WO2011093152A1 - 吸収性物品 - Google Patents

吸収性物品 Download PDFInfo

- Publication number

- WO2011093152A1 WO2011093152A1 PCT/JP2011/050615 JP2011050615W WO2011093152A1 WO 2011093152 A1 WO2011093152 A1 WO 2011093152A1 JP 2011050615 W JP2011050615 W JP 2011050615W WO 2011093152 A1 WO2011093152 A1 WO 2011093152A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- sheet

- web

- connecting sheet

- front body

- region

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/15577—Apparatus or processes for manufacturing

- A61F13/15585—Apparatus or processes for manufacturing of babies' napkins, e.g. diapers

- A61F13/15593—Apparatus or processes for manufacturing of babies' napkins, e.g. diapers having elastic ribbons fixed thereto; Devices for applying the ribbons

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/15577—Apparatus or processes for manufacturing

- A61F13/15707—Mechanical treatment, e.g. notching, twisting, compressing, shaping

- A61F13/15723—Partitioning batts; Cutting

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies

- A61F13/49007—Form-fitting, self-adjusting disposable diapers

- A61F13/49009—Form-fitting, self-adjusting disposable diapers with elastic means

- A61F13/49011—Form-fitting, self-adjusting disposable diapers with elastic means the elastic means is located at the waist region

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies

- A61F13/49007—Form-fitting, self-adjusting disposable diapers

- A61F13/49009—Form-fitting, self-adjusting disposable diapers with elastic means

- A61F13/49019—Form-fitting, self-adjusting disposable diapers with elastic means the elastic means being placed longitudinally, transversely or diagonally over the article

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies

- A61F13/49058—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies characterised by the modular concept of constructing the diaper

- A61F13/4906—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies characterised by the modular concept of constructing the diaper the diaper having an outer chassis forming the diaper and an independent absorbent structure attached to the chassis

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies

- A61F13/49058—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies characterised by the modular concept of constructing the diaper

- A61F13/4906—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies characterised by the modular concept of constructing the diaper the diaper having an outer chassis forming the diaper and an independent absorbent structure attached to the chassis

- A61F13/49061—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies characterised by the modular concept of constructing the diaper the diaper having an outer chassis forming the diaper and an independent absorbent structure attached to the chassis the diaper having one or two waist members forming the diaper waist region and an independent absorbent structure attached to the one or two waist members forming the crotch region

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies

- A61F13/496—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies in the form of pants or briefs

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies

- A61F2013/49088—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies characterized by the leg opening

- A61F2013/49092—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies characterized by the leg opening comprising leg cuffs

Definitions

- the present invention relates to an absorbent article.

- An exterior body that includes a front body, a back body, and a connection sheet that are separate from each other, and the front body and the back body are joined to each other in a side region and connected to each other by a connection sheet that extends in the front-rear direction in the crotch region.

- a pants-type absorbent article including an exterior body and an interior body including an absorbent main body, which is overlapped and fixed on a connection sheet inside the exterior body, is known (see Patent Document 1).

- the width of the connecting sheet and the width of the absorbent main body are substantially equal, and therefore, the lateral edges of the connecting sheet in the region between the front body and the back body are the lateral edges of the interior body. It extends along.

- both lateral edges of the connecting sheet in a region between the front body and the back body define leg leg, and thus both edges are in contact with the wearer's leg or groin.

- the absorbent article of Patent Document 1 if the lateral length, i.e., width, of the interior body is increased in order to enhance the absorption performance of the interior body, the width of the connecting sheet increases, and the wearer's leg becomes difficult to move. There is a fear. If the widths of the interior body and the connecting sheet are reduced in order to cope with this problem, the absorption performance of the interior body will be lowered.

- an exterior body including a front body, a back body, and a connecting sheet that are separate from each other, and the front body and the back body are joined to each other in the side region and connected in the front-rear direction in the crotch region.

- a pant-type absorbent article comprising: an exterior body that is connected to each other by a sheet; and an interior body that includes an absorbent main body that is overlapped and fixed to the connection sheet inside the exterior body.

- An absorbent article is provided in which non-fixed areas are not secured to each other around the lateral edges of the connecting sheet.

- FIG. 1 is a perspective view of a diaper of a first embodiment according to the present invention.

- FIG. 2 is a plan view of the diaper in an unfolded state where a joint portion in a side region is unwound.

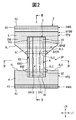

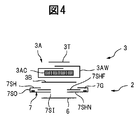

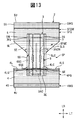

- 3 is a longitudinal sectional view taken along line III-III in FIG. 4 is a cross-sectional view taken along line IV-IV in FIG.

- FIG. 5 is a schematic diagram for explaining a method of manufacturing a diaper.

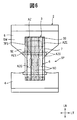

- 6 is a diagram showing an adhesive application pattern.

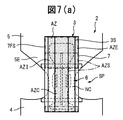

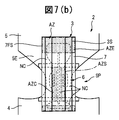

- FIG. 7A and FIG. 7B are diagrams showing another example of the adhesive application pattern.

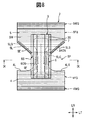

- FIG. 8 is a developed plan view for explaining a second embodiment according to the present invention.

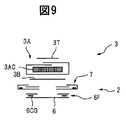

- 9 is a cross-sectional view taken along line IX-IX in FIG. FIG.

- FIG. 10 is a schematic view for explaining a method of manufacturing the diaper of the second embodiment according to the present invention.

- FIG. 11 is a diagram for explaining a third embodiment according to the present invention.

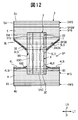

- FIG. 12 is a diagram for explaining a fourth embodiment according to the present invention.

- FIG. 13 is a diagram for explaining a fifth embodiment according to the present invention.

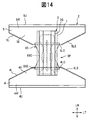

- FIG. 14 is a diagram for explaining a sixth embodiment according to the present invention.

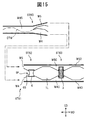

- FIG. 15 is a schematic view for explaining a method of manufacturing the diaper of the sixth embodiment according to the present invention.

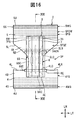

- FIG. 16 is a diagram for explaining a seventh embodiment according to the present invention. 17 is a cross-sectional view taken along line XVII-XVII in FIG.

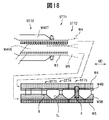

- FIG. 18 is a schematic view for explaining a method of manufacturing the diaper of the seventh embodiment according to the present invention.

- FIG. 19 is a developed plan view for explaining an eighth embodiment according to the present invention.

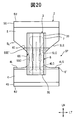

- FIG. 20 is a developed plan view illustrating another example of the end portion

- a diaper 1 includes an exterior body 2 and an interior body 3.

- the exterior body 2 includes a front body 4, a back body 5, and a connecting sheet 6 that are separate from each other.

- the front body 4 and the back body 5 are joined to each other in the side region 1F and connected to each other by a connecting sheet 6 extending in the front-rear direction FR in the crotch region 1C.

- the front body 4 is located on the abdomen side of the wearer

- the back body 5 is located on the back side of the wearer.

- the diaper 1 also includes a waistline or waist hole 1W defined by the upper edge 4U of the front body 4 and the upper edge 5U of the back body 5, and a pair of leg supports or leg holes 1L.

- each leg hole 1L is defined by an edge 1LE, and this edge 1LE is composed of a lower edge 4L of the front body 4, a lower edge 5L of the rear body 5, and both edges 6S of the connecting sheet 6 in the lateral direction LT.

- the interior body 3 includes an absorptive main body, and is fixed to the connection sheet 6 so as to overlap the exterior body 2. Referring to FIG. 2 showing the diaper 1 in the unfolded state, the front body 4 has a rectangular shape.

- the upper edge 4U of the front body 4 extends linearly in the lateral direction LT.

- the lower edge 4L of the front body 4 includes a central portion 4LC in the center of the lateral direction LT and side portions 4LS on both sides of the lateral direction LT of the central portion 4LC.

- the central portion 4LC is substantially in the lateral direction LT.

- the side portion 4LS extends and slightly curves toward the upper edge 4U.

- both side edges 4S of the front body 4 in the horizontal direction LT extend substantially in the vertical direction LN.

- the vertical direction LN is perpendicular to the horizontal direction LT.

- the back body 5 has a hexagonal shape protruding toward the front body 4.

- the back body 5 includes a rectangular waist part 5W and a trapezoidal extension part 5E extending from the waist part 5W toward the front body 4.

- the upper edge of the back body 5, that is, the upper edge 5U of the waistline portion 5W extends substantially in the lateral direction LT.

- the lower edge 5L of the back body 5, that is, the lower edge 5L of the extending portion 5E includes a central portion 5LC at the center in the lateral direction LT and side portions 5LS on both sides of the lateral direction LT of the central portion 5LC.

- the central portion 5LC extends substantially in the lateral direction LT, and the side portion 5LS extends while being inclined toward the upper edge 5U while being inclined with respect to the lateral direction LT.

- both side edges 5S of the back body 5 in the horizontal direction LT extend substantially in the vertical direction LN.

- the front body 4 and the back body 5 are arranged with a separation region SP in the longitudinal direction LN perpendicular to the lateral direction LT.

- the connecting sheet 6 extends in the longitudinal direction LN across the separation region SP at the approximate center of the front body 4 and the back body 5 in the lateral direction LT, and the front body 4 around the lower edge 4L and the rear around the lower edge 5L.

- the body 5 is fixed to the extension portion 5E.

- the connection sheet 6 has a shape in which a constriction is provided at the substantially center in the longitudinal direction LN among both side edges of the rectangle.

- the length and width of the connecting sheet 6 in the horizontal direction LT are shorter than the width of the front body 4 and the back body 5 in the horizontal direction LT, and the length of the connecting sheet 6 in the vertical direction LN is the vertical direction of the interior body 3. It is shorter than the length of LN.

- the side edge 6S of the connecting sheet 6 includes a central portion 6SC that is substantially in the center in the vertical direction LN and end portions 6SE that are on both sides of the central portion 6SC in the vertical direction LN, and the central portion 6SC is curved inward.

- the end portion 6SE extends substantially in the longitudinal direction LN.

- the end portion 6SE does not coincide with the edge of the exterior body 2 that defines the leg hole 1L, that is, the lower edge 4L of the front body 4 and the lower edge 5L of the rear body 5, and is less than these lower edges 4L and 5L.

- the end portion 6SE corresponds to both edges in the lateral direction LT of the portion of the connecting sheet 6 that overlaps the front body 4 and the back body 5.

- both end edges 6E of the connecting sheet 6 in the vertical direction LN extend substantially in the horizontal direction LT.

- the interior body 3 has a rectangular shape extending in the vertical direction LN.

- Both side edges 3S of the inner body 3 in the horizontal direction LT extend substantially in the vertical direction LN, and both end edges 3E of the vertical direction LN extend substantially in the horizontal direction.

- a pair of leak-proof members 7 are provided along both side edges 3 ⁇ / b> S of the interior body 3 on both sides of the interior body 3 in the lateral direction LT.

- a free edge or outer edge 7SO in the lateral direction LN of the leakage preventing member 7 extends in the longitudinal direction LN.

- the interior body 3 is overlaid on the connecting sheet 6 and fixed. In this case, the interior body 3 extends beyond the connection sheet 6 in the longitudinal direction LT and is also fixed to the front body 4 and the back body 5.

- the central portion 6SC of the both side edges 6S of the connecting sheet 6 is inside the lateral direction LT with respect to the outer edge 7SO of the leakage preventing member 7, and moreover than both side edges 3S of the interior body 3.

- the end portions 6SE of the side edges 6S are on the outer side in the lateral direction LT with respect to the side edges 3S of the interior body 3, and further on the outer side in the lateral direction LT with respect to the outer edge 7SO of the leakage preventing member 7. As shown in FIG.

- the front body 4 includes two sheets, that is, a top sheet 4T facing the wearer when worn, and a back sheet 4B facing the outside when worn, and the top sheet 4T and the back sheet. 4B are superimposed on each other.

- the back body 5 also includes two sheets, that is, a top sheet 5T facing the wearer when worn, and a back sheet 5B facing the outside when worn, and the top sheet 5T and the back sheet 5B are overlapped with each other.

- the connecting sheet 6 is composed of one sheet. In this case, the sheet may be liquid permeable or liquid impermeable. In this way, the connecting sheet 6 becomes softer than the front body 4 and the back body 5.

- seat 6 can be selected so that it may become softer than the front body 4 and the back body 5.

- FIG. The degree of softness of the sheet material can be measured by a cantilever method, for example.

- seat 6 is attached to the inner side thru

- the connecting sheet 6 may be attached to the outside of the front body 4 and the back body 5, that is, the back sheets 4B and 5B. Or you may make it the periphery of the both ends of the longitudinal direction LN of the connection sheet

- the top sheets 4T and 5T and the back sheets 4B and 5B of the front body 4 and the back body 5 and the connection sheet 6 are polyolefin fibers such as polypropylene (PP) and polyethylene (PE), polyethylene terephthalate (PET), respectively.

- each of the top sheets 4T and 5T is made of an SMS nonwoven fabric having a basis weight of 15 g / m 2 formed from PP, and each of the back sheets 4B and 5B is formed by a basis weight of 17 g / m 2. It consists spunbonded nonwoven m 2, the connecting sheet 6 is composed of basis weight 15 g / m 2 of an SMS nonwoven fabric formed from PP.

- the front body 4 around the upper edge 4U is provided with an elastic member 4WG

- the front body 4 between the elastic member 4WG and the lower edge 4L is provided with an elastic member 4FG.

- a folded portion 4F in which the back sheet 4B is folded on the top sheet 4T side is provided around the upper edge 4U

- the elastic member 4WG is arranged between the back sheets 4B in the folded portion 4F. Fixed between.

- the elastic member 4FG is fixed between the top sheet 4T and the back sheet 4B.

- an elastic member 5WG is provided on the back body 5 around the upper edge 5U

- an elastic member 5FG is provided on the back body 5 between the elastic member 5WG and the lower edge 5L.

- the elastic member 5WG is fixed between the back sheets 5B at the folded portion 5F.

- the elastic member 5FG is fixed between the top sheet 5T and the back sheet 5B.

- These elastic members 4WG, 4FG, 5WG, and 5FG are, for example, thread-like and attached to the front body 4 and the back body 5 in a state of being stretched in the lateral direction LT.

- the elastic member 5FG includes an elastic member 5FGW provided in the waist part 5W of the back body 5 and an elastic member 5FGE provided in the extension part 5E.

- the elastic member 5FGE is provided so as to overlap the interior body 3 and the leak-proof member 7.

- the elastic member 5FGE provides an elastic action between the side region 1F and the crotch region 1C of the diaper 1 when worn.

- the upper edges of the top sheets 4T and 5T are arranged substantially along the lower edges of the elastic members 4WG and 5WG, and the lower edges of the top sheets 4T and 5T are arranged substantially along the lower edges of the back sheets 4B and 5T.

- the elastic members 4WG, 4FG, 5WG, and 5FG are made of elastic fibers such as natural rubber, synthetic rubber, and spandex, and the expansion ratio is, for example, 1.3 to 3.5 times.

- the thickness of the elastic members 4WG, 4FG, 5WG, and 5FG is, for example, 300 to 1200 dtex.

- the elastic members 4WG and 5WG are each composed of spandex having a thickness of 940 dtex and an expansion ratio of 3.0, and the elastic members 4FG and 5FG are spandex having a thickness of 780 dtex and an expansion ratio of 2.5. Consists of Each of the elastic member 4WG and the elastic member 5WG includes five, the elastic member 4FG includes ten, the elastic member 5FGW of the waistline portion 5W includes eleven, and the elastic member 5FGE of the extension portion 5E includes two spandexes.

- the elastic members 4WG, 4FG, 5WG, and 5FG may be formed of an elastic sheet.

- the interior body 3 includes a liquid-permeable top sheet 3T, a liquid-impermeable back sheet 3B, and an absorber disposed between the top sheet 3T and the back sheet 3B.

- the absorbent body 3A includes an absorbent core 3AC and a wrap sheet 3AW that wraps the absorbent core 3AC.

- a widened portion 3ACW is formed at both ends of the absorbent core 3AC in the longitudinal direction or the longitudinal direction LN and an intermediate portion between both ends, and these widened portions 3ACW are connected to each other by a narrowed portion 3ACN.

- the absorber core 3AC is provided with a plurality of slits 3ACS extending in the longitudinal direction or the longitudinal direction LN.

- These slits 3ACS include a central slit substantially at the center in the lateral direction LT and side slits on both sides of the central slit.

- the central slit is 320 mm long and 12 mm wide

- the side slit is 80 mm long and 10 mm wide. If it does in this way, absorber core 3AC will bend easily along slit 3ACS, and absorber 3A will become easy to stick to a wearer.

- the top sheet 3T is a hydrophilic nonwoven fabric formed from polyolefin fibers, PET fibers, and the like, and is composed of a nonwoven fabric manufactured by a manufacturing method such as spunbonding or air-through.

- the back sheet 3B is composed of a waterproof and moisture permeable film formed of PE or the like.

- the absorbent core 3AC is made of pulp, super absorbent polymer (SAP), a mixture thereof, or the like.

- the wrap sheet 3AW is a hydrophilic nonwoven fabric formed from polyolefin fibers, PET fibers, and the like, and is configured from a nonwoven fabric manufactured by a manufacturing method such as spunbonding or air-through.

- the top sheet 3T is made of a non-woven fabric having a basis weight of 25 g / m 2 manufactured by air-through

- the back sheet 3B is made of a moisture-permeable PE film having a basis weight of 22 g / m 2

- the absorbent core 3AC has a weight of 250 g.

- the wrap sheet 3AW is composed of an SMS non-woven fabric having a basis weight of 13 g / m 2 , from a 1 layer mixture of / m 2 pulp and a basis weight of 200 g / m 2 SAP. As shown in FIG.

- each leak-proof member 7 includes a fixed edge or inner edge 7SI fixed to the exterior body 2 or the interior body 3, and a free edge or outer edge 7SO not fixed to the exterior body 2 or the interior body 3. And have.

- Each leak-proof member 7 includes a liquid-impermeable sheet 7SH and an elastic member 7G, and the liquid-impermeable sheet 7SH includes a leak-proof nonwoven fabric 7SHN and a leak-proof film 7SHF.

- the leakage prevention nonwoven fabric 7SHN is folded and overlapped on the outer edge of the leakage prevention film 7SHF, and the elastic member 7G is fixed between the folded leakage prevention nonwoven fabrics 7SHN. .

- the outer edge of the leak-proof film 7SHF does not reach the outer edge 7SO of the leak-proof member 7.

- the edges of the leakage prevention nonwoven fabric 7SHN and the waterproof film 7SHF are substantially aligned with each other.

- Each leak-proof member 7 rises toward the wearer when worn and acts as a leak-proof wall.

- the leak-proof nonwoven fabric 7SHN is composed of polyolefin fiber, PET fiber, or the like, and is manufactured by a spunbond method or the like.

- the leak-proof film 7SHF is composed of PE, PET, or the like.

- the leak-proof nonwoven fabric 7SHN is composed of a hydrophobic SMS nonwoven fabric having a basis weight of 15 g / m 2

- the leak-proof film 7SHF is composed of a moisture-permeable PE film having a basis weight of 18 g / m 2

- the elastic member 7G is made of an elastic fiber such as natural rubber, synthetic rubber, or spandex.

- the elastic member 7G is composed of two spandex having a thickness of 620 dtex and an expansion ratio of 2.2. These members are connected or fixed by, for example, heat sealing, sonic sealing, adhesive, or the like.

- a hot melt adhesive containing styrene-isoprene-styrene (SIS), styrene-butadiene-styrene (SBS), styrene-ethylene-butylene-styrene (SEBS), or the like can be used.

- HMA hot melt adhesive

- the top sheets 4T and 5T and the back sheets 4B and 5B of the front body 4 and the back body 5 are connected to each other by an HMA previously applied to the elastic members 4WG, 4FG, 5WG, and 5FG.

- the top sheets 4T and 5T and the back sheets 4B and 5B are applied to the top sheets 4T and 5T by a coating method such as spiral or control seam.

- HMA is applied.

- HMA is applied to the top sheets 4T and 4B and the back sheets 5T and 5B around the lower edges 4L and 5L to prevent peeling.

- the connecting sheet 6 is connected to the front body 4 and the back body 5 by a sonic seal, an adhesive, or the like.

- HMA is applied in advance to the back surface of the connecting sheet 6 using a slot coat coating method.

- the top surface and the bottom surface of the absorber core 3AC are connected to the core wrap sheet 3AW by an adhesive such as HMA.

- the adhesive is applied by a coating method such as spiral, slot coat, control seam, bead, curtain coater or the like so as to have a basis weight of 1.5 to 10 g / m 2 .

- HMA is applied by a spiral coating method so that the basis weight is 5 g / m 2 .

- HMA is applied to the back surface 3B of the interior body 3 or the side of the leak-proof member 7 facing the exterior body 2 by a control seam coating method, whereby the interior body 3 and the leak-proof member 7 are connected to the front body. 4.

- HMA is applied to the elastic member 7G by a slit nozzle method

- the elastic member 7G is fixed to the leak-proof nonwoven fabric 7SHN by this HMA.

- the leak-proof nonwoven fabric 7SHN and the leak-proof film 7SHF are joined to each other by applying HMA to the leak-proof nonwoven fabric 7SHN by a spiral coating method.

- the front body 4 around the side edges 4S and the back body 5 around the side edges 5S are joined together by heat sealing, ultrasonic sealing, or the like.

- the edge LE that defines the leg hole 1L includes a side portion 4LS of the lower edge 4L of the front body 4, a side portion 5LS of the lower edge 5L of the rear body 5, and both edges 6S of the connecting sheet 6. .

- the edge 1LE is formed by one cutting action and is smoothly connected and curved.

- at least a part of both side edges 6S of the connecting sheet 6 in the separation region SP between the front body 4 and the back body 5 is both side edges 3S of the interior body 3.

- the movable range of the wearer's leg can be increased while maintaining the absorption surface of the interior body 3 large. That is, it is possible to prevent the wearer's legs from becoming difficult to move while securing the good absorption performance of the interior body 3.

- the end portion 6SE of the connecting sheet 6 is located on the outer side in the lateral direction LT from both side edges 3S of the interior body 3 (FIG. 2). As a result, it is possible to reliably connect the connecting sheet 6 to the front body 4 and the back body 5 while facilitating movement of the wearer's legs.

- the extended part 5E which has the elastic member 5FGE is provided in the back body 5, the shape of the diaper 1 becomes underwear shape and the wearer's buttocks are entirely covered with the back body 5. Therefore, it is possible to suppress leakage, and to reduce anxiety about the wearer's leakage. Furthermore, since the inner body 3 is pulled up toward the side region 1F (FIG. 1) by the elastic member 5FGE, the inner body 3 is prevented from being swung inside, and thus the absorbability of the inner body 3 is maintained. Further, since the edge 1LE that defines the leg hole 1L is smoothly connected and curved, the curved shape follows the wearer's leg and adhesion to the wearer is enhanced.

- connection sheet 6 may be shorter than the length of the interior body 3. Therefore, the quantity of the connection sheet

- seat 6 is comprised from one sheet

- a nonwoven fabric containing rayon, polyolefin fibers and polyester fibers for example, a nonwoven fabric produced by a spunlace method having a basis weight of 26 g / m 2 ), or a nonwoven fabric containing pulp and polyester (eg, spunlace).

- Nonwoven fabric manufactured by the above method and having a basis weight of 40 g / m 2 is used.

- seat 6 it can suppress that the interior body 3 hangs inside. For this reason, the leak-proof member 7 comes to rise reliably toward the wearer. That is, the connecting sheet 6 provides a starting point for the leakage preventing member 7 to rise toward the wearer.

- the manufacturing method of the diaper 1 of 1st Example by this invention includes a step ST ⁇ b> 1 for manufacturing the interior body 3 including the leak-proof member 7, a step ST ⁇ b> 2 for manufacturing the connecting sheet 6, and a continuum of the diaper 1. And a step ST3 of manufacturing the diaper web W1.

- step ST1 first, the absorbent core 3AC in which the slit 3ACS is formed in advance is wrapped by a wrap sheet web W3AW, which is a continuous body of the wrap sheet 3AW (ST11). In this case, the absorber core 3AC is transported so that the slit 3ACS is parallel to the transport direction MD.

- top sheet web W3T and the back sheet web W3B which are continuous bodies of the top sheet 3T and the back sheet 3B, are respectively attached to the upper surface and the lower surface of the wrap sheet web W3AW that wraps the absorbent core 3AC.

- the interior body web W3 which is a continuous body is formed (ST12).

- a continuous elastic body W7G which is a continuum of a leakproof non-woven web W7SHN, which is a continuous body of two leakproof nonwoven fabrics 7SHN, and a leakproof film web W7SHF, which is a continuous body of two leakproof films 7SHF, and an elastic member 7G. are attached (ST13).

- the leak-proof nonwoven fabric web W7SHN is divided along the conveyance direction MD to form a leak-proof member web W7 that is a continuous body of the leak-proof member 7 (ST14).

- each leakage preventing member web W7 is attached to the back surface of the interior body web W3, that is, the back sheet web W3B (ST15).

- the HMA is applied in a predetermined pattern to the back surfaces of the interior body web W3 and the leakage preventing member web W7, that is, the surface facing the exterior body web W2 (ST16).

- the interior body web W3 and the leakage preventing member web W7 are cut into a length corresponding to one product, and the interior body 3 including the leakage preventing member 7 is formed (ST17).

- step ST2 HMA is applied to the bottom surface of the connection sheet web W6 that is a continuous body of the connection sheets 6 (ST21).

- step ST22 the connecting sheet web W6 is cut into one product to form the connecting sheet 6 (ST22).

- step ST3 the top sheet web W45T is divided along the conveying direction MD, and a top sheet web W4T that is a continuous body of the top sheet 4T of the front body 4 and a top sheet that is a continuous body of the top sheet 5T of the back body 5.

- a web W5T is formed (ST31).

- the back sheet web W45B is divided along the conveyance direction MD, and the back sheet web W4B, which is a continuous body of the back sheet 4B of the front body 4, and the back sheet web, which is a continuous body of the back sheet 5B of the back body 5.

- W5B is formed (ST32).

- the top sheet web W4T and the back sheet web W5B are conveyed along the conveyance direction MD with a separation area SP in a direction CD substantially orthogonal to the conveyance direction MD.

- the back elastic webs W4B and W5WG which are continuous bodies of the elastic members 4WG and 5WG, and the continuous elastic bodies W4FG and W5FG which are continuous bodies of the elastic members 4FG and 5FG are respectively stretched in the conveying direction MD.

- the connecting sheet 6 is attached to the front body web W4 and the back body web W5 at intervals in the transport direction MD so as to straddle the separation region SP, and thereby the exterior body web that is a continuous body of the exterior body 2 W2 is formed (ST36).

- the connecting sheet 6 is first attached to the top sheet webs W4T and W5T, Next, the back sheet webs W4B and W5B are superimposed on the connecting sheet 6 and the top sheet webs W4T and W5T.

- the connecting sheet 6 is first attached to the backsheet webs W4B and W5B, and then the topsheet webs W4T and W5T are superimposed on the connecting sheet 6 and the backsheet webs W4B and W5B.

- the exterior body web W2 is cut at an interval in the transport direction MD (ST37).

- both side edges 6S of the connection sheet 6 are curved inward, or at least a part of both side edges 6S of the connection sheet 6 in the separation region SP is more lateral in the lateral direction LT than both side edges 3S of the interior body 3.

- the connecting sheet 6 is cut so as to be inside.

- the cutting action is performed once, for example, along the annular cutting line CT.

- the interior body 3 provided with the leakage preventing member 7 is attached to the front body web W4, the back body web W5, and the connecting sheet 6 to form the diaper web W1 (ST38).

- the diaper web W1 is folded along a fold line FL along the conveyance direction MD (not shown).

- the fold line FL may be the center in the orthogonal direction CD of the diaper web W1, or may be offset from the center.

- the front body web W4 and the back body web W5 are partially joined at intervals in the transport direction MD, thereby forming a joined portion.

- the diaper web 1 is cut in the orthogonal direction CD at these joint portions, thereby forming the diaper 1 (not shown).

- the cutting action for forming the edge 1LE that defines the leg hole 1L is performed.

- the outer body web W2, that is, the front body web W4 and the back body web W5 connected to each other by the connection sheet 6 can be cut in a state in which wrinkles are eliminated by pulling outward in the orthogonal direction CD. It becomes. Therefore, the leg hole 1L can be formed in a regular shape.

- the front body web W4 and the back body web W5 that are not connected to each other by the connection sheet 6 may be wrinkled. If the cutting action is performed in this state, the edge 1LE that defines the leg hole 1L is formed. There is a risk of deviating from the regular shape. In addition, it is difficult to securely attach the interior body 3 to the exterior body web W2 in this state. On the other hand, when the cutting action is performed, the front body web W4 and the back body web W5 around the edge 1LE defining the leg hole 1L are discontinuous in the transport direction MD.

- the connecting sheet 6 or the interior body 3 is attached to the front body web W4 and the back body web W5 in which wrinkles or tackle are generated, the connection sheet 6 or the interior body 3 is securely connected to the front body web W4 and the back body web W5. Therefore, the productivity of the diaper 1 may be reduced.

- a cutting action for forming the edge 1LE is performed, and the interior body 3 is formed. It is attached. Therefore, the above problems do not occur.

- seat 6 is not attached to the front body web W4 and the back body web W5 in the form of a web, but is attached intermittently after cut

- FIG. 20 shows a case where the connecting sheet web W6 is attached to the front body web W4 and the back body web W5. In this case, the end portion 6SE ′ on the back body 5 side is aligned with the side portion 5LS.

- the connecting sheet 6 there is a connecting sheet 6 around the side portion 5LS. Further, a portion 6 ′ of the connecting sheet 6 that overlaps the front body 4 extends along the side portion 4LS to the side edge 4S of the front body 4, and thus the connecting sheet 6 exists around the side portion 4LS. As a result, the side portions 4LS and 5LS are relatively hard, and there is a possibility that the wearer's leg may feel uncomfortable.

- the end portion 6SE is located inside the lateral direction LT with respect to the side portions 4LS and 5LS, so that the above-described problems do not occur. And since the area of the connection sheet

- FIG. 6 shows an adhesive application pattern in step ST16.

- the width of the region AZ to which the adhesive is applied varies along the vertical direction LN. That is, the adhesive application area AZ includes both end areas AZE in the vertical direction LN, and a central area AZC in the center in the vertical direction LN, and an intermediate area AZI between the end area AZ on the back body 5 side and the central area AZC. .

- both end regions AZ and the intermediate region AZI do not overlap with the connecting sheet 6, and the central region AZC overlaps with the connecting sheet 6.

- the width of both end regions AZE is substantially the same as the entire width of the interior body 3 and the leak-proof member 7 and is the widest. This is to prevent the inner body 3 and the leak-proof member 7 from being peeled off from the front body 4 and the back body 5 and to eliminate the feeling of discomfort.

- the width of the central region AZC is narrower than the width of the interior body 3 and is the narrowest. In the first embodiment according to the present invention, the width of the central region AZC is about 90 mm.

- the width of the intermediate area AZI is between the width of the both end areas AZ and the width of the central area AZC.

- a non-fixed region NC is formed on both sides of the central region AZC and the intermediate region AZI in the lateral direction LT, and thus the inner body 3 and the leakage preventing member 7 are not fixed to the outer body 2. become.

- the width of the non-fixed area NC around the central area AZC is larger than the width of the non-fixed area NC around the intermediate area AZI.

- the non-fixed region NC is also formed at the center in the lateral direction LT of the central portion AZC.

- the exterior body 2 that is, the portion around both edges 6S of the connecting sheet 6 and the interior body 3 are not fixed to each other. Therefore, the interior body 3 is easily deformed according to the body shape of the wearer, and the adhesion of the interior body 3 is enhanced.

- the leakage preventing member 7 rises starting from the lateral side edges AZS of the central region AZC and the intermediate region AZI. Therefore, around the central region AZC, the rising amount of the leakage preventing member 7 can be increased by increasing the non-fixed region NC. Moreover, the adhesiveness to the wearer of the interior body 3 is also improved.

- the non-fixed area NC is made smaller around the intermediate area AZI, and therefore the rise of the leakage preventing member 7 is suppressed.

- the leakage preventing member 7 is prevented from rising excessively and covering the absorption surface of the interior body 3.

- the intermediate region AZI is provided on the back body 5 side, that is, on the wearer's buttocks side, the leak-proof member 7 is prevented from being difficult to break in the buttocks and the wearing feeling is enhanced.

- step ST16 (FIG. 5) when an adhesive is applied to the conveyance direction MD of the interior body web W3 and the leakage preventing member web W7, the above-described patterning can be easily performed. Note that, as shown in FIG.

- the width of the intermediate region AZI may substantially coincide with the entire width of the interior body 3 and the leakage preventing member 7. Also in this case, excessive twisting of the leakage preventing member 7 can be prevented.

- the center non-fixed area NC in the lateral direction LT is omitted.

- a non-fixed region NC may be provided adjacent to both end regions AZE. If it does in this way, it will be suppressed that a wrinkle is caused to interior 3. As a result, the feeling of wearing is enhanced, and the stable absorption performance of the interior body 3 is maintained.

- 8 and 9 show a second embodiment according to the present invention. The difference from the first embodiment according to the present invention will be described.

- the elastic member 5LG is intermittently provided along the lower edge 5L of the back body 5. That is, the elastic member 5LG is provided along the side portion 5LS of the lower edge 5L, but is not provided along the central portion 5LC.

- the elastic member 5LG provides an elastic action between the side region 1F and the crotch region 1C of the diaper 1. As a result, the interior body 3 is further pulled up toward the side region 1F. In addition, the adhesion is improved in the leg hole 1L. In addition, you may abbreviate

- an elastic member 6CG is provided adjacent to both side edges 6S of the connecting sheet 6.

- the elastic member 6CG is attached to the connecting sheet 6 in a state of being stretched in the vertical direction LN.

- a folded portion 6F in which the connecting sheet 6 is folded is provided, and the elastic member 6CG is fixed to the connecting sheet 6 at the folded portion 6F.

- the elastic members 5LG and 6CG can be configured similarly to the above-described elastic members.

- the elastic members 5LG and 6CG are each composed of spandex having a thickness of 620 dtex and an expansion ratio of 2.2.

- FIG. 10 shows the manufacturing method of the second embodiment according to the present invention.

- a continuous elastic body W6CG which is a continuous body of elastic members 6CG, is attached to the connection sheet web W6 (ST40), and the connection sheet web W6 is folded. Overlapping portion 6F is formed (ST41). Next, on both sides of the connecting sheet web W6, a cutting action is performed at intervals in the transport direction MD, and side edges 6S curved inward are formed (ST42). Next, an adhesive is applied to the surface of the connecting sheet web W6 that faces the interior body web W3 and the leakage preventing member web W7 (ST43). In this case, the adhesive is applied with the application pattern shown in FIG. 6, FIG. 7 (a), and FIG. 7 (b).

- the connecting sheet web W6 is attached to the interior body web W3 and the leakage preventing member web W7 (ST44).

- an adhesive is applied to the back surface of the connecting sheet web W6, that is, the surface facing the exterior body web W2 (ST45).

- the connecting sheet web W6 is cut together with the interior body web W3 and the leakage preventing member web W7 (ST17 ′).

- an adhesive for fixing the continuous elastic body W5LG which is a continuous body of the elastic member 5LG, is applied to the backsheet web W5B of the back body web W5 (ST50).

- the continuous elastic body W5LG is attached to the back seat web W5B at substantially the same position as the continuous elastic bodies W4FG and W5FG (ST51).

- the continuous elastic body W5LG is supplied while being swung in the orthogonal direction CD.

- the top sheet webs W4T and W5T are overlapped to form the front body web W4 and the back body web W5 (ST34 ').

- the continuous elastic body W5LG that protrudes into the separation region SP is held by the pair of belts and cut and removed (ST52). In this way, the intermittent elastic member 5LG is formed.

- seat 6 is first attached to the interior body 3, and is then attached to the exterior body 2.

- FIG. 11 shows a third embodiment according to the present invention.

- the elastic member 5LG is provided not continuously but continuously. That is, the elastic member 5LG is provided along the side portion 5LS and the central portion 5LC of the lower edge 5L. As a result, the elastic member 5LG overlaps the interior body 3, so that the interior body 3 is further brought into close contact with the wearer.

- the continuous elastic body W5LG is swung without protruding from the back body web W5 (see ST51).

- FIG. 12 shows a fourth embodiment according to the present invention.

- the elastic member 4LG is provided along the lower edge 4L of the front body 4 in the same manner as the elastic member 5LG of the back body 5.

- the inner body 3 is pulled up toward the side region 1F on the abdomen side of the wearer, and the displacement of the inner body 3 is further suppressed.

- These elastic members 4LT and 5LG may be intermittent as shown in FIG. 12, or may be continuous.

- the elastic member 4LG of the front body 4 is provided intermittently, that is, if the elastic member 4LG does not overlap with the interior body 3 or the connecting sheet 6, the width of the interior body 3 on the abdomen side is suppressed. The Therefore, it is particularly preferable when the wearer is a male.

- the elastic member 4LG continuously if elastic member 4LG is provided adjacent to a woman's excretion opening, the adhesion nature of interior body 3 will be raised.

- the elastic member 4LG is provided so as to pass below the male genitals, a space can be formed in the diaper 1, and thus the wearing feeling of the male wearer is enhanced.

- the elastic member 4LG can be attached in the same manner as the elastic member 5LG.

- FIG. 13 shows a fifth embodiment according to the present invention.

- the front body 4 is provided with the elastic member 4LG, and the back body 5 is not provided with the elastic member 5LG.

- the elastic member 4LT may be intermittent or continuous.

- 14 and 15 show a sixth embodiment according to the present invention.

- the front body 4 and the back body 5 have substantially the same shape. That is, the front body 4 includes a rectangular waistline portion 4W and a trapezoidal extension portion 4E extending from the waistline portion 4W toward the back body 5, and the back body 5 has a rectangular waistline portion 5W.

- the lower edge 4L of the front body 4 that is, the lower edge 4L of the extended portion 4E includes a central portion 4LC at the center in the lateral direction LT and side portions 4LS on both sides of the lateral direction LT of the central portion 4LC.

- 4LC extends substantially in the lateral direction LT

- the side portion 4LS extends linearly toward the upper edge 4U and inclined with respect to the lateral direction LT.

- the lower edge 5L of the back body 5, that is, the lower edge 5L of the extending portion 5E includes a central portion 5LC at the center in the lateral direction LT and side portions 5LS on both sides of the lateral direction LT of the central portion 5LC.

- connection sheet 6 is fixed to the front body 4 around the central portion 4LC and the back body 5 around the central portion 5LC.

- the sheet web W45 formed by laminating the top sheet web W45T and the backsheet web W45B to each other is swung in the orthogonal direction CD while being conveyed in the conveyance direction MD. Cut along the moving cutting line CTW to form the front body web W4 and the back body web W5 (ST60).

- the front body 4 and the back body 5 respectively have convex portions W4C and W5C and concave portions W4D and W5D that are alternately continuous.

- the convex portions W4C and W5C correspond to the extended portions 4E and 5E.

- the convex portions W4C, W5C and the concave portions W4D, W5D of the front body web W4 and the back body web W5 are aligned with each other (ST61).

- a separation region SP is formed between the convex portions W4C and W5C (see Japanese Patent No. 3916878).

- the connecting sheet 6 is connected to the front body web W4 and the back body web W5 to form the outer package web W2 (ST62).

- the side edge 6S of the connection sheet 6 is cut in advance so that the connection sheet 6 has a constriction.

- the inner body 3 is attached to the outer body web W2 (ST63).

- the edge 1LE that defines the leg hole 1L is formed without requiring a cutting action, so that trim loss is greatly reduced.

- 16 to 18 show a seventh embodiment according to the present invention.

- the top sheets 4T and 5T are comprised from a non-stretchable nonwoven fabric

- the back sheets 4B and 5B are comprised from a stretchable sheet.

- the stretchable sheet for example, a stretchable nonwoven fabric containing stretchable thermoplastic fibers and elastomer fibers can be used.

- the thermoplastic fiber for example, polyolefin fibers such as polypropylene and polyethylene, and polyester fibers such as polyethylene terephthalate and polybutylene terephthalate can be used.

- the elastomer fiber for example, urethane-based, polystyrene-based, rubber-based fibers such as polyurethane can be used.

- the stretchable nonwoven fabric can be produced by a production method such as spunbond or air-through. The stretchable nonwoven fabric is used after being subjected to gear stretching and exhibiting stretchability in the transport direction MD.

- the back sheets 4B and 5B formed of the elastic sheet provide an elastic action between the side region 1F and the crotch region 1C of the diaper 1.

- the stretchable sheet may be provided continuously in the conveyance direction MD or may be provided intermittently. Moreover, it can also be provided in one or both of the front body 4 and the back body 5.

- the back sheet web W45B is bonded to the top sheet web W45T in a state of being stretched in the conveying direction MD (ST70).

- the continuous elastic bodies W4WG, W5WG, W4FG, and W5FG to which the adhesive is applied have already been supplied up to the top sheet web W45T.

- the top sheet web W45T is folded back and overlapped with the back sheet web W45B at both side edges in the transport direction MD (ST71).

- an integrated web WI in which the top sheet web W45T, the back sheet web W45B, and the continuous elastic bodies W4WG, W5WG, W4FG, and W5FG are integrated is formed.

- the integrated web WI is divided into a front body web W4 and a back body web W5 (ST72).

- the connecting sheet 6 is connected to the front body web W4 and the back body web W5 (ST73), and an edge 1LE that defines the leg hole 1L is formed (ST74).

- the interior body 3 is attached (ST75).

- the backsheet web W45B contracts in the orthogonal direction CD when extended in the conveying direction MD, a position controller is provided in front of each processing location, and the orthogonal direction of the integrated web WI, front body web W4, and back body web W5.

- the CD width is maintained at a normal value.

- the front body 4 and the back body 5 are formed of a stretchable sheet and a non-stretchable nonwoven fabric that overlap each other.

- at least a part of the front body 4 or the back body 5, for example, a part around the leg hole 1L can be formed only from the stretchable sheet.

- only the stretchable sheet is composed of one or a plurality of stretchable sheets.

- the basis weight of the part is preferably 50 g / m 2 or more, for example, 80 g / m 2 .

- the stretchability of the front body 4 or the back body 5 is improved, that is, the maximum stretch dimension of the front body 4 or the back body 5 is increased, or the stretchability in the longitudinal direction LN of the diaper 1 (see FIG. 2). I get out.

- the front body 4 or the back body 5 fits around the leg of the wearer around the leg hole 1L, and the wearing feeling is improved.

- FIG. 19 shows an eighth embodiment according to the present invention.

- the connecting sheet 6 has a rectangular shape with no constriction, and therefore the entire side edges 6S of the connecting sheet 6 are inside the lateral direction LT from the side edges 3S of the interior body 3. In this way, the leg of the wearer becomes easier to move.

- Such a shape of the connecting sheet 6 can be obtained by performing a cutting action (ST37 in FIG. 5) for forming the edge 1LE that defines the leg hole 1L so that the connecting sheet 6 is not cut.

- a cutting action ST37 in FIG. 5

- the load of the cutting blade used in the cutting action can be reduced, and therefore the life of the cutting blade can be reduced. Can be extended.

- the embodiments described so far can also be combined with each other.

Landscapes

- Health & Medical Sciences (AREA)

- Engineering & Computer Science (AREA)

- Vascular Medicine (AREA)

- Epidemiology (AREA)

- Biomedical Technology (AREA)

- Heart & Thoracic Surgery (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Absorbent Articles And Supports Therefor (AREA)

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP11736867.0A EP2529718B1 (en) | 2010-01-29 | 2011-01-11 | Absorbent article |

| AU2011210934A AU2011210934B2 (en) | 2010-01-29 | 2011-01-11 | Absorbent article |

| EA201200965A EA023249B1 (ru) | 2010-01-29 | 2011-01-11 | Абсорбирующее изделие |

| US13/576,024 US8932274B2 (en) | 2010-01-29 | 2011-01-11 | Absorbent article |

| CN201180006599.4A CN102711701B (zh) | 2010-01-29 | 2011-01-11 | 吸收性物品 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010019806A JP5534839B2 (ja) | 2010-01-29 | 2010-01-29 | 吸収性物品 |

| JP2010-019806 | 2010-01-29 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2011093152A1 true WO2011093152A1 (ja) | 2011-08-04 |

Family

ID=44319144

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2011/050615 Ceased WO2011093152A1 (ja) | 2010-01-29 | 2011-01-11 | 吸収性物品 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US8932274B2 (enExample) |

| EP (1) | EP2529718B1 (enExample) |

| JP (1) | JP5534839B2 (enExample) |

| CN (1) | CN102711701B (enExample) |

| AU (1) | AU2011210934B2 (enExample) |

| EA (1) | EA023249B1 (enExample) |

| WO (1) | WO2011093152A1 (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU2570498C1 (ru) * | 2012-11-22 | 2015-12-10 | Као Корпорейшн | Впитывающее изделие типа трусов |

| JP2017518812A (ja) * | 2014-05-27 | 2017-07-13 | ザ プロクター アンド ギャンブル カンパニー | 湾曲した吸収性材料領域及び真っ直ぐな吸収性材料領域を有する吸収性コア |

Families Citing this family (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2376044A1 (en) * | 2009-01-15 | 2011-10-19 | The Procter & Gamble Company | Reusable wearable absorbent articles with anchoring subsystems |

| AU2011243572B2 (en) * | 2010-04-19 | 2015-06-25 | Unicharm Corporation | Absorbent article |

| JP5947610B2 (ja) * | 2012-04-23 | 2016-07-06 | ユニ・チャーム株式会社 | 吸収性物品 |

| JP5945446B2 (ja) * | 2012-04-23 | 2016-07-05 | ユニ・チャーム株式会社 | 吸収性物品 |

| JP6250926B2 (ja) * | 2012-06-18 | 2017-12-20 | ユニ・チャーム株式会社 | 吸収性物品 |

| JP6103834B2 (ja) * | 2012-06-26 | 2017-03-29 | ユニ・チャーム株式会社 | 使い捨て着用物品 |

| JP5616952B2 (ja) * | 2012-12-20 | 2014-10-29 | 花王株式会社 | パンツ型吸収性物品の製造方法 |

| JP6108340B2 (ja) * | 2013-01-31 | 2017-04-05 | 大王製紙株式会社 | 使い捨ておむつの製造方法及び使い捨ておむつ |

| US9820894B2 (en) | 2013-03-22 | 2017-11-21 | The Procter & Gamble Company | Disposable absorbent articles |

| JP6468724B2 (ja) * | 2014-05-02 | 2019-02-13 | ユニ・チャーム株式会社 | 使い捨てオムツ |

| JP6338277B2 (ja) * | 2014-07-16 | 2018-06-06 | 大王製紙株式会社 | 吸収性物品 |

| MX372779B (es) | 2014-12-19 | 2020-05-26 | Essity Hygiene & Health Ab | Artículo absorbente. |

| CA2969881C (en) * | 2014-12-19 | 2019-06-18 | Sca Hygiene Products Ab | Absorbent article |

| JP6150357B2 (ja) * | 2015-09-30 | 2017-06-21 | 大王製紙株式会社 | 吸収性物品及びその製造方法 |

| JP6412846B2 (ja) * | 2015-10-13 | 2018-10-24 | ユニ・チャーム株式会社 | 使い捨ておむつ |

| JP2017159011A (ja) * | 2015-12-31 | 2017-09-14 | エスジェイ サークル スンディリアン ブルハドSj Circle Sdn. Bhd. | おむつ |

| RU2711679C1 (ru) * | 2016-11-23 | 2020-01-21 | Эссити Хайджин Энд Хелт Актиеболаг | Комплект гендерно специфических впитывающих изделий |

| JP6396549B1 (ja) * | 2017-07-19 | 2018-09-26 | 大王製紙株式会社 | 使い捨て着用物品 |

| KR102512662B1 (ko) * | 2017-09-27 | 2023-03-22 | 다이오 페이퍼 코퍼레이션 | 신축 부재 및 이 신축 부재를 갖는 일회용 착용 물품 |

| JP2021104239A (ja) * | 2019-12-26 | 2021-07-26 | 花王株式会社 | 使い捨ておむつ |

| CN115802991B (zh) | 2020-07-31 | 2025-06-13 | 宝洁公司 | 包括弹性层合体的可穿着制品 |

| WO2022021294A1 (en) | 2020-07-31 | 2022-02-03 | The Procter & Gamble Company | Wearable article comprising an elastic laminate |

| WO2022021295A1 (en) | 2020-07-31 | 2022-02-03 | The Procter & Gamble Company | Wearable article comprising an elastic laminate having good wicking properties |

| CN115867239A (zh) * | 2020-07-31 | 2023-03-28 | 宝洁公司 | 包括具有亲水内部纤维网和外部纤维网的弹性带层合体的可穿着制品 |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH11107007A (ja) * | 1997-10-07 | 1999-04-20 | Daio Paper Corp | パンツタイプ紙おむつおよびパンツタイプ紙おむつの製造方法 |

| JP2001029389A (ja) * | 1999-07-15 | 2001-02-06 | Zuiko Corp | 使い捨てパンツ及びその製造方法 |

| JP2003339768A (ja) * | 2002-05-30 | 2003-12-02 | Uni Charm Corp | 表示要素形成方法 |

| JP2003339769A (ja) * | 2002-05-30 | 2003-12-02 | Uni Charm Corp | 表示要素形成方法 |

| JP2008194160A (ja) * | 2007-02-09 | 2008-08-28 | Livedo Corporation | 吸収性物品 |

| JP2008228760A (ja) * | 2007-03-16 | 2008-10-02 | Kao Corp | パンツ型吸収性物品の製造方法 |

| JP2009536865A (ja) * | 2006-05-12 | 2009-10-22 | エスセーアー・ハイジーン・プロダクツ・アーベー | パンツ型の吸収性物品及びパンツ型の吸収性物品を製作する方法 |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3130453B2 (ja) * | 1995-08-25 | 2001-01-31 | ユニ・チャーム株式会社 | 使い捨てのパンツ型体液吸収性着用物品 |

| US6755808B2 (en) * | 2001-11-02 | 2004-06-29 | Kimberly-Clark Worldwide, Inc. | Absorbent garment having a body comforming absorbent composite |

| US7837665B2 (en) * | 2002-10-01 | 2010-11-23 | Kimberly-Clark Worldwide, Inc. | Three-piece disposable undergarment with folded crotch member |

| JP4298377B2 (ja) * | 2003-05-22 | 2009-07-15 | ユニ・チャーム株式会社 | 使い捨てのパンツ型着用物品 |

| US7018369B2 (en) * | 2003-05-30 | 2006-03-28 | Kimberly-Clark Worldwide, Inc. | Disposable pant-like undergarment having an elastic band adjacent the waist opening |

| US7604624B2 (en) * | 2003-05-30 | 2009-10-20 | Kimberly-Clark Worldwide, Inc. | Disposable absorbent article with overlapping absorbent assembly secured to front and back panels |

| EP1661535B1 (en) * | 2003-08-06 | 2012-12-19 | Zuiko Corporation | Disposable wearing article |

| JP5363015B2 (ja) * | 2007-03-28 | 2013-12-11 | 花王株式会社 | 着用物品の製造方法 |

| EP2215998A1 (en) | 2007-11-15 | 2010-08-11 | Unicharm Corporation | Disposable diaper |

| JP5227002B2 (ja) * | 2007-11-15 | 2013-07-03 | ユニ・チャーム株式会社 | 使い捨ておむつ |

| JP4435240B2 (ja) * | 2008-02-29 | 2010-03-17 | 大王製紙株式会社 | 使い捨て吸収性物品 |

| WO2009084642A1 (ja) * | 2007-12-28 | 2009-07-09 | Daio Paper Corporation | 使い捨て吸収性物品 |

-

2010

- 2010-01-29 JP JP2010019806A patent/JP5534839B2/ja active Active

-

2011

- 2011-01-11 AU AU2011210934A patent/AU2011210934B2/en not_active Ceased

- 2011-01-11 US US13/576,024 patent/US8932274B2/en not_active Expired - Fee Related

- 2011-01-11 WO PCT/JP2011/050615 patent/WO2011093152A1/ja not_active Ceased

- 2011-01-11 CN CN201180006599.4A patent/CN102711701B/zh active Active

- 2011-01-11 EP EP11736867.0A patent/EP2529718B1/en not_active Not-in-force

- 2011-01-11 EA EA201200965A patent/EA023249B1/ru not_active IP Right Cessation

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH11107007A (ja) * | 1997-10-07 | 1999-04-20 | Daio Paper Corp | パンツタイプ紙おむつおよびパンツタイプ紙おむつの製造方法 |

| JP2001029389A (ja) * | 1999-07-15 | 2001-02-06 | Zuiko Corp | 使い捨てパンツ及びその製造方法 |

| JP2003339768A (ja) * | 2002-05-30 | 2003-12-02 | Uni Charm Corp | 表示要素形成方法 |

| JP2003339769A (ja) * | 2002-05-30 | 2003-12-02 | Uni Charm Corp | 表示要素形成方法 |

| JP2009536865A (ja) * | 2006-05-12 | 2009-10-22 | エスセーアー・ハイジーン・プロダクツ・アーベー | パンツ型の吸収性物品及びパンツ型の吸収性物品を製作する方法 |

| JP2008194160A (ja) * | 2007-02-09 | 2008-08-28 | Livedo Corporation | 吸収性物品 |

| JP2008228760A (ja) * | 2007-03-16 | 2008-10-02 | Kao Corp | パンツ型吸収性物品の製造方法 |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP2529718A4 * |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU2570498C1 (ru) * | 2012-11-22 | 2015-12-10 | Као Корпорейшн | Впитывающее изделие типа трусов |

| JP2017518812A (ja) * | 2014-05-27 | 2017-07-13 | ザ プロクター アンド ギャンブル カンパニー | 湾曲した吸収性材料領域及び真っ直ぐな吸収性材料領域を有する吸収性コア |

Also Published As

| Publication number | Publication date |

|---|---|

| EA201200965A1 (ru) | 2013-01-30 |

| EP2529718B1 (en) | 2017-12-06 |

| AU2011210934B2 (en) | 2015-05-21 |

| AU2011210934A1 (en) | 2012-08-09 |

| JP2011156121A (ja) | 2011-08-18 |

| EP2529718A4 (en) | 2014-07-16 |

| JP5534839B2 (ja) | 2014-07-02 |

| CN102711701A (zh) | 2012-10-03 |

| US8932274B2 (en) | 2015-01-13 |

| EP2529718A1 (en) | 2012-12-05 |

| US20120302985A1 (en) | 2012-11-29 |

| CN102711701B (zh) | 2014-08-13 |

| EA023249B1 (ru) | 2016-05-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5534839B2 (ja) | 吸収性物品 | |

| JP5495823B2 (ja) | 吸収性物品の製造方法 | |

| JP5595055B2 (ja) | 吸収性物品の製造方法 | |

| CN104394820B (zh) | 吸收性物品以及吸收性物品的制造方法 | |

| CN105307616A (zh) | 短裤型穿着用物品和其制造方法 | |

| JP4953730B2 (ja) | 吸収性物品 | |

| JP2014124288A (ja) | パンツ型吸収性物品及びその製造方法 | |

| JP4996882B2 (ja) | 使い捨ておむつ | |

| JP6255203B2 (ja) | 吸収性物品 | |

| JP5922365B2 (ja) | パンツ型吸収性物品 | |

| JP4726673B2 (ja) | パンツ型吸収性物品及びその製造方法 | |

| JP4996899B2 (ja) | 使い捨ておむつ | |

| JP4202831B2 (ja) | パンツ型使い捨ておむつ | |

| JP5462232B2 (ja) | 使い捨ておむつ | |

| JP4535980B2 (ja) | パンツ型使い捨ておむつ | |

| JP2016002391A (ja) | パンツ型吸収性物品 | |

| JP4996900B2 (ja) | 使い捨ておむつ | |

| JP3210618U (ja) | パンツ型吸収性物品 | |

| JP5207389B2 (ja) | 着用物品の製造方法 | |

| JP2012050549A (ja) | 吸収性物品 | |

| JP2012024392A (ja) | 使い捨ておむつ | |

| JP2010162183A (ja) | ウエストベルトの製造方法及び使い捨ておむつの製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| WWE | Wipo information: entry into national phase |

Ref document number: 201180006599.4 Country of ref document: CN |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 11736867 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2011736867 Country of ref document: EP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2011210934 Country of ref document: AU |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 201200965 Country of ref document: EA |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 13576024 Country of ref document: US |

|

| ENP | Entry into the national phase |

Ref document number: 2011210934 Country of ref document: AU Date of ref document: 20110111 Kind code of ref document: A |