JP5719377B2 - 網状コージエライト組成物、物品およびその製造 - Google Patents

網状コージエライト組成物、物品およびその製造 Download PDFInfo

- Publication number

- JP5719377B2 JP5719377B2 JP2012542107A JP2012542107A JP5719377B2 JP 5719377 B2 JP5719377 B2 JP 5719377B2 JP 2012542107 A JP2012542107 A JP 2012542107A JP 2012542107 A JP2012542107 A JP 2012542107A JP 5719377 B2 JP5719377 B2 JP 5719377B2

- Authority

- JP

- Japan

- Prior art keywords

- cordierite

- batch

- elongated particles

- certain embodiments

- porosity

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 229910052878 cordierite Inorganic materials 0.000 title claims description 98

- JSKIRARMQDRGJZ-UHFFFAOYSA-N dimagnesium dioxido-bis[(1-oxido-3-oxo-2,4,6,8,9-pentaoxa-1,3-disila-5,7-dialuminabicyclo[3.3.1]nonan-7-yl)oxy]silane Chemical compound [Mg++].[Mg++].[O-][Si]([O-])(O[Al]1O[Al]2O[Si](=O)O[Si]([O-])(O1)O2)O[Al]1O[Al]2O[Si](=O)O[Si]([O-])(O1)O2 JSKIRARMQDRGJZ-UHFFFAOYSA-N 0.000 title claims description 98

- 239000000203 mixture Substances 0.000 title description 46

- 229910010293 ceramic material Inorganic materials 0.000 claims description 26

- 210000004027 cell Anatomy 0.000 claims description 14

- QSHDDOUJBYECFT-UHFFFAOYSA-N mercury Chemical compound [Hg] QSHDDOUJBYECFT-UHFFFAOYSA-N 0.000 claims description 13

- 229910052753 mercury Inorganic materials 0.000 claims description 13

- 238000002459 porosimetry Methods 0.000 claims description 7

- 238000012360 testing method Methods 0.000 claims description 7

- 238000013001 point bending Methods 0.000 claims description 5

- 210000002421 cell wall Anatomy 0.000 claims description 4

- 239000011159 matrix material Substances 0.000 claims description 4

- 230000001747 exhibiting effect Effects 0.000 claims 1

- 239000002245 particle Substances 0.000 description 128

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 50

- 239000011148 porous material Substances 0.000 description 47

- 239000000463 material Substances 0.000 description 46

- 239000000919 ceramic Substances 0.000 description 37

- 238000010438 heat treatment Methods 0.000 description 28

- 239000000454 talc Substances 0.000 description 26

- 229910052623 talc Inorganic materials 0.000 description 26

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 23

- 238000001816 cooling Methods 0.000 description 23

- 229910000323 aluminium silicate Inorganic materials 0.000 description 22

- HNPSIPDUKPIQMN-UHFFFAOYSA-N dioxosilane;oxo(oxoalumanyloxy)alumane Chemical compound O=[Si]=O.O=[Al]O[Al]=O HNPSIPDUKPIQMN-UHFFFAOYSA-N 0.000 description 22

- 238000001125 extrusion Methods 0.000 description 21

- 238000009826 distribution Methods 0.000 description 16

- 239000002994 raw material Substances 0.000 description 15

- 239000004927 clay Substances 0.000 description 14

- 229910052570 clay Inorganic materials 0.000 description 14

- 239000013078 crystal Substances 0.000 description 13

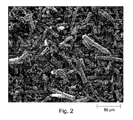

- 238000001878 scanning electron micrograph Methods 0.000 description 13

- 238000000034 method Methods 0.000 description 12

- 239000000377 silicon dioxide Substances 0.000 description 11

- CPLXHLVBOLITMK-UHFFFAOYSA-N Magnesium oxide Chemical compound [Mg]=O CPLXHLVBOLITMK-UHFFFAOYSA-N 0.000 description 10

- 230000000052 comparative effect Effects 0.000 description 10

- 239000011521 glass Substances 0.000 description 10

- 229920002261 Corn starch Polymers 0.000 description 9

- 239000008120 corn starch Substances 0.000 description 9

- 229920001592 potato starch Polymers 0.000 description 9

- 238000010304 firing Methods 0.000 description 8

- 230000015572 biosynthetic process Effects 0.000 description 7

- 238000001887 electron backscatter diffraction Methods 0.000 description 7

- 239000011230 binding agent Substances 0.000 description 6

- 230000035939 shock Effects 0.000 description 6

- KZHJGOXRZJKJNY-UHFFFAOYSA-N dioxosilane;oxo(oxoalumanyloxy)alumane Chemical compound O=[Si]=O.O=[Si]=O.O=[Al]O[Al]=O.O=[Al]O[Al]=O.O=[Al]O[Al]=O KZHJGOXRZJKJNY-UHFFFAOYSA-N 0.000 description 5

- 239000000395 magnesium oxide Substances 0.000 description 5

- 229910052863 mullite Inorganic materials 0.000 description 5

- 238000006243 chemical reaction Methods 0.000 description 4

- 238000013507 mapping Methods 0.000 description 4

- 238000002156 mixing Methods 0.000 description 4

- 239000002243 precursor Substances 0.000 description 4

- 238000004458 analytical method Methods 0.000 description 3

- 230000001186 cumulative effect Effects 0.000 description 3

- 230000007423 decrease Effects 0.000 description 3

- 239000000835 fiber Substances 0.000 description 3

- 239000007789 gas Substances 0.000 description 3

- 238000005259 measurement Methods 0.000 description 3

- 238000012545 processing Methods 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- 239000004593 Epoxy Substances 0.000 description 2

- 238000002441 X-ray diffraction Methods 0.000 description 2

- 239000003125 aqueous solvent Substances 0.000 description 2

- 239000003054 catalyst Substances 0.000 description 2

- 239000003795 chemical substances by application Substances 0.000 description 2

- 238000013480 data collection Methods 0.000 description 2

- 230000003247 decreasing effect Effects 0.000 description 2

- 238000010894 electron beam technology Methods 0.000 description 2

- 238000002003 electron diffraction Methods 0.000 description 2

- 239000010419 fine particle Substances 0.000 description 2

- 238000000227 grinding Methods 0.000 description 2

- 239000004615 ingredient Substances 0.000 description 2

- 238000001000 micrograph Methods 0.000 description 2

- 230000035699 permeability Effects 0.000 description 2

- 238000005498 polishing Methods 0.000 description 2

- 230000009467 reduction Effects 0.000 description 2

- 229910052596 spinel Inorganic materials 0.000 description 2

- 239000011029 spinel Substances 0.000 description 2

- 238000005382 thermal cycling Methods 0.000 description 2

- RPZANUYHRMRTTE-UHFFFAOYSA-N 2,3,4-trimethoxy-6-(methoxymethyl)-5-[3,4,5-trimethoxy-6-(methoxymethyl)oxan-2-yl]oxyoxane;1-[[3,4,5-tris(2-hydroxybutoxy)-6-[4,5,6-tris(2-hydroxybutoxy)-2-(2-hydroxybutoxymethyl)oxan-3-yl]oxyoxan-2-yl]methoxy]butan-2-ol Chemical compound COC1C(OC)C(OC)C(COC)OC1OC1C(OC)C(OC)C(OC)OC1COC.CCC(O)COC1C(OCC(O)CC)C(OCC(O)CC)C(COCC(O)CC)OC1OC1C(OCC(O)CC)C(OCC(O)CC)C(OCC(O)CC)OC1COCC(O)CC RPZANUYHRMRTTE-UHFFFAOYSA-N 0.000 description 1

- 239000005995 Aluminium silicate Substances 0.000 description 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 229920000896 Ethulose Polymers 0.000 description 1

- 239000001859 Ethyl hydroxyethyl cellulose Substances 0.000 description 1

- 229920000663 Hydroxyethyl cellulose Polymers 0.000 description 1

- 239000004354 Hydroxyethyl cellulose Substances 0.000 description 1

- 229920001479 Hydroxyethyl methyl cellulose Polymers 0.000 description 1

- 229920002153 Hydroxypropyl cellulose Polymers 0.000 description 1

- MXRIRQGCELJRSN-UHFFFAOYSA-N O.O.O.[Al] Chemical compound O.O.O.[Al] MXRIRQGCELJRSN-UHFFFAOYSA-N 0.000 description 1

- OAICVXFJPJFONN-UHFFFAOYSA-N Phosphorus Chemical compound [P] OAICVXFJPJFONN-UHFFFAOYSA-N 0.000 description 1

- 239000004793 Polystyrene Substances 0.000 description 1

- 238000003991 Rietveld refinement Methods 0.000 description 1

- 229920002472 Starch Polymers 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- DPXJVFZANSGRMM-UHFFFAOYSA-N acetic acid;2,3,4,5,6-pentahydroxyhexanal;sodium Chemical compound [Na].CC(O)=O.OCC(O)C(O)C(O)C(O)C=O DPXJVFZANSGRMM-UHFFFAOYSA-N 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 238000007605 air drying Methods 0.000 description 1

- 235000012211 aluminium silicate Nutrition 0.000 description 1

- 238000002048 anodisation reaction Methods 0.000 description 1

- 239000011324 bead Substances 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 239000001768 carboxy methyl cellulose Substances 0.000 description 1

- 239000000969 carrier Substances 0.000 description 1

- 230000001413 cellular effect Effects 0.000 description 1

- 210000003850 cellular structure Anatomy 0.000 description 1

- 229920003086 cellulose ether Polymers 0.000 description 1

- 238000012512 characterization method Methods 0.000 description 1

- 239000007795 chemical reaction product Substances 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 239000008119 colloidal silica Substances 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 238000003487 electrochemical reaction Methods 0.000 description 1

- 238000002149 energy-dispersive X-ray emission spectroscopy Methods 0.000 description 1

- 235000019326 ethyl hydroxyethyl cellulose Nutrition 0.000 description 1

- 239000002657 fibrous material Substances 0.000 description 1

- 238000001914 filtration Methods 0.000 description 1

- 230000009969 flowable effect Effects 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 238000009472 formulation Methods 0.000 description 1

- 239000012634 fragment Substances 0.000 description 1

- 239000010439 graphite Substances 0.000 description 1

- 229910002804 graphite Inorganic materials 0.000 description 1

- 238000009499 grossing Methods 0.000 description 1

- 238000001198 high resolution scanning electron microscopy Methods 0.000 description 1

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 1

- 235000019447 hydroxyethyl cellulose Nutrition 0.000 description 1

- 229920003063 hydroxymethyl cellulose Polymers 0.000 description 1

- 229940031574 hydroxymethyl cellulose Drugs 0.000 description 1

- 239000001863 hydroxypropyl cellulose Substances 0.000 description 1

- 235000010977 hydroxypropyl cellulose Nutrition 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 229910010272 inorganic material Inorganic materials 0.000 description 1

- 239000011147 inorganic material Substances 0.000 description 1

- 239000013067 intermediate product Substances 0.000 description 1

- 229910052741 iridium Inorganic materials 0.000 description 1

- GKOZUEZYRPOHIO-UHFFFAOYSA-N iridium atom Chemical compound [Ir] GKOZUEZYRPOHIO-UHFFFAOYSA-N 0.000 description 1

- NLYAJNPCOHFWQQ-UHFFFAOYSA-N kaolin Chemical compound O.O.O=[Al]O[Si](=O)O[Si](=O)O[Al]=O NLYAJNPCOHFWQQ-UHFFFAOYSA-N 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 238000011068 loading method Methods 0.000 description 1

- 239000000314 lubricant Substances 0.000 description 1

- 229920000609 methyl cellulose Polymers 0.000 description 1

- 239000001923 methylcellulose Substances 0.000 description 1

- 239000011859 microparticle Substances 0.000 description 1

- 239000011236 particulate material Substances 0.000 description 1

- 239000004014 plasticizer Substances 0.000 description 1

- 229920002223 polystyrene Polymers 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 239000000047 product Substances 0.000 description 1

- 238000011002 quantification Methods 0.000 description 1

- 239000012925 reference material Substances 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 235000019812 sodium carboxymethyl cellulose Nutrition 0.000 description 1

- 229920001027 sodium carboxymethylcellulose Polymers 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 239000002904 solvent Substances 0.000 description 1

- 239000004071 soot Substances 0.000 description 1

- 239000012798 spherical particle Substances 0.000 description 1

- 239000008107 starch Substances 0.000 description 1

- 235000019698 starch Nutrition 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 238000010998 test method Methods 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- 238000009736 wetting Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/24—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies

- B01D46/2403—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies characterised by the physical shape or structure of the filtering element

- B01D46/2418—Honeycomb filters

- B01D46/2451—Honeycomb filters characterized by the geometrical structure, shape, pattern or configuration or parameters related to the geometry of the structure

- B01D46/2474—Honeycomb filters characterized by the geometrical structure, shape, pattern or configuration or parameters related to the geometry of the structure of the walls along the length of the honeycomb

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/24—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies

- B01D46/2403—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies characterised by the physical shape or structure of the filtering element

- B01D46/2418—Honeycomb filters

- B01D46/2425—Honeycomb filters characterized by parameters related to the physical properties of the honeycomb structure material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/24—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies

- B01D46/2403—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies characterised by the physical shape or structure of the filtering element

- B01D46/2418—Honeycomb filters

- B01D46/2425—Honeycomb filters characterized by parameters related to the physical properties of the honeycomb structure material

- B01D46/2429—Honeycomb filters characterized by parameters related to the physical properties of the honeycomb structure material of the honeycomb walls or cells

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/24—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies

- B01D46/2403—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies characterised by the physical shape or structure of the filtering element

- B01D46/2418—Honeycomb filters

- B01D46/2425—Honeycomb filters characterized by parameters related to the physical properties of the honeycomb structure material

- B01D46/24491—Porosity

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/24—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies

- B01D46/2403—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies characterised by the physical shape or structure of the filtering element

- B01D46/2418—Honeycomb filters

- B01D46/2425—Honeycomb filters characterized by parameters related to the physical properties of the honeycomb structure material

- B01D46/24492—Pore diameter

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/24—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies

- B01D46/2403—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies characterised by the physical shape or structure of the filtering element

- B01D46/2418—Honeycomb filters

- B01D46/2425—Honeycomb filters characterized by parameters related to the physical properties of the honeycomb structure material

- B01D46/24493—Modulus of rupture

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/24—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies

- B01D46/2403—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies characterised by the physical shape or structure of the filtering element

- B01D46/2418—Honeycomb filters

- B01D46/2425—Honeycomb filters characterized by parameters related to the physical properties of the honeycomb structure material

- B01D46/24494—Thermal expansion coefficient, heat capacity or thermal conductivity

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/24—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies

- B01D46/2403—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies characterised by the physical shape or structure of the filtering element

- B01D46/2418—Honeycomb filters

- B01D46/2451—Honeycomb filters characterized by the geometrical structure, shape, pattern or configuration or parameters related to the geometry of the structure

- B01D46/247—Honeycomb filters characterized by the geometrical structure, shape, pattern or configuration or parameters related to the geometry of the structure of the cells

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/24—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies

- B01D46/2403—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies characterised by the physical shape or structure of the filtering element

- B01D46/2418—Honeycomb filters

- B01D46/2451—Honeycomb filters characterized by the geometrical structure, shape, pattern or configuration or parameters related to the geometry of the structure

- B01D46/2482—Thickness, height, width, length or diameter

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/24—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies

- B01D46/2403—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies characterised by the physical shape or structure of the filtering element

- B01D46/2418—Honeycomb filters

- B01D46/2451—Honeycomb filters characterized by the geometrical structure, shape, pattern or configuration or parameters related to the geometry of the structure

- B01D46/2484—Cell density, area or aspect ratio

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B35/00—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/01—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on oxide ceramics

- C04B35/16—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on oxide ceramics based on silicates other than clay

- C04B35/18—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on oxide ceramics based on silicates other than clay rich in aluminium oxide

- C04B35/195—Alkaline earth aluminosilicates, e.g. cordierite or anorthite

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B38/00—Porous mortars, concrete, artificial stone or ceramic ware; Preparation thereof

- C04B38/0006—Honeycomb structures

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/24—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies

- B01D46/2403—Particle separators, e.g. dust precipitators, using rigid hollow filter bodies characterised by the physical shape or structure of the filtering element

- B01D46/2418—Honeycomb filters

- B01D46/2498—The honeycomb filter being defined by mathematical relationships

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2111/00—Mortars, concrete or artificial stone or mixtures to prepare them, characterised by specific function, property or use

- C04B2111/00474—Uses not provided for elsewhere in C04B2111/00

- C04B2111/00793—Uses not provided for elsewhere in C04B2111/00 as filters or diaphragms

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2111/00—Mortars, concrete or artificial stone or mixtures to prepare them, characterised by specific function, property or use

- C04B2111/00474—Uses not provided for elsewhere in C04B2111/00

- C04B2111/0081—Uses not provided for elsewhere in C04B2111/00 as catalysts or catalyst carriers

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/30—Constituents and secondary phases not being of a fibrous nature

- C04B2235/32—Metal oxides, mixed metal oxides, or oxide-forming salts thereof, e.g. carbonates, nitrates, (oxy)hydroxides, chlorides

- C04B2235/3205—Alkaline earth oxides or oxide forming salts thereof, e.g. beryllium oxide

- C04B2235/3206—Magnesium oxides or oxide-forming salts thereof

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/30—Constituents and secondary phases not being of a fibrous nature

- C04B2235/32—Metal oxides, mixed metal oxides, or oxide-forming salts thereof, e.g. carbonates, nitrates, (oxy)hydroxides, chlorides

- C04B2235/3217—Aluminum oxide or oxide forming salts thereof, e.g. bauxite, alpha-alumina

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/30—Constituents and secondary phases not being of a fibrous nature

- C04B2235/32—Metal oxides, mixed metal oxides, or oxide-forming salts thereof, e.g. carbonates, nitrates, (oxy)hydroxides, chlorides

- C04B2235/3217—Aluminum oxide or oxide forming salts thereof, e.g. bauxite, alpha-alumina

- C04B2235/3218—Aluminium (oxy)hydroxides, e.g. boehmite, gibbsite, alumina sol

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/30—Constituents and secondary phases not being of a fibrous nature

- C04B2235/34—Non-metal oxides, non-metal mixed oxides, or salts thereof that form the non-metal oxides upon heating, e.g. carbonates, nitrates, (oxy)hydroxides, chlorides

- C04B2235/3418—Silicon oxide, silicic acids or oxide forming salts thereof, e.g. silica sol, fused silica, silica fume, cristobalite, quartz or flint

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/30—Constituents and secondary phases not being of a fibrous nature

- C04B2235/34—Non-metal oxides, non-metal mixed oxides, or salts thereof that form the non-metal oxides upon heating, e.g. carbonates, nitrates, (oxy)hydroxides, chlorides

- C04B2235/3427—Silicates other than clay, e.g. water glass

- C04B2235/3436—Alkaline earth metal silicates, e.g. barium silicate

- C04B2235/3445—Magnesium silicates, e.g. forsterite

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/30—Constituents and secondary phases not being of a fibrous nature

- C04B2235/34—Non-metal oxides, non-metal mixed oxides, or salts thereof that form the non-metal oxides upon heating, e.g. carbonates, nitrates, (oxy)hydroxides, chlorides

- C04B2235/3427—Silicates other than clay, e.g. water glass

- C04B2235/3463—Alumino-silicates other than clay, e.g. mullite

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/30—Constituents and secondary phases not being of a fibrous nature

- C04B2235/34—Non-metal oxides, non-metal mixed oxides, or salts thereof that form the non-metal oxides upon heating, e.g. carbonates, nitrates, (oxy)hydroxides, chlorides

- C04B2235/349—Clays, e.g. bentonites, smectites such as montmorillonite, vermiculites or kaolines, e.g. illite, talc or sepiolite

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/50—Constituents or additives of the starting mixture chosen for their shape or used because of their shape or their physical appearance

- C04B2235/52—Constituents or additives characterised by their shapes

- C04B2235/5276—Whiskers, spindles, needles or pins

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/50—Constituents or additives of the starting mixture chosen for their shape or used because of their shape or their physical appearance

- C04B2235/54—Particle size related information

- C04B2235/5418—Particle size related information expressed by the size of the particles or aggregates thereof

- C04B2235/5427—Particle size related information expressed by the size of the particles or aggregates thereof millimeter or submillimeter sized, i.e. larger than 0,1 mm

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/50—Constituents or additives of the starting mixture chosen for their shape or used because of their shape or their physical appearance

- C04B2235/54—Particle size related information

- C04B2235/5418—Particle size related information expressed by the size of the particles or aggregates thereof

- C04B2235/5436—Particle size related information expressed by the size of the particles or aggregates thereof micrometer sized, i.e. from 1 to 100 micron

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/65—Aspects relating to heat treatments of ceramic bodies such as green ceramics or pre-sintered ceramics, e.g. burning, sintering or melting processes

- C04B2235/656—Aspects relating to heat treatments of ceramic bodies such as green ceramics or pre-sintered ceramics, e.g. burning, sintering or melting processes characterised by specific heating conditions during heat treatment

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/65—Aspects relating to heat treatments of ceramic bodies such as green ceramics or pre-sintered ceramics, e.g. burning, sintering or melting processes

- C04B2235/656—Aspects relating to heat treatments of ceramic bodies such as green ceramics or pre-sintered ceramics, e.g. burning, sintering or melting processes characterised by specific heating conditions during heat treatment

- C04B2235/6567—Treatment time

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/70—Aspects relating to sintered or melt-casted ceramic products

- C04B2235/96—Properties of ceramic products, e.g. mechanical properties such as strength, toughness, wear resistance

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/70—Aspects relating to sintered or melt-casted ceramic products

- C04B2235/96—Properties of ceramic products, e.g. mechanical properties such as strength, toughness, wear resistance

- C04B2235/9607—Thermal properties, e.g. thermal expansion coefficient

Landscapes

- Chemical & Material Sciences (AREA)

- Physics & Mathematics (AREA)

- Geometry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Ceramic Engineering (AREA)

- Materials Engineering (AREA)

- Structural Engineering (AREA)

- Organic Chemistry (AREA)

- Thermal Sciences (AREA)

- Manufacturing & Machinery (AREA)

- Compositions Of Oxide Ceramics (AREA)

- Catalysts (AREA)

- Filtering Materials (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US12/627,612 US8148297B2 (en) | 2009-11-30 | 2009-11-30 | Reticular cordierite composition, article and manufacture thereof |

| US12/627,612 | 2009-11-30 | ||

| PCT/US2010/058151 WO2011066490A2 (en) | 2009-11-30 | 2010-11-29 | Reticular cordierite composition, article and manufacture thereof |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2013512189A JP2013512189A (ja) | 2013-04-11 |

| JP2013512189A5 JP2013512189A5 (enExample) | 2015-01-15 |

| JP5719377B2 true JP5719377B2 (ja) | 2015-05-20 |

Family

ID=43920065

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012542107A Expired - Fee Related JP5719377B2 (ja) | 2009-11-30 | 2010-11-29 | 網状コージエライト組成物、物品およびその製造 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US8148297B2 (enExample) |

| EP (1) | EP2506949A2 (enExample) |

| JP (1) | JP5719377B2 (enExample) |

| CN (1) | CN102630184B (enExample) |

| WO (1) | WO2011066490A2 (enExample) |

Families Citing this family (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20110290416A1 (en) * | 2010-05-31 | 2011-12-01 | Tangshan Railway Vehicle Co., Ltd. | Method for improving the fireproofing performance of vehicle body |

| JP2013043138A (ja) * | 2011-08-25 | 2013-03-04 | Denso Corp | 触媒担持体及びその製造方法 |

| US9376347B2 (en) | 2013-05-20 | 2016-06-28 | Corning Incorporated | Porous ceramic article and method of manufacturing the same |

| US9623360B2 (en) * | 2013-05-20 | 2017-04-18 | Corning Incorporated | Porous ceramic article and method of manufacturing the same |

| US9908260B2 (en) | 2013-05-20 | 2018-03-06 | Corning Incorporated | Porous ceramic article and method of manufacturing the same |

| JP6231910B2 (ja) * | 2014-03-14 | 2017-11-15 | 日本碍子株式会社 | 目封止ハニカム構造体 |

| WO2017210251A1 (en) * | 2016-05-31 | 2017-12-07 | Corning Incorporated | Porous article and method of manufacturing the same |

| MX2019005471A (es) * | 2016-11-10 | 2019-10-02 | Corning Inc | Materiales ceramicos compuestos, articulos y metodo de fabricacion. |

| WO2019089731A1 (en) | 2017-10-31 | 2019-05-09 | Corning Incorporated | Batch compositions comprising spheroidal pre-reacted inorganic particles and spheroidal pore-formers and methods of manufacture of honeycomb bodies therefrom |

| US10814266B2 (en) | 2017-11-24 | 2020-10-27 | Ngk Insulators, Ltd. | Honeycomb filter |

| EP3717442B1 (en) * | 2017-11-30 | 2021-12-22 | Corning Incorporated | Ceramic articles with bleed-through barrier and methods of manufacture thereof |

| JP6771005B2 (ja) | 2018-09-12 | 2020-10-21 | イビデン株式会社 | ハニカム構造体の製造方法 |

| WO2022026664A1 (en) * | 2020-07-31 | 2022-02-03 | Corning Incorporated | Ceramic articles made from ceramic beads with open porosity |

| CN115867519A (zh) | 2020-08-31 | 2023-03-28 | 康宁股份有限公司 | 用于陶瓷制造的高氧快速烧制方法 |

| JP2022156352A (ja) * | 2021-03-31 | 2022-10-14 | 日本碍子株式会社 | ハニカム構造体 |

| JP7578538B2 (ja) * | 2021-04-29 | 2024-11-06 | 日本特殊陶業株式会社 | セラミックス多孔体 |

| CN117181185B (zh) * | 2023-09-07 | 2024-02-20 | 硅宝石(武汉)高新装备股份有限公司 | 一种nmp蜂窝沸石吸附材料的制备方法 |

| CN119954530B (zh) * | 2025-01-09 | 2025-10-17 | 宜兴摩根热陶瓷有限公司 | 一种基于废弃镁碳砖的堇青石质多孔陶瓷的制备方法 |

Family Cites Families (39)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS643067A (en) * | 1987-02-12 | 1989-01-06 | Ngk Insulators Ltd | Cordierite honeycomb structure and production thereof |

| JPS6479021A (en) * | 1987-09-22 | 1989-03-24 | Ishizuka Glass | Molding method for glassware |

| JP2644841B2 (ja) | 1988-09-13 | 1997-08-25 | 株式会社クレー・バーン・セラミックス | 板状無機物質焼結体及びその製法 |

| JPH0656551A (ja) | 1992-08-06 | 1994-03-01 | Matsushita Electric Ind Co Ltd | コージライト多孔質耐熱材の製造方法 |

| JPH07206540A (ja) | 1994-01-19 | 1995-08-08 | Matsushita Electric Ind Co Ltd | コージェライト質多孔質耐熱材の製造方法 |

| JPH08337479A (ja) | 1995-06-13 | 1996-12-24 | Ishikawajima Harima Heavy Ind Co Ltd | 無機多孔体 |

| JP3094148B2 (ja) | 1996-03-29 | 2000-10-03 | 長野県 | 軽量耐火物の製造方法 |

| US5866244A (en) * | 1996-12-20 | 1999-02-02 | The United States Of America As Represented By The Secretary Of The Navy | Ceramic structure with backfilled channels |

| KR20010086454A (ko) * | 1998-12-07 | 2001-09-12 | 알프레드 엘. 미첼슨 | 초저열팽창 코디어라이트 구조물의 제조방법 |

| WO2000040521A1 (en) * | 1998-12-31 | 2000-07-13 | Corning Incorporated | Low sintering temperature cordierite batch and cordierite ceramic produced therefrom |

| PL193717B1 (pl) * | 1999-06-11 | 2007-03-30 | Corning Inc | Słabo rozszerzalna, o dużej porowatości i wysokiej wytrzymałości kordierytowa wkładka ceramiczna i sposób jej otrzymywania |

| US6300263B1 (en) * | 1999-12-16 | 2001-10-09 | Corning Incorporated | Low-expansion cordierite glass ceramics |

| JP2005530616A (ja) * | 2002-06-26 | 2005-10-13 | コーニング インコーポレイテッド | Dpf用途向けのケイ酸アルミニウムマグネシウム構造体 |

| US7572311B2 (en) * | 2002-10-28 | 2009-08-11 | Geo2 Technologies, Inc. | Highly porous mullite particulate filter substrate |

| JP2004322027A (ja) * | 2003-04-28 | 2004-11-18 | Bridgestone Corp | 流体フィルタ |

| US7179316B2 (en) * | 2003-06-25 | 2007-02-20 | Corning Incorporated | Cordierite filters with reduced pressure drop |

| JP4358662B2 (ja) * | 2004-03-23 | 2009-11-04 | 日本碍子株式会社 | コーディエライト質ハニカム構造体の製造方法 |

| US20060021308A1 (en) * | 2004-07-29 | 2006-02-02 | Merkel Gregory A | Mullite-aluminum titanate body and method for making same |

| US7445745B2 (en) * | 2004-08-03 | 2008-11-04 | Corning Incorporated | Method for fabricating ceramic articles |

| WO2006137155A1 (ja) | 2005-06-24 | 2006-12-28 | Ibiden Co., Ltd. | ハニカム構造体 |

| US7858554B2 (en) | 2007-05-24 | 2010-12-28 | Geo2 Technologies, Inc. | Cordierite fiber substrate and method for forming the same |

| US7520911B2 (en) * | 2005-11-30 | 2009-04-21 | Corning Incorporated | Porous cordierite ceramic honeycomb article with improved strength and method of manufacturing same |

| WO2007064454A2 (en) * | 2005-11-30 | 2007-06-07 | Corning Incorporated | Controlled pore size distribution porous ceramic honeycomb filter, honeycomb green body, batch mixture and manufacturing method therefor |

| US7744980B2 (en) * | 2005-12-20 | 2010-06-29 | Corning Incorporated | Low CTE cordierite honeycomb article and method of manufacturing same |

| EP1852406A3 (en) | 2006-05-01 | 2008-08-06 | Ibiden Co., Ltd. | honeycomb structured body, method for manufacturing honeycomb structured body, honeycomb filter and method for manufacturing honeycomb filter |

| US20070281127A1 (en) * | 2006-05-30 | 2007-12-06 | Monika Backhaus-Ricoult | Cordierite formation |

| US7927682B2 (en) * | 2006-06-30 | 2011-04-19 | Corning Incorporated | Low-microcracked, porous ceramic honeycombs and methods of manufacturing same |

| JP5113168B2 (ja) | 2006-06-30 | 2013-01-09 | コーニング インコーポレイテッド | 低マイクロクラックの多孔質セラミックハニカム、およびその製造方法 |

| US7618699B2 (en) * | 2006-06-30 | 2009-11-17 | Corning Incorporated | Low-microcracked, porous ceramic honeycombs and methods of manufacturing same |

| US7923093B2 (en) * | 2006-06-30 | 2011-04-12 | Corning Incorporated | High porosity filters for 4-way exhaust gas treatment |

| US7648550B2 (en) * | 2006-08-25 | 2010-01-19 | Corning Incorporated | Narrow pore size distribution cordierite ceramic honeycomb articles and methods for manufacturing same |

| WO2008027424A2 (en) * | 2006-08-29 | 2008-03-06 | Corning Incorporated | High strength substantially non-microcracked cordierite honeycomb body and manufacturing method |

| US7964262B2 (en) | 2006-08-29 | 2011-06-21 | Corning Incorporated | Layered silicate modified cordierite and method |

| JPWO2008096413A1 (ja) | 2007-02-06 | 2010-05-20 | イビデン株式会社 | ハニカム構造体 |

| US7855163B2 (en) | 2007-05-14 | 2010-12-21 | Geo2 Technologies, Inc. | Low coefficient of thermal expansion bonding system for a high porosity ceramic body and methods of manufacture |

| US7704296B2 (en) * | 2007-11-27 | 2010-04-27 | Corning Incorporated | Fine porosity low-microcracked ceramic honeycombs and methods thereof |

| US8501296B2 (en) * | 2008-02-29 | 2013-08-06 | Corning Incorporated | Stabilized low-microcracked ceramic honeycombs and methods thereof |

| US8119234B2 (en) * | 2008-02-29 | 2012-02-21 | Corning Incorporated | Anisotropic porous ceramic article and manufacture thereof |

| US8007557B2 (en) * | 2008-11-26 | 2011-08-30 | Corning Incorporated | High-strength low-microcracked ceramic honeycombs and methods therefor |

-

2009

- 2009-11-30 US US12/627,612 patent/US8148297B2/en not_active Expired - Fee Related

-

2010

- 2010-11-29 WO PCT/US2010/058151 patent/WO2011066490A2/en not_active Ceased

- 2010-11-29 EP EP10787630A patent/EP2506949A2/en not_active Withdrawn

- 2010-11-29 JP JP2012542107A patent/JP5719377B2/ja not_active Expired - Fee Related

- 2010-11-29 CN CN201080054034.9A patent/CN102630184B/zh not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| WO2011066490A2 (en) | 2011-06-03 |

| CN102630184B (zh) | 2016-05-11 |

| WO2011066490A3 (en) | 2011-09-29 |

| EP2506949A2 (en) | 2012-10-10 |

| CN102630184A (zh) | 2012-08-08 |

| JP2013512189A (ja) | 2013-04-11 |

| US20110130276A1 (en) | 2011-06-02 |

| US8148297B2 (en) | 2012-04-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5719377B2 (ja) | 網状コージエライト組成物、物品およびその製造 | |

| JP5572102B2 (ja) | 異方性多孔質セラミック物品およびその製造 | |

| JP3393554B2 (ja) | 低熱膨脹で高気孔率のコージエライトボディおよびその製造方法 | |

| JP6043340B2 (ja) | 多孔質材料、ハニカム構造体及び多孔質材料の製造方法 | |

| JP6006782B2 (ja) | 多孔質材料及びハニカム構造体 | |

| JP3277939B2 (ja) | コージーライトボディの製造方法 | |

| JP5890548B2 (ja) | コージエライト形成バッチ組成物およびそれから製造されたコージエライト体 | |

| JP6125869B2 (ja) | 多孔質材料、ハニカム構造体及び多孔質材料の製造方法 | |

| JP2011504159A (ja) | セラミックモノリスのための低膨張セメント組成物 | |

| JP5478025B2 (ja) | コーディエライトセラミックスおよびその製造方法 | |

| JP6324563B2 (ja) | 多孔質材料の製造方法 | |

| US11976012B2 (en) | Cordierite-containing ceramic bodies, batch composition mixtures, and methods of manufacturing cordierite-containing ceramic bodies | |

| JP4537238B2 (ja) | カオリン粒子のへき開指数測定方法及びコージェライト質ハニカム構造体の製造方法 | |

| JPH0751459B2 (ja) | コージェライト質ハニカム構造体の製造法 | |

| JP4934695B2 (ja) | コージェライト成形体及びその製造方法 | |

| DE102017009873A1 (de) | Poröses Material, Wabenstruktur und Verfahren zur Herstellung eines porösen Materials | |

| JP5932230B2 (ja) | ハニカム構造体およびその製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20131122 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20140717 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20140819 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20141118 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20150224 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20150320 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5719377 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |