WO2015083416A1 - 撮像装置及び内視鏡 - Google Patents

撮像装置及び内視鏡 Download PDFInfo

- Publication number

- WO2015083416A1 WO2015083416A1 PCT/JP2014/074547 JP2014074547W WO2015083416A1 WO 2015083416 A1 WO2015083416 A1 WO 2015083416A1 JP 2014074547 W JP2014074547 W JP 2014074547W WO 2015083416 A1 WO2015083416 A1 WO 2015083416A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- imaging device

- housing

- heat transfer

- transfer member

- main surface

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B1/00—Instruments for performing medical examinations of the interior of cavities or tubes of the body by visual or photographical inspection, e.g. endoscopes; Illuminating arrangements therefor

- A61B1/04—Instruments for performing medical examinations of the interior of cavities or tubes of the body by visual or photographical inspection, e.g. endoscopes; Illuminating arrangements therefor combined with photographic or television appliances

- A61B1/05—Instruments for performing medical examinations of the interior of cavities or tubes of the body by visual or photographical inspection, e.g. endoscopes; Illuminating arrangements therefor combined with photographic or television appliances characterised by the image sensor, e.g. camera, being in the distal end portion

- A61B1/051—Details of CCD assembly

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B1/00—Instruments for performing medical examinations of the interior of cavities or tubes of the body by visual or photographical inspection, e.g. endoscopes; Illuminating arrangements therefor

- A61B1/00064—Constructional details of the endoscope body

- A61B1/0011—Manufacturing of endoscope parts

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B1/00—Instruments for performing medical examinations of the interior of cavities or tubes of the body by visual or photographical inspection, e.g. endoscopes; Illuminating arrangements therefor

- A61B1/00112—Connection or coupling means

- A61B1/00121—Connectors, fasteners and adapters, e.g. on the endoscope handle

- A61B1/00124—Connectors, fasteners and adapters, e.g. on the endoscope handle electrical, e.g. electrical plug-and-socket connection

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B1/00—Instruments for performing medical examinations of the interior of cavities or tubes of the body by visual or photographical inspection, e.g. endoscopes; Illuminating arrangements therefor

- A61B1/005—Flexible endoscopes

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B1/00—Instruments for performing medical examinations of the interior of cavities or tubes of the body by visual or photographical inspection, e.g. endoscopes; Illuminating arrangements therefor

- A61B1/12—Instruments for performing medical examinations of the interior of cavities or tubes of the body by visual or photographical inspection, e.g. endoscopes; Illuminating arrangements therefor with cooling or rinsing arrangements

- A61B1/128—Instruments for performing medical examinations of the interior of cavities or tubes of the body by visual or photographical inspection, e.g. endoscopes; Illuminating arrangements therefor with cooling or rinsing arrangements provided with means for regulating temperature

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B23/00—Telescopes, e.g. binoculars; Periscopes; Instruments for viewing the inside of hollow bodies; Viewfinders; Optical aiming or sighting devices

- G02B23/24—Instruments or systems for viewing the inside of hollow bodies, e.g. fibrescopes

- G02B23/2476—Non-optical details, e.g. housings, mountings, supports

- G02B23/2492—Arrangements for use in a hostile environment, e.g. a very hot, cold or radioactive environment

-

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04N—PICTORIAL COMMUNICATION, e.g. TELEVISION

- H04N23/00—Cameras or camera modules comprising electronic image sensors; Control thereof

- H04N23/50—Constructional details

- H04N23/52—Elements optimising image sensor operation, e.g. for electromagnetic interference [EMI] protection or temperature control by heat transfer or cooling elements

-

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04N—PICTORIAL COMMUNICATION, e.g. TELEVISION

- H04N23/00—Cameras or camera modules comprising electronic image sensors; Control thereof

- H04N23/50—Constructional details

- H04N23/54—Mounting of pick-up tubes, electronic image sensors, deviation or focusing coils

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B1/00—Instruments for performing medical examinations of the interior of cavities or tubes of the body by visual or photographical inspection, e.g. endoscopes; Illuminating arrangements therefor

- A61B1/00163—Optical arrangements

-

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04N—PICTORIAL COMMUNICATION, e.g. TELEVISION

- H04N23/00—Cameras or camera modules comprising electronic image sensors; Control thereof

- H04N23/50—Constructional details

- H04N23/555—Constructional details for picking-up images in sites, inaccessible due to their dimensions or hazardous conditions, e.g. endoscopes or borescopes

Definitions

- the present invention relates to an imaging device in which an imaging device and a heat transfer member joined to the imaging device are housed in a housing, and an endoscope having the imaging device.

- the imaging element which consists of a semiconductor in which the light-receiving part was formed in the main surface is small, it is used for an electronic endoscope etc. However, when the temperature of the imaging device rises during operation, the imaging device may be degraded or the image quality may be deteriorated due to thermal noise.

- the imaging device which suppresses the temperature rise of an imaging device is reported by heat-transferring the heat

- one end of a flexible substrate is connected to a CCD (imaging element), and the other end of the flexible substrate is on the inner wall surface of a protective frame made of metal having high thermal conductivity.

- An electronic endoscope having an imaging device in close proximity is disclosed.

- the protective frame has a spring portion and reliably contacts the inner circumferential surface of the cylindrical portion. As a result, the heat generated from the CCD is dissipated to the protective frame.

- An object of the present invention is to provide an imaging device that efficiently dissipates heat generated by an imaging device, and an endoscope having the imaging device.

- An imaging device includes an imaging element having a first main surface and a second main surface, and a light receiving unit formed on the first main surface, and an external connection of the imaging element.

- a wiring board having a device electrode pad connected to a terminal, a wire connected to the device electrode pad and one end, and a bonding portion bonded to the second main surface of the imaging device;

- a heat transfer member made of a material having a thermal conductivity of 15 W / (m ⁇ K) or more, including a bent portion extended from the joint portion and a fixed portion extended from the bent portion;

- a housing made of metal is in contact with a part of the fixed part of the heat transfer member accommodated and the inner surface.

- an endoscope includes an imaging device having a first main surface and a second main surface, and a light receiving unit formed on the first main surface, A wiring board having an element electrode pad connected to the external connection terminal of the imaging element, and a wire connected to the element electrode pad and one end, and joined to the second main surface of the imaging element Heat transfer comprising a material having a thermal conductivity of 15 W / (m ⁇ K) or more, including a bonding portion, a bending portion extending from the bonding portion, and a fixing portion extending from the bending portion It has an imaging device which comprises a member, and a case which consists of metal which a part of said fixed parts of said heat transfer member stored inside and the inner surface contact.

- an imaging device that efficiently dissipates heat generated by an imaging device, and an endoscope having the imaging device.

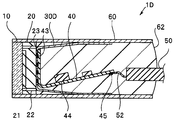

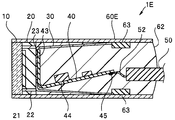

- the imaging device 1 according to the present embodiment is, for example, small in diameter and ultra-compact because the imaging device 1 is disposed at the tip of the electronic endoscope.

- the imaging device 1 includes a cover glass 10, an imaging element 20, a heat transfer member 30, a wiring board 40, a cable 50, and a housing 60.

- An imaging unit including the cover glass 10, the imaging element 20, the heat transfer member 30, and the wiring board 40 is housed inside the housing 60.

- the inside of the case 60 is filled with the resin 62, but it is not shown in FIG. 1 etc.

- the imaging element 20 exchanges electrical signals with a processor (not shown) connected to the cable 50 via the wiring board 40. That is, the plurality of external connection terminals 23 of the imaging element 20 are joined to the respective element electrode pads 42 (hereinafter referred to as “electrode pads 42") of one end of the wiring 43 of the wiring board 40 on which the electronic component 44 is mounted. There is.

- the plurality of cable electrode pads 45 (hereinafter referred to as “electrode pads 45”) at the other end of the wiring 43 are each connected to the conducting wire 52 of the signal cable 50.

- the imaging device 1 has a heat transfer member 30.

- the heat transfer member 30 is partially joined to the imaging device 20, and transfers heat generated by the imaging device 20 to the housing 60 in contact with the other portion.

- the imaging element 20 is a substantially rectangular chip in which the light receiving unit 21 formed of a solid-state imaging circuit is formed on the first main surface 20SA.

- the solid-state imaging circuit is formed of a CCD, a CMOS sensor or the like.

- the imaging device 20 may be a backside illumination type.

- An external connection terminal 23 for exchanging signals with the light receiving unit 21 is formed on the second main surface 20SB via the through wiring 22. That is, the plurality of external connection terminals 23 are arranged in an array on the second main surface 20SB.

- the first main surface 20SA has a wiring from the light receiving unit 21 to the through wiring 22, and the second main surface 20SB has a wiring from the through wiring 22 to the external connection terminal 23, but Absent.

- the cover glass 10 is bonded to the first main surface 20SA of the imaging device 20 via an adhesive layer (not shown). As will be described later, in the imaging device 1, the transparent wafer is bonded to a semiconductor wafer on which a plurality of light receiving portions and the like are formed, and then separated into pieces by dicing. It is the same as the planar view size of. Although the cover glass 10 has a protection function of the light receiving unit 21, it is not an essential component of the imaging device 1.

- the wiring board 40 is a flexible wiring board which uses a flexible resin such as polyimide as a base material and has a wiring 43 made of copper or the like.

- the wiring board 40 may be a single layer wiring board, or may be a multilayer wiring board in which wiring layers are formed on at least both surfaces.

- An electrode pad 42 is formed on the front end side of the wiring board 40, and an electrode pad 45 (see FIG. 2) is formed on the rear end side. The electrode pad 42 and the electrode pad 45 are electrically connected by the wiring 43.

- a connection pad (not shown) is formed on the wiring 43 of the wiring board 40, and an electronic component 44 such as a chip capacitor is mounted. That is, the wiring 43 constitutes an electronic circuit that processes a signal input from the imaging device 20 and outputs the processed signal to the signal cable 50.

- the wiring board 40 is bent halfway and is accommodated within the projection plane of the main surface of the imaging device 20.

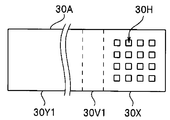

- the heat transfer member 30 includes a joint 30X joined to the second main surface 20SB of the imaging device 20, bent portions 30V1 and 30V2 extended from the joint 30X, and bent portions 30V1 and 30V2 respectively. And fixed portions 30Y1 and 30Y2 extended from the above.

- the last digit of the code may be omitted.

- each of the bending portions 30V1 and 30V2 is referred to as a bending portion 30V.

- the fixing portion 30Y is pressed against the inner surface of the housing 60 by the biasing force, and reliably abuts against the inner surface of the metal housing 60. . That is, the bending portion 30V, which is a spring, presses the fixing portion 30Y to the inner surface of the housing 60.

- the heat generated by the imaging element 20 is transferred to the housing 60 through the heat transfer member 30 having high thermal conductivity, so that the heat is efficiently dissipated. Therefore, the temperature of the image pickup device 20 does not excessively rise at the time of operation, so that the image pickup device 20 is not deteriorated or the image quality is not deteriorated by the thermal noise.

- the external connection terminal 23 is provided on the second main surface 20SB of the imaging element 20, the position facing the external connection terminal 23 of the heat transfer member 30, in other words, the electrode pad 42 of the wiring board 40 There is a through hole 30H at the opposite position.

- the plan view shape of the joint portion 30X of the heat transfer member 30 is substantially rectangular like the imaging device 20, and the bent portion 30V and the fixing portion 30Y are opposed among the four sides of the joint portion 30X. It extends from two sides. That is, although the heat transfer member 30 includes the plurality of extended bending portions 30V and the plurality of fixing portions 30Y, these are integrated, and the boundaries thereof are not clearly distinguishable.

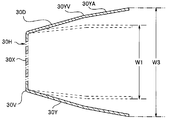

- the heat transfer member 30 is a thin plate made of an elastic metal material having high thermal conductivity such as stainless steel, copper, phosphor bronze, copper alloy and the like. Then, as shown in FIG. 3, the bending portion 30 ⁇ / b> V is bent and plastically deformed before being accommodated inside the housing 60.

- the length of the end of the fixing portion 30Y1 of the heat transfer member 30 in which the bent portion 30V is plastically deformed and the end of the fixing portion 30Y2 is illustrated as W3.

- the length W3 is longer than the inner dimension W1 of the housing 60.

- the fixing portion 30Y when the fixing portion 30Y is housed inside the housing 60, the fixing portion 30Y is pressed against the inner surface of the housing 60 by the biasing force, and reliably abuts on the housing 60.

- the housing 60 may use a material having a high thermal conductivity ⁇ , for example, the same material as the material of the heat transfer member 30. However, as a material of the heat transfer member 30, it is preferable to use a material having a thermal conductivity ⁇ higher than that of the housing 60. For example, it is particularly preferable to configure the case 60 with stainless steel and the heat transfer member 30 with copper.

- the adhesive agent which consists of resin with high heat conductivity.

- the thermal conductivity of the bonding member is preferably 1 W / (m ⁇ K) or more, and particularly preferably 15 W / (m ⁇ K) or more.

- a plurality of imaging devices 20 each having a light receiving unit 21 are formed on a silicon substrate using a known semiconductor process. Then, after adhering to the formation surface of the light receiving unit 21 with a glass wafer of substantially the same size as the silicon substrate as a protective material, grinding is performed from the back surface side of the silicon substrate. After the thickness of the silicon substrate is reduced by grinding, through holes are formed from the back surface side by etching or the like. An insulating film is formed on the side wall of the formed through hole, and the inside is made conductive by a conductive paste, a plating method, a sputtering method or the like, whereby the through wiring 22 is formed. Thereafter, the silicon substrate to which the glass wafer is bonded is cut into pieces, whereby the imaging device 20 to which the cover glass 10 is bonded is manufactured.

- electrode pads 42, 45 and wiring 43 are manufactured by bonding and etching a copper foil and a polyimide as a base material or using a plating method or the like, and an electronic component 44 is mounted.

- the heat transfer member 30 is produced, for example, by pressing or etching a copper plate.

- local heat treatment or the like may be applied to only the bending portion 30V by laser irradiation or the like. Then, the bent portion 30V is bent and plastically deformed so that the length between the end of the fixed portion 30Y1 and the end of the fixed portion 30Y2 is W3.

- the length W3 may be larger than the inner size W1 of the housing 60, but it is 110% or more and 200% or less of W1 in consideration of the balance between the ease of insertion into the housing and the strength of the biasing force. Is preferred.

- a shape memory alloy such as a titanium nickel alloy may be used as the material of the heat transfer member 30. That is, after bending bent portion 30V of heat transfer member 30 storing the state in which bent portion 30V is deformed and fixing portion 30Y is largely opened, heat is applied to a predetermined temperature after housing fixed portion 30Y. The inner surface of the case 60 can be pressed by the biasing force.

- the bonding portion 30X of the heat transfer member 30 is bonded to the second main surface 20SB of the imaging element 20 by a bonding member. At this time, bonding is performed so that the external connection terminal 23 of the imaging element 20 is positioned inside the through hole 30H of the heat transfer member 30.

- the periphery of the bonding portion 30X may be resin-sealed so that the resin is injected into the through hole 30H.

- an imaging unit in which the cover glass 10, the imaging element 20, the heat transfer member 30, the wiring board 40, and the signal cable 50 are integrated is inserted into the inside of the housing 60.

- the plan view shape and the inner size of the housing 60 are substantially the same and slightly larger than the plan view shape and the outer size of the imaging device 20.

- the inner dimension W1 in the vertical direction of the housing 60 shown in FIG. 3 is substantially the same as the outer dimension W2 in the vertical direction of the imaging device 20.

- the inside of the housing 60 is filled with the resin 62 to complete the imaging device 1.

- the heat transfer member 30 is in contact with the metal case 60 while being pressed.

- the heat transfer member 30 is deformed by being pressed against the inner surface of the housing 60 by adjusting the thickness, size, shape, etc., using an elastic body as the material, and makes the surface contact with the housing 60 be able to.

- the surface contact makes it possible to transfer the heat generated by the imaging device 20 to the housing 60 more efficiently.

- the imaging device 1 can efficiently dissipate the heat generated by the imaging element 20.

- the heat transfer member 30 and the wiring board 40 are housed in a casing of the same inner size as the outer size of the imaging device 20, the diameter is small.

- the bending portions 30V1 and 30V2 and the fixing portions 30Y1 and 30Y2 extend from the two opposing sides of the bonding portion 30X.

- the bent portion 30V1 and the fixing portion 30Y1 extend from one side of the joint portion 30X.

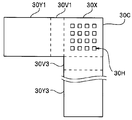

- bent portions 30V1, 30V2, 30V3 and fixed portions 30Y1, 30Y2, 30Y3 extend from three sides of the joint portion 30X.

- the bent portions 30V1 and 30V3 and the fixing portions 30Y1 and 30Y3 extend from two orthogonal sides of the bonding portion 30X.

- the imaging devices of Modifications 1 to 3 including the heat transfer members 30A, 30B, and 30C also have the same effect as the imaging device 1 of the first embodiment.

- the shape of the heat transfer member is selected according to the arrangement of the wiring board 40, the electronic component 44, and the signal cable 50 disposed inside the housing 60, the amount of heat generation of the imaging device, that is, the amount of heat to be dissipated. Ru.

- an imaging device 1D according to a second embodiment will be described. Since the imaging device 1D is similar to the imaging device 1 and the like, the same components will be denoted by the same reference numerals and descriptions thereof will be omitted.

- the heat transfer member 30D of the imaging device 1D has a bending portion 30YV in the fixing portion 30Y.

- the bent portion 30YV is plastically deformed in advance so that the tip end portion 30YA of the fixed portion 30Y is parallel to the inner surface of the housing 60 when the heat transfer member 30D is accommodated in the housing 60. Therefore, the front end portion 30YA is in surface contact with the inner surface of the housing 60 on the entire surface.

- the imaging device 1D has the same effect as the imaging device 1 and the contact area between the heat transfer member 30D and the housing 60 is wide, the heat generated by the imaging element 20 can be dissipated more efficiently.

- an imaging device 1E according to a third embodiment will be described. Since the imaging device 1E is similar to the imaging device 1 and the like, the same components will be denoted by the same reference numerals and descriptions thereof will be omitted.

- a positioning portion 63 defining the position of the fixing portion 30Y in the inside of the housing 60E in the longitudinal direction, that is, the position of the imaging unit in the longitudinal direction It is arranged.

- the imaging unit in which the cover glass 10, the imaging element 20, the heat transfer member 30, the wiring board 40, and the signal cable 50 are integrated is inserted into the housing 60E from the front end side.

- the positioning position of the imaging unit in the longitudinal direction is defined by the positioning unit 63.

- the positioning portion 63 may be formed by arranging another member, or may be formed by processing a part of the housing 60E. In addition, a projection may be provided so that a part of the fixing portion 30Y is processed to be locked or engaged with the positioning portion 63.

- the imaging device 1E has effects of the imaging device 1 and the like, and can easily ensure the accuracy of the arrangement position of the imaging unit, for example, the imaging element 20.

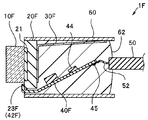

- an elongated hole 60FH is formed in the contact surface of the heat transfer member 30F of the housing 60F. And, a part of the fixing portion 30Y of the heat transfer member 30F is processed into the convex portion 30FH so as to be fitted to the hole 60FH. That is, the hole 60FH of the housing 60F is a positioning portion having the function of a positioning member that defines the position of the fixing portion.

- heat transfer member 30F and housing 60F are fitted, material having high heat conductivity such as high thermal conductivity resin, solder, or Ag paste is injected into hole 60FH, and housing 60F and heat transfer member 30F The portion in contact may be fixed and sealed.

- material having high heat conductivity such as high thermal conductivity resin, solder, or Ag paste is injected into hole 60FH, and housing 60F and heat transfer member 30F The portion in contact may be fixed and sealed.

- the imaging device 1F of the modification has the effect of the imaging device 1E, and the hole 60H of the housing 60 and the convex portion 30FH of the fixed portion 30Y are fitted, so the contact area is large. Moreover, when the contact part of the housing

- an imaging device 1G according to a fourth embodiment will be described. Since the imaging device 1G is similar to the imaging device 1 and the like, the same components are denoted by the same reference numerals and descriptions thereof will be omitted.

- the external connection terminal 23G is disposed on the first main surface 20SA.

- the wiring board 40G is connected at one end to the external connection terminal 23G of the first main surface 20SA of the imaging element 20C, and the other end is disposed on the rear end side via the bent portion.

- the imaging device 1G has effects of the imaging device 1 and the like. Furthermore, the imaging device 20C without the through wiring is easy to manufacture. Moreover, there is no through hole 30H in the joint portion 30XG of the heat transfer member 30G. Therefore, the heat transfer member 30G can be easily manufactured. Furthermore, since the contact area between the imaging device 20G and the heat transfer member 30G is large, the heat generated by the imaging device 20 can be dissipated more efficiently.

- the endoscope 9 is an electronic endoscope having the imaging device 1 of the first embodiment at the distal end portion 2 of the insertion portion 3.

- the endoscope 9 includes an operation unit 4 disposed on the proximal end side of the insertion unit 3 and a universal cord 5 extending from the operation unit 4.

- the operation unit 4 is provided with various switches and the like operated by the operator while holding.

- the cable 50 of the imaging device 1 is connected to a main unit (not shown) that performs image processing and the like through the insertion portion 3 and the universal cord 5 and through the connector 6 disposed at the proximal end of the universal cord 5 Be done.

- the endoscope 9 having the imaging device 1 at its tip is minimally invasive. Then, in the endoscope 9, there is no possibility that the imaging device 1 is deteriorated due to an excessive temperature rise, or the image quality is not deteriorated due to the thermal noise.

- imaging device 2 endoscope 10: cover glass 20: imaging device 21: light receiving portion 30: heat transfer member 30V: bending portion 30X: bonding portion 30Y: fixing portion 42: element electrode pad 43: wiring 44: Electronic component 45: Cable electrode pad 50: Cable 60: Case

Landscapes

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Surgery (AREA)

- Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Optics & Photonics (AREA)

- Radiology & Medical Imaging (AREA)

- Biomedical Technology (AREA)

- Nuclear Medicine, Radiotherapy & Molecular Imaging (AREA)

- Public Health (AREA)

- Pathology (AREA)

- Veterinary Medicine (AREA)

- General Health & Medical Sciences (AREA)

- Biophysics (AREA)

- Medical Informatics (AREA)

- Molecular Biology (AREA)

- Heart & Thoracic Surgery (AREA)

- Animal Behavior & Ethology (AREA)

- Signal Processing (AREA)

- Multimedia (AREA)

- Manufacturing & Machinery (AREA)

- Astronomy & Astrophysics (AREA)

- General Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Endoscopes (AREA)

- Studio Devices (AREA)

- Instruments For Viewing The Inside Of Hollow Bodies (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US15/172,203 US10485412B2 (en) | 2013-12-04 | 2016-06-03 | Image pickup apparatus and endoscope |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013-251239 | 2013-12-04 | ||

| JP2013251239A JP6411731B2 (ja) | 2013-12-04 | 2013-12-04 | 撮像装置及び内視鏡 |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US15/172,203 Continuation US10485412B2 (en) | 2013-12-04 | 2016-06-03 | Image pickup apparatus and endoscope |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2015083416A1 true WO2015083416A1 (ja) | 2015-06-11 |

Family

ID=53273193

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2014/074547 Ceased WO2015083416A1 (ja) | 2013-12-04 | 2014-09-17 | 撮像装置及び内視鏡 |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US10485412B2 (enExample) |

| JP (1) | JP6411731B2 (enExample) |

| WO (1) | WO2015083416A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2018116533A1 (ja) * | 2016-12-19 | 2018-06-28 | オリンパス株式会社 | 医療用撮像装置 |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6681734B2 (ja) * | 2016-02-18 | 2020-04-15 | イリソ電子工業株式会社 | 電子機器用筐体 |

| JP6650378B2 (ja) * | 2016-09-08 | 2020-02-19 | 富士フイルム株式会社 | 内視鏡 |

| WO2018198158A1 (ja) | 2017-04-24 | 2018-11-01 | オリンパス株式会社 | 内視鏡、および、撮像モジュール |

| JP7043947B2 (ja) * | 2018-04-09 | 2022-03-30 | 株式会社島津製作所 | 治療支援装置 |

| DE102019129815B4 (de) * | 2019-11-05 | 2021-11-04 | Karl Storz Se & Co. Kg | Kühlvorrichtung für ein Endoskop oder Exoskop |

| EP3964116A1 (en) | 2020-09-02 | 2022-03-09 | Ambu A/S | Endoscope tip part |

| TWI747606B (zh) * | 2020-11-11 | 2021-11-21 | 群光電子股份有限公司 | 內視鏡裝置 |

| EP4011270A1 (en) | 2020-12-08 | 2022-06-15 | Ambu A/S | Endoscope tip part with improved optical properties |

| WO2025053702A1 (ko) * | 2023-09-08 | 2025-03-13 | 엘지전자 주식회사 | 내시경 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2003305004A (ja) * | 2002-04-15 | 2003-10-28 | Olympus Optical Co Ltd | 固体撮像装置及び電子内視鏡 |

| JP2011200338A (ja) * | 2010-03-24 | 2011-10-13 | Fujifilm Corp | 電子内視鏡 |

| JP2011200401A (ja) * | 2010-03-25 | 2011-10-13 | Fujifilm Corp | 内視鏡 |

| JP2012050756A (ja) * | 2010-09-02 | 2012-03-15 | Fujifilm Corp | 内視鏡装置及びその撮像素子放熱方法 |

| JP2012071064A (ja) * | 2010-09-29 | 2012-04-12 | Fujifilm Corp | 内視鏡装置及びその撮像素子放熱方法 |

| JP2013233215A (ja) * | 2012-05-07 | 2013-11-21 | Fujifilm Corp | 内視鏡用撮像モジュール及び電子内視鏡装置 |

Family Cites Families (30)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7306559B2 (en) * | 1997-07-02 | 2007-12-11 | Lumitex, Inc. | Illuminated surgical retractor |

| US20050171408A1 (en) * | 1997-07-02 | 2005-08-04 | Parker Jeffery R. | Light delivery systems and applications thereof |

| JP5063834B2 (ja) * | 2000-10-12 | 2012-10-31 | オリンパス株式会社 | 電子内視鏡システム |

| JP3875505B2 (ja) * | 2001-03-29 | 2007-01-31 | オリンパス株式会社 | 撮像装置 |

| US20070185379A1 (en) * | 2005-01-10 | 2007-08-09 | Perceptron, Inc. | Modular remote inspection device with digital imager |

| WO2008019367A2 (en) * | 2006-08-07 | 2008-02-14 | Innovative Medical Devices, Inc. | System to aid in the positioning, confirmation and documentation of an endotracheal tube |

| JP2010022815A (ja) * | 2008-06-18 | 2010-02-04 | Olympus Corp | 内視鏡装置 |

| TW201028125A (en) * | 2009-01-19 | 2010-08-01 | hui-yu Zhang | Micro image pick-up apparatus |

| US8106569B2 (en) * | 2009-05-12 | 2012-01-31 | Remphos Technologies Llc | LED retrofit for miniature bulbs |

| US9642513B2 (en) * | 2009-06-18 | 2017-05-09 | Endochoice Inc. | Compact multi-viewing element endoscope system |

| US20140296866A1 (en) * | 2009-06-18 | 2014-10-02 | Endochoice, Inc. | Multiple Viewing Elements Endoscope Having Two Front Service Channels |

| US9713417B2 (en) * | 2009-06-18 | 2017-07-25 | Endochoice, Inc. | Image capture assembly for use in a multi-viewing elements endoscope |

| WO2011010499A1 (ja) * | 2009-07-23 | 2011-01-27 | オリンパスメディカルシステムズ株式会社 | 内視鏡装置 |

| KR101101658B1 (ko) * | 2009-11-16 | 2011-12-30 | 삼성전기주식회사 | 내시경 카메라 모듈 패키지 및 그의 제조방법 |

| JP5452282B2 (ja) * | 2010-02-26 | 2014-03-26 | オリンパス株式会社 | 固体撮像装置 |

| US8698887B2 (en) * | 2010-04-07 | 2014-04-15 | Olympus Corporation | Image pickup apparatus, endoscope and manufacturing method for image pickup apparatus |

| JP5675151B2 (ja) * | 2010-04-07 | 2015-02-25 | オリンパス株式会社 | 撮像装置、電子内視鏡および撮像装置の製造方法 |

| CN107361721B (zh) * | 2010-12-09 | 2019-06-18 | 恩多巧爱思创新中心有限公司 | 用于多摄像头内窥镜的柔性电子电路板 |

| EP3420886B8 (en) * | 2010-12-09 | 2020-07-15 | EndoChoice, Inc. | Flexible electronic circuit board multi-camera endoscope |

| JP5436470B2 (ja) * | 2011-01-31 | 2014-03-05 | 富士フイルム株式会社 | 撮像装置及びこれを備えた電子内視鏡 |

| US9622649B2 (en) * | 2011-08-05 | 2017-04-18 | Ambu A/S | Endoscope with a T-shaped flexible circuit board |

| TWM421800U (en) * | 2011-08-05 | 2012-02-01 | Limit Optics Co Ltd | Endoscope device having flexible printed circuit board |

| DE102011055526A1 (de) * | 2011-11-18 | 2013-05-23 | Invendo Medical Gmbh | Medizinisches Endoskop mit Kühlvorrichtung für eingebaute elektrische Bauteile |

| JP5412601B2 (ja) * | 2011-12-07 | 2014-02-12 | オリンパスメディカルシステムズ株式会社 | 電子内視鏡 |

| EP3099248A4 (en) * | 2014-01-28 | 2017-01-25 | Invuity, Inc. | Drop in surgical illuminator |

| US9357906B2 (en) * | 2014-04-16 | 2016-06-07 | Engineered Medical Solutions Company LLC | Surgical illumination devices and methods therefor |

| DE102014107205A1 (de) * | 2014-05-22 | 2015-11-26 | Karl Storz Gmbh & Co. Kg | Optisches medizinisches Instrument, insbesondere Endoskop oder Exoskop |

| DE102014209980B4 (de) * | 2014-05-26 | 2021-06-17 | Olympus Winter & Ibe Gmbh | Videoendoskop |

| EP3272272A4 (en) * | 2016-02-02 | 2019-02-20 | Olympus Corporation | IMAGING DEVICE WITH ENDOSCOPE |

| EP3419497B1 (en) * | 2016-02-24 | 2022-06-01 | Endochoice, Inc. | Circuit board assembly for a multiple viewing element endoscope using cmos sensors |

-

2013

- 2013-12-04 JP JP2013251239A patent/JP6411731B2/ja active Active

-

2014

- 2014-09-17 WO PCT/JP2014/074547 patent/WO2015083416A1/ja not_active Ceased

-

2016

- 2016-06-03 US US15/172,203 patent/US10485412B2/en active Active

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2003305004A (ja) * | 2002-04-15 | 2003-10-28 | Olympus Optical Co Ltd | 固体撮像装置及び電子内視鏡 |

| JP2011200338A (ja) * | 2010-03-24 | 2011-10-13 | Fujifilm Corp | 電子内視鏡 |

| JP2011200401A (ja) * | 2010-03-25 | 2011-10-13 | Fujifilm Corp | 内視鏡 |

| JP2012050756A (ja) * | 2010-09-02 | 2012-03-15 | Fujifilm Corp | 内視鏡装置及びその撮像素子放熱方法 |

| JP2012071064A (ja) * | 2010-09-29 | 2012-04-12 | Fujifilm Corp | 内視鏡装置及びその撮像素子放熱方法 |

| JP2013233215A (ja) * | 2012-05-07 | 2013-11-21 | Fujifilm Corp | 内視鏡用撮像モジュール及び電子内視鏡装置 |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2018116533A1 (ja) * | 2016-12-19 | 2018-06-28 | オリンパス株式会社 | 医療用撮像装置 |

| JP6401427B1 (ja) * | 2016-12-19 | 2018-10-10 | オリンパス株式会社 | 医療用撮像装置 |

| US11644661B2 (en) | 2016-12-19 | 2023-05-09 | Olympus Corporation | Medical image pickup apparatus |

Also Published As

| Publication number | Publication date |

|---|---|

| US10485412B2 (en) | 2019-11-26 |

| JP2015107218A (ja) | 2015-06-11 |

| JP6411731B2 (ja) | 2018-10-24 |

| US20160278620A1 (en) | 2016-09-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6411731B2 (ja) | 撮像装置及び内視鏡 | |

| JP6000859B2 (ja) | 半導体装置の製造方法、半導体装置、及び内視鏡 | |

| US8471392B2 (en) | Semiconductor apparatus and endoscope apparatus | |

| JP6021618B2 (ja) | 撮像装置、内視鏡及び撮像装置の製造方法 | |

| JPWO2018092318A1 (ja) | 内視鏡用撮像モジュール、および内視鏡 | |

| US9509890B2 (en) | Solid image pickup apparatus | |

| JP5730678B2 (ja) | 撮像装置及びこれを用いた電子機器 | |

| JP2018121022A (ja) | 光モジュール | |

| JP2013123628A (ja) | 内視鏡用撮像ユニット | |

| JPWO2016166888A1 (ja) | 撮像装置 | |

| JP2014000314A (ja) | 内視鏡先端部の放熱構造 | |

| JP6335636B2 (ja) | 撮像モジュールおよび内視鏡 | |

| JP6605632B2 (ja) | 撮像装置および内視鏡 | |

| TWI557926B (zh) | 電路板裝置及影像感測器封裝結構 | |

| JPWO2016157376A1 (ja) | 撮像装置および内視鏡 | |

| JP2006339291A (ja) | 中空パッケージとこれを用いた半導体装置及び固体撮像装置 | |

| JP2012061255A (ja) | 撮像装置、電子内視鏡装置及び撮像装置の製造方法 | |

| JP2012023667A (ja) | 固体撮像装置 | |

| JP2006319124A (ja) | 固体撮像装置 | |

| JP7149489B2 (ja) | 固体撮像装置 | |

| JP2014000208A (ja) | 撮像装置及びこの撮像装置を用いた内視鏡 | |

| JP2013254600A (ja) | コネクタ、回路モジュールおよび電子機器 | |

| JP2014060689A (ja) | 撮像装置、該撮像装置を具備する内視鏡 | |

| JP2014068675A (ja) | 撮像装置及びこの撮像装置を用いた内視鏡 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 14867507 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 14867507 Country of ref document: EP Kind code of ref document: A1 |