JP2006346856A - 二次研磨媒体容積制御溝を有するケミカルメカニカル研磨パッド - Google Patents

二次研磨媒体容積制御溝を有するケミカルメカニカル研磨パッド Download PDFInfo

- Publication number

- JP2006346856A JP2006346856A JP2006166826A JP2006166826A JP2006346856A JP 2006346856 A JP2006346856 A JP 2006346856A JP 2006166826 A JP2006166826 A JP 2006166826A JP 2006166826 A JP2006166826 A JP 2006166826A JP 2006346856 A JP2006346856 A JP 2006346856A

- Authority

- JP

- Japan

- Prior art keywords

- polishing

- grooves

- pad

- groove

- layer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

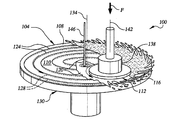

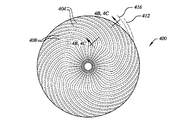

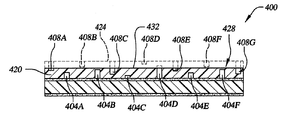

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/11—Lapping tools

- B24B37/20—Lapping pads for working plane surfaces

- B24B37/26—Lapping pads for working plane surfaces characterised by the shape of the lapping pad surface, e.g. grooved

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24479—Structurally defined web or sheet [e.g., overall dimension, etc.] including variation in thickness

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24479—Structurally defined web or sheet [e.g., overall dimension, etc.] including variation in thickness

- Y10T428/2457—Parallel ribs and/or grooves

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Mechanical Treatment Of Semiconductor (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US69132105P | 2005-06-16 | 2005-06-16 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2006346856A true JP2006346856A (ja) | 2006-12-28 |

| JP2006346856A5 JP2006346856A5 (enExample) | 2009-07-09 |

Family

ID=37643214

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006166826A Pending JP2006346856A (ja) | 2005-06-16 | 2006-06-16 | 二次研磨媒体容積制御溝を有するケミカルメカニカル研磨パッド |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US7807252B2 (enExample) |

| JP (1) | JP2006346856A (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2010274338A (ja) * | 2009-05-26 | 2010-12-09 | Kuraray Co Ltd | 研磨装置及び研磨パッドの固定方法 |

| JP2014124718A (ja) * | 2012-12-26 | 2014-07-07 | Toyo Tire & Rubber Co Ltd | 積層研磨パッドの製造方法 |

Families Citing this family (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9180570B2 (en) | 2008-03-14 | 2015-11-10 | Nexplanar Corporation | Grooved CMP pad |

| TWI360459B (en) * | 2008-04-11 | 2012-03-21 | Bestac Advanced Material Co Ltd | A polishing pad having groove structure for avoidi |

| US9199354B2 (en) | 2012-10-29 | 2015-12-01 | Wayne O. Duescher | Flexible diaphragm post-type floating and rigid abrading workholder |

| US9233452B2 (en) | 2012-10-29 | 2016-01-12 | Wayne O. Duescher | Vacuum-grooved membrane abrasive polishing wafer workholder |

| US9039488B2 (en) | 2012-10-29 | 2015-05-26 | Wayne O. Duescher | Pin driven flexible chamber abrading workholder |

| US9604339B2 (en) | 2012-10-29 | 2017-03-28 | Wayne O. Duescher | Vacuum-grooved membrane wafer polishing workholder |

| US8998677B2 (en) | 2012-10-29 | 2015-04-07 | Wayne O. Duescher | Bellows driven floatation-type abrading workholder |

| US9011207B2 (en) | 2012-10-29 | 2015-04-21 | Wayne O. Duescher | Flexible diaphragm combination floating and rigid abrading workholder |

| US8998678B2 (en) | 2012-10-29 | 2015-04-07 | Wayne O. Duescher | Spider arm driven flexible chamber abrading workholder |

| US8845394B2 (en) | 2012-10-29 | 2014-09-30 | Wayne O. Duescher | Bellows driven air floatation abrading workholder |

| US9308620B2 (en) * | 2013-09-18 | 2016-04-12 | Texas Instruments Incorporated | Permeated grooving in CMP polishing pads |

| TWI599447B (zh) | 2013-10-18 | 2017-09-21 | 卡博特微電子公司 | 具有偏移同心溝槽圖樣之邊緣排除區的cmp拋光墊 |

| US10189143B2 (en) * | 2015-11-30 | 2019-01-29 | Taiwan Semiconductor Manufacturing Company Limited | Polishing pad, method for manufacturing polishing pad, and polishing method |

| US10926378B2 (en) | 2017-07-08 | 2021-02-23 | Wayne O. Duescher | Abrasive coated disk islands using magnetic font sheet |

| CN114126803B (zh) | 2019-05-07 | 2024-07-16 | Cmc材料有限责任公司 | 具有固定沟槽体积的化学机械平坦化垫 |

| CN110253423A (zh) * | 2019-07-11 | 2019-09-20 | 德淮半导体有限公司 | 一种研磨垫 |

| US11691241B1 (en) * | 2019-08-05 | 2023-07-04 | Keltech Engineering, Inc. | Abrasive lapping head with floating and rigid workpiece carrier |

| TWI812936B (zh) * | 2021-04-01 | 2023-08-21 | 智勝科技股份有限公司 | 研磨墊及研磨方法 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH1010062A (ja) * | 1996-03-15 | 1998-01-16 | Dylog It Spa | ガラス容器及び/又は缶のための非破壊x線検査装置 |

| JP2002192455A (ja) * | 2000-12-25 | 2002-07-10 | Toyobo Co Ltd | 研磨パッド |

| JP2004074314A (ja) * | 2002-08-12 | 2004-03-11 | Nikon Corp | 研磨体、この研磨体を備えた研磨装置、この研磨装置を用いた半導体デバイス製造方法及びこの半導体デバイス製造方法により製造された半導体デバイス |

| JP2004202666A (ja) * | 2002-12-26 | 2004-07-22 | Sony Corp | 研磨装置、研磨部材、および研磨方法 |

| JP2004345048A (ja) * | 2003-05-23 | 2004-12-09 | Jsr Corp | 研磨パッド |

| JP2005294410A (ja) * | 2004-03-31 | 2005-10-20 | Toyo Tire & Rubber Co Ltd | 研磨パッド |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3042593B2 (ja) | 1995-10-25 | 2000-05-15 | 日本電気株式会社 | 研磨パッド |

| US6093651A (en) * | 1997-12-23 | 2000-07-25 | Intel Corporation | Polish pad with non-uniform groove depth to improve wafer polish rate uniformity |

| US6331137B1 (en) * | 1998-08-28 | 2001-12-18 | Advanced Micro Devices, Inc | Polishing pad having open area which varies with distance from initial pad surface |

| US6626740B2 (en) * | 1999-12-23 | 2003-09-30 | Rodel Holdings, Inc. | Self-leveling pads and methods relating thereto |

| US20040259479A1 (en) | 2003-06-23 | 2004-12-23 | Cabot Microelectronics Corporation | Polishing pad for electrochemical-mechanical polishing |

-

2006

- 2006-05-19 US US11/437,050 patent/US7807252B2/en not_active Expired - Fee Related

- 2006-06-16 JP JP2006166826A patent/JP2006346856A/ja active Pending

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH1010062A (ja) * | 1996-03-15 | 1998-01-16 | Dylog It Spa | ガラス容器及び/又は缶のための非破壊x線検査装置 |

| JP2002192455A (ja) * | 2000-12-25 | 2002-07-10 | Toyobo Co Ltd | 研磨パッド |

| JP2004074314A (ja) * | 2002-08-12 | 2004-03-11 | Nikon Corp | 研磨体、この研磨体を備えた研磨装置、この研磨装置を用いた半導体デバイス製造方法及びこの半導体デバイス製造方法により製造された半導体デバイス |

| JP2004202666A (ja) * | 2002-12-26 | 2004-07-22 | Sony Corp | 研磨装置、研磨部材、および研磨方法 |

| JP2004345048A (ja) * | 2003-05-23 | 2004-12-09 | Jsr Corp | 研磨パッド |

| JP2005294410A (ja) * | 2004-03-31 | 2005-10-20 | Toyo Tire & Rubber Co Ltd | 研磨パッド |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2010274338A (ja) * | 2009-05-26 | 2010-12-09 | Kuraray Co Ltd | 研磨装置及び研磨パッドの固定方法 |

| JP2014124718A (ja) * | 2012-12-26 | 2014-07-07 | Toyo Tire & Rubber Co Ltd | 積層研磨パッドの製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20060286350A1 (en) | 2006-12-21 |

| US7807252B2 (en) | 2010-10-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2006346856A (ja) | 二次研磨媒体容積制御溝を有するケミカルメカニカル研磨パッド | |

| JP4916657B2 (ja) | プロセスに依存した溝構造を有するケミカルメカニカル研磨パッド | |

| JP4689240B2 (ja) | スラリー消費を減らすための溝構造を有する研磨パッド | |

| JP5453075B2 (ja) | 高速研磨方法 | |

| JP5208467B2 (ja) | 不均等に離間した溝を有するcmpパッド | |

| JP4820555B2 (ja) | 溝付き研磨パッド及び方法 | |

| JP4949677B2 (ja) | 重複する段差溝構造を有するcmpパッド | |

| US7771251B2 (en) | Three-dimensional network for chemical mechanical polishing | |

| US6620031B2 (en) | Method for optimizing the planarizing length of a polishing pad | |

| JP2008068394A (ja) | 重複する面積一定のらせん溝を有するcmpパッド | |

| JP2009056586A (ja) | 化学機械研磨のための層状フィラメント格子 | |

| JP4786946B2 (ja) | 研磨中に混合伴流を促進するように配置された溝を有する研磨パッド | |

| JP2008507148A (ja) | 流れ変更性溝ネットワークを有する研磨パッド | |

| JP5208530B2 (ja) | スラリー消費を低減するための溝を有する研磨パッド | |

| JP2008500198A (ja) | 揺動経路溝ネットワークを有する研磨パッド | |

| JP5033357B2 (ja) | 研磨パッド | |

| JP5033356B2 (ja) | 研磨パッド | |

| JP5022635B2 (ja) | 研磨パッド |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090526 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20090526 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20111018 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20120313 |