WO2011007816A1 - 半導体発光素子、半導体発光装置、半導体発光素子の製造方法、および半導体発光装置の製造方法 - Google Patents

半導体発光素子、半導体発光装置、半導体発光素子の製造方法、および半導体発光装置の製造方法 Download PDFInfo

- Publication number

- WO2011007816A1 WO2011007816A1 PCT/JP2010/061929 JP2010061929W WO2011007816A1 WO 2011007816 A1 WO2011007816 A1 WO 2011007816A1 JP 2010061929 W JP2010061929 W JP 2010061929W WO 2011007816 A1 WO2011007816 A1 WO 2011007816A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- substrate

- light emitting

- semiconductor light

- main surface

- emitting device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10H—INORGANIC LIGHT-EMITTING SEMICONDUCTOR DEVICES HAVING POTENTIAL BARRIERS

- H10H20/00—Individual inorganic light-emitting semiconductor devices having potential barriers, e.g. light-emitting diodes [LED]

- H10H20/80—Constructional details

- H10H20/81—Bodies

- H10H20/822—Materials of the light-emitting regions

- H10H20/824—Materials of the light-emitting regions comprising only Group III-V materials, e.g. GaP

- H10H20/825—Materials of the light-emitting regions comprising only Group III-V materials, e.g. GaP containing nitrogen, e.g. GaN

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10H—INORGANIC LIGHT-EMITTING SEMICONDUCTOR DEVICES HAVING POTENTIAL BARRIERS

- H10H20/00—Individual inorganic light-emitting semiconductor devices having potential barriers, e.g. light-emitting diodes [LED]

- H10H20/80—Constructional details

- H10H20/81—Bodies

- H10H20/819—Bodies characterised by their shape, e.g. curved or truncated substrates

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/10—Bump connectors; Manufacturing methods related thereto

- H01L2224/12—Structure, shape, material or disposition of the bump connectors prior to the connecting process

- H01L2224/13—Structure, shape, material or disposition of the bump connectors prior to the connecting process of an individual bump connector

Definitions

- the present invention relates to a semiconductor light emitting element, a semiconductor light emitting device, a method for manufacturing a semiconductor light emitting element, and a method for manufacturing a semiconductor light emitting device. Specifically, the light extraction efficiency of a light emitting device formed on a nitride substrate that can achieve high output characteristics as an absolute value is improved, and high output and high efficiency are realized by a simple method, and light distribution is further achieved.

- the present invention relates to a semiconductor light-emitting element, a semiconductor light-emitting device, a method for manufacturing a semiconductor light-emitting element, and a method for manufacturing a semiconductor light-emitting device that can also control characteristics.

- Blue light-emitting elements and ultraviolet light-emitting elements can be used as white light sources in combination with appropriate wavelength conversion materials.

- white light sources have been actively studied for application as backlights for liquid crystal displays, light-emitting diode illumination, automotive lighting, or general lighting instead of fluorescent lamps, and some of them have already been put into practical use. ing.

- a light emitting element is mainly realized by a semiconductor light emitting element (LED).

- a semiconductor light emitting device (hereinafter sometimes simply referred to as “light emitting device”) is usually realized by a GaN-based material formed on a sapphire substrate.

- the mainstream is that the planar shape projected from the main surface direction of the substrate is substantially square.

- the light emitting element which has the AlGaInN type-semiconductor layer part formed on the sapphire substrate is a very hard material, the thickness of the sapphire substrate inherent in the light emitting element is about 100 ⁇ m because of its cleavage. Things are mainstream.

- Mainly disclosed methods for improving light extraction efficiency in semiconductor light-emitting elements mainly formed on GaN substrates include the following.

- Patent Document 1 discloses a device for a light emitting element structure for efficiently extracting light in a normal direction (vertical direction) from a light emitting layer.

- the surface of the LED element that is, the back surface of the substrate or the semiconductor layer exposed by peeling off the substrate is subjected to a predetermined optical shape to be refracted.

- the predetermined optical shape is formed on a substrate having a refractive index substantially equal to that of the light emitting layer of the LED element, or a semiconductor layer that is peeled and exposed.

- a light emitting device is disclosed.

- the substrate is made transparent so that light can be extracted in the normal direction of the light emitting layer, where n1 is the refractive index of the light emitting layer of the LED element, n2 is the refractive index of the sealing material, and w is the element width.

- the material layer (thickness t) the t is w / (2 tan (sin ⁇ 1 (n1 / n2))) ⁇ t

- t is w / (2 tan (sin ⁇ 1 (n1 / n2))) ⁇ t

- Patent Document 2 Patent Document 3, and Patent Document 4 are attempts to efficiently extract light from the light emitting layer from the side surface of the light emitting element.

- Patent Document 2 discloses a semiconductor light emitting device in which a substrate side is mounted on a translucent substrate, and the thickness from the rear surface of the translucent substrate to the surface of the p-type semiconductor layer is in the range of 60 to 460 ⁇ m. An element is disclosed.

- Patent Document 3 has a substrate, a plurality of radiation output elements having a width b and a height h that are spaced apart from each other on the substrate, and a contact element disposed on each radiation output element.

- the radiation output element has an active layer stack including a light emitting zone

- the contact element has a width b ′ smaller than the width b of the corresponding radiation output element

- the width b of the radiation output element is high. The light emitted from the light-emitting zone to the side when the length h is determined is selected so that the light is almost directly reflected by the side surface of the radiation output element and is directly output through this.

- An electroluminescent body is disclosed.

- ⁇ T is the critical angle of total reflection of light incident on the surrounding medium from the active layer stack

- ⁇ T is the critical angle of total reflection of light incident on the surrounding medium from the active layer stack

- n made of ZnO or a ZnO compound is formed on the growth surface side of the p-type GaN-based semiconductor layer.

- n made of ZnO or a ZnO compound is formed on the growth surface side of the p-type GaN-based semiconductor layer.

- a nitride light emitting device characterized in that a type ZnO film is formed and a ZnO substrate is disposed on the growth surface side of the n type ZnO film.

- Patent Documents 1 to 4 have been sufficient in terms of intrinsically high output and high efficiency of a light emitting device having an AlGaInN-based semiconductor layer on a nitride substrate such as GaN or AlN. .

- Patent Document 2 discloses an element having a thickness up to a p-type semiconductor layer of 60 to 460 ⁇ m in order to extract light from a side surface of a light-transmitting substrate in an element mounted on the substrate side.

- the element disclosed here is completely silent on the relationship between the planar element size and the substrate thickness.

- the active layer is made of a GaN-based material

- both the case where the substrate is sapphire and the case where GaN is used are treated in the same row, and the essential technical idea for thickening the substrate is disclosed. Absent. Therefore, even if the technique of Patent Document 2 is used, essentially sufficient light extraction cannot be performed.

- Patent Document 2 In the range of the technical idea described in (1), a sufficient light extraction effect could not be expected.

- the electroluminescent body disclosed in Patent Document 3 has a GaN-based material formed on a sapphire or SiC substrate, the side surface of the epitaxial growth layer can be obtained by sufficiently reducing the emission point in the so-called epitaxial growth portion.

- this technical idea is not suitable for increasing the size of a light emitting point that is indispensable for increasing the output of the device.

- Patent Document 4 it is not preferable because bonding of different materials is required to extract light from the side wall of the light emitting element, which complicates the element creation process. Furthermore, since the internal reflection increases due to the difference in refractive index between the GaN-based material and the ZnO-based material, which are the active layer materials, ideal light extraction from the device side surface cannot be realized.

- the present invention has been made in view of these circumstances, and a semiconductor light emitting device capable of realizing ideal light extraction of a light emitting device formed on a nitride substrate by a simple manufacturing process and a method for manufacturing the same

- the purpose is to provide.

- the present inventors have found that in a light emitting device having an AlGaInN-based semiconductor layer portion on a nitride substrate, there is a direction in which the internal emission intensity density is strong in a direction close to the parallel direction of the active layer structure. .

- substrate is not large, it discovered that the method of taking out the light from the side wall surface of a light emitting element and improving efficiency is an essentially excellent method.

- a physical thickness of the substrate that greatly exceeds the technical common sense of those skilled in the art is required to improve the light extraction efficiency from the wall surface.

- the gist of the present invention is as follows. 1.

- a semiconductor substrate comprising: a nitride substrate; and a semiconductor layer portion including an active layer structure that emits light having a peak emission wavelength ⁇ and formed on a main surface of the nitride substrate, and satisfying the following formula: element.

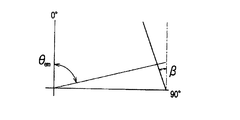

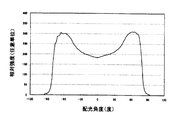

- the semiconductor light-emitting device wherein the light-emitting element is in an arbitrary plane perpendicular to the main surface of the nitride substrate and has a direction that is a light extraction direction of 0 degrees and one direction parallel to the main surface is 90 degrees.

- the external direction emitted from the light emitting element is set to -90 degrees.

- a semiconductor light emitting element characterized in that there is a plane having a light distribution characteristic in which the direction ⁇ em max indicating the maximum value of light emission intensity density satisfies at least one of the following formulas.

- the semiconductor light-emitting device according to 1 or 2, wherein the light-emitting element is in an arbitrary plane perpendicular to the main surface of the nitride substrate and has a direction that is a light extraction direction of 0 degree and a direction parallel to the main surface.

- the direction opposite to the 90 degree direction is -90 degrees, and when the element is installed in the air and the light distribution characteristics are measured effectively without disturbance, the external emission intensity density A plane satisfying at least one of the following formulas in the direction ⁇ em max indicating the maximum value of the internal light emission intensity density inside the semiconductor light emitting element, which is obtained from the direction ⁇ em max indicating the maximum value using Snell's law.

- a semiconductor light-emitting element that exists. -90.0 degrees ⁇ em max ⁇ -67.5 degrees 67.5 degrees ⁇ ⁇ em max ⁇ 90.0 degrees 4.

- the semiconductor light-emitting device according to any one of 1 to 3, wherein the light-emitting direction is in an arbitrary plane perpendicular to the main surface, and the light extraction direction is 0 degrees, and one direction parallel to the main surface

- the light emitted from the light emitting element is emitted.

- a semiconductor light emitting element characterized in that there is a plane in which the maximum value of the external light emission intensity density is 20% or more larger than the external light emission intensity density at 0 degrees. 5.

- a nitride substrate whose shape projected in a direction perpendicular to the main surface of the substrate is substantially triangular, and a semiconductor layer portion including an active layer structure that emits light having a peak emission wavelength ⁇ and formed on the main surface of the substrate A semiconductor light emitting device satisfying the following formula.

- a nitride substrate whose shape projected in a direction perpendicular to the main surface of the substrate is substantially quadrilateral, and a semiconductor layer portion including an active layer structure that emits light having a peak emission wavelength ⁇ and formed on the main surface of the substrate A semiconductor light emitting device, i) When the main surface is substantially congruent with the shape projected in the vertical direction on the substrate main surface, the following formula 1 and the following formula 2 are satisfied, ii) When the main surface is not substantially congruent with the shape projected in the direction perpendicular to the substrate main surface, only the following formula 1 is satisfied.

- a nitride substrate whose shape projected in a direction perpendicular to the main surface of the substrate is substantially m-square (m is an integer of 5 or more) or a shape including a curve at least in part, and an active layer structure that emits light having a peak emission wavelength ⁇

- a semiconductor light emitting device having a semiconductor layer portion formed on the main surface of the substrate, i) When the main surface is substantially congruent with the shape projected in the direction perpendicular to the substrate main surface, the following formula 3 and the following formula 4 are satisfied, ii) When the main surface is not substantially congruent with the shape projected onto the substrate main surface in the vertical direction, only the following formula 3 is satisfied.

- a semiconductor light emitting device having a nitride substrate whose shape projected in a direction perpendicular to the main surface of the substrate is substantially square, and a semiconductor layer portion including an active layer structure and formed on the main surface of the substrate, i) When the main surface is substantially congruent with the shape projected in the direction perpendicular to the substrate main surface, the following formula 5 and the following formula 6 are satisfied, ii) A semiconductor light-emitting device that satisfies only the following formula 5 when the main surface is not substantially congruent with the shape projected in the vertical direction on the substrate main surface.

- the semiconductor light-emitting device according to any one of 1 to 10, wherein the main surface of the nitride substrate is a (0001) surface or a surface having an off angle of 5 degrees or less from the surface.

- a semiconductor light emitting device. 12 10.

- the semiconductor light emitting device according to any one of 1 to 12, wherein the semiconductor layer portion also has a second conductivity type semiconductor layer, and the active layer structure includes a quantum well layer and a barrier layer.

- the number of the quantum well layers is NUM QW , the average physical thickness of the layers constituting the quantum well layers is T QW (nm), and the average refractive index at the wavelength ⁇ of the layers constituting the quantum well layers is n QW ( ⁇ ), the number of the barrier layers is NUM BR , the average physical thickness of the layers constituting the barrier layer is T BR (nm), and the average refractive index at the wavelength ⁇ of the layers constituting the barrier layer is n BR ( ⁇ )

- the semiconductor light emitting device according to any one of 1 to 12, wherein the semiconductor layer portion also has a second conductivity type semiconductor layer, and the active layer structure includes a quantum well layer,

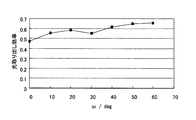

- the direction ⁇ em L- minimum (degrees) closest to the direction ⁇ em max (degrees) indicating the maximum value of the light emission intensity density and giving the minimum value to the internal light emission intensity density satisfies the following expression 7 and the direction (90 ⁇ sin ⁇ 1 (1 / n s ( ⁇ ))) (degrees) and the internal emission intensity density J in (90 ⁇ sin ⁇ 1 (1 / n s ( ⁇ ))) and the internal angle at ⁇ em max (degrees).

- the second conductivity type side semiconductor layer thickness, the number of quantum well layers, and the quantum well layer thickness such that the ratio to the maximum value J in ( ⁇ em max degree) of the emission intensity density satisfies the following formula 8.

- a semiconductor light emitting element characterized by the above.

- Formula 7 ⁇ em L-minimal ⁇ 90-sin ⁇ 1 (1 / n s ( ⁇ ))

- Formula 8 (J in (90 ⁇ sin ⁇ 1 (1 / n s ( ⁇ ))) / J in ( ⁇ em max )) ⁇ 0.9 15.

- the method for manufacturing a semiconductor light emitting device wherein a substrate thickness adjusting step for adjusting the thickness of the entire substrate, a substrate exposed surface forming step for forming a new exposed surface by processing a part of the substrate, And the manufacturing method of the semiconductor light-emitting device characterized by performing at least 1 process of the uneven

- the present invention it is possible to provide a semiconductor light emitting device capable of realizing ideal light extraction of a semiconductor light emitting device that can be formed on a nitride substrate by a simple manufacturing process, and a manufacturing method thereof.

- the light-emitting element of the present invention is particularly useful in a light-emitting element having a so-called flip chip type structure or a vertical conduction type structure from the viewpoint that it is suitable for extracting light from the side wall surface of the substrate.

- FIG. 3B is a side view of FIG. 3A. It is a figure which shows the behavior of light. It is a figure which shows the behavior of light. It is a figure which shows the behavior of light. It is a figure which shows the behavior of light. (A) And (b) is a figure which shows the triangle used for the calculation model of light extraction efficiency.

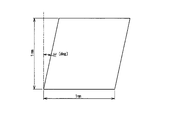

- (A) And (b) is a figure which shows the triangle which reduced the symmetry of the figure used for the calculation model of light extraction efficiency. It is a figure for demonstrating an external light emission profile. It is a figure for demonstrating the farthest side wall part inclined by angle (beta).

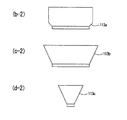

- (A), (b-1), (c-1), and (d-1) are diagrams showing examples in which the shape of the side wall portion, the substrate surface facing the main surface, and the like are variously changed.

- (B-2), (c-2), and (d-2) are diagrams showing examples in which the shape of the side wall portion, the substrate surface facing the main surface, and the like are variously changed.

- (B-3), (c-3), and (d-3) are diagrams showing examples in which the shape of the side wall portion, the substrate surface facing the main surface, and the like are variously changed.

- (E-1), (e-2), and (e-3) are diagrams showing examples in which the shape of the side wall portion, the substrate surface facing the main surface, and the like are variously changed.

- (A-1), (b-1), (b-2) and (b-3) are diagrams showing examples in which the shape of the side wall portion and the like are variously changed.

- (C-1), (c-2) and (c-3) are views showing examples in which the shape of the side wall portion and the like are variously changed.

- (D-1), (d-2), and (d-3) are diagrams showing examples in which the shape of the side wall and the like is variously changed. It is a figure for demonstrating an integrated type structure.

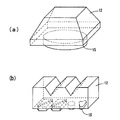

- (A) And (b) is a perspective view which shows the other structural example of the element of this invention. It is a figure for demonstrating the measuring method of curvature.

- (A) And (b) is a figure which shows the substantially triangular shape example by which uneven

- (A) And (b) is the figure which showed the projection shape of the board

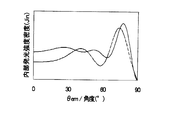

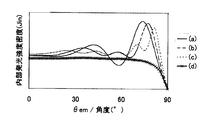

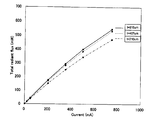

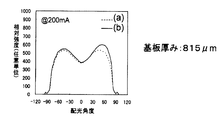

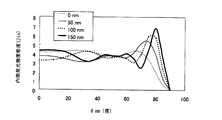

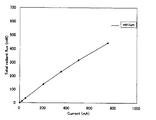

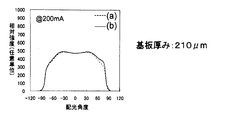

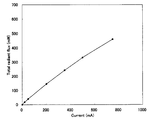

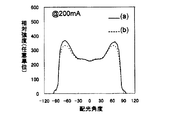

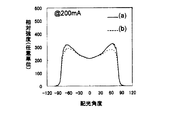

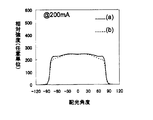

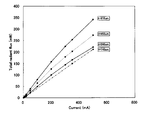

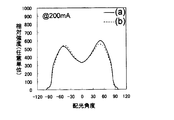

- FIG. 6 is a simulation graph showing an internal light emission profile when the thickness of a second conductivity type semiconductor layer is changed in a range of 150 to 500 nm. It is a figure which shows the measurement result of the total radiant flux of the semiconductor light-emitting device manufactured in Example 2 regarding 1st embodiment of this invention. It is a figure which shows the light distribution characteristic at the time of 200 mA current injection

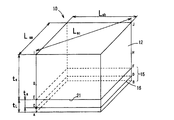

- FIG. 19A It is a perspective view which shows typically the geometric shape of the semiconductor light-emitting device concerning 2nd embodiment. It is a longitudinal cross-sectional view of FIG. 19A.

- (A) And (b) is a figure which shows the square used for the calculation model of light extraction efficiency.

- (A) And (b) is a figure which shows the unequal square used for the calculation model of light extraction efficiency.

- (A-1), (b-1), (b-2) and (b-3) are diagrams showing examples in which the shape of the side wall portion and the like are variously changed.

- C-1), (c-2) and (c-3) are views showing examples in which the shape of the side wall portion and the like are variously changed.

- (D-1), (d-2) and (d-3) are diagrams showing examples in which the shape of the side wall portion and the like are variously changed. It is a figure for demonstrating an integrated type structure.

- (A) And (b) is a perspective view which shows the other structural example of the element of this invention.

- (A) And (b) is a figure which shows the substantially square shape example by which uneven

- FIG. 28A It is a perspective view which shows typically the geometric shape of the semiconductor light-emitting device concerning 3rd embodiment. It is a longitudinal cross-sectional view of FIG. 28A.

- (A) And (b) is a figure which shows the regular hexagon used for the calculation model of light extraction efficiency.

- (A) And (b) is a figure which shows the hexagon which reduced the symmetry of the figure used for the calculation model of light extraction efficiency.

- (A-1), (b-1), (b-2) and (b-3) are diagrams showing examples in which the shape of the side wall portion and the like are variously changed.

- C-1), (c-2) and (c-3) are views showing examples in which the shape of the side wall portion and the like are variously changed.

- (D-1), (d-2) and (d-3) are diagrams showing examples in which the shape of the side wall portion and the like are variously changed. It is a figure for demonstrating an integrated type structure.

- (A) And (b) is a perspective view which shows the other structural example of the element of this invention.

- (A), (b), (c) and (d) is a figure which shows the example of the substantially polygon shape by which uneven

- the planar shape of the substrate is substantially triangular (details will be described later) will be described.

- the gist of the invention is as follows. 1. A nitride substrate whose shape projected in a direction perpendicular to the substrate main surface is substantially triangular; A semiconductor light emitting device having an active layer structure that emits light having a peak emission wavelength ⁇ , and a semiconductor layer portion formed on the main surface of the substrate, wherein the semiconductor light emitting device satisfies formula a1.

- a semiconductor light emitting device comprising: a GaN substrate whose shape projected in a direction perpendicular to the substrate main surface is substantially triangular; and a semiconductor layer portion including an active layer structure and formed on the main surface of the substrate;

- the semiconductor light emitting element characterized by satisfy

- a nitride substrate whose shape projected in a direction perpendicular to the main surface of the substrate is substantially triangular, and a semiconductor layer portion including an active layer structure that emits light having a peak emission wavelength ⁇ and formed on the main surface of the substrate

- a GaN substrate whose shape projected in a direction perpendicular to the main surface of the substrate is substantially triangular;

- a semiconductor light emitting device having an active layer structure and a semiconductor layer portion formed on the main surface of the substrate, wherein the semiconductor light emitting device satisfies formula a7.

- Formula a7 L sc ⁇ 0.418 ⁇ t t ⁇ L sc ⁇ 2.395 (Where t t represents the sum of the maximum physical thickness t s of the substrate and the maximum physical thickness t L of the semiconductor layer portion, and L sc is the longest line segment length formed by any two points on the main surface of the substrate. Represents.)

- the semiconductor light-emitting device according to any one of the above 1 to 4, A semiconductor light-emitting element, wherein the substrate is substantially transparent to light having a peak emission wavelength ⁇ emitted from the active layer structure.

- a refractive index at a wavelength ⁇ of the substrate is n s ( ⁇ ) at a peak wavelength ⁇ of the semiconductor light-emitting device, and a layer constituting the semiconductor layer portion

- the refractive index at the wavelength ⁇ of X is n LX ( ⁇ )

- the semiconductor light emitting element characterized by satisfy

- a main surface of the nitride substrate is a (0001) surface or a surface having an off angle of 5 degrees or less from the surface.

- a main surface of the nitride substrate is a (1-10n) plane or a (11-2n) plane (where n is 0, 1, 2, 3) or a semiconductor light emitting device characterized in that the off angle from these surfaces is 5 ° or less.

- the semiconductor light emitting device wherein the exposed surface of the nitride substrate includes both a surface substantially parallel to the main surface and a surface substantially perpendicular to the main surface. element.

- 21 The semiconductor light-emitting device according to any one of 1 to 20, wherein a planar shape of an end portion of the semiconductor layer portion matches or substantially corresponds to the substantially triangular shape that is a projected shape of the substrate.

- 26 The semiconductor light emitting device as described in 25 above, wherein the thickness of the second conductivity type semiconductor layer is 10 nm or more and 180 nm or less.

- the semiconductor light emitting device according to any one of 30 to 32, wherein the number of the quantum well layers is NUM QW , the average physical thickness of the layers constituting the quantum well layers is T QW (nm), and the quantum wells N QW ( ⁇ ) is the average refractive index of the layers constituting the layer, NUM BR is the number of the barrier layers, T BR is the average physical thickness of the layers constituting the barrier layers, and the barrier layers are The average refractive index of the constituent layers at the wavelength ⁇ is n BR ( ⁇ ), the physical thickness of the second conductive semiconductor layer is T P (nm), and the refractive index of the second conductive semiconductor layer is n P ( ⁇ ).

- the semiconductor light emitting element satisfying the following formula 1

- 35 The semiconductor light emitting device according to any one of 1 to 34, wherein there are a plurality of light emitting units formed in the semiconductor layer portion.

- the semiconductor light-emitting device according to any one of 1 to 40 above, wherein the light-emitting direction is in an arbitrary plane perpendicular to the main surface, and the direction that is a light extraction direction is 0 degrees, and one direction parallel to the main surface Is 90 degrees, the direction opposite to the 90 degree direction is -90 degrees, and when the element is installed in the air and the light distribution characteristics are measured effectively without disturbance, the external emission intensity density

- the direction ⁇ em max indicating the maximum value of the internal light emission intensity density inside the semiconductor light emitting element obtained by using Snell's law from the direction ⁇ em max indicating the maximum value satisfies at least one of the following formulas

- the semiconductor light-emitting device according to any one of 1 to 42 above, wherein the light-emitting direction is in an arbitrary plane perpendicular to the main surface, and the direction as the light extraction direction is 0 degrees, and one direction parallel to the main surface

- the light emitted from the light emitting element is emitted.

- a semiconductor light emitting element characterized in that there is a plane in which the maximum value of the external light emission intensity density is 20% or more larger than the external light emission intensity density at 0 degrees.

- a semiconductor light emitting device comprising the semiconductor light emitting element according to any one of 1 to 43, wherein a semiconductor layer portion side of the semiconductor light emitting element is close to a heat sink.

- a semiconductor light-emitting device comprising the semiconductor light-emitting device according to any one of 1 to 44, wherein the semiconductor light-emitting device is covered with a silicone-based material or a glass material.

- a method for manufacturing a semiconductor light emitting device having a peak light emission wavelength ⁇ in which a shape projected in a direction perpendicular to the main surface of the substrate is substantially triangular, and a nitride substrate having a refractive index at wavelength ⁇ of n s ( ⁇ ) is prepared.

- a first step, a second step of forming a semiconductor layer portion on the main surface of the nitride substrate, a third step of processing the semiconductor layer portion, and the substrate and the processed semiconductor layer portion for each element A method for manufacturing a semiconductor light emitting element, comprising a fourth step of separating, and performing shape processing so as to satisfy formula a1.

- a step, a second step of forming a semiconductor layer portion on the main surface of the GaN substrate, a third step of processing the semiconductor layer portion, and separating the GaN substrate and the processed semiconductor layer portion into each element A method of manufacturing a semiconductor light emitting device, comprising performing a shape process so as to satisfy formula a3.

- a method for manufacturing a semiconductor light emitting device having a peak light emission wavelength ⁇ in which a shape projected in a direction perpendicular to the main surface of the substrate is substantially triangular, and a nitride substrate having a refractive index at wavelength ⁇ of n s ( ⁇ ) is prepared.

- a first step, a second step of forming a semiconductor layer portion having a maximum physical thickness t L on a main surface of the nitride substrate, a third step of processing the semiconductor layer portion, and the substrate and the processed semiconductor A method for manufacturing a semiconductor light emitting device, comprising a fourth step of separating the layer portion into each device, and performing shape processing so as to satisfy only formula a5.

- One step, a second step of forming a semiconductor layer portion having a maximum physical thickness t L on the main surface of the GaN substrate, a third step of processing the semiconductor layer portion, and the processed semiconductor layer with the GaN substrate A method of manufacturing a semiconductor light emitting device, comprising a fourth step of separating the portion into each device, and performing shape processing so as to satisfy only formula a7.

- nitride substrate is a GaN substrate.

- a method for manufacturing a semiconductor light emitting device comprising: performing a substrate exposed surface forming step for forming a substrate, and forming a concavo-convex shape on a substrate for applying a concavo-convex process to at least a part of the substrate exposed surface.

- a substrate thickness adjusting step for adjusting the thickness of the entire substrate, a part of the substrate is processed.

- Manufacturing of a semiconductor light emitting device comprising: performing a substrate exposed surface forming step for forming a new exposed surface; and forming a concavo-convex shape on a substrate for imparting concavo-convex processing to at least a part of the substrate exposed surface.

- the manufacturing method of the semiconductor light-emitting device characterized by the above-mentioned.

- a substrate thickness adjusting step for adjusting the thickness of the entire substrate in the step between the second and third steps, a part of the substrate is processed.

- Manufacturing of a semiconductor light emitting device comprising: performing a substrate exposed surface forming step for forming a new exposed surface; and forming a concavo-convex shape on a substrate for imparting concavo-convex processing to at least a part of the substrate exposed surface.

- 65 A method for manufacturing a semiconductor light emitting device according to any one of the above 46 to 64, wherein the semiconductor layer portion is etched in the third step.

- the manufacturing method of the semiconductor light-emitting element characterized by implementing in either of the depth to.

- 72 The method of manufacturing a semiconductor light emitting device according to any one of 66 to 71, wherein the processing of the end portion of the semiconductor layer portion is any one of dry etching, wet etching, dicing, mechanical scribing, and optical scribing.

- 73 A method of manufacturing a semiconductor light emitting device according to any one of 66 to 72, wherein a planar uneven shape is imparted to an end portion of the semiconductor layer portion.

- 74 A method of manufacturing a semiconductor light emitting device according to 74, wherein a plurality of light emitting units are separated by a light emitting unit separating groove.

- a substrate thickness adjusting step for adjusting the thickness of the entire substrate in the third inter-fourth inter-step process, a part of the substrate is processed.

- Manufacturing of a semiconductor light emitting device comprising: performing a substrate exposed surface forming step for forming a new exposed surface; and forming a concavo-convex shape on a substrate for imparting concavo-convex processing to at least a part of the substrate exposed surface.

- a method of manufacturing a semiconductor light emitting device according to any one of 46 to 77, wherein in the fourth step, a substrate thickness adjusting step for adjusting the thickness of the entire substrate, a part of the substrate is processed, and a new exposed surface is formed.

- a method for manufacturing a semiconductor light emitting device comprising: performing a substrate exposed surface forming step for forming a substrate, and forming a concavo-convex shape on a substrate for applying a concavo-convex process to at least a part of the substrate exposed surface.

- 81. 79. The method for producing a semiconductor light-emitting device according to 79 or 80, wherein the separation starting point is formed by any one of mechanical scribing, optical scribing, dicing, dry etching, and wet etching, or a combination thereof.

- a method for manufacturing a semiconductor light emitting device is any one of mechanical scribing, optical scribing, dicing, dry etching, and wet etching, or a combination thereof.

- a method of manufacturing a semiconductor light emitting device comprising:

- a method of manufacturing a semiconductor light emitting device according to any one of the above 46 to 84, wherein a substrate thickness adjusting step for adjusting the thickness of the entire substrate in a step after the fourth step, a part of the substrate is processed, and a new A method of manufacturing a semiconductor light emitting element, comprising performing at least one of a substrate exposed surface forming step of forming an exposed surface, and a step of forming a concavo-convex shape on a substrate that imparts concavo-convex processing to at least a part of the substrate exposed surface.

- 86 A method of manufacturing a semiconductor light emitting device according to any one of 57, 58, 64, 77, 78, and 85, wherein the substrate thickness adjusting step is performed by any one of polishing and etching, or a combination thereof. A method for manufacturing a semiconductor light emitting device.

- a method of manufacturing a semiconductor light emitting device according to any one of 57, 58, 64, 77, 78, and 85, wherein the substrate exposed surface forming step includes dicing, mechanical scribing, optical scribing, dry etching, and wet.

- the manufacturing method of the semiconductor light-emitting device characterized by implementing by any one method of etching, or these combination.

- a method of manufacturing a semiconductor light emitting device according to any one of 57, 58, 64, 77, 78, and 85, wherein the step of forming a concavo-convex shape on a substrate includes wet etching, dry etching, dicing, mechanical scribing, and optical

- the manufacturing method of the semiconductor light-emitting device characterized by implementing by any one method of scribing, or these combination.

- the semiconductor light-emitting element of the present embodiment is a semiconductor light-emitting element having a semiconductor layer portion on a main surface of a nitride substrate whose shape projected in a direction perpendicular to the main surface of the substrate is substantially triangular.

- the main requirement is that (1) to (3) have a specific relationship.

- Peak emission wavelength ⁇ of a semiconductor light emitting device (2) maximum physical thickness t s or a sum t t of the maximum physical thickness t L of the maximum physical thickness t s and a semiconductor layer portion of the substrate, the substrate (3) The longest line segment length L sc formed by any two points on the substrate main surface

- the substrate thickness with respect to the length of L sc becomes a shape having a substrate having a physical thickness that greatly exceeds the technical common knowledge of those skilled in the art.

- high output and high efficiency can be achieved.

- the main structural requirements of the semiconductor light emitting device of the present invention are supported by a technical idea using the natural law that has been clarified by the present inventors, as will be described later.

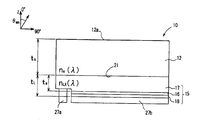

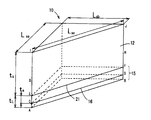

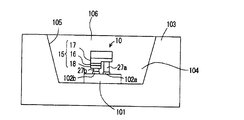

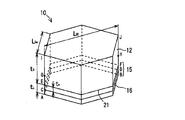

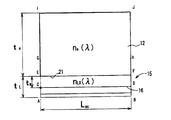

- FIG. 1A shows a semiconductor light-emitting device of one embodiment of the present invention.

- the semiconductor light emitting device 10 of the present invention includes a nitride substrate 12 and a semiconductor layer portion 15 formed on the surface thereof.

- Nitride substrate 12 when a peak emission wavelength of the light emitting element and a lambda, a refractive index of n s (lambda) at the wavelength lambda, the maximum physical thickness of t s.

- the semiconductor layer portion 15 has an active layer structure 16 that can constitute a light emitting element.

- the semiconductor layer portion 15 preferably has one or both of the first conductivity type semiconductor layer 17 and the second conductivity type semiconductor layer 18. Either one or both of the first conductivity type semiconductor layer and the second conductivity type semiconductor layer can arbitrarily include layers having various functions such as a contact layer and a carrier overflow suppression layer.

- the semiconductor light emitting element 10 preferably has a first conductivity type side electrode 27a and a second conductivity type side electrode 27b.

- the substrate surface on which the semiconductor layer portion 15 is formed is expressed as a main surface (see reference numeral 21).

- the Z-axis is taken in a direction perpendicular to the main surface 21, and this direction is set to 0 degrees in the directions of internal light emission and external light emission described later.

- the “side wall portion (side wall surface)” of the semiconductor light emitting element is used when referring to either the substrate side wall portion (side wall surface) or the semiconductor layer side wall portion (side wall surface).

- the “exposed surface” includes a main surface, a substrate surface (12a) facing the main surface, a wall surface, for example, a surface exposed when the substrate is processed, a processed sidewall surface of the semiconductor layer portion 15, and the like.

- the surface used as the boundary with the surrounding medium of a semiconductor light-emitting device is shown.

- a plurality of semiconductor light emitting elements 10 are formed on one substrate during the manufacturing process, and a surface formed by separation from adjacent elements at this time is sometimes referred to as a “separation surface”. As a result, the separation surface may become an exposed surface.

- Exposed surface formation means to form an exposed surface by an arbitrary method and an arbitrary form.

- the nuance for increasing the amount of light entering the critical angle at the interface and increasing the light extraction efficiency is indicated. Sometimes it is used.

- Concavity and convexity processing indicates that irregularities are formed by an arbitrary method and an arbitrary form, and in particular, it may be used with a nuance for increasing the light scattering effect.

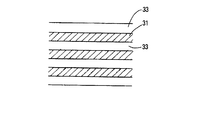

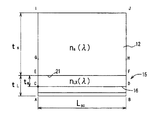

- the active layer structure 16 that the semiconductor light emitting device 10 can optionally have is preferably a quantum well active layer structure having a quantum well layer 31 and a barrier layer 33.

- FIG. 1A shows a structure of a general semiconductor light emitting device.

- the semiconductor light emitting device 10 is provided with a first conductivity type side electrode 27a and a second conductivity type side electrode 27b. Electrons and holes injected from these electrodes 27 a and 27 b are recombined in the active layer structure 16, for example, in the quantum well active layer in the case of a quantum well active layer structure, and light is emitted into the semiconductor light emitting device 10. To do.

- the angular distribution of the emission intensity density in the semiconductor light emitting device 10 strongly depends on the optical interference effect.

- This angular distribution of the light emission intensity density is called an internal light emission profile in the present invention, and is obtained as follows.

- Each quantum well layer portion in the multiple quantum well layer extending in the XY plane direction and substantially parallel to the substrate main surface (21) is assumed to be a planar set of electric dipoles (dipole plane). In the dipole plane, the dipole orientation is uniform in all directions.

- the light emitted from the dipole is multiplexed in each layer of the semiconductor layer portion (multiple quantum well layer portion, second conductivity type side semiconductor layer, second conductivity type side electrode, etc.) and electrode portion in the semiconductor light emitting device 10. Subjected to reflection and multiple interference. As a result, the light emission intensity density J in inside the semiconductor light emitting device 10 is dependent on the radiation direction (the angle between the radiation direction and the Z axis direction is expressed as ⁇ em when the Z axis direction is 0 degree). become.

- the internal light emission profile refers to the dependence of the light emission intensity density (J in ) inside the semiconductor light emitting element on the radiation direction ( ⁇ em ).

- the angle that defines the internal light emitting direction includes an angle (azimuth angle) that the projection of the light emitting direction onto the XY plane makes with the X axis direction, in addition to the angle ⁇ em made with the Z axis direction.

- angle ⁇ em made with the Z axis direction.

- the light emitted from the active layer portion of the semiconductor light emitting device is “isotropic internal light emission profile”, that is, J in is constant in every ⁇ em . Based on the assumption, the invention and the like have been made on the shape and layer structure of the semiconductor light emitting device.

- the internal light emission profile is Can be described as follows.

- I 0 Radiation intensity from dipole r s : Amplitude reflection coefficient in s-polarized electrode surface reflection r p : Amplitude reflection coefficient in p-polarized electrode surface reflection ⁇ : 2 ⁇ nd / ⁇ n: Refractive index at wavelength ⁇ in a region where a dipole surface exists d: Physical distance ⁇ between dipole surface and electrode: Peak wavelength of semiconductor light emitting device.

- multiple reflection and multiple interference between various phases constituting the semiconductor layer portion 15, J in can be calculated using the characteristic matrix method. preferable.

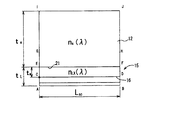

- FIG. 2A shows an example of a model used for obtaining the internal light emission profile of the semiconductor light emitting device of the present invention.

- the active layer structure in the semiconductor light emitting device 10 is a quantum well active layer structure.

- the quantum well layer 31, that is, the dipole surface is present at a distance d from the barrier layer 33 and the second conductivity type semiconductor layer 18 to the second conductivity type side electrode 27b.

- the light emitted from a certain dipole becomes anisotropic due to the interference effect with itself, but the lights emitted from different dipoles do not interfere with each other, and the overall internal emission intensity density Is the sum of the internal emission intensity densities of each anisotropic light.

- the direction in which the internal light emission intensity from the dipole in each light emitting layer increases and the direction in which they weaken may cancel each other, but according to the study of the present invention, for example, As a result of having a quantum well active layer structure that satisfies (formula A) to be described later, it always strengthens in a certain direction, that is, a direction close to a direction parallel to the active layer structure. It was found that an internal emission intensity density distribution having a maximum value in the direction of.

- the angle ⁇ em where the horizontal axis is the Z-axis direction and the vertical axis is the internal emission intensity density It becomes a characteristic, that is, an anisotropic internal light emission profile.

- the direction of the maximum value of the internal light emission intensity density varies depending on conditions such as the thickness of the second conductivity type semiconductor layer 18 and the reflectance of the second conductivity type side electrode 27b.

- the direction is close to the direction parallel to the structure (the direction in which ⁇ em is close to 90 °).

- Such a tendency that the internal emission intensity density increases in a direction nearly parallel to the active layer structure becomes more conspicuous in, for example, a light-emitting element having a quantum well active layer structure that satisfies (Formula A) described later.

- FIG. 2B shows that the internal emission profile from dipole radiation with an isotropic orientation becomes essentially anisotropic. That is, when it is assumed that an appropriate refractive index difference exists between the quantum well layer, the barrier layer, and the second conductivity type semiconductor layer 18 and the light emitting layer has an appropriate thickness, the following natural law is used. Is obtained. “When there is a moderate difference in refractive index between the quantum well layer, the barrier layer, and the second conductivity type semiconductor layer 18, for example, when the quantum well active layer structure satisfies the following (formula A), isotropic Dipolar radiation with a specific orientation results in an anisotropic internal emission profile, and the internal emission intensity density increases in a direction near the active layer structure. "formula A)

- Isotropic orientation when it is assumed that there is an excessive refractive index difference between the quantum well layer, the barrier layer, and the second conductivity type semiconductor layer 18 or the light emitting layer has an excessive thickness

- the refractive index difference increases beyond an appropriate range, or when the light emitting layer exceeds the appropriate range and is thick, the degree is as shown in FIG. 2C (a) and (b).

- the refractive index difference between the quantum well layer, the barrier layer, and the second conductivity type semiconductor layer 18 increases, the light emitted in the direction close to the parallel to the active layer structure is reflected more strongly, resulting in multiple reflection. It is absorbed by an electrode with finite reflectivity. Further, when the thickness of the light emitting layer is increased, light emitted in a direction nearly parallel to the active layer structure is canceled out in the sum of light emission from the respective dipoles. As a result, it is assumed that the refractive index difference between the quantum well layer, the barrier layer, and the second conductivity type semiconductor layer 18 is larger than an appropriate range, or the light emitting layer has an excessive thickness. If you get the following natural law:

- Isotropic when the difference in refractive index between the quantum well layer, the barrier layer, and the second conductivity type semiconductor layer 18 increases beyond an appropriate range, or when the light emitting layer has an excessive thickness, etc. Dipole radiation with a common orientation results in an isotropic internal emission profile.

- the semiconductor light-emitting element of the present invention has an appropriate refractive index difference between the quantum well layer, the barrier layer, and the second conductivity type semiconductor layer 18. Or the case where a light emitting layer has moderate thickness etc. is preferable.

- the active layer structure preferably has a quantum well active layer structure, whereby an internal light emission profile can be realized that is anisotropic with a maximum value of internal light emission intensity density in a direction parallel to the active layer structure.

- such an active layer structure can be realized, for example, by appropriately selecting a difference in refractive index between the quantum well layer and the barrier layer.

- it can be realized by appropriately selecting the number of repetitions of the quantum well layer and the barrier layer, or appropriately selecting the thicknesses of the quantum well layer and the barrier layer.

- NUM QW represents the number of quantum well layers included in the active layer structure

- T QW (nm) represents the average physical thickness of the layers constituting the quantum well layer

- NUM BR represents the number of barrier layers included in the active layer structure

- T BR (nm) represents the average physical thickness of the layers constituting the barrier layer

- T P (nm) represents the physical thickness of the second conductivity type semiconductor layer

- n QW ( ⁇ ) represents the average refractive index at the wavelength ⁇ of the layers constituting the quantum well layer

- n BR ( ⁇ ) represents an average refractive index at a wavelength ⁇ of a layer constituting the barrier layer

- n P ( ⁇ ) represents the average refractive index of the second conductivity type semiconductor layer at the wavelength ⁇

- n s ( ⁇ ) represents the refractive index at the wavelength ⁇ of the substrate as described above.

- the number of quantum well layers is preferably 4 or more and 30 or less.

- the maximum value of the thickness of the quantum well layer included in the active layer structure is 40 nm or less.

- the present application also discloses a semiconductor light emitting device having an anisotropic internal light emission profile, in which the quantum well active layer satisfies the above formula.

- the present invention can be independently configured without combining with other configurations disclosed in the present application. It can also be combined with other configurations disclosed in the present application.

- the semiconductor light emitting device of the present invention is anisotropic in the internal light emission profile as shown in the graphs (a) to (c) of FIG. 2B or FIG.

- the maximum value of the intensity density has a characteristic close to the direction parallel to the active layer structure. That is, it is preferable that the emission intensity density distribution with respect to the internal emission direction ( ⁇ em ) of the semiconductor light emitting device of the present invention is not isotropic.

- the direction ( ⁇ em max ) having the maximum value is a direction close to the parallel direction of the active layer structure.

- the direction ( ⁇ em max ) giving the maximum value of internal light emission varies depending on the material constituting the semiconductor layer portion, the structure of each layer, the electrode material, and the structure thereof.

- the direction ( ⁇ em max ) giving the maximum value of internal light emission includes the first conductivity type semiconductor layer constituting the semiconductor layer portion, the active layer structure including the quantum well active layer and the barrier layer, and the second conductivity type. It varies depending on the semiconductor layer, the contact layer, various structures that can be arbitrarily introduced, the constituent material of the first conductivity type side electrode, the constituent material of the second conductivity type side electrode, the structure thereof, and the like.

- ⁇ em max can be most strongly changed by the reflection effect due to the difference in refractive index between the quantum well layer, the barrier layer, and the second conductivity type semiconductor layer 18 and the different bipolar from the light emitting layer having a certain thickness. This is an effect of canceling anisotropy as a result of the addition of light emission by the child.

- ⁇ em max is It can be changed in the range of 67.5 degrees ⁇ ⁇ em max ⁇ 90 degrees. This is simultaneously ⁇ 90 degrees ⁇ em max ⁇ ⁇ 67.5 degrees.

- the present inventors have found the following. That is, it is more effective to extract the light emitted in such a direction from the side wall surface than to extract from the “upper surface (the substrate surface 12 a facing the main surface in FIG. 1A)” of the semiconductor light emitting element 10.

- the angle ( ⁇ em max ) indicating the maximum value of the internal light emission intensity density emitted from the active layer structure 16 of the semiconductor light emitting device 10 to the inside of the semiconductor light emitting device has a lower limit of the absolute value of 67.5 degrees or more. It is preferably 70.0 degrees or more, more preferably 72.5 degrees or more, and further preferably 75.0 degrees or more.

- the upper limit of the absolute value of ⁇ em max is preferably smaller than 90 degrees, more preferably 87.5 degrees or less, more preferably 85.0 degrees or less, and 82.5 degrees or less. More preferably it is.

- light mainly extracted from the side surface of the light emitting device is mainly light in the direction in which the light is emitted at a high density internally. It is an essential and effective method for improving efficiency. This is a conclusion that cannot be reached from the isotropic internal light emission profile disclosed heretofore.

- the active layer structure has a quantum well structure and the refractive index difference between the quantum well layer and the barrier layer is small within an appropriate range

- the light emitted internally from the active layer structure 16 is 67.5 degrees ⁇ Since ⁇ em max ⁇ 90 degrees, the side wall of the semiconductor light emitting element 10 can be reached.

- the refractive index difference at the interface of the semiconductor layer constituting the active layer structure 16 and the other semiconductor layer portion is small in an appropriate range

- the refractive index difference at the interface between the semiconductor layer portion and the nitride substrate is also in an appropriate range. The same is true for small cases. Therefore, it is most effective to extract the light emitted internally from the active layer structure 16 from here.

- the present application is a semiconductor light emitting device having an anisotropic internal light emission profile, and the absolute value of the angle ⁇ em max indicating the maximum value of the internal light emission intensity density is 67.

- a semiconductor light emitting device satisfying 5 degrees or more and less than 90 degrees is also disclosed, and the invention can be independently configured without combining with other structures disclosed in the present application. It can also be combined with other configurations disclosed in the present application.

- the external light emission profile that is, the light distribution characteristic is determined according to Snell's law as a comprehensive result of reflection, transmission, refraction, and the like of light at the interface between the internal light emission profile and the peripheral medium of the semiconductor light emitting element.

- the external light emission profile is a distribution of the emission intensity density (J out ) outside the semiconductor light emitting element with respect to the radiation direction ( ⁇ em ). That is, ⁇ em max cannot be observed directly, but by observing the ( ⁇ em max ) direction indicating the maximum value of the emission intensity density (J out ) outside the semiconductor light emitting element, It is possible to obtain by calculating backward from the law of.

- the light distribution characteristics are measured in the air by mounting the light emitting elements on a stem or the like that eliminates the portion that can be a reflecting mirror as much as possible. It is preferable to do.

- the present inventors take out the internal light emitted in the other direction including the direction having the maximum value of the above-mentioned internal light emission intensity density as much as possible from the side wall of the semiconductor. Has been found to be effective in improving the light extraction efficiency of the semiconductor light emitting device. That is, the semiconductor light emitting device of the present invention is characterized in that the shape of the nitride substrate projected in the direction perpendicular to the main surface of the substrate is substantially triangular. In addition, one of the features is that a specific relationship is satisfied between the longest line segment length formed by any two points on the substrate main surface and the maximum physical thickness of the nitride substrate.

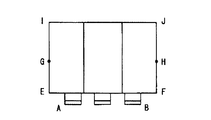

- FIG. 3A is a perspective view schematically showing the geometric shape of the semiconductor light emitting device.

- the semiconductor light emitting device 10 includes a semiconductor layer portion 15 including an active layer structure 16 that emits light having a peak emission wavelength ⁇ on the main surface (the lower side of the drawing) of the nitride substrate 12. is doing.

- the nitride substrate 12 when the nitride substrate 12 is projected onto the main surface 21 in the vertical direction, it has a substantially triangular shape. Further, since all of the side wall surfaces are perpendicular to the main surface 21, the projected shape of the nitride substrate 12 matches the planar shape of the main surface 21, and the main surface also has a substantially triangular shape.

- the shape projected in the vertical direction on the main surface of the substrate generally matches the shape of the adjacent element isolation end.

- the planar shape of the main surface 21 is smaller than the shape of the substrate projected perpendicularly to the substrate main surface.

- the main surface shape of the substrate may be substantially triangular (however, smaller than the shape in which the substrate is projected in the vertical direction on the main surface of the substrate). 4 or a natural number of 100 or less), a circular shape, an elliptical shape, an indefinite shape surrounded by a curve, an indefinite shape surrounded by a straight line and a curve, or the like.

- the longest line segment length formed by any two points on the main surface of the substrate is L sc

- the refractive index at the wavelength ⁇ of the substrate is n s ( ⁇ ).

- the maximum physical thickness t s of the substrate satisfies the following equation a1.

- the configuration satisfying these equations can effectively improve the light extraction efficiency from the side wall of the semiconductor light emitting device in which the direction of the maximum value of the internal light emission intensity density is close to the parallel direction to the active layer structure.

- such a structure can be realized by a simple manufacturing method. Further, such a structure is advantageous in that the light distribution characteristic can be controlled.

- all of the side wall surfaces are perpendicular to the main surface 21, and the projection shape of the nitride substrate 12 matches the planar shape of the main surface 21. It is also an end shape.

- the projected shape is a substantially triangular shape, the shape is superior to that of a pentagonal or more polygonal structure, and the surface filling property is superior, which is advantageous when a large number of semiconductor light emitting devices are formed on a nitride substrate.

- the square planar shape can be formed by scribing from two orthogonal directions, but to form a triangular planar structure, it is only necessary to add scribe formation from one direction. It can be taken out from the nitride substrate.

- the fact that a large number of semiconductor light-emitting elements can be taken out from the nitride substrate means that the semiconductor light-emitting element of the present invention having a shape having a substrate having a physical thickness that greatly exceeds the technical common sense of those skilled in the art. It is also extremely effective from the viewpoint of effective use of the nitride substrate and cost reduction.

- a triangular planar structure that can be formed by scribing from three directions, at least one of the three sides can be designed to have a side with a different length from the other side. Triangular shapes can be designed for control purposes. Such a design is particularly effective in the present invention which is characterized in that light emitted into the semiconductor light emitting element is extracted from the side wall surface.

- the proportion of vertices whose angles are acute among all vertices can be easily increased compared to other figures.

- all corners are acute angles, but there are no acute angles in squares, regular pentagons, and regular hexagons.

- the two angles are acute angles, so the ratio of the acute angles is 2/3 or more.

- the acute angle part forms a planar shape that is advantageous in extracting light emitted in the vicinity of the acute angle part. Therefore, in the semiconductor light emitting device of the present invention mainly focusing on light extraction from the side wall surface. It is particularly preferable that the shape projected in the vertical direction on the main surface of the substrate is a substantially triangular shape.

- the projection shape of the semiconductor light emitting element is selected to be a triangle

- a shape having low symmetry is preferable because it is advantageous for light extraction.

- an isosceles triangle is more preferable than an equilateral triangle, and an unequal triangle having different lengths and angles of all sides is advantageous for light extraction. This is because in the case of a highly symmetric figure, planar stay light is generated due to the symmetry. On the other hand, when the symmetry is low, such staying light is unlikely to occur. This “symmetry” will be supplemented with “H: symmetry” in the latter half of this specification.

- FIG. 3F and FIG. 3G respectively show the case where the shape projected from the vertical direction on the main surface of the substrate is an equilateral triangle in the semiconductor light emitting device in which the substrate portion is surrounded by an optically flat surface, and the symmetry of the figure is lowered.

- a model for calculating the light extraction efficiency is shown. As a result, it has been confirmed that the light extraction efficiency of the inequilateral triangle is 1.4 times that of the regular triangle.

- the projection shape is a triangle

- a shape with low symmetry is preferable because it is advantageous for light extraction.

- This is preferable in a semiconductor light-emitting device that mainly emits light from the side surface as in the present invention, and has a remarkable synergistic effect.

- the light extraction efficiency from the side wall surface is synergistically improved in combination with the increase in the physical thickness of the substrate described above, and a remarkable effect that cannot be predicted by those skilled in the art can be realized.

- the combination of the physical thickness of the substrate and the projected shape has great technical significance.

- the shape of the substrate projected from the direction perpendicular to the main surface is substantially triangular.

- substantially triangular refers to a figure (triangle) surrounded by three sides, such as a regular triangle, an isosceles triangle, and an unequal triangle, and generally has a triangular shape, but the three sides are strictly straight lines. Instead, it is intended that a part of or all of one or more sides may have a fine corrugated shape or irregular shape regularly or irregularly.

- the shape of the fine unevenness is, for example, as described later in the section ⁇ Substrate surface orientation and unevenness formation on the substrate>, the unevenness size (height difference from the line) is the peak wavelength of the semiconductor light emitting element ⁇ Can have dimensions of about ⁇ / 50 to 50 ⁇ . Preferably, it has a dimension of about ⁇ / 10 to 10 ⁇ , more preferably a dimension of about ⁇ / 7 to 7 ⁇ , and more preferably a dimension of about ⁇ / 5 to 5 ⁇ .

- the distance between the concave portions adjacent to the concave portion can have a dimension of about ⁇ / 50 to 50 ⁇ , where ⁇ is the peak wavelength of the semiconductor light emitting element.

- ⁇ is the peak wavelength of the semiconductor light emitting element.

- it has a dimension of about ⁇ / 10 to 10 ⁇ , more preferably a dimension of about ⁇ / 7 to 7 ⁇ , and more preferably a dimension of about ⁇ / 5 to 5 ⁇ .

- the refractive index at the wavelength ⁇ of the surrounding medium is expressed as n out ( ⁇ )

- the refractive index at wavelength ⁇ of the nitride substrate is expressed as n s ( ⁇ )

- t s be the physical thickness of the thickest part of the substrate

- the refractive index at the wavelength ⁇ of the layer X constituting the semiconductor layer portion is represented by n LX ( ⁇ ) (that is, the layer X represents an arbitrary layer constituting the semiconductor layer portion, and n LX ( ⁇ ) is the wavelength of the layer X. represents the refractive index at ⁇ ).

- the maximum physical thickness from the substrate main surface to the active layer structure is t a

- Let t L be the maximum physical thickness of the semiconductor layer portion.

- the longest line segment length (straight line length) formed by any two points on the main surface of the substrate is L sc .

- the length of the shortest side of the substantially triangular shape of the main surface of the substrate is L sa .

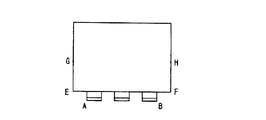

- points A and B are points at the end of the semiconductor layer portion 15 (the lower side of the figure).

- Points C and D are end points of the active layer structure 16.

- Points E and F are points at the end of the boundary between the main surface 21 and the semiconductor layer portion 15.

- Point G and point H are points where the element is separated from other semiconductor light emitting elements 10 adjacent to each other in manufacturing (in this shape, the other points are also the ends where the elements are separated). is there.

- Point I and point J are points at the end of the substrate on the surface opposite to the main surface 21 (upper side in the figure).

- the maximum value of the internal emission intensity density of light emitted from the active layer structure 16 (the maximum value of the internal profile) is relatively close to the parallel direction of the active layer structure.

- the light emitted from the point C in FIG. 3A is assumed, and this includes the direction of the maximum value of the internal emission intensity density and includes the point C as much as possible. Assuming internal light emission radiated in the other direction from the semiconductor light emitting device shape in which these lights can be effectively extracted from the wall portion (the farthest side wall portion) of the light emitting device farthest from the point C You can do it.

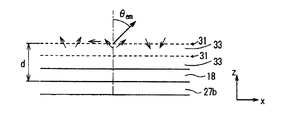

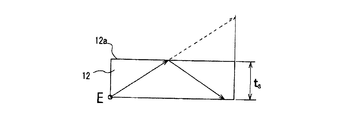

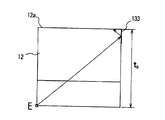

- FIG. 3B is a view of the surface surrounded by the symbol IABJ of the element of FIG. 3A viewed from the vertical direction.

- FIG. 3B a straight line including point A to point I, a straight line including point B to point J (farthest side wall portion), and a plane surrounded by point A, point B, and point I, point J are illustrated.

- the distance between the points A and B is the longest line segment length L sc formed by any two points on the main surface of the substrate, and in this case, corresponds to the longest side (see FIG. 3A).

- n s ( ⁇ ) and n LX ( ⁇ ) do not differ greatly, light generated from the active layer structure sufficiently reaches the side surface of the nitride substrate.

- the maximum physical thickness t a from the main surface 21 to the active layer structure is sufficiently thin compared to the thickness t s of the nitride substrate. Therefore, assuming that the light emission from the point C is the light emission from the point E, the critical angle in the farthest side wall portion including the point B point D point F point H point J may be considered.

- FIG. 3C is a diagram showing the behavior of light.

- the farthest side wall (the right wall in the figure) is divided into the following three regions 131, 132, and 133 corresponding to the behavior of light.

- the first is the lowermost region 131 of the farthest side wall.

- n out ( ⁇ ) is the refractive index of the peripheral medium at the emission wavelength ⁇ of the semiconductor light emitting element.

- the second is an area 132 existing on the above-described area 131.

- - ⁇ c The second region of the farthest side wall with respect to the point E, or the intrinsic confinement light generation region).

- the third is a region 133 further above the region 132 described above.

- the light incident on the first region 131 on the farthest side wall is not totally reflected. Therefore, light can be effectively extracted from the first region 131 in the farthest side wall portion.

- light incident on the second region 132 on the farthest side wall and light incident on the third region 133 on the farthest side wall are subjected to total reflection.

- the second region 132 of the farthest side wall portion is a region where even if the light that has undergone total reflection is reflected and reaches the other light emitting element side wall surface, it is further subjected to total reflection on that surface. In other words, it is a region that creates “intrinsic confinement light” in the semiconductor light emitting device.

- the light incident on the third region 133 is totally reflected at the farthest side wall, but has an incident angle smaller than the critical angle at the other part (for example, the substrate surface 21a), so that it can be taken out by repeating the reflection. .

- the thickness t s (FIG. 3B) of the nitride substrate 12 is thin so as to be within the first region 131 of the farthest side wall portion, as shown in FIG.

- Light that can be extracted from the farthest side wall portion if there is a thickness is totally reflected by the substrate surface 12a facing the main surface, and is absorbed when the light is incident on the active layer structure again, or Since it may be absorbed by the second conductivity type side electrode, the first conductivity type side electrode, etc., it is not preferable.

- the reflectivity of the electrode or the like is 100% and the loss of the nitride substrate and the semiconductor layer portion is 0, the light can be emitted from the side wall by repeating multiple reflection. Environment is not realized. That is, the thickness t s of the nitride substrate may such that the first region 131 is not preferable from the viewpoint of efficient extraction of light.

- the thickness t s of the preferred nitride substrate in the present invention is given as follows.

- the intensity of light emitted internally from the active layer structure has its maximum value in a direction relatively close to the direction parallel to the active layer structure 16

- light in a direction with a high internal emission intensity density is converted into a semiconductor.

- the thickness t s of the nitride substrate first The thickness is within the two regions (intrinsic confinement light generation region) 132.

- the thickness t s of the nitride substrate in the present invention is preferably more than the thickness (t 1 in FIG. 3C) the lower limit of the thickness of the intrinsic confinement light generation region 132.

- the upper limit of the thickness t s is preferably less 5500 ⁇ m in terms of isolation.

- thickness t s of the nitride substrate is preferably to a thickness of at least the thickness of the lower limit of the intrinsic confinement light generation region 132 (t 1 in the figure), the upper limit of the intrinsic confinement light generation region thickness (in FIG. t 2 ) More preferably, the thickness is less than or equal to. That is, the thickness t s of the nitride substrate, the thickness of the intrinsic confining light generation region, i.e., t 1 ⁇ t s ⁇ t 2 More preferably.

- the thickness t s of the nitride substrate of the present invention the aspect ratio of the longest line segment lengths to make the two arbitrary points overlaying the substrate main surface and L sc (t s / L sc )

- tan ⁇ t s / L sc tan ⁇ sin ⁇ 1 (n out ( ⁇ ) / n s ( ⁇ )) ⁇ ⁇ t s / L sc ⁇ tan ⁇ 90 ⁇ sin ⁇ 1 (n out ( ⁇ ) / n s ( ⁇ )) ⁇ It is.

- t s of the nitride substrate 12 of the semiconductor light-emitting device 10 of the present invention L sc ⁇ tan ⁇ sin ⁇ 1 (n out ( ⁇ ) / n s ( ⁇ )) ⁇ ⁇ t s ⁇ L sc ⁇ tan ⁇ 90 ⁇ sin ⁇ 1 (n out ( ⁇ ) / n s ( ⁇ )) ⁇ (formula a1a) It becomes.

- n out ( ⁇ ) can be set to 1 assuming vacuum or effectively air. Therefore, the preferred substrate thickness of the semiconductor light emitting device in the present invention is: L sc ⁇ tan ⁇ sin ⁇ 1 (1 / n s ( ⁇ )) ⁇ ⁇ t s ⁇ L sc ⁇ tan ⁇ 90 ⁇ sin ⁇ 1 (1 / n s ( ⁇ )) ⁇ (formula a1) It becomes.

- the thickness t s of the nitride substrate in the present invention as described below, the maximum thickness length extended from the main surface vertically thickest.

- the substrate thickness preferably satisfies the formula a1, and the light emitted in the direction giving the maximum value of the internal light emission intensity density directly enters the farthest side wall portion within the specified thickness. Further, from the viewpoint of manufacturing cost and the like, it is advantageous that the thickness of the substrate is set to the minimum necessary thickness while satisfying these.

- the index that can be the lower limit of the thickness t s of the semiconductor light-emitting device of the present invention (A) L sc ⁇ tan ⁇ sin ⁇ 1 (1 / n s ( ⁇ )) ⁇ (B) L sc ⁇ tan ⁇ 1 ⁇ (90 ⁇ em max ) ⁇ (C) L sc ⁇ tan ⁇ 1.5 ⁇ (90 ⁇ em max ) ⁇ (D) L sc ⁇ tan ⁇ 2.0 ⁇ (90 ⁇ em max ) ⁇ It is.