JP2011507719A - ゆがみデータからのフィードバックを用いたナノトポグラフィーの制御及び最適化 - Google Patents

ゆがみデータからのフィードバックを用いたナノトポグラフィーの制御及び最適化 Download PDFInfo

- Publication number

- JP2011507719A JP2011507719A JP2010540928A JP2010540928A JP2011507719A JP 2011507719 A JP2011507719 A JP 2011507719A JP 2010540928 A JP2010540928 A JP 2010540928A JP 2010540928 A JP2010540928 A JP 2010540928A JP 2011507719 A JP2011507719 A JP 2011507719A

- Authority

- JP

- Japan

- Prior art keywords

- wafer

- nanotopography

- ground

- double side

- grinding

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000005457 optimization Methods 0.000 title description 11

- 238000000034 method Methods 0.000 claims description 57

- 238000005259 measurement Methods 0.000 claims description 35

- 238000005498 polishing Methods 0.000 claims description 17

- 239000004065 semiconductor Substances 0.000 claims description 14

- 238000012545 processing Methods 0.000 claims description 11

- 238000005530 etching Methods 0.000 claims description 5

- 238000001914 filtration Methods 0.000 claims 1

- 235000012431 wafers Nutrition 0.000 description 209

- 230000006870 function Effects 0.000 description 16

- 230000002706 hydrostatic effect Effects 0.000 description 16

- 238000003860 storage Methods 0.000 description 12

- 239000012530 fluid Substances 0.000 description 9

- 230000015556 catabolic process Effects 0.000 description 6

- 238000006731 degradation reaction Methods 0.000 description 6

- 230000007547 defect Effects 0.000 description 5

- 238000010586 diagram Methods 0.000 description 4

- 238000003672 processing method Methods 0.000 description 4

- 230000004888 barrier function Effects 0.000 description 3

- 238000005516 engineering process Methods 0.000 description 3

- 238000002347 injection Methods 0.000 description 2

- 239000007924 injection Substances 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 238000003908 quality control method Methods 0.000 description 2

- 238000012935 Averaging Methods 0.000 description 1

- 238000000149 argon plasma sintering Methods 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 230000001934 delay Effects 0.000 description 1

- 238000011143 downstream manufacturing Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 238000005305 interferometry Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 230000010363 phase shift Effects 0.000 description 1

- 238000007517 polishing process Methods 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 238000004441 surface measurement Methods 0.000 description 1

- 238000012876 topography Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

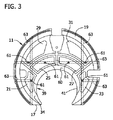

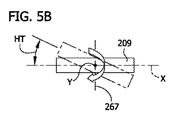

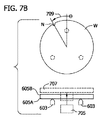

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/27—Work carriers

- B24B37/28—Work carriers for double side lapping of plane surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/005—Control means for lapping machines or devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B51/00—Arrangements for automatic control of a series of individual steps in grinding a workpiece

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B7/00—Machines or devices designed for grinding plane surfaces on work, including polishing plane glass surfaces; Accessories therefor

- B24B7/20—Machines or devices designed for grinding plane surfaces on work, including polishing plane glass surfaces; Accessories therefor characterised by a special design with respect to properties of the material of non-metallic articles to be ground

- B24B7/22—Machines or devices designed for grinding plane surfaces on work, including polishing plane glass surfaces; Accessories therefor characterised by a special design with respect to properties of the material of non-metallic articles to be ground for grinding inorganic material, e.g. stone, ceramics, porcelain

- B24B7/228—Machines or devices designed for grinding plane surfaces on work, including polishing plane glass surfaces; Accessories therefor characterised by a special design with respect to properties of the material of non-metallic articles to be ground for grinding inorganic material, e.g. stone, ceramics, porcelain for grinding thin, brittle parts, e.g. semiconductors, wafers

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Ceramic Engineering (AREA)

- Inorganic Chemistry (AREA)

- Mechanical Treatment Of Semiconductor (AREA)

- Constituent Portions Of Griding Lathes, Driving, Sensing And Control (AREA)

- Grinding Of Cylindrical And Plane Surfaces (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/967,743 US7930058B2 (en) | 2006-01-30 | 2007-12-31 | Nanotopography control and optimization using feedback from warp data |

| PCT/US2008/088452 WO2009088832A1 (en) | 2007-12-31 | 2008-12-29 | Nanotopography control and optimization using feedback from warp data |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2011507719A true JP2011507719A (ja) | 2011-03-10 |

| JP2011507719A5 JP2011507719A5 (enExample) | 2011-05-26 |

Family

ID=40538746

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2010540928A Pending JP2011507719A (ja) | 2007-12-31 | 2008-12-29 | ゆがみデータからのフィードバックを用いたナノトポグラフィーの制御及び最適化 |

Country Status (7)

| Country | Link |

|---|---|

| US (2) | US7930058B2 (enExample) |

| EP (1) | EP2225070B1 (enExample) |

| JP (1) | JP2011507719A (enExample) |

| KR (1) | KR20100110803A (enExample) |

| CN (1) | CN101909817A (enExample) |

| TW (1) | TWI446992B (enExample) |

| WO (1) | WO2009088832A1 (enExample) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20150084764A (ko) * | 2012-11-13 | 2015-07-22 | 신에쯔 한도타이 가부시키가이샤 | 양면 연마 방법 |

| JP2016505214A (ja) * | 2012-12-28 | 2016-02-18 | サンエディソン・セミコンダクター・リミテッドSunEdison Semiconductor Limited | エピタキシャル後反りの予測および制御方法 |

| JP2019067952A (ja) * | 2017-10-02 | 2019-04-25 | 株式会社Sumco | 半導体ウェーハの評価方法および該方法を用いた半導体ウェーハの製造方法 |

| JP2023513276A (ja) * | 2020-02-10 | 2023-03-30 | グローバルウェーハズ カンパニー リミテッド | 強化されたウエハ製造のためのシステムおよび方法 |

Families Citing this family (30)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2005095054A1 (en) * | 2004-03-19 | 2005-10-13 | Memc Electronic Materials, Inc. | Wafer clamping device for a double side grinder |

| US7544112B1 (en) * | 2006-12-13 | 2009-06-09 | Huffman Corporation | Method and apparatus for removing coatings from a substrate using multiple sequential steps |

| US8221199B2 (en) * | 2007-01-11 | 2012-07-17 | Smith Abrasives, Inc | Abrasive sharpener |

| DE102007056628B4 (de) * | 2007-03-19 | 2019-03-14 | Siltronic Ag | Verfahren und Vorrichtung zum gleichzeitigen Schleifen mehrerer Halbleiterscheiben |

| US8214178B2 (en) * | 2008-06-04 | 2012-07-03 | Vibration Technologies, Llc | Method and system for optimizing the vibrational characteristics of a structure |

| US8360817B2 (en) * | 2009-04-01 | 2013-01-29 | Ebara Corporation | Polishing apparatus and polishing method |

| DE102009024125B4 (de) * | 2009-06-06 | 2023-07-27 | Lapmaster Wolters Gmbh | Verfahren zum Bearbeiten von flachen Werkstücken |

| US8815110B2 (en) * | 2009-09-16 | 2014-08-26 | Cabot Microelectronics Corporation | Composition and method for polishing bulk silicon |

| US8883034B2 (en) * | 2009-09-16 | 2014-11-11 | Brian Reiss | Composition and method for polishing bulk silicon |

| US8697576B2 (en) * | 2009-09-16 | 2014-04-15 | Cabot Microelectronics Corporation | Composition and method for polishing polysilicon |

| JP5504901B2 (ja) | 2010-01-13 | 2014-05-28 | 株式会社Sumco | 研磨パッドの形状修正方法 |

| US8712575B2 (en) * | 2010-03-26 | 2014-04-29 | Memc Electronic Materials, Inc. | Hydrostatic pad pressure modulation in a simultaneous double side wafer grinder |

| JP5862492B2 (ja) * | 2012-07-09 | 2016-02-16 | 信越半導体株式会社 | 半導体ウェーハの評価方法及び製造方法 |

| US9881783B2 (en) * | 2013-02-19 | 2018-01-30 | Sumco Corporation | Method for processing semiconductor wafer |

| US9490186B2 (en) * | 2013-11-27 | 2016-11-08 | Applied Materials, Inc. | Limiting adjustment of polishing rates during substrate polishing |

| US9375824B2 (en) * | 2013-11-27 | 2016-06-28 | Applied Materials, Inc. | Adjustment of polishing rates during substrate polishing with predictive filters |

| CN104108062B (zh) * | 2014-06-17 | 2017-06-06 | 北京石晶光电科技股份有限公司济源分公司 | 一种超薄晶片纳米级抛光方法 |

| JP6447472B2 (ja) * | 2015-11-26 | 2019-01-09 | 株式会社Sumco | ウェーハ研磨方法 |

| TWI779986B (zh) * | 2016-11-30 | 2022-10-01 | 美商應用材料股份有限公司 | 使用神經網路的光譜監測 |

| JP6436255B1 (ja) * | 2018-02-27 | 2018-12-12 | 株式会社Sumco | シリコンウェーハの反り量の予測方法およびシリコンウェーハの製造方法 |

| CN108493116A (zh) * | 2018-03-13 | 2018-09-04 | 英特尔产品(成都)有限公司 | 置球模块的制造方法及该方法制造的置球模块 |

| DE102018221922A1 (de) | 2018-12-17 | 2020-06-18 | Siltronic Ag | Verfahren zur Herstellung von Halbleiterscheiben mittels einer Drahtsäge, Drahtsäge und Halbleiterscheibe aus einkristallinem Silizium |

| CN110193776B (zh) * | 2019-06-11 | 2020-07-03 | 英特尔半导体(大连)有限公司 | 晶圆抛光的抛光压力控制方法、装置和设备 |

| TWI763112B (zh) * | 2020-04-22 | 2022-05-01 | 財團法人工業技術研究院 | 研磨拋光模擬方法、系統及研磨拋光製程轉移方法 |

| US12174596B2 (en) * | 2020-04-22 | 2024-12-24 | Industrial Technology Research Institute | Grinding and polishing simulation method and system and grinding and polishing process transferring method |

| CN112071765B (zh) * | 2020-08-18 | 2024-07-30 | 中环领先(徐州)半导体材料有限公司 | 确定晶圆加工参数的方法和晶圆的加工方法 |

| CN112259442B (zh) * | 2020-09-11 | 2024-05-24 | 中环领先(徐州)半导体材料有限公司 | 晶圆双面减薄的方法和装置、存储介质 |

| US12386340B2 (en) | 2022-02-25 | 2025-08-12 | Globalwafers Co., Ltd. | Systems and methods for generating post-polishing topography for enhanced wafer manufacturing |

| CN115194639B (zh) * | 2022-06-30 | 2023-12-29 | 江西兆驰半导体有限公司 | 一种蓝宝石衬底片切割后的分类加工方法及外延片 |

| CN116175397A (zh) * | 2022-12-13 | 2023-05-30 | 西安奕斯伟材料科技有限公司 | 一种用于研磨硅片的设备和方法 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2007130708A1 (en) * | 2006-01-30 | 2007-11-15 | Memc Electronic Materials, Inc. | Double side wafer grinder and methods for assessing workpiece nanotopology |

Family Cites Families (69)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2448751A (en) | 1946-08-10 | 1948-09-07 | Volkel Bros Machine Works | Record edging lathe |

| KR920002268A (ko) * | 1990-07-17 | 1992-02-28 | 유끼노리 가까즈 | 인텔리젠트가공장치 |

| US5402354A (en) * | 1990-10-12 | 1995-03-28 | Mitsubishi Jukogyo Kabushiki Kaisha | Control apparatus and control method for machine tools using fuzzy reasoning |

| JPH0577159A (ja) * | 1991-09-18 | 1993-03-30 | Mitsubishi Heavy Ind Ltd | 研削盤の被削材たわみ量演算方法 |

| US5700180A (en) * | 1993-08-25 | 1997-12-23 | Micron Technology, Inc. | System for real-time control of semiconductor wafer polishing |

| JP3386548B2 (ja) * | 1994-01-31 | 2003-03-17 | トヨタ自動車株式会社 | フィードバック式加工条件補正装置 |

| JP3702496B2 (ja) * | 1995-07-10 | 2005-10-05 | 三菱電機株式会社 | 数値制御装置を用いた加工方法 |

| KR100227924B1 (ko) | 1995-07-28 | 1999-11-01 | 가이데 히사오 | 반도체 웨이퍼 제조방법, 그 방법에 사용되는 연삭방법 및 이에 사용되는 장치 |

| JP3620554B2 (ja) * | 1996-03-25 | 2005-02-16 | 信越半導体株式会社 | 半導体ウェーハ製造方法 |

| US5989108A (en) | 1996-09-09 | 1999-11-23 | Koyo Machine Industries Co., Ltd. | Double side grinding apparatus for flat disklike work |

| US6594542B1 (en) * | 1996-10-04 | 2003-07-15 | Applied Materials, Inc. | Method and system for controlling chemical mechanical polishing thickness removal |

| US5816895A (en) | 1997-01-17 | 1998-10-06 | Tokyo Seimitsu Co., Ltd. | Surface grinding method and apparatus |

| EP0875809A3 (en) * | 1997-04-28 | 2000-09-06 | Seiko Seiki Kabushiki Kaisha | CAD/CAM apparatus and machining apparatus |

| JPH11198009A (ja) * | 1998-01-13 | 1999-07-27 | Koyo Mach Ind Co Ltd | 薄板円板状ワークの両面研削装置および断面形状測定装置 |

| JPH11254282A (ja) | 1998-03-04 | 1999-09-21 | Super Silicon Kenkyusho:Kk | 両頭研削装置及び両頭研磨装置 |

| JP2000015557A (ja) * | 1998-04-27 | 2000-01-18 | Ebara Corp | 研磨装置 |

| JP3292835B2 (ja) * | 1998-05-06 | 2002-06-17 | 信越半導体株式会社 | 薄板ワークの平面研削方法およびその研削装置 |

| US6875085B2 (en) | 1998-11-06 | 2005-04-05 | Mosel Vitelic, Inc. | Polishing system including a hydrostatic fluid bearing support |

| US6428388B2 (en) * | 1998-11-06 | 2002-08-06 | Beaver Creek Concepts Inc. | Finishing element with finishing aids |

| JP3951496B2 (ja) | 1999-03-30 | 2007-08-01 | 光洋機械工業株式会社 | 薄板円板状ワークの両面研削装置 |

| JP3969956B2 (ja) | 1999-05-07 | 2007-09-05 | 信越半導体株式会社 | 両面同時研削方法および両面同時研削盤並びに両面同時ラップ方法および両面同時ラップ盤 |

| US6198294B1 (en) * | 1999-05-17 | 2001-03-06 | Vlsi Technology, Inc. | In-situ backgrind wafer thickness monitor |

| WO2001021356A1 (fr) | 1999-09-24 | 2001-03-29 | Shin-Etsu Handotai Co., Ltd. | Procede et dispositif de meulage des deux faces d'un disque fin |

| US6479386B1 (en) | 2000-02-16 | 2002-11-12 | Memc Electronic Materials, Inc. | Process for reducing surface variations for polished wafer |

| US6368881B1 (en) * | 2000-02-29 | 2002-04-09 | International Business Machines Corporation | Wafer thickness control during backside grind |

| US20010024877A1 (en) * | 2000-03-17 | 2001-09-27 | Krishna Vepa | Cluster tool systems and methods for processing wafers |

| US20020052169A1 (en) * | 2000-03-17 | 2002-05-02 | Krishna Vepa | Systems and methods to significantly reduce the grinding marks in surface grinding of semiconductor wafers |

| DE10023002B4 (de) * | 2000-05-11 | 2006-10-26 | Siltronic Ag | Satz von Läuferscheiben sowie dessen Verwendung |

| US20020086625A1 (en) * | 2000-05-23 | 2002-07-04 | Wafer Solutions, Inc. | Vacuum mount wafer polishing methods and apparatus |

| US6556884B1 (en) * | 2000-06-16 | 2003-04-29 | Advanced Micro Devices, Inc. | Method and apparatus for interfacing a statistical process control system with a manufacturing process control framework |

| US7332437B2 (en) * | 2000-06-29 | 2008-02-19 | Shin-Etsu Handotai Co., Ltd. | Method for processing semiconductor wafer and semiconductor wafer |

| EP1307321A2 (en) | 2000-08-07 | 2003-05-07 | MEMC Electronic Materials, Inc. | Method for processing a semiconductor wafer using double-side polishing |

| US6709981B2 (en) * | 2000-08-16 | 2004-03-23 | Memc Electronic Materials, Inc. | Method and apparatus for processing a semiconductor wafer using novel final polishing method |

| US6556876B1 (en) * | 2000-10-12 | 2003-04-29 | National Semiconductor Corporation | Hybrid fuzzy closed-loop sub-micron critical dimension control in wafer manufacturing |

| GB2368971B (en) * | 2000-11-11 | 2005-01-05 | Pure Wafer Ltd | Process for Reclaimimg Wafer Substrates |

| US6672943B2 (en) * | 2001-01-26 | 2004-01-06 | Wafer Solutions, Inc. | Eccentric abrasive wheel for wafer processing |

| JP2002307303A (ja) | 2001-04-10 | 2002-10-23 | Koyo Mach Ind Co Ltd | 薄板円板状ワークの両面研削方法および装置 |

| JP2002343772A (ja) * | 2001-05-18 | 2002-11-29 | Speedfam Co Ltd | 局所プラズマエッチング方法 |

| US20020185053A1 (en) | 2001-05-24 | 2002-12-12 | Lu Fei | Method for calibrating nanotopographic measuring equipment |

| US6594024B1 (en) * | 2001-06-21 | 2003-07-15 | Advanced Micro Devices, Inc. | Monitor CMP process using scatterometry |

| JP4876345B2 (ja) * | 2001-08-22 | 2012-02-15 | 株式会社ニコン | シミュレーション方法及び装置、並びに、これを用いた研磨方法及び装置 |

| DE10142400B4 (de) | 2001-08-30 | 2009-09-03 | Siltronic Ag | Halbleiterscheibe mit verbesserter lokaler Ebenheit und Verfahren zu deren Herstellung |

| US6914000B2 (en) * | 2001-09-04 | 2005-07-05 | Matsushita Electric Industrial Co., Ltd. | Polishing method, polishing system and process-managing system |

| JP3995926B2 (ja) | 2001-09-18 | 2007-10-24 | 株式会社富士通長野システムエンジニアリング | 構造解析プログラム、構造解析方法、構造解析装置および半導体集積回路の製造方法 |

| US6630360B2 (en) * | 2002-01-10 | 2003-10-07 | Advanced Micro Devices, Inc. | Advanced process control (APC) of copper thickness for chemical mechanical planarization (CMP) optimization |

| DE10208165C1 (de) | 2002-02-26 | 2003-10-02 | Advanced Micro Devices Inc | Verfahren, Steuerung und Vorrichtung zum Steuern des chemisch-mechanischen Polierens von Substraten |

| US6613591B1 (en) * | 2002-03-07 | 2003-09-02 | Memc Electronic Materials, Inc. | Method of estimating post-polishing waviness characteristics of a semiconductor wafer |

| DE10314212B4 (de) * | 2002-03-29 | 2010-06-02 | Hoya Corp. | Verfahren zur Herstellung eines Maskenrohlings, Verfahren zur Herstellung einer Transfermaske |

| US7363099B2 (en) * | 2002-06-07 | 2008-04-22 | Cadence Design Systems, Inc. | Integrated circuit metrology |

| JP4464033B2 (ja) * | 2002-06-13 | 2010-05-19 | 信越半導体株式会社 | 半導体ウエーハの形状評価方法及び形状評価装置 |

| US7416962B2 (en) * | 2002-08-30 | 2008-08-26 | Siltronic Corporation | Method for processing a semiconductor wafer including back side grinding |

| EP1616662B1 (en) | 2002-10-09 | 2009-03-11 | Koyo Machine Industries Co., Ltd. | Both side grinding method and both side grinder of thin disc-like work |

| EP1457828A3 (en) | 2003-03-10 | 2009-04-22 | ASML Netherlands B.V. | Focus spot monitoring in a lithographic projection apparatus |

| US7118446B2 (en) * | 2003-04-04 | 2006-10-10 | Strasbaugh, A California Corporation | Grinding apparatus and method |

| TWI224037B (en) * | 2003-12-30 | 2004-11-21 | Ind Tech Res Inst | Grinder structure for wafer |

| DE102004005702A1 (de) * | 2004-02-05 | 2005-09-01 | Siltronic Ag | Halbleiterscheibe, Vorrichtung und Verfahren zur Herstellung der Halbleiterscheibe |

| DE102004011996B4 (de) | 2004-03-11 | 2007-12-06 | Siltronic Ag | Vorrichtung zum simultanen beidseitigen Schleifen von scheibenförmigen Werkstücken |

| WO2005095054A1 (en) | 2004-03-19 | 2005-10-13 | Memc Electronic Materials, Inc. | Wafer clamping device for a double side grinder |

| JP4163145B2 (ja) * | 2004-04-30 | 2008-10-08 | 株式会社ルネサステクノロジ | ウェハの研磨方法 |

| WO2005123335A1 (en) * | 2004-06-21 | 2005-12-29 | Ebara Corporation | Polishing apparatus and polishing method |

| US7814456B2 (en) * | 2004-11-22 | 2010-10-12 | Tela Innovations, Inc. | Method and system for topography-aware reticle enhancement |

| JP2006228843A (ja) * | 2005-02-16 | 2006-08-31 | Renesas Technology Corp | 半導体デバイスのプロセス制御方法および製造方法 |

| US7810383B2 (en) * | 2005-04-08 | 2010-10-12 | Shin-Etsu Handotai Co., Ltd. | Method for evaluating semiconductor wafer, apparatus for evaluating semiconductor wafer, and method for manufacturing semiconductor wafer |

| US20070006652A1 (en) | 2005-07-06 | 2007-01-11 | Abnaki Systems, Inc. | Load measuring sensor and method |

| US7636611B2 (en) | 2005-10-28 | 2009-12-22 | Samsung Austin Semiconductor, L.P. | Fuzzy logic system for process control in chemical mechanical polishing |

| US7601049B2 (en) * | 2006-01-30 | 2009-10-13 | Memc Electronic Materials, Inc. | Double side wafer grinder and methods for assessing workpiece nanotopology |

| JP2008010818A (ja) * | 2006-06-01 | 2008-01-17 | Sumitomo Electric Ind Ltd | 基板、基板検査方法、素子および基板の製造方法 |

| DE102007056628B4 (de) * | 2007-03-19 | 2019-03-14 | Siltronic Ag | Verfahren und Vorrichtung zum gleichzeitigen Schleifen mehrerer Halbleiterscheiben |

| JP4985451B2 (ja) * | 2008-02-14 | 2012-07-25 | 信越半導体株式会社 | ワークの両頭研削装置およびワークの両頭研削方法 |

-

2007

- 2007-12-31 US US11/967,743 patent/US7930058B2/en active Active

-

2008

- 2008-12-29 KR KR1020107014398A patent/KR20100110803A/ko not_active Ceased

- 2008-12-29 WO PCT/US2008/088452 patent/WO2009088832A1/en not_active Ceased

- 2008-12-29 JP JP2010540928A patent/JP2011507719A/ja active Pending

- 2008-12-29 EP EP08869803.0A patent/EP2225070B1/en active Active

- 2008-12-29 CN CN2008801235079A patent/CN101909817A/zh active Pending

- 2008-12-31 TW TW097151687A patent/TWI446992B/zh active

-

2010

- 2010-09-27 US US12/891,357 patent/US8145342B2/en active Active

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2007130708A1 (en) * | 2006-01-30 | 2007-11-15 | Memc Electronic Materials, Inc. | Double side wafer grinder and methods for assessing workpiece nanotopology |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20150084764A (ko) * | 2012-11-13 | 2015-07-22 | 신에쯔 한도타이 가부시키가이샤 | 양면 연마 방법 |

| KR102004701B1 (ko) * | 2012-11-13 | 2019-07-29 | 신에쯔 한도타이 가부시키가이샤 | 양면 연마 방법 |

| JP2016505214A (ja) * | 2012-12-28 | 2016-02-18 | サンエディソン・セミコンダクター・リミテッドSunEdison Semiconductor Limited | エピタキシャル後反りの予測および制御方法 |

| JP2019067952A (ja) * | 2017-10-02 | 2019-04-25 | 株式会社Sumco | 半導体ウェーハの評価方法および該方法を用いた半導体ウェーハの製造方法 |

| JP2023513276A (ja) * | 2020-02-10 | 2023-03-30 | グローバルウェーハズ カンパニー リミテッド | 強化されたウエハ製造のためのシステムおよび方法 |

| JP7661348B2 (ja) | 2020-02-10 | 2025-04-14 | グローバルウェーハズ カンパニー リミテッド | 強化されたウエハ製造のためのシステムおよび方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20080166948A1 (en) | 2008-07-10 |

| US7930058B2 (en) | 2011-04-19 |

| TW200946284A (en) | 2009-11-16 |

| EP2225070B1 (en) | 2014-02-12 |

| EP2225070A1 (en) | 2010-09-08 |

| TWI446992B (zh) | 2014-08-01 |

| KR20100110803A (ko) | 2010-10-13 |

| CN101909817A (zh) | 2010-12-08 |

| US20110045740A1 (en) | 2011-02-24 |

| US8145342B2 (en) | 2012-03-27 |

| WO2009088832A1 (en) | 2009-07-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2225070B1 (en) | Nanotopography control and optimization using feedback from warp data | |

| TWI520202B (zh) | 在一同步雙面晶圓研磨器中之流體靜力墊壓力調變 | |

| JP6146213B2 (ja) | ワークの両面研磨装置及び両面研磨方法 | |

| JP6166383B2 (ja) | エピタキシャル後反りの予測および制御方法 | |

| KR100642879B1 (ko) | 양면동시 연삭방법, 양면동시 연삭기, 양면동시 래핑방법및 양면동시 래핑기 | |

| WO2010013390A1 (ja) | ウェーハの研磨方法および両面研磨装置 | |

| JP2013524484A5 (enExample) | ||

| KR19990045021A (ko) | 여ㄴ마 패드의 마모 측정수단을 구비한 연마 장치 및그의 조작방법 | |

| KR102041240B1 (ko) | 반도체 웨이퍼의 매엽식 편면 연마 방법 및 반도체 웨이퍼의 매엽식 편면 연마 장치 | |

| US10180316B2 (en) | Method and device for the contactless assessment of the surface quality of a wafer | |

| JP5028354B2 (ja) | ウェーハの研磨方法 | |

| JP6539467B2 (ja) | 研削加工装置 | |

| KR101247065B1 (ko) | 양면 웨이퍼 그라인더 및 가공물 나노토폴로지 평가 방법 | |

| JP2004022676A (ja) | 半導体ウエーハの加工方法及びプラズマエッチング装置 | |

| WO2003107402A1 (ja) | 半導体ウエーハ | |

| JPH11245162A (ja) | 平面の作業面を有する工具 | |

| JP5699783B2 (ja) | ワークの研磨方法及び研磨装置 | |

| CN108153111A (zh) | 形成模板的衬底以及检测方法 | |

| TWI740606B (zh) | 工件的兩面研磨方法 | |

| CN114871940A (zh) | 一种基板背面研磨方法及研磨系统 | |

| KR20250034609A (ko) | 기판 처리 장치 및 방법 | |

| KR20250061622A (ko) | 워크 가공 장치 | |

| JP2007095987A (ja) | 半導体ウェーハの製造方法及び研削装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110407 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110407 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20130207 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130212 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20130513 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20130520 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20130611 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20130618 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20131008 |