper and a lower horizontal web 77, between which the holding part 34 can be inserted.

- a side plate 98 is plugged onto the webs 77, into which pins 99 of the webs 77 project.

- the support part 33 and the side plate 98 have punched holes 101 through which the pin 102, which forms the axis of the tilting segment 90, projects.

- the holding part 34 is provided with a hook 100.

- the tilting segments 90 are in the position shown in FIG. 13, ie it becomes acted upon by the spring 85 in a clockwise direction and rotated until the nose 105 abuts the web 77.

- the nose 100 engages in the notch 94 and rotates the tilting segment 90 counterclockwise.

- the tilting segment 90 is also rotated counterclockwise by the spring 85 and thus the holding part 34 is drawn into the supporting part 33 and the front panel 39 is pressed against the drawer frame 28.

- the tilt segment 90 is provided with a cross slot 108.

- the locking bolt 95 has a lateral web 107 which laterally engages over the tilting segment 90. If the front panel 39 is now to be detached from the drawer frame 28, a Phillips screwdriver is inserted into the Phillips 108. As a result, the locking bolt 95 is raised because the screwdriver strikes the side bar 107. At the same time, the locking flange 97 is lifted out of the notch 93 of the rocker arm 90 and the rocker arm 90 is thus released. Now, when the Phillips screwdriver protrudes into the Phillips, the rocker arm 90 can be turned clockwise, whereby the holding part 34 is released.

- a shock absorber effect also occurs when the drawer is pushed too forcefully into the furniture body. If the front panel 39 abuts the side walls 36 of the piece of furniture, the drawer frames 28 and the pull-out rails 15 can be raised against the action of the spring 85 as far from the front panel 39 as the distance between the locking flange 97 and the stop surface 109 on the rocker arm 90 allows. The pull-out rails 15 and the drawer frame 28 are then pressed against the front panel 39 again by the spring 85.

- the holding part 34 can also be connected to a coupling part 103 for a front panel.

- a front panel 39 which lies against the front of the drawer frames 28, the front plate is located between the two drawer frames 28 and closes with them at the front.

- the front plate 104 does not protrude beyond the body side walls 36 and the furniture body can be closed with doors.

- the rearmost adapter 18 carries a coupling part 25 for the rear wall 27.

- the coupling part 25 is provided with pins 105 which protrude into punched holes 106 from angled tabs 107 of the rear wall 27.

- the coupling part 25 has a downwardly projecting, preferably resilient hook 108 which hooks into the adapter 18 when the coupling part is mounted.

- the rear wall 27 is also provided with a lower horizontal web 109 on which the drawer bottom 38 rests.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT7594 | 1994-01-17 | ||

| AT0007594A AT401715B (de) | 1994-01-17 | 1994-01-17 | Differentialauszug für schubladen |

| AT75/94 | 1994-01-17 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0664984A2 true EP0664984A2 (fr) | 1995-08-02 |

| EP0664984A3 EP0664984A3 (fr) | 1997-02-05 |

| EP0664984B1 EP0664984B1 (fr) | 2000-03-22 |

Family

ID=3480868

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP94120260A Expired - Lifetime EP0664984B1 (fr) | 1994-01-17 | 1994-12-21 | Coulisse de tiroir séquentielle ou similaire |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US5564807A (fr) |

| EP (1) | EP0664984B1 (fr) |

| JP (1) | JP2791753B2 (fr) |

| AT (2) | AT401715B (fr) |

| CA (1) | CA2140212A1 (fr) |

| DE (1) | DE59409231D1 (fr) |

| ES (1) | ES2144482T3 (fr) |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NL1003665C2 (nl) * | 1996-07-23 | 1998-01-28 | Thomas Regout B V | Overuittrekbare diferentiële ladegeleider. |

| EP0820712A2 (fr) * | 1996-07-26 | 1998-01-28 | Karl Baliko | Dispositif de guidage de tiroir à glissière double |

| WO2008028808A1 (fr) * | 2006-09-08 | 2008-03-13 | Paul Hettich Gmbh & Co. Kg | Dispositif de connexion monté sur un tiroir |

| WO2008028811A1 (fr) * | 2006-09-08 | 2008-03-13 | Paul Hettich Gmbh & Co. Kg | Tiroir |

| DE202008014042U1 (de) * | 2008-10-22 | 2010-03-11 | Paul Hettich Gmbh & Co. Kg | Auszugsführung für ein Möbelteil |

| AT505207B1 (de) * | 2007-04-23 | 2011-08-15 | Blum Gmbh Julius | Einzugsvorrichtung für ein bewegbares möbelteil |

| WO2014032063A1 (fr) * | 2012-08-31 | 2014-03-06 | Julius Blum Gmbh | Dispositif pour faire rentrer ou sortir une partie de meuble montée mobile |

| CN108078254A (zh) * | 2016-11-22 | 2018-05-29 | 世塑有限公司 | 抽屉同步构件 |

| AT520402A1 (de) * | 2017-08-17 | 2019-03-15 | Blum Gmbh Julius | Schubladenausziehführung |

Families Citing this family (34)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ATA34396A (de) * | 1996-02-26 | 1998-10-15 | Blum Gmbh Julius | Ausziehführungsgarnitur für schubladen |

| US5722749A (en) * | 1996-06-05 | 1998-03-03 | Grass America, Inc. | Self-positioning cabinet rail for a drawer guide |

| US5876103A (en) * | 1996-06-05 | 1999-03-02 | Grass America, Inc. | Self-positioning cabinet rail for a drawer guide |

| AT407002B (de) * | 1997-04-01 | 2000-11-27 | Blum Gmbh Julius | Ausziehführungsgarnitur für schubladen |

| US6273534B1 (en) | 1999-11-05 | 2001-08-14 | Spacesaver Corporation | Shelving accessory mounting system for a cabinet assembly |

| ITMC20000049A1 (it) * | 2000-06-06 | 2001-12-06 | Compagnucci Spa | Componente polivalente per cesti metallici scorrevoli, collocati all'interno di mobili. |

| US6619771B2 (en) | 2001-12-06 | 2003-09-16 | Grass America, Inc. | Self-positioning cabinet rail for a drawer guide |

| DE20209416U1 (de) * | 2002-06-17 | 2003-10-30 | Alfit Ag Goetzis | Anordnung für die Verbindung einer Schubladenzarge mit dem Boden einer Schublade |

| CA2521444C (fr) * | 2003-05-13 | 2008-07-08 | Grass America Inc. | Mecanisme de fermeture d'un tiroir |

| US7549712B2 (en) * | 2003-05-13 | 2009-06-23 | Grass America, Inc. | Front locking device for releasably engaging a drawer to a drawer slide |

| EP1793702B1 (fr) * | 2004-09-30 | 2010-04-07 | Horst Lautenschläger | Tiroir de meuble |

| DE102005007001A1 (de) * | 2005-02-16 | 2006-08-17 | Lautenschläger, Horst | Einrichtung zur Aufnahme einer Schublade |

| US20060226748A1 (en) * | 2005-04-08 | 2006-10-12 | Merillat Industries, Llc | Drawer guide support bracket |

| CN101330850B (zh) * | 2005-12-15 | 2012-05-23 | 尤利乌斯·布卢姆有限公司 | 带有至少一个第一家具部件和一个第二家具部件的家具 |

| DE102007005948A1 (de) * | 2007-02-06 | 2008-08-07 | BSH Bosch und Siemens Hausgeräte GmbH | Kältegerät mit Teleskopauszug |

| AT505208B1 (de) * | 2007-04-23 | 2011-08-15 | Blum Gmbh Julius | Antrieb mit einem zugmittel und einer kupplung für ein bewegbares möbelteil |

| GB2472959B (en) * | 2008-08-07 | 2013-04-10 | Accuride Int Inc | A synchronizing/stabilizing system and self moving mechanism for drawer applications |

| MY151706A (en) * | 2009-08-12 | 2014-06-30 | Harn Marketing Sdn Bhd | Drawer assembly |

| TW201117701A (en) * | 2009-11-03 | 2011-05-16 | Inventec Corp | Rail device and server |

| TW201117702A (en) * | 2009-11-04 | 2011-05-16 | Inventec Corp | Rail apparatus and server |

| DE102010060583A1 (de) * | 2010-11-16 | 2012-05-16 | Paul Hettich Gmbh & Co. Kg | Auszugsführung für ein Auszugsteil eines Möbels |

| DE102010060720A1 (de) * | 2010-11-22 | 2012-05-24 | Paul Hettich Gmbh & Co. Kg | Trageinrichtung zur Festlegung einer Frontblende |

| AT510018B1 (de) * | 2010-11-23 | 2012-01-15 | Blum Gmbh Julius | Vorrichtung zur anbringung eines funktionsteiles an einer schiene einer schubladenausziehführung |

| AT511417B1 (de) * | 2011-04-27 | 2018-08-15 | Blum Gmbh Julius | Schubladenseitenwand mit einer innenwand und einer aussenwand |

| US8876232B2 (en) | 2011-10-27 | 2014-11-04 | Rsi Home Products Management, Inc. | Drawer glide mechanism |

| US8764135B1 (en) * | 2013-03-18 | 2014-07-01 | Nan Juen International Co., Ltd. | Linking mechanism |

| DE102013113672A1 (de) * | 2013-06-14 | 2014-12-18 | Paul Hettich Gmbh & Co. Kg | Auszugssystem |

| CN103504836B (zh) * | 2013-08-30 | 2016-04-06 | 伍志勇 | 抽屉 |

| WO2015171945A1 (fr) | 2014-05-09 | 2015-11-12 | Rsi Home Products Management, Inc. | Mécanisme de glissière de tiroir |

| DE202014104929U1 (de) * | 2014-10-16 | 2016-01-19 | Grass Gmbh | Zarge für eine Schublade mit einem Zargenkörper sowie Schublade und Möbel mit einer Schublade |

| DE102016111857A1 (de) * | 2016-06-29 | 2018-01-04 | Paul Hettich Gmbh & Co. Kg | Verfahren zur Montage eines Schubelementes und Bausatz zur verschiebbaren Lagerung eines Schubelementes, Möbel und Haushaltsgerät |

| WO2019074271A1 (fr) * | 2017-10-12 | 2019-04-18 | (주)세고스 | Dispositif de coulissement |

| AT520822B1 (de) * | 2018-02-01 | 2019-08-15 | Blum Gmbh Julius | Schubladenseitenwand |

| DE202020107093U1 (de) * | 2020-12-09 | 2022-03-10 | Grass Gmbh | Möbelschublade |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4019124A1 (de) * | 1990-06-15 | 1991-12-19 | Grass Ag | Vollauszug |

| EP0635226A1 (fr) * | 1993-06-29 | 1995-01-25 | Julius Blum Gesellschaft m.b.H. | Coulisse de tiroir séquentielle ou similaire |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2267043A (en) * | 1939-12-22 | 1941-12-23 | Owen D Premo | Pulley slide |

| GB660567A (en) * | 1947-05-22 | 1951-11-07 | William Lawrence & Company Ltd | Improvements in or relating to collapsible or knock-down furniture |

| US3078129A (en) * | 1960-06-22 | 1963-02-19 | Otto A Beeck | Band controlled extension slide |

| US3545833A (en) * | 1969-02-14 | 1970-12-08 | Instrument Systems Corp | Progressive slide assembly |

| US3687505A (en) * | 1971-06-11 | 1972-08-29 | Fall Herbert S | Slide with synchronizing cable drive |

| US3722964A (en) * | 1971-07-07 | 1973-03-27 | Oxford Pendaflex Corp | Extensible drawer support |

| US4025138A (en) * | 1975-02-20 | 1977-05-24 | Halle Industries Inc. | Progressive slide assemblies |

| US3980364A (en) * | 1975-06-04 | 1976-09-14 | Amerock Corporation | Roller bracket assembly for drawers |

| US4199200A (en) * | 1978-08-29 | 1980-04-22 | Amerock Corporation | Roller bracket assembly for drawers |

| DE2844850A1 (de) * | 1978-10-14 | 1980-04-30 | Grass Alfred Metallwaren | Fuehrungsschiene fuer schubladen mit einstellanordnung |

| DE2904116A1 (de) * | 1979-02-03 | 1980-08-07 | Standard Praezision Gmbh | Teleskopschiene |

| DE3335700A1 (de) * | 1983-10-01 | 1985-04-11 | Günter 7144 Asperg Grötzinger | Keilriemen |

| JPH0617347Y2 (ja) * | 1984-07-24 | 1994-05-02 | 北川工業株式会社 | 板材保持具 |

| AT401851B (de) * | 1991-01-21 | 1996-12-27 | Blum Gmbh Julius | Beschlag |

| US5275064A (en) * | 1992-06-12 | 1994-01-04 | General Devices Co., Inc. | Extensible platform with cable drive system |

| DE4226812B4 (de) * | 1992-08-13 | 2004-10-21 | Grass Gmbh | Schubladenführung mit Vollauszug und Zugmittel |

| ATE173589T1 (de) * | 1994-01-17 | 1998-12-15 | Blum Gmbh Julius | Schublade |

-

1994

- 1994-01-17 AT AT0007594A patent/AT401715B/de not_active IP Right Cessation

- 1994-12-21 ES ES94120260T patent/ES2144482T3/es not_active Expired - Lifetime

- 1994-12-21 EP EP94120260A patent/EP0664984B1/fr not_active Expired - Lifetime

- 1994-12-21 AT AT94120260T patent/ATE190814T1/de not_active IP Right Cessation

- 1994-12-21 DE DE59409231T patent/DE59409231D1/de not_active Expired - Lifetime

-

1995

- 1995-01-12 JP JP7018845A patent/JP2791753B2/ja not_active Expired - Fee Related

- 1995-01-13 US US08/372,373 patent/US5564807A/en not_active Expired - Fee Related

- 1995-01-13 CA CA002140212A patent/CA2140212A1/fr not_active Abandoned

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4019124A1 (de) * | 1990-06-15 | 1991-12-19 | Grass Ag | Vollauszug |

| EP0635226A1 (fr) * | 1993-06-29 | 1995-01-25 | Julius Blum Gesellschaft m.b.H. | Coulisse de tiroir séquentielle ou similaire |

Cited By (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NL1003665C2 (nl) * | 1996-07-23 | 1998-01-28 | Thomas Regout B V | Overuittrekbare diferentiële ladegeleider. |

| WO1998003099A1 (fr) * | 1996-07-23 | 1998-01-29 | Thomas Regout B.V. | Glissiere de tiroir differentielle a surextension |

| US6231143B1 (en) | 1996-07-23 | 2001-05-15 | Thomas Regout B.V. | Over-extendible differential drawer guide |

| CZ298152B6 (cs) * | 1996-07-23 | 2007-07-11 | Thomas Regout B. V. | Zásuvkové vodítko roztazitelného typu |

| EP0820712A2 (fr) * | 1996-07-26 | 1998-01-28 | Karl Baliko | Dispositif de guidage de tiroir à glissière double |

| EP0820712B1 (fr) * | 1996-07-26 | 2001-05-30 | Julius Blum Gesellschaft m.b.H. | Dispositif de guidage de tiroir à glissière double |

| JP2010502328A (ja) * | 2006-09-08 | 2010-01-28 | ポール ヘティッヒ ゲーエムベーハー ウント ツェーオー. カーゲー | 引出しの接続デバイス |

| WO2008028811A1 (fr) * | 2006-09-08 | 2008-03-13 | Paul Hettich Gmbh & Co. Kg | Tiroir |

| WO2008028808A1 (fr) * | 2006-09-08 | 2008-03-13 | Paul Hettich Gmbh & Co. Kg | Dispositif de connexion monté sur un tiroir |

| AT505207B1 (de) * | 2007-04-23 | 2011-08-15 | Blum Gmbh Julius | Einzugsvorrichtung für ein bewegbares möbelteil |

| US8344670B2 (en) | 2007-04-23 | 2013-01-01 | Julius Blum Gmbh | Coupling for a movable furniture part |

| DE202008014042U1 (de) * | 2008-10-22 | 2010-03-11 | Paul Hettich Gmbh & Co. Kg | Auszugsführung für ein Möbelteil |

| WO2014032063A1 (fr) * | 2012-08-31 | 2014-03-06 | Julius Blum Gmbh | Dispositif pour faire rentrer ou sortir une partie de meuble montée mobile |

| CN108078254A (zh) * | 2016-11-22 | 2018-05-29 | 世塑有限公司 | 抽屉同步构件 |

| AT520402A1 (de) * | 2017-08-17 | 2019-03-15 | Blum Gmbh Julius | Schubladenausziehführung |

| US11013320B2 (en) | 2017-08-17 | 2021-05-25 | Julius Blum Gmbh | Drawer pull-out guide |

| AT17935U1 (de) * | 2017-08-17 | 2023-08-15 | Blum Gmbh Julius | Schubladenausziehführung |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2791753B2 (ja) | 1998-08-27 |

| US5564807A (en) | 1996-10-15 |

| CA2140212A1 (fr) | 1995-07-18 |

| JPH07213359A (ja) | 1995-08-15 |

| AT401715B (de) | 1996-11-25 |

| EP0664984A3 (fr) | 1997-02-05 |

| ATA7594A (de) | 1996-04-15 |

| DE59409231D1 (de) | 2000-04-27 |

| EP0664984B1 (fr) | 2000-03-22 |

| ATE190814T1 (de) | 2000-04-15 |

| ES2144482T3 (es) | 2000-06-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0664984A2 (fr) | Coulisse de tiroir séquentielle ou similaire | |

| EP0267477B1 (fr) | Dispositif de fixation de parois avant ajustables pour tiroirs | |

| EP0636327B1 (fr) | Dispositif pour fixer le panneau avant de tiroir sur les parois latérales | |

| EP0740917B1 (fr) | Dispositif pour fixer le panneau avant de tiroir, en particulier tiroir à double paroi, sur les parois latérales | |

| AT404664B (de) | Vorrichtung zur befestigung der frontblende einer schublade an schubladenzargen | |

| EP0862873B1 (fr) | Ferrure pour fixation et tiroir pour une telle ferrure | |

| EP0814687B1 (fr) | Monture de guidage pour extraire un tiroir | |

| EP0545329B1 (fr) | Accessoire pour glissière de tiroir | |

| EP1080290A1 (fr) | Dispositif tampon | |

| EP0581325A2 (fr) | Dispositif de fixation pour un rail de tiroir | |

| EP0097766B1 (fr) | Charnière pour meuble | |

| EP1647206A2 (fr) | Glissière télesopique pour une pièce de meuble coulissante | |

| AT401714B (de) | Differentialauszug für schubladen od. dgl. | |

| AT398516B (de) | Schubkastenauszug | |

| EP0367274B1 (fr) | Guidage à glissière double simplifié | |

| EP2064972B1 (fr) | Tiroir d'armoire doté d'une partie de support et d'une façade de meuble pouvant être fixée dessus | |

| EP0809956A2 (fr) | Dispositif à tiroirs pour un élément coulissant, encastrable dans une unité d'armoire | |

| EP1518482A2 (fr) | Dispositif de suspension pour un placard le long d'un mur | |

| DE4241612A1 (de) | Beschlag für einen Eckschrank | |

| DE19707741A1 (de) | Möbelscharnier | |

| DE2821101C3 (de) | Auszugführung für in einem Gestell gehaltene Schubladen o.dgl | |

| AT398263B (de) | Auszugschiene mit einer integrierten seitenzarge | |

| AT404665B (de) | Befestigungsvorrichtung einer frontblende einer schublade | |

| DE2420307A1 (de) | Rollenfuehrung fuer moebelschubkaesten | |

| EP0093107B1 (fr) | Dispositif pour fixer des objets à une structure de support |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT CH DE ES FR GB IT LI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT CH DE ES FR GB IT LI |

|

| 17P | Request for examination filed |

Effective date: 19970521 |

|

| 17Q | First examination report despatched |

Effective date: 19980313 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE ES FR GB IT LI |

|

| REF | Corresponds to: |

Ref document number: 190814 Country of ref document: AT Date of ref document: 20000415 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59409231 Country of ref document: DE Date of ref document: 20000427 |

|

| ITF | It: translation for a ep patent filed |

Owner name: BUGNION S.P.A. |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: ISLER & PEDRAZZINI AG |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20000515 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2144482 Country of ref document: ES Kind code of ref document: T3 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001221 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20011217 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20011218 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20011219 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20021212 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20021221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20021231 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20021231 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20021221 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030901 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031222 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20031222 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20051221 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20140228 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59409231 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59409231 Country of ref document: DE |