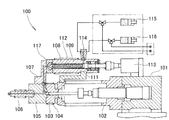

JP5802689B2 - 二液用射出機 - Google Patents

二液用射出機 Download PDFInfo

- Publication number

- JP5802689B2 JP5802689B2 JP2013005608A JP2013005608A JP5802689B2 JP 5802689 B2 JP5802689 B2 JP 5802689B2 JP 2013005608 A JP2013005608 A JP 2013005608A JP 2013005608 A JP2013005608 A JP 2013005608A JP 5802689 B2 JP5802689 B2 JP 5802689B2

- Authority

- JP

- Japan

- Prior art keywords

- plunger

- liquid

- mixing

- injection cylinder

- screw

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/18—Feeding the material into the injection moulding apparatus, i.e. feeding the non-plastified material into the injection unit

- B29C45/1866—Feeding multiple materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/46—Means for plasticising or homogenising the moulding material or forcing it into the mould

- B29C45/53—Means for plasticising or homogenising the moulding material or forcing it into the mould using injection ram or piston

- B29C45/54—Means for plasticising or homogenising the moulding material or forcing it into the mould using injection ram or piston and plasticising screw

- B29C45/542—Means for plasticising or homogenising the moulding material or forcing it into the mould using injection ram or piston and plasticising screw using an accumulator between plasticising and injection unit, e.g. for a continuously operating plasticising screw

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/46—Means for plasticising or homogenising the moulding material or forcing it into the mould

- B29C45/53—Means for plasticising or homogenising the moulding material or forcing it into the mould using injection ram or piston

- B29C45/54—Means for plasticising or homogenising the moulding material or forcing it into the mould using injection ram or piston and plasticising screw

- B29C2045/547—Means for plasticising or homogenising the moulding material or forcing it into the mould using injection ram or piston and plasticising screw continuously rotating plasticising screw cooperating with a single injection plunger

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/46—Means for plasticising or homogenising the moulding material or forcing it into the mould

- B29C45/53—Means for plasticising or homogenising the moulding material or forcing it into the mould using injection ram or piston

- B29C45/54—Means for plasticising or homogenising the moulding material or forcing it into the mould using injection ram or piston and plasticising screw

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Processing And Handling Of Plastics And Other Materials For Molding In General (AREA)

- Injection Moulding Of Plastics Or The Like (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013005608A JP5802689B2 (ja) | 2013-01-16 | 2013-01-16 | 二液用射出機 |

| CN201410001155.7A CN103921412B (zh) | 2013-01-16 | 2014-01-02 | 双液用注塑机 |

| US14/153,920 US9931774B2 (en) | 2013-01-16 | 2014-01-13 | Injecting machine for two different liquid materials having mixing mechanism supported entirely by injection cylinder |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013005608A JP5802689B2 (ja) | 2013-01-16 | 2013-01-16 | 二液用射出機 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2014136356A JP2014136356A (ja) | 2014-07-28 |

| JP2014136356A5 JP2014136356A5 (enExample) | 2014-09-04 |

| JP5802689B2 true JP5802689B2 (ja) | 2015-10-28 |

Family

ID=51139926

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013005608A Expired - Fee Related JP5802689B2 (ja) | 2013-01-16 | 2013-01-16 | 二液用射出機 |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US9931774B2 (enExample) |

| JP (1) | JP5802689B2 (enExample) |

| CN (1) | CN103921412B (enExample) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5799031B2 (ja) * | 2013-01-16 | 2015-10-21 | 日精樹脂工業株式会社 | 二液用射出機 |

| US10690665B2 (en) | 2014-07-01 | 2020-06-23 | Nippon Steel Chemical & Materials Co., Ltd. | Marker, immunoassay method, immunoassay reagent, method for assaying analyte, analyte measurement kit, and lateral-flow chromatographic test strip |

| CN111312981B (zh) * | 2020-03-30 | 2025-07-08 | 无锡先导智能装备股份有限公司 | 一种注液装置 |

| AT524927A1 (de) * | 2021-04-07 | 2022-10-15 | Engel Austria Gmbh | Plastifiziereinheit für eine Formgebungsmaschine und Verfahren zum Betreiben einer solchen |

Family Cites Families (42)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2359840A (en) * | 1942-12-21 | 1944-10-10 | Prophylactic Brush Co | Injection molding machine |

| US3372434A (en) * | 1965-05-27 | 1968-03-12 | Borg Warner | Mounting of extruder-feeder onto injection cylinder with relief for heat expansion |

| CH445838A (de) * | 1965-09-16 | 1967-10-31 | Buehler Ag Geb | Schnecken-Spritzgiessmaschine |

| US4473299A (en) * | 1981-06-10 | 1984-09-25 | Raul Guibert | Gluten producing system |

| US4983045A (en) * | 1985-11-22 | 1991-01-08 | Reica Corporation | Mixer |

| US5123833A (en) * | 1991-04-01 | 1992-06-23 | Parker John C | Fast cycle plasticator/injector unit for molding machines |

| TW259748B (enExample) * | 1994-03-18 | 1995-10-11 | Nissei Zyushi Kogyo Kk | |

| JP2770131B2 (ja) * | 1994-07-20 | 1998-06-25 | 日精樹脂工業株式会社 | 射出成形方法及び射出成形機 |

| US5773042A (en) * | 1994-10-14 | 1998-06-30 | Kabushiki Kaisha Kobe Seiko Sho | Injection molding unit for long fiber-reinforced thermoplastic resin |

| JP3608856B2 (ja) * | 1994-10-14 | 2005-01-12 | 株式会社神戸製鋼所 | 長繊維強化熱可塑性樹脂の射出成形方法及び射出成形装置 |

| JP2782419B2 (ja) * | 1994-12-29 | 1998-07-30 | 日精樹脂工業株式会社 | プリプラ式射出装置における逆流防止方法 |

| JP2923220B2 (ja) * | 1995-02-08 | 1999-07-26 | 株式会社日本製鋼所 | ガラス長繊維入り樹脂材料の成形方法及び装置 |

| JP2899862B2 (ja) * | 1995-02-13 | 1999-06-02 | 日精樹脂工業株式会社 | プリプラ式射出成形機 |

| JP2865022B2 (ja) * | 1995-06-16 | 1999-03-08 | サンケン電気株式会社 | 直流変換装置 |

| US6187229B1 (en) * | 1995-11-10 | 2001-02-13 | Nissei Plastic Industrial Co., Ltd. | Process for injection molding information recording disks |

| JP2965902B2 (ja) * | 1996-01-31 | 1999-10-18 | 日精樹脂工業株式会社 | 光学成形品の射出成形機 |

| JP3173359B2 (ja) * | 1996-01-31 | 2001-06-04 | 日精樹脂工業株式会社 | スクリュプリプラ式射出装置における操作方法 |

| JP3066521B2 (ja) * | 1996-04-30 | 2000-07-17 | 日精樹脂工業株式会社 | プリプラ式射出成形機の制御方法 |

| JPH10235701A (ja) * | 1997-02-27 | 1998-09-08 | Mitsubishi Heavy Ind Ltd | 射出成形機の射出装置 |

| JPH11179766A (ja) * | 1997-10-17 | 1999-07-06 | Bh Kogyo Kk | 複合樹脂の混練射出成形方法および装置 |

| JP2000061992A (ja) * | 1998-08-21 | 2000-02-29 | Bando Chem Ind Ltd | 速硬化型樹脂成型品の成形方法及びその装置 |

| JP3316800B2 (ja) * | 1998-10-20 | 2002-08-19 | 日精樹脂工業株式会社 | プリプラ式射出成形機の可塑化装置 |

| JP3620380B2 (ja) * | 1998-12-25 | 2005-02-16 | 株式会社村田製作所 | 熱可塑性樹脂用射出成形機 |

| JP2000326376A (ja) * | 1999-05-17 | 2000-11-28 | Toshiba Mach Co Ltd | プリプラ式射出装置 |

| JP2000334775A (ja) * | 1999-05-31 | 2000-12-05 | Ge Toshiba Silicones Co Ltd | 射出成形装置及び射出成形方法 |

| JP3554739B2 (ja) * | 1999-06-25 | 2004-08-18 | 日精樹脂工業株式会社 | プリプラ式射出成形機における計量方法 |

| DE10031087A1 (de) * | 2000-06-30 | 2002-01-10 | Krauss Maffei Kunststofftech | Spritzgießmaschine mit kontinuierlich arbeitender Plastifiziereinheit |

| DE10230331B3 (de) * | 2002-07-05 | 2004-04-15 | Krauss-Maffei Kunststofftechnik Gmbh | Vorrichtung und Verfahren zum Herstellen von geschäumten Kunststoffartikeln |

| US7090391B2 (en) * | 2002-09-25 | 2006-08-15 | Reika Kogyo Kabushiki Kaisha | Apparatus and method for mixing by agitation in a multichambered mixing apparatus including a pre-agitation mixing chamber |

| JP4312564B2 (ja) * | 2003-09-30 | 2009-08-12 | 株式会社Triサイタマ | 液状射出成形材料の供給装置及び射出成形金型内への液状射出成形材料の供給方法 |

| JP4708094B2 (ja) * | 2005-06-03 | 2011-06-22 | 株式会社ソディックプラステック | 液状樹脂成形機の射出装置 |

| JP4628229B2 (ja) | 2005-09-16 | 2011-02-09 | 株式会社ソディックプラステック | 液状樹脂成形射出装置の混合装置 |

| US8123394B2 (en) * | 2005-10-17 | 2012-02-28 | Evonik Degussa Gmbh | Mixer for liquid colorants and method for mixing liquid colorants |

| DE102005049926A1 (de) * | 2005-10-17 | 2007-09-27 | Degussa Gmbh | Mischer für Flüssigfarben und Verfahren zum Mischen von Flüssigfarben |

| JP4797661B2 (ja) * | 2006-02-02 | 2011-10-19 | マツダ株式会社 | 繊維強化樹脂成形品の成形方法および成形装置 |

| JP4390789B2 (ja) * | 2006-08-02 | 2009-12-24 | 宏平 澤 | 混練部及び射出部を有する一体化装置 |

| JP2009103803A (ja) * | 2007-10-22 | 2009-05-14 | Nikon Corp | 光学素子の加工方法、光学素子、露光装置 |

| AT11630U1 (de) * | 2008-02-21 | 2011-02-15 | Nestal Maschinen Ag | Verfahren für das aufbereiten der schmelze und plastifiziereinheit |

| ES2694773T3 (es) * | 2008-07-30 | 2018-12-27 | Elkem Silicones USA Corp. | Método para producir productos de caucho de silicona moldeados usando caucho de silicona líquida |

| JP6080611B2 (ja) * | 2013-02-26 | 2017-02-15 | 東洋製罐株式会社 | 発泡性射出成形体の製造方法及びその射出装置 |

| JP5657049B2 (ja) * | 2013-03-28 | 2015-01-21 | 株式会社ソディック | 射出装置におけるスクリュ位置調整装置 |

| DE112015004156T5 (de) * | 2014-09-12 | 2017-06-08 | Toshiba Kikai Kabushiki Kaisha | Plastifizierungsvorrichtung; Einspritzvorrichtung; Formeinrichtung und Herstellungsverfahren von Formteilen |

-

2013

- 2013-01-16 JP JP2013005608A patent/JP5802689B2/ja not_active Expired - Fee Related

-

2014

- 2014-01-02 CN CN201410001155.7A patent/CN103921412B/zh not_active Expired - Fee Related

- 2014-01-13 US US14/153,920 patent/US9931774B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN103921412B (zh) | 2016-06-29 |

| US9931774B2 (en) | 2018-04-03 |

| JP2014136356A (ja) | 2014-07-28 |

| CN103921412A (zh) | 2014-07-16 |

| US20140198600A1 (en) | 2014-07-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5799031B2 (ja) | 二液用射出機 | |

| JP5802689B2 (ja) | 二液用射出機 | |

| CN104884225B (zh) | 螺杆位置调整装置 | |

| CN105984084B (zh) | 用于塑料材料的注射成型的装置 | |

| CN107225742B (zh) | 注射成型机 | |

| EP3590678B1 (en) | Injection molding machine | |

| JP5758968B2 (ja) | プランジャを備えたインライン式射出成形機 | |

| JP6622675B2 (ja) | 射出成形機 | |

| CN109228199A (zh) | 一种微型硅胶的注塑结构 | |

| CN108568933A (zh) | 注射成型机 | |

| JP6026219B2 (ja) | 射出成形機 | |

| TWI626144B (zh) | 射出裝置 | |

| JP6644442B2 (ja) | 射出装置 | |

| CN115139463A (zh) | 热流道装置 | |

| JP6361787B1 (ja) | 2プレート式射出装置 | |

| JP2008284691A (ja) | 射出成形装置 | |

| JP7246991B2 (ja) | 射出装置及びブラケット | |

| JP3725802B2 (ja) | 射出装置 | |

| KR101666404B1 (ko) | 사출기용 가스배출 어댑터 노즐기 | |

| CN107225741A (zh) | 注射装置 | |

| JP2001191375A (ja) | 予備可塑化式射出装置 | |

| JP5802694B2 (ja) | 射出成形装置 | |

| JP6036283B2 (ja) | 射出成形機の射出装置 | |

| JP2007061880A (ja) | 射出成形装置 | |

| JP2025082105A (ja) | 射出装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140717 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20140717 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20150417 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20150512 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20150623 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20150825 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20150831 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5802689 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |