EP3169179B2 - Boucle de ceinture - Google Patents

Boucle de ceinture Download PDFInfo

- Publication number

- EP3169179B2 EP3169179B2 EP15744121.3A EP15744121A EP3169179B2 EP 3169179 B2 EP3169179 B2 EP 3169179B2 EP 15744121 A EP15744121 A EP 15744121A EP 3169179 B2 EP3169179 B2 EP 3169179B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- belt buckle

- housing

- light

- light guide

- light conductor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000003780 insertion Methods 0.000 claims description 25

- 230000037431 insertion Effects 0.000 claims description 25

- 230000008878 coupling Effects 0.000 claims description 22

- 238000010168 coupling process Methods 0.000 claims description 22

- 238000005859 coupling reaction Methods 0.000 claims description 22

- 239000004020 conductor Substances 0.000 claims description 16

- 230000007704 transition Effects 0.000 claims description 3

- 238000009432 framing Methods 0.000 claims description 2

- 239000000463 material Substances 0.000 description 12

- 238000001746 injection moulding Methods 0.000 description 8

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 description 5

- 238000005286 illumination Methods 0.000 description 5

- 238000004519 manufacturing process Methods 0.000 description 5

- 238000003466 welding Methods 0.000 description 5

- 238000002347 injection Methods 0.000 description 4

- 239000007924 injection Substances 0.000 description 4

- 239000004417 polycarbonate Substances 0.000 description 4

- 229920000515 polycarbonate Polymers 0.000 description 4

- 230000008859 change Effects 0.000 description 3

- 238000009826 distribution Methods 0.000 description 3

- 230000007246 mechanism Effects 0.000 description 3

- 230000005855 radiation Effects 0.000 description 3

- 239000004743 Polypropylene Substances 0.000 description 2

- 239000004676 acrylonitrile butadiene styrene Substances 0.000 description 2

- 239000000853 adhesive Substances 0.000 description 2

- 230000001070 adhesive effect Effects 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 230000002093 peripheral effect Effects 0.000 description 2

- 229920003023 plastic Polymers 0.000 description 2

- 229920001155 polypropylene Polymers 0.000 description 2

- 238000004026 adhesive bonding Methods 0.000 description 1

- 238000000149 argon plasma sintering Methods 0.000 description 1

- 230000004323 axial length Effects 0.000 description 1

- 239000003086 colorant Substances 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 239000004922 lacquer Substances 0.000 description 1

- 230000002045 lasting effect Effects 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 230000008450 motivation Effects 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- -1 polypropylene Polymers 0.000 description 1

- 230000008569 process Effects 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A44—HABERDASHERY; JEWELLERY

- A44B—BUTTONS, PINS, BUCKLES, SLIDE FASTENERS, OR THE LIKE

- A44B11/00—Buckles; Similar fasteners for interconnecting straps or the like, e.g. for safety belts

- A44B11/25—Buckles; Similar fasteners for interconnecting straps or the like, e.g. for safety belts with two or more separable parts

- A44B11/2503—Safety buckles

- A44B11/2546—Details

- A44B11/2565—Illuminated buckles

-

- A—HUMAN NECESSITIES

- A44—HABERDASHERY; JEWELLERY

- A44B—BUTTONS, PINS, BUCKLES, SLIDE FASTENERS, OR THE LIKE

- A44B11/00—Buckles; Similar fasteners for interconnecting straps or the like, e.g. for safety belts

- A44B11/25—Buckles; Similar fasteners for interconnecting straps or the like, e.g. for safety belts with two or more separable parts

- A44B11/2503—Safety buckles

- A44B11/2546—Details

- A44B11/2561—Tongue elements

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V23/00—Arrangement of electric circuit elements in or on lighting devices

- F21V23/003—Arrangement of electric circuit elements in or on lighting devices the elements being electronics drivers or controllers for operating the light source, e.g. for a LED array

- F21V23/007—Arrangement of electric circuit elements in or on lighting devices the elements being electronics drivers or controllers for operating the light source, e.g. for a LED array enclosed in a casing

- F21V23/009—Arrangement of electric circuit elements in or on lighting devices the elements being electronics drivers or controllers for operating the light source, e.g. for a LED array enclosed in a casing the casing being inside the housing of the lighting device

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V3/00—Globes; Bowls; Cover glasses

- F21V3/04—Globes; Bowls; Cover glasses characterised by materials, surface treatments or coatings

- F21V3/06—Globes; Bowls; Cover glasses characterised by materials, surface treatments or coatings characterised by the material

- F21V3/062—Globes; Bowls; Cover glasses characterised by materials, surface treatments or coatings characterised by the material the material being plastics

- F21V3/0625—Globes; Bowls; Cover glasses characterised by materials, surface treatments or coatings characterised by the material the material being plastics the material diffusing light, e.g. translucent plastics

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V7/00—Reflectors for light sources

- F21V7/0091—Reflectors for light sources using total internal reflection

Definitions

- the invention relates to a seat belt buckle.

- a seat belt buckle is part of a safety device in a vehicle and is firmly connected to the vehicle body.

- a tongue can be inserted into the belt buckle, on which a belt strap is provided which, when the tongue is inserted, partially surrounds a vehicle occupant in order to fix the occupant to the vehicle seat in the event of a strong deceleration of the vehicle.

- Belt buckles with lighting devices are generally known from the prior art, with the lighting serving to identify a receiving area for a tongue so that the vehicle occupant can find the belt buckle more quickly. Finding the seatbelt buckle quickly increases the rate of buckling because the vehicle occupant does not have to look for the seatbelt buckle, which can reduce motivation to buckle up.

- the lighting devices should ensure reliable and permanent lighting of the recording area.

- the belt buckles known from the prior art usually have a belt buckle housing, which is usually produced by a welding process in which two housing halves are materially connected to one another. Due to this cohesive connection, the lighting device can only be replaced with considerable effort, which is perceived as disadvantageous. Furthermore, the installation space within the belt buckle is limited, which is why a very compact design of the lighting device is necessary. In addition, the recording area should be illuminated over a large area and with high light intensity so that the vehicle occupant can find the recording area even if the seat belt buckle is in an unfavorable position. Previous belt buckles do not meet these requirements to the fullest satisfaction.

- a belt buckle according to the preamble of claim 1 is from the document US 2012/089302 A1 known.

- the object of the invention is to provide a belt buckle that enables the best possible and lasting illumination of the receiving area of the tongue while requiring minimal space and provides an illuminated tongue insertion opening.

- Another object of the invention is to provide a belt buckle that is simple and inexpensive to manufacture and also allows individual adjustments of the belt buckle, for example according to customer requirements for different vehicle types.

- a belt buckle with a housing and a lighting device present in the area of a tongue insertion opening, the lighting device comprising a lamp and a light guide with a light exit area and the light guide having an annular section which at least largely surrounds the tongue insertion opening.

- the provision of an annular section on the light guide allows the tongue insertion opening to be illuminated in a targeted manner at any point along its circumference and preferably over its entire circumference and thus to produce a clear, valuable identification of the tongue insertion opening.

- the lighting takes place in an area that, on the one hand, is clearly visible to the vehicle occupant when inserting the tongue and, on the other hand, is positioned in such a way that the use of any design elements in the area of the body of the housing is possible.

- the housing also referred to below as a belt buckle housing

- a belt buckle housing can, for example, have a peripheral edge which surrounds a receiving area for a tongue, as well as a lighting device which has a light guide and a light source, the light guide having a light exit area in the form of a coupling surface which is located on the Edge of the belt buckle housing is provided, which forms the light exit area.

- the edge of the belt buckle housing represents the section of the belt buckle housing that is directly in the vehicle occupant's field of vision when the belt buckle assumes its typical position in the vehicle.

- the decoupling surface of the light guide is provided on this edge, it is ensured that the receiving area, which forms the tongue insertion opening, is so well illuminated that the vehicle occupant can find it even when the belt buckle is in unfavorable positions.

- the light emitted by the lamp is guided to the output surface via the light guide, which enables a compact arrangement of the lighting device. This is because the lamp itself can be arranged at a position within the belt buckle where more space is available than directly at the edge.

- the light source can in particular be an LED, which is particularly compact.

- the light exit region is formed circumferentially on an axial end face of the annular section of the light guide, which enables illumination encircling the tongue insertion opening.

- the light exit area can, for example, be approximately 1 mm wide in the radial direction (radial to the insertion direction), which results in subtle, but still clearly perceptible lighting in the area of the tongue insertion opening without increasing the volume of the belt buckle.

- the light guide preferably consists of a transparent plastic, in particular a polycarbonate (PC).

- PC polycarbonate

- the light guide can have a structured surface on an outer surface facing away from the light exit area.

- This structured surface is then designed so that it is not flat, but rather one Has a plurality of small structures arranged next to one another, which are designed and aligned so that they reflect the light back into the interior of the annular region of the light guide and thus bring about a homogeneous distribution of the light within the light guide.

- the structured surface is preferably provided on an end face of the annular section of the light guide opposite the light exit region.

- the structured surface has, for example, a plurality of prisms arranged next to one another, each of which in particular has a trapezoidal or triangular cross-section and forms a type of sawtooth structure along the rear end face of the light guide. In this way, very uniform illumination of the entire annular section can be achieved even when the light is coupled into the light guide at specific points.

- the light guide can have an extension or a coupling element that projects axially from the annular section of the light guide.

- the extension preferably extends to an area in which the lamp of the lighting device can be easily placed and directs the light from the lamp to the annular section and to the light exit area.

- a recess can be provided in the annular section in the light guide, for example in the area of the transition of the extension into the annular section.

- This recess is shaped in such a way that the coupled-in light is distributed evenly in the annular section.

- the coupled light is reflected into the annular section in the circumferential direction, in particular at edges of the recess lying obliquely to the axial direction, and is thus evenly distributed in the annular section.

- the recess is a breakthrough in the annular section, which has an approximately triangular shape, with the tip directed towards the extension.

- other shapes can also be used, which suitably have reflection surfaces that run obliquely to the axial direction and can thus cause a reflection into the annular section.

- the annular section of the light guide is arranged radially within an at least largely circumferentially closed front panel of the housing, which is to be viewed as a further housing part, the front panel framing the insertion opening.

- the front panel shields the light guide radially outwards, and can extend over the entire axial length of the light guide and beyond.

- the outer surface of the front panel can be designed in any way and can be used as a customer-specific design element.

- the front panel has an annular, at least partially transparent diffuser, which adjoins the light exit area of the light guide axially on the front side.

- This diffuser can also darken areas of the light exit area or can change the color of the emerging light.

- An air gap is arranged between the diffuser and the light guide to reduce total reflections and to ensure a high level of light emission through the diffuser.

- the height of the air gap between the diffuser and the light guide is less than 0.5 mm, preferably in the range from 0.15 mm to 0.35 mm.

- the outside of the diffuser facing away from the light guide has a very fine-grained structure, which further improves the homogeneity of the light emission.

- the diffuser is roughened with a very low graininess.

- the front panel is preferably opaque, so that light only emerges through the diffuser.

- the front panel and diffuser can be manufactured in one piece using a two-component injection molding process, for example from acrylonitrile butadiene styrene (ABS) and polycarbonate (PC).

- ABS acrylonitrile butadiene styrene

- PC polycarbonate

- front panel and light guide are preferably separate components, although one-piece production would also be conceivable.

- the front panel can be attached to the light guide during production of the belt buckle, and the light guide and front panel can be welded together for final attachment, for example by ultrasonic or laser welding.

- the housing of the belt buckle preferably has a first shell part which has an annular, circumferential projection which is arranged radially within the light guide.

- This circumferential projection is arranged at an end of the first shell part on the insertion opening side, and the annular section of the light guide is designed so that it can be plugged onto the projection of the first shell part.

- the ring-shaped, circumferential projection of the first shell part shields the light guide radially inwards from the tongue insertion opening, so that no unwanted light emerges there.

- the light guide can be welded to the annular projection of the first shell part or attached to it in another suitable way.

- the lighting device preferably comprises an electronic control module in which the lamp and electronics are arranged.

- the electronic control module is attached to the inside of the first shell part of the housing.

- one or more LEDs are used as lighting devices.

- a way to change the color of the This makes it easy to provide a light source.

- the color selection can be stored in a memory in the electronic control module and thus adapted to different vehicle types.

- the electrical supply line can be integrated into an electrical supply line of a seat occupancy detection switch in the belt buckle in order to reduce the number of separate electrical cables. Excessive strain on the supply line can be prevented by strain relief on the first shell part of the housing

- the electronic control module can also be placed on another part of the housing.

- the electrical control module is preferably designed as a LIN module (Local Interconnect Network Bus) and can be connected to general vehicle electronics.

- LIN module Local Interconnect Network Bus

- the housing of the belt buckle consists only of the first shell part, the front panel and a second shell part, so that the belt buckle can be installed quickly and easily.

- the light guide is connected to the belt buckle housing, in particular latched or permanently attached to it.

- This enables a particularly compact design of the belt buckle housing, since the light guide does not have to be attached to the belt buckle housing using fasteners.

- This also simplifies the manufacture of the belt buckle.

- a snap connection also makes it possible to change the light guide.

- the light guide can in particular be injection molded with the associated housing part in a 2-component injection molding process, so that no assembly is necessary. The light guide can therefore be molded onto the belt buckle housing.

- the decoupling surface can be designed to be circumferential.

- the decoupling surface provided on the edge can therefore surround the insertion opening forming the receiving area in a ring, so that the vehicle occupant can quickly see where the receiving area is located, namely in the area enclosed by the decoupling surface. This increases the rate of wearing a seat belt because the vehicle occupant does not have to spend a long time searching for the recording area.

- the light guide has a coupling element which is coupled to the lamp and is in particular designed to taper in a wedge shape.

- the coupling element of the light guide ensures that the light emitted by the lamp is completely coupled into the light guide. This increases the luminosity in the area of the coupling surface. Due to the wedge shape of the coupling element, a space-saving light guide is nevertheless created which only has a correspondingly large cross section in the coupling area.

- the belt buckle housing is composed of several shell parts, with the light guide being assigned to a housing section on which the edge is formed.

- the multi-part design of the belt buckle housing makes it possible to open the belt buckle housing quickly and easily, which means that the lighting device can be changed quickly and easily. Furthermore, it is ensured that the decoupling surface is provided on the edge of the belt buckle housing, since the light guide is arranged on the housing section of the multi-part belt buckle housing.

- the light guide is essentially embedded in the housing section. This means that the light guide is essentially surrounded by housing material, which means that no additional light decoupling surfaces are created, as would be the case if the light guide were only arranged on the inside of the belt buckle housing. The light guide is therefore essentially completely enclosed by the housing section. Only the coupling-out and coupling-in areas are not enclosed by the housing material of the housing section in which the light guide is embedded.

- the belt buckle housing can be designed in two parts and comprise two shell parts or housing shells, with the housing section being provided on a first housing shell.

- the two-part design makes it possible to open the belt buckle housing quickly and easily, as well as simple production, since a first housing shell has the essential parts of the belt buckle, for example the lighting device, whereas the second housing shell only serves to close the belt buckle housing.

- the second housing shell therefore represents a type of cover element.

- the second housing shell can be a standardized housing shell.

- the belt buckle housing can be designed in three parts and include two shell parts and a, in particular insertable, housing part, corresponding to the front panel described above, on which the housing section is provided.

- the two shell parts can be conventional, standardized belt buckle shells that can be coupled together to form a type of base body of the housing lock.

- the housing part which can be inserted or plugged into the base body, has the housing section on which the light guide is provided.

- the housing part is therefore ring-shaped and provides the edge of the belt buckle housing, which surrounds the receiving area for the tongue.

- the light guide can have a connection structure with which the housing part forming the front panel can be connected to the other shell parts.

- the housing part is connected via the light guide firmly coupled to the two shell parts, thereby providing a complete belt buckle housing.

- a belt buckle described above can be produced in such a way that the light guide and at least one housing section are injection molded at the same time, in particular in a multi-component injection molding process. This makes it possible to produce the belt buckle particularly quickly and easily, since the belt buckle housing is at least partially formed directly with the light guide. The light guide therefore no longer needs to be subsequently coupled to the belt buckle housing. This also ensures that the orientation of the light guide within the belt buckle housing is correct, which guarantees homogeneous illumination of the decoupling surface.

- the remaining parts of the belt buckle can be designed as a simple and inexpensive injection molded part that only has one material component.

- the light guide and the at least one housing section are injection molded in such a way that the light guide is essentially embedded in the housing section.

- the light guide is protected by the housing material surrounding it, and on the other hand, it is ensured that the light guide only has the decoupling surface provided at the edge. As a result, the light intensity on the output surface is correspondingly high, since no scattering losses or the like occur.

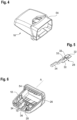

- FIG 1 shows a belt buckle 10 with a housing 12, in which a tongue insertion opening 14 is provided for a tongue, not shown, of a seat belt system in a vehicle.

- the housing 12 encloses a support 16, on which an internal mechanism for fixing the tongue including a button 17 for releasing the tongue is mounted (see also Figure 14 ).

- the carrier 16 has a section which extends out of the housing 12 in the axial direction A and which serves to fasten the belt buckle 10 to the vehicle.

- the housing 12 consists of several housing parts, namely a first shell part 18 (see also Figures 4 and 6 ) an opposite second shell part 20 (see also Figure 13 ) and a front panel 22 (shown in more detail in the Figures 11 and 12 ), which axially adjoins both shell parts 18.

- the belt buckle 10 has a lighting device 24 (see Figure 14 ), which has a light guide 26 (see in detail Figures 7 to 10 ) and an electronic control module 28 (see in particular Figures 5 and 6 ).

- the electronic control module 28 of the lighting device 24 has a control board 30 on which one or more LEDs are provided as lamps 32 as well as corresponding electronics 33, which can control the lamps 32 in terms of lighting duration, light intensity and, if necessary, light color.

- the lamps 32 can optionally be provided in just one color, or there can be several lamps 32 in different colors, which are controlled by the electronics 33 in such a way that any color is generated. The choice of color can be made depending on the situation, and color changes are also possible.

- the electronic control module 28 is designed, for example, as a LIN module for connection to a LIN bus in the vehicle.

- An electrical supply line 34 enables the electronic control module 28 to be supplied with electrical energy.

- the electrical supply line 34 is, for example, combined with a supply line for a switch (not shown) for detecting the inserted tongue.

- the electronic control module 28 is fixed to the inside of the first shell part 18, for example by a snap or welded connection.

- a cable guide 36 is integrated into the inside of the first shell part 18 (see Figure 6 ) and also provides strain relief for the supply line 34.

- the light guide 26 has an extension 38 which extends in the axial direction A away from the insertion opening 14 and which serves as a coupling element and which has a frontal coupling surface 40 at a free end into which the light emitted by the lamps 32 enters.

- the extension 38 merges into an annular section 42, which is circumferentially closed here.

- a recess 44 designed as an opening in the annular section 42 is provided, here in the form of a triangle, the tip of which points towards the coupling surface 40.

- the sides 46 of the recess 44 which are directed obliquely to the axial direction A, serve to reflect the light entering the annular section 42 through the extension 38 in the circumferential direction into the annular section 42.

- the end face 48 of the annular section 42 of the light guide 26 facing away from the extension 38 forms a light exit region 60.

- the end face 48 is designed to be flat.

- the end face 50 of the annular section 42 opposite the end face 48 has a structured surface here.

- a plurality of uniform structures 52 are placed next to each other, in which case the structures 52 are formed by prisms, each of which has a trapezoidal cross section and whose longitudinal direction is oriented transversely to the circumferential direction. This is in the Figures 8 and 9 indicated.

- the structures 52 serve to reflect the light in the annular section 42 towards the front end face 48, where it is intended to leave the light guide 26.

- Figure 10 shows a variant of a light guide 26 '.

- the extension 38' is shorter, but the coupling surface 40' is wider, so that, for example, the light source 32 can more easily have several LEDs next to one another.

- several coupling surfaces 40' can lie next to one another or for a coupling surface to be present which extends in an arc around the lamp 32.

- the rear end face can also be structured or smooth here.

- the first shell part 18 of the housing 12 has an annular projection 54 (see Figures 6 and 12 ), which runs around the tongue insertion opening 14.

- the projection 54 is formed in one piece with the remaining first shell part 18.

- the entire first shell part 18, but in particular the projection 54, is designed to be opaque in this example.

- Suitable materials for the first shell part 18, but also the other parts of the housing 12, are, for example, acrylonitrile butadiene styrene (ABS) or polypropylene (PP).

- the light guide 26, 26' consists, for example, of polycarbonate (PC).

- the light guide 26 with its annular section 42 is plugged onto the projection 54 on the first shell part 18 and can be connected to the projection 54, for example by welding (ultrasonic or laser welding) or gluing.

- the projection 54 extends in the axial direction A in this example at least to the end face 48 of the light guide 26 or even a little beyond that, as in Figure 14 can be recognized.

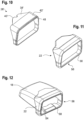

- the front panel 22 of the housing 12 is also designed here as a circumferentially closed ring (see Figures 11 and 12 ) and is attached to the light guide 26 ( Figure 12 and Figure 14 ). Front panel 22 and light guide 26 are also fastened to one another in a suitable manner, for example by a snap-in, adhesive or welded connection, for example via ultrasonic or laser welding, and are firmly and non-detachably connected to one another.

- the front panel 22 is designed to be opaque along its peripheral surface and thus blocks radiation of light from the light guide 26 in the radial direction r to the outside.

- the front panel 22 can be designed as a design element, for example with a chrome-plated outer surface or with a piano lacquer look.

- the front panel 22 is manufactured separately from the other housing parts, so that the appearance of the belt buckle 10 can be changed by providing a differently designed front panel 22.

- a transparent, ring-shaped diffuser 58 surrounding the tongue insertion opening 14, through which the light emerging from the end face 48 of the light guide 26 penetrates to the outside.

- the diffuser 58 connects to the end face 48 of the light guide 26 in the axial direction A.

- An air gap is formed between the diffuser and the end face 48 of the light guide 26, which has a height of 0.25 mm in this exemplary embodiment.

- the diffuser 58 can be designed in such a way that it influences the color of the emerging light and/or changes the radiation characteristics of the end face 48 of the light guide 26. However, it also ensures that the housing 12 is sealed to the outside without a gap and prevents dirt from penetrating into the housing 12.

- the diffuser 58 and the front panel 22 are therefore manufactured in one piece in a two-component injection molding process.

- polycarbonate (PC) is used as a material for the diffuser.

- the front face of the diffuser is structured to improve the homogeneity of the light emission, i.e. fine-grained with a low roughness.

- the second shell part 20 is connected to the first shell part 18, for example by a snap-in, adhesive or welded connection.

- the width of the end face 48 is, for example, approximately 1 mm.

- the width of the diffuser 58 in the radial direction r is chosen here to be of the same order of magnitude. In this way, a light exit area 60 of the belt buckle 10 is created, which is formed circumferentially around the tongue insertion opening 14 and which is approximately 1 mm wide.

- the projection 54 of the first shell part 18 and the front panel 22 prevent light from being emitted from the light guide 26 in the radial direction r, so that light only emerges from the light exit area 60 and the light exit area 60 forms the only illuminated section of the belt buckle 10.

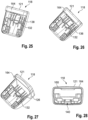

- a belt buckle 100 is shown according to a further embodiment, the locking mechanism of the belt buckle 100, which interacts with a tongue, not being shown for reasons of clarity.

- the belt buckle 100 has a belt buckle housing 112, which in the embodiment shown is designed in three parts.

- the housing 112 has a first shell part 118, also known as the first housing shell, a second shell part 120, also referred to as the second housing shell, and a housing part which forms a front panel 122 and which has an edge 121 which has a receiving area 114 for a

- the tongue is surrounded by an insertion opening for the tongue.

- the two shell parts 118, 120 together form a base body 123 of the housing 112, into which the front panel 122 is inserted.

- the two shell parts 118, 120 and the front panel 122 are coupled together so that they form the complete housing 112.

- the belt buckle 100 has a lighting device 124, which includes a light source 132 and a light guide 126.

- the light source 132 can be an LED that emits red light, for example.

- a multicolored LED can also be provided so that the color of the emitted light can be adapted to the preferences of the vehicle occupant.

- the light source 132 is provided within the belt buckle 100, being arranged on the first shell part 118.

- the light guide 126 is arranged in a housing section 129 of the housing 112, which is formed by the second shell part 120 in the embodiment shown. Therefore, the lamp 132 and the light guide 126 are arranged on different parts of the three-part housing 12.

- the light guide 132 also has a coupling element 138, which in the assembled state of the belt buckle 100 is coupled to the light source 132 in such a way that the light emanating from the light source 132 is coupled into the light guide 126 via the coupling element 138.

- the coupling element 138 is designed to taper in a wedge shape, whereby the coupling element 138 has a large coupling surface 140.

- the light coupled in via the coupling element 138 runs via the light guide 126 to an outcoupling surface 160, which is arranged at the edge 121 of the housing 112.

- the decoupling surface 160 is designed as a circumferential band on the edge 121, so that it encloses the insertion opening and the receiving area 122 in a ring.

- the decoupling surface 160 in particular has a width of 0.5 mm to 1.5 mm, preferably 1 mm, and is arranged directly on the surface of the housing 112, which is in the field of view of the belt buckle 100 if this is a typical position in a vehicle takes.

- the light guide 126 in addition to the coupling-out surface 160 and the coupling-in element 138, has a connecting structure 162, via which the front panel 122 can be coupled to the two shell parts 118, 120 or to the base body 123.

- the connecting structure 162 is formed at an end of the front panel 122 opposite the edge 121.

- the figures also show that the light guide 126 is embedded in the front panel 122, since the light guide 126 is essentially surrounded by the housing material of the front panel 122. Only the coupling-out surface 160 on the edge 121 as well as the coupling-in element 138 and the connecting structure 162 are not surrounded by the housing material. The light-guiding structure of the light guide 126 therefore runs essentially inside the front panel 122, so that only the coupling-out surface 160, the coupling-in element 138 and the connecting structure 162 of the light guide 126 can be seen.

- the light guide 126 is therefore formed in one piece with the housing section 129 or the front panel 122.

- the front panel 122 can therefore preferably be manufactured in a multi-component injection molding process. This ensures that the inner and outer housing surfaces of the front panel 122 are made of a first, opaque material, whereas the light guide 126 embedded therein is made of a second, light-conducting material. As a result, the light guide 126 is surrounded by the housing material of the front panel 122 or the front panel 122 and only has a single coupling-out surface 160.

- the material for the light guide 126 can be, for example, high-tech refined plastics that have special light scattering, light guiding properties or an additional metallic effect.

- first and second shell parts 118, 120 in this embodiment may have been manufactured in a one-component injection molding process, since they may be standardized components.

- the light guide 126 can also be manufactured as a separate component and locked with the housing section 129 or the front panel 122.

- both the light guide 126 and the housing section 129 or the front panel 122 can have a latching structure.

- the first shell part 118 of a belt buckle 100 is shown according to a further embodiment, which is only designed in two parts. Components that are the same or have the same effect are therefore provided with the reference numbers already introduced.

- the housing 112 which is only partially shown, is therefore formed in this embodiment by the two shell parts 118, 120, of which only the first shell part 118 is shown.

- the first shell part 118 has a housing section 164, which essentially corresponds to the front panel 122 in the first embodiment according to the Figures 15 to 21 corresponds.

- the housing section 164 has the circumferential edge 121 and the light guide 126, which is embedded in the first shell part 118 in the previous embodiment.

- the decoupling surface 160 of the light guide 126 is provided on the edge 121, analogous to the first embodiment, which is now arranged on the first shell part 118.

- the first shell part 118 according to the previous embodiment therefore, in comparison to the first shell part 118 according to this embodiment, additionally has the front panel 122, which in this embodiment is formed in one piece with the first shell part 118 and is referred to as the housing section 162.

- the lamp is 132, which is in the Figures 25 to 27 is shown, also arranged on the inner surface of the first shell part 118. Accordingly, in this embodiment, both the lamp 132 and the light guide 126 are provided on the same housing section or part of the housing 12. This also applies to the coupling element 138, which interacts with the lamp 132 via its coupling surface 140.

- the first shell part 118 since it has the light guide 126, has preferably been manufactured in a multi-component injection molding process.

- the light guide 126 is therefore essentially completely surrounded by the housing material of the first shell part 118 or essentially embedded in the first shell part 118.

- the second shell part 120 in this embodiment can be designed analogously to the second shell part 120 according to the previous embodiment and can be manufactured in a one-component injection molding process, since it can be a standardized component.

- the second shell part 120 is placed or pushed on and fixed with the first shell part 118, so that the complete belt buckle housing 112 is trained.

- the parts forming the housing 112 i.e. the two shell parts 118, 120 and possibly the front panel 122, are placed on one another or pushed on or inserted in order to provide an easily detachable housing 112. This means that the lamp 26 can be replaced quickly and easily if necessary.

- the components for the belt buckle mechanism which interact with the tongue, are generally inserted into the first shell part 118 before the belt buckle 100 is assembled.

- the geometry of the light guide 126 and the optional insertion of lenses ensure that the decoupling surface 160 is homogeneously illuminated, so that a uniformly circumferential band of light marks the recording area 114, whereby it can be easily found by the vehicle occupant.

- a chrome element is provided on the edge 121 in order to make the appearance of the belt buckle housing 112 appear more high-quality.

- the chrome element can be designed as a circumferential chrome ring and in particular can be arranged adjacent to the coupling-out surface 160 in such a way that the coupled-out light is reflected on the chrome surface.

- the chrome element is preferably provided next to the coupling-out surface 160 on the side of the coupling-out surface 160 facing away from the insertion opening 114.

- the light source 132 can generally be designed as a type of pre-assembly unit, which means that electrical connections and optionally a series resistor are provided, which only need to be contacted when installing the belt buckle 100.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Buckles (AREA)

- Automotive Seat Belt Assembly (AREA)

Claims (17)

- Dispositif de verrouillage de ceinture avec un boîtier (12) et un dispositif d'éclairage (24) dans la zone d'une ouverture d'insertion de languette (14), pour lequel le dispositif d'éclairage (24) comprend une source lumineuse (32) et un guide optique (26, 26 ') avec une zone de sortir de lumière et pour lequel le guide optique (26; 26') comporte une partie annulaire (42; 42'), qui entoure au moins une grande partie de l'ouverture d'insertion de languette (14), caractérisé en ce que la partie annulaire (42; 42 ') du guide optique (26; 26') est disposée radialement à l'intérieur d'un panneau avant (22) fermé au moins sensiblement sur la circonférence du boîtier (12),pour lequel le panneau avant (14) encadre l'ouverture d'insertion (14),

et en ce que le panneau avant (22) comporte un diffuseur (58) annulaire transparent au moins partiellement qui est axialement adjacent à la zone de sortie de lumière du guide optique (26; 26 '). - Dispositif de verrouillage de ceinture de ceinture selon la revendication 1, caractérisé en ce que la zone de sortie de lumière est formée s'étendant sur la circonférence d'une face d'extrémité axiale (48, 48 ') de la partie annulaire (42, 42') du guide optique (26, 26 ').

- Dispositif de verrouillage de ceinture de ceinture selon l'une des revendications précédentes, caractérisé en ce que le guide optique (26) présente une surface texturée sur une face d'extrémité opposée (50) de la zone de sortie de la lumière.

- Dispositif de verrouillage de ceinture de ceinture selon la revendication 3, caractérisé en ce que la surface structurée comporte une pluralité de structures juxtaposées (52), en particulier des prismes.

- Dispositif de verrouillage de ceinture selon l'une quelconque des revendications précédentes, caractérisé en ce que le guide optique (26, 26 ') présente une extension (38, 38'), qui s'étend en saillie axialement depuis la partie annulaire (42, 42 ') du guide optique (26, 26') et sur laquelle est couplée la lumière de la source lumineuse (32) dans le guide optique (26, 26').

- Dispositif de verrouillage de ceinture de ceinture selon la revendication 5, caractérisé en ce que dans la région de la transition de l'extension (38) est prévue dans la partie annulaire (42) une cavité (44) qui est formée de sorte que la lumière injectée soit uniformément répartie dans la partie annulaire (42).

- Dispositif de verrouillage de ceinture de ceinture selon la revendication 1, caractérisé en ce que le panneau avant (22) à l'exception du diffuseur (58) est opaque.

- Dispositif de verrouillage de ceinture de ceinture selon les revendications 1 ou 7, caractérisé en ce qu'entre le diffuseur (58) et la zone de sortie de lumière du guide optique (26; 26 ') est formé un jeu.

- Dispositif de verrouillage de ceinture de ceinture selon l'une quelconque des revendications précédentes, caractérisé en ce que le boîtier (12) possède une première partie en coque (18) qui comporte une saillie (54) annulaire circonférentielle, laquelle est disposée radialement vers l'intérieur du guide optique (26, 26').

- Dispositif de verrouillage de ceinture de ceinture selon les revendications 1 et 9, caractérisé en ce que le boîtier (12) est constitué de la première partie en coque (18), du panneau avant (22) et d'une seconde partie en coque (20).

- Dispositif de verrouillage de ceinture selon l'une quelconque des revendications précédentes, caractérisé en ce que le dispositif d'éclairage (24) comprend un module de commande électronique (28), dans lequel sont disposés la source (32) et l'électronique (33), et en particulier pour lequel le module de commande électronique (28 ) est fixé à l'intérieur de la première partie en coque (18) du boîtier (12).

- Dispositif de verrouillage de ceinture (100) selon l'une quelconque des revendications précédentes, caractérisé en ce que le guide optique (126) est relié avec le boitier du dispositif de verrouillage de ceinture (112), en particulier verrouillé ou fixé de manière permanente à celui-ci.

- Dispositif de verrouillage de ceinture (100) selon l'une quelconque des revendications précédentes, caractérisé en ce que le guide optique (126) comprend un élément d'accouplement (138), qui est couplé à la source lumineuse (132) et qui est réalisé en particulier en cône en forme de coin.

- Dispositif de verrouillage de ceinture (100) selon l'une quelconque des revendications précédentes, caractérisé en ce que le boîtier du dispositif de verrouillage de ceinture (112) est en plusieurs parties, pour lequel la zone de sortie de lumière du guide optique (126) est disposée sur un bord (121) du boîtier du dispositif de verrouillage de ceinture (112) et pour lequel est prévu une section de boîtier (129, 164), sur laquelle est disposé le bord (121).

- Dispositif de verrouillage de ceinture (100) selon la revendication 14, caractérisé en ce que le guide optique (126) est sensiblement encastré dans la section de boitier (129, 164).

- Dispositif de verrouillage de ceinture (100) selon les revendications 14 ou 15, caractérisé en ce que le boîtier du dispositif de verrouillage de ceinture (112) est formé en deux parties et en ce qu'il comprend deux parties en coque (118, 120), pour lequel la section de boîtier (164) est prévue sur la première partie en coque (118).

- Dispositif de verrouillage de ceinture (100) selon les revendications 14 ou 15, caractérisé en ce que le boitier de dispositif de verrouillage de ceinture (112) est formé de trois parties et comprend deux parties en coque (118, 120) ainsi qu'un panneau avant (122), en particulier insérable, sur lequel la section du boitier (129) est prévue.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102014010403 | 2014-07-15 | ||

| DE102014016520.5A DE102014016520B4 (de) | 2014-11-10 | 2014-11-10 | Gurtschloss |

| PCT/EP2015/001451 WO2016008585A1 (fr) | 2014-07-15 | 2015-07-15 | Boucle de ceinture |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP3169179A1 EP3169179A1 (fr) | 2017-05-24 |

| EP3169179B1 EP3169179B1 (fr) | 2018-09-19 |

| EP3169179B2 true EP3169179B2 (fr) | 2023-12-06 |

Family

ID=53761321

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP15744121.3A Active EP3169179B2 (fr) | 2014-07-15 | 2015-07-15 | Boucle de ceinture |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US10631597B2 (fr) |

| EP (1) | EP3169179B2 (fr) |

| CN (1) | CN106572724B (fr) |

| WO (1) | WO2016008585A1 (fr) |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102015206602A1 (de) | 2014-12-19 | 2016-06-23 | Volkswagen Aktiengesellschaft | Beleuchtetes Gurtschloss |

| DE102015210450A1 (de) | 2015-06-08 | 2016-12-08 | Autoliv Development Ab | Beleuchtetes Gurtschloss für eine Sicherheitsgurteinrichtung eines Kraftfahrzeuges |

| JP6541182B2 (ja) * | 2015-07-02 | 2019-07-10 | Joyson Safety Systems Japan株式会社 | バックルおよびこれを備えるシートベルト装置 |

| DE102016204961B4 (de) * | 2016-03-24 | 2022-08-11 | Autoliv Development Ab | Beleuchtetes Gurtschloss für eine Sicherheitsgurteinrichtung eines Kraftfahrzeuges |

| DE102016117099A1 (de) * | 2016-09-12 | 2018-03-15 | Autoliv Development Ab | Gurtschloss mit Beleuchtung |

| JP6475305B1 (ja) * | 2017-11-02 | 2019-02-27 | 株式会社東海理化電機製作所 | バックル装置 |

| CN109793318B (zh) * | 2017-11-16 | 2022-10-04 | 天合汽车科技(上海)有限公司 | 用于安全带的发光锁扣 |

| CN108422961B (zh) * | 2018-03-06 | 2023-09-29 | 延锋汽车智能安全系统有限责任公司 | 一种发光插锁 |

| DE102018122239A1 (de) * | 2018-09-12 | 2020-03-12 | Trw Automotive Gmbh | Gurtschloss und Verfahren zur Herstellung eines Gurtschlosses |

| DE102019135914A1 (de) * | 2019-12-31 | 2021-07-01 | Zf Automotive Germany Gmbh | Verfahren für ein Sicherheitsgurtsystem, Sicherheitsgurtsystem für ein Fahrzeug und Fahrzeug mit einem Sicherheitsgurtsystem |

| CN114009903B (zh) * | 2021-10-28 | 2023-07-11 | 浙江松原汽车安全系统股份有限公司 | 一种安全带锁扣 |

| USD1034299S1 (en) * | 2021-11-08 | 2024-07-09 | Brogent Technologies Inc. | Illuminated buckle |

| USD1020435S1 (en) * | 2021-11-08 | 2024-04-02 | Brogent Technologies Inc. | Illuminated buckle |

| CN115153162A (zh) * | 2022-07-01 | 2022-10-11 | 浙江松原汽车安全系统股份有限公司 | 一种安全带发光锁扣 |

| DE102023107196B3 (de) * | 2023-03-22 | 2024-09-26 | Autoliv Development Ab | Beleuchtetes Gurtschloss für eine Sicherheitsgurteinrichtung eines Kraftfahrzeuges |

| TWI847646B (zh) * | 2023-04-11 | 2024-07-01 | 宏裕汽車股份有限公司 | 可顯光安全帶扣座 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5892436A (en) † | 1996-11-08 | 1999-04-06 | Trw Inc. | Illuminated seat belt buckle |

| DE69510941T2 (de) † | 1994-12-08 | 1999-11-11 | Valeo Vision, Bobigny | Leuchtring für zigarettenanzünder, insbesondere für kraftfahrzeuge |

| DE102007017394A1 (de) † | 2006-04-07 | 2007-10-18 | TK Holdings, Inc., Auburn Hills | Beleuchtetes Soft-Touch-Schloss für Rückhaltesystem |

| US20100013622A1 (en) † | 2008-07-18 | 2010-01-21 | Tk Holdings Inc. | Adaptive light seatbelt buckle |

Family Cites Families (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1598519A (fr) | 1967-12-20 | 1970-07-06 | ||

| GB1201853A (en) * | 1968-07-30 | 1970-08-12 | Wingard Ltd | Fastening device for releasably connecting two members |

| SE440307B (sv) | 1977-04-04 | 1985-07-29 | Nsk Warner Kk | Spenne for sekerhetsbelten |

| US4237586A (en) * | 1977-10-21 | 1980-12-09 | Nsk-Warner K.K. | Buckle device for safety belt |

| FR2630057B1 (fr) | 1988-04-13 | 1990-07-20 | Neiman Sa | Perfectionnements aux allume-cigares lumineux pour vehicules automobiles |

| JP3103090B2 (ja) * | 1990-05-11 | 2000-10-23 | タカタ株式会社 | シートベルト装置のバックル照明機構 |

| DE9012325U1 (de) | 1990-08-28 | 1990-10-31 | Schoeller & Co Elektrotechnische Fabrik Gmbh & Co, 6000 Frankfurt | Beleuchtungsvorrichtung für das Zündschloß eines Kraftfahrzeugs |

| DE4202120C2 (de) | 1992-01-27 | 1995-04-13 | Schoeller & Co Elektrotech | Elektrischer Zigarrenanzünder, insbesondere für Kraftfahrzeuge |

| DE19528093A1 (de) | 1995-07-31 | 1997-02-13 | Siemens Ag | Diebstahlschutzsystem für ein Kraftfahrzeug |

| AU784343B2 (en) | 2001-03-09 | 2006-03-16 | Robert Bosch Gmbh | Illumination ring |

| DE10119010C2 (de) | 2001-04-18 | 2003-05-28 | Visteon Global Tech Inc | Beleuchtungsanordnung für das Zündschloss eines Kraftfahrzeugs |

| DE202004007872U1 (de) * | 2004-05-15 | 2004-09-23 | Juhren, Holger | Sicherheitsgurtschloßbeleuchtung für Pkw |

| JP2007014359A (ja) | 2005-06-15 | 2007-01-25 | Takata Corp | バックル装置及びシートベルト装置 |

| CN101639200A (zh) | 2008-07-30 | 2010-02-03 | 深圳富泰宏精密工业有限公司 | 导光体及具有该导光体的光源装置 |

| DE102008042472B4 (de) | 2008-09-30 | 2021-04-22 | BSH Hausgeräte GmbH | Leuchtring |

| JP2011125575A (ja) | 2009-12-18 | 2011-06-30 | Inoac Corp | シートベルトバックルの製造方法 |

| US8131144B2 (en) * | 2010-07-09 | 2012-03-06 | Wgi Innovations, Ltd. | Action camera with capability of capturing images in daylight and infrared |

| US20120089302A1 (en) * | 2010-10-06 | 2012-04-12 | Griffin John A | Illuminated seat belt receptacle |

| DE102011114538A1 (de) | 2011-09-29 | 2013-04-04 | Trw Automotive Gmbh | Gurtschlossbaugruppe |

| DE202012012254U1 (de) * | 2012-12-20 | 2013-02-22 | Key Safety Systems, Inc. | Gurtschloss für einen Fahrzeugsicherheitsgurt |

| DE102013003978B4 (de) | 2013-03-08 | 2022-06-09 | Zf Automotive Germany Gmbh | Gurtschloss und Verfahren zum Montieren eines Gurtschlosses |

| EP3031341B1 (fr) * | 2014-12-12 | 2018-06-13 | AGM Automotive LLC | Système de retenue de sécurité éclairé |

-

2015

- 2015-07-15 WO PCT/EP2015/001451 patent/WO2016008585A1/fr active Application Filing

- 2015-07-15 US US15/322,744 patent/US10631597B2/en active Active

- 2015-07-15 CN CN201580038689.XA patent/CN106572724B/zh active Active

- 2015-07-15 EP EP15744121.3A patent/EP3169179B2/fr active Active

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE69510941T2 (de) † | 1994-12-08 | 1999-11-11 | Valeo Vision, Bobigny | Leuchtring für zigarettenanzünder, insbesondere für kraftfahrzeuge |

| US5892436A (en) † | 1996-11-08 | 1999-04-06 | Trw Inc. | Illuminated seat belt buckle |

| DE102007017394A1 (de) † | 2006-04-07 | 2007-10-18 | TK Holdings, Inc., Auburn Hills | Beleuchtetes Soft-Touch-Schloss für Rückhaltesystem |

| US20100013622A1 (en) † | 2008-07-18 | 2010-01-21 | Tk Holdings Inc. | Adaptive light seatbelt buckle |

Also Published As

| Publication number | Publication date |

|---|---|

| CN106572724B (zh) | 2020-08-21 |

| EP3169179A1 (fr) | 2017-05-24 |

| WO2016008585A1 (fr) | 2016-01-21 |

| US20170127765A1 (en) | 2017-05-11 |

| EP3169179B1 (fr) | 2018-09-19 |

| CN106572724A (zh) | 2017-04-19 |

| US10631597B2 (en) | 2020-04-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3169179B2 (fr) | Boucle de ceinture | |

| DE102014016520B4 (de) | Gurtschloss | |

| EP3232849B1 (fr) | Boucle de ceinture lumineuse | |

| EP2662241B1 (fr) | Véhicule comprenant un ciel de toit | |

| EP3194210A1 (fr) | Dispositif d'éclairage dans lequel peut être verrouillé un ensemble guide de lumière | |

| WO2019137699A1 (fr) | Volant de direction pour véhicule automobile, procédé de fabrication d'un volant de direction pour véhicule automobile et véhicule automobile | |

| EP2989273B1 (fr) | Dispositif muni d'une coque de poignée et d'un système d'éclairage de la coque de poignée, et procédé de montage dudit dispositif | |

| WO2018149741A1 (fr) | Dispositif d'éclairage pour une pièce d'équipement intérieur | |

| DE102015215254B4 (de) | Beleuchtetes Gurtschloss für eine Sicherheitsgurteinrichtung eines Kraftfahrzeuges | |

| DE102016204961A1 (de) | Beleuchtetes Gurtschloss für eine Sicherheitsgurteinrichtung eines Kraftfahrzeuges | |

| DE102014202025A1 (de) | Lampe | |

| DE102005038830B4 (de) | Lichtleiterstruktur für Kraftfahrzeugscheinwerfer | |

| EP3844028A1 (fr) | Dispositif d'éclairage destiné à un véhicule automobile | |

| DE202008005748U1 (de) | Beleuchtung für das Gurtschloss eines Sicherheitsgurtes | |

| DE102017213369A1 (de) | Beleuchtbare Abdeckung für einen Funktionsraum eines Fahrzeugs | |

| DE102015011412A1 (de) | Verfahren zum Herstellen eines Bauteils mit einer beleuchtbaren Symbolik für eine Bedieneinrichtung eines Kraftfahrzeugs | |

| EP3727073B1 (fr) | Boucle de ceinture éclairée pour système de ceinture de sécurité d'un véhicule automobile | |

| DE102010054929A1 (de) | Leuchteinrichtung für ein Fahrzeug mit einem lichtleitenden Optikelement | |

| WO2018041479A1 (fr) | Habillage intérieur pour un véhicule à moteur | |

| EP3302161B1 (fr) | Boucle de ceinture éclairée pour système de ceinture de sécurité d'un véhicule automobile | |

| DE102018104043A1 (de) | Luftausströmer für ein Fahrzeug | |

| DE102018205120A1 (de) | Fahrzeuglampe | |

| DE102012103309A1 (de) | Lichtleitvorrichtung | |

| DE102023114230B3 (de) | Beleuchtetes Gurtschloss für eine Sicherheitsgurteinrichtung eines Kraftfahrzeuges und Verfahren zur Ansteuerung eines beleuchteten Gurtschlosses für eine Sicherheitsgurteinrichtung eines Kraftfahrzeuges | |

| DE102022003970A1 (de) | Beleuchtetes Exterieur Zierelement mit Chromoptik |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE INTERNATIONAL PUBLICATION HAS BEEN MADE |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20161220 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAV | Request for validation of the european patent (deleted) | ||

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20180309 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502015005998 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1042256 Country of ref document: AT Kind code of ref document: T Effective date: 20181015 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20180919 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181220 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181219 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181219 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190119 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190119 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 502015005998 Country of ref document: DE |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| 26 | Opposition filed |

Opponent name: VOLKSWAGEN AKTIENGESELLSCHAFT Effective date: 20190617 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20190715 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20190731 |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: ZF AUTOMOTIVE GERMANY GMBH |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190715 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190731 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190731 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190715 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190715 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20150715 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 |

|

| APBQ | Date of receipt of statement of grounds of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA3O |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 1042256 Country of ref document: AT Kind code of ref document: T Effective date: 20200715 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200715 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180919 |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230628 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20231206 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 502015005998 Country of ref document: DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240731 Year of fee payment: 10 |