WO2012124599A1 - 徐放性粒子およびその製造方法 - Google Patents

徐放性粒子およびその製造方法 Download PDFInfo

- Publication number

- WO2012124599A1 WO2012124599A1 PCT/JP2012/055969 JP2012055969W WO2012124599A1 WO 2012124599 A1 WO2012124599 A1 WO 2012124599A1 JP 2012055969 W JP2012055969 W JP 2012055969W WO 2012124599 A1 WO2012124599 A1 WO 2012124599A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- suspension

- polymerization

- release particles

- sustained release

- compound

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/48—Preparations in capsules, e.g. of gelatin, of chocolate

- A61K9/50—Microcapsules having a gas, liquid or semi-solid filling; Solid microparticles or pellets surrounded by a distinct coating layer, e.g. coated microspheres, coated drug crystals

- A61K9/5005—Wall or coating material

- A61K9/5021—Organic macromolecular compounds

- A61K9/5026—Organic macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds, e.g. polyvinyl pyrrolidone, poly(meth)acrylates

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01N—PRESERVATION OF BODIES OF HUMANS OR ANIMALS OR PLANTS OR PARTS THEREOF; BIOCIDES, e.g. AS DISINFECTANTS, AS PESTICIDES OR AS HERBICIDES; PEST REPELLANTS OR ATTRACTANTS; PLANT GROWTH REGULATORS

- A01N25/00—Biocides, pest repellants or attractants, or plant growth regulators, characterised by their forms, or by their non-active ingredients or by their methods of application, e.g. seed treatment or sequential application; Substances for reducing the noxious effect of the active ingredients to organisms other than pests

- A01N25/26—Biocides, pest repellants or attractants, or plant growth regulators, characterised by their forms, or by their non-active ingredients or by their methods of application, e.g. seed treatment or sequential application; Substances for reducing the noxious effect of the active ingredients to organisms other than pests in coated particulate form

- A01N25/28—Microcapsules or nanocapsules

Definitions

- the present invention relates to sustained release particles and a method for producing the same, and more particularly to sustained release particles for sustained release of an antibiotic compound and a method for producing the same.

- antibiotic active compounds such as bactericides, preservatives, and fungicides are microencapsulated to gradually release the antibiotic active compounds to ensure sustained efficacy.

- a microcapsule containing a microbial growth inhibitor obtained by blending and dispersing an oil phase containing a microbial growth inhibitor and a polyisocyanate component and an aqueous phase containing an active hydrogen group-containing component and interfacial polymerization has been proposed.

- an oil phase containing a microbial growth inhibitor and a polyisocyanate component and an aqueous phase containing an active hydrogen group-containing component and interfacial polymerization has been proposed.

- An object of the present invention is to provide sustained release particles excellent in sustained release and a method for producing the same.

- the present inventors diligently studied the above-mentioned sustained release particles and the production method thereof, and found that the core containing the antibiotic compound and the polymer can be reliably coated with the shell. As a result of the heading and further research, the present invention has been completed.

- the present invention (1) Suspension polymerization of a first component containing an antibiotic compound and a polymerizable vinyl monomer, which is a sustained release particle comprising a core containing an antibiotic compound and a shell covering the core.

- the interfacial polymerization is started simultaneously with the start of the suspension polymerization in the first step, or the suspension of the first step is obtained.

- Sustained release particles characterized by starting after the time when turbid polymerization is started, (2)

- the antibiotic compound is defined by Hansen, and the dipole force term ⁇ p, compound of the solubility parameter ⁇ calculated by the van Krevelen and Hoftyzer method is 2 to 8 [(J / cm 3 ) 1 / 2 ], the hydrogen bonding force term ⁇ h, compound of the solubility parameter ⁇ is 5.5 to 9.5 [(J / cm 3 ) 1/2 ], and the polymer is a dipole of the solubility parameter ⁇ .

- the sustained release particles according to (1) above, (3) First forming a core containing the antibiotic compound and the polymer of the polymerizable vinyl monomer by suspension polymerization of the first component containing the antibiotic compound and the polymerizable vinyl monomer. And a second step of interfacially polymerizing a second component containing a shell-forming component to form a shell that covers the core. In the second step, the interfacial polymerization is suspended from the first step.

- the method for producing sustained-release particles is characterized in that the suspension polymerization is started at the same time as the suspension polymerization, or after the suspension polymerization in the first step is started.

- the interfacial polymerization is started simultaneously with the start of the suspension polymerization in the first step, or the suspension polymerization in the first step. Since it starts later than when starting, the shell can reliably cover the core containing the antibiotic compound and the polymer.

- the sustained-release particles of the present invention having excellent sustained-release properties and capable of exhibiting excellent efficacy sustaining effects can be obtained.

- FIG. 1 shows an image processing diagram of an SEM photograph of sustained-release particles of Example 1.

- FIG. 2 shows an image processing diagram of an SEM photograph of sustained-release particles of Example 2.

- FIG. 3 shows an image processing diagram of an SEM photograph of sustained-release particles of Example 3.

- FIG. 4 shows an image processing diagram of an SEM photograph of sustained release particles of Example 4.

- FIG. 5 shows an image processing diagram of an SEM photograph of sustained-release particles of Example 5.

- FIG. 6 shows an image processing diagram of an SEM photograph of sustained-release particles of Example 6.

- FIG. 7 shows an image processing diagram of an SEM photograph of sustained-release particles of Example 7.

- FIG. 8 shows an image processing diagram of an SEM photograph of sustained-release particles of Example 8.

- FIG. 9 shows an image processing diagram of the SEM photograph of the sustained release particles of Comparative Example 1.

- FIG. 10 shows an image processing diagram of an SEM photograph of sustained release particles of Comparative Example 2.

- FIG. 11 shows an image processing diagram of an SEM photograph of sustained-release particles of Comparative Example 4.

- FIG. 12 shows an image processing diagram of a TEM photograph of sustained-release particles of Example 2.

- FIG. 13 shows an image processing diagram of a TEM photograph of sustained-release particles of Example 3.

- FIG. 14 shows an image processing diagram of a TEM photograph of sustained-release particles of Example 5.

- FIG. 15 is an image processing diagram of a TEM photograph of the sustained release particles of Comparative Example 1.

- FIG. 16 shows an image processing diagram of a TEM photograph of sustained release particles of Comparative Example 2.

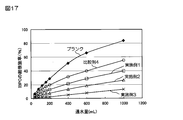

- FIG. 17 shows graphs of sustained release tests of Examples 1 to 3 and Comparative Example 4.

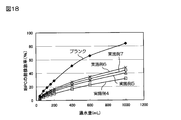

- FIG. 18 shows a graph of sustained release tests of Examples 4 to 7.

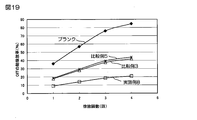

- FIG. 19 shows a graph of sustained release test of Example 8 and Comparative Examples 3 and 5.

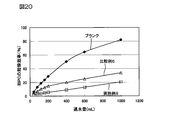

- FIG. 20 shows a graph of sustained release tests of Example 9 and Comparative Example 6.

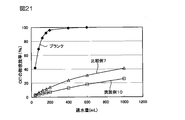

- FIG. 21 shows a graph of sustained release tests of Example 10 and Comparative Example 7.

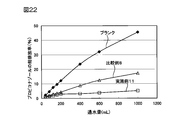

- FIG. 22 shows a graph of sustained release test of Example 11 and Comparative Example 8.

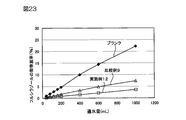

- FIG. 23 shows a graph of sustained release test of Example 12 and Comparative Example 9.

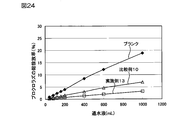

- FIG. 24 is a graph showing sustained release tests of Example 13 and Comparative Example 10.

- FIG. 25 shows a graph of sustained release test of Example 14 and Comparative Example 11.

- the sustained-release particles of the present invention comprise a core containing an antibiotic compound and a shell covering the core.

- the core is formed in a substantially spherical shape.

- the shell is formed in a film shape covering the surface of the core. As shown in the TEM photographs of FIGS. 12 to 14, the shell (3) is formed with a non-uniform thickness along the outer periphery of the core (2). Also, the shell (3) has a relatively smooth surface, as seen in FIG. 12, or relative to that of FIG. 12, as seen in FIGS. Have a rough surface.

- grains of this invention contain the polymer of an antibiotic compound and a polymerizable vinyl monomer by carrying out suspension polymerization of the 1st component containing an antibiotic compound and a polymerizable vinyl monomer. It can be obtained by a production method comprising a first step of forming a core and a second step of forming a shell by interfacial polymerization of a second component containing a shell-forming component.

- the antibiotic compound has, for example, at least two functional moieties that can interact with a polymer of a polymerizable vinyl monomer.

- Examples of such a functional moiety include polar functional groups such as a carbonyl group, a nitro group, an amino group, a cyano group, a phosphate ester group, a carboxyl group, and an ether group, such as a carboxylate bond, a phosphate bond, a urea bond, Examples thereof include a polar bond containing a polar group such as a carbon-halogen bond, for example, a benzene ring, and a conjugated cyclic moiety such as a conjugated heterocycle such as a triazine ring, an imidazole ring, and an isothiazoline ring.

- polar functional groups such as a carbonyl group, a nitro group, an amino group, a cyano group, a phosphate ester group, a carboxyl group, and an ether group, such as a carboxylate bond, a phosphate bond, a urea bond

- Examples thereof include a polar bond

- the molecular weight of the antibiotic compound is, for example, 200 to 600, preferably 200 to 500.

- the compatibility of the antibiotic compound with the polymer may decrease.

- the molecular weight of the antibiotic compound is less than the above range, the antibiotic compound remains in the aqueous phase during suspension polymerization, and the antibiotic compound precipitates after suspension polymerization.

- the suspension may solidify.

- the melting point of the antibiotic compound is, for example, 100 ° C. or less, preferably 90 ° C. or less, and more preferably 80 ° C. or less.

- the antibiotic compound may not be encapsulated in the core and may be deposited outside the core, and even if the antibiotic compound is encapsulated in the core. However, the antibiotic compound may not be released slowly from the core.

- the antibiotic compound is an antibacterial agent, antibacterial agent, antiseptic agent, antifungal agent, antifungal agent, insecticide having antibacterial activity such as antibacterial agent, antibacterial agent, antiseptic agent, antialgal agent, antifungal agent and insecticide. Selected from agents, herbicides, attractants, repellents and rodenticides.

- the compounds having antibiotic activity include bactericidal antiseptic and algal fungicides such as iodine compounds, triazole compounds, carbamoylimidazole compounds, dithiol compounds, isothiazoline compounds, nitroalcohol compounds, and paraoxybenzoic acid esters.

- anticides such as pyrethroid compounds, neonicotinoid compounds, organochlorine compounds, organophosphorus compounds, carbamate compounds, alkoxyamine compounds, oxadiazine compounds, etc. .

- iodine compounds include 3-iodo-2-propynylbutylcarbamate (IPBC), 1-[[(3-iodo-2-propynyl) oxy] methoxy] -4-methoxybenzene, 3-bromo-2, And 3-diiodo-2-propenyl ethyl carbonate.

- triazole compound examples include 1- [2- (2,4-dichlorophenyl) -4-n-propyl-1,3-dioxolan-2-ylmethyl] -1H-1,2,4-triazole (propico Nazole), bis (4-fluorophenyl) methyl (1H-1,2,4-triazol-1-ylmethylsilane) (also known as flusilazole, 1-[[bis (4-fluorophenyl) methylsilyl] methyl] -1H -1,2,4-triazole) and the like.

- carbamoylimidazole compound examples include N-propyl-N- [2- (2,4,6-trichloro-phenoxy) ethyl] imidazole-1-carboxamide (prochloraz).

- dithiol-based compound examples include 4,5-dichloro-1,2-dithiol-3-one.

- isothiazoline-based compound examples include 2-n-octyl-4-isothiazolin-3-one (OIT), 5,6-dichloro-2-n-octyl-4-isothiazolin-3-one (DCOIT), 5- And chloro-2-methyl-4-isothiazolin-3-one (Cl-MIT).

- OIT 2-n-octyl-4-isothiazolin-3-one

- DCOIT 5,6-dichloro-2-n-octyl-4-isothiazolin-3-one

- Cl-MIT 5- And chloro-2-methyl-4-isothiazolin-3-one

- nitroalcohol compound examples include 2,2-dibromo-2-nitro-1-ethanol (DBNE).

- paraoxybenzoic acid ester examples include butyl paraoxybenzoate and propyl paraoxybenzoate.

- pyrethroid compound examples include pyrethrin, cineline, jasmolin and the like obtained from Shirovanamushiyogiiku, and examples thereof include allethrin, bifenthrin, acrinathrin, alpha cypermethrin, tralomethrin, cyfluthrin ((RS) - ⁇ -cyano derived therefrom.

- neonicotinoid compounds include (E) -N 1 -[(6-chloro-3-pyridyl) methyl] -N 2 -cyano-N 1 -methylacetamidine (acetamipride).

- organochlorine compounds examples include Kelsen.

- organophosphorus compounds examples include oxime, pyridafenthion, fenitrothion, tetrachlorbinphos, diclofenthion, propetanephos, and the like.

- carbamate compounds examples include fenocarb and propoxur.

- alkoxyamine compound examples include 3-lauryloxypropylamine.

- Examples of the oxadiazine compound include indoxacarb.

- insecticide examples include pyriproxyfen.

- herbicides examples include pyraclonyl, pendimethalin, indanophan and the like.

- repellents examples include diet.

- Antibiotic active compounds are, for example, substantially hydrophobic and specifically have, for example, extremely low solubility in water at room temperature (20-30 ° C., more specifically 25 ° C.).

- the solubility at room temperature is 1 part by mass / 100 parts by mass of water (10000 ppm) or less, preferably 0.5 parts by mass / 100 parts by mass of water (5000 ppm) or less, more preferably 0.1 parts by mass / 100 parts by mass of water (1000 ppm) or less, and on a volume basis, for example, 1 g / 100 mL or less of water, preferably 0.5 g / 100 mL or less of water, more preferably 0.1 g / 100 mL of water. It is as follows.

- the suspension of the first component containing the polymerizable vinyl monomer causes the antibiotic compound to move out of the core (that is, in the aqueous phase). Since the antibiotic active compound dissolved in the aqueous phase is easily precipitated after polymerization, it may be difficult to form a core containing the antibiotic active compound.

- antibiotic compounds can be used alone or in combination of two or more.

- the above-mentioned antibiotic compound may contain, for example, impurities having a melting point outside the above range at an appropriate ratio during the production process.

- impurities having a melting point outside the above range at an appropriate ratio during the production process.

- a mixture of isomer I (melting point: 57 ° C.), isomer II (melting point: 74 ° C.) and isomer III (melting point: 66 ° C.) of cyfluthrin is, for example, isomer IV (impurity) Melting point 102 ° C.).

- the polymerizable vinyl monomer is, for example, a monomer having at least one polymerizable carbon-carbon double bond in the molecule.

- polymerizable vinyl monomer examples include (meth) acrylic acid ester monomers, (meth) acrylic acid monomers, aromatic vinyl monomers, vinyl ester monomers, maleic acid ester monomers, and halogenated monomers.

- vinyl monomers and nitrogen-containing vinyl monomers examples include (meth) acrylic acid ester monomers, (meth) acrylic acid monomers, aromatic vinyl monomers, vinyl ester monomers, maleic acid ester monomers, and halogenated monomers.

- vinyl monomers and nitrogen-containing vinyl monomers examples include (meth) acrylic acid ester monomers, (meth) acrylic acid monomers, aromatic vinyl monomers, vinyl ester monomers, maleic acid ester monomers, and halogenated monomers. Examples thereof include vinyl monomers and nitrogen-containing vinyl monomers.

- Examples of (meth) acrylic acid ester monomers include methacrylic acid esters and // acrylic acid esters, and specifically include methyl (meth) acrylate, ethyl (meth) acrylate, and (meth) acrylic acid n.

- -Propyl iso-propyl (meth) acrylate, n-butyl (meth) acrylate, iso-butyl (meth) acrylate, tert-butyl (meth) acrylate, cyclohexyl (meth) acrylate, (meth) acryl

- Examples include 2-methoxyethyl acid.

- Examples of the (meth) acrylic acid monomer include methacrylic acid and acrylic acid.

- aromatic vinyl monomer examples include styrene, chlorostyrene, p-methylstyrene, o-methylstyrene, ⁇ -methylstyrene, and the like.

- vinyl ester monomers examples include vinyl acetate and vinyl propionate.

- maleate ester monomers examples include dimethyl maleate, diethyl maleate, and dibutyl maleate.

- Examples of the vinyl halide monomer include vinyl chloride and vinyl fluoride.

- Examples of the vinyl halide monomer include vinylidene halide monomers, and specific examples include vinylidene chloride and vinylidene fluoride.

- nitrogen-containing vinyl monomer examples include (meth) acrylonitrile, N-phenylmaleimide, vinylpyridine, and the like.

- the polymerizable vinyl monomer is, for example, substantially hydrophobic, and specifically has, for example, extremely low solubility in water at room temperature. More specifically, the solubility at room temperature is, for example, 10 parts by mass / It is 100 mass parts or less of water, Preferably, it is 8 mass parts / 100 mass parts or less of water.

- an antibiotic compound compatible with an antibiotic compound having a strong compatibility with an antibiotic compound and capable of dissolving (compatible) the antibiotic compound (hereinafter simply referred to as a compatible monomer). May be selected).

- These compatible monomers can be used alone or in combination of two or more.

- a (meth) acrylic acid ester monomer is used alone, or a (meth) acrylic acid ester monomer and a (meth) acrylic acid monomer are used in combination.

- methyl methacrylate can be used alone, or methyl methacrylate and methacrylic acid can be used in combination.

- the blending ratio of the (meth) acrylic acid monomer is, for example, 30 masses with respect to 100 parts by mass of the compatible monomer. Less than 20 parts by weight, preferably 20 parts by weight or less, for example 1 part by weight or more, preferably 3 parts by weight or more.

- the antibiotic active compound and the compatible monomer are preferably selected such that the polymer of the polymerizable vinyl monomer and the antibiotic active compound are compatible at the polymerization temperature (heating temperature) described below.

- the polymerizable vinyl monomer can contain a crosslinkable monomer as a compatible monomer.

- the crosslinkable monomer is blended as necessary in order to adjust the sustained release property of the sustained release particles.

- mono- or polyethylene glycol di (meth) such as ethylene glycol di (meth) acrylate and diethylene glycol di (meth) acrylate.

- Acrylates for example alkanediol di (meth) acrylates such as 1,3-propanediol di (meth) acrylate, 1,4-butanediol di (meth) acrylate, 1,5-pentanediol di (meth) acrylate, for example , Alkane polyol poly (meth) acrylates such as trimethylolpropane tri (meth) acrylate, pentaerythritol tetra (meth) acrylate, for example, allyl monomers such as allyl (meth) methacrylate, triallyl (iso) cyanurate, Eg to such divinyl monomers such as divinylbenzene.

- mono or polyethylene glycol di (meth) acrylate is used.

- the crosslinkable monomer has a molecular structure similar to the molecular structure of the compatible monomer excluding the crosslinkable monomer in order to ensure compatibility between the monomer mixture containing the crosslinkable monomer (polymerizable vinyl monomer) and the antibiotic compound.

- the monomer is selected. Specifically, for example, when the compatible monomer excluding the crosslinkable monomer contains a (meth) acrylic acid ester monomer, mono- or polyethylene glycol di (meth) acrylate is selected as the crosslinkable monomer. Is done.

- the blending ratio of the crosslinkable monomer is, for example, 1 to 100 parts by mass, preferably 10 to 80 parts by mass with respect to 100 parts by mass of the compatible monomer excluding the crosslinkable monomer.

- the dipole force term ⁇ p, compound of the solubility parameter ⁇ defined by Hansen and calculated by the van Krevelen and Hoftyzer method is, for example, 2 to 8 [(J / cm 3 ) 1/2 ]

- the hydrogen bond term ⁇ h, compound of the solubility parameter ⁇ is, for example, 5.5 to 9.5 [(J / cm 3 ) 1/2 ]

- the dipole force term ⁇ p, polymer of the solubility parameter ⁇ is, for example, 5 to 7 [(J / cm 3 ) 1/2 ]

- the hydrogen bonding force term ⁇ h, polymer of the solubility parameter ⁇ is, for example, 8-10 [(J / cm 3 ) 1/2 ] in combination with a polymerizable vinyl monomer that produces a polymer.

- ⁇ ( ⁇ p and ⁇ h ) indicate an antibiotic compound and a polymer, respectively.

- the dipole force term ⁇ p and the hydrogen bond force term ⁇ h of the solubility parameter ⁇ defined by Hansen and calculated by the van Krevelen and Hoftyzer method are the type and number of atomic groups (including chemical bonds or substituents). Specifically, it is represented by the following formulas (1) and (2), respectively.

- F p is a dipole force element of intermolecular force (polar component of the molar attraction function), and V is a molar volume.)

- the F p of the substituents> Si ⁇ , ⁇ N— and ⁇ C— is also calculated by the same calculation process as described above.

- E h of the substituents —I,> Si ⁇ , ⁇ N—, and ⁇ C— are also calculated by performing the same calculation processing as described above.

- the above calculation processing is recorded on a computer as a program and optimized.

- n represents the degree of polymerization.

- ⁇ p Dipole force term

- PMMA In the monomer unit (—CH 2 —C (CH 3 ) COOCH 3 —) of the above formula (3), F p and V corresponding to each atomic group are described below.

- the above-described monomer unit dipole force term ⁇ p, monomer unit is the polymethyl methacrylate dipole force term ⁇ p, PMMA which is a repeating structure of the monomer unit.

- Hydrogen bond strength term ⁇ h, PMMA In the monomer unit (—CH 2 —C (CH 3 ) COOCH 3 —) of the above formula (3), E h corresponding to each atomic group is described below.

- the hydrogen bond strength term ⁇ h, polymer of the monomer unit described above is used as the hydrogen bond strength term ⁇ h, PMMA of polymethyl methacrylate which is a repeating structure of the monomer unit. 2.

- Co-dipole force term ⁇ p and hydrogen bond force term ⁇ h of the copolymer Next, a dipole force term ⁇ p and a hydrogen bond force term ⁇ h of the copolymer are calculated.

- the dipole force term ⁇ p, monomer unit of each monomer unit by the monomer mass ratio and adding them together the dipole force term ⁇ p, copolymer of the solubility parameter ⁇ of the copolymer is calculated.

- the hydrogen bond strength term ⁇ h, copolymer of the solubility parameter ⁇ of the copolymer is calculated by multiplying the hydrogen bond strength term ⁇ h, monomer unit of each monomer unit by the monomer mass ratio and adding them together. To do.

- polymethyl methacrylate which is a copolymer of monomers containing methyl methacrylate and ethylene glycol dimethacrylate in a mass ratio of 70:30 (corresponding to the mass ratio of Examples 1 to 7 described later)

- PMMA-EGDMA ethylene glycol dimethacrylate

- Dipole force term ⁇ p, PMMA-EGDMA The dipole force term ⁇ p, MMA unit of the monomer unit of methyl methacrylate is 5.98 [(J / cm 3 ) 1/2 ] as calculated above.

- dipole force term ⁇ p, EDGMA of the monomer unit of ethylene glycol dimethacrylate is 5.37 [(J / cm 3 ) 1/2 ] by calculation in the same manner as described above.

- the dipole force term ⁇ p, PMMA-EGDMA of this copolymer is calculated as in the following formula (6).

- ⁇ p, PMMA-EGDMA (70/100) ⁇ p , MMA unit + (30/100) ⁇ p

- Hydrogen bond term ⁇ h, PMMA-EGDMA The hydrogen bond term ⁇ h, MMA unit of the monomer unit of methyl methacrylate is 9.25 [(J / cm 3 ) 1/2 ].

- the hydrogen bond term ⁇ h, EGDMA of the monomer unit of ethylene glycol dimethacrylate is 10.42 [(J / cm 3 ) 1/2 ].

- the hydrogen bonding force term ⁇ h, PMMA-EGDMA of this copolymer is calculated as in the following formula (7).

- the dipole force term ⁇ p, polymer of the solubility parameter ⁇ of the polymer is preferably 5 to 6.5 [(J / cm 3 ) 1/2 ], and the hydrogen of the solubility parameter ⁇ of the polymer is

- the binding force term ⁇ h, polymer is preferably 9 to 10 [(J / cm 3 ) 1/2 ].

- the dipole force term ⁇ p, polymer and / or the hydrogen bond force term ⁇ h, polymer of the polymer is less than the above range , the polymer is excessively hydrophobic and sufficient with the antibiotic compound. In some cases, the compatibility cannot be obtained. Even if the compatibility is obtained, the antibiotic active compound leaks out of the core during suspension polymerization, and the sustained release in which the antibiotic active compound is sufficiently encapsulated. It may be difficult to synthesize the conductive particles.

- Dipole force term ⁇ p, compound and hydrogen bond term ⁇ h, compound of solubility ⁇ of antibiotic compound The dipole force term ⁇ p, compound and the hydrogen bond term ⁇ h, compound of the solubility ⁇ of the antibiotic compound are also calculated in the same manner as the monomer unit described above.

- the dipole force term ⁇ p, compound of the solubility parameter ⁇ of the antibiotic compound is preferably 3-7 [(J / cm 3 ) 1/2 ], and the hydrogen bond force term ⁇ h, compound is Preferably, it is 5.8 to 9.5 [(J / cm 3 ) 1/2 ].

- the dipole force term ⁇ p, compound and / or the hydrogen bond force term ⁇ h, compound of the antibiotic compound is not within the above range, the hydrophobic property of the antibiotic compound is excessively high, In some cases, sufficient compatibility cannot be obtained.

- the dipole force term ⁇ p, compound and hydrogen bond force term ⁇ h, compound of the antibiotic compound are within the above-mentioned range, and the dipole force term ⁇ p, polymer and hydrogen bond force term of the polymer If ⁇ h , polymer is within the above range, the antibiotic compound is defined as being compatible with the polymer without escaping from the core during suspension polymerization.

- the ratio of the antibiotic compound to the polymerizable vinyl monomer is, for example, 10/90 to 60/40 (that is, 0.00%) on a mass basis (that is, the mass part of the antibiotic compound / the mass part of the polymerizable vinyl monomer). 11 to 1.5).

- the proportion of the antibiotic compound to the polymerizable vinyl monomer is determined by polymerization of the antibiotic compound. For example, 1/99 to 60/40 (that is, 0.01 to 1.5), preferably 5/95 to 50/50 on a mass basis. (That is, 0.05 to 1.0).

- the sustained release rate is slower than the diffusion rate of the antibiotic compound at room temperature, so that, for example, 10/90 to 70 on a mass basis. / 30 (that is, 0.11 to 2.33), preferably 10/90 to 60/40 (that is, 0.11 to 1.5).

- the shell-forming component is at least two components that react with each other by polycondensation (condensation polymerization) or polyaddition, and include, for example, a first shell-forming component and a second shell-forming component.

- the first shell forming component is, for example, substantially hydrophobic and specifically has a very low solubility in water at room temperature. More specifically, for example, the solubility at room temperature is 1 on a mass basis. Parts by mass / 100 parts by mass of water (10000 ppm) or less, preferably 0.5 parts by mass / 100 parts by mass of water (5000 ppm) or less, more preferably 0.1 parts by mass / 100 parts by mass of water (1000 ppm) or less. .

- the first shell-forming component is an oil-soluble compound that forms a shell by polymerization (reaction) with the second shell-forming component, and examples thereof include polyisocyanate, polycarboxylic acid chloride, and polysulfonic acid chloride.

- polyisocyanate examples include aromatic polyisocyanates (aromatic diisocyanates) such as diphenylmethane diisocyanate and toluene diisocyanate, aliphatic polyisocyanates (aliphatic diisocyanates) such as hexamethylene diisocyanate, for example, isophorone diisocyanate (IPDI), hydrogen Aliphatic polyisocyanates (alicyclic diisocyanates) such as added xylylene diisocyanate and hydrogenated diphenylmethane diisocyanate, for example, araliphatic polyisocyanates (araliphatic diisocyanate) such as xylylene diisocyanate and tetramethyl xylylene diisocyanate, etc. It is done.

- aromatic polyisocyanates aromatic diisocyanates

- aliphatic polyisocyanates such as hexamethylene diisocyanate

- multimers of the above-described polyisocyanates are also exemplified, and specific examples include dimers, trimers (isocyanurate group-containing polyisocyanates, trimer-modified products), pentamers, and heptamers.

- a trimer specifically, a trimer of IPDI is used.

- modified polyisocyanates (excluding multimers) are also exemplified, and examples thereof include polyol-modified polyisocyanate.

- polycarboxylic acid chloride examples include sebacic acid dichloride, adipic acid dichloride, azelaic acid dichloride, terephthalic acid dichloride, and trimesic acid dichloride.

- polysulfonic acid chloride examples include benzenesulfonyl dichloride.

- the first shell forming component can be used alone or in combination.

- the first shell forming component is preferably a polyisocyanate, and more preferably a polyisocyanate multimer.

- the second shell forming component is a water-soluble compound present in the aqueous phase before interfacial polymerization.

- the second shell forming component is an active hydrogen group-containing compound, and as such an active hydrogen group-containing compound, for example, a compound having an active hydrogen group such as a hydroxyl group or an amino group, specifically, For example, a polyamine, a polyol, water, etc. are mentioned.

- polyamines examples include diamines such as ethylenediamine, propylenediamine, hexamethylenediamine, diaminotoluene, phenylenediamine, and piperazine, for example, triamines such as diethylenetriamine, tetraamines such as triethylenetetramine, such as tetraethylenepentamine, and the like.

- triamines such as diethylenetriamine, tetraamines such as triethylenetetramine, such as tetraethylenepentamine, and the like.

- pentaamine for example, hexamine such as pentaethylenehexamine.

- triamine is used.

- polystyrene resin examples include ethylene glycol, propanediol, 1,4-butanediol, 1,6-hexanediol, neopentyl glycol, diethylene glycol, triethylene glycol, dipropylene glycol, cyclohexane dimethanol, polyethylene glycol, polypropylene glycol, etc.

- Diols such as triols such as glycerin and trimethylolpropane, and tetraols such as pentaerythritol.

- the second shell forming component can be used alone or in combination.

- polyamine is used.

- the first component is prepared as a hydrophobic solution.

- the hydrophobic solution is prepared by blending the above antibiotic active compound and a polymerizable vinyl monomer. Specifically, a hydrophobic solution is prepared by dissolving an antibiotic compound in a polymerizable vinyl monomer in the absence of a solvent.

- an initiator is preferably added to the hydrophobic solution.

- the initiator is an oil-soluble radical polymerization initiator.

- the radical polymerization initiator include dilauroyl peroxide (10 hour half-life temperature T 1/2 : 61.6 ° C.), 1,1,3, 3-tetramethylbutylperoxy-2-ethylhexanoate (10-hour half-temperature T 1/2 : 65.3 ° C.), t-hexylperoxy-2-ethylhexanoate (10-hour half-temperature T 1/2 2 : 69.9 ° C.), diisopropyl peroxydicarbonate (10-hour half-life temperature T 1/2 : 40.5 ° C.), benzoyl peroxide (10-hour half-life temperature T 1/2 : 73.6 ° C.), etc.

- peroxides for example, 2,2'-azobisisobutyronitrile (10 hours half-life temperature T 1/2: 60 ° C.), 2,2'-azobis (2,4-dimethylvaleronitrile) (10 hours half Degrees T 1/2: 51 °C), 2,2'- azobis (2-methylbutyronitrile) (10 hours half-life temperature T 1/2: 67 ° C.), and the like azo compounds such as.

- an organic peroxide is used.

- the 10-hour half-life temperature T 1/2 of the initiator is, for example, 40 to 90 ° C., preferably 50 to 80 ° C.

- the 10-hour half-life temperature T 1/2 of the initiator is the temperature of the 10-hour value in the graph obtained by plotting the concentration half-life at several arbitrary temperature points.

- the mixing ratio of the initiator is, for example, 0.01 to 2 parts by mass, preferably 0.1 to 1 part by mass with respect to 100 parts by mass of the polymerizable vinyl monomer.

- the initiator is blended at the same time as or before or after the blending of the antibiotic compound and the polymerizable vinyl monomer.

- the initiator is dissolved simultaneously when the antibiotic compound is dissolved in the polymerizable vinyl monomer.

- the first shell forming component can be blended in the hydrophobic solution. That is, a part of the second component (shell forming component) (all or part of the first shell forming component) and the first component can be contained in the hydrophobic solution.

- the blending ratio of the first shell forming component blended in the hydrophobic solution is, for example, 5 to 80 parts by weight, preferably 10 to 70 parts by weight, and more preferably 20 parts by weight with respect to 100 parts by weight of the polymerizable vinyl monomer. -60 parts by mass, particularly preferably 25-50 parts by mass.

- the ratio of the first shell forming component to the polymerizable vinyl monomer is on a mass basis (that is, the mass part of the first shell forming component / the mass part of the polymerizable vinyl monomer), for example, 0.05 to 0. .8, preferably 0.1 to 0.7, more preferably 0.2 to 0.6, and particularly preferably 0.25 to 0.5.

- the effect of suppressing the sustained release rate may be insufficient, and the thickness of the shell may not be uniform, and the redispersibility (described later) may be reduced.

- the sustained release particles cannot release the antibiotic compound, and the content rate of the antibiotic compound is excessively lowered, and the sustained release particles exhibit the antibiotic activity. There are cases where it is not possible.

- the preparation of the hydrophobic solution may be performed at room temperature, for example, or may be performed by heating to 30 to 100 ° C. as necessary.

- the hydrophobic solution is prepared at room temperature without heating.

- the hydrophobic solution is then suspended (dispersed in water).

- the hydrophobic solution and water are mixed, and the hydrophobic solution is suspended by stirring uniformly. Thereby, a suspension in which the hydrophobic solution is suspended is obtained.

- the suspension conditions are not particularly limited, and may be carried out at room temperature, for example, or may be carried out by heating at 30 to 100 ° C., for example.

- Suspension is performed without heating.

- the mixing ratio of water is, for example, 50 to 1500 parts by mass, preferably 100 to 1000 parts by mass, and more preferably 120 to 500 parts by mass with respect to 100 parts by mass of the hydrophobic solution.

- a dispersant is blended in the suspension of the hydrophobic solution.

- dispersant examples include polyvinyl alcohol (PVA, including partially saponified polyvinyl alcohol), polyvinyl pyrrolidone, gelatin, gum arabic, hydroxyethyl cellulose, hydroxypropyl cellulose, carboxymethyl cellulose, cationized starch, polyacrylic acid and salts thereof.

- PVA polyvinyl alcohol

- polyvinyl pyrrolidone polyvinyl pyrrolidone

- gelatin gum arabic

- hydroxyethyl cellulose hydroxypropyl cellulose

- carboxymethyl cellulose cationized starch

- polyacrylic acid and salts thereof examples include polyacrylic acid and salts thereof.

- water-soluble polymers such as styrene-maleic acid copolymers and salts thereof, for example, inorganic dispersants such as tricalcium phosphate, colloidal silica, montmorillonite, magnesium carbonate, aluminum hydroxide and zinc white.

- polyvinyl alcohol and tricalcium phosphate are preferable. If it is tribasic calcium phosphate, when the obtained sustained release particles are formulated as a suspension, the redispersibility of the suspension is very good, and the sustained release particles are a powder. When formulated as (described later) or granules (described later), the redispersibility of the powder or granules in water is very good.

- the mixing ratio of the dispersing agent is, for example, 0.1 to 20 parts by mass, preferably 0.5 to 10 parts by mass with respect to 100 parts by mass of the hydrophobic solution.

- a surfactant when suspending the hydrophobic solution, a surfactant can be used in combination with the above-described dispersant.

- Surfactant is blended in order to effectively prevent core aggregation during suspension polymerization.

- examples of the surfactant include sodium dodecylbenzene sulfonate (DBN), sodium lauryl sulfate, sodium di-2-ethylhexyl sulfosuccinate, sodium dodecyl diphenyl ether disulfonate, sodium nonyl diphenyl ether sulfonate, sodium polyoxyethylene alkyl ether sulfate.

- DBN sodium dodecylbenzene sulfonate

- sodium lauryl sulfate sodium di-2-ethylhexyl sulfosuccinate

- sodium dodecyl diphenyl ether disulfonate sodium nonyl diphenyl ether sulfonate

- sodium polyoxyethylene alkyl ether sulfate sodium polyoxyethylene alkyl ether sulfate.

- Anionic surfactants such as polyoxyethylene alkyl ether ammonium phosphate, sodium naphthalene sulfonic acid formaldehyde condensate sodium salt, such as polyoxyethylene lauryl ether, polyoxyethylene nonyl phenyl ether, polyoxyethylene monostearate, polyoxy Such as ethylene sorbitan monooleate, polyoxyethylene polyoxypropylene block copolymer Nonionic surface active agents and the like.

- an anionic surfactant is used.

- the blending ratio of the surfactant is, for example, 0.0001 to 1.0 part by mass, preferably 0.001 to 0.1 part by mass with respect to 100 parts by mass of the hydrophobic solution.

- the dispersant and the surfactant can be blended, for example, before or after blending the hydrophobic solution and water.

- the dispersant and surfactant are preferably blended in the water prior to blending with the hydrophobic solution. Thereby, an aqueous solution or dispersion of the dispersant and the surfactant is prepared.

- a disperser such as a homomixer, a disper, an ultrasonic homogenizer, a pressure type homogenizer, a milder, or a porous membrane press-in disperser is used.

- a homomixer is used, and the rotation speed thereof is, for example, 100 to 10,000 rpm, preferably 1000 to 8000 rpm.

- the first component is subjected to suspension polymerization by raising the temperature of the suspension to a predetermined temperature.

- the polymerizable vinyl monomer reacts (specifically, vinyl polymerization) while stirring the suspension so that the suspension state of the suspension is maintained. A polymer is produced. Moreover, since the polymerizable vinyl monomer used as a raw material is in a hydrophobic phase (oil phase), it is considered to be in situ polymerization.

- the suspension is first heated to a temperature that is, for example, 1 to 30 ° C., preferably 5 to 20 ° C. higher than the 10-hour half-temperature T 1/2 of the initiator.

- the temperature rise temperature (that is, the polymerization temperature) is, for example, 30 to 100 ° C., preferably 40 to 80 ° C., and more preferably 50 to 70 ° C.

- the polymerization temperature of this suspension polymerization is preferably set higher than the melting point of the antibiotic compound described above.

- suspension polymerization starts when the initiator is thermally decomposed at a predetermined temperature.

- the temperature at which suspension polymerization starts (starting temperature) Ti is, for example, in the relationship of the above-described initiator 10-hour half-temperature T1 / 2 and the following formula (1).

- T 1/2 ⁇ 10 ⁇ T i ⁇ T 1/2 +10 (1)

- T i represents the initiation temperature of suspension polymerization

- T 1/2 represents the 10 hour half-life temperature of the initiator.

- the pressure during suspension polymerization is not particularly limited, and is a normal pressure. Alternatively, for example, it can be carried out under high pressure. Preferably, it is carried out at normal pressure.

- suspension polymerization is carried out in an inert gas atmosphere such as nitrogen.

- the polymerization time for suspension polymerization is, for example, 1 hour or longer, preferably 3 hours or longer, more preferably 4 hours or longer, and usually 10 hours or shorter.

- the polymerization time of suspension polymerization can be set to, for example, less than 3 hours, or even 2 hours or less.

- the polymerization time of the suspension polymerization is less than the above lower limit value, the polymerization time becomes excessively short, so that the remaining polymerizable vinyl monomer and the first shell-forming component are present on the surface of the core and a portion slightly inside thereof.

- the next interfacial polymerization proceeds with the polymerization of the remaining polymerizable vinyl monomer.

- a core containing an antibiotic compound and a polymer of a polymerizable vinyl monomer is formed by the suspension polymerization described above.

- the polymer of the polymerizable vinyl monomer is compatible with, for example, an antibiotic compound. That is, the polymer is dissolved in the antibiotic compound to form an antibiotic compound solution of the polymer, and the antibiotic compound solution is suspended in the aqueous phase.

- the polymerizable vinyl monomer is selected in such a combination that the polymer of the polymerizable vinyl monomer and the antibiotic compound are compatible with each other at the polymerization temperature during the suspension polymerization described above. Therefore, phase separation is unlikely to occur during suspension polymerization, and the polymer (polymer in the middle of the reaction) is dissolved in the antibiotic compound, or the polymer (polymer in the middle of the reaction) is dissolved in the antibiotic compound.

- the reaction proceeds in a swollen state, and a core in which a uniform phase is formed can be obtained.

- the second component is carried out by interfacial polymerization of the second component.

- the first shell forming component in the core and the second shell forming component are reacted.

- the interfacial polymerization in the second step starts when the first polymerizable vinyl monomer decreases with the progress of the suspension polymerization in the first step.

- interfacial polymerization is initiated by adding the second shell forming component to the suspension in which suspension polymerization is in progress. Thereby, the interfacial polymerization of the second component starts after the time when the suspension polymerization of the first step starts.

- the mixing ratio of the second shell forming component is such that the equivalent ratio of the isocyanate group of the first shell forming component (isocyanate group / amino group) to the amino group (primary amino group and secondary amino group) of the second shell forming component is

- the ratio is 0.4 to 1.2, preferably 0.6 to 1.0, and more preferably 0.7 to 0.9.

- the second shell-forming component is preferably diluted with water to prepare a second shell-forming component aqueous solution, and the second shell-forming component aqueous solution is added to the suspension in which suspension polymerization is in progress. .

- an emulsion of the first shell-forming component can be prepared, and the prepared emulsion and the second shell-forming component (second shell-forming component aqueous solution) can be blended in the suspension and reacted.

- the second shell forming component is added.

- interfacial polymerization is performed on the surface of the polymer (core).

- a silane coupling agent can be blended in the second shell forming component aqueous solution.

- the silane coupling agent is, for example, an alkoxysilyl compound having at least a primary amino group, such as ⁇ -aminopropyltriethoxysilane (3-aminopropyltriethoxysilane), N-phenyl- ⁇ -aminopropyltrimethyl.

- alkoxysilyl group-containing monoamines such as methoxysilane.

- the equivalent ratio of the isocyanate group to the amino group is changed. It is the ratio which substituted a part of 2nd shell formation component by the silane coupling agent, without having.

- the blending ratio of the silane coupling agent is, for example, 0.5 to 20 parts by mass, preferably 2 to 10 parts by mass with respect to 100 parts by mass of the second shell forming component.

- the first shell-forming component present in the core (polymer) and the second shell-forming component in the aqueous phase react on the surface of the polymer particles.

- Interfacial polymerization can be performed, for example, at the same temperature as the polymerization temperature in the first step (suspension polymerization), or at a temperature higher than the polymerization temperature in the first step (suspension polymerization).

- Such temperature is, for example, 1 to 20 ° C. higher, preferably 2 to 15 ° C. higher, more preferably 5 to 10 ° C. higher than the polymerization temperature in the first step.

- the polymerization time for the interfacial polymerization is, for example, 0.1 to 8 hours, preferably 0.5 to 6 hours, and more preferably 1 to 4 hours.

- the interfacial polymerization can be completed completely.

- the completion of interfacial polymerization is confirmed by the disappearance of infrared absorption spectrum due to the isocyanate group derived from polyisocyanate.

- the completion of the interfacial polymerization can also be confirmed by lowering the pH of the suspension to near the value before the addition of the polyamine.

- a shell covering the core can be formed by interfacial polymerization of the second component and performing the second step.

- the polymerizable vinyl monomer remaining when starting the interfacial polymerization is present so as to be compatible with the first shell forming component, and the interfacial polymerization in the second step proceeds with the polymerization of the remaining polymerizable vinyl monomer.

- the first shell forming component is The shell (3) extends along the outer periphery of the core (2) as it is in solution and phase-separated from the core containing the polymer formed by suspension polymerization, as seen in the TEM picture of FIG. Has a smooth surface. Therefore, as shown in the SEM photograph of FIG. 5, the sustained release particles are formed in a substantially spherical shape.

- the first shell-forming component is phase-separated from the core containing the polymer formed by suspension polymerization in a highly viscous solution state or solid phase state. Therefore, as shown in FIG. 12 and FIG. 13, the first shell forming component is unevenly distributed on the surface of the core (2) and phase-separated so as to be unevenly distributed on the surface of the core (2). As a result, the shell (3) formed by interfacial polymerization is formed with a non-uniform thickness along the outer periphery of the core (2).

- the shell (2) is formed with a protruding portion (4) protruding outward.

- a plurality of protruding portions (4) are formed at intervals along the circumferential direction of the shell (2).

- the sustained release particles (1) are formulated as a suspension, the redispersibility of the suspension is improved, and the occurrence of caking can be prevented.

- the suspension after the reaction is cooled, for example, by cooling or water cooling.

- the cooling temperature is, for example, room temperature (20 to 30 ° C., more specifically 25 ° C.).

- the antibiotic compound is compatible with the polymer in the core if it is liquid at room temperature.

- the compatible state is frozen in the polymer in the core to maintain a uniform state.

- the antibiotic compound is preferably not compatible with the shell.

- the particle diameter of the sustained-release particles is not particularly limited, and is an average particle diameter (median diameter), for example, 1 ⁇ m to 1 mm, preferably 2 ⁇ m to 100 ⁇ m.

- sustained-release particles comprising a core containing an antibiotic compound and a polymer of a polymerizable vinyl monomer and a shell covering the core are suspended.

- the sustained-release particles thus obtained may be used as they are (suspension), that is, as a suspending agent, and after solid-liquid separation by filtration and / or centrifugation, for example, Alternatively, it may be formulated into a known dosage form such as powder or granule. Further, if necessary, water washing and / or acid washing can be performed. Furthermore, the suspension can be spray-dried or air-dried as it is to form a dosage form such as a powder or granule.

- the solid concentration (sustained release particle concentration) in the suspension is, for example, 1 to 50% by mass, and preferably 5 to 40% by mass.

- the concentration of the antibiotic compound in the suspension is, for example, 0.5 to 40% by mass, preferably 1 to 25% by mass.

- the powder is excellent in fluidity especially when tribasic calcium phosphate is used as a dispersant. Moreover, an aqueous dispersion or suspension can be re-prepared by dispersing or suspending the powder again in water. Therefore, such a powder is excellent in re-water dispersibility or re-suspension.

- sustained-release particles as a powder at the time of transportation, and preparing (re-formulation, regeneration) as an aqueous dispersion or suspension at the time of use. Can be enlarged.

- the shell contains the antibiotic compound and the polymer.

- the core can be reliably coated.

- the sustained-release particles of the present invention having excellent sustained-release properties and capable of exhibiting excellent efficacy sustaining effects can be obtained.

- the sustained release property is a property capable of slowly releasing the encapsulated compound.

- the second shell forming component aqueous solution contains a silane coupling agent (alkoxysilyl compound having a primary amino group), a silanol group derived from the silane coupling agent is present in the shell, and the silanol group

- a silane coupling agent alkoxysilyl compound having a primary amino group

- organic substances specifically, cellulose forming paper or wood. Therefore, when the sustained-release particles are used after being added (blended) to paints, sealants, adhesives, etc., the sustained-release particles can be chemically bonded to the above-described inorganic or organic substrate. Can maintain long-term antibiotic activity.

- the interfacial polymerization is started after the suspension polymerization in the first step is started.

- the start time of the interfacial polymerization is not limited to the above.

- the interfacial polymerization in the second step can be started simultaneously with the start of the suspension polymerization in the first step.

- the second shell-forming component (specifically , The second shell-forming component aqueous solution) is added to the suspension.

- the shell is first formed on the surface while forming the core by suspension polymerization. Can be reliably formed.

- the suspension polymerization is substantially completed before the start of the interfacial polymerization.

- coloring of the core due to the active hydrogen group (specifically, amino group) of the second shell forming component (specifically, polyamine or the like) can be effectively prevented.

- the sustained release rate of the sustained release particles of the present invention is determined by the ratio of the remaining polymerizable vinyl monomer at the start of the interfacial polymerization in the second step (that is, the charged polymerizable vinyl, as illustrated in the examples described below).

- the ratio of the remaining polymerizable vinyl monomer to the monomer (hereinafter sometimes referred to as the residual monomer ratio) is controlled.

- the sustained release rate of the sustained-release particles is the fastest, and the residual monomer ratio is substantially 0%.

- the sustained release rate of the sustained release particles is the slowest. That is, if the residual monomer ratio at the start of the interfacial polymerization is close to 100% to 0%, the sustained release rate of the obtained sustained release particles is slowed accordingly.

- sustained-release particles when the sustained-release particles are present in the presence of a solvent, or when the sustained-release particles are used at a high temperature, etc.

- the sustained-release particles of the present invention having a core-shell structure comprising a core containing an antibiotic compound and a shell covering the same are preferably used.

- IPBC Trade name “Fangitrol 400”, 3-iodo-2-propynylbutyl carbamate, molecular weight 281, melting point: 60 ° C., solubility in water: 150 ppm, dipole force term ⁇ p, compound of solubility parameter ⁇ : 3 .23 [(J / cm 3 ) 1/2 ], hydrogen bond strength term ⁇ h, compound of solubility parameter ⁇ : 7.83 [(J / cm 3 ) 1/2 ], OIT manufactured by International Specialty Products : Trade name “Caisson 893T” (“Caisson” is a registered trademark), 2-n-octyl-4-isothiazolin-3-one, molecular weight 213, melting point: less than 20 ° C., solubility in water: 300 ppm, solubility parameter ⁇ polar term ⁇ p, compound: 5.47 [( J / cm 3) 1/2], water solubility

- T-1890 trade name “VESTANAT T 1890/100” (“VESTANAT” is a registered trademark), trimer of isophorone diisocyanate (IPDI), first shell forming component, melting point 110 to 120 ° C., water Solubility in water: 20 ppm, dilauroyl peroxide manufactured by Evonik Industries, Inc .: trade name “Parroyl L” (“Parroyl” is a registered trademark), 10-hour half-temperature T 1/2 : 61.6 ° C., dilaurin manufactured by NOF Corporation Dibutyltin acid: chemical reagent, polyaddition catalyst, PVA-217 manufactured by Wako Pure Chemical Industries, Ltd .: trade name “Kuraray Poval 21” "Partially saponified polyvinyl alcohol, manufactured by Kuraray Co., Ltd.," TCP-10 U “: trade name, 10% water suspension of tert calcium phosphate (3 [Ca 3 (PO 4 ) 2] ⁇ Ca (OH) 2), Matsuo DBN,

- Neo-Perex is a registered trademark

- sodium dodecylbenzenesulfonate Kalex Plex SS-L: trade name (" Pelex "is registered trademark)

- sodium dodecyl diphenyl ether disulfonate Kao diethylenetriamine: Wako First grade reagent, second shell forming component, manufactured by Wako Pure Chemical Industries, Ltd.

- Example 1 (Formulation of suspension containing IPBC-containing sustained release particles) (After starting suspension polymerization, start interfacial polymerization) A 200 mL beaker (1) was charged with 40 g of IPBC, 35 g of methyl methacrylate, 15 g of ethylene glycol dimethacrylate, 10 g of T-1890 and 300 mg of dilauroyl peroxide, and stirred at room temperature to prepare a uniform hydrophobic solution.

- a 500 mL beaker (2) was charged with 233 g of ion-exchanged water, 40 g of a 10% by weight aqueous solution of PVA-217 and 200 mg of a 5% by weight aqueous DBN solution, and stirred at room temperature to obtain a uniform aqueous solution.

- the hydrophobic solution was added to a 500 mL beaker (2).

- K The suspension was prepared by suspending the hydrophobic solution by stirring for 10 minutes at a rotational speed of 3000 rpm with a homomixer MARK 2.5 (manufactured by PRIMIX Corporation).

- the suspension was transferred to a 500 mL 4 neck Kolben equipped with a stirrer, a reflux condenser, a thermometer and a nitrogen introduction tube, heated to 70 ° C. with stirring under a nitrogen stream, and suspended for 3 hours. Polymerized.

- interfacial polymerization was performed. Specifically, an aqueous diethylenetriamine solution obtained by diluting 1.2 g of diethylenetriamine in 25 g of ion-exchanged water was added to the above suspension, and the suspension was heated to 75 ° C. and subsequently maintained at 75 ° C. .

- suspension agent sustained-release particles comprising a core containing IPBC and a shell covering the core was obtained.

- Example 2 (Formulation of suspension containing IPBC-containing sustained release particles) (After starting suspension polymerization, start interfacial polymerization) The amounts of methyl methacrylate, ethylene glycol dimethacrylate and T-1890 in the hydrophobic solution were changed to 31.5 g, 13.5 g and 15 g, respectively, and the amount of diethylenetriamine in the diethylenetriamine aqueous solution added at the start of interfacial polymerization was 1. Except for the change to 8 g, suspension polymerization and interfacial polymerization were sequentially carried out in the same manner as in Example 1 to effect suspension of sustained-release particles comprising a core containing IPBC and a shell covering the core. A suspension (suspension) was obtained.

- Example 3 (Formulation of suspension containing IPBC-containing sustained release particles) (After starting suspension polymerization, start interfacial polymerization) The amount of methyl methacrylate, ethylene glycol dimethacrylate and T-1890 in the hydrophobic solution was changed to 28 g, 12 g and 20 g, respectively, and the amount of diethylenetriamine in the diethylenetriamine aqueous solution added at the start of interfacial polymerization was changed to 2.4 g. In the same manner as in Example 1, suspension polymerization and interfacial polymerization were sequentially performed, so that a suspension of sustained-release particles comprising a core containing IPBC and a shell covering the same (suspension release particle suspension) A suspension was obtained.

- Example 4 (Formulation of suspension containing IPBC-containing sustained release particles) (After starting suspension polymerization, start interfacial polymerization) The amount of IPBC, methyl methacrylate, ethylene glycol dimethacrylate and T-1890 in the hydrophobic solution was changed to 45 g, 28 g, 12 g and 15 g, respectively, and the amount of ion-exchanged water in the aqueous solution was changed to 133 g. In addition, T.W. K.

- the number of rotations at the time of suspension of the hydrophobic solution by the homomixer MARK 2.5 type was changed to 4000 rpm, and the amount of diethylenetriamine in the diethylenetriamine aqueous solution added at the start of interfacial polymerization was changed to 1.8 g.

- suspension polymerization and interfacial polymerization were sequentially performed, so that a suspension of sustained-release particles comprising a core containing IPBC and a shell covering the same (suspension release particle suspension) A suspension was obtained.

- Example 5 (Formulation of suspension containing IPBC-containing sustained release particles) (After starting suspension polymerization, start interfacial polymerization) Except that the polymerization time of suspension polymerization was changed from 3 hours to 2 hours, the core containing IPBC was coated by performing suspension polymerization and interfacial polymerization in the same manner as in Example 2. A suspension (suspension agent) of sustained-release particles provided with a shell is obtained.

- Example 6 (Formulation of suspension containing IPBC-containing sustained release particles) (Start suspension polymerization and interfacial polymerization simultaneously) A suspension (suspension of sustained release particles containing IPBC) was prepared in the same manner as in Example 2 except that the polymerization was started simultaneously with suspension polymerization and interfacial polymerization, and the polymerization time was set to 7 hours. Agent).

- the temperature of the suspension was raised to 70 ° C., and an aqueous diethylenetriamine solution was added to start interfacial polymerization and suspension polymerization simultaneously.

- suspension agent sustained-release particles comprising a core containing IPBC and a shell covering the core was obtained.

- the obtained suspension was colored pink.

- Example 7 (Formulation of suspension containing IPBC-containing sustained release particles) (After starting suspension polymerization, start interfacial polymerization) In Example, except that 40 g of 10 wt% aqueous solution of PVA-217 and 200 mg of 5 wt% aqueous solution of DBN were replaced with 40 g of TCP-10U and 200 mg of 5 wt% aqueous solution of Perex SS-L. In the same manner as in No. 2, suspension polymerization and interfacial polymerization are sequentially carried out to obtain a suspension (suspension agent) of sustained release particles comprising a core containing IPBC and a shell covering the core. It was.

- Example 8 (Formulation of suspension containing OIT-containing sustained release particles) (After starting suspension polymerization, start interfacial polymerization) A 200 mL beaker (1) was charged with 40 g of OIT, 27 g of methyl methacrylate, 4.5 g of methacrylic acid, 13.5 g of ethylene glycol dimethacrylate, 15 g of T-1890 and 300 mg of dilauroyl peroxide, and stirred uniformly at room temperature. A hydrophobic solution was prepared.

- the hydrophobic solution was added to a 500 mL beaker (2).

- K The suspension was prepared by suspending the hydrophobic solution by stirring for 10 minutes at a rotational speed of 3000 rpm with a homomixer MARK 2.5 (manufactured by PRIMIX Corporation).

- the suspension was transferred to a 500 mL 4 neck Kolben equipped with a stirrer, a reflux condenser, a thermometer and a nitrogen introduction tube, heated to 70 ° C. with stirring under a nitrogen stream, and suspended for 3 hours. Polymerized. Thereafter, interfacial polymerization was performed.

- a diethylenetriamine aqueous solution obtained by diluting 1.8 g of diethylenetriamine in 25 g of ion-exchanged water was added to the suspension, the suspension was heated to 75 ° C., and subsequently maintained at a temperature of 75 ° C.

- Example 9 (Formulation of suspension containing IPBC-containing sustained release particles) (After starting suspension polymerization, start interfacial polymerization) A 200 mL beaker (1) was charged with 25 g of IPBC, 50 g of methyl methacrylate, 10 g of ethylene glycol dimethacrylate, 15 g of T-1890 and 300 mg of dilauroyl peroxide, and stirred at room temperature to prepare a uniform hydrophobic solution.

- a 500 mL beaker (2) was charged with 82.7 g of ion-exchanged water, 40 g of TCP-10U and 200 mg of a 5% by weight aqueous solution of PELEX SSL, and stirred at room temperature to obtain a uniform suspension.

- the hydrophobic solution was added to a 500 mL beaker (2).

- K The suspension was prepared by suspending the hydrophobic solution by stirring for 10 minutes at a rotational speed of 4000 rpm with a homomixer MARK 2.5 (manufactured by PRIMIX).

- interfacial polymerization was performed. Specifically, an aqueous diethylenetriamine solution obtained by diluting 1.8 g of diethylenetriamine in 25 g of ion-exchanged water was added to the above suspension, and the suspension was heated to 75 ° C. and subsequently maintained at 75 ° C. .

- suspension agent sustained-release particles comprising a core containing IPBC and a shell covering the core was obtained.

- Example 10 (Formulation of suspension containing OIT-containing sustained release particles) (After starting suspension polymerization, start interfacial polymerization) A 200 mL beaker (1) was charged with 25 g of OIT, 36 g of methyl methacrylate, 6.0 g of methacrylic acid, 18 g of ethylene glycol dimethacrylate, 15 g of T-1890 and 300 mg of dilauroyl peroxide. A neutral solution was prepared.

- the hydrophobic solution was added to a 500 mL beaker (2).

- K The suspension was prepared by suspending the hydrophobic solution by stirring for 10 minutes at a rotation speed of 3500 rpm with a homomixer MARK 2.5 (manufactured by Primix).

- a diethylenetriamine aqueous solution obtained by diluting 1.8 g of diethylenetriamine in 25 g of ion-exchanged water was added to the suspension, and the suspension was heated to 75 ° C. and subsequently maintained at 75 ° C.

- Example 11 (Formulation of suspension containing propiconazole-containing sustained-release particles) (After starting suspension polymerization, start interfacial polymerization) In the hydrophobic solution, 25 g of propiconazole was used instead of 25 g of IPBC, and in the aqueous solution, 10 g of PVA-217 was substituted for 40 g of TCP-10U and 200 mg of 5% aqueous solution of Perex SS-L. A core containing propiconazole was obtained by sequentially carrying out suspension polymerization and interfacial polymerization in the same manner as in Example 9 except that 40 g of a 50% aqueous solution and 200 mg of a 5% by mass aqueous solution of DBN were charged. A suspension (suspension agent) of sustained-release particles comprising a shell covering the same was obtained.

- Example 12 (Formulation of suspension containing flusilazole-containing sustained-release particles) (After starting suspension polymerization, start interfacial polymerization) In the hydrophobic solution, except that 25 g of flusilazole was used instead of 25 g of propiconazole, a suspension-containing and interfacial polymerization were sequentially performed in the same manner as in Example 11 to obtain a core containing flusilazole, A suspension (suspension agent) of sustained release particles provided with a shell covering the same was obtained.

- Example 13 (Formulation of suspension containing prochloraz-containing sustained-release particles) (After starting suspension polymerization, start interfacial polymerization) In the hydrophobic solution, a core containing prochloraz was obtained by sequentially performing suspension polymerization and interfacial polymerization in the same manner as in Example 11, except that 25 g of prochloraz was charged instead of 25 g of propiconazole. A suspension (suspension agent) of sustained release particles provided with a shell covering the same was obtained.

- Example 14 (Formulation of suspension containing cyfluthrin-containing sustained release particles) (After starting suspension polymerization, start interfacial polymerization) In the hydrophobic solution, except that 25 g of cyfluthrin was charged instead of 25 g of propiconazole, a core containing cyfluthrin was obtained by sequentially performing suspension polymerization and interfacial polymerization in the same manner as in Example 11. A suspension (suspension agent) of sustained release particles provided with a shell covering the same was obtained.

- Comparative Example 1 (Formulation of suspension containing IPBC-containing sustained release particles) (After the start of interfacial polymerization, suspension polymerization is started) The order of suspension polymerization and interfacial polymerization in Example 2 was reversed. That is, a suspension (suspension) of sustained-release particles containing IPBC was obtained in the same manner as in Example 2 except that interfacial polymerization was first performed and then suspension polymerization was performed.

- Example 2 the suspension prepared in the same manner as in Example 2 was transferred to a 500 mL 4-neck Kolben equipped with a stirrer, reflux condenser, thermometer, and nitrogen introduction tube, and the mixture was lifted while stirring in an air atmosphere. Warm up.

- the obtained suspension was colored pink.

- Example 2 Formulation of suspension containing IPBC-containing sustained release particles

- the order of suspension polymerization and interfacial polymerization in Example 2 was reversed. That is, first, interfacial polymerization was performed, then suspension polymerization was performed, and further, interfacial polymerization was performed at a low temperature (38 ° C.), and the sustained release property containing IPBC was the same as in Example 2. A suspension of particles was obtained.

- the hydrophobic solution was added to a 500 mL beaker (2).

- K The suspension was prepared by suspending the hydrophobic solution by stirring for 10 minutes at a rotational speed of 3000 rpm with a homomixer MARK 2.5 (manufactured by PRIMIX Corporation).

- the suspension was transferred to a 500 mL 4-neck Kolben equipped with a stirrer, reflux condenser, thermometer and nitrogen introduction tube, and heated with stirring to carry out interfacial polymerization and then suspension polymerization.

- the suspension is heated to 38 ° C. in an air atmosphere, and carbon dioxide bubbles are removed by a decarboxylation urea reaction (chain extension reaction) between an isocyanate group of T-1890 and water. Generation was observed and interfacial polymerization started. At 38 ° C., it was confirmed that the suspension polymerization of the above formulation did not substantially start within 5 hours.

- suspension was heated to 75 ° C. under a nitrogen stream, and suspension polymerization was carried out for 4 hours. Thereafter, the suspension after the reaction was cooled to 30 ° C. or lower to obtain a suspension (suspension) of sustained-release particles containing IPBC.

- Comparative Example 3 (Formulation of suspension containing OIT-containing sustained release particles) (After the start of interfacial polymerization, suspension polymerization is started) The order of suspension polymerization and interfacial polymerization in Example 8 was reversed. That is, a suspension (suspension) of sustained-release particles containing OIT was obtained in the same manner as in Example 8, except that suspension polymerization was first performed and then interfacial polymerization was performed.

- Example 8 the suspension prepared in the same manner as in Example 8 was transferred to a 500 mL 4-cervical Kolben equipped with a stirrer, reflux condenser, thermometer, and nitrogen introduction tube, and the temperature was increased while stirring. Polymerization was performed, followed by suspension polymerization.

- the suspension was heated to 50 ° C. in an air atmosphere, and an aqueous diethylenetriamine solution in which 1.8 g of diethylenetriamine was diluted in 25 g of ion-exchanged water was added to initiate interfacial polymerization.

- the suspension is heated to 50 ° C. in an air atmosphere, and carbon dioxide bubbles are removed by a decarboxylation urea formation reaction (chain extension reaction) between an isocyanate group of T-1890 and water. Reflection was observed and interfacial polymerization started. At 50 ° C., it was confirmed that the suspension polymerization of the above formulation did not substantially start within 4 hours.

- suspension was heated to 75 ° C. under a nitrogen stream, and suspension polymerization was carried out for 4 hours. Thereafter, the suspension after the reaction was cooled to 30 ° C. or lower to obtain a suspension (suspension) of sustained-release particles containing IPBC.

- Comparative Example 4 Formulation of suspension containing IPBC-containing sustained release particles

- Suspension polymerization A 200 mL beaker (1) was charged with 40 g of IPBC, 42 g of methyl methacrylate, 18 g of ethylene glycol dimethacrylate and 300 mg of dilauroyl peroxide, and stirred at room temperature to prepare a uniform hydrophobic solution.

- a 500 mL beaker (2) was charged with 280 g of ion-exchanged water, 20 g of a 10% by weight aqueous solution of PVA-217 and 200 mg of a 5% by weight aqueous DBN solution, and stirred at room temperature to obtain a uniform aqueous solution.

- the hydrophobic solution was added to a 500 mL beaker (2).

- K The suspension was prepared by suspending the hydrophobic solution by stirring for 10 minutes at a rotational speed of 3000 rpm with a homomixer MARK 2.5 (manufactured by PRIMIX Corporation).

- the suspension was transferred to a 500 mL 4-neck Kolben equipped with a stirrer, reflux condenser, thermometer and nitrogen introduction tube, and heated with stirring under a nitrogen stream, and suspension polymerization was carried out for 6 hours. .

- the suspension is heated to 60 ° C. and maintained for 1 hour, then heated to 70 ° C. and maintained for 3 hours, and then heated to 80 ° C. Performed by warming and maintaining for 2 hours.

- the suspension after the reaction was cooled to 30 ° C. or lower to obtain a suspension (suspension) of sustained release particles containing IPBC.

- Comparative Example 5 (Formulation of suspension containing OIT-containing sustained release particles) (Suspension polymerization) A 200 mL beaker (1) was charged with 40 g of OIT, 36 g of methyl methacrylate, 6.0 g of methacrylic acid, 18 g of ethylene glycol dimethacrylate and 300 mg of dilauroyl peroxide, and stirred at room temperature to prepare a uniform hydrophobic solution. .

- a 500 mL beaker (2) was charged with 280 g of ion-exchanged water, 20 g of TCP-10U and 200 mg of a 5% by mass aqueous solution of Perex SS-L, and stirred at room temperature to obtain a uniform suspension.

- the hydrophobic solution was added to a 500 mL beaker (2).

- K The suspension was prepared by suspending the hydrophobic solution by stirring for 10 minutes at a rotational speed of 3000 rpm with a homomixer MARK 2.5 (manufactured by PRIMIX Corporation).

- the suspension was transferred to a 500 mL 4-neck Kolben equipped with a stirrer, reflux condenser, thermometer and nitrogen introduction tube, and heated with stirring under a nitrogen stream, and suspension polymerization was carried out for 6 hours. .

- the suspension is heated to 60 ° C. and maintained for 1 hour, then heated to 70 ° C. and maintained for 3 hours, and then heated to 80 ° C. Performed by warming and maintaining for 2 hours.

- the suspension after the reaction was cooled to 30 ° C. or lower to obtain a suspension (suspension) of sustained release particles containing OIT.

- Comparative Example 6 Formulation of suspension containing IPBC-containing sustained release particles

- Suspension polymerization A 200 mL beaker (1) was charged with 25 g of IPBC, 52.5 g of methyl methacrylate, 22.5 g of ethylene glycol dimethacrylate and 300 mg of dilauroyl peroxide, and stirred at room temperature to prepare a uniform hydrophobic solution.

- the hydrophobic solution was added to a 500 mL beaker (2).

- K The suspension was prepared by suspending the hydrophobic solution by stirring for 10 minutes at a rotation speed of 3500 rpm with a homomixer MARK 2.5 (manufactured by Primix).

- the suspension was transferred to a 300 mL 4-neck Kolben equipped with a stirrer, a reflux condenser, a thermometer, and a nitrogen introduction tube, and heated with stirring under a nitrogen stream, and suspension polymerization was carried out for 6 hours. .

- the suspension is heated to 60 ° C. and maintained for 1 hour, then heated to 70 ° C. and maintained for 3 hours, and then heated to 80 ° C. Performed by warming and maintaining for 2 hours.

- the suspension after the reaction was cooled to 30 ° C. or lower to obtain a suspension (suspension) of sustained release particles containing IPBC.

- Comparative Example 7 (Formulation of suspension containing OIT-containing sustained release particles) (Suspension polymerization) A 200 mL beaker (1) was charged with 25 g of OIT, 45 g of methyl methacrylate, 7.5 g of methacrylic acid, 22.5 g of ethylene glycol dimethacrylate and 300 mg of dilauroyl peroxide, and stirred at room temperature to obtain a uniform hydrophobic solution. Prepared.

- the hydrophobic solution was added to a 500 mL beaker (2).

- K The suspension was prepared by suspending the hydrophobic solution by stirring for 10 minutes at a rotational speed of 3000 rpm with a homomixer MARK 2.5 (manufactured by PRIMIX Corporation).

- the suspension was transferred to a 300 mL 4-neck Kolben equipped with a stirrer, a reflux condenser, a thermometer, and a nitrogen introduction tube, and heated with stirring under a nitrogen stream, and suspension polymerization was carried out for 6 hours. .

- the suspension is heated to 60 ° C. and maintained for 1 hour, then heated to 70 ° C. and maintained for 3 hours, and then heated to 80 ° C. Performed by warming and maintaining for 2 hours.