EP2305061B1 - Dispositif de lissage des cheveux - Google Patents

Dispositif de lissage des cheveux Download PDFInfo

- Publication number

- EP2305061B1 EP2305061B1 EP10176179A EP10176179A EP2305061B1 EP 2305061 B1 EP2305061 B1 EP 2305061B1 EP 10176179 A EP10176179 A EP 10176179A EP 10176179 A EP10176179 A EP 10176179A EP 2305061 B1 EP2305061 B1 EP 2305061B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- hair

- mouldings

- straightening device

- hair straightening

- teeth

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A45—HAND OR TRAVELLING ARTICLES

- A45D—HAIRDRESSING OR SHAVING EQUIPMENT; EQUIPMENT FOR COSMETICS OR COSMETIC TREATMENTS, e.g. FOR MANICURING OR PEDICURING

- A45D2/00—Hair-curling or hair-waving appliances ; Appliances for hair dressing treatment not otherwise provided for

- A45D2/001—Hair straightening appliances

- A45D2/002—Hair straightening appliances with combs

-

- A—HUMAN NECESSITIES

- A45—HAND OR TRAVELLING ARTICLES

- A45D—HAIRDRESSING OR SHAVING EQUIPMENT; EQUIPMENT FOR COSMETICS OR COSMETIC TREATMENTS, e.g. FOR MANICURING OR PEDICURING

- A45D20/00—Hair drying devices; Accessories therefor

- A45D20/48—Hair-drying combs or hair-drying brushes, with internal heating means

Definitions

- the invention relates to a hair straightening device comprising a comb-like smoothing tool with spaced in each case by a hair receptacle, arranged in a row tines, associated with at least one each prong, opposite the further, this hair receiving bordering prong arranged first molded part and with one of further, this hair receptacle enclosing prong associated second molding for forming a hair styling gap between the two mold parts of a hair receptacle.

- Hair straighteners can be equipped with a comb-like smoothing tool.

- the smoothing tool of such hair straightening devices comprises a comb row formed from spaced-apart prongs, with two adjacent and spaced-apart prongs enclosing a hair receptacle.

- each hair receptacle or at least one of the two prongs enclosing each hair receptacle has a first molding. This is movable relative to the other, the hair-receiving tine mounted.

- the first molded part of each hair pick is associated with a second molded part.

- a hair styling gap in which a hair strand provided for smoothing is inserted.

- Smoothing as such is achieved by applying the hair straightener to the hair root end of the hair section to be straightened, inserting the hair strands into the hair receivers of the smoothing tool, and pulling the hair strands through the hair straighteners through the smoothing tool. This is typically done by a corresponding movement of the hair straightening device relative to the head of a person wearing the hair to be smoothed, whose hair is to be smoothed.

- the first movably mounted moldings are each spring-mounted individually on a prong.

- the insertion of a strand of hair takes place in a hair-shaped gap against the force of the force acting on the first mold parts spring element. If the hair is located or if individual strands of hair are in the several hair-form gaps, the smoothing movement is carried out.

- the spring force acting on the individual first molded parts determines the force that acts on the hair for the process of smoothing.

- the second molded part then constitutes the abutment.

- this prior art hair straightening device has a hot air blower whose warm air flow is introduced into the smoothing tool.

- the smoothing tool itself has air outlet openings in the region of the root areas of the stationary prongs, so that the hot air stream emerging therefrom reaches the hair to be formed.

- EP 1 721 539 A1 Another generic hair straightening device is known.

- This hair straightening device differs from the previously described, characterized in that the first mold parts are interconnected by a web and these mold parts can be moved as a molding unit as a whole relative to the fixed prongs against the force of a return spring. It is provided that the molding unit can be brought by means of an actuating element in her hair styling opening position.

- This has the advantage that an introduction of the hair strands to be inserted into the respective hair-form gaps is simplified.

- the restoring force and thus to be able to adjust the force acting on the hair for the process of hair straightening force.

- This previously known hair straightening device has a hot air blower for supplying the heat required for a hair shaping.

- Heat is supplied to the hair to be formed by means of an air flow, This not only results in a heating of the hair to be formed, but the stream of hot air also dries the hair. Sometimes too fast drying of the hair to be formed is undesirable.

- hair straightening devices of the aforementioned type, those are also used which consist of two tongs-like abutting arms, each arm comprising a molded part pointing to the other arm. These moldings are in the design of a straightener plate-like with a flat surface.

