EP1531139B1 - Maschinenrahmenlose Antriebseinheit für einen Aufzug - Google Patents

Maschinenrahmenlose Antriebseinheit für einen Aufzug Download PDFInfo

- Publication number

- EP1531139B1 EP1531139B1 EP04026113.3A EP04026113A EP1531139B1 EP 1531139 B1 EP1531139 B1 EP 1531139B1 EP 04026113 A EP04026113 A EP 04026113A EP 1531139 B1 EP1531139 B1 EP 1531139B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- brake

- motor

- drive unit

- supported

- bearing block

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000006835 compression Effects 0.000 claims description 5

- 238000007906 compression Methods 0.000 claims description 5

- 238000010276 construction Methods 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000012544 monitoring process Methods 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 238000009416 shuttering Methods 0.000 description 1

- 125000006850 spacer group Chemical group 0.000 description 1

- 238000009423 ventilation Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66B—ELEVATORS; ESCALATORS OR MOVING WALKWAYS

- B66B11/00—Main component parts of lifts in, or associated with, buildings or other structures

- B66B11/04—Driving gear ; Details thereof, e.g. seals

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66B—ELEVATORS; ESCALATORS OR MOVING WALKWAYS

- B66B11/00—Main component parts of lifts in, or associated with, buildings or other structures

- B66B11/04—Driving gear ; Details thereof, e.g. seals

- B66B11/043—Driving gear ; Details thereof, e.g. seals actuated by rotating motor; Details, e.g. ventilation

Definitions

- the invention relates to a machine frame-less drive unit for a lift consisting of at least one motor, at least one brake and a traction sheave arranged between bearing plates, wherein the motor is arranged on a bearing plate.

- a drive unit consisting essentially of an electric motor, a motor stand, a bearing block, a traction sheave and a machine frame with Gegenrollenanbau known.

- the stator of the electric motor is screwed by means of a flange to the motor stand.

- the rotor of the electric motor is seated on a free end of a shaft carrying the traction sheave, which is mounted on the bearing block and the motor stator.

- the traction sheave is mounted by means of the shaft on the motor stand and on the bearing block.

- a brake is arranged in the inner region of the motor stand and covered with a shuttering.

- a disadvantage of the known device is that the brake is arranged on the inside. For maintenance, the brake parts are difficult to access.

- Another disadvantage is that no Evakuier horr is provided.

- the invention aims to remedy this situation.

- the invention as characterized in claim 1 solves the problem of avoiding the disadvantages of the known device and To provide an elevator drive with brake, which works reliably in any case and is simple.

- the advantages achieved by the invention are to be seen essentially in the fact that a drive unit with a short shaft and thus a small overall length of the drive unit can be realized. It is also advantageous that the brake release cylinder and leads are arranged separately from the brake disc. In the case of leakage or line break, the braking surfaces can not oil. Brake readiness remains guaranteed. It is also advantageous that there is more freedom for the cable guide between the traction sheave and the counter-roller with the machine frame-less design of the drive unit. As a result, larger wire rope distances are feasible. For example, the drive unit designed for large elevator cars and for large delivery heights and high speeds has a height of more than two meters and a total weight of more than ten tons, whereby weight and costs can be saved with the frame-less design. It is also advantageous that an evacuation engages over a sprocket and a pinion with the brake disc.

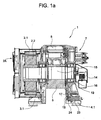

- Fig. 1 shows the ready assembled drive unit 1, consisting essentially of a motor 2A, serving as a bearing plate motor stand 3, serving as a bearing plate bearing block 4, a traction sheave 5 and a Gegenrollenanbau 6.

- the stator 2.1 of the electric motor 2A is arranged on the motor stator 3.

- the rotor 2.2 of the electric motor 2A is seated on a free end of a shaft 15 carrying the traction sheave 15, which is mounted on the bearing block 4 and on the motor stator 3.

- the free end of the shaft projects beyond the motor stand 3.

- the traction sheave 5 is mounted on the motor stand 3 and on the bearing block 4 by means of the shaft.

- Per side of a brake 7 is arranged on the bearing block 4.

- Webs 8.9 connect the motor stand 3 with the bearing block 4, wherein, for example, an upper web 8 and a side web 9 are provided on each side.

- Motor stand 3, bracket 4 and the webs 8.9 form a stable framework without a motor stand 3 and bearing block 4 supporting machine frame is necessary.

- Motor stand 3 and bearing block 4 are supported by means of supporting elements 10 on a boom 3.1 or on a boom 4.1 without a frame on each base 11 or carrier.

- the Schmidtenanbau 6 consisting of side plates 12 and counter-roller 13 is right on Motor stand 3 and arranged on the bearing block 4.

- a hydraulic unit 14 serves to supply the actuator of the brake 7. The actuator can also be operated electrically.

- Supporting cables 25 form the cable strand, which are guided on the one hand by the traction sheave 5 via the counter-roller 13 and on the other hand by the traction sheave 5 directly into the elevator shaft.

- the cable string spacing is adjustable by means of the Schmidtrollenanbaus 6, wherein the side plates 12 are screwed to holes 12.1 with the motor stand 3 and with the bearing block 4.

- Fig. 2 shows the motor stand 3 with traction sheave 5, the lateral webs 9 and the upper web 8.

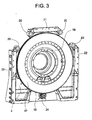

- the bearing block 4 is in the Fig. 3 shown.

- a shaft 15 carrying the traction sheave 15 is mounted at one end on the motor stand 3 and at the other end on the bearing block 4.

- the bearing block side bearing is designated 16.

- a brake disc 17 is arranged with ring gear 18 through which the traction sheave 5 is driven in the evacuation operation.

- Fig. 3 shows an interior view of the bearing block 4 with bearing housing 19 for receiving the bearing 16.

- eyelets 20 are visible on which the brake 7 is mounted.

- the support surface for the upper web 8 is 21 and the Aufläge vom for the lateral webs 9 are designated 22, wherein the webs are 8.9 screwed to the bearing block 4 and the motor stand 3, for example.

- the Evakuierantrieb consists of a motor 23 with pinion 24, wherein in evacuation operation, the pinion 24 engages the ring gear 18 and the traction sheave 5 is set in motion.

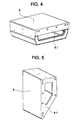

- Fig. 4 shows the upper web 8, which is box-shaped and the support surface 8.1 fits on the support surface 21.

- Fig. 5 shows the lateral web 9, which is wedge-shaped and the support surface 9.1 fits on the support surface 22.

- Fig. 6 and Fig. 7 show the bearing block 4 on each side arranged brake 7 of the drive unit 1, wherein a brake caliper 30 to the lugs 20 penetrating axes 31 is floatingly mounted.

- the caliper 30 can move at most to the adjustable by means of adjusting screws 32 distance d, wherein each axle 31, a spring 33 is provided which acts on the caliper 30 in the direction of traction sheave 5.

- the axles 31 are fastened to a supporting bracket 34 connected to the bearing block 4.

- the caliper 30 carries the drive pulley side, inner brake shoe 40 and serves as a support for spacer tubes 35 and threaded rods 36 which hold a support plate 37 for a hydraulic actuator 38, for example.

- Compression springs 39 are supported at one end on the carrier plate 37 and at the other end against a pressure plate 41, which transmits the spring force of the compression springs 39 to the outer brake shoe 43 by means of bolts 42 guided by the brake caliper 30.

- the activated actuator 38 acts by means of a pull rod 44 on the pressure plate 41 and lifts the spring force of coaxial with the pull rod 44 arranged compression springs 39 on the outer brake shoe 43.

- the caliper 30 moves due to the spring force of the spring 33 in the direction of traction sheave 5, wherein the inner brake shoe 40 moves away from the brake disk 17.

- a sensor 45 is provided for monitoring the braking state.

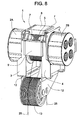

- Fig. 8 shows the fully assembled drive unit 1 with two motors, consisting essentially of a motor 2A and a motor 2B, serving as a bearing plate motor stand 3, serving as a bearing plate bearing block 4, a traction sheave 5 and a Gegenrollenanbau 6.

- the drive pulley 5 supporting, mounted on the bearing plates 3.4 shaft 15 has two free ends, wherein at one free end of the rotor of a motor 2A and at the other free end of the rotor of the other motor 2B is arranged.

- Webs 8.9 connect the motor stand 3 with the bearing block 4, wherein, for example, an upper web 8 and a side web 9 are provided on each side.

- Motor stand 3, bracket 4 and the webs 8.9 form a stable framework without a motor stand 3 and bearing block 4 supporting machine frame is necessary.

Landscapes

- Engineering & Computer Science (AREA)

- Civil Engineering (AREA)

- Mechanical Engineering (AREA)

- Structural Engineering (AREA)

- Cage And Drive Apparatuses For Elevators (AREA)

- Connection Of Motors, Electrical Generators, Mechanical Devices, And The Like (AREA)

- Braking Arrangements (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP04026113.3A EP1531139B1 (de) | 2003-11-13 | 2004-11-04 | Maschinenrahmenlose Antriebseinheit für einen Aufzug |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP03405807 | 2003-11-13 | ||

| EP03405807 | 2003-11-13 | ||

| EP04026113.3A EP1531139B1 (de) | 2003-11-13 | 2004-11-04 | Maschinenrahmenlose Antriebseinheit für einen Aufzug |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1531139A1 EP1531139A1 (de) | 2005-05-18 |

| EP1531139B1 true EP1531139B1 (de) | 2014-01-15 |

Family

ID=34560256

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04026113.3A Expired - Lifetime EP1531139B1 (de) | 2003-11-13 | 2004-11-04 | Maschinenrahmenlose Antriebseinheit für einen Aufzug |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US7533868B2 (zh) |

| EP (1) | EP1531139B1 (zh) |

| JP (1) | JP4938973B2 (zh) |

| KR (1) | KR101168185B1 (zh) |

| CN (1) | CN100364875C (zh) |

| CA (1) | CA2487580C (zh) |

| HK (1) | HK1077560A1 (zh) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7975807B2 (en) * | 2004-01-20 | 2011-07-12 | Franklin Samuel H | Elevator climbing system |

| US7165653B2 (en) * | 2004-11-19 | 2007-01-23 | Magil Corporation | Elevator gearless traction machine construction |

| DE102010034302A1 (de) * | 2010-08-13 | 2012-02-16 | Gustav Magenwirth Gmbh & Co. Kg | Bremssattel, Fahrrad und Montageverfahren |

| CA2903865A1 (en) * | 2013-03-20 | 2014-09-25 | Axon Ep, Inc. | Drawworks system |

| JP2015157662A (ja) * | 2014-02-24 | 2015-09-03 | 株式会社日立製作所 | 巻上機 |

| US10208817B2 (en) * | 2016-10-10 | 2019-02-19 | Cameron International Corporation | Drawworks gearbox with redundant braking on input side |

| CN112225041A (zh) * | 2020-11-04 | 2021-01-15 | 天津市航昊机电设备有限公司 | 一种提升罐笼变速机控制系统的压力释放装置 |

| CN112320545A (zh) * | 2020-11-04 | 2021-02-05 | 天津市航昊机电设备有限公司 | 一种提升罐笼变速机控制系统的压力释放装置 |

| CN112320546A (zh) * | 2020-11-04 | 2021-02-05 | 天津市航昊机电设备有限公司 | 一种提升罐笼变速机控制系统 |

Family Cites Families (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3559768A (en) * | 1969-12-22 | 1971-02-02 | Henry P Cox | Emergency elevator evacuation of tall buildings |

| FR2398014A1 (fr) * | 1977-07-18 | 1979-02-16 | Mitsubishi Electric Corp | Appareil de secours pour l'arret automatique d'une cabine d'ascenseur au niveau d'un etage lors d'une panne de courant en service |

| JPS54146361A (en) * | 1978-05-10 | 1979-11-15 | Hitachi Ltd | Elevator driving apparatus for use at the time of interruption of power supply |

| JPS6039627B2 (ja) * | 1979-12-26 | 1985-09-06 | 株式会社日立製作所 | 停電時におけるエレベ−タ制御装置 |

| JPS5954477A (ja) * | 1982-09-20 | 1984-03-29 | Toyo Seikan Kaisha Ltd | 缶胴体の製造方法 |

| JPS5954477U (ja) * | 1982-10-04 | 1984-04-10 | 三菱電機株式会社 | エレベ−タ用巻上機 |

| ES8403081A1 (es) * | 1982-11-15 | 1984-04-01 | Perez Marcelino De La | Dispositivo de seguridad para la evacuacion de ascensores en casos de emergencia. |

| FI84051C (fi) * | 1988-03-09 | 1991-10-10 | Kone Oy | Linupphaengning foer en hiss. |

| US5101939A (en) * | 1990-04-13 | 1992-04-07 | Otis Elevator Company | Disk brake for elevator |

| EP0468168B1 (de) * | 1990-07-26 | 1994-08-24 | Inventio Ag | Getriebelose Antriebsmaschine für Aufzüge |

| EP0745553A1 (de) * | 1995-06-02 | 1996-12-04 | Inventio Ag | Antriebseinheit für einen Aufzug |

| JPH09142761A (ja) * | 1995-11-24 | 1997-06-03 | Mitsubishi Electric Corp | エレベータ用巻上機 |

| JP3537348B2 (ja) | 1999-04-05 | 2004-06-14 | 三菱電機株式会社 | トラクション式エレベーター用巻上機 |

| EP1069068B1 (de) * | 1999-07-16 | 2006-06-07 | Inventio Ag | Kompakter Antrieb für einen Aufzug |

| JP2001294385A (ja) * | 2000-04-07 | 2001-10-23 | Mitsubishi Electric Corp | エレベーター用巻上機装置 |

| EP1156008B1 (de) * | 2000-05-19 | 2005-04-06 | Inventio Ag | Bremseinrichtung für eine Antriebsmaschine eines Aufzuges |

| DE50102939D1 (de) * | 2000-05-19 | 2004-08-26 | Inventio Ag | Betätigungseinrichtung für den notbetrieb einer getrieblosen antriebsmaschine eines aufzuges |

| EP1338550B1 (de) | 2002-02-18 | 2008-04-02 | Inventio Ag | Antriebseinheit mit Bremse für einen Aufzug |

| SG110016A1 (en) * | 2002-02-18 | 2005-04-28 | Inventio Ag | Engine frame with counter-roller support for an elevator drive |

| MY135844A (en) * | 2002-02-18 | 2008-07-31 | Inventio Ag | Drive unit with brake for a lift |

| MY130686A (en) * | 2002-02-18 | 2007-07-31 | Inventio Ag | Portable emergency drive for an elevator |

-

2004

- 2004-10-29 JP JP2004315239A patent/JP4938973B2/ja not_active Expired - Fee Related

- 2004-11-01 US US10/979,440 patent/US7533868B2/en active Active

- 2004-11-04 EP EP04026113.3A patent/EP1531139B1/de not_active Expired - Lifetime

- 2004-11-10 CN CNB2004100923802A patent/CN100364875C/zh active Active

- 2004-11-12 KR KR1020040092238A patent/KR101168185B1/ko active IP Right Grant

- 2004-11-12 CA CA2487580A patent/CA2487580C/en active Active

-

2005

- 2005-10-25 HK HK05109468.9A patent/HK1077560A1/zh unknown

Also Published As

| Publication number | Publication date |

|---|---|

| CN100364875C (zh) | 2008-01-30 |

| CN1616337A (zh) | 2005-05-18 |

| CA2487580C (en) | 2012-04-03 |

| JP4938973B2 (ja) | 2012-05-23 |

| US20050103574A1 (en) | 2005-05-19 |

| JP2005145717A (ja) | 2005-06-09 |

| EP1531139A1 (de) | 2005-05-18 |

| CA2487580A1 (en) | 2005-05-13 |

| KR101168185B1 (ko) | 2012-07-25 |

| US7533868B2 (en) | 2009-05-19 |

| KR20050046594A (ko) | 2005-05-18 |

| HK1077560A1 (zh) | 2006-02-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69403684T2 (de) | Aufzugsmotor im Gegengewicht eingesetzt | |

| EP1531139B1 (de) | Maschinenrahmenlose Antriebseinheit für einen Aufzug | |

| EP0578069B1 (de) | Antriebseinheit für ein Hebezeug, insbesondere für einen Personen- oder Lastenaufzug | |

| EP1724227B1 (de) | Ablenkmodul für einen Aufzug | |

| EP2303750B1 (de) | Aufzuganlage mit selbstfahrender aufzugskabine | |

| EP0673874B1 (de) | Antriebsmaschine für Aufzüge | |

| EP1069068B1 (de) | Kompakter Antrieb für einen Aufzug | |

| DE102006037253A1 (de) | Aufzugsanlage | |

| EP1338550B1 (de) | Antriebseinheit mit Bremse für einen Aufzug | |

| DE10205170B4 (de) | Treibscheibenaufzug | |

| AT9838U1 (de) | Liftsystem und aufzug ohne maschinenraum | |

| DE4131668C1 (zh) | ||

| EP0228513A1 (de) | Aufzug-Anlage | |

| EP1338546B1 (de) | Maschinenrahmen mit Gegenrollenträger für einen Aufzugsantrieb | |

| EP1588978B1 (de) | Antrieb für eine Aufzugsanlage | |

| EP2303751B1 (de) | Aufzuganlage mit selbstfahrendem gegengewicht | |

| EP1555232B1 (de) | Verfahren zur modernisierung eines antriebes in einer aufzugsanlage | |

| DE20320004U1 (de) | Treibscheibenaufzug in Rucksackbauweise | |

| EP3235770B1 (de) | Verfahren zur nachrüstung eines aufzugs und korrespondierender aufzug | |

| WO2005082766A2 (de) | Hydraulischer antrieb mit feststehendem kolben für aufzüge | |

| DE102005001964B3 (de) | Maschinenraumloser Treibscheibenaufzug | |

| DE20000913U1 (de) | Getriebehebewerk | |

| EP1013598B1 (de) | Antriebseinheit für Aufzüge | |

| DE19714848A1 (de) | Vorrichtung, welche sich, einschließlich eines angeschlossenen Personenaufnahmemittels, an zwei vorzugsweise parallel auseinander gelagerten Anhängetrumms, bestehend aus je einem Tragmittel und je einem Fangmittel, senkrecht oder geneigt auf und ab verlagert | |

| DE20312167U1 (de) | Maschinenraumlose Anordnung einer Aufzugsmaschine in Langbauweise |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK YU |

|

| 17P | Request for examination filed |

Effective date: 20051020 |

|

| AKX | Designation fees paid |

Designated state(s): AT CH DE FR GB LI |

|

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: DE Ref document number: 1077560 Country of ref document: HK |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Ref document number: 502004014498 Country of ref document: DE Free format text: PREVIOUS MAIN CLASS: B66B0011000000 Ipc: B66B0011040000 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B66B 11/04 20060101AFI20131029BHEP |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| INTG | Intention to grant announced |

Effective date: 20131113 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE FR GB LI |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 649741 Country of ref document: AT Kind code of ref document: T Effective date: 20140215 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502004014498 Country of ref document: DE Effective date: 20140227 |

|

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: GR Ref document number: 1077560 Country of ref document: HK |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502004014498 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20141016 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502004014498 Country of ref document: DE Effective date: 20141016 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141130 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141130 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 649741 Country of ref document: AT Kind code of ref document: T Effective date: 20141104 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141104 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R084 Ref document number: 502004014498 Country of ref document: DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20221122 Year of fee payment: 19 Ref country code: FR Payment date: 20221122 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20231127 Year of fee payment: 20 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20231104 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20231104 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20231130 |