WO2022209158A1 - 電解液およびリチウムイオン二次電池 - Google Patents

電解液およびリチウムイオン二次電池 Download PDFInfo

- Publication number

- WO2022209158A1 WO2022209158A1 PCT/JP2022/001511 JP2022001511W WO2022209158A1 WO 2022209158 A1 WO2022209158 A1 WO 2022209158A1 JP 2022001511 W JP2022001511 W JP 2022001511W WO 2022209158 A1 WO2022209158 A1 WO 2022209158A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- ion secondary

- active material

- secondary battery

- lithium ion

- electrode active

- Prior art date

Links

- 239000008151 electrolyte solution Substances 0.000 title claims abstract description 172

- HBBGRARXTFLTSG-UHFFFAOYSA-N Lithium ion Chemical compound [Li+] HBBGRARXTFLTSG-UHFFFAOYSA-N 0.000 title claims description 250

- 229910001416 lithium ion Inorganic materials 0.000 title claims description 250

- 159000000002 lithium salts Chemical class 0.000 claims abstract description 75

- 229910003002 lithium salt Inorganic materials 0.000 claims abstract description 73

- 229940017219 methyl propionate Drugs 0.000 claims abstract description 69

- RJUFJBKOKNCXHH-UHFFFAOYSA-N Methyl propionate Chemical compound CCC(=O)OC RJUFJBKOKNCXHH-UHFFFAOYSA-N 0.000 claims abstract description 68

- -1 alkylene cyclic carbonate Chemical class 0.000 claims abstract description 52

- 239000003792 electrolyte Substances 0.000 claims abstract description 38

- 229910001290 LiPF6 Inorganic materials 0.000 claims abstract description 7

- 239000007774 positive electrode material Substances 0.000 claims description 90

- 239000007773 negative electrode material Substances 0.000 claims description 77

- 229910013870 LiPF 6 Inorganic materials 0.000 claims description 58

- 238000007789 sealing Methods 0.000 claims description 55

- 239000003125 aqueous solvent Substances 0.000 claims description 33

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 29

- 239000010439 graphite Substances 0.000 claims description 15

- 229910002804 graphite Inorganic materials 0.000 claims description 15

- 239000002904 solvent Substances 0.000 abstract description 22

- 239000010410 layer Substances 0.000 description 134

- 230000000052 comparative effect Effects 0.000 description 101

- 238000012360 testing method Methods 0.000 description 50

- 239000012452 mother liquor Substances 0.000 description 41

- KMTRUDSVKNLOMY-UHFFFAOYSA-N Ethylene carbonate Chemical compound O=C1OCCO1 KMTRUDSVKNLOMY-UHFFFAOYSA-N 0.000 description 39

- 239000012046 mixed solvent Substances 0.000 description 33

- 239000011888 foil Substances 0.000 description 31

- 229910052782 aluminium Inorganic materials 0.000 description 30

- 238000003860 storage Methods 0.000 description 30

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 28

- 210000000352 storage cell Anatomy 0.000 description 27

- 239000011230 binding agent Substances 0.000 description 24

- 238000011156 evaluation Methods 0.000 description 22

- 229940021013 electrolyte solution Drugs 0.000 description 21

- 239000000203 mixture Substances 0.000 description 21

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 19

- 239000011889 copper foil Substances 0.000 description 17

- VAYTZRYEBVHVLE-UHFFFAOYSA-N 1,3-dioxol-2-one Chemical compound O=C1OC=CO1 VAYTZRYEBVHVLE-UHFFFAOYSA-N 0.000 description 16

- 230000014759 maintenance of location Effects 0.000 description 14

- 238000000034 method Methods 0.000 description 14

- 239000011149 active material Substances 0.000 description 12

- 229920005989 resin Polymers 0.000 description 12

- 239000011347 resin Substances 0.000 description 12

- 239000000654 additive Substances 0.000 description 11

- 239000000126 substance Substances 0.000 description 11

- SECXISVLQFMRJM-UHFFFAOYSA-N N-Methylpyrrolidone Chemical compound CN1CCCC1=O SECXISVLQFMRJM-UHFFFAOYSA-N 0.000 description 10

- 239000010450 olivine Substances 0.000 description 10

- 229910052609 olivine Inorganic materials 0.000 description 10

- 125000001424 substituent group Chemical group 0.000 description 10

- 229920002134 Carboxymethyl cellulose Polymers 0.000 description 9

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 9

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 9

- 239000001768 carboxy methyl cellulose Substances 0.000 description 9

- 235000010948 carboxy methyl cellulose Nutrition 0.000 description 9

- 239000008112 carboxymethyl-cellulose Substances 0.000 description 9

- 239000002002 slurry Substances 0.000 description 9

- 229920003048 styrene butadiene rubber Polymers 0.000 description 9

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 9

- 229910052799 carbon Inorganic materials 0.000 description 8

- 150000002148 esters Chemical class 0.000 description 8

- 239000007789 gas Substances 0.000 description 8

- 230000006872 improvement Effects 0.000 description 8

- 239000000463 material Substances 0.000 description 8

- 238000002844 melting Methods 0.000 description 8

- 230000008018 melting Effects 0.000 description 8

- 229910052751 metal Inorganic materials 0.000 description 8

- 239000002243 precursor Substances 0.000 description 8

- 238000003825 pressing Methods 0.000 description 8

- 125000005309 thioalkoxy group Chemical group 0.000 description 8

- KRHYYFGTRYWZRS-UHFFFAOYSA-N Fluorane Chemical compound F KRHYYFGTRYWZRS-UHFFFAOYSA-N 0.000 description 7

- 229910010707 LiFePO 4 Inorganic materials 0.000 description 7

- 239000004743 Polypropylene Substances 0.000 description 7

- 125000000217 alkyl group Chemical group 0.000 description 7

- 238000000576 coating method Methods 0.000 description 7

- 238000007599 discharging Methods 0.000 description 7

- 229910052736 halogen Inorganic materials 0.000 description 7

- 150000002367 halogens Chemical class 0.000 description 7

- 229910000040 hydrogen fluoride Inorganic materials 0.000 description 7

- 229910052742 iron Inorganic materials 0.000 description 7

- 230000007774 longterm Effects 0.000 description 7

- 125000003545 alkoxy group Chemical group 0.000 description 6

- 238000009835 boiling Methods 0.000 description 6

- 239000011248 coating agent Substances 0.000 description 6

- 125000001651 cyanato group Chemical group [*]OC#N 0.000 description 6

- 150000005676 cyclic carbonates Chemical class 0.000 description 6

- 125000000753 cycloalkyl group Chemical group 0.000 description 6

- 238000009792 diffusion process Methods 0.000 description 6

- IEJIGPNLZYLLBP-UHFFFAOYSA-N dimethyl carbonate Chemical compound COC(=O)OC IEJIGPNLZYLLBP-UHFFFAOYSA-N 0.000 description 6

- 230000000694 effects Effects 0.000 description 6

- JBTWLSYIZRCDFO-UHFFFAOYSA-N ethyl methyl carbonate Chemical compound CCOC(=O)OC JBTWLSYIZRCDFO-UHFFFAOYSA-N 0.000 description 6

- 229910052731 fluorine Inorganic materials 0.000 description 6

- 229910052748 manganese Inorganic materials 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 6

- 239000002184 metal Substances 0.000 description 6

- 229910052759 nickel Inorganic materials 0.000 description 6

- 229920001155 polypropylene Polymers 0.000 description 6

- 229910052710 silicon Inorganic materials 0.000 description 6

- JGFBQFKZKSSODQ-UHFFFAOYSA-N Isothiocyanatocyclopropane Chemical compound S=C=NC1CC1 JGFBQFKZKSSODQ-UHFFFAOYSA-N 0.000 description 5

- 239000002033 PVDF binder Substances 0.000 description 5

- 239000006230 acetylene black Substances 0.000 description 5

- 125000003118 aryl group Chemical group 0.000 description 5

- WVQUCYVTZWVNLV-UHFFFAOYSA-N boric acid;oxalic acid Chemical class OB(O)O.OC(=O)C(O)=O WVQUCYVTZWVNLV-UHFFFAOYSA-N 0.000 description 5

- PWLNAUNEAKQYLH-UHFFFAOYSA-N butyric acid octyl ester Natural products CCCCCCCCOC(=O)CCC PWLNAUNEAKQYLH-UHFFFAOYSA-N 0.000 description 5

- 230000008859 change Effects 0.000 description 5

- 150000001875 compounds Chemical class 0.000 description 5

- 229910052802 copper Inorganic materials 0.000 description 5

- 239000010949 copper Substances 0.000 description 5

- 238000000354 decomposition reaction Methods 0.000 description 5

- 125000000623 heterocyclic group Chemical group 0.000 description 5

- 125000004435 hydrogen atom Chemical class [H]* 0.000 description 5

- 150000002500 ions Chemical class 0.000 description 5

- UUIQMZJEGPQKFD-UHFFFAOYSA-N n-butyric acid methyl ester Natural products CCCC(=O)OC UUIQMZJEGPQKFD-UHFFFAOYSA-N 0.000 description 5

- 229920002981 polyvinylidene fluoride Polymers 0.000 description 5

- 125000000547 substituted alkyl group Chemical group 0.000 description 5

- YCKRFDGAMUMZLT-UHFFFAOYSA-N Fluorine atom Chemical compound [F] YCKRFDGAMUMZLT-UHFFFAOYSA-N 0.000 description 4

- 239000004698 Polyethylene Substances 0.000 description 4

- 230000000996 additive effect Effects 0.000 description 4

- 150000001336 alkenes Chemical class 0.000 description 4

- 210000004027 cell Anatomy 0.000 description 4

- 230000006866 deterioration Effects 0.000 description 4

- 239000002270 dispersing agent Substances 0.000 description 4

- 239000011737 fluorine Substances 0.000 description 4

- 229910052739 hydrogen Inorganic materials 0.000 description 4

- 239000001257 hydrogen Substances 0.000 description 4

- 239000011254 layer-forming composition Substances 0.000 description 4

- 229910052749 magnesium Inorganic materials 0.000 description 4

- 239000011777 magnesium Substances 0.000 description 4

- 238000005259 measurement Methods 0.000 description 4

- 229910044991 metal oxide Inorganic materials 0.000 description 4

- 150000004706 metal oxides Chemical class 0.000 description 4

- 238000002156 mixing Methods 0.000 description 4

- 229920000573 polyethylene Polymers 0.000 description 4

- 230000002829 reductive effect Effects 0.000 description 4

- 125000005415 substituted alkoxy group Chemical group 0.000 description 4

- 125000005346 substituted cycloalkyl group Chemical group 0.000 description 4

- 229910052720 vanadium Inorganic materials 0.000 description 4

- 229910052725 zinc Inorganic materials 0.000 description 4

- 239000011701 zinc Substances 0.000 description 4

- HNAGHMKIPMKKBB-UHFFFAOYSA-N 1-benzylpyrrolidine-3-carboxamide Chemical compound C1C(C(=O)N)CCN1CC1=CC=CC=C1 HNAGHMKIPMKKBB-UHFFFAOYSA-N 0.000 description 3

- XEKOWRVHYACXOJ-UHFFFAOYSA-N Ethyl acetate Chemical compound CCOC(C)=O XEKOWRVHYACXOJ-UHFFFAOYSA-N 0.000 description 3

- 229910010375 LiaMbPO4 Inorganic materials 0.000 description 3

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 3

- XBDQKXXYIPTUBI-UHFFFAOYSA-M Propionate Chemical compound CCC([O-])=O XBDQKXXYIPTUBI-UHFFFAOYSA-M 0.000 description 3

- 229910001128 Sn alloy Inorganic materials 0.000 description 3

- KXKVLQRXCPHEJC-UHFFFAOYSA-N acetic acid trimethyl ester Natural products COC(C)=O KXKVLQRXCPHEJC-UHFFFAOYSA-N 0.000 description 3

- 230000004913 activation Effects 0.000 description 3

- OBNCKNCVKJNDBV-UHFFFAOYSA-N butanoic acid ethyl ester Natural products CCCC(=O)OCC OBNCKNCVKJNDBV-UHFFFAOYSA-N 0.000 description 3

- 229910052791 calcium Inorganic materials 0.000 description 3

- 239000011575 calcium Substances 0.000 description 3

- 230000007423 decrease Effects 0.000 description 3

- 238000010586 diagram Methods 0.000 description 3

- 239000007772 electrode material Substances 0.000 description 3

- 229910052738 indium Inorganic materials 0.000 description 3

- 239000005001 laminate film Substances 0.000 description 3

- 239000007788 liquid Substances 0.000 description 3

- 229910052744 lithium Inorganic materials 0.000 description 3

- 229910052750 molybdenum Inorganic materials 0.000 description 3

- 150000003013 phosphoric acid derivatives Chemical class 0.000 description 3

- 238000010248 power generation Methods 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 239000003566 sealing material Substances 0.000 description 3

- 229910052718 tin Inorganic materials 0.000 description 3

- 239000011135 tin Substances 0.000 description 3

- UHOPWFKONJYLCF-UHFFFAOYSA-N 2-(2-sulfanylethyl)isoindole-1,3-dione Chemical compound C1=CC=C2C(=O)N(CCS)C(=O)C2=C1 UHOPWFKONJYLCF-UHFFFAOYSA-N 0.000 description 2

- BTBUEUYNUDRHOZ-UHFFFAOYSA-N Borate Chemical compound [O-]B([O-])[O-] BTBUEUYNUDRHOZ-UHFFFAOYSA-N 0.000 description 2

- BVKZGUZCCUSVTD-UHFFFAOYSA-L Carbonate Chemical compound [O-]C([O-])=O BVKZGUZCCUSVTD-UHFFFAOYSA-L 0.000 description 2

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 2

- 229910013275 LiMPO Inorganic materials 0.000 description 2

- WHXSMMKQMYFTQS-UHFFFAOYSA-N Lithium Chemical compound [Li] WHXSMMKQMYFTQS-UHFFFAOYSA-N 0.000 description 2

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 2

- 239000004642 Polyimide Substances 0.000 description 2

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 2

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 2

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 2

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 description 2

- 239000000853 adhesive Substances 0.000 description 2

- 230000001070 adhesive effect Effects 0.000 description 2

- 229910045601 alloy Inorganic materials 0.000 description 2

- 239000000956 alloy Substances 0.000 description 2

- 229910052787 antimony Inorganic materials 0.000 description 2

- 229920003235 aromatic polyamide Polymers 0.000 description 2

- 229910052788 barium Inorganic materials 0.000 description 2

- 229910052796 boron Inorganic materials 0.000 description 2

- 229910052794 bromium Inorganic materials 0.000 description 2

- 125000004432 carbon atom Chemical group C* 0.000 description 2

- 239000006229 carbon black Substances 0.000 description 2

- 239000003575 carbonaceous material Substances 0.000 description 2

- SYLNJGIBLUVXCG-UHFFFAOYSA-N carbonic acid;prop-1-yne Chemical compound CC#C.OC(O)=O SYLNJGIBLUVXCG-UHFFFAOYSA-N 0.000 description 2

- 150000005678 chain carbonates Chemical class 0.000 description 2

- 239000002800 charge carrier Substances 0.000 description 2

- 238000006243 chemical reaction Methods 0.000 description 2

- 229910052801 chlorine Inorganic materials 0.000 description 2

- 229910052804 chromium Inorganic materials 0.000 description 2

- 239000011651 chromium Substances 0.000 description 2

- 239000002131 composite material Substances 0.000 description 2

- 238000012790 confirmation Methods 0.000 description 2

- QXYJCZRRLLQGCR-UHFFFAOYSA-N dioxomolybdenum Chemical compound O=[Mo]=O QXYJCZRRLLQGCR-UHFFFAOYSA-N 0.000 description 2

- FKRCODPIKNYEAC-UHFFFAOYSA-N ethyl propionate Chemical compound CCOC(=O)CC FKRCODPIKNYEAC-UHFFFAOYSA-N 0.000 description 2

- YVIVRJLWYJGJTJ-UHFFFAOYSA-N gamma-Valerolactam Chemical compound CC1CCC(=O)N1 YVIVRJLWYJGJTJ-UHFFFAOYSA-N 0.000 description 2

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 2

- 229910052737 gold Inorganic materials 0.000 description 2

- 239000010931 gold Substances 0.000 description 2

- 239000008187 granular material Substances 0.000 description 2

- APFVFJFRJDLVQX-UHFFFAOYSA-N indium atom Chemical compound [In] APFVFJFRJDLVQX-UHFFFAOYSA-N 0.000 description 2

- 229910052740 iodine Inorganic materials 0.000 description 2

- 239000012528 membrane Substances 0.000 description 2

- ZKATWMILCYLAPD-UHFFFAOYSA-N niobium pentoxide Chemical compound O=[Nb](=O)O[Nb](=O)=O ZKATWMILCYLAPD-UHFFFAOYSA-N 0.000 description 2

- 239000011255 nonaqueous electrolyte Substances 0.000 description 2

- JRZJOMJEPLMPRA-UHFFFAOYSA-N olefin Natural products CCCCCCCC=C JRZJOMJEPLMPRA-UHFFFAOYSA-N 0.000 description 2

- 229910052760 oxygen Inorganic materials 0.000 description 2

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 2

- 229920001721 polyimide Polymers 0.000 description 2

- 229920001343 polytetrafluoroethylene Polymers 0.000 description 2

- 239000004810 polytetrafluoroethylene Substances 0.000 description 2

- RUOJZAUFBMNUDX-UHFFFAOYSA-N propylene carbonate Chemical compound CC1COC(=O)O1 RUOJZAUFBMNUDX-UHFFFAOYSA-N 0.000 description 2

- 230000000452 restraining effect Effects 0.000 description 2

- 239000010703 silicon Substances 0.000 description 2

- 229910052709 silver Inorganic materials 0.000 description 2

- 239000004332 silver Substances 0.000 description 2

- 125000006850 spacer group Chemical group 0.000 description 2

- 239000010935 stainless steel Substances 0.000 description 2

- 229910001220 stainless steel Inorganic materials 0.000 description 2

- 229910052712 strontium Inorganic materials 0.000 description 2

- 125000000472 sulfonyl group Chemical group *S(*)(=O)=O 0.000 description 2

- 229910052717 sulfur Inorganic materials 0.000 description 2

- 229910052714 tellurium Inorganic materials 0.000 description 2

- 229910052719 titanium Inorganic materials 0.000 description 2

- 239000010936 titanium Substances 0.000 description 2

- 229910052723 transition metal Inorganic materials 0.000 description 2

- 150000003624 transition metals Chemical class 0.000 description 2

- 229910052721 tungsten Inorganic materials 0.000 description 2

- 125000004417 unsaturated alkyl group Chemical group 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

- ZPFAVCIQZKRBGF-UHFFFAOYSA-N 1,3,2-dioxathiolane 2,2-dioxide Chemical compound O=S1(=O)OCCO1 ZPFAVCIQZKRBGF-UHFFFAOYSA-N 0.000 description 1

- NEAQRZUHTPSBBM-UHFFFAOYSA-N 2-hydroxy-3,3-dimethyl-7-nitro-4h-isoquinolin-1-one Chemical compound C1=C([N+]([O-])=O)C=C2C(=O)N(O)C(C)(C)CC2=C1 NEAQRZUHTPSBBM-UHFFFAOYSA-N 0.000 description 1

- AOCWQPKHSMJWPL-UHFFFAOYSA-N 3-methylpyrrolidin-2-one Chemical compound CC1CCNC1=O AOCWQPKHSMJWPL-UHFFFAOYSA-N 0.000 description 1

- ZTTYKFSKZIRTDP-UHFFFAOYSA-N 4,4-difluoro-1,3-dioxolan-2-one Chemical compound FC1(F)COC(=O)O1 ZTTYKFSKZIRTDP-UHFFFAOYSA-N 0.000 description 1

- DSMUTQTWFHVVGQ-UHFFFAOYSA-N 4,5-difluoro-1,3-dioxolan-2-one Chemical compound FC1OC(=O)OC1F DSMUTQTWFHVVGQ-UHFFFAOYSA-N 0.000 description 1

- RMYFSKOGEWSTQR-UHFFFAOYSA-N 4,5-difluoro-4,5-dimethyl-1,3-dioxolan-2-one Chemical compound CC1(F)OC(=O)OC1(C)F RMYFSKOGEWSTQR-UHFFFAOYSA-N 0.000 description 1

- QYIOFABFKUOIBV-UHFFFAOYSA-N 4,5-dimethyl-1,3-dioxol-2-one Chemical compound CC=1OC(=O)OC=1C QYIOFABFKUOIBV-UHFFFAOYSA-N 0.000 description 1

- RNNVXAXTORCUFA-UHFFFAOYSA-N 4-(fluoromethyl)-1,3-dioxolan-2-one Chemical compound FCC1COC(=O)O1 RNNVXAXTORCUFA-UHFFFAOYSA-N 0.000 description 1

- GKZFQPGIDVGTLZ-UHFFFAOYSA-N 4-(trifluoromethyl)-1,3-dioxolan-2-one Chemical compound FC(F)(F)C1COC(=O)O1 GKZFQPGIDVGTLZ-UHFFFAOYSA-N 0.000 description 1

- BJWMSGRKJIOCNR-UHFFFAOYSA-N 4-ethenyl-1,3-dioxolan-2-one Chemical compound C=CC1COC(=O)O1 BJWMSGRKJIOCNR-UHFFFAOYSA-N 0.000 description 1

- SBLRHMKNNHXPHG-UHFFFAOYSA-N 4-fluoro-1,3-dioxolan-2-one Chemical compound FC1COC(=O)O1 SBLRHMKNNHXPHG-UHFFFAOYSA-N 0.000 description 1

- PYKQXOJJRYRIHH-UHFFFAOYSA-N 4-fluoro-4-methyl-1,3-dioxolan-2-one Chemical compound CC1(F)COC(=O)O1 PYKQXOJJRYRIHH-UHFFFAOYSA-N 0.000 description 1

- NIXOWILDQLNWCW-UHFFFAOYSA-M Acrylate Chemical compound [O-]C(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-M 0.000 description 1

- 229920000856 Amylose Polymers 0.000 description 1

- 238000007088 Archimedes method Methods 0.000 description 1

- 229910001558 CF3SO3Li Inorganic materials 0.000 description 1

- OYPRJOBELJOOCE-UHFFFAOYSA-N Calcium Chemical compound [Ca] OYPRJOBELJOOCE-UHFFFAOYSA-N 0.000 description 1

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 description 1

- 229910005187 FSO3Li Inorganic materials 0.000 description 1

- 108010022355 Fibroins Proteins 0.000 description 1

- 108010076876 Keratins Proteins 0.000 description 1

- 102000011782 Keratins Human genes 0.000 description 1

- 229910002986 Li4Ti5O12 Inorganic materials 0.000 description 1

- 229910013098 LiBF2 Inorganic materials 0.000 description 1

- 229910011157 LiMBO Inorganic materials 0.000 description 1

- 229910015645 LiMn Inorganic materials 0.000 description 1

- 229910015643 LiMn 2 O 4 Inorganic materials 0.000 description 1

- 229910015004 LiMnxFeyPO4 Inorganic materials 0.000 description 1

- 229910012258 LiPO Inorganic materials 0.000 description 1

- 229910012265 LiPO2F2 Inorganic materials 0.000 description 1

- 229910015868 MSiO Inorganic materials 0.000 description 1

- NTIZESTWPVYFNL-UHFFFAOYSA-N Methyl isobutyl ketone Chemical compound CC(C)CC(C)=O NTIZESTWPVYFNL-UHFFFAOYSA-N 0.000 description 1

- UIHCLUNTQKBZGK-UHFFFAOYSA-N Methyl isobutyl ketone Natural products CCC(C)C(C)=O UIHCLUNTQKBZGK-UHFFFAOYSA-N 0.000 description 1

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 description 1

- 229910004008 NLi Inorganic materials 0.000 description 1

- MUBZPKHOEPUJKR-UHFFFAOYSA-N Oxalic acid Chemical compound OC(=O)C(O)=O MUBZPKHOEPUJKR-UHFFFAOYSA-N 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- 239000004962 Polyamide-imide Substances 0.000 description 1

- 239000004372 Polyvinyl alcohol Substances 0.000 description 1

- KJTLSVCANCCWHF-UHFFFAOYSA-N Ruthenium Chemical compound [Ru] KJTLSVCANCCWHF-UHFFFAOYSA-N 0.000 description 1

- 229910006145 SO3Li Inorganic materials 0.000 description 1

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 1

- 229920002125 Sokalan® Polymers 0.000 description 1

- 229930183415 Suberin Natural products 0.000 description 1

- QAOWNCQODCNURD-UHFFFAOYSA-L Sulfate Chemical compound [O-]S([O-])(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-L 0.000 description 1

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- 125000002252 acyl group Chemical group 0.000 description 1

- 125000004442 acylamino group Chemical group 0.000 description 1

- 125000004423 acyloxy group Chemical group 0.000 description 1

- 239000012790 adhesive layer Substances 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 229910052784 alkaline earth metal Inorganic materials 0.000 description 1

- 150000001342 alkaline earth metals Chemical class 0.000 description 1

- 125000003342 alkenyl group Chemical group 0.000 description 1

- 125000004453 alkoxycarbonyl group Chemical group 0.000 description 1

- 125000004466 alkoxycarbonylamino group Chemical group 0.000 description 1

- 125000005370 alkoxysilyl group Chemical group 0.000 description 1

- 125000003282 alkyl amino group Chemical group 0.000 description 1

- 125000004414 alkyl thio group Chemical group 0.000 description 1

- 125000000304 alkynyl group Chemical group 0.000 description 1

- 125000003277 amino group Chemical group 0.000 description 1

- 125000004397 aminosulfonyl group Chemical group NS(=O)(=O)* 0.000 description 1

- WATWJIUSRGPENY-UHFFFAOYSA-N antimony atom Chemical compound [Sb] WATWJIUSRGPENY-UHFFFAOYSA-N 0.000 description 1

- 239000004760 aramid Substances 0.000 description 1

- 125000005162 aryl oxy carbonyl amino group Chemical group 0.000 description 1

- 125000005161 aryl oxy carbonyl group Chemical group 0.000 description 1

- 125000005110 aryl thio group Chemical group 0.000 description 1

- 125000004104 aryloxy group Chemical group 0.000 description 1

- 229910052797 bismuth Inorganic materials 0.000 description 1

- JCXGWMGPZLAOME-UHFFFAOYSA-N bismuth atom Chemical compound [Bi] JCXGWMGPZLAOME-UHFFFAOYSA-N 0.000 description 1

- 229910052795 boron group element Inorganic materials 0.000 description 1

- 150000001642 boronic acid derivatives Chemical class 0.000 description 1

- ZTCLFSRIWSZUHZ-UHFFFAOYSA-N but-1-yne;carbonic acid Chemical compound CCC#C.OC(O)=O ZTCLFSRIWSZUHZ-UHFFFAOYSA-N 0.000 description 1

- 229910052793 cadmium Inorganic materials 0.000 description 1

- BDOSMKKIYDKNTQ-UHFFFAOYSA-N cadmium atom Chemical compound [Cd] BDOSMKKIYDKNTQ-UHFFFAOYSA-N 0.000 description 1

- 125000003917 carbamoyl group Chemical group [H]N([H])C(*)=O 0.000 description 1

- 125000001951 carbamoylamino group Chemical group C(N)(=O)N* 0.000 description 1

- 229910052800 carbon group element Inorganic materials 0.000 description 1

- 239000002134 carbon nanofiber Substances 0.000 description 1

- 239000002041 carbon nanotube Substances 0.000 description 1

- 229910021393 carbon nanotube Inorganic materials 0.000 description 1

- WTDFOGSFVBZUNY-UHFFFAOYSA-N carbonic acid 3-fluoroprop-1-yne Chemical compound OC(O)=O.FCC#C WTDFOGSFVBZUNY-UHFFFAOYSA-N 0.000 description 1

- RDXQKAROFYREEQ-UHFFFAOYSA-N carbonic acid;hex-1-yne Chemical compound OC(O)=O.CCCCC#C RDXQKAROFYREEQ-UHFFFAOYSA-N 0.000 description 1

- DOAYJNMCHKRFLA-UHFFFAOYSA-N carbonic acid;hex-3-yne Chemical compound OC(O)=O.CCC#CCC DOAYJNMCHKRFLA-UHFFFAOYSA-N 0.000 description 1

- DYCIODWFEIGZLV-UHFFFAOYSA-N carbonic acid;oct-4-yne Chemical compound OC(O)=O.CCCC#CCCC DYCIODWFEIGZLV-UHFFFAOYSA-N 0.000 description 1

- VJRTZEWWUALMFH-UHFFFAOYSA-N carbonic acid;pent-1-yne Chemical compound OC(O)=O.CCCC#C VJRTZEWWUALMFH-UHFFFAOYSA-N 0.000 description 1

- 125000003178 carboxy group Chemical group [H]OC(*)=O 0.000 description 1

- 239000006182 cathode active material Substances 0.000 description 1

- 229920002678 cellulose Polymers 0.000 description 1

- 239000001913 cellulose Substances 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 239000006231 channel black Substances 0.000 description 1

- 229910017052 cobalt Inorganic materials 0.000 description 1

- 239000010941 cobalt Substances 0.000 description 1

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 description 1

- 239000004020 conductor Substances 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 230000008602 contraction Effects 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- DMSZORWOGDLWGN-UHFFFAOYSA-N ctk1a3526 Chemical group NP(N)(N)=O DMSZORWOGDLWGN-UHFFFAOYSA-N 0.000 description 1

- 238000007766 curtain coating Methods 0.000 description 1

- 125000004122 cyclic group Chemical group 0.000 description 1

- 238000005262 decarbonization Methods 0.000 description 1

- 238000009831 deintercalation Methods 0.000 description 1

- 230000032798 delamination Effects 0.000 description 1

- 230000002542 deteriorative effect Effects 0.000 description 1

- 125000004663 dialkyl amino group Chemical group 0.000 description 1

- 238000007607 die coating method Methods 0.000 description 1

- 238000003618 dip coating Methods 0.000 description 1

- 238000010494 dissociation reaction Methods 0.000 description 1

- 230000005593 dissociations Effects 0.000 description 1

- 238000004090 dissolution Methods 0.000 description 1

- 238000007606 doctor blade method Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 239000012777 electrically insulating material Substances 0.000 description 1

- 230000005611 electricity Effects 0.000 description 1

- 239000011532 electronic conductor Substances 0.000 description 1

- 125000004494 ethyl ester group Chemical group 0.000 description 1

- 230000001747 exhibiting effect Effects 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- 229920001973 fluoroelastomer Polymers 0.000 description 1

- 239000006232 furnace black Substances 0.000 description 1

- 230000004927 fusion Effects 0.000 description 1

- 229910052733 gallium Inorganic materials 0.000 description 1

- 238000007429 general method Methods 0.000 description 1

- 229910052732 germanium Inorganic materials 0.000 description 1

- GNPVGFCGXDBREM-UHFFFAOYSA-N germanium atom Chemical compound [Ge] GNPVGFCGXDBREM-UHFFFAOYSA-N 0.000 description 1

- 150000004676 glycans Chemical class 0.000 description 1

- 238000009499 grossing Methods 0.000 description 1

- 229910001849 group 12 element Inorganic materials 0.000 description 1

- 229910052735 hafnium Inorganic materials 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 125000000717 hydrazino group Chemical group [H]N([*])N([H])[H] 0.000 description 1

- 150000003949 imides Chemical class 0.000 description 1

- 125000001841 imino group Chemical group [H]N=* 0.000 description 1

- 239000011256 inorganic filler Substances 0.000 description 1

- 229910003475 inorganic filler Inorganic materials 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 238000009830 intercalation Methods 0.000 description 1

- 230000016507 interphase Effects 0.000 description 1

- 229910052741 iridium Inorganic materials 0.000 description 1

- JEIPFZHSYJVQDO-UHFFFAOYSA-N iron(III) oxide Inorganic materials O=[Fe]O[Fe]=O JEIPFZHSYJVQDO-UHFFFAOYSA-N 0.000 description 1

- 239000003273 ketjen black Substances 0.000 description 1

- 229910052745 lead Inorganic materials 0.000 description 1

- 229920005610 lignin Polymers 0.000 description 1

- 235000013490 limbo Nutrition 0.000 description 1

- 229910001540 lithium hexafluoroarsenate(V) Inorganic materials 0.000 description 1

- MHCFAGZWMAWTNR-UHFFFAOYSA-M lithium perchlorate Chemical compound [Li+].[O-]Cl(=O)(=O)=O MHCFAGZWMAWTNR-UHFFFAOYSA-M 0.000 description 1

- 229910001486 lithium perchlorate Inorganic materials 0.000 description 1

- 229910001496 lithium tetrafluoroborate Inorganic materials 0.000 description 1

- 239000011572 manganese Substances 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 239000002923 metal particle Substances 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 150000004702 methyl esters Chemical class 0.000 description 1

- 238000010295 mobile communication Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000011733 molybdenum Substances 0.000 description 1

- 229920005615 natural polymer Polymers 0.000 description 1

- 229910052758 niobium Inorganic materials 0.000 description 1

- 150000004767 nitrides Chemical group 0.000 description 1

- 125000000449 nitro group Chemical group [O-][N+](*)=O 0.000 description 1

- 239000004745 nonwoven fabric Substances 0.000 description 1

- 229910052763 palladium Inorganic materials 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 229910052698 phosphorus Inorganic materials 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 238000007747 plating Methods 0.000 description 1

- 229910052697 platinum Inorganic materials 0.000 description 1

- 229910052696 pnictogen Inorganic materials 0.000 description 1

- 239000004584 polyacrylic acid Substances 0.000 description 1

- 229920002239 polyacrylonitrile Polymers 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 229920002312 polyamide-imide Polymers 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 229920013716 polyethylene resin Polymers 0.000 description 1

- 229920001282 polysaccharide Polymers 0.000 description 1

- 239000005017 polysaccharide Substances 0.000 description 1

- 229920002451 polyvinyl alcohol Polymers 0.000 description 1

- 235000019422 polyvinyl alcohol Nutrition 0.000 description 1

- 229920000036 polyvinylpyrrolidone Polymers 0.000 description 1

- 239000001267 polyvinylpyrrolidone Substances 0.000 description 1

- 235000013855 polyvinylpyrrolidone Nutrition 0.000 description 1

- 229910052700 potassium Inorganic materials 0.000 description 1

- 239000011241 protective layer Substances 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 230000002441 reversible effect Effects 0.000 description 1

- 229910052702 rhenium Inorganic materials 0.000 description 1

- 229910052703 rhodium Inorganic materials 0.000 description 1

- 229910052707 ruthenium Inorganic materials 0.000 description 1

- 150000003839 salts Chemical class 0.000 description 1

- 239000002210 silicon-based material Substances 0.000 description 1

- 125000003808 silyl group Chemical group [H][Si]([H])([H])[*] 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 229910052708 sodium Inorganic materials 0.000 description 1

- 239000007784 solid electrolyte Substances 0.000 description 1

- 239000006104 solid solution Substances 0.000 description 1

- 238000007711 solidification Methods 0.000 description 1

- 230000008023 solidification Effects 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 125000000213 sulfino group Chemical group [H]OS(*)=O 0.000 description 1

- 125000000475 sulfinyl group Chemical group [*:2]S([*:1])=O 0.000 description 1

- 125000000020 sulfo group Chemical group O=S(=O)([*])O[H] 0.000 description 1

- 125000006296 sulfonyl amino group Chemical group [H]N(*)S(*)(=O)=O 0.000 description 1

- 229920003002 synthetic resin Polymers 0.000 description 1

- 239000000057 synthetic resin Substances 0.000 description 1

- 229910052715 tantalum Inorganic materials 0.000 description 1

- GUVRBAGPIYLISA-UHFFFAOYSA-N tantalum atom Chemical compound [Ta] GUVRBAGPIYLISA-UHFFFAOYSA-N 0.000 description 1

- RBYFNZOIUUXJQD-UHFFFAOYSA-J tetralithium oxalate Chemical compound [Li+].[Li+].[Li+].[Li+].[O-]C(=O)C([O-])=O.[O-]C(=O)C([O-])=O RBYFNZOIUUXJQD-UHFFFAOYSA-J 0.000 description 1

- 229920005992 thermoplastic resin Polymers 0.000 description 1

- ZMZDMBWJUHKJPS-UHFFFAOYSA-N thiocyanic acid Chemical compound SC#N ZMZDMBWJUHKJPS-UHFFFAOYSA-N 0.000 description 1

- 239000011366 tin-based material Substances 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- NDZWKTKXYOWZML-UHFFFAOYSA-N trilithium;difluoro oxalate;borate Chemical compound [Li+].[Li+].[Li+].[O-]B([O-])[O-].FOC(=O)C(=O)OF NDZWKTKXYOWZML-UHFFFAOYSA-N 0.000 description 1

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 1

- 239000010937 tungsten Substances 0.000 description 1

- DZKDPOPGYFUOGI-UHFFFAOYSA-N tungsten dioxide Inorganic materials O=[W]=O DZKDPOPGYFUOGI-UHFFFAOYSA-N 0.000 description 1

- 238000004804 winding Methods 0.000 description 1

- 239000002759 woven fabric Substances 0.000 description 1

- 229910009207 xMxN Inorganic materials 0.000 description 1

- 229910052727 yttrium Inorganic materials 0.000 description 1

- 229910052726 zirconium Inorganic materials 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/05—Accumulators with non-aqueous electrolyte

- H01M10/056—Accumulators with non-aqueous electrolyte characterised by the materials used as electrolytes, e.g. mixed inorganic/organic electrolytes

- H01M10/0564—Accumulators with non-aqueous electrolyte characterised by the materials used as electrolytes, e.g. mixed inorganic/organic electrolytes the electrolyte being constituted of organic materials only

- H01M10/0566—Liquid materials

- H01M10/0569—Liquid materials characterised by the solvents

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/05—Accumulators with non-aqueous electrolyte

- H01M10/052—Li-accumulators

- H01M10/0525—Rocking-chair batteries, i.e. batteries with lithium insertion or intercalation in both electrodes; Lithium-ion batteries

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/05—Accumulators with non-aqueous electrolyte

- H01M10/056—Accumulators with non-aqueous electrolyte characterised by the materials used as electrolytes, e.g. mixed inorganic/organic electrolytes

- H01M10/0564—Accumulators with non-aqueous electrolyte characterised by the materials used as electrolytes, e.g. mixed inorganic/organic electrolytes the electrolyte being constituted of organic materials only

- H01M10/0566—Liquid materials

- H01M10/0568—Liquid materials characterised by the solutes

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/36—Selection of substances as active materials, active masses, active liquids

- H01M4/58—Selection of substances as active materials, active masses, active liquids of inorganic compounds other than oxides or hydroxides, e.g. sulfides, selenides, tellurides, halogenides or LiCoFy; of polyanionic structures, e.g. phosphates, silicates or borates

- H01M4/583—Carbonaceous material, e.g. graphite-intercalation compounds or CFx

- H01M4/587—Carbonaceous material, e.g. graphite-intercalation compounds or CFx for inserting or intercalating light metals

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M2300/00—Electrolytes

- H01M2300/0017—Non-aqueous electrolytes

- H01M2300/002—Inorganic electrolyte

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M2300/00—Electrolytes

- H01M2300/0017—Non-aqueous electrolytes

- H01M2300/0025—Organic electrolyte

- H01M2300/0028—Organic electrolyte characterised by the solvent

- H01M2300/0037—Mixture of solvents

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

Definitions

- the present invention relates to an electrolyte that can be used in lithium ion secondary batteries, and a lithium ion secondary battery using the electrolyte.

- Lithium-ion secondary batteries which have excellent capacity, are used as power sources for mobile terminals, personal computers, and electric vehicles.

- decarbonization In recent years, there has been an increasing demand for decarbonization, and many efforts are being made to electrify the drive sources of various devices. Along with this, there is a demand for further improvement in the characteristics of lithium ion secondary batteries.

- the inventors of the present invention aimed to improve the characteristics of lithium-ion secondary batteries by optimizing the electrolyte of the lithium-ion secondary batteries.

- Patent Document 1 introduces an electrolytic solution in which LiPF 6 is dissolved at a concentration of 1 mol/L in a mixed non-aqueous solvent in which ethylene carbonate and ethyl methyl carbonate are mixed at a volume ratio of 3:7.

- Patent Document 2 introduces an electrolytic solution in which LiPF 6 is dissolved at a concentration of 1 mol/L in a mixed non-aqueous solvent in which ethylene carbonate, dimethyl carbonate, and ethyl methyl carbonate are mixed at a volume ratio of 3:2:5. .

- chain carbonate is used as the main solvent of the electrolytic solution in the above patent documents.

- the inventor of the present invention found that an alkylene cyclic carbonate and methyl propionate were used in combination as a non-aqueous solvent for the electrolytic solution.

- An application for an ion secondary battery has already been filed (Japanese Patent Application No. 2020-026926).

- the electrolytic solution described above can contribute to improving the characteristics of the lithium ion secondary battery.

- the inventor of the present invention was not satisfied with this, and conducted extensive research to further improve the characteristics.

- the present invention has been made in view of such circumstances, and an object thereof is to provide an electrolytic solution capable of imparting excellent characteristics to a lithium ion secondary battery, and a lithium ion secondary battery exhibiting excellent characteristics. do.

- the inventors of the present invention found that lithium It was found that the characteristics of the ion secondary battery are further improved.

- the inventors of the present invention completed the electrolytic solution of the present invention based on such findings.

- the applicant of the present invention has developed a structure of an electric storage cell and an electric storage device capable of suppressing a decrease in sealing performance as part of efforts to improve the durability of an electric storage device including a lithium ion secondary battery, and has already filed an application.

- Japanese Patent Application No. 2021-003409 Japanese Patent Application No. 2021-003409

- the inventors of the present invention also conducted various studies on the electrolytic solution in order to further improve the sealing performance of the storage cell in the lithium ion secondary battery having the structure. In the process, it was found that by combining the structure with the electrolytic solution of the present invention described above, the sealing property of the storage cell in the lithium ion secondary battery can be further improved, and the lithium ion secondary battery of the present invention completed.

- the electrolytic solution of the present invention that solves the above problems is having an electrolyte comprising a lithium salt and a non-aqueous solvent comprising an alkylene cyclic carbonate and methyl propionate;

- the electrolyte contains 30 mol% or more of a lithium salt other than LiPF 6 with respect to the total lithium salt,

- the nonaqueous solvent is an electrolytic solution containing 75% by volume or more of the methyl propionate.

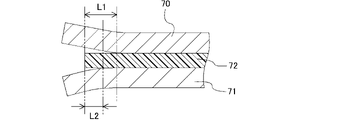

- the lithium ion secondary battery of the present invention for solving the above problems is a positive electrode having a first current collector and a positive electrode active material layer provided on one surface of the first current collector; It has a second current collector and a negative electrode active material layer provided on one side of the second current collector, and is stacked on the positive electrode while facing the positive electrode active material layer. a negative electrode; a separator disposed between the positive electrode active material layer and the negative electrode active material layer; disposed between the first current collector and the second current collector to surround the positive electrode active material layer and the negative electrode active material layer; and a sealing portion that seals the electrolytic solution in the space between It is a lithium ion secondary battery using the electrolyte solution of the present invention described above as the electrolyte solution.

- the electrolyte solution of the present invention excellent characteristics can be imparted to lithium ion secondary batteries. Moreover, the lithium ion secondary battery of the present invention exhibits excellent characteristics, particularly excellent structural durability.

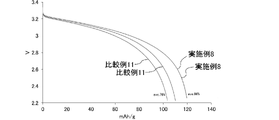

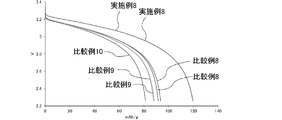

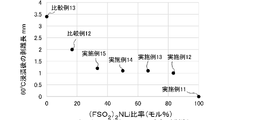

- FIG. 10 is a graph showing changes over time in CC discharge capacity in each lithium ion secondary battery of Example 8 and Comparative Example 11.

- FIG. 10 is a graph showing changes over time in CC discharge capacity in each lithium ion secondary battery of Example 8 and Comparative Examples 8 to 10.

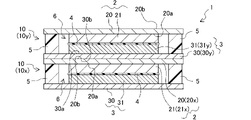

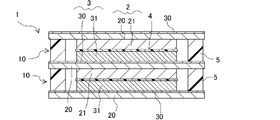

- FIG. 11 is an explanatory diagram schematically showing a lithium ion secondary battery of Example 9;

- FIG. 11 is an explanatory diagram schematically showing a lithium-ion secondary battery of Example 10;

- FIG. 11 is an explanatory diagram for explaining measurement positions of the natural peel length in Evaluation Example 9;

- 10 is a graph showing the natural peel length of each test piece in Evaluation Example 9.

- the numerical range "x to y" described in this specification includes the lower limit x and the upper limit y.

- a new numerical range can be formed by arbitrarily combining these upper and lower limits and the numerical values listed in the examples.

- numerical values arbitrarily selected from any of the above numerical ranges can be used as upper and lower numerical values of the new numerical range.

- the electrolytic solution of the present invention can improve the characteristics of lithium ion secondary batteries by providing all of the following (1) to (3).

- the non-aqueous solvent contains 75% by volume or more of methyl propionate.

- the above (1) can contribute particularly to improving the structural durability.

- the above (2) can contribute to smooth charging and discharging among the characteristics of the lithium ion secondary battery. Specifically, it is derived from alkylene cyclic carbonate, and lithium ions are smoothly generated and inserted into and detached from the negative electrode, and the disadvantages of alkylene cyclic carbonate such as high viscosity and high melting point are compensated by methyl propionate.

- the above (3) can contribute to the improvement of the capacity retention rate, output, and the like among the characteristics of the lithium ion secondary battery. It can be said that the electrolytic solution of the present invention can improve the characteristics of the lithium-ion secondary battery by these cooperation.

- the structural durability of the lithium ion secondary battery of the present invention can be improved by providing both (4) and (5) below.

- a positive electrode having a first current collector and a positive electrode active material layer provided on one surface of the first current collector; It has a second current collector and a negative electrode active material layer provided on one side of the second current collector, and is stacked on the positive electrode while facing the positive electrode active material layer.

- a negative electrode a separator disposed between the positive electrode active material layer and the negative electrode active material layer; disposed between the first current collector and the second current collector to surround the positive electrode active material layer and the negative electrode active material layer; and a sealing portion that seals the electrolytic solution in the space between (5)

- the electrolytic solution of the present invention described above is used.

- the above (4) can contribute to suppressing deterioration of the sealing performance among the characteristics of the lithium ion secondary battery.

- the above (5) can further contribute to the improvement of structural durability among the characteristics of the lithium ion secondary battery provided with the above (4), specifically, the improvement of sealing performance.

- the lithium-ion secondary battery of the present invention can realize improvement in its characteristics through these cooperation.

- the electrolytic solution and the lithium ion secondary battery of the present invention will be described below for each component.

- the lithium ion concentration in the electrolytic solution of the present invention is preferably in the range of 0.8 to 1.8 mol / L, more preferably in the range of 0.9 to 1.5 mol / L, from the viewpoint of ionic conductivity.

- the range of 0 to 1.4 mol/L is more preferable, and the range of 1.1 to 1.3 mol/L is particularly preferable.

- the electrolyte used in the electrolytic solution of the present invention contains a lithium salt, and contains 30 mol % or more of the lithium salt other than LiPF 6 with respect to the total lithium salt.

- the electrolytic solution of the present invention may contain LiPF 6 as a lithium salt or may not contain LiPF 6 .

- LiPF 6 is widely used as an electrolyte for electrolyte solutions for lithium ion secondary batteries, and is relatively inexpensive.

- the reason why the electrolytic solution of the present invention uses a lithium salt other than LiPF 6 is as follows.

- LiPF 6 It is known that the reaction of LiPF 6 with water produces hydrogen fluoride. Since a small amount of water is present in the electrolyte of a general lithium ion secondary battery, hydrogen fluoride may be contained in the electrolyte in the lithium ion secondary battery containing LiPF 6 in the electrolyte. It is also known that LiPF 6 is thermally unstable, forming PF 5 at temperatures above 60° C., for example. The PF5 can react with water to produce hydrogen fluoride.

- the inventors of the present invention have studied the composition of the electrolytic solution in order to improve the characteristics of the lithium ion secondary battery.

- hydrogen fluoride and PF 5 present in the electrolyte may corrode the electrodes and containers of the lithium-ion secondary battery, and corrosion of the electrodes and containers may reduce the durability of the lithium-ion secondary battery.

- the lithium ion secondary battery has a structure having a sealing portion between two current collectors as disclosed in Japanese Patent Application No.

- the surface of the metal portion contained in the current collectors corrodes ( Specifically, when fluorinated, the bonding strength between the sealing portion and the current collector is weakened, structurally deteriorating the battery, and the sealing performance of the sealing portion is likely to be reduced. This problem is particularly pronounced when the current collector contains aluminum.

- the inventors of the present invention aimed to suppress the above-mentioned problems caused by LiPF 6 in order to improve the structural durability of lithium ion secondary batteries. They have also found that the above problem is suppressed when the electrolyte contains a lithium salt other than LiPF 6 in an amount of 30 mol % or more with respect to the total lithium salt. Although details will be described in the section of Examples described later, as a result of actual tests by the inventors of the present invention, in a lithium ion secondary battery having a sealing portion between two current collectors, electrolytes other than LiPF 6 When the lithium salt of 30 mol % or more of the total lithium salt is contained, the durability is improved as compared with the case where only LiPF 6 is contained as the electrolyte.

- lithium salts other than LiPF 6 those represented by the following general formula (1) are particularly preferred. Lithium salts of this type are less likely to produce hydrogen fluoride and PF5 .

- R1X1 )( R2SO2 )NLi General formula ( 1 )

- R 1 is hydrogen, halogen, an optionally substituted alkyl group, an optionally substituted cycloalkyl group, an optionally substituted unsaturated alkyl group, a substituent

- R 2 is hydrogen, halogen, an optionally substituted alkyl group, an optionally substituted cycloalkyl group, an optionally substituted unsaturated alkyl group, or a substituent; optionally substituted unsaturated cycloalkyl group, optionally substituted aromatic group, optionally substituted heterocyclic group, optionally substituted alkoxy group, optionally substituted unsaturated alkoxy group, optionally substituted thioalkoxy group, optionally substituted unsaturated thioalkoxy group, CN, SCN, OCN be. Also, R 1 and R 2 may combine with each other to form a ring.

- R a and R b each independently represent hydrogen, halogen, an optionally substituted alkyl group, an optionally substituted cycloalkyl group, or an optionally substituted unsubstituted group.

- R a and R b may combine with R 1 or R 2 to form a ring.

- an optionally substituted alkyl group means an alkyl group in which one or more of the hydrogen atoms in the alkyl group is substituted with a substituent, or an unsubstituted alkyl group. do.

- substituents in the phrase "optionally substituted” include alkyl groups, alkenyl groups, alkynyl groups, cycloalkyl groups, unsaturated cycloalkyl groups, aromatic groups, heterocyclic groups, halogens, OH , SH, CN, SCN, OCN, nitro group, alkoxy group, unsaturated alkoxy group, amino group, alkylamino group, dialkylamino group, aryloxy group, acyl group, alkoxycarbonyl group, acyloxy group, aryloxycarbonyl group, acylamino group, alkoxycarbonylamino group, aryloxycarbonylamino group, sulfonylamino group, sulfamoyl group, carbamoyl group, alkylthio group, arylthio group, sulfonyl group, sulfinyl group, ureido group, phosphoramide group, sulfo group,

- the lithium salt is preferably represented by the following general formula (1-1).

- R 13 and R 14 are each independently C n Ha F b Cl c Br d I e (CN) f (SCN ) g (OCN) h .

- R c and R d each independently represent hydrogen, halogen, an optionally substituted alkyl group, an optionally substituted cycloalkyl group, or an optionally substituted unsubstituted group.

- R c and R d may combine with R 23 or R 24 to form a ring.

- n is preferably an integer of 0 to 6, more preferably an integer of 0 to 4, and particularly preferably an integer of 0 to 2.

- n is preferably an integer of 1 to 8, and 1 to 7 is more preferred, and integers from 1 to 3 are particularly preferred.

- the lithium salt is represented by the following general formula (1-2).

- R 15 SO 2 (R 16 SO 2 )NLi

- R 15 and R 16 are each independently C n Ha F b Cl c Br d Ie .

- n is preferably an integer of 0 to 6, more preferably an integer of 0 to 4, and particularly preferably an integer of 0 to 2.

- n is preferably an integer of 1 to 8, and 1 to 7 is more preferred, and integers from 1 to 3 are particularly preferred.

- the lithium salts represented by the general formula (1), (1-1) or (1-2) are (CF 3 SO 2 ) 2 NLi, (FSO 2 ) 2 NLi, (C 2 F 5 SO 2 ) at least one imide salt selected from 2NLi , FSO2 ( CF3SO2 ) NLi , ( SO2CF2CF2SO2 ) NLi , or ( SO2CF2CF2CF2SO2 ) NLi ; It is preferable to have Of these, (FSO 2 ) 2 NLi improves the output and durability of the lithium ion secondary battery. This is probably because the use of (FSO 2 ) 2 NLi reduces the viscosity of the electrolytic solution and forms a good film on the surfaces of the negative electrode and the positive electrode.

- the amount of the lithium salt other than LiPF 6 contained in the electrolytic solution of the present invention may be 30 mol% or more with respect to the total lithium salt, but the preferred range is 50 mol% with respect to the total lithium salt. As mentioned above, each range of 75 mol% or more and 90 mol% or more can be exemplified.

- the electrolytic solution of the present invention contains an alkylene cyclic carbonate and methyl propionate as a non-aqueous solvent.

- Alkylene cyclic carbonate is a non-aqueous solvent with a high dielectric constant, and is thought to contribute to dissolution and ion dissociation of the lithium salt. Further, it is generally known that an SEI (Solid Electrolyte Interphase) film is formed on the surface of the negative electrode by reductive decomposition of the alkylene cyclic carbonate during charging of the lithium ion secondary battery. It is believed that the presence of such an SEI coating enables reversible insertion and extraction of lithium ions into and from a negative electrode comprising graphite.

- the electrolytic solution of the present invention may use only one type of alkylene cyclic carbonate, or may use a plurality of types of alkylene cyclic carbonates in combination. Examples of alkylene cyclic carbonates include ethylene carbonate and propylene carbonate, with ethylene carbonate being particularly preferred.

- alkylene cyclic carbonates are useful as non-aqueous solvents for electrolytic solutions, they have high viscosity. Therefore, if the ratio of the alkylene cyclic carbonate is too high, the ionic conductivity of the electrolyte and the diffusion of lithium ions in the electrolyte may be adversely affected. In addition, since the alkylene cyclic carbonate has a relatively high melting point, if the proportion of the alkylene cyclic carbonate is too high, the electrolytic solution may solidify under low temperature conditions.

- methyl propionate is a non-aqueous solvent with low dielectric constant, low viscosity and low melting point.

- the coexistence of alkylene cyclic carbonate and methyl propionate offsets the disadvantage of alkylene cyclic carbonate with methyl propionate. That is, methyl propionate is considered to contribute to lowering the viscosity of the electrolytic solution, optimizing the ionic conductivity, optimizing the diffusion coefficient of lithium ions, and preventing solidification under low-temperature conditions.

- methyl acetate, ethyl acetate, ethyl propionate, methyl butyrate, and ethyl butyrate exist as esters having a chemical structure similar to that of methyl propionate.

- methyl ester is superior to ethyl ester in terms of physical properties of the electrolyte and battery characteristics.

- the melting points and boiling points of the methyl esters methyl propionate, methyl acetate, and methyl butyrate are as follows.

- Methyl propionate Melting point -88°C, boiling point 80°C Methyl acetate Melting point -98°C, boiling point 57°C Methyl butyrate Melting point -95°C, boiling point 102°C

- the non-aqueous solvent contained in the electrolytic solution preferably has a boiling point of 60°C or higher. From the point of view of the production environment, it is preferable that the boiling point of the non-aqueous solvent to be used is high.

- the number of carbon atoms in the ester increases, the lipophilicity of the ester increases, which is disadvantageous for dissolving and dissociating the lithium salt. Therefore, the number of carbon atoms in the ester is preferably as small as possible.

- the non-aqueous solvent in the electrolytic solution of the present invention contains 75% by volume or more of methyl propionate.

- the electrolytic solution of the present invention can improve both the charge/discharge capacity of the positive electrode and the charge/discharge capacity of the negative electrode in the lithium ion secondary battery. is possible.

- methyl propionate is preferably contained in the non-aqueous solvent in an amount of 85% by volume or less, more preferably 80% by volume or less.

- the non-aqueous solvent in the electrolytic solution of the present invention may contain other non-aqueous solvents in addition to the alkylene cyclic carbonate and methyl propionate, or may consist of alkylene cyclic carbonate and methyl propionate.

- the electrolytic solution of the present invention should contain 75% by volume or more of methyl propionate when the total non-aqueous solvent is taken as 100% by volume.

- 100% by volume of the entire non-aqueous solvent means the sum of the volumes of the non-aqueous solvents at normal temperature of 25° C. and normal pressure before mixing.

- the ratio of methyl propionate to the total volume of alkylene cyclic carbonate and methyl propionate is preferably in the range of 72 to 95% by volume, more preferably in the range of 75 to 90% by volume. is more preferred, most preferably in the range of 75 to 85% by volume.

- the ratio of the alkylene cyclic carbonate to the total volume of the alkylene cyclic carbonate and methyl propionate is preferably within the range of 5 to 28% by volume, more preferably within the range of 10 to 25% by volume, Most preferably it is in the range of 15-25% by volume.

- non-aqueous solvents mentioned above include fluorine-containing cyclic carbonates and unsaturated cyclic carbonates. These may be used alone or in combination. By using these non-aqueous solvents together with the alkylene cyclic carbonate and methyl propionate, the performance of the lithium ion secondary battery can be improved.

- Fluorine-containing cyclic carbonates include fluoroethylene carbonate, 4-(trifluoromethyl)-1,3-dioxolan-2-one, 4,4-difluoro-1,3-dioxolan-2-one, 4-fluoro-4 -methyl-1,3-dioxolan-2-one, 4-(fluoromethyl)-1,3-dioxolan-2-one, 4,5-difluoro-1,3-dioxolan-2-one, 4-fluoro- Examples include 5-methyl-1,3-dioxolan-2-one and 4,5-difluoro-4,5-dimethyl-1,3-dioxolan-2-one.

- unsaturated cyclic carbonates include vinylene carbonate, fluorovinylene carbonate, methyl vinylene carbonate, fluoromethyl vinylene carbonate, ethyl vinylene carbonate, propyl vinylene carbonate, butyl vinylene carbonate, dimethyl vinylene carbonate, diethyl vinylene carbonate, dipropyl vinylene carbonate, trifluoro Examples include methyl vinylene carbonate and vinyl ethylene carbonate. Particularly preferably, the electrolytic solution of the present invention contains vinylene carbonate.

- the amount of fluorine-containing cyclic carbonate and/or unsaturated cyclic carbonate added to the electrolytic solution of the present invention is in the range of 0.1 to 5% by mass, 0.3 to 4% by mass with respect to the total mass other than these. Within the range, within the range of 0.5 to 3% by mass, and within the range of 1 to 2% by mass can be exemplified.

- the electrolytic solution of the present invention may contain additives.

- the additive it is preferable to select an additive that initiates reductive decomposition at a potential higher than the potential at which other components of the electrolytic solution, specifically, alkylene cyclic carbonate and methyl propionate, initiate reductive decomposition.

- specific examples of additives include cyclic sulfates, oxalate borates, and dihalogenated phosphates. These additives may be used alone or in combination of multiple types.

- a cyclic sulfate is a compound represented by the following chemical formula.

- R--O--SO 2 --OR Two R's are alkyl groups and are bonded together to form a ring together with --O--S--O--.

- Examples of cyclic sulfate esters include 5- to 9-membered rings, 5- to 8-membered rings, and 5- to 7-membered rings. 4 can be exemplified.

- Lithium salts are preferred as oxalate borates.

- LiB(C 2 O 4 ) 2 and LiB(C 2 O 4 )X 2 (X is a halogen selected from F, Cl, Br and I) can be exemplified as specific oxalate borate salts.

- the borate oxalate is LiB(C 2 O 4 ) 2 , lithium bis(oxalate)borate and/or LiB(C 2 O 4 )F 2 , lithium difluoro(oxalate)borate.

- LiPO 2 X 2 (X is a halogen selected from F, Cl, Br and I) can be exemplified as a specific dihalogenated phosphate.

- the amount of the additive added to the electrolytic solution of the present invention is within the range of 0.1 to 5% by mass, within the range of 0.3 to 4% by mass, and 0.3% by mass to the total mass other than the additive. Within the range of 5 to 3% by mass and within the range of 1 to 2% by mass can be exemplified.

- the lithium ion secondary battery of the present invention using the electrolytic solution of the present invention will be described below.

- the lithium ion secondary battery of the present invention has a positive electrode, a negative electrode, a separator, a sealing portion and an electrolytic solution.

- the electrolytic solution is as described above.

- the positive electrode has a first current collector and a positive electrode active material layer provided on one surface of the first current collector.

- the negative electrode has a second current collector and a negative electrode active material layer provided on one surface of the second current collector.

- the negative electrode is stacked on the positive electrode with the negative electrode active material layer facing the positive electrode active material layer of the positive electrode.

- the first current collector and the second current collector are collectively referred to.

- the positive electrode active material and the negative electrode active material shall be collectively referred to, and when referring to the electrode active material layer, the positive electrode active material and the negative electrode active material shall be collectively referred to.

- a current collector is a chemically inactive electronic conductor that keeps current flowing through an electrode during discharging or charging of a lithium-ion secondary battery.

- metal materials such as The effect of improving durability, which is the effect of the lithium ion secondary battery of the present invention, is particularly remarkable when the first current collector, which is the current collector for the positive electrode, is made of aluminum. That is, it is particularly preferable that the first current collector is made of aluminum.

- the current collector may be covered with a known protective layer.

- a current collector whose surface has been treated by a known method may be used as the current collector.

- the current collector can be in the form of foil, sheet, film, wire, rod, mesh, etc. Therefore, metal foils such as copper foil, nickel foil, aluminum foil, and stainless steel foil can be preferably used as the current collector.

- the thickness is preferably in the range of 1 ⁇ m to 100 ⁇ m.

- the positive electrode active material should be capable of intercalating and deintercalating lithium ions .

- D is W, Mo, Re, Pd, Ba, Cr, B, Sb, Sr, Pb, Ga, Al, Nb, Mg, Ta, Ti, La, Zr, Cu, Ca, Ir , Hf, Rh, Fe, Ge, Zn, Ru, Sc, Sn, In, Y, Bi, S, Si, Na, K, P, V, 1.7 ⁇ f ⁇ 3)

- Lithium composite metal oxide represented by and Li 2 MnO 3 can be mentioned.

- a spinel-structured metal oxide such as LiMn 2 O 4

- a solid solution composed of a mixture of a spinel-structured metal oxide and a layered compound, LiMPO 4 , LiMVO 4 or Li 2 MSiO 4 in the formula is selected from at least one of Co, Ni, Mn and Fe.

- positive electrode active materials include taborite compounds represented by LiMPO 4 F (M is a transition metal) such as LiFePO 4 F, and borate compounds represented by LiMBO 3 (M is a transition metal) such as LiFeBO 3 . be able to.

- Any metal oxide used as a positive electrode active material may have the above compositional formula as a basic composition, and those in which the metal elements contained in the basic composition are replaced with other metal elements can also be used. Only one type of these positive electrode active materials may be used, or a plurality of types may be used in combination.

- positive electrode active materials having an olivine structure are suitable as positive electrode active materials for lithium ion secondary batteries because of their excellent thermal stability.

- a commercially available product may be purchased, or the method described in the following literature may be used as a reference.

- the positive electrode active material having an olivine structure one coated with carbon is preferable.

- LiaMbPO4 ( M is Mn , Fe, Co, Ni, Cu, Mg, Zn, V, Ca, Sr, Ba, Ti, Al; is at least one element selected from Si, B, Te, and Mo. a satisfies 0.9 ⁇ a ⁇ 1.2, and b satisfies 0.6 ⁇ b ⁇ 1.1).

- Examples of the range of a include 0.95 ⁇ a ⁇ 1.1 and 0.97 ⁇ a ⁇ 1.05.

- M in LiaMbPO4 is preferably at least one element selected from Mn, Fe, Co, Ni, Mg, V, and Te, and M is composed of two or more elements. is more preferred. More preferably M is selected from Mn, Fe and V. b preferably satisfies 0.95 ⁇ b ⁇ 1.05.

- the ranges of x and y are 0.5 ⁇ x ⁇ 0.9, 0.1 ⁇ y ⁇ 0.5, 0.6 ⁇ x ⁇ 0.8, 0.2 ⁇ y ⁇ 0.4, and Examples include 0.7 ⁇ x ⁇ 0.8 and 0.2 ⁇ y ⁇ 0.3.

- LiFePO 4 is widely used as a positive electrode active material having an olivine structure, but LiMn x Fe y PO 4 in which Mn and Fe coexist is known to have a higher reaction potential than LiFePO 4 .

- the positive electrode active material layer may contain additives such as a conductive aid, a binder, and a dispersant in addition to the positive electrode active material.

- additives such as a conductive aid, a binder, and a dispersant in addition to the positive electrode active material. Examples of the proportion of the positive electrode active material in the positive electrode active material layer are within the range of 70 to 99% by mass, within the range of 80 to 98% by mass, and within the range of 90 to 97% by mass.

- a conductive aid is added to increase the conductivity of the electrode. Therefore, the conductive aid may be added arbitrarily when the conductivity of the electrode is insufficient, and may not be added when the conductivity of the electrode is sufficiently excellent.

- the conductive aid may be any chemically inactive electron conductor, and examples include carbon black, graphite, vapor grown carbon fiber, carbon nanotube, and various metal particles, which are carbonaceous fine particles. be done. Examples of carbon black include acetylene black, Ketjenblack (registered trademark), furnace black, and channel black. These conductive aids can be added to the positive electrode active material layer singly or in combination of two or more.

- the blending amount of the conductive aid is not particularly limited.

- the proportion of the conductive aid in the positive electrode active material layer is preferably in the range of 1 to 7% by mass, more preferably in the range of 2 to 6% by mass, and even more preferably in the range of 3 to 5% by mass.

- Binders serve to bind the positive electrode active material and conductive aid to the surface of the current collector.

- Binders include fluorine-containing resins such as polyvinylidene fluoride, polytetrafluoroethylene, and fluororubber; thermoplastic resins such as polypropylene and polyethylene; imide resins such as polyimide and polyamideimide; alkoxysilyl group-containing resins; Examples include meth)acrylate resins, polyacrylic acid, polyvinyl alcohol, polyvinylpyrrolidone, carboxymethylcellulose, and styrene-butadiene rubber.

- the blending amount of the binder is not particularly limited.

- the proportion of the binder in the positive electrode active material layer is preferably in the range of 0.5 to 7% by mass, more preferably in the range of 1 to 5% by mass, and even more preferably in the range of 2 to 4% by mass.

- additives such as dispersants other than conductive aids and binders can be used.

- a material that can store and release charge carriers can be used as the negative electrode active material. Therefore, there is no particular limitation as long as it is a simple substance, alloy or compound that can occlude and release charge carriers such as lithium ions.

- the negative electrode active material Li, carbon, silicon, germanium, group 14 elements such as tin, aluminum, group 13 elements such as indium, zinc, group 12 elements such as cadmium, antimony, group 15 elements such as bismuth, magnesium , alkaline earth metals such as calcium, and Group 11 elements such as silver and gold may be used singly.

- alloys or compounds include tin-based materials such as Ag--Sn alloys, Cu--Sn alloys and Co--Sn alloys, carbon-based materials such as various types of graphite, and SiO x ( 0.3 ⁇ x ⁇ 1.6), silicon alone, or a composite of a silicon-based material and a carbon-based material.

- the ratio of the negative electrode active material in the negative electrode active material layer is in the range of 70 to 99% by mass, in the range of 80 to 98.5% by mass, in the range of 90 to 98% by mass, and in the range of 95 to 97.5% by mass.

- the inside can be exemplified.

- the negative electrode active material layer may contain additives such as binders and dispersants in addition to the negative electrode active material.

- additives such as binders and dispersants in addition to the negative electrode active material.

- the binder the one described for the positive electrode may be appropriately adopted.

- additives such as dispersants can be employed.

- the blending amount of the binder is not particularly limited.

- the proportion of the binder in the negative electrode active material layer is preferably in the range of 0.5 to 7% by mass, more preferably in the range of 1 to 5% by mass, and even more preferably in the range of 2 to 4% by mass.

- a conventionally known method such as a roll coating method, a die coating method, a dip coating method, a doctor blade method, a spray coating method, a curtain coating method, etc. is used to form a current collector.

- the active material may be applied to the surface of the body. Specifically, an active material, a solvent, and, if necessary, a binder and a conductive aid are mixed to produce a slurry composition for forming an active material layer, and the composition for forming an active material layer is collected. After coating on the surface of the electric body, it is dried.

- solvents include N-methyl-2-pyrrolidone, methanol, methyl isobutyl ketone, and water. In order to increase the electrode density, it may be compressed after drying.

- the active material layer may be formed using a manufacturing method disclosed in Japanese Patent Application Laid-Open No. 2015-201318. Specifically, a wet granule is obtained by granulating a mixture containing an active material, a binder, and a solvent. An aggregate of the granules is placed in a predetermined mold to obtain a flat molded body. After that, a transfer roll is used to adhere a flat plate-like molded body to the surface of the current collector, thereby forming an active material layer.

- an olivine structure can be selected as the positive electrode active material, and graphite can be selected as the negative electrode active material.

- a lithium ion secondary battery comprising a positive electrode comprising a positive electrode active material having an olivine structure and a negative electrode comprising graphite as a negative electrode active material can be said to have excellent thermal stability, but the capacity per unit volume of the electrode is low.

- the mass of the positive electrode active material layer existing on the area of 1 square centimeter on one side of the current collector foil of the positive electrode (hereinafter referred to as "positive weight basis weight )

- the mass of the negative electrode active material layer present on the area of 1 square centimeter on one side of the current collector foil of the negative electrode (hereinafter sometimes referred to as “the basis weight of the negative electrode”) increases. .

- the basis weight of the positive electrode is preferably 20 mg/cm 2 or more. Suitable positive electrode weight per unit area is 30 to 200 mg/cm 2 , 35 to 150 mg/cm 2 , 40 to 120 mg/cm 2 , and 50 to 100 mg/cm 2 . .

- the basis weight of the negative electrode is preferably 10 mg/cm 2 or more.

- suitable coating weight of the negative electrode are 15 to 100 mg/cm 2 , 17 to 75 mg/cm 2 , 20 to 60 mg/cm 2 , and 25 to 50 mg/cm 2 . .

- the charge / discharge capacity at a high rate is higher than the charge / discharge capacity at a low rate. If it becomes insufficient, a rate characteristic deterioration phenomenon occurs.

- the phenomenon of rate deterioration is believed to be related to the diffusion resistance of lithium ions in the lithium ion secondary battery, and the diffusion resistance of lithium ions is believed to be related to the viscosity of the electrolyte and the diffusion coefficient of lithium ions in the electrolyte. .