EP1567445B1 - Verfahren und vorrichtung zum dosieren flüssiger hefe - Google Patents

Verfahren und vorrichtung zum dosieren flüssiger hefe Download PDFInfo

- Publication number

- EP1567445B1 EP1567445B1 EP03778330A EP03778330A EP1567445B1 EP 1567445 B1 EP1567445 B1 EP 1567445B1 EP 03778330 A EP03778330 A EP 03778330A EP 03778330 A EP03778330 A EP 03778330A EP 1567445 B1 EP1567445 B1 EP 1567445B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- yeast cream

- opening

- outlet passage

- liters

- use according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 240000004808 Saccharomyces cerevisiae Species 0.000 title claims abstract description 174

- 238000000034 method Methods 0.000 title abstract description 3

- 239000006071 cream Substances 0.000 claims abstract description 166

- 239000000463 material Substances 0.000 claims description 13

- 238000005303 weighing Methods 0.000 claims description 7

- 239000000654 additive Substances 0.000 claims description 4

- 239000004615 ingredient Substances 0.000 claims description 4

- 230000001681 protective effect Effects 0.000 claims description 4

- 230000011664 signaling Effects 0.000 claims 1

- 238000000605 extraction Methods 0.000 abstract description 2

- 235000014680 Saccharomyces cerevisiae Nutrition 0.000 description 138

- -1 enzyme preparations Substances 0.000 description 10

- 238000004806 packaging method and process Methods 0.000 description 8

- 239000007787 solid Substances 0.000 description 8

- 239000007788 liquid Substances 0.000 description 7

- 238000003860 storage Methods 0.000 description 7

- 239000004698 Polyethylene Substances 0.000 description 6

- 235000013305 food Nutrition 0.000 description 6

- 238000009434 installation Methods 0.000 description 6

- 239000010410 layer Substances 0.000 description 6

- 229920000573 polyethylene Polymers 0.000 description 6

- 238000002360 preparation method Methods 0.000 description 6

- 239000000725 suspension Substances 0.000 description 6

- 238000001514 detection method Methods 0.000 description 5

- 230000003014 reinforcing effect Effects 0.000 description 5

- 239000004744 fabric Substances 0.000 description 4

- 210000005253 yeast cell Anatomy 0.000 description 4

- 239000004952 Polyamide Substances 0.000 description 3

- 239000004743 Polypropylene Substances 0.000 description 3

- 239000000356 contaminant Substances 0.000 description 3

- 229920001684 low density polyethylene Polymers 0.000 description 3

- 239000004702 low-density polyethylene Substances 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 235000015927 pasta Nutrition 0.000 description 3

- 229920002647 polyamide Polymers 0.000 description 3

- 229920001155 polypropylene Polymers 0.000 description 3

- 239000003381 stabilizer Substances 0.000 description 3

- CIWBSHSKHKDKBQ-JLAZNSOCSA-N Ascorbic acid Chemical compound OC[C@H](O)[C@H]1OC(=O)C(O)=C1O CIWBSHSKHKDKBQ-JLAZNSOCSA-N 0.000 description 2

- 229920000881 Modified starch Polymers 0.000 description 2

- 239000006057 Non-nutritive feed additive Substances 0.000 description 2

- 235000013361 beverage Nutrition 0.000 description 2

- 239000003638 chemical reducing agent Substances 0.000 description 2

- 238000004140 cleaning Methods 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- 230000001934 delay Effects 0.000 description 2

- 235000005911 diet Nutrition 0.000 description 2

- 230000000378 dietary effect Effects 0.000 description 2

- 230000002255 enzymatic effect Effects 0.000 description 2

- 230000005484 gravity Effects 0.000 description 2

- 229920001903 high density polyethylene Polymers 0.000 description 2

- 239000004700 high-density polyethylene Substances 0.000 description 2

- 229920000092 linear low density polyethylene Polymers 0.000 description 2

- 239000004707 linear low-density polyethylene Substances 0.000 description 2

- 239000006194 liquid suspension Substances 0.000 description 2

- 235000019426 modified starch Nutrition 0.000 description 2

- 230000003287 optical effect Effects 0.000 description 2

- 239000007800 oxidant agent Substances 0.000 description 2

- 229920000728 polyester Polymers 0.000 description 2

- 239000005020 polyethylene terephthalate Substances 0.000 description 2

- 229920000139 polyethylene terephthalate Polymers 0.000 description 2

- 229920001343 polytetrafluoroethylene Polymers 0.000 description 2

- 239000004810 polytetrafluoroethylene Substances 0.000 description 2

- 238000004321 preservation Methods 0.000 description 2

- ZIIUUSVHCHPIQD-UHFFFAOYSA-N 2,4,6-trimethyl-N-[3-(trifluoromethyl)phenyl]benzenesulfonamide Chemical compound CC1=CC(C)=CC(C)=C1S(=O)(=O)NC1=CC=CC(C(F)(F)F)=C1 ZIIUUSVHCHPIQD-UHFFFAOYSA-N 0.000 description 1

- PWKSKIMOESPYIA-UHFFFAOYSA-N 2-acetamido-3-sulfanylpropanoic acid Chemical compound CC(=O)NC(CS)C(O)=O PWKSKIMOESPYIA-UHFFFAOYSA-N 0.000 description 1

- 239000004382 Amylase Substances 0.000 description 1

- 102000013142 Amylases Human genes 0.000 description 1

- 108010065511 Amylases Proteins 0.000 description 1

- 101710121765 Endo-1,4-beta-xylanase Proteins 0.000 description 1

- 239000004366 Glucose oxidase Substances 0.000 description 1

- 108010015776 Glucose oxidase Proteins 0.000 description 1

- 239000004367 Lipase Substances 0.000 description 1

- 102000004882 Lipase Human genes 0.000 description 1

- 108090001060 Lipase Proteins 0.000 description 1

- 239000004368 Modified starch Substances 0.000 description 1

- 108090000854 Oxidoreductases Proteins 0.000 description 1

- 102000004316 Oxidoreductases Human genes 0.000 description 1

- 102000015439 Phospholipases Human genes 0.000 description 1

- 108010064785 Phospholipases Proteins 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- 239000001318 acylated distarch adipate Substances 0.000 description 1

- WNLRTRBMVRJNCN-UHFFFAOYSA-L adipate(2-) Chemical compound [O-]C(=O)CCCCC([O-])=O WNLRTRBMVRJNCN-UHFFFAOYSA-L 0.000 description 1

- 238000013019 agitation Methods 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 235000019418 amylase Nutrition 0.000 description 1

- 239000007900 aqueous suspension Substances 0.000 description 1

- 239000011668 ascorbic acid Substances 0.000 description 1

- 235000010323 ascorbic acid Nutrition 0.000 description 1

- 229960005070 ascorbic acid Drugs 0.000 description 1

- 235000015173 baked goods and baking mixes Nutrition 0.000 description 1

- 230000033228 biological regulation Effects 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 238000011109 contamination Methods 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 229940079919 digestives enzyme preparation Drugs 0.000 description 1

- 239000003814 drug Substances 0.000 description 1

- 239000003995 emulsifying agent Substances 0.000 description 1

- 239000003623 enhancer Substances 0.000 description 1

- 235000010037 flour treatment agent Nutrition 0.000 description 1

- 235000003086 food stabiliser Nutrition 0.000 description 1

- 229940116332 glucose oxidase Drugs 0.000 description 1

- 235000019420 glucose oxidase Nutrition 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 230000002427 irreversible effect Effects 0.000 description 1

- 239000002648 laminated material Substances 0.000 description 1

- 235000019421 lipase Nutrition 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000012569 microbial contaminant Substances 0.000 description 1

- 244000005700 microbiome Species 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 239000002357 osmotic agent Substances 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 230000002572 peristaltic effect Effects 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920000515 polycarbonate Polymers 0.000 description 1

- 239000004417 polycarbonate Substances 0.000 description 1

- 229920005862 polyol Polymers 0.000 description 1

- 150000003077 polyols Chemical class 0.000 description 1

- 239000003755 preservative agent Substances 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 230000001737 promoting effect Effects 0.000 description 1

- 238000005057 refrigeration Methods 0.000 description 1

- 230000002787 reinforcement Effects 0.000 description 1

- 150000003839 salts Chemical class 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 230000006641 stabilisation Effects 0.000 description 1

- 238000011105 stabilization Methods 0.000 description 1

- 238000003756 stirring Methods 0.000 description 1

- 238000012360 testing method Methods 0.000 description 1

- 238000013022 venting Methods 0.000 description 1

- 238000012795 verification Methods 0.000 description 1

- 230000035899 viability Effects 0.000 description 1

- 230000000007 visual effect Effects 0.000 description 1

- 235000010493 xanthan gum Nutrition 0.000 description 1

- 239000000230 xanthan gum Substances 0.000 description 1

- 229920001285 xanthan gum Polymers 0.000 description 1

- 229940082509 xanthan gum Drugs 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67D—DISPENSING, DELIVERING OR TRANSFERRING LIQUIDS, NOT OTHERWISE PROVIDED FOR

- B67D1/00—Apparatus or devices for dispensing beverages on draught

- B67D1/08—Details

- B67D1/12—Flow or pressure control devices or systems, e.g. valves, gas pressure control, level control in storage containers

- B67D1/1202—Flow control, e.g. for controlling total amount or mixture ratio of liquids to be dispensed

- B67D1/1204—Flow control, e.g. for controlling total amount or mixture ratio of liquids to be dispensed for ratio control purposes

- B67D1/1225—Weighing

- B67D1/1227—Weighing the cup to be filled

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67D—DISPENSING, DELIVERING OR TRANSFERRING LIQUIDS, NOT OTHERWISE PROVIDED FOR

- B67D3/00—Apparatus or devices for controlling flow of liquids under gravity from storage containers for dispensing purposes

- B67D3/0009—Apparatus or devices for controlling flow of liquids under gravity from storage containers for dispensing purposes provided with cooling arrangements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67D—DISPENSING, DELIVERING OR TRANSFERRING LIQUIDS, NOT OTHERWISE PROVIDED FOR

- B67D3/00—Apparatus or devices for controlling flow of liquids under gravity from storage containers for dispensing purposes

- B67D3/0029—Apparatus or devices for controlling flow of liquids under gravity from storage containers for dispensing purposes provided with holders for bottles or similar containers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67D—DISPENSING, DELIVERING OR TRANSFERRING LIQUIDS, NOT OTHERWISE PROVIDED FOR

- B67D3/00—Apparatus or devices for controlling flow of liquids under gravity from storage containers for dispensing purposes

- B67D3/0058—Details

- B67D3/008—Supports

- B67D3/0083—Supports for the liquid container

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67D—DISPENSING, DELIVERING OR TRANSFERRING LIQUIDS, NOT OTHERWISE PROVIDED FOR

- B67D3/00—Apparatus or devices for controlling flow of liquids under gravity from storage containers for dispensing purposes

- B67D3/04—Liquid-dispensing taps or cocks adapted to seal and open tapping holes of casks, e.g. for beer

- B67D3/041—Liquid-dispensing taps or cocks adapted to seal and open tapping holes of casks, e.g. for beer operated by pinching action on flexible tubes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67D—DISPENSING, DELIVERING OR TRANSFERRING LIQUIDS, NOT OTHERWISE PROVIDED FOR

- B67D1/00—Apparatus or devices for dispensing beverages on draught

- B67D1/08—Details

- B67D1/0801—Details of beverage containers, e.g. casks, kegs

- B67D2001/0827—Bags in box

Definitions

- the present invention relates to the use of a device and method for the determination of stable baker's yeast cream and the device, and in particular stabilized yeast cream.

- baker's yeast in the form of a baker's yeast cream.

- baker's yeast cream is meant a liquid suspension, typically an aqueous suspension, of live baker's yeast cells, said suspension having a solids content of at least 12% by weight and generally between 12 and 50% by weight. mass (extended definition of yeast cream).

- the cream of baker's yeast meets the normal definition of yeast cream, that is to say that it has a solids content of between 12 and 25% by weight, and even more preferably between 15 and 22% in mass.

- the present invention is also useful for creams of yeast bakery high solids content, that is to say at least 25% by weight, such as in particular creams of yeast bakery high density containing a or several osmotic agents, such as, for example, polyhydroxy food compounds and food salts.

- Such creams of high-density bakery yeast which may in particular have a solids content of 25 to 48% by weight, or 25 to 46% by weight, are known and are for example described in WO91 / 1235 and W003 / 048342 .

- a stable yeast cream is a yeast cream long enough to retain its homogeneity so that it can be stored without agitation, during storage and possibly transport, until it is used in the preparation of a dough in a bakery.

- a stabilized baker's yeast cream is a baker's yeast cream containing one or more dietary stabilizers that delay or prevent the settling of yeast cells from the suspension. Thanks to the presence of said food stabilizer (s) in the suspension, the yeast cream retains its homogeneity for a longer time when it is kept without stirring.

- various dietary stabilizers useful for the stabilization of yeast cream there may be mentioned gums, such as xanthan gum, and thermally and / or chemically modified starches, such as acetylated diamidon adipate as defined by US Pat. modified starch E1422.

- Such stabilized yeast creams are for example described in EP-A-0 792 930 .

- the stable yeast cream is preferably a stabilized yeast cream.

- the homogeneity of the yeast cream that is to say the substantial absence of a concentration gradient of solids in the cream, is an important property for the baker.

- the main advantage for the baker of using a baker's yeast cream is that it allows easy dosing thanks to its liquid form.

- this yeast dosage can be accurate and reliable only if the yeast cream is homogeneous.

- the absence of homogeneity or, in other words, the presence in the baker's yeast cream of a perceptible gradient in dry matter concentration leads to errors in the quantity of yeast cells assayed during successive dosing of the yeast. cream for its introduction into pasta and thus causes variations in the quality of baked goods baked with these pasta.

- Stable or stabilized baker's yeast cream may also include one or more other ingredients, such as bread improvers (oxidants, reducers, enzyme preparations, emulsifiers) and / or preservatives and / or other processing aids such as polyols.

- bread improvers oxidants, reducers, enzyme preparations, emulsifiers

- preservatives / or other processing aids

- polyols such as polyols.

- Stable or stable baker's yeast cream is a highly perishable food product and must be kept cool.

- the temperature prevailing in the baker's shop where the pasta is prepared is generally at least 15 ° C. Such a temperature does not allow adequate preservation of stable or stabilized yeast cream because it causes an acceleration of the loss of viability and fermentative power of the yeast and the growth of microbial contaminants possibly present.

- the baker must store the yeast cream in his refrigerator and take it out of his refrigerator, when introducing the cream of yeast. yeast in the dough for the preparation of a dough.

- the stable or stabilized yeast cream is packaged in quantities corresponding to the amount of yeast cream necessary for the preparation of a single batch of dough.

- This option which may be suitable for the housewife, is not for the baker because it causes a higher price of the cream and removes bakers flexibility in its fabrications, which are generally multiple.

- the yeast cream is packaged in amounts corresponding to the amount of yeast cream required for the preparation of a series of batches of dough.

- the baker then has to either go out of his workshop and enter his refrigerator to measure the desired amount of yeast cream, or take the yeast cream pack out of his refrigerator, measure the desired quantity. of yeast cream and immediately replace the yeast cream package in its refrigerator.

- the present invention provides an elegant solution to these problems and allows the baker who consumes, for example, between 3 and 300 liters of yeast cream per week, to use stable yeast cream stabilized under the best conditions.

- the present invention relates in particular to a device for the bakery dosage of stable or stabilized baker's yeast cream.

- Said device comprises a piece of furniture provided with a compartment or refrigerating chamber.

- the internal temperature of this refrigerating compartment is - 2 ° C to 12 ° C, preferably 0 to 10 ° C and more preferably 0 to 5 ° C.

- the device also includes an exchangeable transport container containing stable or stabilized yeast cream.

- This exchangeable transport tank has a total internal volume of between 1 and 100 liters, preferably between 3 and 100 liters, more preferably between 5 and 50 liters, and more preferably between 10 and 25 liters.

- the exchangeable transport tank is located in the refrigerating compartment and has an outlet opening for the yeast cream.

- the device also has an outlet passage for the determination of the yeast cream. Said passage connects the outlet opening of the exchangeable transport tank with a withdrawal opening located outside the refrigerating chamber.

- the device also includes an opening / closing mechanism including a manual lever of said outlet passage.

- This opening / closing mechanism makes it possible, on the one hand, to open the outlet passage for the withdrawal of the yeast cream and, on the other hand, to close the outlet passage to stop the withdrawal of the cream. yeast.

- the device according to the invention for the determination of yeast cream allows the withdrawal of a metered amount of yeast cream from the exchangeable transport tank via the withdrawal opening by the actuation of the opening / closing mechanism.

- the device according to the invention therefore allows the baker consuming, for example, between 3 and 300 liters of yeast cream per week to use yeast cream under the best conditions. Indeed, the yeast cream is kept cool and the baker has access without having to look inside his refrigerator.

- the invention makes it possible to maintain the quality of the yeast cream during a maximum preservation time, since the yeast cream is kept at a controlled storage temperature until it is drawn off.

- the invention also has the advantage of allowing space-saving dosing devices and allowing dosing devices of simple and easy-to-use design. It is noted for example that the device according to the invention does not require the presence of a pump for withdrawing the yeast cream from the reservoir.

- the device comprises a pump for yeast cream, it is preferably a peristaltic pump.

- the furniture of the device according to the invention is advantageously provided with transport means, such as wheels. This facilitates the movement of the device in the baker's workshop.

- a transport container is a container for transporting a stable or stabilized yeast cream under hygienic conditions, for example when transporting the supplier's yeast cream to the baker.

- the transport tank can be in various embodiments.

- rigid containers or containers self-supporting

- more or less flexible bags including in particular deflatable bags.

- the more or less flexible bags themselves are preferably contained in another rigid package (self-supporting) as a carton.

- a self-supporting packaging or overpack is a package or overpack which can, in the filled state, be stored in height on several layers without deforming.

- the rigidity of the whole is provided essentially by the or over-packaging.

- the transport tank whether rigid or flexible, is made of suitable materials for the transport of food products, such as yeast cream.

- PE polyethylene

- HDPE high density polyethylene

- LDPE low density polyethylene

- LDPE linear low density polyethylene

- PBT polyethylene terephthalate

- PTFE polytetrafluoroethylene

- PP polypropylene

- PA polyamide

- the walls of the transport tank may be made of single-layer materials or multi-layer materials, such as laminated or laminated materials, including for example a metal layer, such as an aluminum layer, and corrugated board or non-corrugated plasticized.

- the transport tank allows the baker to visually determine or estimate the amount of yeast cream present in the tank, in particular because the tank is transparent or translucent or has one or more transparent or translucent parts.

- the total internal volume of the exchangeable transport tank corresponds to the maximum volumetric content that can contain said tank.

- the total internal volume simply corresponds to the internal volume of said tank.

- the total internal volume of the tank is the volume of the bag in the inflated state.

- the transport tank is an exchangeable tank.

- the transport tank can therefore be mounted in the refrigerating compartment and can then be removed from the refrigerating compartment, for example, after the determination of all the stable or stabilized yeast cream present in the tank, or after a period of time. Stable or stabilized yeast cream is given in order to replace it with fresh stable or stabilized yeast cream.

- the present invention has the advantage of not requiring mechanical means for maintaining the homogeneity of the yeast cream which is in the exchangeable transport tank.

- the device according to the invention does not particularly require the presence of an agitator inside the transport tank.

- the device according to the invention does not require the presence of a horizontal axis for rotating the transport container containing stable or stabilized yeast cream.

- the outlet opening of the exchangeable transport tank is typically located at the bottom of the refrigerating compartment.

- said outlet opening is situated at the bottom of the refrigerating compartment and the outlet passage is preferably such that the yeast cream present in the exchangeable transport tank can be extracted by gravity via the outlet passage and the opening. racking.

- the outlet passage of the device according to the invention may also be such that the yeast cream present in the exchangeable transport tank may be siphoned via the outlet passage to the withdrawal opening.

- the exit passage may consist of a single piece or may consist of several cooperating elements.

- the outlet passage is an open-ended tube.

- the outlet passage for example in the form of an open-ended tube, forms an integral part of the exchangeable transport tank.

- the outlet passage for example in the form of an open-ended tube, is a separate part mounted on the exchangeable transport tank.

- the outlet passage for example in the form of an open-ended tube, advantageously comprises a flexible part. Indeed, in this case the outlet passage can be closed simply by pinching said flexible portion and can be opened simply by releasing it.

- the closure / opening mechanism of the device according to the invention is designed to allow the closure of the outlet passage by pinching the flexible portion and its opening by releasing said flexible portion.

- the device according to the invention may comprise a weighing apparatus provided with a support surface for a container.

- a weighing apparatus provided with a support surface for a container.

- Such weighing apparatus makes it possible to weigh the quantity of the yeast cream introduced into the container during the withdrawal of the yeast cream.

- the opening / closing mechanism is operated manually or by the presence or absence of a container below the withdrawal opening.

- the opening / closing mechanism may, for example, be actuated by means of a lever which is moved with the hand or by the container to contain the amount of stable or stabilized yeast cream necessary for the production of a batch of dough to be kneaded.

- the device may also be provided with a system detecting the presence or absence of a container below the withdrawal opening. Such a detection system may for example be an optical system.

- the exchangeable transport tank may be a rigid container or container (self-supporting) having, according to the invention, a total internal volume of between 1 and 100 liters, preferably between 3 and 100 liters, more preferably between 5 and 50 liters, and more preferably between 10 and 25 liters, or a flexible bag, especially a deflatable bag, having such a total internal volume, that is to say an internal volume in the inflated state between 1 and 100 liters, preferably between 3 and 100 liters, more preferably between 5 and 50 liters, and more preferably between 10 and 25 liters.

- the deflatable bag may be a polyethylene bag having a wall thickness of 10 to 200 ⁇ m, preferably 10 to 100 ⁇ m, such as for example 25 or 30 to 50 ⁇ m.

- the preferred solution is the flexible bag made of standard polyethylene, that is to say in linear low density polyethylene or not.

- the embodiment of the device according to the invention according to which the device comprises such a deflatable bag is particularly advantageous because it allows the withdrawal of a quantity of yeast cream from the deflatable bag via the withdrawal opening. actuating the opening / closing mechanism without gas penetration from the outside of the deflatable bag into the deflating bag.

- deflatable bags are known in particular for the transport and storage of beverages, such as wine, and in drip in medicine.

- the essential characteristic of the deflatable bags is that they are flexible enough to allow the outflow of a liquid present in the bag, without compensation of the volume of liquid exiting through a gas inlet.

- the deflatable bags are characterized by the fact that they deflate and therefore their internal volume decreases as the liquid comes out.

- deflatable bag makes it possible, in particular, to preserve the yeast cream in the refrigerating compartment of the device without the yeast cream coming into contact with contaminants, such as microorganisms, present in the environment at home. baker.

- the deflatable bag is in a carrier mesh basket or a rigid box (self-supporting).

- This type of deflatable bag in box or basket is known commercially as "bag-in-box".

- An example of such a “bag-in-box” is described in US-B-6,223,981 .

- the deflatable bag is suspended in the refrigerating compartment.

- the refrigerating compartment is provided with means for suspending the bag.

- the deflatable bag is provided with means facilitating its suspension, such as one or eyelets, or said eyelets being advantageously reinforced.

- the device may be provided with means for applying pressure to the outside of the deflatable bag present in the refrigerating compartment.

- the device may be provided with means for increasing the pressure in the refrigerating compartment.

- Mechanical means can also be envisaged to apply pressure to the deflatable bag.

- a pressure medium is particularly useful in the case of highly viscous yeast creams and / or when the deflating bag is almost empty.

- Such pressure means are in particular known from DE-A-3,502,455 .

- the refrigerating chamber and / or the deflatable bag can also be provided with other means promoting an emptying or easier and / or more complete drainage of the deflatable bag.

- Such means are described in particular in DE-A-3,502,455 , WO 89/00535 , WO 85/04383 , WO 90/06888 , WO 01/79072 and EP-A-0 138 620 .

- the transport tank according to the invention is preferably resistant to free falls of a height of 110 cm.

- the transport container containing stable yeast cream remains tight when it is subjected to a single free fall of a height of 110 cm, even if the impact between the tank and the ground is made obliquely, especially on the upper or lower edge of the transport tank.

- baskets and boxes for flexible or deflatable bags that are specifically designed to have a high resistance to falls and in particular oblique falls.

- the contribution of the basket or the box to the resistance to falls is particularly effective when the outer transverse contour of the pocket is greater than the internal transverse contour of the basket or the box.

- the flexible or deflatable bag may also be provided with a reinforcing layer or bag, for example polypropylene, polyester, polyethylene or polyamide, which surrounds the flexible or deflatable bag.

- This reinforcing layer or pocket may, for example, be a net or reinforcing fabric, it has the same reinforcing role as the mesh basket.

- a preferred solution is in the field of food liquids, such as yeast creams to use a flexible pouch, standard polyethylene, a reinforcement pouch and a carton, all being self-supporting as defined above.

- the baker can avoid annoying delays or interruptions of work at the moment when a first exchangeable transport tank of a device is empty or almost empty, passing at this time for the withdrawal of yeast cream to a second exchangeable transport tank of the device .

- the device preferably comprises for each of its exchangeable transport tanks an outlet passage connecting the outlet opening of said reservoir with a withdrawal opening outside the refrigerating chamber in which the reservoir is located, as well as an opening / closing mechanism for opening and closing this outlet passage.

- the cabinet of the device according to the invention may thus comprise at least two refrigerated compartments which contain an exchangeable transport container containing stable or stabilized yeast cream as described above.

- the furniture of the device according to the invention may also comprise a refrigerating compartment which contains at least two such exchangeable transport tanks containing stable or stabilized yeast cream.

- the baker can also avoid troublesome delays or work interruptions by using an installation according to the invention comprising at least two devices according to the invention.

- the invention also relates to transport containers containing stable or stabilized yeast cream.

- Said tanks have a total internal volume of between 3 and 100 liters, preferably between 5 and 50 liters, and more preferably between 10 and 25 liters.

- the transport tank according to the invention is further provided with an outlet opening and a hollow tube comprising a flexible portion located outside the tank. The outlet opening ends in the hollow tube or vice versa.

- the hollow tube may be an open ended tube.

- the hollow tube can be closed in a sealed manner, the closed end being removed or opened for the withdrawal of the transport tank dosed amounts of cream yeast.

- Such tanks for the transport and storage of yeast which are provided with a vent are described in JP-A-062 709 681 , JP-A-06 181 751 , EP-A-0 599 776 and EP-A-0 792 930 .

- the transport tank according to the invention is generally usefully provided with a vent means.

- the transport tank according to the invention provided with vent means is preferably oriented so that the vent means is at least partially above the level of the yeast cream.

- the presence of a vent on the transport tank is much smaller or even, depending on the case, superfluous, because the transport tank is in the compartment refrigeration.

- the venting means of the transport tank according to the invention is located on the hollow tube, for example at the end of the hollow tube opposite the outlet opening of the transport tank. .

- the transport tank according to this embodiment is typically oriented with the hollow tube, operating as a vent positioned above the level of the yeast cream.

- the hollow tube can be converted into an outlet passage by removing the vent located on the tube opposite the outlet opening.

- the hollow tube can be converted into an outlet passage allowing gravity to be withdrawn from the yeast cream by changing the orientation of the tank so that the outlet opening is at the bottom of the cooling compartment and removing the Vent of the hollow tube.

- the CO 2 permeable and liquid-tight vents are particularly preferred.

- Suitable vents and materials for their manufacture are known in the state of the art and are for example described in DE-A-2 509 258 , US-A-4,136,796 , FR-A-2,259,026 , EP-A-0 593 840 and EP-A-0 729 901 .

- the transport tank according to the invention is a deflatable bag.

- a first over-packaging may for example be a protective over-packaging providing mechanical strength in a flexible resistant material, such as a net or a fabric made of said flexible resistant material.

- a second over-packaging may for example be constituted by a rigid box, the assembly being self-supporting as defined above.

- the over-pack of flexible material of the flexible or deflatable bag for reinforcing the mechanical strength of said flexible or deflatable bag, is welded at least partially to the contour of the flexible bag.

- the transport tank according to the invention as it is placed in the refrigerating compartment according to the invention, is advantageously transparent or translucent or comprises one or more transparent or translucent parts.

- the present invention also relates to kits for producing transport tanks according to the invention.

- Such a kit comprises a transport tank containing stable or stabilized yeast cream.

- Said tank has a total internal volume of between 3 and 100 liters, preferably between 5 and 50 liters, more preferably between 10 and 25 liters.

- the kit also includes a hollow tube having a flexible portion.

- the transport tank and the hollow tube of the kit can be supplied together or separately to the baker.

- Said transport tank and said hollow tube are provided with connecting means for mounting the hollow tube on the transport tank so as to provide a transport tank according to the invention.

- connection means of the transport tank and the hollow tube may, for example, be designed so that an outlet opening is created in the transport tank, for example by perforating said tank, when the tube is mounted on The reservoir.

- the hollow tube of the kit may be a disposable hollow tube.

- the connection means are useful such that the mounting of the hollow tube on the tank is irreversible.

- the hollow tube of the kit may also be a multipurpose hollow tube, which after being mounted on a first tank of the kit, can be detached from said first tank to be mounted on a second tank, preferably after cleaning.

- the transport tank of the kit according to the invention may be a deflatable bag, said bag being advantageously surrounded by one or more mechanical protective overpackages, such as mesh or flexible fabric providing mechanical strength and / or rigid box (freestanding), preferably cardboard, or a wire basket.

- mechanical protective overpackages such as mesh or flexible fabric providing mechanical strength and / or rigid box (freestanding), preferably cardboard, or a wire basket.

- yeast cream or “cream of baker's yeast »relates to a liquid suspension, typically aqueous, of living baker's yeast cells, this suspension having a solids content of at least 12% by weight and generally between 12 and 50% by weight (extended definition), that the yeast cream may be a dry baker's yeast cream with a solids content greater than 25% by weight, but that, preferably, the yeast cream has a solids content between 12 and 25% by weight (normal definition ), and more preferably between 15 and 22% by weight.

- said yeast cream may further comprise ingredients, additives or technological aids having a bread-making enhancer role and / or a role of maintaining the homogeneity of the suspension composed by the mixture thus obtained.

- Said ingredients, additives or processing aids improving breadmaking are, for example, taken alone or in combination, oxidants such as ascorbic acid, reducing agents such as L-cysteine, enzymatic preparations having one or more enzymatic activities such as amylase (s), xylanase (s), lipase (s) and / or phospholipase (s), oxidase (s) such as glucose oxidase.

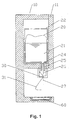

- the device for dosing stabilized bakery yeast cream comprises a refrigerated compartment 10 provided with a door 11.

- the temperature inside the refrigerating chamber 10 is set at about 3 ° C.

- a deflatable bag 20 containing stabilized yeast cream 21 is inside the refrigerating compartment 10.

- the deflatable bag 20 is in a rigid box 22 of cardboard.

- the deflatable bag 20 is suspended in the refrigerating compartment 10.

- eyelets 23 are provided in the deflatable bag 20 and the refrigerating compartment 10 is provided with hooks 12 which enter the eyelets 23 of the bag 20.

- the outlet opening 24 of the deflatable bag 20 is located at the bottom of the refrigerating compartment 10.

- a rigid plastic ring 25 surrounds the outlet opening 24 which ends in a hollow tube 26 of flexible material.

- Said hollow tube 26 constitutes the outlet passage for the determination of yeast cream and ends in the withdrawal opening 27.

- An opening / closing mechanism 30 opens the outlet passage for the withdrawal of the yeast cream by releasing the flexible hollow tube 26 and also allows, after the withdrawal of the desired amount of yeast cream, to close the outlet passage by pinching the flexible hollow tube 26 so as to prevent the yeast cream from flowing out of the deflatable bag 20.

- the bag 20 is a deflatable bag, there are no gas bubbles entering the bag 20 to compensate for the volume of the yeast cream dosed.

- the yeast cream 21 remaining in the bag 20 is thus preserved under the best hygienic conditions.

- the outlet passage is opened and closed by means of a lever 31.

- the lever 31 By pushing said lever back, for example by means of the container in which it is desired to collect the dosed amount of yeast cream, the lever 31 releases the passage of outlet so that the yeast cream flows from the withdrawal opening 27.

- the lever 31 By releasing the lever 31, for example by removing the container, the lever rests against the flexible hollow tube 26, and closes thus the output passage.

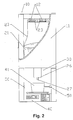

- the figure 2 shows a more sophisticated form of execution.

- the device is provided with a weighing means 40.

- the baker enters the desired amount of yeast cream.

- a control station (no shown) actuates the automatic opening of the outlet passage by the opening / closing mechanism 30.

- the control station actuates the automatic closure of the outlet passage by the opening / closing mechanism 30.

- the device is provided with an optical system 50 for detecting the presence of a receptacle 41, the control station only actuating the opening of the outlet passage when the detection system 50 detects the presence of a container 41 below the withdrawal opening 27.

- the device is provided with a security means detecting flows of yeast cream not captured by a container.

- detection means may be in the form of a collection basin 60 below the outlet opening 27, said basin 60 being provided with a level detector, the control station actuating the closing of the outlet passage as soon as possible. detecting a predetermined level of liquid in the collection basin 60.

- the figure 3 shows a device according to the invention mounted on wheels whose refrigerating compartment contains two exchangeable transport tanks containing stabilized baker's yeast cream.

- the refrigerating compartment is designed to accommodate two transport tanks according to the invention of the bag-in box type.

- Said transport tanks are supplied to the baker in the form of a kit according to the invention comprising, on the one hand, one or more transport tanks containing stabilized baker's yeast cream and, on the other hand, one or more flexible hollow tubes.

- the baker Before placing a transport tank in the refrigerating compartment 10, the baker assembles the hollow tube 26 on the transport tank so as to form an outlet passage for the yeast cream contained in the tank. When the tank is emptied, the hollow tube 26 is detached from the tank to be reassembled on a new transport tank after cleaning.

- the front part of the opening / closing mechanism 30 can be disassembled or opened to facilitate the extraction of the empty transport tank and the insertion of a new full transport tank, after which the front part of the mechanism of opening / closing 30 is put back in place or closed.

- the rigid cardboard box 22 in which the deflating bag is located is provided with a series of openings 28 enabling the baker to visually check the level of the stabilized yeast cream present in the transport tank. This visual verification is further facilitated when the door 11 of the refrigerating chamber is transparent in front of this series of openings 28.

- the rigid box 22 is also provided with a detection means 29a, 29b making it possible to check whether the reservoir and the baker's yeast cream that it contains have been kept at a sufficiently low temperature to allow a good conservation of the cream, especially during transport and storage of the filled tank.

- a detection means 29a, 29b making it possible to check whether the reservoir and the baker's yeast cream that it contains have been kept at a sufficiently low temperature to allow a good conservation of the cream, especially during transport and storage of the filled tank.

- the portion 29a of the detection means gradually changes color so as to alert the baker or his supplier.

- the device is also provided with an indicator 13 of the temperature inside said refrigerating compartment 10, as well as an alarm 14a and b warning the baker when the temperature inside the refrigerating compartment 10 does not correspond to the temperature.

- this alarm consists of two light indicators 14a and b, the green indicator 14a being lit when the temperature inside the refrigerating compartment 10 is in this temperature range, the red indicator 14b being turned on in the opposite case. This alarm can be replaced or supplemented by an audible alarm system.

- the manual lever 31 of the opening / closing mechanism 30 makes it possible to open and close the outlet passage formed by the hollow tube 26.

- the front part of the opening / closing mechanism 30 can be temporarily removed or opened to facilitate the introduction of a new tank in the refrigerating compartment 10.

- the bag 20 may be further over-packaged in a flexible over-packaging, such as an over-packing type net or fabric, resistant material to ensure the bag mechanical protection, this variant is not shown in the figures.

- a flexible over-packaging such as an over-packing type net or fabric, resistant material to ensure the bag mechanical protection

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Micro-Organisms Or Cultivation Processes Thereof (AREA)

- Bakery Products And Manufacturing Methods Therefor (AREA)

- Dairy Products (AREA)

- Baking, Grill, Roasting (AREA)

Claims (19)

- Verwendung, zum Dosieren von stabilem Heferahm (21), einer Vorrichtung zur Dosierung von stabilem Backheferahm (21) in einer Bäckerei, wobei die Vorrichtung Folgendes umfasst:- ein Möbelstück, das mit einem Kühlfach (10) ausgestattet ist, das eine Innentemperatur aufweist, die auf zwischen -2 °C und 12 °C, vorzugsweise zwischen 0 und 5 °C eingestellt ist;- einen austauschbaren Transportbehälter (20), der sich in dem Kühlfach (10) befindet und den stabilen Heferahm (21) enthält, wobei der Behälter (20) ein Gesamtinnenvolumen zwischen 1 und 100 Litern, vorzugsweise zwischen 3 und 100 Litern, noch bevorzugter zwischen 5 und 50 Litern und noch mehr bevorzugt zwischen 10 und 25 Litern und eine Austrittsöffnung (24) für den Heferahm aufweist;- einen Austrittsdurchlass (26) zur Dosierung des Heferahms, wobei der Durchlass (26) die Austrittsöffnung (24) des austauschbaren Transportbehälters (20) mit einer Entnahmeöffnung (27) außerhalb des Kühlfachs (10) verbindet; und- einen Mechanismus zum Öffnen/Schließen (30) des Austrittsdurchlasses (26), der das Öffnen des Austrittsdurchlasses (26) zur Entnahme des Heferahms und das Schließen des Austrittsdurchlasses (26) zum Stoppen der Entnahme des Heferahms ermöglicht,

wobei die Vorrichtung die Entnahme einer dosierten Menge des Heferahms aus dem austauschbaren Transportbehälter (20) durch die Austrittsöffnung (27) ermöglicht. - Verwendung nach dem vorhergehenden Anspruch, dadurch gekennzeichnet, dass der austauschbare Transportbehälter (20) ein entleerbarer Beutel ist, wobei der entleerbare Beutel vorzugsweise von einer oder mehreren Umverpackungen umschlossen wird.

- Verwendung nach Anspruch 2, dadurch gekennzeichnet, dass der entleerbare Beutel von einer oder mehreren Umverpackungen umschlossen wird, die aus Schutzumverpackungen aus einem flexiblen Material und einem Drahtkorb oder einem selbsttragenden Kasten ausgewählt ist bzw. sind, wobei der entleerbare Beutel vorzugsweise von einer Schutzumpackung aus einem flexiblen Material umschlossen wird, wobei die Einheit von einem Drahtkorb oder einem selbsttragenden Kasten umschlossen wird.

- Verwendung nach Anspruch 1, dadurch gekennzeichnet, dass der austauschbare Transportbehälter ein selbsttragender Container oder Kanister ist.

- Verwendung nach Anspruch 4, dadurch gekennzeichnet, dass der Behälter mit einem System ausgestattet ist, das eine Lüftungsöffnung bildet.

- Verwendung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass der Austrittsdurchlass (26) ein Rohr mit offenen Enden ist.

- Verwendung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass der Austrittsdurchlass (26) einen biegbaren Teil umfasst und dass der Öffnungs-/Schließmechanismus (30) das Schließen des Austrittsdurchlasses (26) ermöglicht, indem der biegbare Teil eingeklemmt wird, und das Öffnen des Austrittsdurchlasses ermöglicht, indem der biegbare Teil freigegeben wird.

- Verwendung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass die Vorrichtung eine Wiegeeinrichtung (40) umfasst, die mit einer Tragefläche für ein Gefäß (41) ausgestattet ist, wobei die Wiegeeinrichtung (40) das Wiegen der Menge des Heferahms ermöglicht, die bei der Entnahme des Heferahms durch die Entnahmeöffnung (27) in das Gefäß (41) eingebracht wurde.

- Verwendung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass die Vorrichtung eine Kontrollstation umfasst, die das Öffnen und das Schließen des Austrittsdurchlasses (26) durch den Öffnungs-/Schließmechanismus (30) antreibt.

- Verwendung nach Anspruch 8, dadurch gekennzeichnet, dass die Vorrichtung eine Kontrollstation umfasst, die das Öffnen und das Schließen des Austrittsdurchlasses (26) durch den Öffnungs-/Schließmechanismus (30) antreibt, wobei die Kontrollstation das Schließen des Austrittsdurchlasses (26) bei Vorliegen einer gewünschten Menge des Heferahms in dem Gefäß (41) antreibt.

- Verwendung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass das Möbelstück mindestens zwei Kühlfächer (10) umfasst, die einen austauschbaren Transportbehälter (20) enthalten, der den stabilen Heferahm (21) enthält und ein Gesamtinnenvolumen zwischen 1 und 100, vorzugsweise zwischen 3 und 100 Litern, noch bevorzugter zwischen 5 und 50 Litern und noch mehr bevorzugt zwischen 10 und 25 Litern und eine Austrittsöffnung (24) für den Heferahm aufweist.

- Verwendung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass das Möbelstück ein Kühlfach (10) umfasst, das mindestens zwei austauschbare Transportbehälter (20) enthält, die den stabilen Heferahm (21) enthalten und ein Gesamtinnenvolumen zwischen 1 und 100 Litern, vorzugsweise zwischen 3 und 100 Litern, noch bevorzugter zwischen 5 und 50 Litern und noch mehr bevorzugt zwischen 10 und 25 Litern und eine Austrittsöffnung (24) für den Heferahm aufweisen.

- Verwendung nach einem der Ansprüche 11 und 12, dadurch gekennzeichnet, dass die Vorrichtung für jeden der austauschbaren Transportbehälter (10) Folgendes umfasst:- einen Austrittsdurchlass (26) zur Dosierung des Heferahms, wobei der Durchlass (26) die Austrittsöffnung (24) des austauschbaren Transportbehälters (20) mit einer Entnahmeöffnung (27) außerhalb des Kühlfachs (10) verbindet; und- einen Mechanismus zum Öffnen/Schließen (30) des Austrittsdurchlasses (26), der das Öffnen des Austrittsdurchlasses (26) zur Entnahme des Heferahms und das Schließen des Austrittsdurchlasses (26) zum Stoppen der Entnahme des Heferahms aus dem Transportbehälter (20) ermöglicht.

- Verwendung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass der stabile Heferahm eine Trockensubstanz zwischen 12 und 25 Massen-%, vorzugsweise zwischen 15 und 22 Massen-% aufweist.

- Verwendung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass der stabile Heferahm ein stabilisierter Heferahm ist.

- Verwendung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass der Heferahm einen oder mehrere Ingredienzien, Zusatzstoffe oder Technologiehilfsmitteln umfasst, die eine Rolle bei der Verbesserung der Brotherstellung und/oder eine Rolle bei der Aufrechterhaltung der Homogenität spielen.

- Verwendung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass die Vorrichtung außerdem Folgendes umfasst:- eine Anzeige (13) der Temperatur im Inneren des Kühlfachs (10);- eine Alarmvorrichtung (14a, 14b), die warnt, wenn die Temperatur im Inneren des Kühlfachs (10) nicht einem für die Aufbewahrung des Heferahms bestimmten Temperaturbereich entspricht.

- Vorrichtung zur Dosierung von stabilem Backheferahm (21) in einer Bäckerei, wobei die Vorrichtung Folgendes umfasst:- ein Möbelstück, das mit einem Kühlfach (10) ausgestattet ist, das eine Innentemperatur aufweist, die auf zwischen -2 °C und 12 °C, vorzugsweise zwischen 0 und 5 °C eingestellt ist;- einen austauschbaren Transportbehälter (20), der sich in dem Kühlfach (10) befindet und den stabilen Heferahm (21) enthält, wobei der Behälter (20) ein Gesamtinnenvolumen zwischen 1 und 100 Litern, vorzugsweise zwischen 3 und 100 Litern, noch bevorzugter zwischen 5 und 50 Litern und noch mehr bevorzugt zwischen 10 und 25 Litern und eine Austrittsöffnung (24) für den Heferahm aufweist;- einen Austrittsdurchlass (26) zur Dosierung des Heferahms, wobei der Durchlass (26) die Austrittsöffnung (24) des austauschbaren Transportbehälters (20) mit einer Entnahmeöffnung (27) außerhalb des Kühlfachs (10) verbindet; und- einen Mechanismus zum Öffnen/Schließen (30) des Austrittsdurchlasses (26), der das Öffnen des Austrittsdurchlasses (26) zur Entnahme des Heferahms und das Schließen des Austrittsdurchlasses (26) zum Stoppen der Entnahme des Heferahms ermöglicht,

wobei die Vorrichtung die Entnahme einer dosierten Menge des Heferahms aus dem austauschbaren Transportbehälter (20) durch die Austrittsöffnung (27) ermöglicht,

dadurch gekennzeichnet, dass die Vorrichtung außerdem Folgendes umfasst:- einen Handhebel (31) des Öffnungs-/Schließmechanismus (30), der das Öffnen und Schließen des Austrittsdurchlasses (26) ermöglicht. - Verwendung nach einem der Ansprüche 1 bis 17 einer Vorrichtung zur Dosierung von Heferahm, die zu einer Anlage zur Dosierung von stabilem Heferahm in einer Bäckerei gehört, die mindestens zwei Vorrichtungen zur Dosierung von Heferahm umfasst.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP03778330A EP1567445B1 (de) | 2002-11-22 | 2003-11-21 | Verfahren und vorrichtung zum dosieren flüssiger hefe |

| SI200332169T SI1567445T1 (sl) | 2002-11-22 | 2003-11-21 | Naprava in postopek doziranja tekočega kvasa |

Applications Claiming Priority (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP02026074 | 2002-11-22 | ||

| EP02026074 | 2002-11-22 | ||

| EP03018279 | 2003-08-12 | ||

| EP03018279 | 2003-08-12 | ||

| PCT/EP2003/013086 WO2004048253A1 (fr) | 2002-11-22 | 2003-11-21 | Dispositif et methode de dosage pour la creme de levure |

| EP03778330A EP1567445B1 (de) | 2002-11-22 | 2003-11-21 | Verfahren und vorrichtung zum dosieren flüssiger hefe |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1567445A1 EP1567445A1 (de) | 2005-08-31 |

| EP1567445B1 true EP1567445B1 (de) | 2012-04-04 |

Family

ID=32395432

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03778330A Expired - Lifetime EP1567445B1 (de) | 2002-11-22 | 2003-11-21 | Verfahren und vorrichtung zum dosieren flüssiger hefe |

Country Status (17)

| Country | Link |

|---|---|

| US (1) | US10189694B2 (de) |

| EP (1) | EP1567445B1 (de) |

| AT (1) | ATE552208T1 (de) |

| AU (1) | AU2003285342B2 (de) |

| BR (2) | BRPI0315690B1 (de) |

| CA (1) | CA2542318C (de) |

| DK (1) | DK1567445T3 (de) |

| ES (1) | ES2385476T3 (de) |

| HR (1) | HRP20050586B8 (de) |

| MA (1) | MA27529A1 (de) |

| MX (1) | MXPA05005473A (de) |

| NO (1) | NO339205B1 (de) |

| NZ (1) | NZ542786A (de) |

| PL (1) | PL206758B1 (de) |

| RU (1) | RU2329194C2 (de) |

| SI (1) | SI1567445T1 (de) |

| WO (1) | WO2004048253A1 (de) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TWI398399B (zh) | 2005-09-13 | 2013-06-11 | Lesaffre & Cie | 具有固定內管及可移動套筒之計量輸出閥 |

| FR2920157B1 (fr) * | 2007-08-23 | 2009-10-16 | Lesaffre Et Cie Sa | Nouvelles souches de levure de panification |

| KR101695332B1 (ko) * | 2009-11-12 | 2017-01-11 | 주식회사 탑 엔지니어링 | 액정공급장치 |

| FR2959003B1 (fr) * | 2010-04-14 | 2016-06-03 | Entreprise Bretonne De Tuyauterie Et Chaudronnerie Inox | Dispositif de maintien en temperature de produits |

| US8534497B2 (en) * | 2010-09-20 | 2013-09-17 | Prince Castle, LLC | Dispensing method and apparatus utilizing a sensor to determine a time that a dispensing valve is open |

| FR2984285B1 (fr) * | 2011-12-14 | 2015-05-01 | Lesaffre & Cie | Materiau et conditionnement pour la conservation des levures |

| US20130248538A1 (en) | 2012-03-23 | 2013-09-26 | Prince Castle, LLC | Holding Tank With Internally Reinforced Sidewalls and Liquid Dispenser Using Same |

| US20140069963A1 (en) * | 2012-09-07 | 2014-03-13 | Jeffrey Stein | Chilled Beverage Dispenser |

| BR112015012533B1 (pt) * | 2012-12-04 | 2020-12-29 | Chr. Hansen A/S | processo para a inoculação contínua de um produto alimentício e equipamento para a inoculação contínua de fermentos para dentro de um líquido a ser inoculado |

| FR3021505A1 (fr) * | 2014-06-03 | 2015-12-04 | Chr Hansen As | Procede d'ensemencement direct a partir de ferments concentres et dispositif associe |

| US10526189B2 (en) * | 2017-05-11 | 2020-01-07 | Grabas Limited | Gravity fed viscous liquid and food product dispensing system |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1949970A1 (de) * | 1969-10-03 | 1971-04-29 | May And Robertson Stevenage Lt | Alarmvorrichtung fuer Kuehlanlagen |

| GB1279646A (en) * | 1969-09-25 | 1972-06-28 | Freez Porter Systems Inc | Process for handling perishable materials under controlled temperature conditions |

Family Cites Families (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US135617A (en) * | 1873-02-11 | Improvement in soda apparatus | ||

| US1994496A (en) * | 1931-12-21 | 1935-03-19 | Charles L Patterson | Stabilized yeasted milk suspension and method of making the same |

| US2147271A (en) * | 1937-07-16 | 1939-02-14 | Schwarz Lab Inc | Pure yeast culture apparatus |

| US2839262A (en) * | 1955-07-18 | 1958-06-17 | Robert S Strom | Liquid heater and dispenser with weigher |

| AT247820B (de) | 1960-01-12 | 1966-06-27 | Winfried Schaefer | Verfahren zum Konservieren von Backhefe in Form von Heferahm |

| US3117695A (en) * | 1960-05-19 | 1964-01-14 | Inland Container Corp | Fluid dispensing container |

| US3138293A (en) * | 1961-03-15 | 1964-06-23 | Scholle Container Corp | Paperboard dispensing container |

| US3178064A (en) * | 1962-07-25 | 1965-04-13 | Inland Container Corp | Carton |

| FR1361910A (fr) * | 1963-02-08 | 1964-05-29 | British Petroleum Co | Procédé de production de concentrés protéines-vitamines à partir des fractions du pétrole |

| US3238978A (en) * | 1963-05-20 | 1966-03-08 | Reddi Wip Inc | Device for dispensing a viscous substance |

| US4450987A (en) * | 1979-10-25 | 1984-05-29 | D.O.V.E. Equipment Corporation | Portion control liquid dispenser |

| DE3332236A1 (de) | 1983-09-07 | 1985-03-21 | Krönert Elektro GmbH, 5880 Lüdenscheid | Verfahren und vorrichtung zum abfuellen von getraenken |

| SU1353723A1 (ru) * | 1984-12-10 | 1987-11-23 | А.С. Шпигельгл с | Устройство дл многокомпонентного дозировани |

| EP0273102B1 (de) * | 1985-11-19 | 1991-07-03 | Carl Edelmann Verpackungstechnik Gmbh | Transport- und Vorratsbehälter für Getränke- oder dgl. Konzentrate |

| EP0237260B1 (de) * | 1986-03-10 | 1989-12-20 | Solly Katz | Ausgeber für Flüssigkeiten |

| DE3622777A1 (de) * | 1986-07-07 | 1988-02-04 | Bosch Siemens Hausgeraete | Anordnung zum bereithalten und zur dosierten abgabe von fluessigkeiten |

| US4997108A (en) * | 1988-07-04 | 1991-03-05 | Hideaki Hata | Tap and liquid dispenser using the same |

| FR2655092B1 (fr) | 1989-11-24 | 1994-07-08 | Bernard Vilbert | Pompe peristaltique ouverte a rotor desaccouplable pour robot de parfumeur. |

| FI900804A7 (fi) * | 1990-02-16 | 1991-08-17 | Alko Ab Oy | Jaestpreparat och foerfarande foer dess framstaellning. |

| US5156297A (en) * | 1990-08-10 | 1992-10-20 | Boyd Coffee Company | Beverage stand with quantity indicator |

| US5244020A (en) * | 1991-07-24 | 1993-09-14 | Middleby Marshall Inc. | Dispenser |

| GB2272965B (en) * | 1992-11-27 | 1996-12-18 | Yeast Products Company | Yeast transportation and storage apparatus |

| US5464120A (en) * | 1994-05-27 | 1995-11-07 | Flurry International, Inc. | Method and apparatus for frozen dessert dispensing |

| US5490547A (en) * | 1994-08-12 | 1996-02-13 | Abadi; Meyer | System for providing a supply of chilled fluid |

| JP3018143B2 (ja) | 1996-02-28 | 2000-03-13 | 株式会社先進材料利用ガスジェネレータ研究所 | ポリイミド樹脂の成形方法及びその装置 |

| BE1010054A3 (nl) * | 1996-03-01 | 1997-12-02 | Algist Bruggeman Nv | Werkwijze voor het bereiden, verpakken en gebruiken van gestabiliseerde gistroom. |

| DE69707176T3 (de) * | 1996-03-08 | 2012-11-08 | Lesaffre Et Compagnie | Dosierung von Hefekreme |

| US6213174B1 (en) * | 1998-04-17 | 2001-04-10 | Blue Boy International Limited | Portioning of flowable products |

| US6220312B1 (en) * | 1998-11-18 | 2001-04-24 | Shandor Motion Systems | Apparatus and method for container filling |

| US6756069B2 (en) * | 1999-05-18 | 2004-06-29 | Nestec S.A. | System and method for dispensing a liquid beverage concentrate |

| TW564160B (en) | 2000-07-11 | 2003-12-01 | Nordischer Maschinenbau | Method and apparatus for filleting decapitated, slaughtered fish with their belly cavities opened |

| US6516625B2 (en) * | 2000-10-13 | 2003-02-11 | Mark Bedard | Juice dispensing apparatus |

-

2003

- 2003-11-21 EP EP03778330A patent/EP1567445B1/de not_active Expired - Lifetime

- 2003-11-21 DK DK03778330.5T patent/DK1567445T3/da active

- 2003-11-21 PL PL376230A patent/PL206758B1/pl unknown

- 2003-11-21 MX MXPA05005473A patent/MXPA05005473A/es active IP Right Grant

- 2003-11-21 ES ES03778330T patent/ES2385476T3/es not_active Expired - Lifetime

- 2003-11-21 CA CA2542318A patent/CA2542318C/fr not_active Expired - Lifetime

- 2003-11-21 BR BRPI0315690-7A patent/BRPI0315690B1/pt unknown

- 2003-11-21 HR HRP20050586AA patent/HRP20050586B8/hr not_active IP Right Cessation

- 2003-11-21 NZ NZ542786A patent/NZ542786A/en not_active IP Right Cessation

- 2003-11-21 SI SI200332169T patent/SI1567445T1/sl unknown

- 2003-11-21 BR BR0315690-7A patent/BR0315690A/pt active IP Right Grant

- 2003-11-21 AU AU2003285342A patent/AU2003285342B2/en not_active Expired

- 2003-11-21 US US10/535,844 patent/US10189694B2/en active Active

- 2003-11-21 RU RU2005119638/12A patent/RU2329194C2/ru active

- 2003-11-21 AT AT03778330T patent/ATE552208T1/de active

- 2003-11-21 WO PCT/EP2003/013086 patent/WO2004048253A1/fr not_active Ceased

-

2005

- 2005-05-23 MA MA28295A patent/MA27529A1/fr unknown

- 2005-06-22 NO NO20053061A patent/NO339205B1/no not_active IP Right Cessation

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1279646A (en) * | 1969-09-25 | 1972-06-28 | Freez Porter Systems Inc | Process for handling perishable materials under controlled temperature conditions |

| DE1949970A1 (de) * | 1969-10-03 | 1971-04-29 | May And Robertson Stevenage Lt | Alarmvorrichtung fuer Kuehlanlagen |

Also Published As

| Publication number | Publication date |

|---|---|

| BRPI0315690B1 (pt) | 2018-05-22 |

| HK1085189A1 (en) | 2006-08-18 |

| EP1567445A1 (de) | 2005-08-31 |

| NO339205B1 (no) | 2016-11-14 |

| MXPA05005473A (es) | 2005-11-17 |

| NZ542786A (en) | 2008-02-29 |

| US20060110512A1 (en) | 2006-05-25 |

| NO20053061L (no) | 2005-06-22 |

| RU2329194C2 (ru) | 2008-07-20 |

| PL206758B1 (pl) | 2010-09-30 |

| AU2003285342B2 (en) | 2009-10-29 |

| CA2542318C (fr) | 2012-08-14 |

| BR0315690A (pt) | 2005-09-20 |

| WO2004048253A1 (fr) | 2004-06-10 |

| HRP20050586B8 (hr) | 2014-09-12 |

| MA27529A1 (fr) | 2005-09-01 |

| HRP20050586A2 (en) | 2006-07-31 |

| ATE552208T1 (de) | 2012-04-15 |

| AU2003285342A1 (en) | 2004-06-18 |

| ES2385476T3 (es) | 2012-07-25 |

| DK1567445T3 (da) | 2012-07-16 |

| PL376230A1 (en) | 2005-12-27 |

| HRP20050586B1 (hr) | 2014-07-04 |

| CA2542318A1 (fr) | 2004-06-10 |

| SI1567445T1 (sl) | 2012-08-31 |

| US10189694B2 (en) | 2019-01-29 |

| RU2005119638A (ru) | 2006-01-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1567445B1 (de) | Verfahren und vorrichtung zum dosieren flüssiger hefe | |

| US9446888B2 (en) | Multi-compartmented flowable-foodstuff storage container plus dispenser and related methods | |

| US5392958A (en) | Liquid receiving and dispensing apparatus including flexible inner container positioned within insulating container | |

| PT2008553E (pt) | Embalagem para armazenar e descarregar material a granel | |

| US20090110786A1 (en) | Food Container and Method of Storing Food | |

| EP3609791A1 (de) | Behälter zur vakuumlagerung von lebensmitteln, deckel, anordnung mit dem behälter und dem deckel und system zum vakuumverpacken von lebensmitteln | |

| EP0792930B1 (de) | Verfahren und Anlage zur Konditionierung und zur Verwendung stabilisierter Hefecreme | |

| EP0377882B1 (de) | Flexible Verpackung für Flüssigkeiten | |

| FR2540850A1 (fr) | Distributeur de liquide notamment de boissons | |

| EP1425962B1 (de) | Vorrichtung zum Konditionieren von Wasserorganismen | |

| FR2871447A1 (fr) | Dispositif conteneur pour un systeme de distribution de boisson de type fontaine, elements de stockage de ces dispositifs conteneurs, fontaine d'eau et procede de conditionnement d'eau associes | |

| FR3121915A3 (fr) | Dispositif de stockage et de distribution d’un produit en vrac | |

| HK1085189B (en) | Yeast cream-dosing device and method | |

| EP2935040B1 (de) | Verpackung für verbrauchsprodukten, insbesondere nahrungsprodukten | |

| WO2015150660A1 (fr) | Contenant pour liquide comportant une poche | |

| FR2928634A1 (fr) | Conteneur pour la reception sans casse ni bruit de recipients pleins en verre | |

| HU230183B1 (hu) | Csomagolóeszköz folyékony élesztőhöz | |

| EP1206397A1 (de) | Verpackungsanordnung | |

| US20130133764A1 (en) | Cylindrical piston assisted blending vessel | |

| FR3147696A1 (fr) | Système de distribution d’un produit à distribuer, notamment d’un produit en vrac | |

| CA2145741A1 (fr) | Contenant reutilisable a volume variable | |

| JP3158539U (ja) | 液卵充填容器 | |

| FR3136455A1 (fr) | Distributeur et système de stockage de produits en vrac équipé d’un dispositif d’ouverture d’un sac de conditionnement | |

| FR3158961A1 (fr) | Equipement de distribution de produit alimentaire liquide ou semi-liquide | |

| FR3099467A1 (fr) | Contenant pour liquide alimentaire et appareil de distribution de liquide alimentaire utilisant le contenant |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20050601 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| RAX | Requested extension states of the european patent have changed |

Extension state: LT Payment date: 20050601 Extension state: MK Payment date: 20050601 Extension state: LV Payment date: 20050601 |

|

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: DE Ref document number: 1085189 Country of ref document: HK |

|

| 17Q | First examination report despatched |

Effective date: 20100624 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: LT LV MK |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 552208 Country of ref document: AT Kind code of ref document: T Effective date: 20120415 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 60340508 Country of ref document: DE Effective date: 20120531 |

|

| REG | Reference to a national code |

Ref country code: RO Ref legal event code: EPE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2385476 Country of ref document: ES Kind code of ref document: T3 Effective date: 20120725 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: ZIMMERLI, WAGNER & PARTNER AG |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| LTLA | Lt: lapse of european patent or patent extension | ||

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: GR Ref document number: 1085189 Country of ref document: HK |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: EP Ref document number: 20120401498 Country of ref document: GR Effective date: 20120903 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120404 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120806 |

|

| REG | Reference to a national code |

Ref country code: SK Ref legal event code: T3 Ref document number: E 12602 Country of ref document: SK |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120404 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20130107 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 60340508 Country of ref document: DE Effective date: 20130107 |

|

| REG | Reference to a national code |

Ref country code: HU Ref legal event code: AG4A Ref document number: E015571 Country of ref document: HU |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120704 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: WAGNER PATENT AG, CH |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121130 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 60340508 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20221021 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20221104 Year of fee payment: 20 Ref country code: SK Payment date: 20221020 Year of fee payment: 20 Ref country code: SE Payment date: 20221125 Year of fee payment: 20 Ref country code: RO Payment date: 20221026 Year of fee payment: 20 Ref country code: LU Payment date: 20221021 Year of fee payment: 20 Ref country code: IT Payment date: 20221109 Year of fee payment: 20 Ref country code: IE Payment date: 20221014 Year of fee payment: 20 Ref country code: GB Payment date: 20221121 Year of fee payment: 20 Ref country code: FR Payment date: 20221122 Year of fee payment: 20 Ref country code: FI Payment date: 20221018 Year of fee payment: 20 Ref country code: ES Payment date: 20221205 Year of fee payment: 20 Ref country code: DK Payment date: 20221025 Year of fee payment: 20 Ref country code: DE Payment date: 20221114 Year of fee payment: 20 Ref country code: CZ Payment date: 20221025 Year of fee payment: 20 Ref country code: AT Payment date: 20221018 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SI Payment date: 20221020 Year of fee payment: 20 Ref country code: HU Payment date: 20221115 Year of fee payment: 20 Ref country code: GR Payment date: 20221014 Year of fee payment: 20 Ref country code: CH Payment date: 20221129 Year of fee payment: 20 Ref country code: BE Payment date: 20221125 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 60340508 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MK Effective date: 20231120 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EUP Expiry date: 20231121 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20231128 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MK Effective date: 20231121 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20231120 |

|

| REG | Reference to a national code |

Ref country code: SK Ref legal event code: MK4A Ref document number: E 12602 Country of ref document: SK Expiry date: 20231121 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK07 Ref document number: 552208 Country of ref document: AT Kind code of ref document: T Effective date: 20231121 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20231121 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20231120 |

|