WO2011045895A1 - 複合成形品 - Google Patents

複合成形品 Download PDFInfo

- Publication number

- WO2011045895A1 WO2011045895A1 PCT/JP2010/005659 JP2010005659W WO2011045895A1 WO 2011045895 A1 WO2011045895 A1 WO 2011045895A1 JP 2010005659 W JP2010005659 W JP 2010005659W WO 2011045895 A1 WO2011045895 A1 WO 2011045895A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- metal member

- micrometers

- polymer material

- fiber

- metal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B3/00—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form

- B32B3/26—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer

- B32B3/30—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer characterised by a layer formed with recesses or projections, e.g. hollows, grooves, protuberances, ribs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/0005—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor using fibre reinforcements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/14—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor incorporating preformed parts or layers, e.g. injection moulding around inserts or for coating articles

- B29C45/14311—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor incorporating preformed parts or layers, e.g. injection moulding around inserts or for coating articles using means for bonding the coating to the articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B15/00—Layered products comprising a layer of metal

- B32B15/04—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B15/08—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B15/00—Layered products comprising a layer of metal

- B32B15/04—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B15/08—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

- B32B15/088—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin comprising polyamides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B15/00—Layered products comprising a layer of metal

- B32B15/20—Layered products comprising a layer of metal comprising aluminium or copper

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/18—Layered products comprising a layer of synthetic resin characterised by the use of special additives

- B32B27/20—Layered products comprising a layer of synthetic resin characterised by the use of special additives using fillers, pigments, thixotroping agents

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/28—Layered products comprising a layer of synthetic resin comprising synthetic resins not wholly covered by any one of the sub-groups B32B27/30 - B32B27/42

- B32B27/286—Layered products comprising a layer of synthetic resin comprising synthetic resins not wholly covered by any one of the sub-groups B32B27/30 - B32B27/42 comprising polysulphones; polysulfides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/34—Layered products comprising a layer of synthetic resin comprising polyamides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2705/00—Use of metals, their alloys or their compounds, for preformed parts, e.g. for inserts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2705/00—Use of metals, their alloys or their compounds, for preformed parts, e.g. for inserts

- B29K2705/02—Aluminium

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/10—Inorganic fibres

- B32B2262/101—Glass fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2305/00—Condition, form or state of the layers or laminate

- B32B2305/08—Reinforcements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2305/00—Condition, form or state of the layers or laminate

- B32B2305/22—Fibres of short length

- B32B2305/24—Whiskers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/50—Properties of the layers or laminate having particular mechanical properties

- B32B2307/538—Roughness

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/12—All metal or with adjacent metals

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/12—All metal or with adjacent metals

- Y10T428/12472—Microscopic interfacial wave or roughness

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24355—Continuous and nonuniform or irregular surface on layer or component [e.g., roofing, etc.]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24479—Structurally defined web or sheet [e.g., overall dimension, etc.] including variation in thickness

- Y10T428/24521—Structurally defined web or sheet [e.g., overall dimension, etc.] including variation in thickness with component conforming to contour of nonplanar surface

- Y10T428/24545—Containing metal or metal compound

Definitions

- the present invention relates to a composite molded article having a structure in which a fiber reinforced polymer material portion is coated on the surface of a metal member.

- Patent Documents 1 to 3 composite molded articles comprising a metal member having a surface having a metal as a base material and a resin portion coated on the surface of the metal member are known (Patent Documents 1 to 3).

- Patent Document 1 chemical etching is performed on the surface of a metal member, and a thermoplastic resin is injection-molded by injection molding to form a resin portion so that a resin is coated on the surface to form a composite molded article.

- Patent Document 2 the surface of a metal member formed of a magnesium alloy is subjected to a chemical conversion treatment to form a surface layer composed of a metal oxide, a metal carbonate oxide, and a metal phosphorus oxide, and thereafter, on uneven portions of the surface layer, There is disclosed a composite molded article coated with a resin layer containing polybutylene terephthalate resin or polyphenylene sulfide resin as a main component. In this case, a large number of circular columns about 10 nm in diameter and about 100 nm in length are formed on the surface. According to Patent Document 3, in a state in which a metal member formed of a metal material and a resin material are superimposed, the resin material present in the joint is heated to 200 to 1500 ° C.

- the shear strength at the interface between the surface of the metal member and the resin portion coated on the surface of the metal member can be increased as much as possible, and peeling of the resin portion can be suppressed.

- the composite molded article when used in a severe use environment where severe thermal cycle cycles repeatedly act, the above-mentioned composite molded article can not necessarily be sufficiently coped with, and the resin part may be exfoliated excessively.

- severe thermal cycle is repeated to act on a composite molded article, so that it can not be sufficiently coped with.

- the present invention has been made in view of the above-described circumstances, and can improve the peel resistance at the interface between the surface of the metal member and the fiber-reinforced polymer material portion coated on the surface of the metal member, and heating and cooling It is an object of the present invention to provide a composite molded article capable of suppressing excessive peeling of a fiber-reinforced polymer material portion even when severe thermal shock caused by the above repeatedly acts on the composite molded article.

- the composite molded article according to the present invention of mode 1 comprises (i) a metal member having a metal-based surface, and (ii) a polymer material which is coated on at least a part of the surface of the metal member and serves as a matrix.

- a fiber-reinforced polymer material portion having a plurality of reinforcing fibers for reinforcing the matrix, and (iii) the surface of the metal member is periodically or not spaced apart by a pitch distance larger than the diameter of the reinforcing fibers (Iv)

- the opposing protrusion is a part of the polymer material constituting the fiber-reinforced polymer material part entering and at least one of the reinforcing fibers. It forms an entry space where a part can enter.

- the plurality of projections formed on the surface of the metal member are periodically or irregularly juxtaposed at pitch intervals larger than the diameter of the reinforcing fibers. Therefore, the strain based on the shear stress generated at the interface between the metal member and the fiber reinforced polymer material portion can be divided by the projection. For this reason, even when the composite molded product is used in a severe environment where thermal shock repeatedly acts, peeling at the interface can be suppressed. Further, a part of the polymer material constituting the matrix of the fiber reinforced polymer material part enters the entrance space. This can further increase the shear strength at the interface between the surface of the metal member and the fiber-reinforced polymer material portion.

- the reinforcing fibers can enter into the entry space formed between the facing projections, which is advantageous for reinforcing the polymer material entering the entry space with the reinforcing fibers. This can further increase the shear strength at the interface described above.

- the thin layer is also referred to as WBL (WBL: Weak Boundaly Layer).

- WBL Weak Boundaly Layer

- the thin layer is formed of a polymer material and has a low probability of the presence of reinforcing fibers, so that the layer is inferior in mechanical strength as compared to the strength of the fiber reinforced polymer material itself. Conceivable. In this case, if a force such as thermal shock acts on the interface, stress concentration may cause the thin layer to break.

- the shear strength at the interface is obtained by the reinforcing effect of the reinforcing fibers, even if the thin layer is present. It is believed that it can be enhanced.

- the wall surface forming the projection further has a plurality of micro concave portions and / or micro convex portions exposed to the entry space.

- the wall surface forming the protrusion has a plurality of micro concave portions and / or micro convex portions exposed to the entry space.

- the minute recess has a minute opening smaller than the opening size of the entrance space.

- the microconvex portion has a protrusion amount smaller than the opening size of the entrance space.

- the distortion based on shear stress at the interface between the metal member and the fiber-reinforced polymer material can be divided by the projection. Therefore, the durability against shear failure at the interface can be enhanced, and peeling at the interface can be suppressed. Therefore, even when the composite molded article is used in an environment where thermal shock due to heating and cooling acts repeatedly over a long period of time, excessive peeling at the interface can be suppressed.

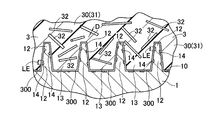

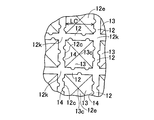

- Embodiment 1 It is sectional drawing which concerns on Embodiment 1 and which shows typically the state which forms a protrusion, rolling the surface of a metal member.

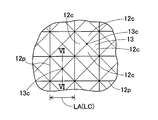

- Embodiment 1 is a top view which shows typically the protrusion currently formed in the surface of a metal member.

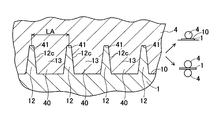

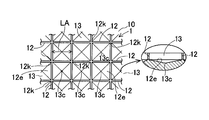

- FIG. 6A relates to the second embodiment

- FIG. 6A is a plan view schematically showing an entering space formed on the surface of the metal member

- FIG. 6B is a cross section schematically showing the entering space formed on the surface of the metal member

- FIG. 6 is a cross-sectional view taken along the line VI-VI.

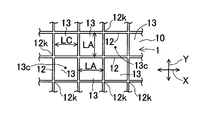

- Embodiment 4 is a top view which shows typically the protrusion currently formed in the surface of a metal member.

- Embodiment 5 is a top view which shows typically the protrusion currently formed in the surface of a metal member.

- FIG. 17A and FIG. 17B relate to the eleventh embodiment, and are plan views schematically showing projections formed on the surface of a metal member.

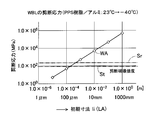

- a horizontal axis is made into a pitch interval of a projection

- a vertical axis is a graph which shows a relation made into shear strength and a retention (%).

- the division of strain based on shear stress generated at the interface will be described by taking a three-layer laminate (initial dimension: li) shown in FIG. 18 of the present invention as an example.

- the actual length of the three-layer stack is l ′.

- the difference between l 'and lx remains as distortion in each layer.

- the shear stress generated by strain exceeds the shear strength of the material, it is believed that cracking occurs and grows.

- the balance of force is basically expressed by Equation 2, and the average dimension l 'of the three-layer laminate can be determined.

- WBL is cracked when the shear stress ⁇ 2 determined by Equation 3 exceeds the shear strength of the second layer WBL.

- the stress due to the difference in linear expansion between the first layer and the third layer is considered, but strain is also generated by the linear expansion of the WBL itself, and shear stress is generated. Therefore, depending on the bonding state of the interface, WBL may generate fine cracks. For this reason, it is considered that the thermal shock based on the repetition of the thermal cycle causes the crack to grow, which leads to the destruction of the WBL.

- the plurality of protrusions such as a wall and a pile are periodically or irregularly formed on the surface of the metal member at a predetermined pitch interval or less.

- the present invention has been developed based on the idea that the strain is divided by the plurality of projections in this manner.

- the pitch interval of the opposing protrusions can be obtained based on Equation 3.

- a composite molded article in which an FRP portion made of PPS resin reinforced with glass fiber is coated on a metal member of aluminum alloy will be added.

- the relationship between the initial dimension li (corresponding to the pitch interval LA between the facing protrusions) and the shear stress ⁇ 2 was determined.

- the result is shown as a characteristic line WA in FIG.

- the thermal cycle of 23 ° C. ⁇ ⁇ 40 ° C. is one cycle

- the thickness of the FRP portion is 3 mm

- the thickness of the metal member is 3 mm

- the thickness of WBL is 10 nm. Physical property values used for calculation are shown in Table 1.

- the shear strength of the PPS resin itself is shown as a characteristic line St.

- a region above the characteristic line St indicates a region in which WBL itself present at the interface may be destroyed, and a region below the characteristic line St indicates a region in which the WBL itself present at the interface is not destroyed.

- the WBL present at the interface may be destroyed if the initial dimension li between the opposing projections (corresponding to the pitch interval LA between the opposing projections) greatly exceeds 500 micrometers or 1000 micrometers. Becomes higher.

- 100 .mu.m and 1000 .mu.m are only one indication, and the pitch interval LA between the facing projections is appropriately adjusted depending on factors such as the material, rigidity and thickness of the WBL, and the intervals between the projections It is considered that setting the pitch interval LA of less than 3000 micro mail can be one standard. If the rigidity of the polymer material changes in this manner, the pitch interval LA is naturally changed.

- the said protrusion is connected in planar view projected from the orthogonal

- the entry space and the projection are preferably formed by a transfer surface formed on the surface of the metal member.

- a transfer surface a rolling surface (transfer surface) in which the unevenness of the mold surface of a rolling element such as a rotating rolling roller and a non-rotating rolling type (transfer processing element) is transferred to the surface of a metal member is cited.

- Be Roll rollers include knurls.

- the transfer surface the mold (transfer processing element) can be clamped, and the unevenness formed on the molding surface of the mold can be transferred by pressing the surface of the metal member.

- the entry space and the projection may be formed of a blasted surface that causes a group of projectiles to strike the surface of the metal member.

- the projectiles constituting the group of projectiles include shots, grids, sand particles and the like.

- the material of the projectile includes metal and ceramics.

- the grid means particles having a more irregular shape than spherical or pseudo-spherical shots, and generally has high grindability.

- a substantially cylindrical or pseudo-cylindrical cut wire shot obtained by cutting a metal wire in the longitudinal direction can also be used. The cut wire shot has high grindability to the surface of the metal member.

- the metal constituting the metal member is preferably at least one of aluminum, an aluminum alloy, magnesium, a magnesium alloy, iron, an iron alloy, titanium, a titanium alloy, copper, and a copper alloy.

- the polymer material constituting the fiber reinforced polymer material portion may be resin or rubber.

- the resin may be either a thermoplastic resin or a thermosetting resin.

- the polymer material includes nylon (polyamide), polyimide, polyacetal, polyethylene terephthalate (PET), polybutylene terephthalate (PBT), polyphenylene sulfide (PPS), polyether sulfone (PES), polyetherimide ( PEI), polyphenylene ether (PPE), polysulfone, polyethylene, polystyrene, polypropylene, acrylic resin, vinyl chloride resin, fluorine resin, polycarbonate, phenol resin, epoxy resin, unsaturated polyester resin, acrylonitrile-butadiene-styrene (ABS) And at least one of acrylonitrile-butadiene (AB) and a liquid crystal polymer. At least one of these may be the main component.

- the surface of the metal member has a plurality of juxtaposed projections.

- the opposing projections (the closest and the opposite projections) are periodically or irregularly formed at a pitch interval LA larger than the diameter D of the reinforcing fiber so as to form an entry space.

- the adjacent protrusions are preferably connected to each other.

- the protrusions are strengthened, and damage to the protrusions is suppressed. Since a part of the polymeric material which comprises a fiber reinforced polymeric material part approachs an approach space, it is advantageous to further raise the joint strength in an interface. At least a part of the reinforcing fibers can enter into the entry space.

- the pitch distance LA between the protrusions is made larger than the diameter D of the reinforcing fiber.

- the wall surface forming the protrusion has a plurality of micro recesses and / or micro protrusions which are exposed to the entry space.

- the minute recess has a minute opening smaller than the opening size of the entrance space.

- the microconvex portion has a microopening having a protrusion amount smaller than the opening size of the entrance space.

- the minute depressions and minute projections can be formed, for example, by etching, rolling, molding, or may be irradiated with a high energy density beam such as a laser beam.

- the reinforcing fibers constituting the fiber-reinforced polymer material portion are preferably at least one of glass fibers, ceramic fibers, metal fibers, carbon fibers, and high molecular weight high-strength fibers.

- the ceramic fibers include at least one of alumina fibers, silica fibers, alumina-silica fibers, silicon nitride fibers, carbon silicon fibers, and zirconia fibers.

- the high molecular weight high molecular weight fibers include ultra high strength polyethylene fibers, ultra high strength polyvinyl alcohol fibers, aramid fibers and polyacetal fibers.

- the reinforcing fibers include short fibers (fiber length: for example, 1 or 2 millimeters or less), long fibers, whiskers.

- the surface of the metal member has a plurality of protrusions arranged periodically or irregularly.

- LA is larger than the diameter D of the reinforcing fiber (LA> D), where LA is the pitch interval between the facing protrusions.

- the pitch distance LA is set according to factors such as the type (rigidity) of the polymer material (rigidity), the thickness of the WBL, and the diameter D of the reinforcing fiber, but it is an arbitrary value in the range of 10 to 5000 micrometers, 20 to 4000 micrometers And an arbitrary value in the range of 30 to 2000 micrometers, and an arbitrary value in the range of 40 to 1000 micrometers.

- the upper limit value of the pitch distance LA 5000 micrometers, 4000 micrometers, 3000 micrometers, 1500 micrometers, 800 micrometers, 500 micrometers depending on factors such as the type of the polymer material and the diameter D of the reinforcing fiber Furthermore, 400 micrometers, 300 micrometers, 200 micrometers, 150 micrometers, and 130 micrometers are mentioned.

- the lower limit of the pitch distance LA is 10 micrometers, 30 micrometers, 50 micrometers, 70 micrometers according to factors such as the type of polymer material (stiffness), the thickness of WBL and the diameter D of reinforcing fibers It can be mentioned.

- the root pitch distance LB is set according to factors such as the type of polymer material (stiffness), the thickness of WBL and the diameter D of reinforcing fibers, but it is an arbitrary value in the range of 10 to 5000 micrometers, 20 to 4000 For example, arbitrary values in the range of micrometers, arbitrary values in the range of 30 to 2000 micrometers, and arbitrary values in the range of 40 to 1000 micrometers can be exemplified.

- the upper limit value of the pitch distance LA 4000 micrometers, 3000 micrometers, 1500 micrometers, 800 micrometers, 500 micrometers can be mentioned according to factors such as the type of the polymer material and the diameter D of the reinforcing fiber, Furthermore, 400 micrometers, 300 micrometers, 200 micrometers, 150 micrometers, and 130 micrometers are mentioned.

- the lower limit of the pitch distance LA is 10 micrometers, 30 micrometers, 50 micrometers, 70 micrometers according to factors such as the type of polymer material (stiffness), the thickness of WBL and the diameter D of reinforcing fibers It can be mentioned.

- the aperture size LC is set according to factors such as the type (rigidity) of the polymer material (rigidity), the thickness of the WBL, and the diameter D of the reinforcing fiber, but an arbitrary value in the range of 10 to 5000 micrometers, 20 to 4000 micrometers And an arbitrary value in the range of 30 to 2000 micrometers, and an arbitrary value in the range of 40 to 1000 micrometers.

- the upper limit value of the pitch distance LA 5000 micrometers, 4000 micrometers, 3000 micrometers, 1500 micrometers, 800 micrometers, 500 micrometers depending on factors such as the type of the polymer material and the diameter D of the reinforcing fiber Furthermore, 400 micrometers, 300 micrometers, 200 micrometers, 150 micrometers, and 130 micrometers are mentioned.

- the lower limit of the pitch distance LA is 10 micrometers, 30 micrometers, 50 micrometers, 70 micrometers according to factors such as the type of polymer material (stiffness), the thickness of WBL and the diameter D of reinforcing fibers It can be mentioned.

- the pitch interval LA can be tw ⁇ (5 to 100). Further, tw ⁇ (10 to 50) and tw ⁇ (20 to 40) can be adopted. Assuming that the height of the projection is HA (corresponding to the depth of the approach space), the height HA can be LA ⁇ (0.5 to 2). Further, LA ⁇ (0.7 to 1.7) and LA ⁇ (1.0 to 1.5) can be adopted.

- the micro opening of the micro concave portion can be 10 micro mail or less, 7 micro mail or less, 5 micro mail or less, 3 micro mail or less.

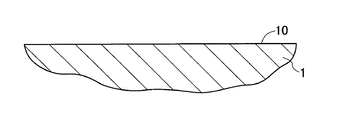

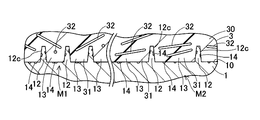

- FIG. 1 shows a cross section of the metal member 1 before covering the FRP portion 3.

- FIG. 2 shows a cross section of the metal member 1 coated with the FRP portion 3.

- the composite molded product includes a metal member 1 having a surface 10 having an aluminum alloy or a magnesium alloy as a base material, and an FRP portion 3 coated on the surface 10 of the metal member 1 (fiber reinforced polymer material Part) is formed.

- the FRP unit 3 has a resin material 31 (polymer material) to be a matrix 30, and a plurality of reinforcing fibers 32 (for example, glass fibers) for reinforcing the matrix 30.

- the surface 10 of the metal member 1 has a plurality of projections 12 periodically arranged in parallel at a pitch interval LA (see FIG. 1) larger than the diameter D of the reinforcing fibers 32.

- the pitch interval LA is, for example, in the range of 40 to 500 micrometers, in the range of 50 to 300 micrometers, and in the range of 70 to 150 micrometers depending on the type of the matrix 30 constituting the FRP portion 3 There is.

- the height HA of the projection 12 is, for example, in the range of 50 to 200 micrometers, and in the range of 70 to 150 micrometers.

- the wall surfaces 12 c forming the projections 12 face each other, and are opposed to the wall surfaces 12 c adjacent to each other and forming the other projections 12 facing each other.

- the wall surface 12c is inclined at an inclination angle ⁇ with respect to the bottom surface 12e so as to approach the top of the protrusion 12 formed by the wall surface 12c.

- the pitch interval LB (see FIG. 1) at the root of the projection 12 can be smaller than the pitch interval LA at the top of the projection 12. In this case, it is advantageous for enhancing the splitting property of the strain at the interface.

- On the wall surface 12 c forming the protrusion 12 a plurality of minute recesses 14 facing the entry space 13 are formed at random.

- the minute recess 14 has a minute opening smaller than the opening dimension LC of the entrance space 13.

- the minute recesses 14 can be formed by an etching process (wet etching process) after rolling. It is preferable to wash the metal member 1 after the etching process.

- etching process wet etching process

- the metal member 1 is an aluminum alloy or the like, a micro surface oxide thin film is often formed on the surface 10 of the metal member 1. In the case where destruction of the surface oxide thin film of the metal member 1 can be expected by pressing by rolling, the etching process can be promoted.

- the etching solution can contain, for example, OF-901 (made by Sugawara Eugelite), magnesium hydroxide.

- the etching solution can contain water as a solvent and contain 10 g / liter or more of sulfuric acid and 10 g / liter or more of ammonium fluoride.

- the components and composition of the etching solution are not limited to these.

- the FRP portion 3 can be formed by injection molding in a state where the metal member 1 is set in the cavity of the forming die.

- the injection conditions can be, for example, a mold temperature of 40 to 150 ° C., a cylinder temperature of 250 to 350 ° C., an injection pressure of 100 to 180 MPa, and an injection speed of 10 to 100 mm / sec. However, it is not limited to these.

- a pressure holding step was performed to maintain the pressure applied to the resin material loaded in the cavity. This is advantageous for allowing the resin material to favorably enter the entry space 13 between the projections 12 and the minute recesses 14.

- the pressure holding pressure was 40 to 80 MPa, and the pressure holding time was 10 to 15 seconds. It is preferable to heat treat the FRP portion 3 after injection molding. In this case, it can be expected to increase the crystallinity of the resin.

- an entrance space 13 is formed by the protrusions 12 facing each other.

- a part of the resin material 31 constituting the matrix 30 of the FRP portion 3 enters the entry space 13 of the metal member 1, and at least a part of the reinforcing fibers 32 enters. .

- the entry space 13 and the projection 12 before the etching process are formed by a rolling surface 15 which functions as a transfer surface formed on the surface 10 of the metal member 1.

- the plurality of projections 12 can be optionally formed on the surface 10 of the metal member 1 so that the pitch interval LA of the projections 12 and the height HA of the projections 12 are as targeted at the target position. Therefore, the pitch interval LA is uniform over all the protrusions 12.

- the wall surface 12c of the projection 12 has a slope ⁇ (see FIG. 1) with respect to the bottom surface 12e.

- a metal member 1 having a flat surface 10 shown in FIG. 3 is used.

- the rolling roller 4 transfer processing element

- the rolling convex portion 40 and the rolling groove portion 41 are The surface 10 of the metal member 1 is transferred.

- the entry space 13 and the projection 12 are formed.

- a single rolling roller 4 may be pressed against the metal member 1, or a pair of two rolling rollers 4 (transfer processing element) may be used so as to sandwich the metal member 1.

- Roll forming may be cold working performed in a normal temperature range or may be hot working performed in a hot state, or warm performed in a warm state between hot and cold. It may be processed. When rolling is performed as cold working, strengthening and consolidation of the protrusions 12 by work hardening can be expected. If it is warm processing or hot processing, since the ease of forming can be expected, the material of the metal member 1 may be hard.

- the strain based on the shear stress generated at the interface between the surface 10 of the metal member 1 and the FRP portion 3 can be divided by the plurality of protrusions 12. Therefore, the durability against shear failure at the interface between the surface 10 of the metal member 1 and the FRP portion 3 can be enhanced. Therefore, even when the thermal shock resulting from heating and cooling repeatedly acts on the composite molded article over a long period of time, the peeling of the interface is suppressed, and thus the peeling of the FRP portion 3 is suppressed. Furthermore, according to the present embodiment, as shown in FIG. 2, a part of the resin material 31 and the reinforcing fibers 32 constituting the matrix 30 of the FRP portion 3 enter the entry space 13.

- a plurality of minute recesses 14 are formed in the wall surface 12 c forming the protrusion 12.

- the minute recess 14 has a minute opening facing the entering space 13 between the protrusions 12 and having an opening dimension LE (see FIG. 2) smaller than the opening dimension LC of the entering space 13.

- the probability that the reinforcing fibers 32 included in the FRP portion 3 are present at the interface is low. It is considered that the probability that the thin layer 300 formed only of the resin constituting the part 3 is present at the interface is high.

- the thin layer 300 is formed only of resin and has a low probability of existence of the reinforcing fibers 32, the thin layer 300 is a layer inferior in mechanical strength as compared to the FRP portion 3 itself, and a force such as thermal shock acts In some cases, stress concentration may cause breakage.

- the shear strength at the above-described interface can be further enhanced.

- FIG. 5 shows an example of a plan view of the surface 10 of the metal member 1.

- the protrusions 12 are formed in a lattice wall shape that is connected in the vertical and horizontal directions in the X direction and the Y direction orthogonal to each other. For this reason, it is advantageous to improve the resistance to peeling in a plurality of directions.

- the plan view of the entry space 13 is quadrangular (square, polygonal). Since the projection 12 is continuously formed so as to make one turn around the central portion 13c of the entrance space 13 in plan view, it is advantageous for reducing the anisotropy of the entrance space 13 with respect to the central portion 13c. . Therefore, it is advantageous to reduce the anisotropy to exfoliation. As shown in FIG.

- the protrusions 12 since the protrusions 12 are cross-connected, they have a plurality of crossing portions 12k.

- the protrusion 12 is reinforced by the intersection 12k. Therefore, even when the shear stress is large, or even when the thickness of the protrusion 12 is thin, the overturn and deformation of the protrusion 12 are suppressed as much as possible. Therefore, the effect of dividing the strain can be maintained for a long time. In particular, when rolling is carried out cold, reinforcement of the projections 12 and the intersection 12k by work hardening can be expected. However, the crossing portion 12k may be eliminated and the respective protrusions 12 may be made independent.

- the etching process may be eliminated and the minute recesses 14 may not be formed in the protrusions 12. Even in this case, since the strain based on the shear stress at the interface can be divided by the protrusions 12, the peeling resistance of the FRP portion 3 can be enhanced.

- FIG. 6 shows a second embodiment. This embodiment basically has the same configuration and the same effects as the first embodiment. The following description will focus on the differences.

- FIG. 6A shows a plan view of a plurality of entry spaces 13 arranged in parallel.

- FIG. 6B shows a cross section taken along line VI-VI of FIG. 6A.

- a plurality of entry spaces 13 formed by the protrusions 12 are formed vertically and horizontally.

- the entrance space 13 has a square pyramid shape. Therefore, the convex part which comprises the approach space 13 among rolling rollers (transfer element) has comprised the regular quadrangular pyramid shape provided with the top equivalent to the center part 13c. The high biting property to the metal member 1 is secured.

- the wall surface 12c which comprises the approach space 13 has comprised triangle shape.

- the central portion 13c at the bottom is the deepest bottom in the entry space 13, and corresponds to the position of the top of the square pyramidal convex portion of the above-described rolling roller.

- the thickness of the top 12p of the projection 12 is substantially zero.

- the thickness of the protrusion 12 increases toward the central portion 13 c, and the strength of the entire protrusion 12 is secured.

- FIG. 7 shows a third embodiment.

- This embodiment basically has the same configuration and the same effects as the first embodiment. The following description will focus on the differences.

- the metal member 1 is installed on the mounting surface 50 a of the holding mold 50.

- the mold 52 transfer processing element

- the transfer mold 52 c is moved downward in one direction (Z direction) to press the surface 10 of the metal member 1.

- the mold 52 is lifted to be separated from the holding mold 50.

- the protrusion 12 and the entry space 13 are formed on the surface 10 of the metal member 1.

- the pressing direction of the forming die 52 is one direction

- the separating direction of the forming die 52 is the direction opposite to the pressing direction, so the transfer accuracy of the projection 12 is high.

- the forming process may be cold working, hot working or warm working. Also in the present embodiment, it is preferable to form the minute concaves by the etching process, but the etching process may be omitted in some cases if the peeling resistance is sufficiently ensured. Even in this case, since the strain based on the shear stress at the interface can be divided by the protrusions 12, the peeling resistance of the FRP portion 3 can be enhanced.

- FIG. 8 shows a fourth embodiment. This embodiment basically has the same configuration and the same effects as the first to third embodiments. The following description will focus on the differences.

- FIG. 8 shows a plan view of the projection 12 and the entry space 13 formed on the surface 10 of the metal member 1.

- the opposing protrusion 12 is reinforced by the intersection 12k, and can maintain the effect of dividing the strain for a long time.

- the entrance space 13 has a rectangular shape (square) in plan view. And the depth of central part 13c of bottom 12e of entrance space 13 is made the deepest. The depth is shallow from the central portion 13 c toward the projection 12.

- the reinforcing fibers 32 can easily enter the central portion 13 c of the entry space 13. In this case, it is advantageous to reinforce the resin material that has entered the entry space 13. Therefore, it is advantageous for suppressing separation of the interface between the FRP portion 3 and the surface 10 of the metal member 1. Also in the present embodiment, it is preferable to form a plurality of minute recesses in the protrusion 12 at random by performing an etching process. However, depending on the case, it is not necessary to abolish the etching process and not to form a minute concave portion. Even in this case, since the strain based on the shear stress at the interface can be divided by the protrusions 12, the peeling resistance of the FRP portion 3 can be enhanced.

- FIG. 9 shows a fifth embodiment.

- the present embodiment basically has the same configuration and the same effects as the first and second embodiments. The following description will focus on the differences.

- FIG. 9 shows a plan view of the projection 12 and the entry space 13 formed on the surface 10 of the metal member 1.

- the entrance space 13 is a plane and has a hexagonal shape (polygon, regular polygon).

- the projections 12 are formed continuously so as to make one round around the central portion 13c of the bottom surface 12e of the entry space 13, which is advantageous for reducing anisotropy with respect to the central portion 13c of the entry space 13. . Therefore, it is advantageous to reduce the anisotropy to exfoliation.

- the depth of the central portion 13c may be the deepest, or the depth of the entrance space 13 may be a uniform depth.

- the pitch interval LA of the protrusions 12 can be the longest distance between the protrusions 12. Also in the present embodiment, it is preferable to perform the etching process to form the minute recess in the protrusion 12. However, depending on the case, it is not necessary to abolish the etching process and not to form a minute concave portion.

- FIG. 10 shows a sixth embodiment.

- the present embodiment basically has the same configuration and the same effects as the first and second embodiments. The following description will focus on the differences.

- a transfer processing element 400 is formed by bundling and collecting a plurality of wire rods 401 having a circular cross-sectional shape. There is a gap 402 between the facing wires 401.

- the protrusion 12 is formed at a portion corresponding to the gap 402. The protrusions 12 are not connected to each other, and independently protrude from the surface of the metal member. As shown in FIG.

- the opening dimension LC between the facing projections 12 basically corresponds to the outer diameter dimension of the wire 401.

- the outer diameter of the wire 401 may be reduced. Since the transfer processing element 400 is formed by bundling and collecting the plurality of wires 401, the structure of the transfer processing element 400 is simplified. Even if broken, the wire rod 401 may be replaced. Also in the present embodiment, it is preferable to form the minute recesses in the projection 12 by performing an etching process. However, depending on the case, it is not necessary to abolish the etching process and not to form a minute concave portion.

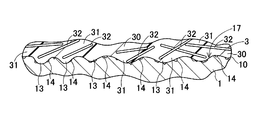

- Seventh Embodiment 11 and 12 show a seventh embodiment.

- the present embodiment basically has the same configuration and the same effects as the first and second embodiments. The following description will focus on the differences.

- the entry space 13 and the projection 12 are formed as a rolling surface that functions as a transfer surface formed on the surface 10 of the metal member 1 formed of an aluminum alloy.

- the pitch intervals between the opposing protrusions 12 are uneven. Specifically, in the region M2 where the thermal shock is relatively small in the composite molded product, the pitch interval LA2 is set relatively large. However, in the region M1 in which the thermal shock is relatively large, the pitch distance LA1 is relatively small, so that the strain due to the shear stress due to the thermal shock can be separated, and the separation at the interface can be suppressed.

- the wall surface 12 c forming the projection 12 has a plurality of minute recesses 14 exposed to the entry space 13.

- the degree of engagement at the interface between the surface 10 of the metal member 1 and the FRP portion 3 can be further enhanced, and the shear strength at the interface described above can be further enhanced.

- peeling of the FRP portion 3 is further suppressed even when the thermal shock due to heating and cooling acts repeatedly on the composite molded article over a long period of time. Be done.

- the etching process may be eliminated and the minute recesses 14 may not be formed.

- (Embodiment 8) 1 to 5 can be applied correspondingly.

- the entry space 13 and the projection 12 are formed by a rolled surface formed on the surface 10 of the metal member 1 formed of an aluminum alloy.

- the strain based on the shear stress caused by the thermal shock can be divided, and the separation at the interface can be suppressed.

- the height of the protrusions 12 is HA

- the pitch interval is LA

- the average fiber length of the reinforcing fibers 32 (for example, glass fibers) embedded in the matrix 30 is K

- the diameter of the reinforcing fibers 32 is D

- LA Is made larger than (1.2-5) ⁇ HA. Furthermore, it is larger than (2.0 to 4.0) ⁇ HA.

- LA is made larger than K and D.

- the reinforcing fiber 32 in addition to the resin of the matrix 30 entering into the entry space 13 formed in the facing protrusion 12, the reinforcing fiber 32 easily enters. In this case, it can be expected that the shear strength of the interface can be as high as possible with glass fibers. According to such this embodiment, even when the thermal shock due to heating and cooling acts repeatedly on the composite molded article over a long period of time, peeling of the FRP portion 3 is further suppressed. Also in the present embodiment, it is preferable to form the minute recess in the projection 12 by performing an etching process or the like. However, depending on the case, it is not necessary to abolish the etching process and not to form a minute concave portion.

- the entry space 13 and the projection 12 are formed of a blast treated surface 17 in which a group of projectiles such as shots, grids, sand particles and the like is made to collide with the surface 10 of the metal member 1 formed of aluminum alloy. It is considered that a portion having a relatively low hardness in the surface 10 of the metal member 1 is scraped to form the entry space 13. Of the surface 10 of the metal member 1, it is considered that the portion with relatively high hardness or the portion with less collisions of the projectile forms the protrusion 12.

- the pitch interval LA between the opposing protrusions 12 is uneven, as in the embodiments described above, the strain based on shear stress caused by thermal shock can be divided by the protrusions 12 and peeling at the interface It can be suppressed.

- a part of resin material 31 which comprises the matrix 30 of the FRP part 3 approachs into the approach space 13

- a part of reinforcement fiber 32 (glass fiber) approachs.

- the shear strength at the interface between the surface 10 of the metal member 1 and the FRP portion 3 can be increased.

- at least a part of the reinforcing fibers 32 can enter into the entry space 13 present between the facing projections 12.

- the resin material 31 entering the entry space 13 can be reinforced, and the shear strength at the interface can be further enhanced.

- the wall surface 12 c forming the protrusion 12 has a plurality of minute recesses 14 exposed to the entry space 13.

- the degree of engagement at the interface between the metal member 1 and the FRP portion 3 can be further enhanced, and the shear strength at the interface described above can be further enhanced.

- the peeling of the FRP portion 3 is further suppressed even when the thermal shock due to heating and cooling acts repeatedly over a long period of time.

- the removal of the surface oxide thin film of the metal member 1 can be expected by the cleaning action or grinding action based on the blast treatment. In this case, since the exposure of the metal base material is increased, the etching process can be promoted. However, depending on the case, it is not necessary to abolish the etching process and not to form a minute concave portion.

- the entry space 13 and the projection 12 are formed by a blast treated surface 17 in which a group of projectiles 500 collide with the surface 10 of the metal member 1 formed of metal such as aluminum alloy.

- a masking member 6 having a covering portion 60 and a space 62 is used.

- a group of projectiles 500 size capable of passing through the space 62 collides with the surface 10 of the metal member 1 from above.

- the portion facing the space 62 is scraped to form an entry space 13 in order to allow collision of the projectile 500 such as a shot, grid, sand or the like.

- the portion covered by the covering portion 60 can limit the collision of the projectile 500, and thus forms the protrusion 12.

- the masking member 6 is preferably made of a hard material (for example, carbon steel, alloy steel, ceramics). In this case, since the pitch distance LA between the protrusions 12 substantially corresponds to the pitch distance of the covering portions 60 of the masking member 6, it is set as a target.

- the pitch interval LA between the protrusions 12 can be adjusted.

- the pitch distance LA between the protrusions 12 can be set as desired.

- the advantage of being able to The masking member 6 may be formed by covering the metal member 1 with a soft material such as a resist film that is worn by blasting. Also in this case, since the wear can be suppressed by the masking member 6 in the initial and middle stages of the blast, the projection can be formed.

- the strain caused by thermal shock can be divided by the protrusions 12, and peeling at the interface between the surface 10 of the metal member 1 and the FRP portion 3 can be suppressed.

- a part of the resin material 31 constituting the matrix 30 of the FRP section 3 enters the entrance space 13 and a part of the reinforcing fiber 32 enters.

- the shear strength at the interface between the surface 10 of the metal member 1 and the FRP portion 3 can be further enhanced.

- the wall surface 12 c forming the protrusion 12 has a plurality of minute recesses 14 exposed to the entry space 13.

- the degree of engagement at the interface between the surface 10 of the metal member 1 and the FRP portion 3 can be further enhanced, and the shear strength at the interface described above can be further enhanced.

- peeling of the FRP portion 3 is further suppressed Ru.

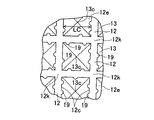

- FIG. 17 shows a plan view of the entry space 13 and the projection 12 before the FRP portion is covered.

- the entry space 13 and the projection 12 are formed by the application of pressure from the form-rolling roll functioning as a transfer processing element or the application of pressure to the molding surface of the mold.

- the protrusions 12 are formed in a grid shape.

- a plurality of minute recesses 14 are formed in the wall surface 12 c of the protrusion 12 so as to be exposed to the entry space 13.

- the minute recess 14 has a minute opening smaller than the opening dimension LC of the entrance space 13.

- a plurality of minute convex portions 19 are formed on the wall surface 12 c of the protrusion 12 so as to face the entry space 13.

- the micro-convex portion 19 has a protrusion amount smaller than the opening size LC of the entry space 13. Furthermore, the amount of protrusion of the micro-convex portion 19 has a smaller amount of protrusion than the wall thickness of the root portion of the protrusion 12 forming the entry space 13.

- the minute recesses 14 and the minute projections 19 can be formed simultaneously with the formation of the projections 12 and the entry space 13 by the pressure of the rolling rolls or the pressure of the forming surface of the forming die, so the process can be simplified. We can expect the abolition and contribute to cost reduction. In addition, when forming the minute recesses 14 and the minute projections 19, if the cold working is performed, it is also possible to expect the reinforcement of the protrusions 12 by work hardening. Here, since the thickness of the protrusion 12 is reduced when the minute recess 14 is formed in the protrusion 12, concern about the strength of the protrusion 12 may occur, but the protrusions 12 are connected to each other. The protrusion 12 can be connected and strengthened by the intersecting portion 12k. Therefore, the durability against peeling can be improved over a long period of time. In some cases, the protrusions 12 may be independent without providing the intersection 12k.

- a part of the matrix 30 constituting the FRP portion 3 can enter the entry space 13 and engage with the minute recesses 14 and the minute projections 19 facing the approach space 13.

- the engagement between the FRP portion 3 and the protrusion 12 of the metal member 1 can be further improved, which is advantageous for suppressing the peeling of the FRP portion 3.

- the minute projections 19 project toward the opposing projections 12 and thus can contribute to reducing the pitch interval LA of the opposing projections 12 and can improve the division of distortion.

- the minute recesses 14 and the minute projections 19 may be mixed on the wall surface 12 c of the protrusion 12.

- the etching process can be eliminated, but in some cases, the etching process may be used in combination.

- Example 1 Rolled roller (material: cemented carbide) on the surface 10 of a metal piece (corresponding to the metal member 1) consisting of a flat plate (aluminium extruded material, JIS A5052) having a size of 25 mm wide, 100 mm long and 3 mm thick )

- a metal piece was fixed on a milling machine and executed using a rolling roller as a blade.

- the stage speed was 75 mm / min

- the outside diameter of the rolling roller was 20 mm

- the depth of cut was 70 micrometers.

- An entrance space 13 is formed by the opposing projections 12.

- the pitch distance LA at the center of the apex of the adjacent protrusion 12 was 100 micrometers

- the depth HA was 67 micrometers

- the inclination angle ⁇ was 60 degrees.

- the etching solution contains water as the solvent, 12 g / L of OF-901 (manufactured by Kugahara Eugelite), and 25 g / L of magnesium hydroxide.

- the target temperature of the etching solution was 50 ° C., and the etching time was 10 minutes. Thereafter, the metal piece was set in the cavity of a mold for injection molding.

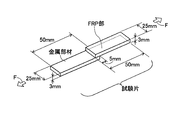

- the dimension of the overlapping portion of the metal member and the FRP portion was 25 mm ⁇ 10 mm.

- injection molding conditions were a mold temperature of 130 ° C., a cylinder temperature of 320 ° C., an injection pressure of 100 MPa, an injection speed of 60 mm / sec, an injection time of 1 second, and a screw rotation speed of 100 rpm.

- a pressure holding step was performed to maintain the pressure applied to the resin material loaded in the cavity. This is advantageous for allowing the resin material to favorably enter the entry space 13 between the projections 12 and the minute recesses 14.

- the pressure holding pressure was 50 MPa, and the pressure holding time was 10 seconds.

- the FRP portion 3 (glass fiber: 30% by mass, PPS: 70% by mass) corresponds to a fiber reinforced polymer material portion.

- the metal piece corresponds to the metal member 1.

- the glass fiber compounded into the resin material before injection molding used had an average diameter of 13 micrometers and an average fiber length of 3 millimeters (Nittobo Co., Ltd.). However, glass fibers may be broken and shortened by injection molding. When measured after molding, the average fiber length of the glass fiber was 100 micrometers.

- Example 2 The present embodiment basically has the same configuration as that of the first embodiment, and the same function and effect.

- a plurality of projections 12 were formed by rolling on the surface 10 of a metal piece (corresponding to the metal member 1) made of a flat plate (aluminum extrusion material) of the same type as that of the first embodiment.

- the pitch distance LA of the apexes of the adjacent protrusions 12 was 200 micrometers

- the depth HA was 67 micrometers

- the inclination angle ⁇ was 38 degrees.

- an etching process was performed to form pores (corresponding to the minute recesses 14) on the surface 10 of the protrusion 12.

- the fine openings of the pores face the entry space 13.

- the aperture of the minute aperture was about 3 micrometers, and the depth was about 10 micrometers.

- the metal piece was set in the cavity of a mold for injection molding.

- a resin material glass fiber: 30% by mass

- FRP portion 3 thickness: 3 mm

- metal piece A test piece (see FIG. 20) formed of the integrated composite molded article was formed.

- the conditions for injection molding were the same as in Example 1.

- the present embodiment basically has the same configuration as that of the first embodiment, and the same function and effect.

- a plurality of projections 12 were formed by rolling on the surface 10 of a metal piece (corresponding to the metal member 1) made of a flat plate (aluminum extrusion material) of the same type as that of the first embodiment.

- the pitch distance LA of the apexes of the adjacent protrusions 12 was 200 micrometers

- the depth HA was 133 micrometers

- the inclination angle ⁇ was 60 degrees.

- an etching process was performed to form pores (corresponding to the minute recesses 14) on the surface 10 of the protrusion 12.

- the aperture of the minute aperture was about 3 micrometers, and the depth was about 10 micrometers.

- Example 1 a resin material (glass fiber: 30% by mass) formed of PPS resin containing glass fiber is injection molded into a cavity, and FRP portion 3 (thickness: 3 mm) and metal piece A test piece (see FIG. 20) formed of the integrated composite molded article was formed.

- the conditions for injection molding were the same as in Example 1.

- Example 4 basically has the same configuration as that of the first embodiment, and the same function and effect.

- a rough surface was formed on the surface 10 of a metal piece (corresponding to the metal member 1) made of a flat plate (aluminum extruded material) of the same type as in Example 1 by blasting.

- the conditions for the blast treatment were a shot diameter of 0.3 to 0.5 mm (indeterminate form), a shot hardness of 40 to 50 HRC, and a projection speed of 80 m / sec.

- the rough surface after blasting had an average roughness of 100 to 120 z (Rz).

- a plurality of projections 12 are irregularly and juxtaposedly arranged in an irregular manner.

- the pitch distance LA between the apexes of the adjacent protrusions 12 was 100 micrometers or more, and the depth HA was about 50 to 150 micrometers.

- an etching process was performed to form pores (corresponding to the minute recesses 14) on the surface 10 of the protrusion 12.

- the aperture of the minute aperture was about 3 micrometers, and the depth was about 10 micrometers.

- the metal piece was set in the cavity of a mold for injection molding.

- a resin material (glass fiber: 30% by mass) formed of PPS resin containing glass fiber is injection molded into a cavity, and FRP portion 3 (thickness: 3 mm) and metal piece A test piece (see FIG. 20) formed of the integrated composite molded article was formed.

- the conditions for injection molding were the same as in Example 1.

- the present embodiment basically has the same configuration as that of the first embodiment, and the same function and effect.

- a plurality of projections 12 were formed by rolling on the surface 10 of a metal piece (corresponding to the metal member 1) made of a flat plate (aluminum extrusion material) of the same type as that of the first embodiment.

- the pitch interval LA at the top of the adjacent protrusion 12 was 100 micrometers

- the depth HA was 67 micrometers

- the inclination angle ⁇ was 60 degrees.

- an etching process was performed to form pores (corresponding to the minute recesses 14) on the surface 10 of the protrusion 12.

- the aperture of the minute aperture was about 3 micrometers, and the depth was about 10 micrometers.

- the piece of metal was then heated to 300 ° C. on a hot plate. Then, the resin sheet (glass fiber: 30 mass%) formed with PPS resin containing glass fiber was crimped

- the present embodiment basically has the same configuration as that of the first embodiment, and the same function and effect.

- a plurality of projections 12 were formed by rolling on the surface 10 of a metal piece (corresponding to the metal member 1) made of a flat plate (aluminum extrusion material) of the same type as that of the first embodiment.

- the pitch distance LA of the apexes of the adjacent protrusions 12 was 200 micrometers

- the depth HA was 67 micrometers

- the inclination angle ⁇ was 38 degrees.

- an etching process was performed to form pores (corresponding to the minute recesses 14) on the surface 10 of the protrusion 12.

- the aperture of the minute aperture was about 3 micrometers, and the depth was about 10 micrometers.

- the piece of metal was then heated to 300 ° C. on a hot plate. Then, the resin sheet (glass fiber: 30 mass%) formed with PPS resin containing glass fiber was crimped

- the present embodiment basically has the same configuration as that of the first embodiment, and the same function and effect.

- a plurality of projections 12 were formed by rolling on the surface 10 of a metal piece (corresponding to the metal member 1) made of a flat plate (aluminum extrusion material) of the same type as that of the first embodiment.

- the pitch distance LA of the apexes of the adjacent protrusions 12 was 200 micrometers

- the depth HA was 133 micrometers

- the inclination angle ⁇ was 60 degrees.

- an etching process was performed to form pores (corresponding to the minute recesses 14) on the surface 10 of the protrusion 12.

- the aperture of the minute aperture was about 3 micrometers, and the depth was about 10 micrometers.

- the piece of metal was then heated to 300 ° C. on a hot plate. Then, the resin sheet (glass fiber: 30 mass%) formed with PPS resin containing glass fiber was crimped

- Example 8 The present embodiment basically has the same configuration as that of the first embodiment, and the same function and effect.

- a rough surface was formed on the surface 10 of a metal piece (corresponding to the metal member 1) made of a flat plate (aluminum extruded material) of the same type as in Example 1 by blasting.

- the rough surface had an average roughness of 100 to 120 z (Rz).

- a plurality of projections 12 are irregularly juxtaposed on the rough surface.

- the pitch interval LA at the top of the adjacent projection 12 is basically 100 micrometers or more, and the depth HA is basically about 50 to 100 micrometers.

- an etching process was performed to form pores (corresponding to the minute recesses 14) on the surface 10 of the protrusion 12.

- the aperture of the minute aperture was about 3 micrometers, and the depth was about 10 micrometers.

- the piece of metal was then heated to 300 ° C. on a hot plate. Then, the resin sheet (glass fiber: 30 mass%) formed with PPS resin containing glass fiber was crimped

- Comparative Example 1 In Comparative Example 1, no protrusion is formed. Pores were formed on the surface of a metal piece (corresponding to a metal member) made of a flat plate (aluminum extruded material) of the same type as in Example 1 by etching. The openings of the micropores of the pores were about 3 micrometers, and the depth was about 10 micrometers. The surface of the metal piece is neither rolled nor blasted. Thereafter, a metal piece is set in a cavity of a mold for injection molding, and as in Example 1, a resin material (glass fiber: 30% by mass) formed of PPS resin containing glass fiber is injection molded in the cavity A test piece (see FIG. 20) was formed of a composite molded product in which the FRP portion 3 (thickness: 3 mm) and the metal piece were integrated. The conditions for injection molding were the same as in Example 1.

- Comparative Example 2 In Comparative Example 1, no protrusion is formed. Pores were formed on the surface of a metal piece (corresponding to a metal member) made of a flat plate (aluminum extruded material) of the same type as in Example 1 by etching. The openings of the micropores of the pores were about 3 micrometers, and the depth was about 10 micrometers. The surface of the metal piece is neither rolled nor blasted. The metal pieces were then heated to 300 ° C. on a hot plate. Then, the resin sheet (glass fiber: 30 mass%) formed with PPS resin containing glass fiber was crimped

- That the shear strength of the test piece is 30 Mpa means that the FRP portion 3 itself is broken, not the peeling at the interface between the metal member 1 and the FRP portion 3 of the test piece. Therefore, as can be understood from Table 2, in Examples 1 to 8, the initial shear strength at the interface was good, and not the peeling at the interface between the metal member 1 and the FRP portion 3 but the FRP portion 3 itself was broken . When the thermal shock is repeatedly applied, in Examples 1, 3, 5 and 7, the shear strength at the interface is good, not the peeling at the interface between the metal member 1 and the FRP portion 3, but the FRP portion 3 itself was destroyed. In Example 2, the interface was broken, and the shear strength at the interface was 23 MPa, which was good.

- Example 4 The interface was broken for Example 4, and the shear strength at the interface was 29 MPa, which was good. In Example 6, the interface was broken, and the shear strength at the interface was 19 MPa, which was good. The interface was broken for Example 8, and the shear strength at the interface was 27 MPa, which was good. In Comparative Examples 1 to 4, the shear strength after thermal shock was low.

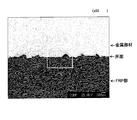

- FIG. 21 shows a photograph of the interface of the test piece (blasted and etched) according to Example 8 taken by a scanning electron microscope.

- FIG. 22 is an enlarged view of a region partitioned by white lines in FIG. As shown in FIG. 21 and FIG. 22, the resin material of the FRP portion is loaded and the glass fiber enters into the entry space between the protrusions.

- the pitch distance LA between the opposing protrusions is considered to be about 100 to 300 micrometers on average.

- Example 1B A mold (material: cemented carbide) is applied to the surface 10 of a metal piece (corresponding to the metal member 1) consisting of a flat plate (aluminium extruded material, JIS A5052) with a size of 25 mm wide, 50 mm long and 3 mm thick. It pressed and formed the some protrusion 12 (refer FIG. 1).

- the mold has pyramidal convexities with a pitch between vertices of 100 micrometers and a depth of 67 micrometers. Thereby, it formed in the surface 10 of a metal piece (equivalent to the metal member 1).

- the pitch distance LA at the center of the apex of the adjacent protrusion 12 was 100 micrometers, the depth HA was 50 micrometers, and the inclination angle ⁇ (see FIG. 1) was 60 degrees.

- the entrance space 13 was formed by the opposing protrusion 12.

- an etching process was performed to form pores (corresponding to the minute recesses 14) on the surface 10 of the protrusion 12.

- the fine openings of the pores face the entry space 13.

- the micro openings had an opening of 3 micrometers or less (about 200 nanometers at the minimum) and a depth of 10 micrometers or less (about 200 nanometers at the minimum).

- the etching solution contains water as the solvent, 12 g / L of OF-901 (manufactured by Sugawara Eugelite), and 25 g / L of magnesium hydroxide.

- the target temperature of the etching solution was 50 ° C., and the etching time was 10 minutes.

- injection molding conditions were a mold temperature of 130 ° C., a cylinder temperature of 320 ° C., an injection pressure of 100 MPa, an injection speed of 60 mm / sec, an injection time of 1 second, and a screw rotation speed of 100 rpm.

- a pressure holding step was performed to maintain the pressure applied to the resin material loaded in the cavity. This is advantageous for allowing the resin material to favorably enter the entry space 13 between the projections 12 and the minute recesses 14.

- the pressure holding pressure was 50 MPa, and the pressure holding time was 10 seconds.

- the FRP part 3 glass fiber: 30% by mass

- the metal piece corresponds to the metal member 1.

- the glass fiber compounded into the resin material before injection molding used had an average diameter of 13 micrometers and an average fiber length of 3 millimeters (Nittobo Co., Ltd.). However, glass fibers may be broken and shortened by injection molding. When measured after molding, the average fiber length of the glass fiber was 100 micrometers.

- the test pieces were heat-treated in a high temperature bath at 120 ° C. for 24 hours, and subjected to an evaluation test described later.

- Example 2B is basically the same as Example 1B.

- the mold material: cemented carbide

- the mold material: cemented carbide

- the mold pressed against the surface 10 of the metal piece (corresponding to the metal member 1) has a pyramidal convex portion with a pitch of 200 micrometers between peaks and a depth of 133 micrometers. Thereby, it formed in the surface 10 of a metal piece (equivalent to the metal member 1).

- the pitch distance LA at the center of the apex of the adjacent protrusion 12 was 200 micrometers

- the depth HA was 100 micrometers

- the inclination angle ⁇ was 60 degrees.

- pores corresponding to the minute recesses 14 were formed on the surface 10 of the projection 12 by etching.

- test piece formed of a composite molded product in which a resin material formed of nylon containing glass fiber is injection molded in a cavity and the FRP portion 3 (thickness: 3 mm) and a metal piece are integrated (FIG. 23) Reference).

- the test pieces were heat-treated in a high temperature bath at 120 ° C. for 24 hours, and subjected to an evaluation test described later.

- Example 3B is basically the same as Example 1B.

- the mold material: cemented carbide

- the mold material: cemented carbide

- the mold pressed against the surface 10 of the metal piece (corresponding to the metal member 1) has a pyramidal convex portion with a pitch of 300 micrometers between peaks and a depth of 200 micrometers. Thereby, it formed in the surface 10 of a metal piece (equivalent to the metal member 1).

- the pitch distance LA at the center of the apex of the adjacent protrusion 12 was 300 micrometers

- the depth HA was 160 micrometers

- the inclination angle ⁇ was 60 degrees.

- pores corresponding to the minute recesses 14 were formed on the surface 10 of the projection 12 by etching.

- test piece formed of a composite molded product in which a resin material formed of nylon containing glass fiber is injection molded in a cavity and the FRP portion 3 (thickness: 3 mm) and a metal piece are integrated (FIG. 23) Reference).

- the test pieces were heat-treated in a high temperature bath at 120 ° C. for 24 hours, and subjected to an evaluation test described later.

- Example 4B is basically the same as Example 1B.

- the mold material: cemented carbide

- the mold material: cemented carbide

- the mold pressed against the surface 10 of the metal piece (corresponding to the metal member 1) has a pyramid-shaped convex portion with a pitch of 600 micrometers between peaks and a depth of 400 micrometers. Thereby, it formed in the surface 10 of a metal piece (equivalent to the metal member 1).

- the pitch distance LA at the center of the apex of the adjacent protrusion 12 was 600 micrometers

- the depth HA was 300 micrometers

- the inclination angle ⁇ was 60 degrees.

- pores corresponding to the minute recesses 14 were formed on the surface 10 of the projection 12 by etching.

- test piece formed of a composite molded product in which a resin material formed of nylon containing glass fiber is injection molded in a cavity and the FRP portion 3 (thickness: 3 mm) and a metal piece are integrated (FIG. 23) Reference).

- the test pieces were heat-treated in a high temperature bath at 120 ° C. for 24 hours, and subjected to an evaluation test described later.

- Example 5B is basically the same as Example 1B.

- the mold material: cemented carbide

- the mold material: cemented carbide

- the mold pressed against the surface 10 of the metal piece (corresponding to the metal member 1) has a pyramidal convex portion with a pitch of 1000 micrometers between peaks and a depth of 400 micrometers. Thereby, it formed in the surface 10 of a metal piece (equivalent to the metal member 1).

- the pitch distance LA at the center of the apex of the adjacent protrusion 12 was 1000 micrometers

- the depth HA was 310 micrometers

- the inclination angle ⁇ was 60 degrees.

- pores corresponding to the minute recesses 14 were formed on the surface 10 of the projection 12 by etching.

- test piece formed of a composite molded product in which a resin material formed of nylon containing glass fiber is injection molded in a cavity and the FRP portion 3 (thickness: 3 mm) and a metal piece are integrated (FIG. 23) Reference).

- the test pieces were heat-treated in a high temperature bath at 120 ° C. for 24 hours, and subjected to an evaluation test described later.

- Example 6B is basically the same as Example 1B.