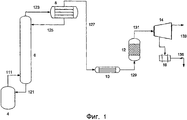

RU2435754C2 - Способ возврата энергии в процессе производства ароматических карбоновых кислот - Google Patents

Способ возврата энергии в процессе производства ароматических карбоновых кислот Download PDFInfo

- Publication number

- RU2435754C2 RU2435754C2 RU2007138833/04A RU2007138833A RU2435754C2 RU 2435754 C2 RU2435754 C2 RU 2435754C2 RU 2007138833/04 A RU2007138833/04 A RU 2007138833/04A RU 2007138833 A RU2007138833 A RU 2007138833A RU 2435754 C2 RU2435754 C2 RU 2435754C2

- Authority

- RU

- Russia

- Prior art keywords

- pressure

- liquid

- gas

- high pressure

- energy

- Prior art date

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C51/00—Preparation of carboxylic acids or their salts, halides or anhydrides

- C07C51/42—Separation; Purification; Stabilisation; Use of additives

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C51/00—Preparation of carboxylic acids or their salts, halides or anhydrides

- C07C51/16—Preparation of carboxylic acids or their salts, halides or anhydrides by oxidation

- C07C51/21—Preparation of carboxylic acids or their salts, halides or anhydrides by oxidation with molecular oxygen

- C07C51/255—Preparation of carboxylic acids or their salts, halides or anhydrides by oxidation with molecular oxygen of compounds containing six-membered aromatic rings without ring-splitting

- C07C51/265—Preparation of carboxylic acids or their salts, halides or anhydrides by oxidation with molecular oxygen of compounds containing six-membered aromatic rings without ring-splitting having alkyl side chains which are oxidised to carboxyl groups

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D3/00—Distillation or related exchange processes in which liquids are contacted with gaseous media, e.g. stripping

- B01D3/009—Distillation or related exchange processes in which liquids are contacted with gaseous media, e.g. stripping in combination with chemical reactions

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C51/00—Preparation of carboxylic acids or their salts, halides or anhydrides

- C07C51/42—Separation; Purification; Stabilisation; Use of additives

- C07C51/43—Separation; Purification; Stabilisation; Use of additives by change of the physical state, e.g. crystallisation

- C07C51/44—Separation; Purification; Stabilisation; Use of additives by change of the physical state, e.g. crystallisation by distillation

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C63/00—Compounds having carboxyl groups bound to a carbon atoms of six-membered aromatic rings

- C07C63/04—Monocyclic monocarboxylic acids

- C07C63/06—Benzoic acid

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2219/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J2219/00002—Chemical plants

- B01J2219/00004—Scale aspects

- B01J2219/00006—Large-scale industrial plants

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P20/00—Technologies relating to chemical industry

- Y02P20/10—Process efficiency

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P20/00—Technologies relating to chemical industry

- Y02P20/50—Improvements relating to the production of bulk chemicals

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P70/00—Climate change mitigation technologies in the production process for final industrial or consumer products

- Y02P70/10—Greenhouse gas [GHG] capture, material saving, heat recovery or other energy efficient measures, e.g. motor control, characterised by manufacturing processes, e.g. for rolling metal or metal working

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Crystallography & Structural Chemistry (AREA)

- Organic Low-Molecular-Weight Compounds And Preparation Thereof (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US66379205P | 2005-03-21 | 2005-03-21 | |

| US60/663,792 | 2005-03-21 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| RU2007138833A RU2007138833A (ru) | 2009-04-27 |

| RU2435754C2 true RU2435754C2 (ru) | 2011-12-10 |

Family

ID=36481307

Family Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| RU2007138833/04A RU2435754C2 (ru) | 2005-03-21 | 2006-03-20 | Способ возврата энергии в процессе производства ароматических карбоновых кислот |

| RU2007134060/04A RU2414448C2 (ru) | 2005-03-21 | 2006-03-20 | Способ и аппарат для производства ароматических карбоновых кислот |

| RU2007138831/04A RU2449980C2 (ru) | 2005-03-21 | 2006-03-20 | Способ и устройство для производства ароматических карбоновых кислот (варианты) |

Family Applications After (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| RU2007134060/04A RU2414448C2 (ru) | 2005-03-21 | 2006-03-20 | Способ и аппарат для производства ароматических карбоновых кислот |

| RU2007138831/04A RU2449980C2 (ru) | 2005-03-21 | 2006-03-20 | Способ и устройство для производства ароматических карбоновых кислот (варианты) |

Country Status (18)

| Country | Link |

|---|---|

| US (4) | US7935845B2 (enExample) |

| EP (3) | EP1861349B1 (enExample) |

| JP (1) | JP5254001B2 (enExample) |

| KR (3) | KR101314005B1 (enExample) |

| CN (3) | CN101146757B (enExample) |

| AT (3) | ATE473958T1 (enExample) |

| BR (3) | BRPI0609328B1 (enExample) |

| CA (3) | CA2599461C (enExample) |

| DE (3) | DE602006008284D1 (enExample) |

| EG (1) | EG25228A (enExample) |

| ES (3) | ES2348062T3 (enExample) |

| MX (3) | MX2007011186A (enExample) |

| PL (3) | PL1861348T3 (enExample) |

| PT (3) | PT1861349E (enExample) |

| RU (3) | RU2435754C2 (enExample) |

| UA (1) | UA96569C2 (enExample) |

| WO (3) | WO2006102336A2 (enExample) |

| ZA (1) | ZA200707537B (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU2760675C1 (ru) * | 2020-03-31 | 2021-11-29 | Наньцзин Яньчан Реэкшн Текнолоджи Рисерч Институт Ко. Лтд | Улучшенные реакционная система с встроенным средством для создания межфазных микроповерхностей и способ для получения терефталевой кислоты с использованием параксилола |

Families Citing this family (63)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7264422B2 (en) * | 2004-03-25 | 2007-09-04 | Owens-Corning Fiberglas Technology Inc. | Rotary separator for mineral fibers |

| RU2435754C2 (ru) | 2005-03-21 | 2011-12-10 | Бп Корпорейшн Норт Америка Инк. | Способ возврата энергии в процессе производства ароматических карбоновых кислот |

| KR100794317B1 (ko) * | 2006-02-20 | 2008-01-11 | (주)에이엠티퍼시픽 | 방향족 화합물의 산화반응시 반응기 배출가스로부터 물을제거하는 방법 |

| US7566802B2 (en) * | 2006-05-24 | 2009-07-28 | Eastman Chemical Company | Process for energy recovery and water removal in the preparation of aromatic carboxylic acids |

| US7465824B2 (en) * | 2007-02-08 | 2008-12-16 | Bp Corporation North America Inc. | Process for the production of high purity aromatic carboxylic acids using a benzoic acid and water solvent for oxidation and purification |

| RU2458038C2 (ru) * | 2007-02-28 | 2012-08-10 | Хитачи Плант Текнолоджиз, Лтд. | Способ получения неочищенной ароматической дикарбоновой кислоты, предназначенной для гидрогенизационной очистки |

| KR100860343B1 (ko) * | 2007-03-15 | 2008-09-26 | 삼성석유화학(주) | 친환경적이고 단순화된 방향족 디카르복실산의 제조방법 |

| KR100894761B1 (ko) | 2007-10-18 | 2009-04-24 | 주식회사 효성 | 에너지를 회수 및 재활용하는 2,6-나프탈렌디카르복실산제조방법 |

| US20100113735A1 (en) * | 2008-10-31 | 2010-05-06 | Eastman Chemical Company | Integrated Co-Production of Dicarboxylic Acids |

| US9493387B2 (en) * | 2008-10-31 | 2016-11-15 | Grupo Petrotemex, S.A. De C.V. | Dicarboxylic acid production with minimal wastewater generation |

| US9505692B2 (en) * | 2008-10-31 | 2016-11-29 | Grupo Petrotemex, S.A. De C.V. | Dicarboxylic acid production with self-fuel oxidative destruction |

| US9493388B2 (en) * | 2008-10-31 | 2016-11-15 | Grupo Petrotemex, S.A. De C.V. | Dicarboxylic acid production with direct fired off-gas heating |

| US9493389B2 (en) * | 2008-10-31 | 2016-11-15 | Grupo Petrotemex, S.A. De C.V. | Dicarboxylic acid production with enhanced energy recovery |

| WO2010064006A1 (en) * | 2008-12-02 | 2010-06-10 | Invista Technologies S.A.R.L. | Systems and methods for managing reactor transients |

| US20100243228A1 (en) * | 2009-03-31 | 2010-09-30 | Price Richard J | Method and Apparatus to Effect Heat Transfer |

| DE102009029912A1 (de) * | 2009-06-19 | 2011-06-30 | E.ON Anlagen Service GmbH, 45896 | Verfahren und Vorrichtung zur Gewinnung von Energie aus einem gasförmigen oder flüssigen Brennstoff |

| EP2457051A2 (en) * | 2009-07-22 | 2012-05-30 | Johnson Controls Technology Company | Compact evaporator for chillers |

| WO2011041337A2 (en) * | 2009-10-02 | 2011-04-07 | Invista Technologies S. A. R. L. | Systems and methods for reducing entrainment background |

| CN102892742B (zh) * | 2010-02-15 | 2014-11-19 | 英威达技术有限公司 | 通过催化加氢纯化羧酸 |

| US20120031096A1 (en) * | 2010-08-09 | 2012-02-09 | Uop Llc | Low Grade Heat Recovery from Process Streams for Power Generation |

| US9963413B2 (en) * | 2010-08-20 | 2018-05-08 | Grupo Petrotemex, S.A. De C.V. | Terephthalic acid purge filtration rate by controlling % water in filter feed slurry |

| US8466312B2 (en) * | 2010-08-20 | 2013-06-18 | Grupo Petrotemex, S.A. De C.V. | Terephthalic acid purge filtration rate by controlling % water in filter feed slurry |

| CN103476738B (zh) * | 2010-11-22 | 2016-03-16 | 英威达技术有限公司 | 芳族羧酸的生产 |

| DE102011000322A1 (de) | 2011-01-25 | 2012-07-26 | saperatec GmbH | Trennmedium, Verfahren und Anlage zum Trennen von Mehrschichtsystemen |

| US8992640B2 (en) * | 2011-02-07 | 2015-03-31 | General Electric Company | Energy recovery in syngas applications |

| FR2990989B1 (fr) * | 2012-05-22 | 2016-03-11 | IFP Energies Nouvelles | Procede de production d'electricite par recuperation de la chaleur residuelle de fluides gazeux issus d'une colonne de distillation |

| GB201219983D0 (en) * | 2012-11-06 | 2012-12-19 | Davy Process Techn Ltd | Apparatus and process |

| US20150014148A1 (en) * | 2013-07-11 | 2015-01-15 | Celanese Acetate Llc | Process for Energy Recovery in Manufacturing Cellulose Esters |

| DE102013016660A1 (de) * | 2013-10-09 | 2015-04-09 | Ralf Spitzl | Verfahren und Vorrichtung zur plasmakatalytischen Umsetzung von Stoffen |

| MX375895B (es) * | 2013-12-18 | 2025-03-07 | Bp Corp North America Inc | Proceso mejorado para fabricar acidos carboxilicos aromaticos. |

| KR20160104705A (ko) | 2013-12-30 | 2016-09-05 | 비피 코포레이션 노쓰 아메리카 인코포레이티드 | 미가공 산물의 정제를 위해 탈수 타워 응축물을 사용하여 테레프탈산을 제조하는 방법 |

| CA2934789C (en) * | 2013-12-30 | 2021-03-02 | Thomas M. Bartos | Pressurized crude aromatic carboxylic acid feed mixes |

| EP3089804B1 (en) | 2013-12-31 | 2021-06-09 | Ineos Us Chemicals Company | Solid-liquid separations with a no-dry rotary pressure filter |

| US9394223B2 (en) | 2013-12-31 | 2016-07-19 | Bp Corporation North America Inc. | Oxidation process for preparing purified aromatic carboxylic acids |

| BR112016015442A2 (pt) * | 2013-12-31 | 2017-10-10 | Bp Corp North America Inc | reciclagem do condensado de alta pressão na produção de ácidos carboxílicos aromáticos purificados. |

| JP6158149B2 (ja) * | 2014-08-11 | 2017-07-05 | 株式会社神戸製鋼所 | 蒸留装置 |

| GB201418362D0 (en) * | 2014-10-16 | 2014-12-03 | Invista Tech Sarl | Production of a polyester |

| GB201418900D0 (en) * | 2014-10-23 | 2014-12-10 | Invista Technologies S.�.R.L. | Production of an aromatic discarboxylic acid |

| KR101645514B1 (ko) * | 2015-10-26 | 2016-08-08 | 주식회사 롤팩 | 진공포장장치 |

| US10173957B2 (en) | 2015-12-31 | 2019-01-08 | Bp Corporation North America Inc. | Process for acetic acid recovery from aqueous streams |

| TW201823194A (zh) * | 2016-12-29 | 2018-07-01 | 美商Bp公司北美股份有限公司 | 經純化的對苯二甲酸(pta)排氣孔蒸汽之利用 |

| TW201823193A (zh) * | 2016-12-29 | 2018-07-01 | 美商Bp公司北美股份有限公司 | 經純化的對苯二甲酸(pta)排氣孔乾燥器蒸氣流出物處理技術 |

| CN108627438B (zh) * | 2017-03-23 | 2020-11-17 | 天华化工机械及自动化研究设计院有限公司 | 旋转压力过滤机试验装置、测试方法及过滤机设计方法 |

| TW201842956A (zh) | 2017-04-28 | 2018-12-16 | 美商Bp公司北美股份有限公司 | 使用加壓濕氣線路以避免於經純化的對苯二甲酸(pta)過濾器及線路的積垢 |

| US10843995B2 (en) | 2017-06-29 | 2020-11-24 | Bp Corporation North America Inc. | Processes for manufacturing aromatic carboxylic acids |

| EP3658526A4 (en) | 2017-07-25 | 2021-03-10 | BP Corporation North America Inc. | ROUTING OF A FILTER RINSING PRODUCT OF A PURIFIED AROMATIC CARBOXYLIC ACID FOR ENERGY OPTIMIZATION |

| WO2019028097A1 (en) | 2017-08-01 | 2019-02-07 | Bp Corporation North America Inc. | METHOD FOR PREHEATING WATER OF BOILER SUPPLY IN THE MANUFACTURE OF PURIFIED AROMATIC CARBOXYLIC ACIDS |

| US20210363091A1 (en) * | 2017-08-01 | 2021-11-25 | Bp Corporation North America Inc. | Electric heating of boiler feedwater in the manufacture of purified aromatic carboxylic acids |

| US11091419B2 (en) | 2017-11-22 | 2021-08-17 | Exxonmobil Chemical Patents Inc. | Preparation and purification of biphenyldicarboxylic acids |

| DE102018110296A1 (de) * | 2018-04-27 | 2019-10-31 | Linde Aktiengesellschaft | Verfahren zur Behandlung einer sulfidhaltigen Ablauge |

| KR20210027388A (ko) | 2018-06-29 | 2021-03-10 | 비피 코포레이션 노쓰 아메리카 인코포레이티드 | 큰 기공 필터를 사용하는 고액 분리 프로세스 |

| WO2020041597A1 (en) | 2018-08-23 | 2020-02-27 | Transform Materials Llc | Systems and methods for processing gases |

| US11633710B2 (en) | 2018-08-23 | 2023-04-25 | Transform Materials Llc | Systems and methods for processing gases |

| WO2020102639A1 (en) | 2018-11-16 | 2020-05-22 | Bp Corporation North America Inc. | Process for manufacturing aromatic carboxylic acids |

| CN110015954A (zh) * | 2019-01-31 | 2019-07-16 | 武汉有机实业有限公司 | 食品添加剂苯甲酸钠的生产方法 |

| EP3769830A1 (en) * | 2019-07-22 | 2021-01-27 | Sulzer Management AG | Process for distilling a crude composition in a rectification plant including an indirect heat pump |

| EP4051658B1 (en) | 2019-10-31 | 2024-09-04 | Ineos Us Chemicals Company | Solid-liquid separation processes |

| CN115803311A (zh) * | 2020-09-27 | 2023-03-14 | 英力士美国化学公司 | 回收氧化副产物的方法 |

| US12017197B2 (en) * | 2021-06-22 | 2024-06-25 | Andreas Döring | Method and apparatus for the production of chemical compounds |

| CN113318471B (zh) * | 2021-07-08 | 2024-05-31 | 山东友道化学有限公司 | 二甲苯氧化反应液的处理方法及系统 |

| CN113416623B (zh) * | 2021-08-10 | 2022-12-23 | 肖斌 | 一种白酒生产用分序排酸设备 |

| CN114057252B (zh) * | 2021-12-07 | 2024-05-03 | 天华化工机械及自动化研究设计院有限公司 | 改善精对苯二甲酸装置脱水塔水质的系统及其方法 |

| WO2023183864A1 (en) | 2022-03-24 | 2023-09-28 | Ineos Us Chemicals Company | Process and apparatus of production of aromatic dicarboxylic acid. |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1996011899A1 (en) * | 1994-10-14 | 1996-04-25 | Amoco Corporation | Process for preparing aromatic carboxylic acids with efficient energy recovery |

| RU2002121869A (ru) * | 2000-01-21 | 2004-01-10 | Бп Корпорейшн Норт Америка Инк. (Us) | Способ получения ароматической карбоновой кислоты |

Family Cites Families (38)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2833816A (en) * | 1954-05-03 | 1958-05-06 | Mid Century Corp | Preparation of aromatic polycarboxylic acids |

| US3584039A (en) | 1967-08-30 | 1971-06-08 | Standard Oil Co | Fiber-grade terephthalic acid by catalytic hydrogen treatment of dissolved impure terephthalic acid |

| GB1373230A (en) | 1971-12-23 | 1974-11-06 | Mitsui Petrochemical Ind | Process for producing terephthalic acid |

| JPS5555138A (en) | 1978-10-19 | 1980-04-22 | Mitsubishi Chem Ind Ltd | Preparation of highly pure terephthalic acid |

| JPS59106435A (ja) | 1982-12-10 | 1984-06-20 | Mitsubishi Chem Ind Ltd | 高純度テレフタル酸の製法 |

| US4626598A (en) | 1985-06-17 | 1986-12-02 | Amoco Corporation | Purification of terephthalic acid |

| US4892972A (en) * | 1985-10-07 | 1990-01-09 | Amoco Corporation | Purification of crude terephthalic acid |

| US4629715A (en) * | 1985-10-07 | 1986-12-16 | Amoco Corporation | Purification of terephthalic acid to relatively low levels of 4-carboxybenzaldehyde and catalyst therefor |

| US5198156A (en) * | 1986-02-17 | 1993-03-30 | Imperial Chemical Industries Plc | Agitators |

| US4914230A (en) | 1986-07-28 | 1990-04-03 | Amoco Corporation | Catalyst recovery method |

| JP2504461B2 (ja) | 1987-04-24 | 1996-06-05 | 三菱化学株式会社 | 高品質テレフタル酸の製法 |

| US4777900A (en) * | 1987-06-01 | 1988-10-18 | Abeene Claris D | Oar storage and carrying rack for boats |

| US4782181A (en) | 1987-06-04 | 1988-11-01 | Amoco Corporation | Process for removal of high molecular weight impurities in the manufacture of purified terephthalic acid |

| US5081290A (en) * | 1990-06-21 | 1992-01-14 | Amoco Corporation | Process for making aromatic polycarboxylic acids and oxidation catalyst system |

| IT1244870B (it) * | 1990-09-11 | 1994-09-12 | Ministero Dall Uni E Della Ric | Composti ammelinici |

| GB9102393D0 (en) * | 1991-02-05 | 1991-03-20 | Ici Plc | Production of terephthalic acid |

| GB9104776D0 (en) * | 1991-03-07 | 1991-04-17 | Ici Plc | Process for the production of terephthalic acid |

| US5175355A (en) | 1991-04-12 | 1992-12-29 | Amoco Corporation | Improved process for recovery of purified terephthalic acid |

| US5200557A (en) | 1991-04-12 | 1993-04-06 | Amoco Corporation | Process for preparation of crude terephthalic acid suitable for reduction to prepare purified terephthalic acid |

| US5103933A (en) * | 1991-05-01 | 1992-04-14 | Huff Larry T | One piece leg |

| US5112992A (en) * | 1991-06-06 | 1992-05-12 | Amoco Corporation | Production of polycarboxylic acids with hafnium-activated cobalt catalyst |

| WO1994000413A1 (en) * | 1992-06-18 | 1994-01-06 | Amoco Corporation | Method for preparing aromatic carboxylic acids |

| US5362908A (en) | 1993-03-10 | 1994-11-08 | Amoco Corporation | Catalyst and method for purifying crude terephthalic acid, isophthalic acid or naphthalene dicarboxylic acid |

| JP3198711B2 (ja) | 1993-03-30 | 2001-08-13 | 三井化学株式会社 | テレフタル酸の製造方法および装置 |

| US5354898A (en) | 1993-06-17 | 1994-10-11 | Amoco Corporation | Method for purifying crude aromatic carboxylic acids |

| US6326130B1 (en) | 1993-10-07 | 2001-12-04 | Mallinckrodt Baker, Inc. | Photoresist strippers containing reducing agents to reduce metal corrosion |

| WO1997027168A1 (en) | 1996-01-25 | 1997-07-31 | E.I. Du Pont De Nemours And Company | Production of aromatic carboxylic acids |

| US5616792A (en) | 1996-02-01 | 1997-04-01 | Amoco Corporation | Catalytic purification of dicarboxylic aromatic acid |

| DE29621683U1 (de) | 1996-12-13 | 1997-02-13 | Ekato Ruehr Mischtechnik | Rührorgan |

| US6137001A (en) * | 1998-02-11 | 2000-10-24 | Bp Amoco Corporation | Process for preparing aromatic carboxylic acids with efficient treatments of gaseous effluent |

| KR20000005733A (ko) | 1998-06-05 | 2000-01-25 | 나까니시 히로유끼 | 방향족카복실산의제조방법 |

| US6194607B1 (en) * | 1998-12-22 | 2001-02-27 | Samsung General Chemicals Co., Ltd. | Method of producing aromatic carboxylic acids by oxidizing alkyl aromatic hydrocarbons or partially oxidized intermediates thereof |

| US6504051B1 (en) * | 2001-06-04 | 2003-01-07 | Eastman Chemical Company | Process for production of aromatic carboxylic acids with improved water removal technique |

| US6852879B2 (en) * | 2001-10-05 | 2005-02-08 | Bp Corporation North America Inc. | Method of removing iron oxide deposits from the surface of titanium components |

| JP2003137833A (ja) * | 2001-11-02 | 2003-05-14 | Mitsubishi Chemicals Corp | テレフタル酸の製造方法 |

| US7135596B2 (en) | 2002-04-23 | 2006-11-14 | Bp Corporation North America Inc. | Method of removing iron contaminants from liquid streams during the manufacture and/or purification of aromatic acids |

| US7049465B2 (en) * | 2003-07-10 | 2006-05-23 | Eastman Chemical Company | Process for energy recovery in processes for the preparation of aromatic carboxylic acids |

| RU2435754C2 (ru) * | 2005-03-21 | 2011-12-10 | Бп Корпорейшн Норт Америка Инк. | Способ возврата энергии в процессе производства ароматических карбоновых кислот |

-

2006

- 2006-03-20 RU RU2007138833/04A patent/RU2435754C2/ru not_active IP Right Cessation

- 2006-03-20 BR BRPI0609328A patent/BRPI0609328B1/pt not_active IP Right Cessation

- 2006-03-20 MX MX2007011186A patent/MX2007011186A/es active IP Right Grant

- 2006-03-20 PL PL06739160T patent/PL1861348T3/pl unknown

- 2006-03-20 CN CN2006800092825A patent/CN101146757B/zh not_active Expired - Fee Related

- 2006-03-20 AT AT06748568T patent/ATE473958T1/de active

- 2006-03-20 PT PT06748436T patent/PT1861349E/pt unknown

- 2006-03-20 PT PT06739160T patent/PT1861348E/pt unknown

- 2006-03-20 DE DE602006008284T patent/DE602006008284D1/de active Active

- 2006-03-20 CN CN2006800092717A patent/CN101146756B/zh not_active Ceased

- 2006-03-20 WO PCT/US2006/010255 patent/WO2006102336A2/en not_active Ceased

- 2006-03-20 AT AT06748436T patent/ATE438610T1/de active

- 2006-03-20 JP JP2008503155A patent/JP5254001B2/ja not_active Expired - Fee Related

- 2006-03-20 CA CA2599461A patent/CA2599461C/en not_active Expired - Fee Related

- 2006-03-20 UA UAA200711597A patent/UA96569C2/ru unknown

- 2006-03-20 PT PT06748568T patent/PT1866273E/pt unknown

- 2006-03-20 BR BRPI0608504A patent/BRPI0608504B1/pt not_active IP Right Cessation

- 2006-03-20 CA CA2601941A patent/CA2601941C/en not_active Expired - Fee Related

- 2006-03-20 PL PL06748436T patent/PL1861349T3/pl unknown

- 2006-03-20 KR KR1020077024162A patent/KR101314005B1/ko not_active Expired - Fee Related

- 2006-03-20 BR BRPI0608502A patent/BRPI0608502B1/pt not_active IP Right Cessation

- 2006-03-20 EP EP06748436A patent/EP1861349B1/en not_active Not-in-force

- 2006-03-20 RU RU2007134060/04A patent/RU2414448C2/ru not_active IP Right Cessation

- 2006-03-20 ES ES06739160T patent/ES2348062T3/es active Active

- 2006-03-20 CA CA2599981A patent/CA2599981C/en not_active Expired - Fee Related

- 2006-03-20 DE DE602006015446T patent/DE602006015446D1/de active Active

- 2006-03-20 KR KR1020077024038A patent/KR101432517B1/ko not_active Expired - Fee Related

- 2006-03-20 KR KR1020077024172A patent/KR101327679B1/ko not_active Ceased

- 2006-03-20 ES ES06748436T patent/ES2328402T3/es active Active

- 2006-03-20 MX MX2007011184A patent/MX2007011184A/es active IP Right Grant

- 2006-03-20 US US11/815,576 patent/US7935845B2/en not_active Expired - Fee Related

- 2006-03-20 ES ES06748568T patent/ES2346560T3/es active Active

- 2006-03-20 RU RU2007138831/04A patent/RU2449980C2/ru not_active IP Right Cessation

- 2006-03-20 EP EP06739160A patent/EP1861348B1/en not_active Revoked

- 2006-03-20 EP EP06748568A patent/EP1866273B1/en active Active

- 2006-03-20 WO PCT/US2006/010486 patent/WO2006102459A1/en not_active Ceased

- 2006-03-20 CN CN200680009300XA patent/CN101146758B/zh active Active

- 2006-03-20 US US11/909,117 patent/US8173834B2/en not_active Expired - Fee Related

- 2006-03-20 MX MX2007011182A patent/MX2007011182A/es active IP Right Grant

- 2006-03-20 WO PCT/US2006/009828 patent/WO2006102137A1/en not_active Ceased

- 2006-03-20 AT AT06739160T patent/ATE477230T1/de active

- 2006-03-20 PL PL06748568T patent/PL1866273T3/pl unknown

- 2006-03-20 DE DE602006016083T patent/DE602006016083D1/de active Active

- 2006-03-20 US US11/817,262 patent/US7935844B2/en not_active Expired - Fee Related

-

2007

- 2007-08-31 ZA ZA200707537A patent/ZA200707537B/xx unknown

- 2007-09-19 EG EGNA2007000990 patent/EG25228A/xx active

-

2012

- 2012-05-07 US US13/465,807 patent/US8779185B2/en not_active Expired - Fee Related

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1996011899A1 (en) * | 1994-10-14 | 1996-04-25 | Amoco Corporation | Process for preparing aromatic carboxylic acids with efficient energy recovery |

| US5723656A (en) * | 1994-10-14 | 1998-03-03 | Amoco Corporation | Process for preparing aromatic carboxylic acids with efficient energy recovery |

| RU2002121869A (ru) * | 2000-01-21 | 2004-01-10 | Бп Корпорейшн Норт Америка Инк. (Us) | Способ получения ароматической карбоновой кислоты |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU2760675C1 (ru) * | 2020-03-31 | 2021-11-29 | Наньцзин Яньчан Реэкшн Текнолоджи Рисерч Институт Ко. Лтд | Улучшенные реакционная система с встроенным средством для создания межфазных микроповерхностей и способ для получения терефталевой кислоты с использованием параксилола |

Also Published As

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| RU2435754C2 (ru) | Способ возврата энергии в процессе производства ароматических карбоновых кислот | |

| RU2687489C1 (ru) | Улучшенный способ и устройство для производства ароматических карбоновых кислот | |

| TWI359132B (en) | Improved recovery of energy during the production |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| MM4A | The patent is invalid due to non-payment of fees |

Effective date: 20210321 |