- the force acting on the hair to be smoothed is manually brought by the respective user as a result of the closing movement and thus by the applied closing force on the arms. Due to the relatively large hair styling surface, these hair straighteners do not pose the risk that individual strands of hair emerge from the hair styling gap during the exercise of the typical smoothing movement. Care must be taken in these hair straightening devices, however, that the hair strand received in the hair styling gap is not too large. This in turn can not occur in the hair straightening tools described above with a comb-like smoothing tool as a result of the Haarsträhnen Vietnamese made by it as a rule.

- the invention is therefore the object of developing a Haarglättvorraum mentioned above in such a way that the indicated to the initially acknowledged prior art disadvantages are at least largely avoided.

- the hair shape gaps enclosed by the two molded parts are undercut.

- the undercut extends in the direction of the delimitation of the hair receptacles extending between the prongs.

- the hair strands to be formed are thus for the process of smoothing in a tapering in the direction of the tip of the tines hair styling gap.

- the hair styling gap located between the two molded parts is basically closed to one another in the process of hair straightening by partially contacting the two molded parts.

- the hair-styling gap is not completely closed after inserting a strand of hair, since a too large strand of hair has been taken up in a hair-styling gap, in the course of the hair-shaping process in which the straightening device is pulled through the hair, those hairs will emerge from the hair-styling gap which forms a closure of the hair-styling gap Hairstyles have prevented.

- the result is that after a sufficient number of hair has been pulled out of the mold gap, the mold gap is then closed by abutting the two mold parts in the region of the throat forming the undercut.

- Such a conception of the hair styling gap or of the molded part enclosing a hair styling gap is equally suitable for hair straightening devices in which the movable molded parts are mounted independently of each other in a respective prong and for hair straightening devices in which the movable hair styling parts are combined to form a shaped part unit.

- the movable shaped parts In order to use the height of the first movably mounted moldings for the process of hair styling as much as possible, is located the mouth of the hair styling gap and thus the bottleneck for forming the undercut typically in the area of the top of the tine top of the moldings.

- the movable shaped parts In order to facilitate the introduction of a strand of hair into a hair-styling gap, the movable shaped parts will be equipped with a bevel inclined in the direction of the constriction.

- the movable mold parts are connected to each other by at least one web and form a rigid objective molding unit.

- This is movably mounted opposite the fixed tines.

- a molding unit is made of a good heat-conducting material, such as an aluminum alloy, for example by means of a die-casting process.

- an electric heater may be provided for heating the moldings.

- the provision of a stream of hot air to bring the heat required for the hair-shaping process to the hair to be formed is not required. Rather, the hair strands introduced into the hair styling gaps are heated directly from the heated first mold parts in such an embodiment.

- a hair straightening device designed in this way can be designed to be relatively small in construction.

- an electric heater is suitable, for example, to the at least one of the molded parts interconnecting web mounted PTC heating element.

- the heat well-conductive properties allow a rapid and uniform heating of the molding unit and thus belonging to this unit moldings.

- a typically cast-in, electrical heating element is integrated in the molded part unit in the one or more webs connecting the individual molded parts.

- the second mold parts cooperating moldings can the serve the first mold parts with respect to the respective hair pick opposite prongs or at least partially.

- the second mold parts are received in the opposite of the first mold parts prongs elements. These may likewise be a molded part unit formed by means of one or more webs. In such an embodiment, it is expedient to produce this second molding unit also from a good heat conducting material, such as an aluminum alloy, such as by a casting process.

- the second mold parts may also be equipped with a heater designed as described above for the first mold part unit. In this embodiment, in each case the two mold parts which cooperate with one another to form a hair styling gap are heated.

- the other, unheated molding is miter stiirmt by the non-use, typically by spring preload on these adjacent other moldings, so that heated for the hair-forming process, the two forming a hair shape moldings.

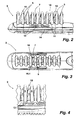

- a hair straightening device 1 has a smoothing tool 3 connected to a handle 2.

- the smoothing tool 3 is electrically heated.

- the hair straightening device 1 has an electrical connection cable 4.

- the smoothing tool 3 is designed like a comb and has a number of spaced, fixed tines 5 on.

- each prong 5 is assigned a movable, first molded part 7.

- the molded parts 7 are combined together to form a molded part unit.

- the molding unit is movable in the direction of the longitudinal extension of the row of tines and can from its in FIG.

- the tines 5 are executed together with a cover 9, which forms part of the housing of the smoothing tool 3, as a plastic injection molded part.

- the tines 5 are designed arcuate and summarize the first molded parts 7, as from FIG. 2 recognizable, one.

- two prongs 5 arranged adjacent to one another enclose a hair receptacle 10.

- Part of the hair intake 10 is an in FIG. 2 open hairline 11 which extends between each first mold part 7 and the side of the adjacent prong 5 facing this mold part 7.

- the first mold parts 7 have been moved as a molded part unit by corresponding actuation of the button 8 against the force of a return spring against the stationary arranged prongs 5.

- FIG. 2 Furthermore, it can be seen that the forming surface of the first mold parts 7 pointing towards the adjacent tines 5 is curved in the direction from the tips of the tines 5 to the lower boundary of the hair shape gaps 11, forming an undercut 13 adjoining a constriction 12.

- the hair receiver 10 and thus also the undercut 13 is limited by a boundary extending between adjacent tines 5, formed by sections of the cover 9. This limitation is in relation to an undercut in FIG. 1 designated by the reference numeral 14.

- the portion of the molded parts 7 located in the boundary 14 with respect to the upper end 15 is curved in the direction of the tines 5 accommodating the molded parts 7, in the illustrated embodiment so far that the curvature extends as far as the tines 5 Arch extends into when the mold parts 7, as in FIG. 2 shown in their hair-forming columns opening position. This facilitates insertion of a strand of hair into a hair receptacle or into a hair styling gap 11.

- FIG. 4 shows an enlarged section of the smoothing tool 3, in which the first mold parts 7 are in their respective hair styling gap 11 occlusive position.

- This, in FIG. 4 shown position represents the position of the mold parts 7 during a smoothing process.

- the hair-forming columns 11 are not closed as a whole are, but only in the region of the bottlenecks 12.

- the hair-forming columns 11 remain open with respect to the hair filling the undercut 13 so that the desired hair styling pressure for smoothing acts on the molded parts on the hairs received in the undercuts 13.

- the tines 5 are as out FIG. 5 recognizable, arcuate executed. This has the advantage that in the open position of the hair-form gaps 11, the molded parts 7 are not only accommodated in the prong 5 associated with the respective molded part 7 (see FIG FIG. 1 ) but also that when receiving only relatively little hair in a hair styling gap 11 facing the adjacent prong 5 front can engage in the back of the adjacent prong.

- FIG. 5 shows the first moldings in a position between the in FIG. 2 shown open position and the in FIG. 4 shown closed position.

- the mold parts 7 are opposite to the adjacent prongs 5, when in the undercut 13 of the hair mold columns 11 a sufficient amount of hair is added so that the mold parts 7 are not further moved into the second mold parts forming adjacent prongs.

- the in the FIGS. 1 to 5 illustrated embodiment act with the first, above-described molded parts 7 to these mold parts respectively facing backs 17 of the adjacent tines 5 together.

- the design of the mold surface of the moldings 17 with their mold flanks 16, 16.1 serves the purpose that a hair shaping on the in FIG. 5 Marked by the reference numeral 18 edge. The acting on the detected hair forming force is then concentrated on these edges.

- the first movable mold parts 7 are connected to each other via a web 20 to form a rigid objective unit.

- This unit formed from the web 20 and the individual molded parts 7 is produced by means of a die-casting process from an aluminum alloy.

- This unit is adjustable against the force of a return spring 21 by means of the button 8 in the direction of the handle 2. If the button 8 is not actuated, the return spring 21 causes the hair styling gaps 11 are closed. An actuation of the button 8 to open the hair styling column 11th serves the purpose of receiving strands of hair in the respective hair shots 10 or hair styling 11th

- a PTC heating element in a heat-coupling on the bottom 22 arrangement.

- Whose performance is adjustable via a control element arranged on the handle 2. Due to the good thermal conductivity of the material used for the web 20 and the molded parts 7, a uniform and rapid distribution of the heat generated by the PTC heating element for heating the mold surfaces of the molded parts 7 takes place.

- FIGS. 6 and 7 show the essential elements of a smoothing tool 23 according to another embodiment.

- the smoothing tool 23 has in addition to the already to the embodiment of FIGS. 1 to 5 described components - a series of tines formed by tines 24 and a mold unit 25 with the two in this embodiment, two webs 26, 26.1 held together first molded parts 27 - via a second mold part unit 28.

- the second mold part unit 28 has individual moldings 29 which through a common web 30 are connected to each other.

- the molding unit 28 is also in the illustrated embodiment, a manufactured by means of a die-casting process of an aluminum alloy molding.

- FIG. 8 shows the smoothing tool 23 in the open position of its moldings 27.

- the mold parts 27, 29 are received in the arcuate tines 24.

- the cross section along the line B - B of FIG. 9 makes it clear that the outline geometry of the molded parts 27 and their dimensions is adapted to the inner circumferential surface of the arc-shaped tines 24.

- the smoothing tool 23 serves as second molded parts.

- the hair styling gap 31 in the direction of the free end of the tines 24 towards closing constriction 32 is in the region of the upper end of the mold parts 27 and thereby the usable height of the hair mold columns 31 and the mold parts 27 for the process of hair styling is correspondingly large , Even with the smoothing tool 23 is the mold unit 25 with respect to the prongs 24 and the equally stationary arranged molding unit 28 with their mold parts 29 adjustable.

- the adjusting movement for closing the constriction 32 also takes place in this embodiment by the force of one or more spring elements.

- the opposite direction of movement is actuated by a typically manually operable control element, such as a button as in the embodiment of FIGS. 1 to 5 described causes.

- the mold parts 27 are released in its open position holding element, so that then the hair shape column 31, as shown FIG. 11 recognizable, be closed.

- the process of hair styling takes place mainly between the mold parts 27, 29.

- the inwardly facing edges of the prongs 24 are used as well as in the embodiment of FIGS. 1 to 5 additionally as a hair-shaped edge.

- the smoothing tool 23 has a heating device, not shown, which may be formed, such as that of the smoothing tool 3 of the hair straightening device 1.

- a heating device not shown, which may be formed, such as that of the smoothing tool 3 of the hair straightening device 1.

Claims (11)

- Dispositif de lissage des cheveux comprenant un outil de lissage (3, 23) conformé à la manière d'un peigne avec des dents (5, 24) disposées sur une rangée, espacées les unes des autres par un passage pour cheveux (10), avec au moins une première pièce de mise en forme (7, 27) affectée à chaque dent (5, 24), disposée de façon mobile par rapport à la dent (5, 24) suivante délimitant ce passage pour cheveux (10) et avec une seconde pièce de mise en forme (5 ; 24, 29) affectée à la dent suivante (5, 24), délimitant ce passage pour cheveux (10), afin de former un interstice de mise en forme des cheveux (11, 31) entre les deux pièces de mise en forme (5, 7 ; 24, 27, 29) d'un passage pour cheveux (10), caractérisé en ce que les interstices de mise en forme des cheveux (11, 31) qui se trouvent entre les pièces de mise en forme (5, 7 ; 24, 27, 29) sont, au moins lorsque les pièces de mise en forme (5, 7 ; 24, 27, 29) se trouvent en position de mise en forme des cheveux, contre-découpés l'un vers l'autre, dans le sens orienté vers la délimitation des passages à cheveux (10), qui relie les dents (5, 24).

- Dispositif de lissage des cheveux selon la revendication 1, caractérisé en ce que la contre-découpe (13, 33) des interstices de mise en forme des cheveux (11, 31) s'étend sur les pièces de mise en forme (5, 7 ; 24, 27, 29) sur sensiblement toute la hauteur effective pendant le processus de lissage dans la position de mise en forme des cheveux.

- Dispositif de lissage des cheveux selon la revendication 1 ou 2, caractérisé en ce que les pièces de mise en forme (7, 27) mobiles sont reliées entre elles par au moins une traverse (20 ; 26, 26.1) et forment une unité (25, 28) constructive rigide de pièces de mise en forme logée de façon mobile par rapport aux dents (5, 24).

- Dispositif de lissage des cheveux selon la revendication 3, caractérisé en ce que l'unité (25, 28) de pièces de mise en forme est fabriquée dans un matériau d'une bonne conductibilité thermique et qu'une partie de l'unité (25, 28) de pièces de mise en forme est un dispositif chauffant électrique destiné à réchauffer les pièces de mise en forme (7, 27).

- Dispositif de lissage des cheveux selon la revendication 4, caractérisé en ce que les dents (5, 24) sont réalisées avec la forme d'un arceau et la zone délimitée par chaque arceau de dent présente une section géométrique correspondant aux surfaces d'enveloppe périphériques des premières pièces de mise en forme (7, 27), avec un dimensionnement qui permet l'encastrement des premières pièces de mise en forme (7, 27) dans celle-ci.

- Dispositif de lissage des cheveux selon la revendication 5, avec sa référence à la revendication 4, caractérisé en ce que les premières pièces de mise en forme (7, 27), en position ouverte des interstices de mise en forme des cheveux (11, 31), sont au moins partiellement engagées dans l'arceau de dent affecté à chaque pièce de mise en forme (7, 27).

- Dispositif de lissage des cheveux selon l'une des revendications 1 à 6, caractérisé en ce que les secondes pièces de mise en forme agissant conjointement avec les premières pièces de mise en forme (7) logées de façon mobile, sont formées de dents (5), lesquelles sont chacune opposées à la première pièce de mise en forme.

- Dispositif de lissage des cheveux selon l'une des revendications 1 à 7 caractérisé en ce que les secondes pièces de mise en forme agissant conjointement avec les premières pièces de mise en forme (27), sont formées par des pièces de mise en forme (29) affectées aux dents (24) opposées aux premières pièces de mise en forme (27).

- Dispositif de lissage des cheveux selon la revendication 8, caractérisé en ce que les secondes pièces de mise en forme (29) sont au moins reliées entre elles par une traverse (26, 26.1).

- Dispositif de lissage des cheveux selon la revendication 8 ou 9, caractérisé en ce que les secondes pièces de mise en forme (29) sont réalisées dans un matériau à bonne conductibilité thermique.

- Dispositif de lissage des cheveux selon l'une des revendications 8 à 10, en référence à la revendication 5, caractérisé en ce que les secondes pièces de mise en forme (29) sont au moins partiellement disposées dans un arceau de dent.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE202009011098U DE202009011098U1 (de) | 2009-10-01 | 2009-10-01 | Haarglättvorrichtung |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2305061A1 EP2305061A1 (fr) | 2011-04-06 |

| EP2305061B1 true EP2305061B1 (fr) | 2012-10-31 |

Family

ID=43086257

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP10176179A Not-in-force EP2305061B1 (fr) | 2009-10-01 | 2010-09-10 | Dispositif de lissage des cheveux |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US8267098B2 (fr) |

| EP (1) | EP2305061B1 (fr) |

| JP (3) | JP5225352B2 (fr) |

| KR (1) | KR20110036515A (fr) |

| CN (1) | CN102028346B (fr) |

| DE (1) | DE202009011098U1 (fr) |

| HK (1) | HK1149888A1 (fr) |

Families Citing this family (41)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20090107518A1 (en) * | 2007-10-29 | 2009-04-30 | Cohen Martin A | Hair styling iron with raised fins |

| DE202011050034U1 (de) * | 2011-05-04 | 2012-08-06 | Wik Far East Ltd. | Haarformvorrichtung |

| DE202011050030U1 (de) | 2011-05-04 | 2012-08-06 | Wik Far East Ltd. | Haarformvorrichtung |

| US20130074867A1 (en) * | 2011-09-28 | 2013-03-28 | Conair Coporation | Hair styling apparatus with novel bristle configuration |

| IL219875A (en) | 2012-05-17 | 2017-04-30 | Sharon Rabi | Heated hair brush |

| DE202013100192U1 (de) * | 2013-01-15 | 2014-04-16 | Wik Far East Ltd. | Haarformgerät |

| US20150122286A1 (en) * | 2013-11-05 | 2015-05-07 | Conair Corporation | Hair styling apparatus |

| EP3139788B1 (fr) * | 2014-05-09 | 2018-05-30 | WIK Far East Ltd. | Appareil de mise en forme des cheveux |

| KR101701340B1 (ko) * | 2014-11-19 | 2017-02-02 | 방삼수 | 머리카락 정발기 |

| AU365950S (en) * | 2015-05-29 | 2015-12-17 | Zhuhai Jindao Electric Appliance Co Ltd | An electric hair straightening comb |

| EP3308669B1 (fr) * | 2015-06-12 | 2021-11-03 | Zhuhai Jindao Electric Appliance Co., Ltd. | Peigne de lissage de cheveux chauffé électriquement |

| GB2543034B (en) * | 2015-09-30 | 2021-03-24 | Jemella Ltd | Hair styling apparatus |

| USD804188S1 (en) * | 2015-10-09 | 2017-12-05 | Yufeng Du | Intelligent electric heating hair straightener |

| CN105146899B (zh) * | 2015-10-13 | 2018-01-30 | 葛翔 | 接发器 |

| CN205358621U (zh) * | 2016-01-27 | 2016-07-06 | 汪昆 | 直发器 |

| CN205671726U (zh) * | 2016-01-29 | 2016-11-09 | 秦海锋 | 一种具有顺发、直发功能的梳子 |

| USD821648S1 (en) * | 2016-02-09 | 2018-06-26 | Shenzhen Mexi Technology Co., Ltd. | Comb |

| USD815774S1 (en) * | 2016-02-17 | 2018-04-17 | M.R.T.R. Mercier Ltd. | Hair styling device |

| USD765911S1 (en) * | 2016-03-25 | 2016-09-06 | E. Mishan & Sons, Inc. | Single blade hair straightener |

| USD766504S1 (en) * | 2016-03-25 | 2016-09-13 | E. Mishan & Sons, Inc. | Double blade hair straightener |

| USD808658S1 (en) * | 2016-08-22 | 2018-01-30 | Conair Corporation | Heated hair paddle |

| DE202016006615U1 (de) | 2016-10-26 | 2018-01-30 | WIK - ELEKTROGERÄTE Entwicklungs- und Service-GmbH & Co. KG | Haarformgerät zur Beaufschlagung eines Pflegestoffes mittels Druckluft |

| USD821754S1 (en) * | 2016-11-02 | 2018-07-03 | Shenzhen Mexi Technology., Ltd | Floating ionic hair straightener |

| USD819336S1 (en) * | 2017-01-17 | 2018-06-05 | Dongguan Quzhi Appliance Technology Co., Ltd. | Hair comb |

| USD826567S1 (en) * | 2017-03-07 | 2018-08-28 | Guangdong Roman Technology Co., Ltd. | Hair dressing device |

| USD815837S1 (en) * | 2017-03-13 | 2018-04-24 | Dongguan Quzhi Appliance Technology Co., Ltd. | Hair comb |

| USD838989S1 (en) * | 2017-05-23 | 2019-01-29 | Guangdong Roman Technology Co., Ltd. | Hair dressing device |

| USD846885S1 (en) | 2017-11-21 | 2019-04-30 | Conair Corporation | Hair brush |

| US10925371B2 (en) | 2017-11-21 | 2021-02-23 | Conair Corporation | Hair brush |

| USD848745S1 (en) * | 2017-11-30 | 2019-05-21 | Everymarket Inc. | Hair brush |

| JP2019123587A (ja) * | 2018-01-16 | 2019-07-25 | 村田機械株式会社 | 自動ワインダにおける静圧制御方法及び自動ワインダ |

| EP3524086A1 (fr) * | 2018-02-09 | 2019-08-14 | Koninklijke Philips N.V. | Fer à lisser |

| USD882957S1 (en) * | 2018-04-09 | 2020-05-05 | Shenzhen Mexi Technology Co., Ltd | Hair straightener |

| WO2020081733A1 (fr) * | 2018-10-17 | 2020-04-23 | Dawkins Jean | Système de coiffure |

| KR102267546B1 (ko) * | 2019-12-27 | 2021-06-21 | 이상두 | 빗형 고데기 |

| USD953743S1 (en) * | 2020-05-26 | 2022-06-07 | Huizhou Shenchuang Industrial Co., Ltd. | Hair straightener brush or comb |

| WO2022012272A1 (fr) * | 2020-07-16 | 2022-01-20 | 深圳市仪成科技有限公司 | Peigne de lissage de cheveux |

| USD979840S1 (en) * | 2020-09-23 | 2023-02-28 | Lin Zhang | Electric hair straightener |

| USD987896S1 (en) | 2020-12-02 | 2023-05-30 | Conair Llc | Hair straightening and styling appliance |

| USD934501S1 (en) * | 2021-02-04 | 2021-10-26 | Guangdong Huanengda Electronic Appliances Co., Ltd | Hair straightener brush or comb |

| USD1021241S1 (en) | 2023-04-28 | 2024-04-02 | Elhadji Ndiaye | Comb for a hair straightener |

Family Cites Families (37)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US466496A (en) * | 1892-01-05 | Isaac w | ||

| US844007A (en) * | 1906-12-11 | 1907-02-12 | Abraham Ehrlich | Comb. |

| US1002942A (en) * | 1910-08-29 | 1911-09-12 | Edward Hiram Taylor | Hair-ironing comb. |

| US1197264A (en) * | 1916-06-13 | 1916-09-05 | Norval Watson Cobb | Comb. |

| US1349425A (en) * | 1920-02-28 | 1920-08-10 | Obadiah D Howard | Comb for drying and straightening hair |

| US1523461A (en) * | 1924-06-02 | 1925-01-20 | Swan Judge | Comb |

| US1614631A (en) * | 1926-05-18 | 1927-01-18 | Sendlbeck Henry | Hair comb |

| US2176460A (en) * | 1938-08-08 | 1939-10-17 | Kruger Louis | Comb |

| US2255618A (en) * | 1940-12-26 | 1941-09-09 | Delamere Co Inc | Hair device |

| US2562465A (en) * | 1945-11-23 | 1951-07-31 | Morris B Kassel | Sanitary comb |

| US2685292A (en) * | 1953-06-16 | 1954-08-03 | Staiano Louis | Combined comb and brush |

| US3088471A (en) * | 1962-07-06 | 1963-05-07 | Joseph C Fiore | Permanent waving devices |

| JPS4120437Y1 (fr) * | 1965-12-27 | 1966-10-03 | ||

| US3850180A (en) * | 1973-03-27 | 1974-11-26 | Gen Electric | Hair detangler |

| US3927684A (en) * | 1974-09-09 | 1975-12-23 | Hodgson R W | Hair-grooming implement |

| US4126143A (en) * | 1977-04-20 | 1978-11-21 | Johnson Products Co., Inc. | Electrically heated comb for hair styling |

| DE7925952U1 (de) | 1979-09-13 | 1980-01-24 | Rowenta-Werke Gmbh, 6050 Offenbach | Well- und lockenkamm mit luftleiteinrichtung |

| DE3029619C2 (de) * | 1980-08-05 | 1983-03-03 | Forfex Alfred Popp Haarpflegegeräte GmbH, 7532 Niefern | Rohrfrisierkamm |

| JPS57196905A (en) * | 1981-05-30 | 1982-12-03 | Matsushita Electric Works Ltd | Hair curler instrument |

| JPS60126101U (ja) * | 1984-02-06 | 1985-08-24 | 池田 完植 | 根本強制アイロン |

| US4702265A (en) * | 1986-05-21 | 1987-10-27 | Weddington Willard T | Combination heated hair and beard comb |

| JP2808691B2 (ja) * | 1989-07-15 | 1998-10-08 | 九州日立マクセル株式会社 | 整髪器具 |

| JPH0483101U (fr) * | 1990-11-30 | 1992-07-20 | ||

| US5449007A (en) * | 1994-05-26 | 1995-09-12 | Arnhols; Bertie I. | Hair comb with moveable gripping elements |

| DE29520134U1 (de) * | 1995-12-08 | 1996-02-08 | Braun Ag | Borsten für eine Haarbürste |

| DE19750119A1 (de) | 1997-11-13 | 1999-05-27 | Braun Gmbh | Haarformgerät |

| US7490615B2 (en) * | 2001-09-25 | 2009-02-17 | Conair Corporation | Hair straightening and styling device |

| DE20200971U1 (de) | 2002-01-24 | 2002-06-06 | Wik Far East Ltd | Warmlufthaarformgerät sowie als Aufsatz ausgebildetes Haarpflegeteil |

| EP1596686B1 (fr) * | 2003-01-30 | 2008-07-23 | Dickson Industrial Co. Ltd. | Accessoire de coiffure |

| DK1721539T3 (da) | 2005-06-13 | 2008-01-14 | Faco Sa | Anordning til udglatning af hår |

| JP4839800B2 (ja) | 2005-11-25 | 2011-12-21 | パナソニック電工株式会社 | 超音波ヘアセット器 |

| US8209877B2 (en) | 2006-05-18 | 2012-07-03 | Faco S.A. | Hair straightening device |

| US20080223387A1 (en) * | 2007-03-12 | 2008-09-18 | Julemont Pierre L M | Hair straightening and styling appliance |

| FR2916947B1 (fr) * | 2007-06-05 | 2009-08-14 | Seb Sa | Appareil de lissage des cheveux |

| FR2933852B1 (fr) * | 2008-07-21 | 2011-03-25 | Seb Sa | Dispositif de lissage des cheveux integrant des moyens de chauffage |

| USD609857S1 (en) | 2009-05-13 | 2010-02-09 | Wik Far East Ltd. | Comb straightener |

| JP5337597B2 (ja) * | 2009-06-29 | 2013-11-06 | パナソニック株式会社 | 髪ケア装置 |

-

2009

- 2009-10-01 DE DE202009011098U patent/DE202009011098U1/de not_active Expired - Lifetime

-

2010

- 2010-09-10 EP EP10176179A patent/EP2305061B1/fr not_active Not-in-force

- 2010-09-30 JP JP2010220180A patent/JP5225352B2/ja not_active Expired - Fee Related

- 2010-09-30 KR KR1020100095377A patent/KR20110036515A/ko not_active Application Discontinuation

- 2010-10-01 US US12/896,772 patent/US8267098B2/en not_active Expired - Fee Related

- 2010-10-08 CN CN2010105066238A patent/CN102028346B/zh not_active Expired - Fee Related

-

2011

- 2011-04-26 HK HK11104119.5A patent/HK1149888A1/xx not_active IP Right Cessation

-

2012

- 2012-11-21 JP JP2012254977A patent/JP5160696B1/ja not_active Expired - Fee Related

-

2013

- 2013-03-12 JP JP2013048601A patent/JP2013135926A/ja not_active Withdrawn

Also Published As

| Publication number | Publication date |

|---|---|

| US8267098B2 (en) | 2012-09-18 |

| DE202009011098U1 (de) | 2011-02-17 |

| JP2011072789A (ja) | 2011-04-14 |

| JP2013135926A (ja) | 2013-07-11 |

| KR20110036515A (ko) | 2011-04-07 |

| HK1149888A1 (en) | 2011-10-21 |

| JP5225352B2 (ja) | 2013-07-03 |

| EP2305061A1 (fr) | 2011-04-06 |

| CN102028346A (zh) | 2011-04-27 |

| US20120080047A1 (en) | 2012-04-05 |

| JP5160696B1 (ja) | 2013-03-13 |

| JP2013056195A (ja) | 2013-03-28 |

| CN102028346B (zh) | 2013-02-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2305061B1 (fr) | Dispositif de lissage des cheveux | |

| EP1334670B1 (fr) | Appareil de coiffure à chaud et accessoire de soin des cheveux | |

| EP3139788B1 (fr) | Appareil de mise en forme des cheveux | |

| DE60316304T2 (de) | Kämmvorrichtung mit einstellbarem zinkenabstand | |

| DE112013004159B4 (de) | Richtdüsenaufsatz | |

| DE202008016616U1 (de) | Haarformgerät | |

| DE202008018013U1 (de) | Elektrische Haarbürste | |

| DE202013105507U1 (de) | Haarformgerät | |

| EP2245953B1 (fr) | Appareil de mise en forme de cheveux | |

| DE4243640A1 (de) | Werkzeug zur Haarformung/-trocknung für ein luftdurchströmtes Gerät des persönlichen Bedarfs | |

| DE69910057T2 (de) | Zubehör zum glätten von haaren | |

| EP2520189B1 (fr) | Dispositif de coiffage | |

| DE212009000096U1 (de) | Haarglättungsvorrichtung mit integrierten Heizmitteln | |

| EP0897275B1 (fr) | Appareil pour onduler ou boucler les cheveux et procede approprie | |

| EP3429420B1 (fr) | Appareil de mise en forme pour le frisage ou l'ondulation des cheveux ainsi que procédé permettant de faire fonctionner un tel appareil de mise en forme des cheveux | |

| EP2520190B1 (fr) | Dispositif de coiffage | |

| DE202009005270U1 (de) | Haarformgerät | |

| DE202013103279U1 (de) | Haarformgerät | |

| DE202008001677U1 (de) | Haarformgerät | |

| DE202007007961U1 (de) | Haarformgerät | |

| DE102010030223A1 (de) | Haarglätter | |

| DE202008012871U1 (de) | Haarform- und -pflegegerät | |

| DE2748601A1 (de) | Federklammer zum ergreifen von haarstraehnen in einer frisur | |

| DE202011050477U1 (de) | Haarformgerät sowie Pflegestoffapplikator | |

| DE102012224043A1 (de) | Haarglätter |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME RS |

|

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: DE Ref document number: 1149888 Country of ref document: HK |

|

| 17P | Request for examination filed |

Effective date: 20110914 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: A45D 2/00 20060101AFI20120621BHEP Ipc: A45D 20/48 20060101ALI20120621BHEP |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH Ref country code: CH Ref legal event code: NV Representative=s name: ALDO ROEMPLER PATENTANWALT Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 581519 Country of ref document: AT Kind code of ref document: T Effective date: 20121115 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502010001549 Country of ref document: DE Effective date: 20121227 |

|

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: GR Ref document number: 1149888 Country of ref document: HK |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20121031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121031 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130211 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130131 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121031 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130228 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121031 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121031 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121031 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130228 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121031 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130201 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121031 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121031 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121031 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121031 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121031 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121031 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20130801 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502010001549 Country of ref document: DE Effective date: 20130801 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121031 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20130918 Year of fee payment: 4 |

|

| BERE | Be: lapsed |

Owner name: WIK FAR EAST LTD Effective date: 20130930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121031 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130910 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130930 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121031 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20150529 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121031 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20100910 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130910 Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121031 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140930 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140930 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 581519 Country of ref document: AT Kind code of ref document: T Effective date: 20150910 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150910 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121031 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20210923 Year of fee payment: 12 Ref country code: DE Payment date: 20210707 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502010001549 Country of ref document: DE Representative=s name: HAVERKAMP PATENTANWAELTE PARTG MBB, DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502010001549 Country of ref document: DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20220910 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230529 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230401 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220910 |