EP0363349A2 - Cour de croisement à pointe coulée en acier dur au manganèse - Google Patents

Cour de croisement à pointe coulée en acier dur au manganèse Download PDFInfo

- Publication number

- EP0363349A2 EP0363349A2 EP89890258A EP89890258A EP0363349A2 EP 0363349 A2 EP0363349 A2 EP 0363349A2 EP 89890258 A EP89890258 A EP 89890258A EP 89890258 A EP89890258 A EP 89890258A EP 0363349 A2 EP0363349 A2 EP 0363349A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- heart

- centerpiece

- sleepers

- frog

- webs

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B7/00—Switches; Crossings

- E01B7/10—Frogs

Definitions

- the invention relates to a heart with a heart tip made of cast manganese steel, in which a part of the wing rail is cast onto the heart tip in the overflow area.

- Composite heart pieces with heart tips made of cast manganese steel are known in different designs. It is known, for example, to cast part of the wing splints with the heart tip in the overflow area and to place such heart tips on the foot of the wing splints. Different designs of composite heart pieces of this type also result in relation to the connection to the connecting rails and it is known to screw such heart pieces to the connecting rails. In recent times, it has also become known to weld hard manganese steel frogs to connecting rails. A construction of the type mentioned at the outset can be found, for example, in US Pat. No. 4,081,162, in which the hard manganese steel core is screwed to the connecting rails with partially cast-on wing rails.

- a closed profile was chosen to improve the load-bearing capacity and the known centerpiece has a continuous base plate.

- the centerpiece was in turn supported on the foot of the wing rails, the design of the base plate additionally also making it possible, at least in part, to support sleepers or base plates. Due to the rolling tolerances, however, a wing rail cannot now be manufactured with sufficient precision in order to form a perfect contact surface for a centerpiece. The height of the tip of such a frog is therefore always dependent on the rolling tolerances of the base of the wing rail and complex fitting work is required to fit such a frog.

- the design of the centerpiece according to the invention essentially consists in the fact that the cast part has transverse webs in the area of the sleepers, which webs can be supported directly on the sleepers or underlay plates, and that the cast part can be supported only on the sleepers on the sleepers .

- the fact that a continuous base plate is avoided and only transverse webs are provided in the area of the sleepers allows the height of the tip to be set exactly, while at the same time ensuring a low weight of the centerpiece or of the cast part.

- the training is so designed that the centerpiece can only be supported on the sleepers via the webs or with the interposition of base plates on the sleepers.

- the webs create a structurally favorable design, in which a closed cross section is produced with a favorable force fit.

- Such a centerpiece can be welded to connecting rails in a particularly advantageous manner in a manner known per se, as a result of which the risk of breakage which can occur when the tip is screwed to connecting rails in the area of the screw connection is avoided.

- Such welding simultaneously leads to a substantial reduction in the overall length and thus to a further reduction in weight. Since the casting is relatively small, it can be produced in excellent quality by casting.

- the design is such that the casting with the wing rails is designed as a spacer or carries spacers. Due to the exact determination of the height of the frog and in particular the frog tip, exact compliance with the height tolerances of the connected wing rails can also be achieved on the basis of such chucks or spacers.

- the training is such that it is not the wing splints that carry the pieces, but rather the heart is supported directly and independently of the wing splints, such a precise fixing of the heart piece being able to be used if necessary to adhere to the exact positioning of the wing rails.

- the design is made in a particularly preferred manner in such a way that the cast part is shorter and that welded connection rails are welded together to the cast part.

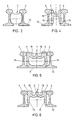

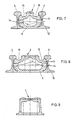

- FIG. 1 shows a plan view of a first embodiment of a heart piece according to the invention with a heart tip made of cast hard manganese steel; 2 shows a section along the line II-II in the longitudinal direction through the heart according to FIG. 1; 3 to 9 sections along the lines III-III to IX-IX through the heart according to FIG. 1 in different cross-sectional areas; 10 shows a plan view of a second embodiment of a heart piece according to the invention; and FIG. 11 shows a section along the line XI-XI in the longitudinal direction through the centerpiece according to FIG. 10, wherein in the embodiment according to FIG. 10, cuts in different cross-sectional areas are provided analogously to the configuration according to FIG the Lines III-III to VII-VII in Fig.10 take place and correspond to the sections shown in Fig.3 to 7.

- FIG. 1 denotes a heart made of hard manganese steel, which has a heart tip 2 and a part 3 of the wing rails is cast onto the heart tip in the overflow area.

- wing rails 4 are indicated in FIG. 1, which, in contrast to the heart 1 made of hard manganese steel and cast, of standard-quality rail profiles, i.e. made of steel, which is generally used for rails.

- the centerpiece 1 is welded at its end 5 to connecting rails 6, whereby an uninterrupted running edge profile is achieved by this welding and the centerpiece can be made shorter and thus lighter and less expensive due to the smaller space requirement for welding with the connecting rails 6 compared to a screw connection.

- the centerpiece 1 and the wing rails 4 are supported by schematically indicated sleepers 7, optionally with the interposition of base plates.

- the centerpiece 1 carries 4 spacers 8 in the areas of the screw connection with the wing rails, which are shown in detail in the following figures.

- the center piece is again designated by 1 and it is clear that the wing rails 4 have an essentially normal rail profile, with only the area of the rail foot 12 facing the center piece correspondingly can be edited.

- the centerpiece 1 has an open cross-section, with webs 9 running only in the area of the support on sleepers or base plates transverse to the longitudinal direction of the centerpiece 1, as can be clearly seen in FIGS. 5, 7 and 8.

- essentially vertical webs 13 of the frog are not supported on the rail foot 12 of the wing rails 4, but at most come into contact with them, so that the frog 1 is supported only via the webs 9 on sleepers (not shown).

- the height of the tip of the heart 2 and the cast-on wing rails 3 can be set exactly and cumbersome fitting work of the centerpiece when the webs 13 are supported on rail profiles of the wing rails 4 and in particular the rail foot 12 that can only be produced with relatively large tolerances can be avoided.

- the frog 1 is screwed to the adjacent wing rails 4 through the openings or bores 11 in the frog, the frog is designed as a spacer from the adjacent wing rails 4, this being done by providing corresponding spacers 8 or by a corresponding design of projections.

- the screw connection to the wing rails 4 takes place through bores or perforations 14 in the web of the wing rail profile 4, the spacers 8 in the area of this screw connection having a shape partially adapted to the inner profile of the web of the wing rails 4, as can be seen in FIGS 8 is clearly visible.

- the frog 1 has, as mentioned above, essentially perpendicular webs 13, which are arranged at a distance from the web of the wing rails 4.

- the driving groove (s) provided in the centerpiece is (are) denoted by 15 in FIGS. 4 to 8.

- the centerpiece is shortened compared to the embodiment shown in FIG. 1, the reference numbers in FIGS. 1 to 9 being retained for identical components.

- the centerpiece 1 with the heart tip 2 and the wing rails 3 cast on in the overflow area is in turn made of hard manganese steel and welded at its end 5 to the welded-together connecting rails 6.

- the welding to the welded-together connecting rails, which only merge into two separate connecting rails 6 at a distance from the end 5 of the frog 1, enables a greatly shortened design of the frog 1.

- the centerpiece 1 in turn has transverse webs 9 provided only in the area of the sleepers 7, as can be seen in particular from FIG. 11.

- spacers 8 of the frog 1 are again provided.

- the fact that the frog 1 is supported only via webs 9 provided in the area of the sleepers and not on the rail foot of the wing rails 4 enables the heart tip and the running edge course of the cast-on wing rail regions 3 to be positioned exactly.

- wing rails 3 Due to the partial casting of the wing rails 3 in the overflow area to the centerpiece 1, rail profiles made of hard manganese steel can be dispensed with, so that the wing rails 4, as already mentioned in detail above, can be formed with a substantially standard rail profile from a standard steel.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Escalators And Moving Walkways (AREA)

- Machines For Laying And Maintaining Railways (AREA)

- Dental Tools And Instruments Or Auxiliary Dental Instruments (AREA)

- Chain Conveyers (AREA)

- Medicines That Contain Protein Lipid Enzymes And Other Medicines (AREA)

- Leg Units, Guards, And Driving Tracks Of Cranes (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT244988 | 1988-10-04 | ||

| AT2449/88 | 1988-10-04 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0363349A2 true EP0363349A2 (fr) | 1990-04-11 |

| EP0363349A3 EP0363349A3 (fr) | 1991-04-10 |

Family

ID=3534555

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19890890258 Withdrawn EP0363349A3 (fr) | 1988-10-04 | 1989-10-03 | Cour de croisement à pointe coulée en acier dur au manganèse |

Country Status (8)

| Country | Link |

|---|---|

| EP (1) | EP0363349A3 (fr) |

| CA (1) | CA2000106A1 (fr) |

| DD (1) | DD289568A5 (fr) |

| FI (1) | FI894686A7 (fr) |

| HU (1) | HU205975B (fr) |

| NO (1) | NO893940L (fr) |

| PT (1) | PT91886A (fr) |

| SK (1) | SK279283B6 (fr) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5101747A (en) * | 1989-12-19 | 1992-04-07 | Gerber Garment Technology, Inc. | Apparatus and method for separating pattern pieces from waste material |

| KR100776202B1 (ko) | 2006-10-18 | 2007-11-16 | 삼표이앤씨 주식회사 | 분기기용 망간크로싱 및 그 제조방법 |

| CN103061212A (zh) * | 2012-12-31 | 2013-04-24 | 中铁宝桥集团有限公司 | 固定型高锰钢整铸辙叉新型结构 |

| CN103643599A (zh) * | 2013-12-23 | 2014-03-19 | 安徽华星消防设备(集团)有限公司 | 高锰钢辙叉 |

| CN108103855A (zh) * | 2018-01-05 | 2018-06-01 | 龙运生 | 一种固定型合金钢组合辙叉 |

| EP3507419A4 (fr) * | 2016-07-21 | 2020-06-03 | DT- Vyhybkárna A Strojirna, A.S. | C ur de croisement avec pièce coulée découpée d'un mono-bloc |

| CN115162063A (zh) * | 2022-06-21 | 2022-10-11 | 中铁山桥集团有限公司 | 铁路道岔用间隔铁及其制作方法 |

| DE102022109744A1 (de) | 2021-04-26 | 2022-10-27 | Deutsche Bahn Aktiengesellschaft | Herzstück einer schienenweiche |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108914719A (zh) * | 2018-06-15 | 2018-11-30 | 中铁宝桥集团有限公司 | 镶嵌式锻造高锰钢组合固定型辙叉 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3263076A (en) * | 1963-10-07 | 1966-07-26 | American Brake Shoe Co | Railroad frogs |

| AT350881B (de) * | 1977-08-19 | 1979-06-25 | Voest Ag | Verfahren zur verbindung von ausmanganhart- stahlguss bestehenden herzstuecken mit aus kohlenstoffstahl bestehenden schienen |

| DE2922406C2 (de) * | 1979-06-01 | 1986-01-09 | BWG Butzbacher Weichenbau GmbH, 6308 Butzbach | Herzstückspitzenblock für Weichen und Kreuzungen |

| US4824055A (en) * | 1987-02-02 | 1989-04-25 | Nortrak Limited | Railroad FROG |

-

1989

- 1989-09-22 HU HU894974A patent/HU205975B/hu not_active IP Right Cessation

- 1989-10-02 DD DD89333239A patent/DD289568A5/de not_active IP Right Cessation

- 1989-10-03 NO NO89893940A patent/NO893940L/no unknown

- 1989-10-03 CA CA002000106A patent/CA2000106A1/fr not_active Abandoned

- 1989-10-03 EP EP19890890258 patent/EP0363349A3/fr not_active Withdrawn

- 1989-10-03 PT PT91886A patent/PT91886A/pt unknown

- 1989-10-03 FI FI894686A patent/FI894686A7/fi not_active Application Discontinuation

- 1989-10-04 SK SK5643-89A patent/SK279283B6/sk unknown

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5101747A (en) * | 1989-12-19 | 1992-04-07 | Gerber Garment Technology, Inc. | Apparatus and method for separating pattern pieces from waste material |

| KR100776202B1 (ko) | 2006-10-18 | 2007-11-16 | 삼표이앤씨 주식회사 | 분기기용 망간크로싱 및 그 제조방법 |

| CN103061212A (zh) * | 2012-12-31 | 2013-04-24 | 中铁宝桥集团有限公司 | 固定型高锰钢整铸辙叉新型结构 |

| CN103061212B (zh) * | 2012-12-31 | 2016-03-02 | 中铁宝桥集团有限公司 | 固定型高锰钢整铸辙叉新型结构 |

| CN103643599A (zh) * | 2013-12-23 | 2014-03-19 | 安徽华星消防设备(集团)有限公司 | 高锰钢辙叉 |

| EP3507419A4 (fr) * | 2016-07-21 | 2020-06-03 | DT- Vyhybkárna A Strojirna, A.S. | C ur de croisement avec pièce coulée découpée d'un mono-bloc |

| AU2017300466B2 (en) * | 2016-07-21 | 2022-08-25 | DT - Výhybkárna a strojírna, a.s. | Frog with trimmed casting of a mono-block |

| CN108103855A (zh) * | 2018-01-05 | 2018-06-01 | 龙运生 | 一种固定型合金钢组合辙叉 |

| DE102022109744A1 (de) | 2021-04-26 | 2022-10-27 | Deutsche Bahn Aktiengesellschaft | Herzstück einer schienenweiche |

| CN115162063A (zh) * | 2022-06-21 | 2022-10-11 | 中铁山桥集团有限公司 | 铁路道岔用间隔铁及其制作方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0363349A3 (fr) | 1991-04-10 |

| PT91886A (pt) | 1990-04-30 |

| SK564389A3 (en) | 1998-09-09 |

| CA2000106A1 (fr) | 1990-04-04 |

| SK279283B6 (sk) | 1998-09-09 |

| FI894686L (fi) | 1990-04-05 |

| HUT54745A (en) | 1991-03-28 |

| HU205975B (en) | 1992-07-28 |

| FI894686A7 (fi) | 1990-04-05 |

| NO893940D0 (no) | 1989-10-03 |

| FI894686A0 (fi) | 1989-10-03 |

| DD289568A5 (de) | 1991-05-02 |

| NO893940L (no) | 1990-04-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3622253C2 (fr) | ||

| EP0343150B1 (fr) | Aiguillage avec un coeur comportant une aiguille principale et une aiguille secondaire mobiles | |

| DE3339442C1 (de) | Herzstueck fuer Weichen oder Kreuzungen und Verfahren zur Herstellung eines solchen Herzstueckes | |

| DE3304783C2 (fr) | ||

| EP0363349A2 (fr) | Cour de croisement à pointe coulée en acier dur au manganèse | |

| AT405657B (de) | Vorrichtung zum festlegen von radlenkern | |

| DE2429547A1 (de) | Drehgestelle fuer eisenbahnwagen und verfahren zu ihrer herstellung | |

| AT403386B (de) | Gleis | |

| DE2817768C3 (de) | Geländer oder dergleichen | |

| DE2616058A1 (de) | Blechprofil | |

| DE1048938B (de) | Federzungenvorrichtung, insbesondere fuer Rillenschienenweichen, in Blockkonstruktion | |

| DE8105454U1 (de) | "herzstueck" | |

| DE3017048C2 (de) | Fugenüberbrückungsvorrichtung für Dehnfugen in Brücken o.dgl. | |

| DE1953959A1 (de) | Herzstueck mit vorzugsweise im Gesenk geschlagener Herzstueckspitze | |

| EP0167106A2 (fr) | Cheville creuse pour la construction des voies ferrées | |

| EP2045394A1 (fr) | Zone de croisement de rails à gorge | |

| DE3238272C2 (de) | Gewölbte Profilplatte, insbesondere Walzprofilblech | |

| DE3203585C2 (de) | Schalung für eine Unterzüge aufweisende Betondecke | |

| DE2427780C3 (de) | Stahldraht zum Herstellen von Stahlwolle | |

| DE19928365C2 (de) | Grundplatte für Maschinen und Anlagen | |

| DE2648565C3 (de) | Lenkgetriebe | |

| DE2429921C3 (de) | Herzstück | |

| EP0979346A1 (fr) | Procede de construction d'un ouvrage pour tunnel sous un ouvrage existant | |

| DE69019978T2 (de) | Treppe mit zwei treppenteilen. | |

| DE1708638C3 (de) | Herzstück |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19911011 |