JP5323867B2 - 基板反転装置、基板反転方法、剥離システム、プログラム及びコンピュータ記憶媒体 - Google Patents

基板反転装置、基板反転方法、剥離システム、プログラム及びコンピュータ記憶媒体 Download PDFInfo

- Publication number

- JP5323867B2 JP5323867B2 JP2011009309A JP2011009309A JP5323867B2 JP 5323867 B2 JP5323867 B2 JP 5323867B2 JP 2011009309 A JP2011009309 A JP 2011009309A JP 2011009309 A JP2011009309 A JP 2011009309A JP 5323867 B2 JP5323867 B2 JP 5323867B2

- Authority

- JP

- Japan

- Prior art keywords

- substrate

- wafer

- processed

- holding unit

- holding

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000000758 substrate Substances 0.000 title claims abstract description 188

- 238000000034 method Methods 0.000 title claims description 36

- 238000003860 storage Methods 0.000 title claims description 6

- 230000007246 mechanism Effects 0.000 claims abstract description 60

- 238000012546 transfer Methods 0.000 claims abstract description 46

- 238000013459 approach Methods 0.000 claims abstract description 9

- 238000004140 cleaning Methods 0.000 claims description 140

- 206010040844 Skin exfoliation Diseases 0.000 claims description 82

- 238000012545 processing Methods 0.000 claims description 63

- 238000007689 inspection Methods 0.000 claims description 39

- 230000007723 transport mechanism Effects 0.000 claims description 35

- 239000000853 adhesive Substances 0.000 claims description 20

- 230000001070 adhesive effect Effects 0.000 claims description 20

- 238000012805 post-processing Methods 0.000 claims description 18

- 230000032258 transport Effects 0.000 claims description 15

- 238000000926 separation method Methods 0.000 claims description 5

- 230000005856 abnormality Effects 0.000 claims description 4

- 235000012431 wafers Nutrition 0.000 description 371

- 239000007788 liquid Substances 0.000 description 39

- 238000012423 maintenance Methods 0.000 description 15

- KFZMGEQAYNKOFK-UHFFFAOYSA-N Isopropanol Chemical compound CC(C)O KFZMGEQAYNKOFK-UHFFFAOYSA-N 0.000 description 9

- 238000010438 heat treatment Methods 0.000 description 9

- 238000007517 polishing process Methods 0.000 description 7

- 239000011261 inert gas Substances 0.000 description 6

- 238000005406 washing Methods 0.000 description 6

- 230000007547 defect Effects 0.000 description 5

- 230000010354 integration Effects 0.000 description 4

- 239000004065 semiconductor Substances 0.000 description 4

- 238000012360 testing method Methods 0.000 description 4

- 230000002950 deficient Effects 0.000 description 3

- 230000003028 elevating effect Effects 0.000 description 3

- 238000005516 engineering process Methods 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 238000005336 cracking Methods 0.000 description 2

- 239000012530 fluid Substances 0.000 description 2

- 239000011521 glass Substances 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 230000002093 peripheral effect Effects 0.000 description 2

- 238000006116 polymerization reaction Methods 0.000 description 2

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 2

- 229910010271 silicon carbide Inorganic materials 0.000 description 2

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 229910001873 dinitrogen Inorganic materials 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 238000003475 lamination Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 239000003960 organic solvent Substances 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/677—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for conveying, e.g. between different workstations

- H01L21/67739—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for conveying, e.g. between different workstations into and out of processing chamber

- H01L21/67748—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for conveying, e.g. between different workstations into and out of processing chamber horizontal transfer of a single workpiece

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/67092—Apparatus for mechanical treatment

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/6715—Apparatus for applying a liquid, a resin, an ink or the like

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/677—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for conveying, e.g. between different workstations

- H01L21/67796—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for conveying, e.g. between different workstations with angular orientation of workpieces

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/683—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L21/6838—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping with gripping and holding devices using a vacuum; Bernoulli devices

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/683—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L21/687—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches

- H01L21/68707—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a robot blade, or gripped by a gripper for conveyance

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/11—Methods of delaminating, per se; i.e., separating at bonding face

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/11—Methods of delaminating, per se; i.e., separating at bonding face

- Y10T156/1126—Using direct fluid current against work during delaminating

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/11—Methods of delaminating, per se; i.e., separating at bonding face

- Y10T156/1126—Using direct fluid current against work during delaminating

- Y10T156/1132—Using vacuum directly against work during delaminating

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/11—Methods of delaminating, per se; i.e., separating at bonding face

- Y10T156/1126—Using direct fluid current against work during delaminating

- Y10T156/1137—Using air blast directly against work during delaminating

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/11—Methods of delaminating, per se; i.e., separating at bonding face

- Y10T156/1168—Gripping and pulling work apart during delaminating

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/19—Delaminating means

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/19—Delaminating means

- Y10T156/1928—Differential fluid pressure delaminating means

- Y10T156/1933—Spraying delaminating means [e.g., atomizer, etc.

- Y10T156/1939—Air blasting delaminating means]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/19—Delaminating means

- Y10T156/1928—Differential fluid pressure delaminating means

- Y10T156/1944—Vacuum delaminating means [e.g., vacuum chamber, etc.]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/19—Delaminating means

- Y10T156/195—Delaminating roller means

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Robotics (AREA)

- Container, Conveyance, Adherence, Positioning, Of Wafer (AREA)

- Cleaning Or Drying Semiconductors (AREA)

Description

次に、以上のように構成された剥離システム1を用いて行われる被処理ウェハWと支持ウェハSの剥離処理方法について説明する。図9は、かかる剥離処理の主な工程の例を示すフローチャートである。

本発明はこの例に限らず種々の態様を採りうるものである。本発明は、基板がウェハ以外のFPD(フラットパネルディスプレイ)、フォトマスク用のマスクレチクルなどの他の基板である場合にも適用できる。

2 搬入出ステーション

3 剥離処理ステーション

4 後処理ステーション

5 インターフェイスステーション

6 検査装置

7 搬送ステーション

8 検査後洗浄ステーション

9 ウェハ搬送領域

10 カセット載置台

20 第1の搬送装置

30 剥離装置

31 第1の洗浄装置

32 第2の搬送装置

33 第2の洗浄装置

40 接合面洗浄装置

41 非接合面洗浄装置

42 基板反転装置

50 搬送路

51 搬送機構

100 筐体

110 上部チャック

111 下部チャック

124 加熱機構

141 加熱機構

150 移動機構

190 ポーラスチャック

230 ベルヌーイチャック

250 筐体

251 搬入出口

260 排気口

261 排気装置

262 排気管

270 第1の保持部

271 第2の保持部

272 移動機構

300 制御部

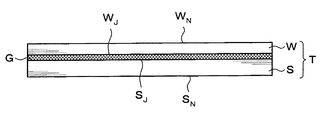

G 接着剤

S 支持ウェハ

T 重合ウェハ

W 被処理ウェハ

Claims (13)

- 基板の表裏面を反転させる基板反転装置であって、

基板の片面を保持する第1の保持部と、

前記第1の保持部に対向して設けられた、基板の片面を保持する第2の保持部と、

少なくとも前記第1の保持部又は前記第2の保持部を相対的に移動させて前記第1の保持部と前記第2の保持部を接近、離隔させる移動機構と、

基板の片面を保持して搬送する搬送機構と、を有し、

前記第1の保持部、前記第2の保持部及び前記搬送機構における基板の保持は、ベルヌーイチャックにより行われることを特徴とする基板反転装置。 - 前記第1の保持部、前記第2の保持部及び前記搬送機構は、基板の片面の全面を保持することを特徴とする、請求項1に記載の基板反転装置。

- 前記搬送機構を水平軸回りに回動させる回動機構を有していることを特徴とする、請求項1または2のいずれかに記載の基板反転装置。

- 被処理基板と支持基板が接着剤で接合された重合基板を、被処理基板と支持基板に剥離する剥離システムであって、

重合基板を被処理基板と支持基板に剥離する剥離装置と、前記剥離装置で剥離された被処理基板を洗浄する第1の洗浄装置と、前記剥離装置で剥離された支持基板を洗浄する第2の洗浄装置と、を備えた剥離処理ステーションと、

前記剥離処理ステーションに対して、被処理基板、支持基板又は重合基板を搬入出する搬入出ステーションと、

前記剥離処理ステーションと前記搬入出ステーションとの間で、被処理基板、支持基板又は重合基板を搬送する搬送ステーションと、

前記剥離処理ステーションと、当該剥離処理ステーションで剥離された被処理基板に所定の後処理を行う後処理ステーションとの間で、被処理基板を搬送するインターフェイスステーションと、

前記インターフェイスステーションに隣接して設けられた、被処理基板を検査する検査装置と、

前記インターフェイスステーションに隣接して設けられた、前記検査装置で検査された基板を洗浄する検査後洗浄ステーションと、

を有し、

前記検査後洗浄ステーションは、被処理基板の接合面を洗浄する接合面洗浄装置と、被処理基板の非接合面を洗浄する非接合面洗浄装置と、被処理基板の裏表面を反転させる基板反転装置を有し、

前記基板反転装置は、

被処理基板の片面を保持する第1の保持部と、

前記第1の保持部に対向して設けられた、被処理基板の片面を保持する第2の保持部と、

少なくとも前記第1の保持部又は前記第2の保持部を相対的に移動させて前記第1の保持部と前記第2の保持部を接近、離隔させる移動機構と、

被処理基板の片面を保持して搬送する搬送機構と、を有し、

前記第1の保持部、前記第2の保持部及び前記搬送機構における被処理基板の保持は、ベルヌーイチャックにより行われることを特徴とする、剥離システム。 - 前記第1の保持部、前記第2の保持部及び前記搬送機構は、基板の片面の全面を保持することを特徴とする、請求項4に記載の剥離システム。

- 前記基板反転装置は、前記搬送機構を水平軸回りに回動させる回動機構を有していることを特徴とする、請求項4または5のいずれかに記載の剥離システム。

- 前記検査装置において被処理基板の接合面の検査を行い、

検査で異常が発見された被処理基板の接合面を、前記接合面洗浄装置で洗浄した後、前記基板反転装置で反転させ、

前記検査装置において、反転させた被処理基板の非接合面の検査を行い、

検査で異常が発見された被処理基板の非接合面を、前記非接合面洗浄装置で洗浄するように、前記基板反転装置を制御する制御部を有することを特徴とする、請求項6に記載の剥離システム。 - 前記接合面洗浄装置及び前記非接合面洗浄装置は、被処理基板を保持するポーラスチャックを有することを特徴とする、請求項4〜7のいずれかに記載の剥離システム。

- 基板反転装置を用いて、基板の裏表面を反転させる基板反転方法であって、

前記基板反転装置は、基板の片面を保持する第1の保持部と、前記第1の保持部に対向して設けられた、基板の片面を保持する第2の保持部と、少なくとも前記第1の保持部又は前記第2の保持部を相対的に移動させて前記第1の保持部と前記第2の保持部を接近、離隔させる移動機構と、基板の片面を保持して搬送する搬送機構と、を有し、

前記第1の保持部、前記第2の保持部及び前記搬送機構における基板の保持は、ベルヌーイチャックにより行われ、

前記基板反転方法は、

前記搬送機構により基板を前記第1の保持部に搬送して前記第1の保持部に当該基板の片面を保持させ、

その後、移動機構により前記第1の保持部と前記第2の保持部を接近させ、基板を第2の保持部に受渡し、

その後、第2の保持部に保持された基板を前記搬送機構により保持することを特徴とする、基板反転方法。 - 前記第1の保持部、前記第2の保持部及び前記搬送機構は、基板の片面の全面を保持することを特徴とする、請求項9に記載の基板反転方法。

- 前記基板反転装置は、前記搬送機構を水平軸回りに回動させる回動機構を有していることを特徴とする、請求項9または10のいずれかに記載の基板反転方法。

- 請求項9〜11のいずかに記載の基板反転方法を基板反転装置によって実行させるために、当該基板反転装置を制御する制御部のコンピュータ上で動作するプログラム。

- 請求項12に記載のプログラムを格納した読み取り可能なコンピュータ記憶媒体。

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011009309A JP5323867B2 (ja) | 2011-01-19 | 2011-01-19 | 基板反転装置、基板反転方法、剥離システム、プログラム及びコンピュータ記憶媒体 |

| PCT/JP2012/050465 WO2012098986A1 (ja) | 2011-01-19 | 2012-01-12 | 基板反転装置、基板反転方法及び剥離システム |

| KR1020137017300A KR101823718B1 (ko) | 2011-01-19 | 2012-01-12 | 기판 반전 장치, 기판 반전 방법 및 박리 시스템 |

| US13/979,549 US8997822B2 (en) | 2011-01-19 | 2012-01-12 | Substrate inverting device, substrate inverting method, and peeling system |

| TW101102051A TWI529778B (zh) | 2011-01-19 | 2012-01-18 | 基板反轉裝置、基板反轉方法、剝離系統及電腦記憶媒體 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011009309A JP5323867B2 (ja) | 2011-01-19 | 2011-01-19 | 基板反転装置、基板反転方法、剥離システム、プログラム及びコンピュータ記憶媒体 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2012151312A JP2012151312A (ja) | 2012-08-09 |

| JP2012151312A5 JP2012151312A5 (ja) | 2012-11-08 |

| JP5323867B2 true JP5323867B2 (ja) | 2013-10-23 |

Family

ID=46515615

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2011009309A Active JP5323867B2 (ja) | 2011-01-19 | 2011-01-19 | 基板反転装置、基板反転方法、剥離システム、プログラム及びコンピュータ記憶媒体 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US8997822B2 (ja) |

| JP (1) | JP5323867B2 (ja) |

| KR (1) | KR101823718B1 (ja) |

| TW (1) | TWI529778B (ja) |

| WO (1) | WO2012098986A1 (ja) |

Families Citing this family (26)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102010048043A1 (de) | 2010-10-15 | 2012-04-19 | Ev Group Gmbh | Vorrichtung und Verfahren zur Prozessierung von Wafern |

| JP6429017B2 (ja) * | 2012-11-30 | 2018-11-28 | 株式会社ニコン | 搬入方法、搬送システム及び露光装置、並びにデバイス製造方法 |

| KR20230055404A (ko) * | 2012-11-30 | 2023-04-25 | 가부시키가이샤 니콘 | 반송 시스템, 노광 장치, 반송 방법, 노광 방법 및 디바이스 제조방법, 및 흡인 장치 |

| JP6188123B2 (ja) | 2012-12-28 | 2017-08-30 | 芝浦メカトロニクス株式会社 | 貼合装置および貼合処理方法 |

| JP6093328B2 (ja) * | 2013-06-13 | 2017-03-08 | 東京エレクトロン株式会社 | 基板処理システム、基板処理方法、プログラム及びコンピュータ記憶媒体 |

| KR102075994B1 (ko) * | 2014-03-25 | 2020-02-12 | 삼성전자주식회사 | 기판 분리 장치 및 기판 분리 시스템 |

| JP6283573B2 (ja) * | 2014-06-03 | 2018-02-21 | 東京エレクトロン株式会社 | 剥離装置、剥離システム、剥離方法、プログラム及びコンピュータ記憶媒体 |

| US9991150B2 (en) | 2014-12-12 | 2018-06-05 | Micro Materials Inc. | Procedure of processing a workpiece and an apparatus designed for the procedure |

| CN104485294A (zh) | 2014-12-12 | 2015-04-01 | 浙江中纳晶微电子科技有限公司 | 一种晶圆临时键合及分离方法 |

| CN104979262B (zh) * | 2015-05-14 | 2020-09-22 | 浙江中纳晶微电子科技有限公司 | 一种晶圆分离的方法 |

| CN106710442B (zh) * | 2015-10-21 | 2021-01-22 | 京东方科技集团股份有限公司 | 背光源分离设备 |

| JP6596342B2 (ja) * | 2016-01-25 | 2019-10-23 | 東京エレクトロン株式会社 | 紫外線処理装置、接合システム、紫外線処理方法、プログラム及びコンピュータ記憶媒体 |

| TWI701708B (zh) * | 2016-02-24 | 2020-08-11 | 德商蘇士微科技印刷術股份有限公司 | 半導體接合設備及相關技術 |

| DE112016006797T5 (de) * | 2016-04-26 | 2019-01-17 | Toshiba Mitsubishi-Electric Industrial Systems Corporation | Schichtaufbringungsvorrichtung |

| CN107665848B (zh) * | 2016-07-29 | 2020-08-25 | 上海微电子装备(集团)股份有限公司 | 一种解键合调平装置及解键合方法 |

| JP6853646B2 (ja) * | 2016-10-04 | 2021-03-31 | 株式会社ディスコ | ロボットハンド及び搬送ロボット |

| WO2018171907A1 (en) * | 2017-03-21 | 2018-09-27 | Applied Materials, Inc. | Apparatus and method for holding a substrate, method for loading a substrate into a vacuum processing module, and system for vacuum processing of a substrate |

| JP7018452B2 (ja) * | 2017-11-22 | 2022-02-10 | 東京エレクトロン株式会社 | 基板処理システム、基板処理方法及びコンピュータ記憶媒体 |

| US10170443B1 (en) * | 2017-11-28 | 2019-01-01 | International Business Machines Corporation | Debonding chips from wafer |

| KR102505213B1 (ko) * | 2017-12-08 | 2023-03-03 | 삼성전자주식회사 | 분리용 전자 장치 및 이의 공정 방법 |

| US10553472B2 (en) * | 2018-06-22 | 2020-02-04 | Jabil Inc. | Apparatus, system and method for providing a bernoulli-based semiconductor wafer pre-aligner |

| CN111483809B (zh) * | 2019-01-28 | 2023-08-18 | 三星显示有限公司 | 基板翻转装置 |

| JP7522572B2 (ja) * | 2020-03-26 | 2024-07-25 | 株式会社Screenホールディングス | 基板処理装置および基板反転方法 |

| JP6836003B1 (ja) * | 2020-08-27 | 2021-02-24 | 信越エンジニアリング株式会社 | ワーク分離装置及びワーク分離方法 |

| CN115706035A (zh) * | 2021-08-12 | 2023-02-17 | 北京北方华创微电子装备有限公司 | 半导体清洗设备及其晶圆翻转装置 |

| CN117645162B (zh) * | 2024-01-29 | 2024-04-12 | 山东澳兴绝缘材料有限公司 | 一种钢板料片分离装置 |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR0165467B1 (ko) | 1995-10-31 | 1999-02-01 | 김광호 | 웨이퍼 디본더 및 이를 이용한 웨이퍼 디본딩법 |

| TW484184B (en) * | 1998-11-06 | 2002-04-21 | Canon Kk | Sample separating apparatus and method, and substrate manufacturing method |

| JP3981241B2 (ja) * | 2000-06-09 | 2007-09-26 | 株式会社ハーモテック | 旋回流形成体および非接触搬送装置 |

| JP2002208625A (ja) * | 2001-01-10 | 2002-07-26 | Matsushita Electric Ind Co Ltd | 半導体ウェハの薄化処理方法 |

| JP4605332B2 (ja) * | 2001-03-07 | 2011-01-05 | 株式会社日立ハイテクノロジーズ | 基板重ね合わせ装置 |

| JP4545996B2 (ja) | 2001-07-03 | 2010-09-15 | 株式会社アイテック | ロボットハンドの駆動装置 |

| JP2004296777A (ja) * | 2003-03-27 | 2004-10-21 | Oki Electric Ind Co Ltd | ワーク吸着装置及びワーク吸着方法 |

| JP2005085882A (ja) | 2003-09-05 | 2005-03-31 | Dainippon Screen Mfg Co Ltd | 基板処理方法および基板処理装置 |

| JP4130167B2 (ja) * | 2003-10-06 | 2008-08-06 | 日東電工株式会社 | 半導体ウエハの剥離方法 |

| JP4401322B2 (ja) * | 2005-04-18 | 2010-01-20 | 日東電工株式会社 | 支持板分離装置およびこれを用いた支持板分離方法 |

| US20090067959A1 (en) * | 2006-02-22 | 2009-03-12 | Nobuyuki Takahashi | Substrate processing apparatus, substrate transfer apparatus, substrate clamp apparatus, and chemical liquid treatment apparatus |

| JP2008124091A (ja) * | 2006-11-09 | 2008-05-29 | Fuji Electric Device Technology Co Ltd | 半導体装置の処理装置および処理方法 |

| JP4616873B2 (ja) * | 2007-09-28 | 2011-01-19 | 東京エレクトロン株式会社 | 半導体製造装置、基板保持方法及びプログラム |

| JP2009088304A (ja) * | 2007-10-01 | 2009-04-23 | Renesas Technology Corp | 半導体装置の製造方法 |

| JP5487740B2 (ja) * | 2009-06-10 | 2014-05-07 | 株式会社ニコン | 重ね合わせ装置、位置合わせ装置、基板貼り合わせ装置および重ね合わせ方法 |

| US20110123913A1 (en) * | 2009-11-19 | 2011-05-26 | Nikon Corporation | Exposure apparatus, exposing method, and device fabricating method |

| JP5552462B2 (ja) * | 2010-08-23 | 2014-07-16 | 東京エレクトロン株式会社 | 剥離システム、剥離方法、プログラム及びコンピュータ記憶媒体 |

| JP5374462B2 (ja) * | 2010-08-23 | 2013-12-25 | 東京エレクトロン株式会社 | 剥離システム、剥離方法、プログラム及びコンピュータ記憶媒体 |

| JP5455987B2 (ja) * | 2010-08-23 | 2014-03-26 | 東京エレクトロン株式会社 | 剥離装置、剥離システム、剥離方法、プログラム及びコンピュータ記憶媒体 |

-

2011

- 2011-01-19 JP JP2011009309A patent/JP5323867B2/ja active Active

-

2012

- 2012-01-12 KR KR1020137017300A patent/KR101823718B1/ko active IP Right Grant

- 2012-01-12 WO PCT/JP2012/050465 patent/WO2012098986A1/ja active Application Filing

- 2012-01-12 US US13/979,549 patent/US8997822B2/en active Active

- 2012-01-18 TW TW101102051A patent/TWI529778B/zh active

Also Published As

| Publication number | Publication date |

|---|---|

| KR101823718B1 (ko) | 2018-01-30 |

| TWI529778B (zh) | 2016-04-11 |

| US8997822B2 (en) | 2015-04-07 |

| WO2012098986A1 (ja) | 2012-07-26 |

| JP2012151312A (ja) | 2012-08-09 |

| TW201246271A (en) | 2012-11-16 |

| US20130292062A1 (en) | 2013-11-07 |

| KR20140021990A (ko) | 2014-02-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5323867B2 (ja) | 基板反転装置、基板反転方法、剥離システム、プログラム及びコンピュータ記憶媒体 | |

| JP5455987B2 (ja) | 剥離装置、剥離システム、剥離方法、プログラム及びコンピュータ記憶媒体 | |

| JP5379171B2 (ja) | 接合システム、基板処理システム、接合方法、プログラム及びコンピュータ記憶媒体 | |

| JP5552462B2 (ja) | 剥離システム、剥離方法、プログラム及びコンピュータ記憶媒体 | |

| JP5829171B2 (ja) | 剥離システム、剥離方法、プログラム及びコンピュータ記憶媒体 | |

| JP5478565B2 (ja) | 接合システム | |

| JP6158721B2 (ja) | 洗浄装置、剥離システム、洗浄方法、プログラム及びコンピュータ記憶媒体 | |

| JP5538282B2 (ja) | 接合装置、接合方法、プログラム及びコンピュータ記憶媒体 | |

| JP5374462B2 (ja) | 剥離システム、剥離方法、プログラム及びコンピュータ記憶媒体 | |

| KR101805964B1 (ko) | 박리 시스템, 박리 방법 및 컴퓨터 기억 매체 | |

| JP5913053B2 (ja) | 剥離装置、剥離システム、剥離方法、プログラム及びコンピュータ記憶媒体 | |

| WO2012176629A1 (ja) | 剥離システム、剥離方法、及びコンピュータ記憶媒体 | |

| JP5580805B2 (ja) | 剥離装置、剥離システム、剥離方法、プログラム及びコンピュータ記憶媒体 | |

| JP5777549B2 (ja) | 剥離装置、剥離システム、剥離方法、プログラム及びコンピュータ記憶媒体 | |

| JP5717614B2 (ja) | 剥離装置、剥離システム、剥離方法、プログラム及びコンピュータ記憶媒体 | |

| JP5717803B2 (ja) | 剥離システム、剥離方法、プログラム及びコンピュータ記憶媒体 | |

| JP6025759B2 (ja) | 剥離システム | |

| JP6466217B2 (ja) | 剥離装置及び剥離システム | |

| JP5552559B2 (ja) | 剥離システム、剥離方法、プログラム及びコンピュータ記憶媒体 | |

| JP2015109360A (ja) | 基板保持機構及び剥離システム |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120924 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20120924 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130709 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130717 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5323867 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |