JP5045461B2 - 車両用ハブユニット - Google Patents

車両用ハブユニット Download PDFInfo

- Publication number

- JP5045461B2 JP5045461B2 JP2008018717A JP2008018717A JP5045461B2 JP 5045461 B2 JP5045461 B2 JP 5045461B2 JP 2008018717 A JP2008018717 A JP 2008018717A JP 2008018717 A JP2008018717 A JP 2008018717A JP 5045461 B2 JP5045461 B2 JP 5045461B2

- Authority

- JP

- Japan

- Prior art keywords

- hardened layer

- outer ring

- hub unit

- ring raceway

- raceway

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/30—Parts of ball or roller bearings

- F16C33/58—Raceways; Race rings

- F16C33/64—Special methods of manufacture

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C19/00—Bearings with rolling contact, for exclusively rotary movement

- F16C19/22—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings

- F16C19/34—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings for both radial and axial load

- F16C19/38—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings for both radial and axial load with two or more rows of rollers

- F16C19/383—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings for both radial and axial load with two or more rows of rollers with tapered rollers, i.e. rollers having essentially the shape of a truncated cone

- F16C19/385—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings for both radial and axial load with two or more rows of rollers with tapered rollers, i.e. rollers having essentially the shape of a truncated cone with two rows, i.e. double-row tapered roller bearings

- F16C19/386—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings for both radial and axial load with two or more rows of rollers with tapered rollers, i.e. rollers having essentially the shape of a truncated cone with two rows, i.e. double-row tapered roller bearings in O-arrangement

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/30—Parts of ball or roller bearings

- F16C33/58—Raceways; Race rings

- F16C33/583—Details of specific parts of races

- F16C33/585—Details of specific parts of races of raceways, e.g. ribs to guide the rollers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C2240/00—Specified values or numerical ranges of parameters; Relations between them

- F16C2240/40—Linear dimensions, e.g. length, radius, thickness, gap

- F16C2240/60—Thickness, e.g. thickness of coatings

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C2326/00—Articles relating to transporting

- F16C2326/01—Parts of vehicles in general

- F16C2326/02—Wheel hubs or castors

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/30—Parts of ball or roller bearings

- F16C33/58—Raceways; Race rings

- F16C33/581—Raceways; Race rings integral with other parts, e.g. with housings or machine elements such as shafts or gear wheels

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49636—Process for making bearing or component thereof

- Y10T29/49643—Rotary bearing

- Y10T29/49679—Anti-friction bearing or component thereof

- Y10T29/49682—Assembling of race and rolling anti-friction members

- Y10T29/49684—Assembling of race and rolling anti-friction members with race making

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Rolling Contact Bearings (AREA)

Description

そこで、軸受寿命を確保するべく、フランジ部が設けられたハブホイールの内輪軌道に、高周波焼き入れによる硬化層を形成したものが提案されている(例えば、特許文献1参照)。

なお、ここでいう硬化層深さとは、軌道の軸方向所定位置において、軌道面に対して垂線を引き、その垂線上にある硬化層の底面と軌道面との間の距離をいう。また、転がり接触域とは、軌道が転動体と転がり接触し得る範囲をいう。

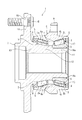

図1は、本発明の実施形態にかかるハブユニット1を示す部分断面図であり、図2は、外輪軌道を示す部分拡大図である。なお、図1の左右方向がハブユニット1の軸方向といい、図1の左側を軸方向外側、右側を軸方向内側という。

なお、図1に示したハブユニット1は、転動体6が円錐ころのものであるが、円錐ころの代わりに玉のものであってもよい。

また、この外輪5には、操舵機構のナックル(図示せず)を固定するためのナックル用フランジ9が設けられている。このナックル用フランジ9は、外輪5の外周面から径外方向に延びるように設けられている。

なお、硬化層Sは、内輪軌道2a,2bのみに形成されてもよく、内輪軌道2a,2bと外輪軌道4a,4bとの両方に形成されてもよい。また、ここでいう転がり接触域とは、軌道が転動体と転がり接触し得る範囲をいう。

また、ハブホイール3には、タイヤのホイールやブレーキディスクを取り付けるためのフランジ部14が設けられている。このフランジ部14は、大径部13の外周面から径外方向に延びるように設けられている。また、フランジ部14には、複数の貫通孔15が形成されており、これらの貫通孔15には、ハブボルトBが圧入によって固定されている。

なお、ここでいう硬化層深さHとは、軌道の軸方向所定位置において、当該軌道に対して垂線を引き、その垂線上にある硬化層の底面と軌道面との間の距離をいう。

この硬化層Sは、高周波電流による誘導加熱作用で外輪軌道4a,4bを加熱する焼入れ工程と、温度を150〜200℃の範囲で行う焼き戻し工程とを有する熱処理方法で形成するとよい。

また、硬化層深さHを小さくすることで、外輪5が受ける熱影響を軽減することができる。このため、外輪5の熱による歪みが抑制され、外輪5の回転精度が向上する。従って、外輪5の回転が安定し、ハブユニット1の寿命が向上する。

例えば、フランジ部14は、外方部材5の外周面に設けられてもよい。

2a 内輪軌道

2b 内輪軌道

3 ハブホイール(内方部材)

4a 外輪軌道

4b 外輪軌道

5 外輪(外方部材)

6 転動体

H 硬化層深さ

S 硬化層

Claims (1)

- 外周面に内輪軌道を有する内方部材と、内周面に外輪軌道を有する外方部材と、これらの内輪軌道と外輪軌道との間に転動自在に設けられた複数の転動体とを備えている車両用ハブユニットにおいて、

前記外輪軌道または内輪軌道の少なくとも一方の転がり接触域に、高周波焼き入れによる硬化層が形成され、その硬化層の軸方向両端部から1mm内方位置での硬化層深さが1.5〜1.9mmであることを特徴とする車両用ハブユニット。

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008018717A JP5045461B2 (ja) | 2008-01-30 | 2008-01-30 | 車両用ハブユニット |

| US12/320,572 US8162545B2 (en) | 2008-01-30 | 2009-01-29 | Hub unit |

| EP09001265A EP2085249B1 (en) | 2008-01-30 | 2009-01-29 | Hub unit |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008018717A JP5045461B2 (ja) | 2008-01-30 | 2008-01-30 | 車両用ハブユニット |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2009180264A JP2009180264A (ja) | 2009-08-13 |

| JP5045461B2 true JP5045461B2 (ja) | 2012-10-10 |

Family

ID=40600039

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008018717A Expired - Fee Related JP5045461B2 (ja) | 2008-01-30 | 2008-01-30 | 車両用ハブユニット |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US8162545B2 (ja) |

| EP (1) | EP2085249B1 (ja) |

| JP (1) | JP5045461B2 (ja) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5776251B2 (ja) * | 2011-03-24 | 2015-09-09 | 株式会社ジェイテクト | 車両用軸受装置 |

| JP2017082945A (ja) * | 2015-10-29 | 2017-05-18 | Ntn株式会社 | 複列円すいころ軸受、軌道輪および複列円すいころ軸受の製造方法 |

| JP6627473B2 (ja) * | 2015-12-10 | 2020-01-08 | 株式会社ジェイテクト | 変速装置 |

| DE102016218094A1 (de) | 2016-09-21 | 2018-03-22 | Continental Teves Ag & Co. Ohg | Elektrohydraulisches Kraftfahrzeugsteuergerät |

| DE102016218095A1 (de) | 2016-09-21 | 2018-03-22 | Continental Teves Ag & Co. Ohg | Elektrohydraulisches Kraftfahrzeugsteuergerät |

| JP6448693B2 (ja) * | 2017-03-16 | 2019-01-09 | Ntn株式会社 | 車輪用軸受装置 |

| JP2019073145A (ja) * | 2017-10-16 | 2019-05-16 | 日本精工株式会社 | ハブユニット軸受 |

Family Cites Families (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS60141827A (ja) | 1983-12-28 | 1985-07-26 | Denki Kogyo Kk | 高周波誘導加熱方法 |

| JPH1151064A (ja) | 1997-08-07 | 1999-02-23 | Ntn Corp | ハブユニット軸受 |

| US6481898B1 (en) * | 1998-01-20 | 2002-11-19 | Nsk Ltd. | Ball bearing |

| US6287009B1 (en) * | 1998-03-06 | 2001-09-11 | Nsk Ltd. | Rolling bearing unit with rotation speed detection instrument for use in cars and method for working outer race for use in this bearing unit |

| US6224266B1 (en) * | 1998-09-18 | 2001-05-01 | Ntn Corporation | Wheel bearing device |

| US6328477B1 (en) * | 1998-11-27 | 2001-12-11 | Ntn Corporation | Tapered roller bearings and gear shaft support devices |

| JP2000211310A (ja) * | 1999-01-21 | 2000-08-02 | Ntn Corp | 車輪の支持構造 |

| JP4282191B2 (ja) | 1999-12-24 | 2009-06-17 | Ntn株式会社 | 車輪軸受装置 |

| JP4306905B2 (ja) | 1999-12-28 | 2009-08-05 | Ntn株式会社 | 車輪軸受装置 |

| US6575637B1 (en) | 1999-09-10 | 2003-06-10 | Ntn Corporation | Brake rotor and wheel bearing assembly |

| DE60131043T2 (de) * | 2000-03-03 | 2008-10-30 | Jtekt Corp. | Lagervorrichtung |

| JP2001294005A (ja) * | 2000-04-14 | 2001-10-23 | Ntn Corp | 車輪軸受装置 |

| JP4193344B2 (ja) | 2000-08-22 | 2008-12-10 | 日本精工株式会社 | 車輪用駆動ユニット |

| EP2030807B1 (en) | 2000-09-20 | 2012-08-08 | NTN Corporation | Wheel bearing device |

| JP4182171B2 (ja) * | 2003-04-09 | 2008-11-19 | 株式会社ジェイテクト | 複列円筒ころ軸受を製造する方法 |

| JP4425652B2 (ja) | 2004-01-27 | 2010-03-03 | Ntn株式会社 | 車輪軸受装置及びその製造方法 |

| JP2006137297A (ja) * | 2004-11-12 | 2006-06-01 | Ntn Corp | 車輪用軸受装置 |

| JP4812376B2 (ja) | 2005-09-09 | 2011-11-09 | Ntn株式会社 | 車輪用軸受装置の製造方法 |

| JP2007285424A (ja) * | 2006-04-18 | 2007-11-01 | Ntn Corp | 車輪用軸受装置およびその製造方法 |

| WO2007125646A1 (ja) | 2006-04-25 | 2007-11-08 | Ntn Corporation | 車輪用軸受装置 |

| JP2007303587A (ja) * | 2006-05-12 | 2007-11-22 | Nsk Ltd | ハブユニット軸受の内輪およびその製造方法 |

| JP5125144B2 (ja) * | 2007-02-23 | 2013-01-23 | 株式会社ジェイテクト | 車軸用軸受装置およびその製造方法 |

| EP1961584B1 (en) * | 2007-02-23 | 2010-11-10 | NTN Corporation | Bearing apparatus for wheel |

-

2008

- 2008-01-30 JP JP2008018717A patent/JP5045461B2/ja not_active Expired - Fee Related

-

2009

- 2009-01-29 EP EP09001265A patent/EP2085249B1/en not_active Not-in-force

- 2009-01-29 US US12/320,572 patent/US8162545B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| US8162545B2 (en) | 2012-04-24 |

| US20090189437A1 (en) | 2009-07-30 |

| EP2085249B1 (en) | 2013-01-02 |

| JP2009180264A (ja) | 2009-08-13 |

| EP2085249A1 (en) | 2009-08-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5045461B2 (ja) | 車両用ハブユニット | |

| JP5183358B2 (ja) | 車輪用軸受装置 | |

| CN101512171B (zh) | 用于车轮支撑的滚动轴承单元 | |

| JP2005188599A (ja) | 車輪用軸受装置 | |

| JP2013159137A (ja) | 車輪用軸受装置 | |

| JP2006036112A (ja) | 車輪用軸受装置 | |

| JP2005096617A (ja) | 車輪用軸受装置 | |

| JP2006137297A (ja) | 車輪用軸受装置 | |

| JP3917992B2 (ja) | 車輪用軸受装置 | |

| JP2006329320A (ja) | 車輪用軸受装置 | |

| JP6167836B2 (ja) | 車輪支持用ハブユニット | |

| JP2008296621A (ja) | 車輪用軸受装置 | |

| JP4797896B2 (ja) | 車輪支持用転がり軸受ユニット | |

| JP4494128B2 (ja) | 車両用軸受装置 | |

| JP2012081817A (ja) | 車輪用軸受装置 | |

| JP2007147078A (ja) | 車輪用軸受装置 | |

| JP2009255644A (ja) | 車輪用軸受装置 | |

| JP2005119383A (ja) | 車輪用軸受装置 | |

| JP2018112225A (ja) | 転がり軸受ユニット | |

| JP4471283B2 (ja) | 車輪用軸受装置 | |

| JP3902391B2 (ja) | 駆動車輪用軸受装置 | |

| JP2007331560A (ja) | 車輪用軸受装置およびその製造方法 | |

| JP2023055544A (ja) | 車輪支持用転がり軸受ユニットの外輪の製造方法及び車輪支持用転がり軸受ユニット | |

| JP4978508B2 (ja) | 転がり軸受ユニット | |

| JP2015124847A (ja) | 車輪支持用転がり軸受ユニット |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20101227 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20111025 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120214 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120216 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120619 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120702 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150727 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5045461 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |