WO2022065286A1 - 接着剤組成物、フィルム状接着剤及び多層フィルム - Google Patents

接着剤組成物、フィルム状接着剤及び多層フィルム Download PDFInfo

- Publication number

- WO2022065286A1 WO2022065286A1 PCT/JP2021/034529 JP2021034529W WO2022065286A1 WO 2022065286 A1 WO2022065286 A1 WO 2022065286A1 JP 2021034529 W JP2021034529 W JP 2021034529W WO 2022065286 A1 WO2022065286 A1 WO 2022065286A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- acid

- adhesive

- polyolefin

- adhesive composition

- mass

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J123/00—Adhesives based on homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Adhesives based on derivatives of such polymers

- C09J123/26—Adhesives based on homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Adhesives based on derivatives of such polymers modified by chemical after-treatment

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B27/08—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/32—Layered products comprising a layer of synthetic resin comprising polyolefins

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J123/00—Adhesives based on homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Adhesives based on derivatives of such polymers

- C09J123/02—Adhesives based on homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Adhesives based on derivatives of such polymers not modified by chemical after-treatment

- C09J123/04—Homopolymers or copolymers of ethene

- C09J123/08—Copolymers of ethene

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J123/00—Adhesives based on homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Adhesives based on derivatives of such polymers

- C09J123/02—Adhesives based on homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Adhesives based on derivatives of such polymers not modified by chemical after-treatment

- C09J123/10—Homopolymers or copolymers of propene

- C09J123/14—Copolymers of propene

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J123/00—Adhesives based on homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Adhesives based on derivatives of such polymers

- C09J123/02—Adhesives based on homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Adhesives based on derivatives of such polymers not modified by chemical after-treatment

- C09J123/16—Elastomeric ethene-propene or ethene-propene-diene copolymers, e.g. EPR and EPDM rubbers

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J151/00—Adhesives based on graft polymers in which the grafted component is obtained by reactions only involving carbon-to-carbon unsaturated bonds; Adhesives based on derivatives of such polymers

- C09J151/06—Adhesives based on graft polymers in which the grafted component is obtained by reactions only involving carbon-to-carbon unsaturated bonds; Adhesives based on derivatives of such polymers grafted on to homopolymers or copolymers of aliphatic hydrocarbons containing only one carbon-to-carbon double bond

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J7/00—Adhesives in the form of films or foils

- C09J7/20—Adhesives in the form of films or foils characterised by their carriers

- C09J7/22—Plastics; Metallised plastics

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J7/00—Adhesives in the form of films or foils

- C09J7/30—Adhesives in the form of films or foils characterised by the adhesive composition

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/24—All layers being polymeric

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2270/00—Resin or rubber layer containing a blend of at least two different polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/30—Properties of the layers or laminate having particular thermal properties

- B32B2307/306—Resistant to heat

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/50—Properties of the layers or laminate having particular mechanical properties

- B32B2307/54—Yield strength; Tensile strength

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/732—Dimensional properties

- B32B2307/737—Dimensions, e.g. volume or area

- B32B2307/7375—Linear, e.g. length, distance or width

- B32B2307/7376—Thickness

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2405/00—Adhesive articles, e.g. adhesive tapes

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2301/00—Additional features of adhesives in the form of films or foils

- C09J2301/30—Additional features of adhesives in the form of films or foils characterized by the chemical, physicochemical or physical properties of the adhesive or the carrier

- C09J2301/312—Additional features of adhesives in the form of films or foils characterized by the chemical, physicochemical or physical properties of the adhesive or the carrier parameters being the characterizing feature

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2451/00—Presence of graft polymer

Definitions

- the present invention relates to an adhesive composition that can be suitably used for adhering various parts, a film-like adhesive formed by processing an adhesive composition into a film, and a multilayer film using a film-like adhesive.

- Polyolefins typified by polypropylene are lightweight, easy to mold, and have excellent chemical stability such as water resistance, oil resistance, acid resistance, and alkali resistance. For this reason, polyolefins are processed into molded products, sheets or films as hot melt adhesives, and are used for bonding various parts.

- the merit of using the thermoplastic polyolefin as an adhesive is that the bonding operation is easy and the bonding can be performed in a short time, which is particularly effective in industrial production.

- polyolefins are extremely stable in storage and have low toxicity and fire risk, so they are easy to manage.

- Polyolefin is a highly hydrophobic resin and has low adhesiveness to inorganic substances such as metal and glass as it is.

- Polyolefins with introduced hydrophilic groups are commonly used to bond inorganic substances.

- a method for introducing a hydrophilic group a method of copolymerizing a monomer having a hydrophilic group together with an olefin monomer and a method of graft-modifying a polyolefin with a monomer having a hydrophilic group are known. ..

- propylene where copolymerization of a monomer having a hydrophilic group is difficult, the latter method is often adopted.

- a carboxylic acid or carboxylic acid anhydride is used as a monomer having a hydrophilic group, and the so-called acid modification of grafting the carboxylic acid or carboxylic acid anhydride to polypropylene can enhance the adhesive force of polypropylene to an inorganic substance. .. Adhesion of inorganic substances by acid-modified polyolefin is also described in the prior art document.

- Patent Document 1 describes acid-modified polypropylene as an adhesive between a metal and a nylon-based resin.

- An object of an embodiment of the present invention is to provide an adhesive composition having high adhesive strength and high adhesive durability in a wide temperature range from low temperature to high temperature even in a high humidity atmosphere and in water.

- the present inventors have studied various methods for improving the adhesive durability to inorganic substances such as metal and glass in water, and completed the present invention.

- the means for solving the above problems include the following aspects.

- the polyolefin (a1) contains 0.2 to 5 parts by mass of the acid-modified polyolefin (A) graft-modified with the acid compound (a2) with respect to 100 parts by mass.

- the acid compound (a2) is selected from the group consisting of unsaturated carboxylic acids, unsaturated carboxylic acid anhydrides, and combinations thereof.

- the polyolefin (a1) is selected from the group consisting of polyethylene and polypropylene polymer blends, propylene-ethylene copolymers, and combinations thereof.

- the mass ratio of ethylene unit to propylene unit (ethylene unit / propylene unit) contained in the polyolefin (a1) is in the range of 15/85 to 35/65.

- the adhesive composition according to [1] wherein the content of the acid-modified polyolefin (A) is 60% by mass or more.

- an adhesive composition that imparts high adhesive strength and high adhesive durability in a wide temperature range from low temperature to high temperature even in a high humidity atmosphere and in water.

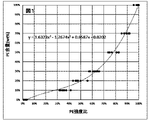

- FIG. 1 is a calibration curve for converting the absorbance ratio of ethylene unit and propylene unit into a mass ratio.

- the adhesive composition contains an acid-modified polyolefin (A).

- the acid-modified polyolefin (A) is an acid compound in which the polyolefin (a1), particularly the unmodified polyolefin (a1), is selected from the group consisting of unsaturated carboxylic acids, unsaturated carboxylic acid anhydrides, and combinations thereof (the acid compound). It is a polyolefin graft-modified in a2).

- the acid-modified polyolefin (A) may partially contain a polyolefin (a1) that has not been graft-modified with the acid compound (a2).

- the acid-modified polyolefin (A) is grafted with an acid compound (a2) in which the polyolefin (a1) and the polyolefin (a1) are selected from the group consisting of unsaturated carboxylic acids, unsaturated carboxylic acid anhydrides, and combinations thereof. It may be a polyolefin composed of a modified polyolefin.

- the graft-modified polyolefin generally has a polyolefin chain based on the polyolefin (a1) and a graft chain which is a polymer of the acid compound (a2).

- the polyolefin (a1) used as a raw material for the acid-modified polyolefin (A) is selected from the group consisting of a polymer blend of polyethylene and polypropylene, an ethylene-propylene copolymer, and a combination thereof.

- Polyethylene is a polymer containing ethylene units as a main component, and may be a homopolymer or a copolymer.

- the content of ethylene unit in polyethylene is preferably 50% by mass or more, more preferably 70% by mass or more.

- Specific examples of polyethylene include homopolymers such as low-density polyethylene, high-density polyethylene, and linear low-density polyethylene, ethylene-diene monomer copolymers, ethylene-vinyl acetate copolymers, and ethylene-acrylic acid ester copolymers. , Copolymers such as ethylene-methacrylate copolymers, halogen-modified products such as chlorinated polyethylene and the like.

- Polypropylene is a polymer containing a propylene unit as a main component, and may be a homopolymer or a copolymer.

- the content of the propylene unit in polypropylene is preferably 50% by mass or more, more preferably 70% by mass or more.

- Specific examples of polypropylene include homopolymers such as amorphous polypropylene and crystalline polypropylene, copolymers such as propylene-diene monomer copolymer, and halogen-modified products such as chlorinated polypropylene.

- the ethylene-propylene copolymer is a polymer containing ethylene units and propylene units, and may be composed of only ethylene units and propylene units, or may further contain other monomer units in addition to ethylene units and propylene units. good.

- Examples of the ethylene-propylene copolymer containing other monomer units include an ethylene-propylene-diene monomer copolymer.

- the total amount of ethylene units and propylene units in the ethylene-propylene copolymer is preferably 50% by mass or more, more preferably 70% by mass or more, further preferably 80% by mass or more, particularly preferably 90% by mass or more, and 100% by mass. May be%.

- polyolefin (a1) in addition to physical blends composed of a plurality of components of these resins, reaction blends in which functional groups are reacted between different polymers in a molding machine, graft copolymers composed of a plurality of segments, and blocks are used. Polymers, compositions in which a physical blend using these as a compatibilizer is microdispersed, and the like are also included.

- the total amount of the ethylene unit and the propylene unit is preferably 50% by mass or more, more preferably 70% by mass or more, still more preferably 80% by mass or more, and particularly preferably 80% by mass or more. It is 90% by mass or more, and may be 100% by mass.

- the mass ratio (ethylene unit / propylene unit) of the ethylene unit and the propylene unit contained in the polyolefin (a1) is 15/85 or more, preferably 20/80 or more.

- the mass ratio (ethylene unit / propylene unit) of the ethylene unit and the propylene unit contained in the polyolefin (a1) is 35/65 or less, preferably 30/70 or less.

- the "mass ratio of ethylene unit and propylene unit contained in the polyolefin (a1)" is the total monomer unit contained in polyethylene and polypropylene. It means the mass ratio of ethylene unit and propylene unit.

- the mass ratio of ethylene unit and propylene unit is determined from the absorbance ratio of polyethylene characteristic absorption (719 cm -1 ) and polypropylene characteristic absorption (1167 cm -1 ) in the IR spectrum. Specifically, a calibration curve for converting the absorbance ratio of ethylene unit to propylene unit into a mass ratio is used.

- the calibration curve can be created by blending commercially available polyethylene and polypropylene in various ratios and plotting the blending ratio and the absorbance ratio.

- the mass ratio of polyethylene to polypropylene is preferably 15/85 or more, more preferably 20/80 or more.

- the mass ratio of polyethylene to polypropylene is preferably 35/65 or less, more preferably 30/70 or less.

- the polyolefin (a1) may contain a monomer unit other than the ethylene unit and the propylene unit.

- monomers that form monomer units other than ethylene units and propylene units include ⁇ -olefins such as 1-butene, 1-pentene, 1-hexene, and 4-methylpentene-1, butadiene, isoprene, and chloroprene.

- examples thereof include unsaturated carboxylic acids such as the diene monomer, vinyl acetate, acrylic acid ester, acrylic acid, methacrylic acid and methacrylic acid ester and derivatives thereof, and aromatic vinyl compounds such as styrene.

- the content of the monomer unit other than the ethylene unit and the propylene unit in the polyolefin (a1) is preferably 30% by mass or less, more preferably 20% by mass or less, and particularly preferably 10% by mass or less. If the content of the monomer unit other than the ethylene unit and the propylene unit is in such a range, the properties such as water resistance, chemical resistance, and durability of the polyolefin are enhanced, and the polyolefin can be produced at low cost. It will be possible.

- Examples of the method for producing the polyolefin (a1) include a known production method using a polymerization catalyst.

- the polymerization catalyst include a Ziegler catalyst and a metallocene catalyst, and examples of the polymerization method include slurry polymerization and vapor phase polymerization.

- Impact-resistant polypropylene, called a polypropylene block polymer is substantially a mixture of polypropylene and a propylene-ethylene random copolymer, the first step in obtaining a homopolymer of propylene and the propylene-ethylene random copolymer. It can be manufactured by a process consisting of a second step.

- the acid compound (a2) is selected from the group consisting of unsaturated carboxylic acids, unsaturated carboxylic acid anhydrides, and combinations thereof.

- the unsaturated carboxylic acid is a compound having an ethylenic double bond and a carboxylic acid group in the same molecule, and examples thereof include various unsaturated monocarboxylic acids and unsaturated dicarboxylic acids.

- unsaturated monocarboxylic acids include acrylic acid, methacrylic acid, crotonic acid, isocrotonic acid and the like.

- unsaturated dicarboxylic acids include maleic acid, fumaric acid, itaconic acid, citraconic acid, nadic acid, endic acid and the like.

- the unsaturated carboxylic acid anhydride is a compound having an ethylenic double bond and a carboxylic acid anhydride group in the same molecule, and examples thereof include the acid anhydride of the unsaturated dicarboxylic acid.

- acid anhydride of unsaturated dicarboxylic acid examples include maleic anhydride, fumaric anhydride, itaconic anhydride, citraconic anhydride, nagic acid anhydride and endic acid anhydride.

- maleic acid and maleic anhydride are preferably used because of their high denaturing effect, and maleic anhydride is particularly preferably used.

- These acid compounds (a2) may be used alone or in combination of two or more.

- a method of graft denaturation a known method can be adopted.

- a method of graft-reacting an acid compound (a2) with a polyolefin (a1) in a molten state or a solution state in the presence of a radical polymerization initiator such as an organic peroxide or an aliphatic azo compound can be mentioned.

- the temperature of the graft reaction is preferably 80 to 160 ° C. when the reaction is carried out in a solution state, and 150 to 300 ° C. when the reaction is carried out in a molten state.

- the reaction rate is high above the lower limit of the above reaction temperature range, and the decrease in the molecular weight of the resin is small below the upper limit of the above reaction temperature range, and the obtained acid-modified polyolefin (A) is obtained.

- the radical polymerization initiator to be used may be selected from commercially available organic peroxides in consideration of the reaction temperature and the like.

- the unreacted acid compound (a2) is prepared by a known method such as distillation under reduced pressure in order to suppress an adverse effect on the adhesive strength. It is preferable to remove it.

- the acid-modified polyolefin (A) may partially contain an unmodified polyolefin (a1) such as polyethylene, polypropylene, or an ethylene-propylene copolymer.

- the amount of the acid compound (a2) grafted to the polyolefin (a1) in the graft modification is 0.2 parts by mass or more, preferably 0.4 parts by mass, based on 100 parts by mass of the polyolefin (a1) before the acid modification. It is more than a mass part.

- the amount of the acid compound grafted in such a range is present, the adhesiveness of the adhesive composition can be enhanced.

- the amount of the acid compound (a2) grafted to the acid-modified polyolefin (A) in the graft modification is 5 parts by mass or less, preferably 2 parts by mass or less, based on 100 parts by mass of the polyolefin (a1).

- the amount of the acid compound (a2) grafted in such a range is present, the adhesive durability of the adhesive composition in water can be enhanced.

- the acid value of the acid-modified polyolefin (A) is preferably 0.041 meq / g or more, and more preferably 0.082 meq / g or more.

- the acid value of the acid-modified olefin (A) is preferably 1.02 meq / g or less, and more preferably 0.408 meq / g or less.

- the melting point of the acid-modified polyolefin (A) is preferably 130 ° C. or higher, more preferably 135 ° C. or higher. When the melting point of the acid-modified polyolefin (A) is within such a range, the heat resistance of the adhesive composition and the adhesive strength at high temperatures are improved.

- the melting point of the acid-modified polyolefin (A) is preferably 150 ° C. or lower, more preferably 145 ° C. or lower. When the melting point of the acid-modified polyolefin (A) is in such a range, the adhesive durability of the adhesive composition at a low temperature is improved.

- the melting point is the endothermic heat generated in the process of using a differential scanning calorimeter (DSC), holding the product at 180 ° C for several minutes, cooling it to 0 ° C, and then raising the temperature to 200 ° C by 10 ° C per minute. It means the temperature of the peak peak.

- DSC differential scanning calorimeter

- the melt flow rate of the acid-modified polyolefin (A) is preferably 3 g / 10 min or more, more preferably 7 g / 10 min or more.

- the melt flow rate of the acid-modified polyolefin (A) is preferably 50 g / 10 min or less, more preferably 30 g / 10 min or less.

- the melt flow rate means a value measured at a resin temperature of 230 ° C. and a load of 2.16 kg in accordance with JIS K7210: 2014.

- the content of the acid-modified polyolefin (A) in the adhesive composition is preferably 60% by mass or more, more preferably 70% by mass or more, particularly preferably 80% by mass or more, and may be 100% by mass.

- the adhesive composition contains polymers other than the acid-modified polyolefin (A) (hereinafter, other polymers) for the purpose of improving adhesive strength at low temperatures, adhesive durability, improvement of molding stability, and compatibility between resins. ) Can be added.

- other polymers include ethylene-propylene rubber, styrene-butadiene-styrene block copolymer and its hydrogenated product, styrene-isoprene-styrene block copolymer and its hydrogenated product, and styrene-isobutylene-styrene.

- examples thereof include styrene-based block polymers such as block copolymers and their hydrogenated products.

- the lower limit of the content of the other polymer in the adhesive composition is preferably 1% by mass or more, more preferably 2% by mass or more, and particularly preferably 3% by mass or more.

- the amount of the other polymer added is in such a range, the improvement effect of the other polymer is enhanced.

- the upper limit of the content of the other polymer in the adhesive composition is preferably 20% by mass or less, more preferably 15% by mass or less, and particularly preferably 10% by mass or less.

- the adhesive composition can obtain high heat resistance and high adhesive strength at high temperature.

- Adhesive compositions include antioxidants, UV absorbers, fillers, reinforcing fibers, mold release agents, processing aids, flame retardants, plasticizers, nucleating agents, antistatic agents, pigments, dyes, foaming agents, etc. And additives selected from the group consisting of combinations thereof may further be included.

- the storage elastic modulus at 23 ° C. measured by a leometer of the adhesive composition is 130 MPa or more, preferably 150 MPa or more, and more preferably 175 MPa or more. When the storage elastic modulus is in such a range, the adhesive strength of the adhesive composition at a high temperature is improved.

- the storage elastic modulus of the adhesive composition at 23 ° C. is 330 MPa or less, preferably 300 MPa or less, and more preferably 200 MPa or less. When the storage elastic modulus is in such a range, the adhesive strength of the adhesive composition at a low temperature is improved.

- the measurement conditions of the leometer are a frequency of 1 Hz, a strain range of 0.01 to 0.2%, and a heating rate of 2 ° C./min, and the storage elastic modulus described in the present specification is under these conditions. It is a storage elastic modulus at 23 ° C. when the temperature is raised from ⁇ 50 ° C. to 180 ° C.

- adjusting the blending amount of amorphous polyolefin such as ethylene-propylene rubber or styrene block copolymer can be mentioned. By increasing these, the storage elastic modulus can be lowered.

- the yield elastic modulus at 23 ° C. in the tensile test of the adhesive composition is 30 MPa or more, preferably 50 MPa or more, and more preferably 60 MPa or more.

- the yield elastic modulus at 23 ° C. in the tensile test of the adhesive composition is 120 MPa or less, preferably 100 MPa or less, and more preferably 80 MPa or less.

- the adhesive strength of the adhesive composition at a low temperature is improved.

- the measurement conditions of the tensile test are a distance between jigs of 35 mm and a tensile speed of 50 mm / min at the start of the test, and the yield elastic modulus described in the present specification is 100 to 300 ⁇ m in thickness and size under these conditions. It is a yield elastic modulus measured by a commercially available tensile tester using a strip-shaped test piece of 10 mm ⁇ 60 mm. A strip-shaped test piece having a thickness of 100 to 300 ⁇ m and a size of 10 mm ⁇ 60 mm can be produced by press molding or the like.

- the yield elastic modulus means the elastic modulus obtained by dividing the stress (yield stress) at the yield point (the point where the stress shows the maximum value) by the strain (yield strain).

- the method of adjusting the yield elastic modulus within an appropriate range there is an example of adjusting the blending amount of an amorphous polyolefin such as ethylene-propylene rubber or styrene block copolymer. By increasing these, the yield elastic modulus can be lowered.

- an amorphous polyolefin such as ethylene-propylene rubber or styrene block copolymer.

- the tensile breaking strain at 23 ° C. and ⁇ 10 ° C. in the tensile test of the adhesive composition is preferably 200% or more.

- the adhesive composition is excellent in adhesive stability at low temperature.

- the tensile test is the same as that carried out in the above-mentioned measurement of yield modulus.

- the upper limit of the tensile breaking strain is not particularly limited, but for example, the tensile breaking strain at 23 ° C. and ⁇ 10 ° C. in the tensile test of the adhesive composition may be 500% or less.

- the yield strain at 23 ° C. in the tensile test of the adhesive composition is preferably 11% or more, more preferably 12% or more, and particularly preferably 15% or more. When there is a yield strain at 23 ° C. in such a range, the adhesive composition is excellent in adhesive strength at low temperature.

- the tensile test is the same as that carried out in the above-mentioned measurement of yield modulus.

- the upper limit of the yield strain is not particularly limited, but for example, the yield strain at 23 ° C. in the tensile test of the adhesive composition may be 30% or less.

- the adhesive composition can be molded into a film and used as a film-like hot melt adhesive.

- a film-like hot melt adhesive By using a film-like hot melt adhesive, it is possible to dramatically increase the productivity of the bonding / sealing process, and a large number of bonded bodies with fine, precise and complicated fusion sites can be produced in a short time and at low cost. Can be manufactured.

- the film-like hot melt adhesive consists of an adhesive composition, but may contain other components such as moisture.

- the content of the adhesive composition in the film-shaped hot melt adhesive is preferably 50% by mass or more, more preferably 70% by mass or more, and particularly preferably 90% by mass or more.

- the thickness of the film-like hot melt adhesive is preferably 10 ⁇ m or more, more preferably 20 ⁇ m or more. When the film-like hot-melt adhesive has a thickness in such a range, the film-like hot-melt adhesive has high adhesiveness.

- the thickness of the film-like hot melt adhesive is preferably 300 ⁇ m or less, more preferably 200 ⁇ m or less. When the film-shaped hot-melt adhesive has a thickness in such a range, the film-shaped hot-melt adhesive can exhibit excellent bonding performance, productivity, and economy. In addition, it is possible to prevent the film-like hot-melt adhesive from squeezing out when the film-like hot-melt adhesive is pressure-bonded to the adherend.

- a film-like hot melt adhesive is used as the surface layer of a multilayer film, it is possible to obtain even higher performance and higher performance adhesive / sealing members.

- a multilayer film including a surface layer formed of a film-like hot melt adhesive and a base layer containing a heat-resistant resin is particularly preferably used.

- the surface layer is a layer laminated on the base material layer, and may be formed only on one surface of the base material layer or may be formed on both sides of the base material layer. Further, a primer layer may be provided between the surface layer and the base material layer.

- the heat-resistant resin preferably has a softening temperature of 130 ° C. or higher. When the softening temperature of the heat-resistant resin is 130 ° C. or higher, the heat resistance, rigidity and dimensional stability of the multilayer film are improved.

- the softening temperature is a temperature at which the storage elastic modulus measured by a leometer is 10 MPa or less. The measurement conditions of the leometer are the same as those used in the above-mentioned measurement of the storage elastic modulus.

- the content of the heat-resistant resin in the base material layer is not particularly limited, but is preferably 50% by mass or more, more preferably 70% by mass or more, particularly preferably 90% by mass or more, and may be 100% by mass. ..

- the heat-resistant resin include polyester resins such as polyethylene terephthalate (PET), polybutylene terephthalate (PBT), polyethylene naphthalate (PEN), and polyarylate, cyclic olefin polymers (COP), cycloolefin copolymers, and methylpentene polymers.

- Polyester resins such as polyethylene terephthalate (PET), polybutylene terephthalate (PBT), polyethylene naphthalate (PEN), and polyarylate, cyclic olefin polymers (COP), cycloolefin copolymers, and methylpentene polymers.

- Polyolefin polymers such as (TPX), nylon-6, nylon-6,6, holiamide resins such as aromatic polyamides, polyetheramides, polyamideimides, polyimides, polyether ether ketones, polyether ketones, polyketones, polysulfones, polyethers.

- an alloy containing 50% or more of polyethylene naphthalate, cyclic olefin polymer, cycloolefin copolymer, polyphenylene ether, and / or polyamide resin is preferably used from the viewpoint of heat resistance, rigidity, and dimensional stability.

- the thickness of the surface layer is the same as the thickness of the film-like hot melt adhesive described above, but 10 to 100 ⁇ m is particularly preferable. By setting the thickness of the surface layer to 10 ⁇ m or more, the multilayer film can have good adhesiveness. By setting the thickness of the surface layer to 100 ⁇ m or less, the multilayer film can have good heat resistance and mechanical strength.

- the thickness of the base material layer is particularly preferably 50 to 300 ⁇ m.

- the multilayer film can have good heat resistance, rigidity, and dimensional stability.

- the thickness of the base material layer By setting the thickness of the base material layer to 300 ⁇ m or less, it is possible to reduce the manufacturing cost and impart appropriate flexibility to the multilayer film.

- a film-like hot melt adhesive or a multilayer film using the same can be adhered to various adherends such as metal, glass, and plastic to prepare a bonded body.

- the metal used as the adherend may be a generally known metal plate, metal flat plate or metal foil, and iron, copper, aluminum, lead, zinc, titanium, chrome, stainless steel and the like can be used. Of these, iron, aluminum, titanium and stainless steel are particularly preferable.

- the acid-modified polyolefin (A) and other components are melt-kneaded with an extruder, a Banbury mixer, a hot roll, etc., and the strands extruded from the nozzle holes of the die head are pulled. It can be manufactured by a method such as cooling and solidifying with water and cutting into pellets.

- the temperature of melt kneading is preferably 150 to 270 ° C., more preferably 170 to 250 ° C., and the kneading time is usually 0.5 to 20 minutes, preferably 1 to 15 minutes.

- the adhesive composition thus obtained is a molded product having various shapes according to an application by a conventionally known method, for example, compression molding, injection molding, extrusion molding, multi-layer extrusion molding, deformed extrusion molding or hollow molding.

- a resin sheet or film suitable for bonding or sealing is produced, it may be melted by a uniaxial extruder, formed into a sheet having a predetermined thickness through a roll, cooled and wound.

- parts means parts by mass and “%” means mass% in the following.

- PP means polypropylene

- PE means polyethylene

- MAH means maleic anhydride.

- An IR spectrum was obtained from the cut surface of the resin sheet by the total reflection absorption method (ATR method) using Spectrum 100 manufactured by PerkinElmer.

- the PE absorbance ratio was determined from the absorbances of 719 cm -1 (PE characteristic absorption) and 1167 cm -1 (PP characteristic absorption) of the obtained IR spectra.

- a calibration curve was created by plotting this absorbance ratio and the blending ratio during melt kneading.

- the results of the PE compounding ratio and the PE absorbance ratio are shown in Table 1, and the plot results are shown in FIG.

- the number of repetitions was set to 4 or more in consideration of measurement error.

- the approximate curve of this plot was used as a calibration curve to determine the PE / PP blending ratio.

- Maleic anhydride-modified polyolefins A to F were molded into a resin sheet having a thickness of 2 mm, and the IR spectrum was measured in the same manner with the cross section as the measurement surface. Based on the obtained IR spectrum, the PE / PP compounding ratio was determined using the prepared calibration curve.

- maleic anhydride contained was quantified by neutralization titration.

- neutralization titration male anhydride-modified polyolefins A to F, which are samples, were heated and dissolved in xylene, and the obtained solution was titrated with an ethanol solution of potassium hydroxide using phenol red as an indicator.

- Table 2 shows the results of the estimated PE / PP blending ratio and the amount of maleic anhydride.

- Test test A strip-shaped test piece having a size of 10 mm ⁇ 60 mm was cut out from a sheet of maleic anhydride-modified polyolefins A to F having a thickness of 100 to 300 ⁇ m prepared using a tabletop press molding machine to prepare a test piece for a tensile test.

- a tensile test device (Instron 5566A) manufactured by Instron was used as a tensile tester, and a tensile test was conducted at a tensile speed of 50 mm / min with a distance between jigs of 35 mm.

- the point where the stress reaches the maximum value through the initial elastic region is defined as the yield point

- the stress at the yield point is defined as the yield stress

- the strain at the yield point is defined as the yield strain.

- the strain was calculated assuming that the initial length of the distance between jigs was 35 mm.

- the elastic modulus obtained by dividing the yield stress by the yield strain was defined as the yield elastic modulus.

- Table 3 shows the yield stress, yield strain, yield modulus, fracture strain, and yield stress and fracture strain measured at ⁇ 10 ° C. as the mechanical properties of the maleic anhydride-modified polyolefins A to F.

- melt flow rate The melt flow rate (MFR) was measured using a commercially available melt indexer (G-02 manufactured by Toyo Seiki Seisakusho Co., Ltd.) in accordance with JIS K7210: 2014 at a resin temperature of 230 ° C. and a load of 2.16 kg.

- Table 3 shows the melt flow rates of the maleic anhydride-modified polyolefins A to F.

- Table 3 shows the results of the constant load immersion test of the maleic anhydride-modified polyolefins A to F.

- the maleic anhydride-modified polyolefins C, D, and E have long peel strength and a long drop time in the constant load immersion test at both low and high temperatures, and have excellent adhesiveness and adhesive durability in water. It turns out to be excellent.

- the adhesive composition of the present invention as well as the film-like adhesive and the multilayer film obtained by processing the adhesive composition, are useful for adhering and sealing metal materials, and the resulting bonded body is continuously or intermittently in contact with moisture. It is suitably used for possible applications.

- Insulation material for, vehicle insulation, fuel cell water distribution pipe, decorative molded product, water cooling tank, boiler exterior case, printer ink peripheral parts / members, water piping, joints, secondary battery alkaline storage battery tank, various layered batteries Gasket sealing material and the like can be mentioned.

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Adhesives Or Adhesive Processes (AREA)

- Compositions Of Macromolecular Compounds (AREA)

- Laminated Bodies (AREA)

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US18/246,139 US12258493B2 (en) | 2020-09-23 | 2021-09-21 | Adhesive composition, film-like adhesive and multilayer film |

| KR1020237013563A KR102880624B1 (ko) | 2020-09-23 | 2021-09-21 | 접착제 조성물, 필름 형상 접착제 및 다층 필름 |

| EP21872415.1A EP4219151A4 (en) | 2020-09-23 | 2021-09-21 | ADHESIVE COMPOSITION, FILM-TYPE ADHESIVE AND MULTILAYER FILM |

| JP2022551985A JP7708115B2 (ja) | 2020-09-23 | 2021-09-21 | 接着剤組成物、フィルム状接着剤及び多層フィルム |

| CA3193479A CA3193479A1 (en) | 2020-09-23 | 2021-09-21 | Adhesive composition, film-like adhesive, and multilayer film |

| CN202180064799.9A CN116209568A (zh) | 2020-09-23 | 2021-09-21 | 粘接剂组合物、膜状粘接剂及多层膜 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2020158485 | 2020-09-23 | ||

| JP2020-158485 | 2020-09-23 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2022065286A1 true WO2022065286A1 (ja) | 2022-03-31 |

Family

ID=80846472

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2021/034529 Ceased WO2022065286A1 (ja) | 2020-09-23 | 2021-09-21 | 接着剤組成物、フィルム状接着剤及び多層フィルム |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US12258493B2 (enExample) |

| EP (1) | EP4219151A4 (enExample) |

| JP (1) | JP7708115B2 (enExample) |

| KR (1) | KR102880624B1 (enExample) |

| CN (1) | CN116209568A (enExample) |

| CA (1) | CA3193479A1 (enExample) |

| WO (1) | WO2022065286A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2024059996A1 (zh) * | 2022-09-20 | 2024-03-28 | 宁德时代新能源科技股份有限公司 | 复合膜及其制备方法、电池模块、电池包和用电装置 |

Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2006036920A (ja) * | 2004-07-27 | 2006-02-09 | Toyo Kasei Kogyo Co Ltd | 水性樹脂組成物およびその製造方法 |

| JP2011177992A (ja) | 2010-02-26 | 2011-09-15 | Mitsubishi Chemicals Corp | 積層体およびそれを使用した包装材料 |

| WO2011129080A1 (ja) * | 2010-04-16 | 2011-10-20 | 株式会社カネカ | 接着性樹脂組成物および成型体 |

| JP2013532197A (ja) * | 2010-05-10 | 2013-08-15 | ダウ グローバル テクノロジーズ エルエルシー | 接着促進剤システム、およびそれを製造する方法 |

| JP2014208784A (ja) * | 2013-03-28 | 2014-11-06 | 三菱化学株式会社 | 接着性樹脂組成物及び積層体 |

| WO2015046378A1 (ja) * | 2013-09-27 | 2015-04-02 | 東亞合成株式会社 | 接着剤組成物及びそれを用いた熱融着性複合部材 |

| JP2015105294A (ja) * | 2013-11-29 | 2015-06-08 | 日本製紙株式会社 | 変性ポリオレフィン系樹脂 |

| JP2017095685A (ja) * | 2015-10-23 | 2017-06-01 | ボスティク エス.アー. | 弾性アタッチメント用のホットメルト接着剤組成物 |

| JP2017109613A (ja) | 2015-12-16 | 2017-06-22 | 株式会社ブリヂストン | タイヤ |

| WO2018221037A1 (ja) * | 2017-05-29 | 2018-12-06 | 東洋紡株式会社 | ポリオレフィン系接着剤組成物 |

| JP2019099769A (ja) * | 2017-12-07 | 2019-06-24 | 東洋インキScホールディングス株式会社 | 接着性樹脂組成物、それを用いたシート、容器用蓋材及び容器 |

| JP2020158485A (ja) | 2015-10-02 | 2020-10-01 | エフ.ホフマン−ラ ロシュ アーゲーF. Hoffmann−La Roche Aktiengesellschaft | 二重特異性抗ヒトa−ベータ/ヒトトランスフェリン受容体抗体及びその使用方法 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB8911609D0 (en) * | 1989-05-19 | 1989-07-05 | Bp Chem Int Ltd | Adhesive blends and multi-layered structures comprising the adhesive blends |

| JPWO2007086425A1 (ja) * | 2006-01-26 | 2009-06-18 | 三井化学株式会社 | 接着剤およびそれを用いた積層体 |

| EP2110408B1 (en) * | 2007-02-02 | 2014-05-07 | Mitsui Chemicals, Inc. | Adhesive and multilayer body using the same |

| JP6015194B2 (ja) * | 2012-07-25 | 2016-10-26 | 油化電子株式会社 | 電池外装用ラミネートフィルム及びその製造方法 |

| JP6859953B2 (ja) * | 2015-10-26 | 2021-04-14 | 東洋紡株式会社 | 接着剤組成物およびホットメルト接着剤 |

| JP6850539B2 (ja) * | 2016-02-25 | 2021-03-31 | 藤森工業株式会社 | 電池外装用積層体、電池外装体及び電池 |

| EP3591019A1 (en) * | 2018-07-02 | 2020-01-08 | E. I. du Pont de Nemours and Company | Universal thermoplastic adhesives for multilayer films |

-

2021

- 2021-09-21 CN CN202180064799.9A patent/CN116209568A/zh active Pending

- 2021-09-21 WO PCT/JP2021/034529 patent/WO2022065286A1/ja not_active Ceased

- 2021-09-21 US US18/246,139 patent/US12258493B2/en active Active

- 2021-09-21 EP EP21872415.1A patent/EP4219151A4/en active Pending

- 2021-09-21 JP JP2022551985A patent/JP7708115B2/ja active Active

- 2021-09-21 CA CA3193479A patent/CA3193479A1/en active Pending

- 2021-09-21 KR KR1020237013563A patent/KR102880624B1/ko active Active

Patent Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2006036920A (ja) * | 2004-07-27 | 2006-02-09 | Toyo Kasei Kogyo Co Ltd | 水性樹脂組成物およびその製造方法 |

| JP2011177992A (ja) | 2010-02-26 | 2011-09-15 | Mitsubishi Chemicals Corp | 積層体およびそれを使用した包装材料 |

| WO2011129080A1 (ja) * | 2010-04-16 | 2011-10-20 | 株式会社カネカ | 接着性樹脂組成物および成型体 |

| JP2013532197A (ja) * | 2010-05-10 | 2013-08-15 | ダウ グローバル テクノロジーズ エルエルシー | 接着促進剤システム、およびそれを製造する方法 |

| JP2014208784A (ja) * | 2013-03-28 | 2014-11-06 | 三菱化学株式会社 | 接着性樹脂組成物及び積層体 |

| WO2015046378A1 (ja) * | 2013-09-27 | 2015-04-02 | 東亞合成株式会社 | 接着剤組成物及びそれを用いた熱融着性複合部材 |

| JP2015105294A (ja) * | 2013-11-29 | 2015-06-08 | 日本製紙株式会社 | 変性ポリオレフィン系樹脂 |

| JP2020158485A (ja) | 2015-10-02 | 2020-10-01 | エフ.ホフマン−ラ ロシュ アーゲーF. Hoffmann−La Roche Aktiengesellschaft | 二重特異性抗ヒトa−ベータ/ヒトトランスフェリン受容体抗体及びその使用方法 |

| JP2017095685A (ja) * | 2015-10-23 | 2017-06-01 | ボスティク エス.アー. | 弾性アタッチメント用のホットメルト接着剤組成物 |

| JP2017109613A (ja) | 2015-12-16 | 2017-06-22 | 株式会社ブリヂストン | タイヤ |

| WO2018221037A1 (ja) * | 2017-05-29 | 2018-12-06 | 東洋紡株式会社 | ポリオレフィン系接着剤組成物 |

| JP2019099769A (ja) * | 2017-12-07 | 2019-06-24 | 東洋インキScホールディングス株式会社 | 接着性樹脂組成物、それを用いたシート、容器用蓋材及び容器 |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP4219151A4 |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2024059996A1 (zh) * | 2022-09-20 | 2024-03-28 | 宁德时代新能源科技股份有限公司 | 复合膜及其制备方法、电池模块、电池包和用电装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP4219151A4 (en) | 2024-10-09 |

| US12258493B2 (en) | 2025-03-25 |

| EP4219151A1 (en) | 2023-08-02 |

| KR20230072492A (ko) | 2023-05-24 |

| CA3193479A1 (en) | 2022-03-31 |

| CN116209568A (zh) | 2023-06-02 |

| JPWO2022065286A1 (enExample) | 2022-03-31 |

| JP7708115B2 (ja) | 2025-07-15 |

| US20240010884A1 (en) | 2024-01-11 |

| KR102880624B1 (ko) | 2025-11-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101027374B (zh) | 衍生自官能化的乙烯共聚物的粘合剂组合物 | |

| JPWO2017104731A1 (ja) | 積層体およびその製造方法、ならびに接着用組成物 | |

| JPH04272950A (ja) | 接着性樹脂組成物 | |

| AU648776B2 (en) | Laminated structures containing adhesive, RF-heatable grafted polymers and blends | |

| JP7415573B2 (ja) | 接着性樹脂組成物及び積層体 | |

| JP6871014B2 (ja) | 脂肪族ポリケトン共押出積層フィルム及びその延伸フィルム、これらを用いた転写フィルム、並びにこれらに用いる脂肪族ポリケトン接着用の接着性樹脂組成物 | |

| JP4699449B2 (ja) | 新規接着剤およびそれを用いた積層体 | |

| US20240301246A1 (en) | Multilayer sheet and production method thereof | |

| WO2022211081A1 (ja) | 多層シート及びその製造方法 | |

| WO2022065286A1 (ja) | 接着剤組成物、フィルム状接着剤及び多層フィルム | |

| JP5104132B2 (ja) | 多層積層体 | |

| JP3724275B2 (ja) | 接着性樹脂組成物及びそれを用いた積層体 | |

| JP6911379B2 (ja) | 接着性樹脂組成物及び積層体 | |

| JP2020111709A (ja) | 接着性樹脂組成物及び積層体 | |

| US20240218210A1 (en) | Multilayer sheet and production method thereof | |

| US20240383240A1 (en) | Multilayer sheet and production method thereof | |

| JP3945140B2 (ja) | 変性エチレン系重合体の製造方法 | |

| JP2002187914A (ja) | 変性エチレン系重合体の製造方法 | |

| JP2024045850A (ja) | ホットメルト接着組成物 | |

| JP2024073857A (ja) | 重合体組成物、単層フィルム及び積層体、並びに単層フィルム及び積層体の製造方法 | |

| JP2006290983A (ja) | カルボジイミド変性芳香族系接着剤およびそれを用いた積層体 | |

| JPS63130649A (ja) | 変性ポリエチレン樹脂組成物 | |

| JP2022029260A (ja) | 接着性樹脂組成物及び積層体 | |

| JP2000290621A (ja) | 接着性重合体組成物 | |

| JPS62280245A (ja) | エチレン系共重合体混合物 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 21872415 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2022551985 Country of ref document: JP Kind code of ref document: A |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 18246139 Country of ref document: US |

|

| ENP | Entry into the national phase |

Ref document number: 3193479 Country of ref document: CA |

|

| ENP | Entry into the national phase |

Ref document number: 20237013563 Country of ref document: KR Kind code of ref document: A |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| ENP | Entry into the national phase |

Ref document number: 2021872415 Country of ref document: EP Effective date: 20230424 |

|

| WWG | Wipo information: grant in national office |

Ref document number: 18246139 Country of ref document: US |