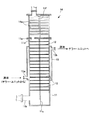

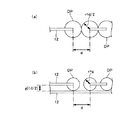

JP5728341B2 - 排気トラップ - Google Patents

排気トラップ Download PDFInfo

- Publication number

- JP5728341B2 JP5728341B2 JP2011199622A JP2011199622A JP5728341B2 JP 5728341 B2 JP5728341 B2 JP 5728341B2 JP 2011199622 A JP2011199622 A JP 2011199622A JP 2011199622 A JP2011199622 A JP 2011199622A JP 5728341 B2 JP5728341 B2 JP 5728341B2

- Authority

- JP

- Japan

- Prior art keywords

- gas

- exhaust

- small

- diameter hole

- baffle plate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000012545 processing Methods 0.000 claims description 26

- 239000000758 substrate Substances 0.000 claims description 11

- 238000000034 method Methods 0.000 claims description 5

- 230000008569 process Effects 0.000 claims description 3

- 238000007599 discharging Methods 0.000 claims 1

- 239000007789 gas Substances 0.000 description 112

- 239000010408 film Substances 0.000 description 26

- 239000000126 substance Substances 0.000 description 26

- 235000012431 wafers Nutrition 0.000 description 24

- 238000000151 deposition Methods 0.000 description 20

- 238000006243 chemical reaction Methods 0.000 description 11

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N silicon dioxide Inorganic materials O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 8

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 description 7

- 239000000463 material Substances 0.000 description 7

- 238000010926 purge Methods 0.000 description 7

- 239000010453 quartz Substances 0.000 description 7

- 229910052581 Si3N4 Inorganic materials 0.000 description 5

- 238000001816 cooling Methods 0.000 description 5

- 239000012530 fluid Substances 0.000 description 5

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 description 5

- 125000006850 spacer group Chemical group 0.000 description 5

- 230000015572 biosynthetic process Effects 0.000 description 4

- MROCJMGDEKINLD-UHFFFAOYSA-N dichlorosilane Chemical compound Cl[SiH2]Cl MROCJMGDEKINLD-UHFFFAOYSA-N 0.000 description 4

- 238000010438 heat treatment Methods 0.000 description 4

- 229910001220 stainless steel Inorganic materials 0.000 description 4

- 239000010935 stainless steel Substances 0.000 description 4

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 3

- 229910021529 ammonia Inorganic materials 0.000 description 3

- 239000006227 byproduct Substances 0.000 description 3

- 239000007795 chemical reaction product Substances 0.000 description 3

- 230000000052 comparative effect Effects 0.000 description 3

- 238000010586 diagram Methods 0.000 description 3

- 238000002347 injection Methods 0.000 description 3

- 239000007924 injection Substances 0.000 description 3

- 230000006911 nucleation Effects 0.000 description 3

- 238000010899 nucleation Methods 0.000 description 3

- 239000012495 reaction gas Substances 0.000 description 3

- 239000004065 semiconductor Substances 0.000 description 3

- 229910052710 silicon Inorganic materials 0.000 description 3

- 239000010703 silicon Substances 0.000 description 3

- 239000010409 thin film Substances 0.000 description 3

- BLRPTPMANUNPDV-UHFFFAOYSA-N Silane Chemical compound [SiH4] BLRPTPMANUNPDV-UHFFFAOYSA-N 0.000 description 2

- 238000005229 chemical vapour deposition Methods 0.000 description 2

- 238000004140 cleaning Methods 0.000 description 2

- 239000011261 inert gas Substances 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 238000005121 nitriding Methods 0.000 description 2

- 229910000077 silane Inorganic materials 0.000 description 2

- 229930091051 Arenine Natural products 0.000 description 1

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 229910003481 amorphous carbon Inorganic materials 0.000 description 1

- 229910021417 amorphous silicon Inorganic materials 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 230000015556 catabolic process Effects 0.000 description 1

- 229910001873 dinitrogen Inorganic materials 0.000 description 1

- 238000001312 dry etching Methods 0.000 description 1

- 238000005530 etching Methods 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- 238000005755 formation reaction Methods 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 230000002401 inhibitory effect Effects 0.000 description 1

- 239000011553 magnetic fluid Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 229920001721 polyimide Polymers 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 239000013049 sediment Substances 0.000 description 1

- 229910052814 silicon oxide Inorganic materials 0.000 description 1

- 238000012360 testing method Methods 0.000 description 1

- 238000005979 thermal decomposition reaction Methods 0.000 description 1

- 239000002341 toxic gas Substances 0.000 description 1

- 238000011179 visual inspection Methods 0.000 description 1

- 239000002912 waste gas Substances 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/67017—Apparatus for fluid treatment

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D45/00—Separating dispersed particles from gases or vapours by gravity, inertia, or centrifugal forces

- B01D45/04—Separating dispersed particles from gases or vapours by gravity, inertia, or centrifugal forces by utilising inertia

- B01D45/08—Separating dispersed particles from gases or vapours by gravity, inertia, or centrifugal forces by utilising inertia by impingement against baffle separators

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/10—Particle separators, e.g. dust precipitators, using filter plates, sheets or pads having plane surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D50/00—Combinations of methods or devices for separating particles from gases or vapours

- B01D50/20—Combinations of devices covered by groups B01D45/00 and B01D46/00

Landscapes

- Chemical Kinetics & Catalysis (AREA)

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Physics & Mathematics (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Chemical Vapour Deposition (AREA)

- Drying Of Semiconductors (AREA)

- Cleaning Or Drying Semiconductors (AREA)

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011199622A JP5728341B2 (ja) | 2011-09-13 | 2011-09-13 | 排気トラップ |

| KR1020120097249A KR101538830B1 (ko) | 2011-09-13 | 2012-09-03 | 배기 트랩 |

| US13/608,695 US20130061969A1 (en) | 2011-09-13 | 2012-09-10 | Exhaust trap |

| CN201210335345.3A CN102989238B (zh) | 2011-09-13 | 2012-09-11 | 排气捕集器 |

| TW101133232A TWI551721B (zh) | 2011-09-13 | 2012-09-12 | 排氣阱 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011199622A JP5728341B2 (ja) | 2011-09-13 | 2011-09-13 | 排気トラップ |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2013062362A JP2013062362A (ja) | 2013-04-04 |

| JP2013062362A5 JP2013062362A5 (enExample) | 2014-04-17 |

| JP5728341B2 true JP5728341B2 (ja) | 2015-06-03 |

Family

ID=47828749

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2011199622A Expired - Fee Related JP5728341B2 (ja) | 2011-09-13 | 2011-09-13 | 排気トラップ |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20130061969A1 (enExample) |

| JP (1) | JP5728341B2 (enExample) |

| KR (1) | KR101538830B1 (enExample) |

| CN (1) | CN102989238B (enExample) |

| TW (1) | TWI551721B (enExample) |

Families Citing this family (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103752122B (zh) * | 2014-02-11 | 2015-11-11 | 江苏佳有环保科技有限公司 | 漆气氧化洗涤塔装置 |

| JP6468884B2 (ja) | 2014-04-21 | 2019-02-13 | 東京エレクトロン株式会社 | 排気システム |

| US10927457B2 (en) * | 2015-03-04 | 2021-02-23 | Toshiba Memory Corporation | Semiconductor manufacturing apparatus |

| WO2017033053A1 (en) | 2015-08-21 | 2017-03-02 | Flisom Ag | Homogeneous linear evaporation source |

| TWI624554B (zh) * | 2015-08-21 | 2018-05-21 | 弗里松股份有限公司 | 蒸發源 |

| RU2724260C1 (ru) | 2016-10-14 | 2020-06-22 | АйЭйчАй КОРПОРЕЙШН | Устройство для отбора повторным нагреванием для газофазного процесса |

| TWI665019B (zh) * | 2017-02-15 | 2019-07-11 | 辛耘企業股份有限公司 | 基板處理裝置 |

| KR102330646B1 (ko) * | 2017-03-22 | 2021-11-23 | 스미스 아날리티컬 엘엘씨 | 증류 프로브 및 유체를 샘플링하고 조절하기 위한 방법 |

| JP7258274B2 (ja) * | 2018-12-25 | 2023-04-17 | 株式会社レゾナック | フィルタ装置、化学気相成長装置およびSiCエピタキシャルウェハの製造方法 |

| KR102209205B1 (ko) * | 2019-08-21 | 2021-02-01 | 주식회사 미래보 | 반도체 공정용 유로방향 전환식 반응부산물 포집장치 |

| US11282491B2 (en) * | 2019-12-17 | 2022-03-22 | Emerson Process Management Regulator Technologies, Inc. | Plates and plate assemblies for noise attenuators and other devices and methods making the same |

| US11562726B2 (en) | 2019-12-17 | 2023-01-24 | Emerson Process Management Regulator Technologies, Inc. | Plates and plate assemblies for noise attenuators and other devices and methods making the same |

| TWI889744B (zh) * | 2020-01-29 | 2025-07-11 | 荷蘭商Asm Ip私人控股有限公司 | 污染物捕集系統、及擋板堆疊 |

| JP2021186785A (ja) * | 2020-06-03 | 2021-12-13 | 東京エレクトロン株式会社 | トラップ装置及び基板処理装置 |

| US11992835B2 (en) | 2020-08-04 | 2024-05-28 | Universal Analyzers Inc. | Distillation probes and methods for sampling and conditioning a fluid |

| KR102442234B1 (ko) * | 2021-02-09 | 2022-09-13 | 주식회사 저스템 | 기류 균일화 장치를 구비한 efem |

| TW202303865A (zh) | 2021-05-28 | 2023-01-16 | 荷蘭商Asm Ip私人控股有限公司 | 污染物捕集系統、及擋板堆疊 |

| CN113818012B (zh) * | 2021-11-25 | 2022-04-01 | 新美光(苏州)半导体科技有限公司 | 一种化学气相沉积装置 |

Family Cites Families (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1186067A (en) * | 1915-09-28 | 1916-06-06 | William A Rawlings | Muffler. |

| US1632325A (en) * | 1924-05-26 | 1927-06-14 | Int Precipitation Co | Gas scrubber |

| GB268163A (en) * | 1926-05-03 | 1927-03-31 | Vilbiss Co | Improvements in apparatus for cleansing air and gases |

| US1857348A (en) * | 1928-05-14 | 1932-05-10 | Bokenkroger William | Filter for gaseous substances |

| US3224171A (en) * | 1963-08-16 | 1965-12-21 | Hyman D Bowman | Exhaust filter for internal combustion engines |

| US3572391A (en) * | 1969-07-10 | 1971-03-23 | Hirsch Abraham A | Flow uniformizing baffling for closed process vessels |

| US3606738A (en) * | 1969-12-02 | 1971-09-21 | Ben Kraus Jr | Fluid separator |

| US4065918A (en) * | 1973-02-12 | 1978-01-03 | Ethyl Corporation | Exhaust systems |

| US4506513A (en) * | 1983-06-17 | 1985-03-26 | Max John K | Cold trap |

| US4488887A (en) * | 1983-10-17 | 1984-12-18 | R. J. Reynolds Tobacco Company | Cold trap |

| DK166260C (da) * | 1990-06-08 | 1993-08-30 | Haldor Topsoe As | Fremgangsmaade til fjernelse af sure, gasformige bestanddele i roeg- og spildgas ved behandling med ammoniak |

| JPH05160029A (ja) * | 1991-12-02 | 1993-06-25 | Hitachi Ltd | 成膜装置およびその排気トラップ |

| US5422081A (en) * | 1992-11-25 | 1995-06-06 | Tokyo Electron Kabushiki Kaisha | Trap device for vapor phase reaction apparatus |

| JPH07193008A (ja) * | 1993-12-27 | 1995-07-28 | Toshiba Corp | 半導体化学気相成長システム |

| JP3540064B2 (ja) * | 1995-09-04 | 2004-07-07 | 株式会社アルバック | ドライ真空ポンプ前段用のトラップ |

| JPH1054356A (ja) * | 1996-08-14 | 1998-02-24 | Ebara Corp | 析出物除去用トラップ |

| JP3991375B2 (ja) * | 1996-11-13 | 2007-10-17 | 東京エレクトロン株式会社 | トラップ装置 |

| US6156107A (en) * | 1996-11-13 | 2000-12-05 | Tokyo Electron Limited | Trap apparatus |

| JPH11300153A (ja) * | 1998-04-24 | 1999-11-02 | Dainippon Screen Mfg Co Ltd | 昇華成分除去ユニットおよびそれを備えた熱処理装置 |

| JP2000045073A (ja) * | 1998-07-29 | 2000-02-15 | Kokusai Electric Co Ltd | 排気トラップ及び処理装置 |

| JP2000256856A (ja) * | 1999-03-11 | 2000-09-19 | Tokyo Electron Ltd | 処理装置及び処理装置用真空排気システム及び減圧cvd装置及び減圧cvd装置用真空排気システム及びトラップ装置 |

| US6206971B1 (en) * | 1999-03-29 | 2001-03-27 | Applied Materials, Inc. | Integrated temperature controlled exhaust and cold trap assembly |

| US6173735B1 (en) * | 1999-04-29 | 2001-01-16 | Perry Equipment Corporation | Method and apparatus for regulating gas flow |

| JP4642379B2 (ja) * | 2004-05-12 | 2011-03-02 | 東京エレクトロン株式会社 | 排気捕集装置 |

| JP4911980B2 (ja) * | 2006-02-02 | 2012-04-04 | 東京エレクトロン株式会社 | 減圧処理装置 |

| JP5036354B2 (ja) * | 2006-04-04 | 2012-09-26 | 東京エレクトロン株式会社 | 成膜装置の排気系構造、成膜装置、および排ガスの処理方法 |

| JP5128168B2 (ja) * | 2006-04-24 | 2013-01-23 | 三菱電線工業株式会社 | 排気装置 |

| US7866345B2 (en) * | 2007-09-28 | 2011-01-11 | Circor Instrumentation Technologies, Inc. | Non-clogging flow restriction for pressure based flow control devices |

| JP5696348B2 (ja) * | 2008-08-09 | 2015-04-08 | 東京エレクトロン株式会社 | 金属回収方法、金属回収装置、排気系及びこれを用いた成膜装置 |

| CN201470229U (zh) * | 2009-09-01 | 2010-05-19 | 中国石油集团西部钻探工程有限公司吐哈钻井工艺研究院 | 环保抑尘器 |

| CN201589723U (zh) * | 2009-12-15 | 2010-09-22 | 东莞市环境保护监测站 | 粒子采样用分级冲撞器 |

-

2011

- 2011-09-13 JP JP2011199622A patent/JP5728341B2/ja not_active Expired - Fee Related

-

2012

- 2012-09-03 KR KR1020120097249A patent/KR101538830B1/ko not_active Expired - Fee Related

- 2012-09-10 US US13/608,695 patent/US20130061969A1/en not_active Abandoned

- 2012-09-11 CN CN201210335345.3A patent/CN102989238B/zh not_active Expired - Fee Related

- 2012-09-12 TW TW101133232A patent/TWI551721B/zh not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| US20130061969A1 (en) | 2013-03-14 |

| CN102989238B (zh) | 2015-06-03 |

| KR101538830B1 (ko) | 2015-07-22 |

| JP2013062362A (ja) | 2013-04-04 |

| KR20130029011A (ko) | 2013-03-21 |

| TWI551721B (zh) | 2016-10-01 |

| CN102989238A (zh) | 2013-03-27 |

| TW201329282A (zh) | 2013-07-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5728341B2 (ja) | 排気トラップ | |

| KR101599431B1 (ko) | Cvd 방법 및 cvd 반응기 | |

| JP6862821B2 (ja) | 成膜装置、成膜方法及び断熱部材 | |

| TWI612178B (zh) | 成膜裝置 | |

| JP5553588B2 (ja) | 成膜装置 | |

| JP4267624B2 (ja) | 基板処理装置および半導体装置の製造方法 | |

| US11274368B2 (en) | Apparatus for selective gas injection and extraction | |

| US20110309562A1 (en) | Support structure and processing apparatus | |

| TW201346994A (zh) | 具有分離的處理氣體與淨化氣體區域之製程腔室 | |

| JP7740821B2 (ja) | 成膜装置 | |

| TWI807192B (zh) | 氣體導入構造、熱處理裝置及氣體供給方法 | |

| JPWO2006093037A1 (ja) | 半導体製造装置及び半導体装置の製造方法 | |

| JP2025096521A (ja) | インジェクタ及び処理装置 | |

| JP2018170387A (ja) | 成膜方法及び縦型熱処理装置 | |

| JP2014116484A (ja) | 基板処理装置および処理容器内圧力調整方法 | |

| JP7616767B2 (ja) | 処理装置及び処理方法 | |

| JP2011216848A (ja) | 半導体装置の製造方法及び基板の製造方法及び基板処理装置 | |

| CN113053725A (zh) | 膜形成方法和膜形成装置 | |

| JP4580833B2 (ja) | 基板処理システム及びトラップ装置 | |

| JP6489478B2 (ja) | 半導体装置の製造方法 | |

| JP2025128453A (ja) | 基板処理装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140305 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20140305 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20141021 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20141028 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20141208 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20150331 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20150406 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5728341 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |