KR20100075622A - 투명 도전막 및 그 제조 방법 - Google Patents

투명 도전막 및 그 제조 방법 Download PDFInfo

- Publication number

- KR20100075622A KR20100075622A KR1020107010260A KR20107010260A KR20100075622A KR 20100075622 A KR20100075622 A KR 20100075622A KR 1020107010260 A KR1020107010260 A KR 1020107010260A KR 20107010260 A KR20107010260 A KR 20107010260A KR 20100075622 A KR20100075622 A KR 20100075622A

- Authority

- KR

- South Korea

- Prior art keywords

- transparent conductive

- conductive film

- film

- magnesium

- carbon

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 238000004519 manufacturing process Methods 0.000 title claims description 32

- 239000011777 magnesium Substances 0.000 claims abstract description 113

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 claims abstract description 104

- 229910052749 magnesium Inorganic materials 0.000 claims abstract description 104

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims abstract description 65

- 229910052799 carbon Inorganic materials 0.000 claims abstract description 61

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 46

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 claims abstract description 22

- 229910052710 silicon Inorganic materials 0.000 claims abstract description 22

- 239000010703 silicon Substances 0.000 claims abstract description 22

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical compound [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 claims abstract description 19

- 229910052796 boron Inorganic materials 0.000 claims abstract description 19

- 229910052760 oxygen Inorganic materials 0.000 claims abstract description 15

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims abstract description 14

- 239000001301 oxygen Substances 0.000 claims abstract description 14

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 claims abstract description 12

- 229910052739 hydrogen Inorganic materials 0.000 claims abstract description 12

- 239000001257 hydrogen Substances 0.000 claims abstract description 12

- 239000012528 membrane Substances 0.000 claims abstract description 6

- 239000000758 substrate Substances 0.000 claims description 45

- 238000000034 method Methods 0.000 claims description 35

- 230000008020 evaporation Effects 0.000 claims description 28

- 238000001704 evaporation Methods 0.000 claims description 28

- 238000004544 sputter deposition Methods 0.000 claims description 25

- 229910052599 brucite Inorganic materials 0.000 claims description 11

- 239000013078 crystal Substances 0.000 claims description 11

- -1 magnesium Chemical compound 0.000 claims description 3

- 238000009834 vaporization Methods 0.000 claims 1

- 230000008016 vaporization Effects 0.000 claims 1

- 239000010408 film Substances 0.000 description 242

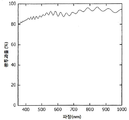

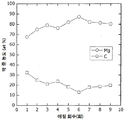

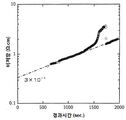

- 238000002834 transmittance Methods 0.000 description 30

- 239000011521 glass Substances 0.000 description 15

- 239000010409 thin film Substances 0.000 description 15

- XLOMVQKBTHCTTD-UHFFFAOYSA-N Zinc monoxide Chemical class [Zn]=O XLOMVQKBTHCTTD-UHFFFAOYSA-N 0.000 description 13

- 230000015572 biosynthetic process Effects 0.000 description 12

- 239000000463 material Substances 0.000 description 12

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 11

- 238000002441 X-ray diffraction Methods 0.000 description 7

- 230000000052 comparative effect Effects 0.000 description 7

- 229910052751 metal Inorganic materials 0.000 description 7

- 239000002184 metal Substances 0.000 description 7

- 239000000203 mixture Substances 0.000 description 7

- 239000002245 particle Substances 0.000 description 7

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 6

- 229910052786 argon Inorganic materials 0.000 description 6

- 238000010586 diagram Methods 0.000 description 6

- 239000011787 zinc oxide Substances 0.000 description 6

- 230000002411 adverse Effects 0.000 description 5

- 238000004458 analytical method Methods 0.000 description 5

- 229910002804 graphite Inorganic materials 0.000 description 5

- 239000010439 graphite Substances 0.000 description 5

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 4

- 238000004833 X-ray photoelectron spectroscopy Methods 0.000 description 4

- 239000000919 ceramic Substances 0.000 description 4

- 229910001873 dinitrogen Inorganic materials 0.000 description 4

- 239000007789 gas Substances 0.000 description 4

- 238000005240 physical vapour deposition Methods 0.000 description 4

- 238000005477 sputtering target Methods 0.000 description 4

- 238000010998 test method Methods 0.000 description 4

- KGBXLFKZBHKPEV-UHFFFAOYSA-N boric acid Chemical compound OB(O)O KGBXLFKZBHKPEV-UHFFFAOYSA-N 0.000 description 3

- 239000004327 boric acid Substances 0.000 description 3

- 239000006185 dispersion Substances 0.000 description 3

- 238000010438 heat treatment Methods 0.000 description 3

- 229910052738 indium Inorganic materials 0.000 description 3

- APFVFJFRJDLVQX-UHFFFAOYSA-N indium atom Chemical compound [In] APFVFJFRJDLVQX-UHFFFAOYSA-N 0.000 description 3

- 239000011229 interlayer Substances 0.000 description 3

- 238000001451 molecular beam epitaxy Methods 0.000 description 3

- 229920000307 polymer substrate Polymers 0.000 description 3

- 239000002994 raw material Substances 0.000 description 3

- 239000000523 sample Substances 0.000 description 3

- 238000005406 washing Methods 0.000 description 3

- FMRLDPWIRHBCCC-UHFFFAOYSA-L Zinc carbonate Chemical compound [Zn+2].[O-]C([O-])=O FMRLDPWIRHBCCC-UHFFFAOYSA-L 0.000 description 2

- 239000002253 acid Substances 0.000 description 2

- 239000003513 alkali Substances 0.000 description 2

- 230000005540 biological transmission Effects 0.000 description 2

- 229910003437 indium oxide Inorganic materials 0.000 description 2

- PJXISJQVUVHSOJ-UHFFFAOYSA-N indium(iii) oxide Chemical compound [O-2].[O-2].[O-2].[In+3].[In+3] PJXISJQVUVHSOJ-UHFFFAOYSA-N 0.000 description 2

- 238000007737 ion beam deposition Methods 0.000 description 2

- 238000005259 measurement Methods 0.000 description 2

- 239000008188 pellet Substances 0.000 description 2

- 230000035699 permeability Effects 0.000 description 2

- 239000000843 powder Substances 0.000 description 2

- 239000008213 purified water Substances 0.000 description 2

- 230000001105 regulatory effect Effects 0.000 description 2

- 238000011160 research Methods 0.000 description 2

- 239000011347 resin Substances 0.000 description 2

- 229920005989 resin Polymers 0.000 description 2

- 239000008399 tap water Substances 0.000 description 2

- 235000020679 tap water Nutrition 0.000 description 2

- 238000001771 vacuum deposition Methods 0.000 description 2

- RZVAJINKPMORJF-UHFFFAOYSA-N Acetaminophen Chemical compound CC(=O)NC1=CC=C(O)C=C1 RZVAJINKPMORJF-UHFFFAOYSA-N 0.000 description 1

- MYMOFIZGZYHOMD-UHFFFAOYSA-N Dioxygen Chemical compound O=O MYMOFIZGZYHOMD-UHFFFAOYSA-N 0.000 description 1

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 description 1

- 125000004429 atom Chemical group 0.000 description 1

- 150000001721 carbon Chemical group 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000000151 deposition Methods 0.000 description 1

- 230000008021 deposition Effects 0.000 description 1

- 229910001882 dioxygen Inorganic materials 0.000 description 1

- 239000012153 distilled water Substances 0.000 description 1

- 238000005530 etching Methods 0.000 description 1

- 238000013213 extrapolation Methods 0.000 description 1

- 150000004677 hydrates Chemical class 0.000 description 1

- 229930195733 hydrocarbon Natural products 0.000 description 1

- 150000002430 hydrocarbons Chemical class 0.000 description 1

- AMGQUBHHOARCQH-UHFFFAOYSA-N indium;oxotin Chemical compound [In].[Sn]=O AMGQUBHHOARCQH-UHFFFAOYSA-N 0.000 description 1

- 239000011261 inert gas Substances 0.000 description 1

- 239000010410 layer Substances 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 239000004973 liquid crystal related substance Substances 0.000 description 1

- VTHJTEIRLNZDEV-UHFFFAOYSA-L magnesium dihydroxide Chemical compound [OH-].[OH-].[Mg+2] VTHJTEIRLNZDEV-UHFFFAOYSA-L 0.000 description 1

- 238000000691 measurement method Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 229910052754 neon Inorganic materials 0.000 description 1

- GKAOGPIIYCISHV-UHFFFAOYSA-N neon atom Chemical compound [Ne] GKAOGPIIYCISHV-UHFFFAOYSA-N 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 239000003960 organic solvent Substances 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 239000005297 pyrex Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- XOLBLPGZBRYERU-UHFFFAOYSA-N tin dioxide Chemical compound O=[Sn]=O XOLBLPGZBRYERU-UHFFFAOYSA-N 0.000 description 1

- 229910001887 tin oxide Inorganic materials 0.000 description 1

- 238000000870 ultraviolet spectroscopy Methods 0.000 description 1

- 238000011179 visual inspection Methods 0.000 description 1

- 229910052724 xenon Inorganic materials 0.000 description 1

- FHNFHKCVQCLJFQ-UHFFFAOYSA-N xenon atom Chemical compound [Xe] FHNFHKCVQCLJFQ-UHFFFAOYSA-N 0.000 description 1

- 229910052725 zinc Inorganic materials 0.000 description 1

- 239000011701 zinc Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/06—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the coating material

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/06—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the coating material

- C23C14/0635—Carbides

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/22—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the process of coating

- C23C14/34—Sputtering

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/58—After-treatment

- C23C14/5846—Reactive treatment

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Physical Vapour Deposition (AREA)

- Manufacturing Of Electric Cables (AREA)

- Non-Insulated Conductors (AREA)

- Laminated Bodies (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JPJP-P-2007-268343 | 2007-10-15 | ||

| JP2007268343A JP5224438B2 (ja) | 2007-10-15 | 2007-10-15 | 透明導電膜およびその製造方法 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20100075622A true KR20100075622A (ko) | 2010-07-02 |

Family

ID=40567342

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020107010260A Ceased KR20100075622A (ko) | 2007-10-15 | 2008-10-10 | 투명 도전막 및 그 제조 방법 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US20100227176A1 (enExample) |

| EP (1) | EP2228805A4 (enExample) |

| JP (1) | JP5224438B2 (enExample) |

| KR (1) | KR20100075622A (enExample) |

| CN (1) | CN101821819B (enExample) |

| SG (1) | SG185923A1 (enExample) |

| TW (1) | TWI466136B (enExample) |

| WO (1) | WO2009051075A1 (enExample) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5881995B2 (ja) * | 2011-08-26 | 2016-03-09 | 久慈 俊郎 | 透明導電膜及びその製造方法 |

| CN108321239A (zh) * | 2017-12-21 | 2018-07-24 | 君泰创新(北京)科技有限公司 | 一种太阳能异质结电池及其制备方法 |

| JP2019173048A (ja) * | 2018-03-26 | 2019-10-10 | Jx金属株式会社 | スパッタリングターゲット部材及びその製造方法 |

| US11520451B2 (en) * | 2018-07-30 | 2022-12-06 | Asahi Kasei Kabushiki Kaisha | Conductive film and conductive film roll, electronic paper, touch panel and flat-panel display comprising the same |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH03183759A (ja) * | 1989-12-12 | 1991-08-09 | Toyobo Co Ltd | 積層プラスチックフイルムおよびその製造方法 |

| EP0924777A3 (en) * | 1997-10-15 | 1999-07-07 | Canon Kabushiki Kaisha | A method for the formation of an indium oxide film by electro deposition process or electroless deposition process, a substrate provided with said indium oxide film for a semiconductor element, and a semiconductor element provided with said substrate |

| JP4429467B2 (ja) * | 1999-04-08 | 2010-03-10 | 帝人株式会社 | 透明導電性フィルム |

| JP4092958B2 (ja) * | 2002-06-11 | 2008-05-28 | コニカミノルタホールディングス株式会社 | Ito膜、ito膜材料及びito膜の形成方法 |

| JP2004179139A (ja) * | 2002-09-30 | 2004-06-24 | Sumitomo Osaka Cement Co Ltd | 導電性粒子とそれを含有する導電性接着材料及び透明導電膜形成用塗料及びそれを用いた透明導電膜並びに表示装置 |

| DE602004010409T2 (de) * | 2003-09-26 | 2008-10-16 | Matsushita Electric Industrial Co., Ltd., Kadoma | Plasmaanzeigetafel |

| JP4752507B2 (ja) | 2003-12-24 | 2011-08-17 | コニカミノルタホールディングス株式会社 | 透明プラスチックフィルム、および有機el素子 |

| CN1957425A (zh) * | 2004-05-21 | 2007-05-02 | Tdk株式会社 | 透明导电材料、透明导电膏、透明导电膜和透明电极 |

| US8728615B2 (en) * | 2004-09-13 | 2014-05-20 | Sumitomo Metal Mining Co., Ltd. | Transparent conductive film and method of fabricating the same, transparent conductive base material, and light-emitting device |

-

2007

- 2007-10-15 JP JP2007268343A patent/JP5224438B2/ja not_active Expired - Fee Related

-

2008

- 2008-10-10 EP EP08840743A patent/EP2228805A4/en not_active Withdrawn

- 2008-10-10 KR KR1020107010260A patent/KR20100075622A/ko not_active Ceased

- 2008-10-10 US US12/682,971 patent/US20100227176A1/en not_active Abandoned

- 2008-10-10 SG SG2012077202A patent/SG185923A1/en unknown

- 2008-10-10 WO PCT/JP2008/068460 patent/WO2009051075A1/ja not_active Ceased

- 2008-10-10 CN CN2008801121097A patent/CN101821819B/zh not_active Expired - Fee Related

- 2008-10-14 TW TW097139319A patent/TWI466136B/zh not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| EP2228805A1 (en) | 2010-09-15 |

| TW200923974A (en) | 2009-06-01 |

| CN101821819B (zh) | 2012-07-25 |

| US20100227176A1 (en) | 2010-09-09 |

| JP2009099327A (ja) | 2009-05-07 |

| EP2228805A4 (en) | 2012-08-22 |

| JP5224438B2 (ja) | 2013-07-03 |

| CN101821819A (zh) | 2010-09-01 |

| SG185923A1 (en) | 2012-12-28 |

| WO2009051075A1 (ja) | 2009-04-23 |

| TWI466136B (zh) | 2014-12-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4759143B2 (ja) | 透明導電積層体、その製造方法及びそれを用いた表示素子 | |

| JP4670877B2 (ja) | 酸化亜鉛系透明導電膜積層体と透明導電性基板およびデバイス | |

| JP5005772B2 (ja) | 導電性積層体およびその製造方法 | |

| JPWO2000051139A1 (ja) | 透明導電積層体、その製造方法及びそれを用いた表示素子 | |

| TWI395231B (zh) | A transparent conductive film for a transparent conductive film and a transparent conductive film produced by using the transparent conductive film and a transparent conductive film | |

| WO2010104111A1 (ja) | 透明導電膜と透明導電膜積層体及びその製造方法、並びにシリコン系薄膜太陽電池 | |

| CN105874544B (zh) | 透明导电膜及其制造方法 | |

| JP2000040429A (ja) | 酸化亜鉛系透明導電膜の製造方法 | |

| KR20100075622A (ko) | 투명 도전막 및 그 제조 방법 | |

| JP4137254B2 (ja) | 透明導電積層体の製造方法 | |

| CN109811308A (zh) | 一种ito导电膜制作工艺 | |

| CN102945694B (zh) | Ito基板及其制备方法 | |

| Huang et al. | Influence of discharge power and annealing temperature on the properties of indium tin oxide thin films prepared by pulsed-DC magnetron sputtering | |

| JP2003105533A (ja) | 透明導電膜の製造方法及び透明導電膜 | |

| CN1944705A (zh) | 一种直流磁控共溅射法制备ZnO∶Al透明导电薄膜的方法 | |

| Park et al. | Properties of ITO films deposited with different conductivity ITO targets | |

| JP5327282B2 (ja) | 透明導電膜製造用焼結体ターゲット | |

| Kwon et al. | Effect of TiO2 buffer layer thickness on properties of ITZO films deposited on flexible substrate | |

| JP2000243160A (ja) | 透明導電積層体の製造方法 | |

| TW202041683A (zh) | 銀合金濺鍍靶及銀合金膜 | |

| JP2010248606A (ja) | 薄膜積層体の作製方法 | |

| JP7478721B2 (ja) | 透明電極付き基板の製造方法 | |

| TW201326443A (zh) | 透明導電膜及其製造方法 | |

| WO2023042849A1 (ja) | 透明導電性フィルム | |

| CN114188446A (zh) | 一种导电玻璃及其制备方法和应用 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20100510 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| N231 | Notification of change of applicant | ||

| PN2301 | Change of applicant |

Patent event date: 20120119 Comment text: Notification of Change of Applicant Patent event code: PN23011R01D |

|

| A201 | Request for examination | ||

| PA0201 | Request for examination |

Patent event code: PA02012R01D Patent event date: 20130917 Comment text: Request for Examination of Application |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20140918 Patent event code: PE09021S01D |

|

| E601 | Decision to refuse application | ||

| PE0601 | Decision on rejection of patent |

Patent event date: 20150305 Comment text: Decision to Refuse Application Patent event code: PE06012S01D Patent event date: 20140918 Comment text: Notification of reason for refusal Patent event code: PE06011S01I |