CN112654434B - 涂装室用的空调装置 - Google Patents

涂装室用的空调装置 Download PDFInfo

- Publication number

- CN112654434B CN112654434B CN202080004579.2A CN202080004579A CN112654434B CN 112654434 B CN112654434 B CN 112654434B CN 202080004579 A CN202080004579 A CN 202080004579A CN 112654434 B CN112654434 B CN 112654434B

- Authority

- CN

- China

- Prior art keywords

- air

- mist

- humidified

- air conditioner

- elements

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F6/00—Air-humidification, e.g. cooling by humidification

- F24F6/12—Air-humidification, e.g. cooling by humidification by forming water dispersions in the air

- F24F6/14—Air-humidification, e.g. cooling by humidification by forming water dispersions in the air using nozzles

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F3/00—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems

- F24F3/044—Systems in which all treatment is given in the central station, i.e. all-air systems

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B14/00—Arrangements for collecting, re-using or eliminating excess spraying material

- B05B14/40—Arrangements for collecting, re-using or eliminating excess spraying material for use in spray booths

- B05B14/43—Arrangements for collecting, re-using or eliminating excess spraying material for use in spray booths by filtering the air charged with excess material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B16/00—Spray booths

- B05B16/40—Construction elements specially adapted therefor, e.g. floors, walls or ceilings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B16/00—Spray booths

- B05B16/60—Ventilation arrangements specially adapted therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B7/00—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas

- B05B7/0075—Nozzle arrangements in gas streams

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F3/00—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems

- F24F3/12—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling

- F24F3/14—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling by humidification; by dehumidification

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F3/00—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems

- F24F3/12—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling

- F24F3/14—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling by humidification; by dehumidification

- F24F3/147—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling by humidification; by dehumidification with both heat and humidity transfer between supplied and exhausted air

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F3/00—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems

- F24F3/12—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling

- F24F3/14—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling by humidification; by dehumidification

- F24F3/153—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling by humidification; by dehumidification with subsequent heating, i.e. with the air, given the required humidity in the central station, passing a heating element to achieve the required temperature

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F6/00—Air-humidification, e.g. cooling by humidification

- F24F6/02—Air-humidification, e.g. cooling by humidification by evaporation of water in the air

- F24F6/04—Air-humidification, e.g. cooling by humidification by evaporation of water in the air using stationary unheated wet elements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B1/00—Nozzles, spray heads or other outlets, with or without auxiliary devices such as valves, heating means

- B05B1/14—Nozzles, spray heads or other outlets, with or without auxiliary devices such as valves, heating means with multiple outlet openings; with strainers in or outside the outlet opening

- B05B1/20—Arrangements of several outlets along elongated bodies, e.g. perforated pipes or troughs, e.g. spray booms; Outlet elements therefor

- B05B1/205—Arrangements of several outlets along elongated bodies, e.g. perforated pipes or troughs, e.g. spray booms; Outlet elements therefor characterised by the longitudinal shape of the elongated body

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B13/00—Machines or plants for applying liquids or other fluent materials to surfaces of objects or other work by spraying, not covered by groups B05B1/00 - B05B11/00

- B05B13/02—Means for supporting work; Arrangement or mounting of spray heads; Adaptation or arrangement of means for feeding work

- B05B13/04—Means for supporting work; Arrangement or mounting of spray heads; Adaptation or arrangement of means for feeding work the spray heads being moved during spraying operation

- B05B13/0431—Means for supporting work; Arrangement or mounting of spray heads; Adaptation or arrangement of means for feeding work the spray heads being moved during spraying operation with spray heads moved by robots or articulated arms, e.g. for applying liquid or other fluent material to 3D-surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B17/00—Apparatus for spraying or atomising liquids or other fluent materials, not covered by the preceding groups

- B05B17/04—Apparatus for spraying or atomising liquids or other fluent materials, not covered by the preceding groups operating with special methods

- B05B17/06—Apparatus for spraying or atomising liquids or other fluent materials, not covered by the preceding groups operating with special methods using ultrasonic or other kinds of vibrations

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B9/00—Spraying apparatus for discharge of liquids or other fluent material, without essentially mixing with gas or vapour

- B05B9/03—Spraying apparatus for discharge of liquids or other fluent material, without essentially mixing with gas or vapour characterised by means for supplying liquid or other fluent material

- B05B9/04—Spraying apparatus for discharge of liquids or other fluent material, without essentially mixing with gas or vapour characterised by means for supplying liquid or other fluent material with pressurised or compressible container; with pump

- B05B9/0403—Spraying apparatus for discharge of liquids or other fluent material, without essentially mixing with gas or vapour characterised by means for supplying liquid or other fluent material with pressurised or compressible container; with pump with pumps for liquids or other fluent material

- B05B9/0423—Spraying apparatus for discharge of liquids or other fluent material, without essentially mixing with gas or vapour characterised by means for supplying liquid or other fluent material with pressurised or compressible container; with pump with pumps for liquids or other fluent material for supplying liquid or other fluent material to several spraying apparatus

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F6/00—Air-humidification, e.g. cooling by humidification

- F24F6/12—Air-humidification, e.g. cooling by humidification by forming water dispersions in the air

- F24F6/14—Air-humidification, e.g. cooling by humidification by forming water dispersions in the air using nozzles

- F24F2006/146—Air-humidification, e.g. cooling by humidification by forming water dispersions in the air using nozzles using pressurised water for spraying

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02B—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO BUILDINGS, e.g. HOUSING, HOUSE APPLIANCES OR RELATED END-USER APPLICATIONS

- Y02B30/00—Energy efficient heating, ventilation or air conditioning [HVAC]

- Y02B30/54—Free-cooling systems

Abstract

提供实现了高效化、节能化和小型化的空调装置。为供给空气至对被涂物(62)进行喷涂的喷涂室(60)的空调装置(10),被构成为设置有:壳体(13),具有该应供给的空气的进气口(11)和出气口(12);加湿机构(30),对经由进气口(11)吸入的空气喷雾加湿雾气;和汽化机构(40),使通过加湿机构(30)喷雾有加湿雾气的空气通过,同时使包含于空气的未汽化的加湿雾气与空气接触而汽化;通过加湿机构(30)和汽化机构(40)进行了湿度调节的空气经由出气口(12)被供给至喷涂室(60)。

Description

技术领域

本发明涉及供给加湿的空气至对被涂物进行涂装的涂装室的空调装置。

背景技术

构成为空气从空调装置被供给至对汽车车体、汽车零件、其他一般被涂物等各种被涂物进行涂装的涂装室。

由于从该空调装置供给至涂装室的空气对针对被涂物的涂装品质产生影响,因而需要控制其温湿度。

为了能够控制空气的温湿度,在空调装置的壳体的内部设置应向涂装室供给的空气的加温机构、加湿机构等。

例如,在专利文献1中公开了涂装室用空调装置1(以下,记为现有的空调装置),其在壳体的内部从应向涂装室供给的空气的通风方向上游侧设置有预热器23、加湿装置24、冷却盘管26和再热器27。此外,附图标记为专利文献1中的附图标记。

该加湿装置24具备储水部24a、循环用配管24b、泵24c、电磁阀24d、水喷雾部24e,构成为通过对经过预热器23的外部空气的水的喷雾来提高外部空气的湿度。

然而,现有的空调装置为从加湿装置24所具备的水喷雾部24e喷雾大量的水的构成。从加湿装置24喷雾的水的粒径大到440μm左右。为了借助这样的水加湿空气,需要确保水与空气的接触时间,因此需要延长通风路。进而,为了借助粒径大的水进行高效的加湿,需要考虑水喷雾部24e中的喷嘴的排列和循环用配管24b的处理。

另外,泵24c为了能够喷雾大量的水而需要具有充分的性能,成为了设备成本和运行成本变高的原因。进而,需要为了使喷雾的水循环而回收的水箱、和用于水箱内水质的维持管理的构成,需要在壳体内部设置其空间。

另外,空气中的未气化的水分在加湿装置24的下游侧产生结露,因而为了避免这个,有时需要从空气中分离回收未气化的水分的消除器。然而,若在壳体中设置消除器,则壳体内部的压力损失升高,不能提高壳体内部的通风速度。因此,为了在涂装室中充分确保需要的空气量,需要增大壳体的通风截面积。

如以上那样,现有的空调装置在高效化、节能化和小型化的观点上有改善的余地。

进而,在使用加湿装置的构成之外,还有如专利文献2所公开的蒸汽喷雾加湿、如专利文献3所公开的使用填料等的加湿、如专利文献4所公开的利用高压雾化的雾化喷洒、一直以来公知的干雾加湿等。

然而,对于如专利文献2所公开的蒸汽喷雾加湿,存在以下问题:蒸汽成本大而运行成本增大;蒸汽能效差而不能节能;局部变得过饱和,因而容易在下游侧装置内产生结露。

对于如专利文献3所公开的使用填料等的加湿,存在以下问题:由于能够在填料保有水,因而控制响应性差;根据填料种类不同,若增大气液接触面积,则在加湿器部分变得需要大的空间。

对于如专利文献4所公开的高压雾化喷洒,存在以下问题:在具有接水箱的情况下不能缩小空调器;由于在喷雾喷嘴的下游侧需要喷雾雾的气化距离,因而不能使空调器小型化。

对于一直以来公知的干雾加湿,存在以下问题:由于在喷雾喷嘴的下游侧需要喷雾雾的气化距离,因而不能小型化空调器;容易出现局部过饱和和喷雾雾的气化不足的点,在下游侧装置内容易产生结露。

现有技术文献

专利文献

专利文献1:日本特开2013-245928号公报

专利文献2:日本特开2011-127812号公报

专利文献3:日本特开2018-162909号公报

专利文献4:国际公开第2018/108746号。

发明内容

发明要解决的课题

本发明是鉴于上述实际情况而做出的,目的在于提供实现了高效化、节能化和小型化的空调装置。

用于解决课题的手段

为了达成上述目的的本发明所涉及的空调装置的特征构成在于以下点:为供给空气至对被涂物进行涂装的涂装室的空调装置,设置有:壳体,具有该应供给的空气的取入口和喷出口;加湿机构,将加湿雾对经由前述取入口取入的前述空气喷雾;和气化机构,一边使借助前述加湿机构喷雾有前述加湿雾的前述空气经过,一边使包含于前述空气的未气化的加湿雾与前述空气接触而气化;构成为,借助前述加湿机构和前述气化机构进行了湿度调节的前述空气经由前述喷出口被供给至前述涂装室。

此外,所谓加湿雾,是指其粒径与从现有加湿装置喷雾的水的粒径(440μm左右)相比具有极小的粒径(100μm以下,优选为30μm左右)。

因而,将应供给至涂装室的前述空气加湿的加湿雾与该空气的接触面积多,因而气化速度快。因此,与现有的空调装置相比,能够缩短前述壳体内部的通风路。本发明所涉及的空调装置通过上述的构成,与现有的空调装置相比,能够达成在从前述取入口朝向前述喷出口的前述空气的通风方向上10%左右的尺寸缩减。

在使用等量的水加湿时,其粒径越小,相对表面积越大,因而能够高效地与前述空气接触。即,若为相同程度的加湿,粒径小的一方用更少的水量即可。即使为加湿所需要的最低限度的水量,高效且控制响应性良好的前述空气的加湿也是可能的,因而用于此的泵的动力可以较小,能够实现设备成本和运行成本的降低。

本发明所涉及的空调装置通过上述的构成,与现有的空调装置相比,能够在泵的动力中达成90%左右的节能化。另外,由于高效且控制响应性良好的前述空气的加湿是可能的,因而喷雾加湿雾的喷嘴的排列的自由度提高,因而连结至喷嘴的配管的处理性好。

设置于前述加湿机构的下游侧的前述气化机构中,仅与前述空气接触并未气化,而以液滴状存在于该空气中的未气化的加湿雾被捕捉,该被捕捉的加湿雾与经过前述气化机构的前述空气的接触被促进。由此,使未气化的加湿雾充分气化。另外,即使在由于前述加湿机构对前述空气的加湿而在该空气中产生局部过饱和状态的部分的情况下,在经过该气化机构时该过饱和状态也被平均,因而能够避免在前述气化机构的下游侧处产生结露的风险。

因而,不需要如现有的空调装置那样在前述壳体的内部设置水箱和消除器,因而不需要确保其相应的空间。本发明所涉及的空调装置如上述那样不需要水箱,因而不需要在现有的空调装置中所需要的用于水箱的水质的维持管理的费用。

如以上那样,达成了空调装置中的加湿的高效化、设备成本和运行成本的节能化和小型化。

另外,由于不进行蒸汽喷雾,因而不会产生蒸汽喷雾加湿所具有的问题;由于不使用填料等,因而不会产生使用填料等的加湿所具有的问题;由于不使用高压雾化喷洒,因而不会产生利用高压雾化的雾化喷洒所具有的问题;由于设置有气化机构,因而不会产生干雾加湿所具有的问题。

在本发明中,前述气化机构适宜为:具备多片板状的元件,前述各元件在上下方向上互相分离而设置,并以倾斜姿势配置为下缘位于比上缘靠从前述取入口朝向前述喷出口的前述空气的通风方向的上游侧,并且配置为在上下相邻的元件彼此中,上侧的前述元件的下缘位于比下侧的前述元件的上缘靠下方。

由此,能够在上侧的元件与下侧的元件之间消除从前述取入口向前述喷出口直线地到达的通风路,并在上下相邻的元件彼此之间设置足够大小的通风路。因此,经过前述气化机构时的压力损失比设置于现有的空调装置的消除器的压力损失小。因而,即使为比现有的空调装置中的通风速度快的速度,也不需要增大通风截面积。本发明所涉及的空调装置通过上述的构成,与现有的空调装置相比,能够达成在从前述取入口朝向前述喷出口的前述空气的通风截面积上约40%的尺寸缩减。

另外,在上侧的元件与下侧的元件之间不存在从前述取入口向前述喷出口直线地到达的通风路。因而,未气化的加湿雾不与元件接触而到达前述喷出口的风险降低。

在本发明中,前述元件适宜为由具有空孔的多孔质体构成,一边使包含前述未气化的加湿雾的前述空气经过前述空孔,一边能够在前述空孔的表面捕捉前述加湿雾。

依据上述构成,关于未气化的加湿雾,在构成元件的多孔质体的表面、包含该未气化的加湿雾的前述空气经过空孔时,因该加湿雾本身的惯性力而碰撞到该空孔的表面,因该加湿雾自身和多孔质体自身的静电力等而在该表面被捕捉。在该空孔被捕捉的加湿雾在该空孔的表面与经过该空孔的前述空气的接触被促进,因而被充分气化。此外,多孔质体从获得和加工的容易性的观点来看,陶瓷板和金属烧结体能够作为示例。

在本发明中,适宜为设置有加温机构,所述加温机构将经由前述取入口取入的前述空气在到达前述加湿机构之前进行加温。

依据上述构成,能够将经由前述取入口取入的前述空气借助加温机构加温至最适合于借助前述加湿机构加湿的温度。在应被取入前述壳体的前述空气的温度不恒定,经由前述取入口取入的前述空气的温度不恒定的情况下,需要使借助前述加湿机构加湿的条件精细地变动。与之相对,通过加温前述空气直至借助加湿机构加湿的条件所优选的温度,从而能够使前述加湿机构的加湿条件保持恒定而高效地加湿。

在本发明中,适宜为设置有温湿度调节机构,所述温湿度调节机构将借助前述加湿机构进行了湿度调节的前述空气在从前述喷出口喷出之前进行温湿度调节。

依据上述的构成,能够将借助加温机构加温,并借助前述加湿机构加湿了的前述空气借助温湿度调节机构调节为成为最适宜在涂装室使用的温湿度。

此外,关于温湿度调节机构,冷却机构和加热机构能够作为示例,可以为设置这些中的任一个的构成,也可以为设置两个的构成。在该情况下,优选为冷却机构设置在比加热机构靠前述空气的通风方向的上游侧。

附图说明

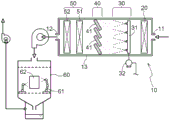

图1是本发明所涉及的空调装置的说明图。

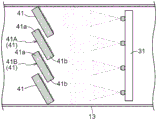

图2是加湿机构和气化机构的说明图。

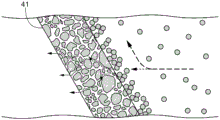

图3是空调装置的主要部分说明图。

具体实施方式

在以下,一边参照附图,一边对本发明所涉及的空调装置的实施方式进行说明。

如图1所示,在对汽车车体、汽车零件、其他一般被涂物等各种被涂物进行涂装的涂装室60中,通过从涂装机61喷雾涂料而进行被涂物62的涂装。

在涂装室60中,为了确保针对被涂物62的涂装品质,供给有借助空调装置10控制温湿度的空气。

该供给的空气也起到了捕捉从涂装机61被过量喷洒而飞散的涂料雾的作用。

空调装置10在具有该空调装置10的外部空气的取入口11和喷出口12的壳体13内部,设置加温机构20、加湿机构30、气化机构40和温湿度调节机构50。

加温机构20是为了将经由取入口11被取入的空气的温度加温至适于借助加湿装置30加湿的温度而设置。

加湿机构30具有雾喷嘴31和供给水至雾喷嘴31的泵32等,且被构成为通过将从泵32供给的水从雾喷嘴31以粒径在30μm左右以下的加湿雾的形态喷雾,从而加湿借助加温机构20调节为适宜温度的空气。雾喷嘴31由单流体型高压喷嘴构成。在本实施方式中,雾喷嘴31配置为朝向该空气的通风方向的下游侧喷雾加湿雾。

气化机构40具备多片板状的元件41而构成。各元件41由为多孔质体的一个示例的陶瓷板构成。陶瓷板所具有的空孔比从雾喷嘴31喷雾的加湿雾的粒径小。

如图2所示,各元件41在上下方向上互相分离而设置,并以倾斜姿势配置为下缘41b位于比上缘41a靠从取入口11朝向喷出口12的空气的通风方向的上游侧。在本实施方式中,各元件41被设置为其正、背面相对于水平成例如60度的角度。该角度只要在45~85度左右的范围内即可,具有能够相对于空调装置10的设计风速调节为能够可靠地捕捉未气化的加湿雾且压力损失变为最小的状态的结构。

另外,各元件41中,配置为在上下相邻的元件41(图2中为了说明的便利而以41A、41B示出一部分元件。)彼此中,上侧的元件41(41A)的下缘41b位于比下侧的元件41(41B)的上缘41a靠下方。

依据该构成,在上侧的元件41(41A)与下侧的元件41(41B)之间不存在从取入口11向喷出口12直线地到达的通风路,因而未气化的加湿雾不接触元件41而到达喷出口12的风险降低。

各元件41能够在上下相邻的元件41(41A、41B)彼此之间设置足够大小的通风路,因而经过气化机构40时的压力损失与设置于现有的涂装室用空调装置的消除器的压力损失相比小。因此,即使是比现有的涂装室用空调装置中的通风速度快的速度,也不需要增大通风截面积。

在图3中,如以粗虚线箭头示出流体那样,包含未气化的加湿雾的空气中的大部分在经由上下相邻的元件41(41A、41B)彼此之间的通风路而流向元件41的下游侧时,因该加湿雾本身的惯性力而碰撞至构成元件41的多孔质体的表面,并因该加湿雾本身和多孔质体本身的静电力等而在该表面被捕捉。此外,在图3中,在元件41的右侧示出的圆形物体为加湿雾,表示在元件41的表面被捕捉的形态。

另外,在图3中,如以细虚线箭头示出流体那样,包含未气化的加湿雾的空气中的一部分经过构成元件41的多孔质体的空孔,该未气化的加湿雾在包含该未气化的加湿雾的空气经过构成元件41的多孔质体的空孔时,因该加湿雾本身的惯性力而碰撞至该空孔的表面,并因该加湿雾本身和多孔质体本身的静电力等而在该表面被捕捉。在该空孔的表面被捕捉的加湿雾与经过该空孔的空气的接触被促进,因而被充分气化。

温湿度调节机构50具备冷却经过气化机构40的空气的冷却机构51、和加热借助冷却机构51冷却的该空气的加热机构52。能够将借助加湿机构30加湿了的空气借助冷却机构51和加热机构52调节为在涂装室60使用的最适宜的温湿度。

在上述实施方式中,对构成元件41的多孔质体为陶瓷板的情况进行了说明,但不限于此。例如,多孔质体还可以为金属烧结体,只要为能够在该多孔质体的表面使未气化的加湿雾与经过该物体的空孔的空气接触的物体即可。

在上述实施方式中,对雾喷嘴31为单流体型高压喷嘴的情况进行了说明,但不限于此。雾喷嘴31还可以为双流体型喷嘴,还可以为超声波式微粒化喷嘴。

在上述实施方式中,对空调装置10在壳体13的内部具有加温机构20、加湿机构30、气化机构40和温湿度调节机构50的情况进行了说明,但不限于此。空调装置10还可以为在壳体13的内部不具有加温机构20和温湿度调节机构50的构成。在该情况下,还可以在壳体13的外部具有加温机构20和温湿度调节机构50。

上述实施方式均为本发明的一个示例,本发明不被该记载所限定,各部分的具体构成可以在能起到本发明的作用效果的范围内适当变更设计。

附图标记说明

10 空调装置

11 取入口

12 喷出口

13 壳体

20 加温机构

30 加湿机构

31 雾喷嘴

40 气化机构

41 元件

41a 上缘

41b 下缘

50 温湿度调节机构

60 涂装室

62 被涂物。

Claims (6)

1.一种空调装置,其特征在于,

具备:

壳体,设置有供给口,所述供给口将空气向对被涂物进行涂装的涂装室供给;

取入口,将空气取入到所述壳体;

加湿机构,将加湿雾对从所述取入口取入的空气喷雾;以及

多片板状的元件,配设于所述加湿机构与所述供给口之间,由设置有空孔的多孔质体构成,所述空孔比加湿雾的粒径小;

所述多片板状的元件,在上下方向上互相分离而设置,以从所述取入口朝向所述供给口成为朝上的方式倾斜而配置,并且,配置为,在上下相邻的元件彼此中,上侧的所述元件的下缘位于比下侧的所述元件的上缘靠下方;

通过使喷雾有所述加湿雾的空气经过所述多片板状的元件,使未气化的加湿雾与空气接触而气化。

2.根据权利要求1所述的空调装置,其特征在于,

各所述元件以相对于水平在45~85度的范围的倾斜姿势配置。

3.根据权利要求1所述的空调装置,其特征在于,

所述元件具有陶瓷板或金属烧结体的多孔质体。

4.根据权利要求2所述的空调装置,其特征在于,

所述元件具有陶瓷板或金属烧结体的多孔质体。

5.根据权利要求1至4中的任一项所述的空调装置,其特征在于,

设置有加温机构,所述加温机构将经由所述取入口取入的所述空气在到达所述加湿机构之前进行加温。

6.根据权利要求1至4中的任一项所述的空调装置,其特征在于,

设置有温湿度调节机构,所述温湿度调节机构将借助所述加湿机构进行了湿度调节的所述空气在从所述供给口供给之前进行温湿度调节。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2019-143733 | 2019-08-05 | ||

| JP2019143733A JP7341779B2 (ja) | 2019-08-05 | 2019-08-05 | 塗装ブース用の空調装置 |

| PCT/JP2020/028873 WO2021024857A1 (ja) | 2019-08-05 | 2020-07-28 | 塗装ブース用の空調装置 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN112654434A CN112654434A (zh) | 2021-04-13 |

| CN112654434B true CN112654434B (zh) | 2023-02-24 |

Family

ID=74503616

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202080004579.2A Active CN112654434B (zh) | 2019-08-05 | 2020-07-28 | 涂装室用的空调装置 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20210325059A1 (zh) |

| JP (1) | JP7341779B2 (zh) |

| KR (1) | KR102619498B1 (zh) |

| CN (1) | CN112654434B (zh) |

| WO (1) | WO2021024857A1 (zh) |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH094887A (ja) * | 1995-06-19 | 1997-01-10 | Kubota Toreen Kk | 蒸気加湿器 |

| CN200952794Y (zh) * | 2006-04-10 | 2007-09-26 | 爱克斯爱尔(北京)加湿系统有限公司 | 中央空调加湿系统 |

| KR20080056595A (ko) * | 2006-12-18 | 2008-06-23 | 강경형 | 증기발생 장치 |

| CN101454616A (zh) * | 2006-05-26 | 2009-06-10 | 美克司株式会社 | 空调装置 |

| CN101617175A (zh) * | 2007-03-28 | 2009-12-30 | 东芝开利株式会社 | 加湿装置和空调机 |

| JP2013245928A (ja) * | 2012-05-29 | 2013-12-09 | Trinity Industrial Co Ltd | 塗装ブース用空調装置及びその温湿度制御方法 |

| CN107735184A (zh) * | 2015-05-28 | 2018-02-23 | 首尔大学校产学协办团 | 超微粒喷雾装置 |

| CN208170612U (zh) * | 2018-03-26 | 2018-11-30 | 维谛技术有限公司 | 一种加湿装置 |

| CN109416232A (zh) * | 2016-08-04 | 2019-03-01 | 艾森曼欧洲公司 | 用于调节气态介质的调节设备和方法以及用于处理工件的设施和方法 |

Family Cites Families (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5922586B2 (ja) * | 1979-02-27 | 1984-05-28 | 日産自動車株式会社 | 塗装用空気調和装置 |

| JPS6125537Y2 (zh) * | 1980-03-14 | 1986-08-01 | ||

| JPS57165063A (en) * | 1981-04-07 | 1982-10-09 | Nissan Motor Co Ltd | Air-conditioner for coating |

| JPS6354535A (ja) * | 1986-08-22 | 1988-03-08 | Chizuko Ozawa | 冷房装置 |

| JP2543648Y2 (ja) * | 1993-12-10 | 1997-08-13 | 株式会社ワコー | スプレー式加湿機 |

| US6059866A (en) * | 1997-09-30 | 2000-05-09 | Sanki Engineering Co., Ltd | Air washer |

| JP2004053238A (ja) * | 2002-07-23 | 2004-02-19 | Shinei Sangyo Kk | 調湿機 |

| US7291196B1 (en) * | 2006-11-16 | 2007-11-06 | Lerner Bernard J | Filamentary pad for improved mist elimination and mass transfer |

| JP5493814B2 (ja) | 2009-12-16 | 2014-05-14 | マツダ株式会社 | 塗装用空調装置の制御方法及びその装置 |

| US8273158B2 (en) * | 2010-11-29 | 2012-09-25 | General Electric Company | Mist eliminator, moisture removal system, and method of removing water particles from inlet air |

| JP5992139B2 (ja) * | 2010-12-08 | 2016-09-14 | 三機工業株式会社 | 水噴霧加湿装置 |

| JP2013213616A (ja) * | 2012-04-02 | 2013-10-17 | Fuji Electric Co Ltd | 気化冷却装置、およびその制御方法 |

| JP6167326B2 (ja) * | 2013-03-14 | 2017-07-26 | パナソニックIpマネジメント株式会社 | 塗装ミスト処理装置 |

| JP6169432B2 (ja) * | 2013-07-26 | 2017-07-26 | 大阪瓦斯株式会社 | 加湿器 |

| US9982907B2 (en) * | 2015-07-17 | 2018-05-29 | Valeriy S. Maisotsenko | Method and systems for energy-saving heating and humidifying of buildings using outside air |

| DE102016124478A1 (de) | 2016-12-15 | 2018-06-21 | Eisenmann Se | Vorrichtung zum Befeuchten eines Luftstroms |

| JP2018162909A (ja) | 2017-03-24 | 2018-10-18 | トヨタ自動車株式会社 | 気化式加湿器 |

| KR101938689B1 (ko) * | 2017-04-21 | 2019-04-10 | 한정흠 | 미세먼지포집 및 가습기능을 갖는 에너지 절약형 공기조화기 |

| JP6970962B2 (ja) * | 2017-09-22 | 2021-11-24 | 株式会社Japan Zero | 塗装システム |

| JP2019072695A (ja) * | 2017-10-18 | 2019-05-16 | 株式会社エー・イー・エス | クローズド塗装装置 |

-

2019

- 2019-08-05 JP JP2019143733A patent/JP7341779B2/ja active Active

-

2020

- 2020-07-28 WO PCT/JP2020/028873 patent/WO2021024857A1/ja active Application Filing

- 2020-07-28 KR KR1020217020592A patent/KR102619498B1/ko active IP Right Grant

- 2020-07-28 CN CN202080004579.2A patent/CN112654434B/zh active Active

- 2020-07-28 US US17/272,480 patent/US20210325059A1/en active Pending

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH094887A (ja) * | 1995-06-19 | 1997-01-10 | Kubota Toreen Kk | 蒸気加湿器 |

| CN200952794Y (zh) * | 2006-04-10 | 2007-09-26 | 爱克斯爱尔(北京)加湿系统有限公司 | 中央空调加湿系统 |

| CN101454616A (zh) * | 2006-05-26 | 2009-06-10 | 美克司株式会社 | 空调装置 |

| KR20080056595A (ko) * | 2006-12-18 | 2008-06-23 | 강경형 | 증기발생 장치 |

| CN101617175A (zh) * | 2007-03-28 | 2009-12-30 | 东芝开利株式会社 | 加湿装置和空调机 |

| JP2013245928A (ja) * | 2012-05-29 | 2013-12-09 | Trinity Industrial Co Ltd | 塗装ブース用空調装置及びその温湿度制御方法 |

| CN107735184A (zh) * | 2015-05-28 | 2018-02-23 | 首尔大学校产学协办团 | 超微粒喷雾装置 |

| CN109416232A (zh) * | 2016-08-04 | 2019-03-01 | 艾森曼欧洲公司 | 用于调节气态介质的调节设备和方法以及用于处理工件的设施和方法 |

| CN208170612U (zh) * | 2018-03-26 | 2018-11-30 | 维谛技术有限公司 | 一种加湿装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20210099083A (ko) | 2021-08-11 |

| US20210325059A1 (en) | 2021-10-21 |

| KR102619498B1 (ko) | 2023-12-28 |

| CN112654434A (zh) | 2021-04-13 |

| WO2021024857A1 (ja) | 2021-02-11 |

| JP7341779B2 (ja) | 2023-09-11 |

| JP2021025697A (ja) | 2021-02-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4544380A (en) | Air conditioner for a coating booth | |

| US8070138B2 (en) | Sauna apparatus | |

| CN102016434B (zh) | 超声增湿器 | |

| US5699983A (en) | Atomizing and mixing nozzle for humidification process | |

| JP3907255B2 (ja) | エアワッシャ | |

| JP2002372385A (ja) | 熱交換装置 | |

| CN110073150A (zh) | 用于加湿气体流的设备 | |

| CN112654434B (zh) | 涂装室用的空调装置 | |

| KR100874886B1 (ko) | 크린룸내 직접분무식 기화가습장치 및 습도제어방법 | |

| JPH04215815A (ja) | ガス流れ中における均一な給湿及び収着剤分散のための翼形ランス装置 | |

| CN101274144A (zh) | 液体蒸发方法及实施该方法的装置 | |

| KR101451358B1 (ko) | 크린룸내 직접분무식 기화가습장치의 습도제어방법 | |

| JP2002322916A (ja) | ガスタービン吸気冷却装置 | |

| JP3544836B2 (ja) | エアワッシャ | |

| EP2516934A1 (en) | A method and an apparatus in a ventilation system | |

| WO2020019635A1 (zh) | 恒温恒湿机 | |

| CN113062799B (zh) | 一种燃气轮机加湿减排装置及其控制方法 | |

| CN215951648U (zh) | 加湿装置和空调系统 | |

| JP2007263416A (ja) | 加湿装置 | |

| WO2023241099A1 (zh) | 电子雾化装置及其加热组件 | |

| KR20160053696A (ko) | 직접분무식 수가습 장치 | |

| JP2021025697A5 (zh) | ||

| WO2020158561A1 (ja) | 空調機 | |

| KR20160053680A (ko) | 직접분무식 수가습 시스템 | |

| JPS6229841A (ja) | 空気調和機 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |