KR20120049399A - 반도체 디바이스, 반도체 디바이스 제조 방법 및 반도체 디바이스 제조 장치 - Google Patents

반도체 디바이스, 반도체 디바이스 제조 방법 및 반도체 디바이스 제조 장치 Download PDFInfo

- Publication number

- KR20120049399A KR20120049399A KR1020127008779A KR20127008779A KR20120049399A KR 20120049399 A KR20120049399 A KR 20120049399A KR 1020127008779 A KR1020127008779 A KR 1020127008779A KR 20127008779 A KR20127008779 A KR 20127008779A KR 20120049399 A KR20120049399 A KR 20120049399A

- Authority

- KR

- South Korea

- Prior art keywords

- substrate

- semiconductor device

- oxygen plasma

- plasma

- insulating film

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 239000004065 semiconductor Substances 0.000 title claims abstract description 38

- 238000000034 method Methods 0.000 title claims description 64

- 239000000758 substrate Substances 0.000 claims abstract description 88

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims abstract description 66

- 239000001301 oxygen Substances 0.000 claims abstract description 66

- 229910052760 oxygen Inorganic materials 0.000 claims abstract description 66

- 238000004519 manufacturing process Methods 0.000 claims abstract description 23

- 125000006850 spacer group Chemical group 0.000 claims description 24

- 238000012545 processing Methods 0.000 claims description 16

- 239000007789 gas Substances 0.000 description 66

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 47

- 229910052710 silicon Inorganic materials 0.000 description 47

- 239000010703 silicon Substances 0.000 description 47

- 238000005530 etching Methods 0.000 description 36

- 230000003647 oxidation Effects 0.000 description 28

- 238000007254 oxidation reaction Methods 0.000 description 28

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 14

- 239000010453 quartz Substances 0.000 description 13

- 239000004020 conductor Substances 0.000 description 12

- 238000010586 diagram Methods 0.000 description 11

- 239000003507 refrigerant Substances 0.000 description 8

- 229910004298 SiO 2 Inorganic materials 0.000 description 7

- 238000000151 deposition Methods 0.000 description 7

- 230000008021 deposition Effects 0.000 description 7

- 239000002826 coolant Substances 0.000 description 6

- 239000000463 material Substances 0.000 description 6

- 230000007246 mechanism Effects 0.000 description 5

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 4

- 229910052782 aluminium Inorganic materials 0.000 description 4

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 4

- 230000005540 biological transmission Effects 0.000 description 4

- 238000001020 plasma etching Methods 0.000 description 4

- BOTDANWDWHJENH-UHFFFAOYSA-N Tetraethyl orthosilicate Chemical compound CCO[Si](OCC)(OCC)OCC BOTDANWDWHJENH-UHFFFAOYSA-N 0.000 description 3

- 238000004380 ashing Methods 0.000 description 3

- 229910052751 metal Inorganic materials 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- 238000012546 transfer Methods 0.000 description 3

- -1 Phosphorus ions Chemical class 0.000 description 2

- 238000005229 chemical vapour deposition Methods 0.000 description 2

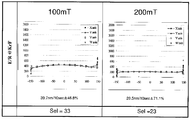

- 238000005259 measurement Methods 0.000 description 2

- 229910052757 nitrogen Inorganic materials 0.000 description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- MYMOFIZGZYHOMD-UHFFFAOYSA-N Dioxygen Chemical compound O=O MYMOFIZGZYHOMD-UHFFFAOYSA-N 0.000 description 1

- PXGOKWXKJXAPGV-UHFFFAOYSA-N Fluorine Chemical compound FF PXGOKWXKJXAPGV-UHFFFAOYSA-N 0.000 description 1

- 229910052785 arsenic Inorganic materials 0.000 description 1

- 238000005513 bias potential Methods 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000000903 blocking effect Effects 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 239000003989 dielectric material Substances 0.000 description 1

- 229910001882 dioxygen Inorganic materials 0.000 description 1

- 230000005672 electromagnetic field Effects 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 229910052731 fluorine Inorganic materials 0.000 description 1

- 239000011737 fluorine Substances 0.000 description 1

- 239000001307 helium Substances 0.000 description 1

- 229910052734 helium Inorganic materials 0.000 description 1

- SWQJXJOGLNCZEY-UHFFFAOYSA-N helium atom Chemical compound [He] SWQJXJOGLNCZEY-UHFFFAOYSA-N 0.000 description 1

- 239000011810 insulating material Substances 0.000 description 1

- 150000002500 ions Chemical class 0.000 description 1

- 230000001590 oxidative effect Effects 0.000 description 1

- 238000005192 partition Methods 0.000 description 1

- 229910052698 phosphorus Inorganic materials 0.000 description 1

- 239000011574 phosphorus Substances 0.000 description 1

- 230000010287 polarization Effects 0.000 description 1

- 229910021420 polycrystalline silicon Inorganic materials 0.000 description 1

- 229920005591 polysilicon Polymers 0.000 description 1

- 230000001902 propagating effect Effects 0.000 description 1

- 239000000376 reactant Substances 0.000 description 1

- 239000011435 rock Substances 0.000 description 1

- 229910052814 silicon oxide Inorganic materials 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 230000007723 transport mechanism Effects 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/28—Manufacture of electrodes on semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/268

- H01L21/28008—Making conductor-insulator-semiconductor electrodes

- H01L21/28017—Making conductor-insulator-semiconductor electrodes the insulator being formed after the semiconductor body, the semiconductor being silicon

- H01L21/28158—Making the insulator

- H01L21/28167—Making the insulator on single crystalline silicon, e.g. using a liquid, i.e. chemical oxidation

- H01L21/28176—Making the insulator on single crystalline silicon, e.g. using a liquid, i.e. chemical oxidation with a treatment, e.g. annealing, after the formation of the definitive gate conductor

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/32009—Arrangements for generation of plasma specially adapted for examination or treatment of objects, e.g. plasma sources

- H01J37/32082—Radio frequency generated discharge

- H01J37/32091—Radio frequency generated discharge the radio frequency energy being capacitively coupled to the plasma

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/32009—Arrangements for generation of plasma specially adapted for examination or treatment of objects, e.g. plasma sources

- H01J37/32192—Microwave generated discharge

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02041—Cleaning

- H01L21/02057—Cleaning during device manufacture

- H01L21/0206—Cleaning during device manufacture during, before or after processing of insulating layers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/31—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to form insulating layers thereon, e.g. for masking or by using photolithographic techniques; After treatment of these layers; Selection of materials for these layers

- H01L21/3105—After-treatment

- H01L21/311—Etching the insulating layers by chemical or physical means

- H01L21/31105—Etching inorganic layers

- H01L21/31111—Etching inorganic layers by chemical means

- H01L21/31116—Etching inorganic layers by chemical means by dry-etching

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10D—INORGANIC ELECTRIC SEMICONDUCTOR DEVICES

- H10D30/00—Field-effect transistors [FET]

- H10D30/01—Manufacture or treatment

- H10D30/021—Manufacture or treatment of FETs having insulated gates [IGFET]

- H10D30/0223—Manufacture or treatment of FETs having insulated gates [IGFET] having source and drain regions or source and drain extensions self-aligned to sides of the gate

- H10D30/0227—Manufacture or treatment of FETs having insulated gates [IGFET] having source and drain regions or source and drain extensions self-aligned to sides of the gate having both lightly-doped source and drain extensions and source and drain regions self-aligned to the sides of the gate, e.g. lightly-doped drain [LDD] MOSFET or double-diffused drain [DDD] MOSFET

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10D—INORGANIC ELECTRIC SEMICONDUCTOR DEVICES

- H10D30/00—Field-effect transistors [FET]

- H10D30/60—Insulated-gate field-effect transistors [IGFET]

- H10D30/601—Insulated-gate field-effect transistors [IGFET] having lightly-doped drain or source extensions, e.g. LDD IGFETs or DDD IGFETs

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Chemical & Material Sciences (AREA)

- Manufacturing & Machinery (AREA)

- General Physics & Mathematics (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Plasma & Fusion (AREA)

- Analytical Chemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Inorganic Chemistry (AREA)

- Crystallography & Structural Chemistry (AREA)

- Drying Of Semiconductors (AREA)

- Insulated Gate Type Field-Effect Transistor (AREA)

- Plasma Technology (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US12/573,138 | 2009-10-04 | ||

| US12/573,138 US8497196B2 (en) | 2009-10-04 | 2009-10-04 | Semiconductor device, method for fabricating the same and apparatus for fabricating the same |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020147001310A Division KR101384590B1 (ko) | 2009-10-04 | 2010-10-02 | 반도체 디바이스 제조 방법 및 반도체 디바이스 제조 장치 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20120049399A true KR20120049399A (ko) | 2012-05-16 |

Family

ID=43822528

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020147001310A Active KR101384590B1 (ko) | 2009-10-04 | 2010-10-02 | 반도체 디바이스 제조 방법 및 반도체 디바이스 제조 장치 |

| KR1020127008779A Ceased KR20120049399A (ko) | 2009-10-04 | 2010-10-02 | 반도체 디바이스, 반도체 디바이스 제조 방법 및 반도체 디바이스 제조 장치 |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020147001310A Active KR101384590B1 (ko) | 2009-10-04 | 2010-10-02 | 반도체 디바이스 제조 방법 및 반도체 디바이스 제조 장치 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US8497196B2 (enExample) |

| JP (1) | JP5442871B2 (enExample) |

| KR (2) | KR101384590B1 (enExample) |

| CN (1) | CN102549756B (enExample) |

| TW (1) | TWI423336B (enExample) |

| WO (1) | WO2011040047A1 (enExample) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2016104206A1 (ja) * | 2014-12-24 | 2016-06-30 | 東京エレクトロン株式会社 | ドーピング方法、ドーピング装置および半導体素子の製造方法 |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07142447A (ja) * | 1993-11-16 | 1995-06-02 | Kawasaki Steel Corp | 半導体装置の製造方法 |

| JP3402937B2 (ja) | 1996-06-28 | 2003-05-06 | 三洋電機株式会社 | 半導体装置の製造方法 |

| US5902134A (en) | 1996-08-07 | 1999-05-11 | Matsushita Electronics Corporation | Dry etching post-treatment method and method for manufacturing a semiconductor device |

| JP3217280B2 (ja) | 1996-10-30 | 2001-10-09 | 松下電器産業株式会社 | ドライエッチング後処理方法とmos型半導体装置の製造方法 |

| JP4048618B2 (ja) * | 1998-10-07 | 2008-02-20 | ソニー株式会社 | 半導体装置の製造方法 |

| US7223676B2 (en) * | 2002-06-05 | 2007-05-29 | Applied Materials, Inc. | Very low temperature CVD process with independently variable conformality, stress and composition of the CVD layer |

| CN100347832C (zh) | 2001-01-25 | 2007-11-07 | 东京毅力科创株式会社 | 电子器件材料的制造方法 |

| US6534420B2 (en) * | 2001-07-18 | 2003-03-18 | Micron Technology, Inc. | Methods for forming dielectric materials and methods for forming semiconductor devices |

| TW200402796A (en) * | 2002-03-29 | 2004-02-16 | Tokyo Electron Ltd | Forming method of substrate insulation film |

| TWI225668B (en) * | 2002-05-13 | 2004-12-21 | Tokyo Electron Ltd | Substrate processing method |

| JP2005051140A (ja) * | 2003-07-31 | 2005-02-24 | Toshiba Corp | 半導体装置およびその製造方法 |

| US6982196B2 (en) * | 2003-11-04 | 2006-01-03 | International Business Machines Corporation | Oxidation method for altering a film structure and CMOS transistor structure formed therewith |

| JP2006165335A (ja) * | 2004-12-08 | 2006-06-22 | Toshiba Corp | 半導体装置 |

| JP5084169B2 (ja) * | 2005-04-28 | 2012-11-28 | 株式会社半導体エネルギー研究所 | 半導体装置の作製方法 |

| TWI408734B (zh) * | 2005-04-28 | 2013-09-11 | Semiconductor Energy Lab | 半導體裝置及其製造方法 |

| JP5422854B2 (ja) * | 2007-08-31 | 2014-02-19 | 国立大学法人東北大学 | 半導体装置の製造方法 |

| JP2008098640A (ja) * | 2007-10-09 | 2008-04-24 | Toshiba Corp | 半導体装置の製造方法 |

| KR101250057B1 (ko) * | 2008-02-08 | 2013-04-03 | 도쿄엘렉트론가부시키가이샤 | 절연막의 플라즈마 개질 처리 방법 및 플라즈마 처리 장치 |

-

2009

- 2009-10-04 US US12/573,138 patent/US8497196B2/en active Active

-

2010

- 2010-10-01 TW TW099133451A patent/TWI423336B/zh active

- 2010-10-02 JP JP2012531562A patent/JP5442871B2/ja active Active

- 2010-10-02 CN CN201080044368.8A patent/CN102549756B/zh active Active

- 2010-10-02 KR KR1020147001310A patent/KR101384590B1/ko active Active

- 2010-10-02 WO PCT/JP2010/005926 patent/WO2011040047A1/en not_active Ceased

- 2010-10-02 KR KR1020127008779A patent/KR20120049399A/ko not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| US8497196B2 (en) | 2013-07-30 |

| WO2011040047A1 (en) | 2011-04-07 |

| KR101384590B1 (ko) | 2014-04-11 |

| TW201131654A (en) | 2011-09-16 |

| CN102549756B (zh) | 2015-03-04 |

| JP5442871B2 (ja) | 2014-03-12 |

| KR20140016433A (ko) | 2014-02-07 |

| TWI423336B (zh) | 2014-01-11 |

| US20110079826A1 (en) | 2011-04-07 |

| CN102549756A (zh) | 2012-07-04 |

| JP2013506986A (ja) | 2013-02-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US6870123B2 (en) | Microwave applicator, plasma processing apparatus having same, and plasma processing method | |

| US6884318B2 (en) | Plasma processing system and surface processing method | |

| US7138767B2 (en) | Surface wave plasma processing system and method of using | |

| US7268084B2 (en) | Method for treating a substrate | |

| US7396431B2 (en) | Plasma processing system for treating a substrate | |

| US6652709B1 (en) | Plasma processing apparatus having circular waveguide, and plasma processing method | |

| KR20200058298A (ko) | 격리 구조를 위한 스케일링된 라이너 층 | |

| US11319630B2 (en) | Deposition apparatus and deposition method | |

| WO2012066779A1 (en) | Apparatus for plasma treatment and method for plasma treatment | |

| TW201532143A (zh) | 蝕刻雙鑲嵌結構中的介電阻隔層之方法 | |

| US9263283B2 (en) | Etching method and apparatus | |

| CN102959692B (zh) | 蚀刻方法和装置 | |

| US7584714B2 (en) | Method and system for improving coupling between a surface wave plasma source and a plasma space | |

| CN101356638A (zh) | 半导体装置和半导体装置的制造方法 | |

| JP4478352B2 (ja) | プラズマ処理装置及びプラズマ処理方法並びに構造体の製造方法 | |

| KR101384590B1 (ko) | 반도체 디바이스 제조 방법 및 반도체 디바이스 제조 장치 | |

| TWI791106B (zh) | 處理系統及處理方法 | |

| KR100425658B1 (ko) | 마이크로파 공급기, 이를 구비한 플라즈마 처리 장치, 및 플라즈마 처리 방법 | |

| KR100466684B1 (ko) | 불소 첨가 카본막 및 그 형성 방법 | |

| JPH0969518A (ja) | シリコン化合物系絶縁膜の成膜方法 | |

| JP2006012962A (ja) | 斜め貫通孔付真空紫外光遮光板を用いたマイクロ波プラズマ処理装置及び処理方法 | |

| JP4217420B2 (ja) | マイクロ波プラズマ処理装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A201 | Request for examination | ||

| PA0105 | International application |

Patent event date: 20120404 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PA0201 | Request for examination | ||

| PG1501 | Laying open of application | ||

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20130605 Patent event code: PE09021S01D |

|

| E601 | Decision to refuse application | ||

| PE0601 | Decision on rejection of patent |

Patent event date: 20131218 Comment text: Decision to Refuse Application Patent event code: PE06012S01D Patent event date: 20130605 Comment text: Notification of reason for refusal Patent event code: PE06011S01I |

|

| A107 | Divisional application of patent | ||

| PA0104 | Divisional application for international application |

Comment text: Divisional Application for International Patent Patent event code: PA01041R01D Patent event date: 20140117 |